Middle Power Class-D Speaker Amplifiers

Analog Input / BTL Output

Class-D Speaker Amplifier

BD5413EFV

●Description

BD5413EFV is a 5W + 5W stereo class-D power amplifier specifically developed for low power consumption and low heat

generation applications like powered speakers. BD5413EFV employs the state-of-the-art BCD (Bipolar, CMOS and DMOS)

process technology to eliminate a turn-on resistance in the output power stage and an internal loss due to a wiring

resistance as much as possible, achieving a high performance of 80% (4W + 4W output with a load resistance of 8Ω). In

addition, BD5413EFV employs a compact power package which dissipates heat via the rear to achieve low power

consumption and low heat generation so that the need for connecting an external heat radiator can be eliminated up to a

total output of 12.8W. This product meets the needs for compact, thin sound generation systems and powerful, high-quality

sound reproduction.

●Features

1) Small output noise voltage capable of achieving a high S/N set

Input conversion noise voltage = 2.8μVrms

A bipolar differential is used for input amplifier to eliminate 1/f noise.

2) Support of power supply voltage ranging from 6V to 10.5V

A supply voltage range is supported that matches an AC adaptor or battery cell driven set.

When a set is battery driven, its operating time can be extended by means of a high performance class-D amplifier.

3) Support of low current consumption mode

A circuit current in shut-down mode is 1μA or less.

4) Built-in soft muting function for reducing pop at shut-down ON or OFF

When a signal is present, its smooth envelope waveform is realized owing to this function.

In addition, when no signal is present, pop generation is eliminated.

A transit time can be adjusted easily through the use of an external capacitor.

5) Realization of high efficiency and low heat generation

Efficiency = 80% (4W+4W (Vcc=9V, R

A compact power package HTSSOP-B24 (7.8mm x 7.6mm) is employed.

6) Built-in function for reducing pop generation at disconnection from the outlet

7) Support of function for sampling frequency selection

An internal PWM sampling frequency can be selected from three frequencies (200kHz, 250kHz and 300kHz).

Countermeasures against interference (beat noise) due to a switching power source can be taken as needed.

8) Realization of high reliability

Countermeasures against short-circuits due to output terminals shorted to V

(support of automatic recovery).

A temperature protection circuit is incorporated (support of automatic recovery).

9) Support of ERROR pin

ERROR output takes place as a warning which indicates an error.

(short-circuits due to output terminals shorted to V

=8Ω) output can be made without using an external heat radiator.)

L

or ground can be taken

CC

or ground, or IC high temperature abnormality).

CC

No.10075EBT01

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

1/14

2010.05 - Rev.B

BD5413EFV

Technical Note

●Absolute maximum ratings

A circuit must be designed and evaluated not to exceed absolute maximum rating in any cases and even momentarily, to

prevent reduction in functional performances and thermal destruction of a semiconductor product and secure useful life and

reliability.

The following values assume Ta =25℃. For latest values, refer to delivery specifications.

Parameter

Symbol Ratings Unit Conditions

Supply voltage VCC +15 V Pin 3, 5, 10, 12, 16, 21 (Note 1,2)

Power dissipation Pd

1.1 W (Note 3)

2.8 W (Note 4)

Input voltage for signal pin VIN -0.2 to Vcc+0.2 V Pin 23, 24 (Note 1)

Input voltage for control pin VCONT -0.2 to Vcc+0.2 V Pin 14, 15 (Note 1)

Operating temperature range Topr -40 to +85 ℃

Storage temperature range Ts tg -55 to +150 ℃

Maximum junction temperature Tjmax +150 ℃

(Note 1) A voltage that can be applied with reference to GND (pins 1, 7, 8, 13, 18 and 19)

(Note 2) Pd and Tjmax=150℃ must not be exceeded.

(Note 3) 70mm × 70mm × 1.6mm FR4 One-sided glass epoxy board (Back copper foil 0%) installed.

If used under Ta=25℃ or higher, reduce 8.8 mW for increase of every 1℃. The board is provided with thermal via.

(Note 4) 70mm × 70mm × 1.6mm FR4 Both-sided glass epoxy board (Back copper foil 100%) installed.

If used under Ta=25℃ or higher, reduce 22.4 mW for increase of every 1℃. The board is provided with thermal via.

●Operating conditions

The temperature (Ta) is 25℃. For the latest temperature, refer to the delivery specifications.

Parameter Symbol Ratings Unit Conditions

Supply voltage VCC +6 to +10.5 V Pin 3, 5, 10, 12, 16, 21

Load resistance RL 6 to 16 Ω (Note 5)

(Note 5) This value must not exceed Pd.

●Electrical characteristics

Unless otherwise stated, Ta=25℃, Vcc=9V, f

IN=1kHz, Rg=0Ω, RL=8Ω, SDX="H" and FC="M (OPEN)"

are assumed. For the latest values, refer to the delivery specifications.

Parameter Symbol Limits Unit Conditions

Whole circuit

Circuit current 1 (sampling mode) ICC1 12 mA No signal, no load

Circuit current 2 (mute mode) ICC2 1 µA SDX = “L”

Control

Input voltage with SDX pin set to "H" VIHSDX 2.5 to 9 V Sampling state

Input voltage with SDX pin set to "L" VILSDX 0 to 0.5 V Shut-down state

Input voltage with FC pin set to "H" VIHFC 8.2 to 9 V Setting of Fs=300kHz

Input voltage with FC pin set to "M" VIMFC 3.8 to 5.2 V Setting of Fs=250kHz

Input voltage with FC pin set to "L" VILFC 0 to 0.8 V Setting of Fs=200kHz

Audio output

Voltage gain GV 30 dB PO = 1W

Maximum output power 1 (Note 6) PO1 4 W THD+N = 10%, RL = 8Ω

Maximum output power 2 (Note 6) PO2 5 W THD+N = 10%, RL = 6Ω

Total harmonic distortion ratio (Note 6) THD 0.2 % PO = 1W, BW=20Hz to 20kHz

Crosstalk CT 65 dB PO = 1W, Rg = 0Ω, BW = IHF-A

Output noise voltage (sampling mode) VNO 90 µVrms Rg = 0Ω, BW = IHF-A

Residual noise voltage (mute mode) VNOM 1 µVrms Rg = 0Ω, BW = IHF-A, MUTEX = “L”

200

Internal sampling clock frequency FS

250

kHz

300

(Note 6) The rated values of items above indicate average performances of the device, which largely depend on circuit layouts, components,

and power supplies. The reference values are those applicable to the device and components directly installed on a board specified by us.

FC = L

FC = M(OPEN)

FC = H

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

2/14

2010.05 - Rev.B

BD5413EFV

r

r

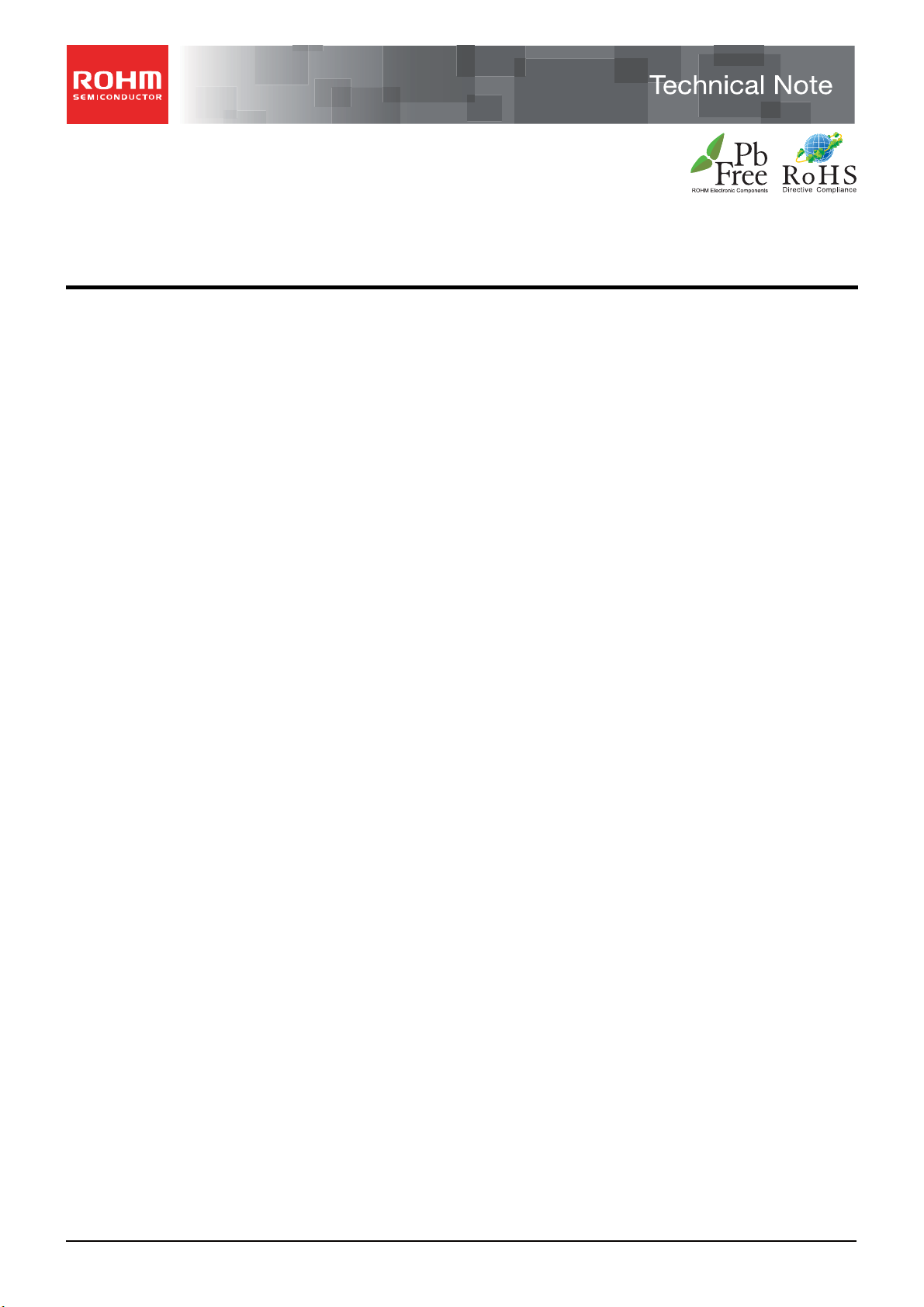

●Electrical characteristic curves (Ta=25℃) (Reference data)

(1) Under Stereo Operation (R

L=8Ω)

Technical Note

100

Vcc=9V

=8Ω

R

L

BW=20~20kHz

10

1

THD+N (%)

0.1

0.01

0.001 0.01 0.1 1 10

6kHz

1kHz

100Hz

OUTPUT POWER (W)

Fig. 1 THD+N - Output Powe

40

35

30

25

20

Vcc=9V

=8Ω

R

L

15

Po=1W

L=33µH

VOLTAGE GAIN (dB)

10

C=0.47µF

Cg=0.1µF

5

0

10 100 1000 10000 100000

FREQUENCY (Hz)

Fig. 3 Voltage Gain - Frequency Fig. 4 Crosstalk - Frequency

100

Vcc=9V

=8Ω

R

L

Po=1W

10

BW=20~20kHz

1

THD+N (%)

0.1

0.01

10 100 1000 10000 100000

FREQUENCY (Hz)

Fig. 2 THD+N - Frequency

0

-20

-40

-60

CROSSTALK (dB)

-80

-100

10 100 1000 10000 100000

FREQUENCY (Hz)

Vcc=9V

=8Ω

R

L

Po=1 W

BW=20~20kHz

0

-20

-40

-60

CROSSTALK (dB)

-80

-100

0.001 0.01 0.1 1 10

OUTPUT POWER (W)

Fig. 5 Crosstalk - Output Powe

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

Vcc=12V

R

=8Ω

L

fin=1kHz

BW=20~20kHz

3/14

14

RL=8Ω

12

fin=1kHz

10

8

6

THD=10%

THD=1%

4

OUTPUT POWER (W)

2

0

456789101112

VCC (V)

Fig. 6 Output Power - Supply Voltage

2010.05 - Rev.B

BD5413EFV

V

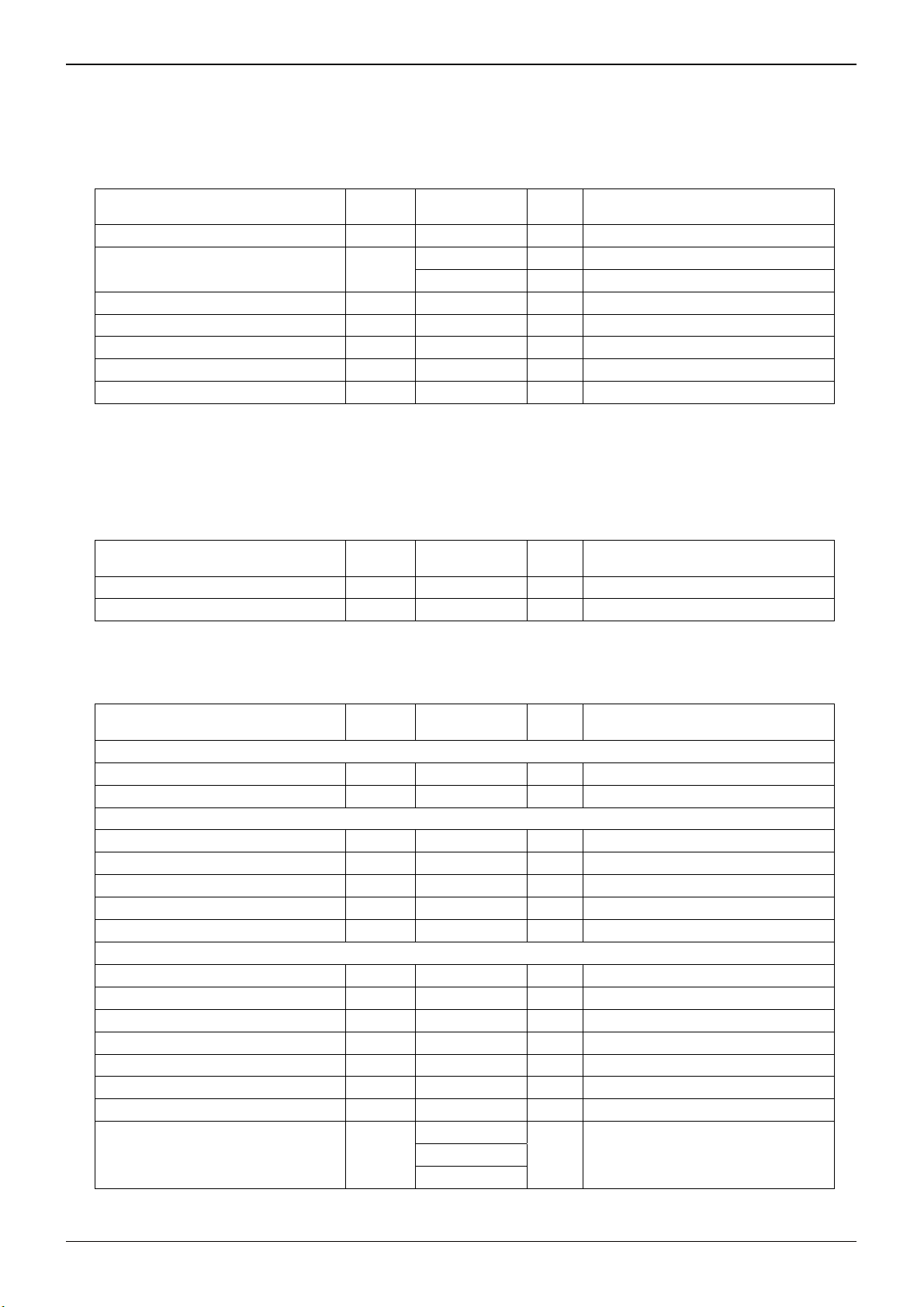

●Electrical characteristic curves (Reference data) – Continued

Technical Note

100

90

80

70

60

50

40

EFFICIENCY (% )

30

20

10

0

0246

OUTPUT POWER (W/ch)

Vcc=6V

R

=8Ω

L

fin=1kHz

100

90

80

70

60

50

40

EFFICIENCY (% )

30

20

10

0

0246

OUTPUT POWER (W/ch)

Vcc=9V

R

=8Ω

L

fin=1kHz

Fig. 7 Efficiency - Output Power Fig. 8 Efficiency - Output Power

100

90

80

70

60

50

40

EFFICIENCY (% )

30

20

10

0

0246

OUTPUT POWER (W/ch)

Vcc=10.5V

R

=8Ω

L

fin=1kHz

2

Vcc=9V Vcc=10.5

1

ICC (A)

Vcc=6V

RL=8Ω

fin=1kHz

0

051015

TOTAL OUTPUT POWER (W)

Fig. 9 Efficiency - Output Power Fig. 10 Current Consumption - Output Power

50

RL=8Ω

No signal

40

30

20

ICC(mA)

Sampling

10

ShutDown

0

4681012

VCC(V)

Fig. 11 50 Current Consumption - Supply Voltage Fig. 12 Output Noise Voltage FFT

-10

-30

-50

-70

-90

-110

NOISE FFT (dBV)

-130

-150

10 100 1000 10000 100000

FREQUENCY (Hz)

Vcc=9V

RL=8Ω

No signal

Gain=29.6dB

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

4/14

2010.05 - Rev.B

BD5413EFV

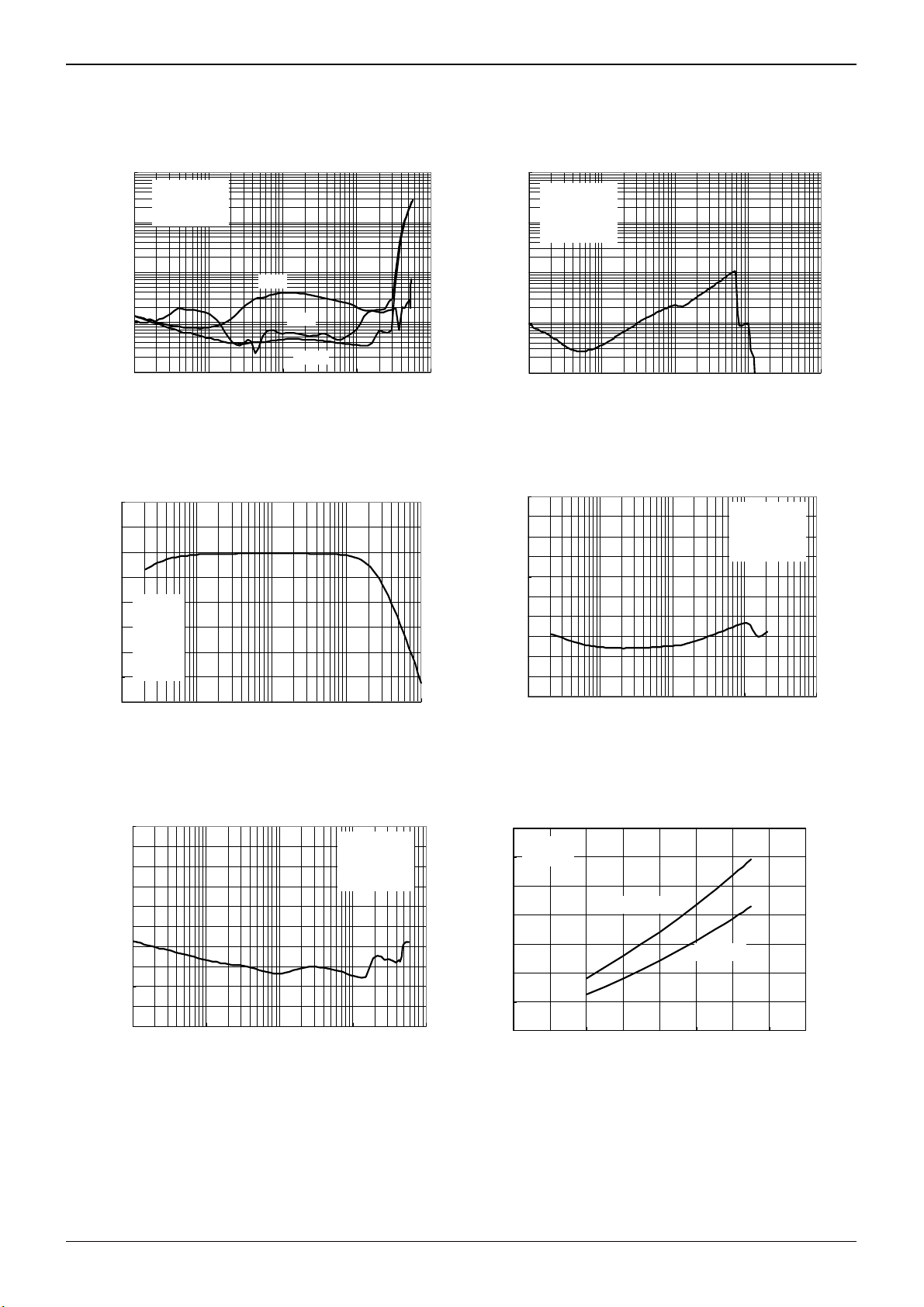

●Electrical characteristic curves (Reference data) – Continued

Technical Note

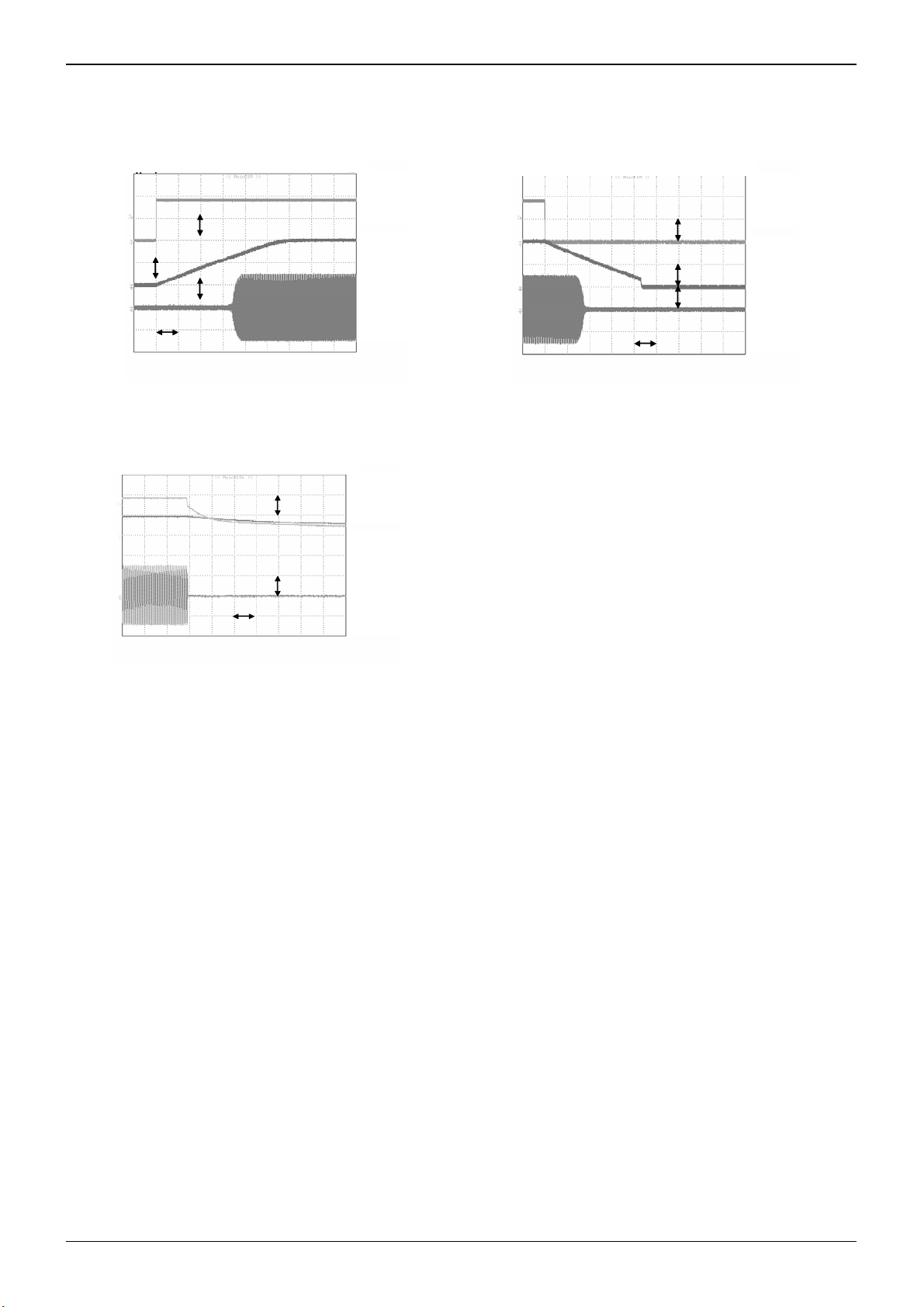

SDX

Pin14

TS

Pin22

Speaker

Output

2V/div

200msec/ div

5V/div

2V/div

Vcc=9V

L

R

Ω

=8

Po=500mW

fin=100Hz

SDX

Pin14

TS

Pin22

Speaker

Output

5V/div

2V/div

2V/div

200msec/ div

Vcc=9V

L

R

Ω

=8

Po=500mW

fin=100Hz

Fig. 13 Waveform at Soft Mute Reset Fig. 14 Waveform at Soft Mute

VCCA

FIL

Pin2

Speaker

Output

5V/div

2V/div

20msec/div

Vcc=9V

L

R

=8Ω

Po=500mW

fin=1kHz

Fig. 15 Waveform at Instantaneous Power

Interruption (20msec/div)

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

5/14

2010.05 - Rev.B

BD5413EFV

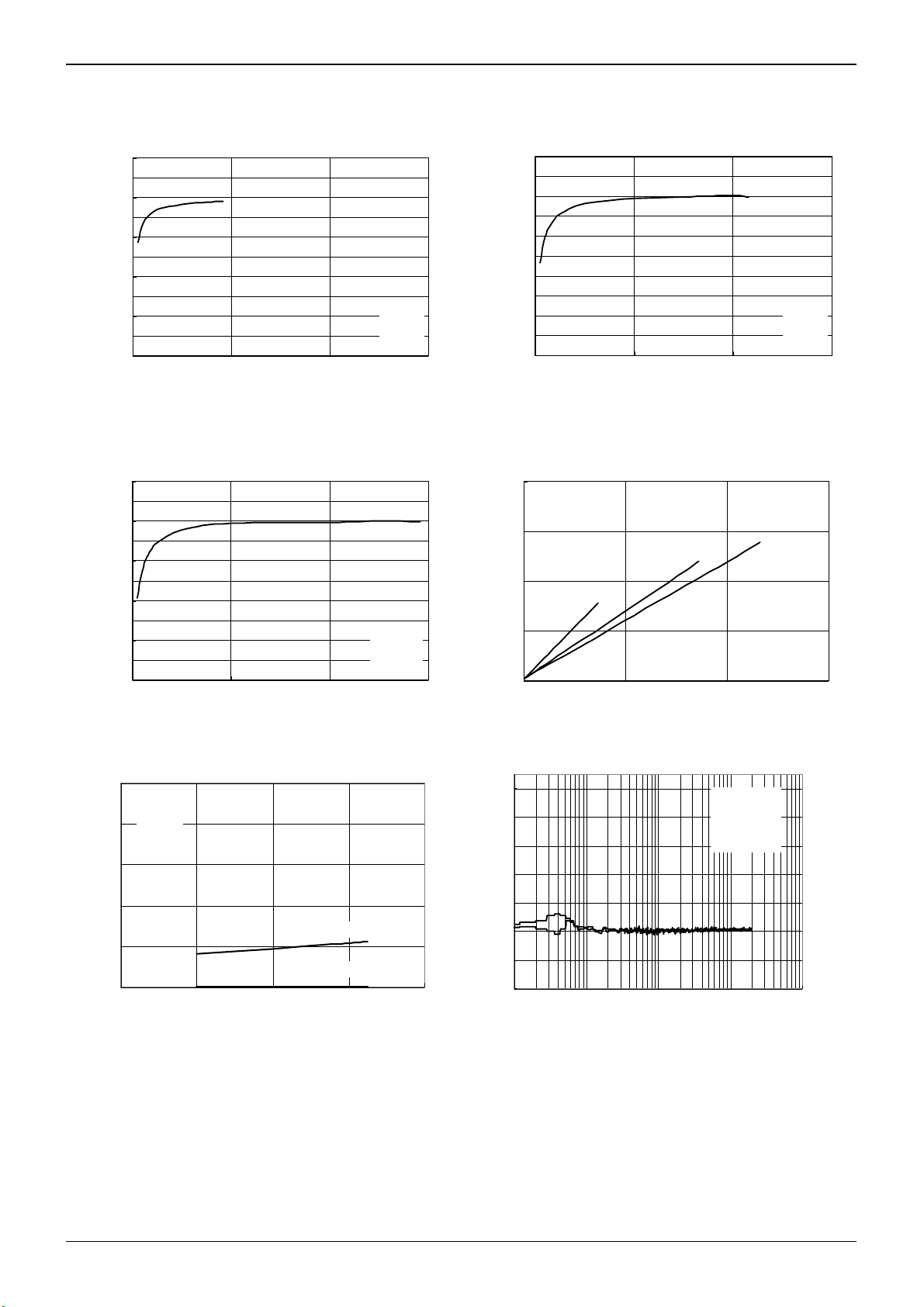

●Electrical characteristic curves (Reference data) – Continued

THD=10%

VCC (V)

L=16 Ω)

Vcc=6V

R

=8Ω

L

fin=1kHz

(2) Under Stereo Operation (R

100

10

RL=16Ω

90

fin=1kHz

80

8

70

6

60

50

4

40

EFFICIENCY (% )

30

OUTPUT POW ER (W)

2

20

10

0

0

4681012

0246

OUTPUT POWER (W/ch)

Fig. 16 Output Power - Supply Voltage Fig. 17 Efficiency - Output Power

Technical Note

100

90

80

70

60

50

40

EFFICIENC Y (% )

30

20

10

0

024

OUTPUT POWER (W/c h)

Vcc=6V

R

=16Ω

L

fin=1kHz

100

90

80

70

60

50

40

EFFICIENC Y (% )

30

20

10

0

024

OUTPUT POWER (W/ch)

Vcc=9V

=16Ω

R

L

fin=1kHz

100

90

80

70

60

50

40

EFFICIENC Y (% )

30

20

10

0

024

Fig. 18 Efficiency - Output Power Fig. 19 Efficiency - Output Power

2

1.5

1

ICC(A)

0.5

0

02468

Vcc=6V

TOTAL OUTPUT POWER (W)

Vcc=9V

Vcc=10.5V

RL=16

Ω

fin=1kHz

Fig. 20 Current Consumption - Output Power

OUTPUT POWER (W/ch)

Vcc=10.5V

R

=16Ω

L

fin=1kHz

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

6/14

2010.05 - Rev.B

BD5413EFV

V

●Electrical characteristic curves (Reference data) – Continued

(3) Under Stereo Operation (R

L=6Ω)

Technical Note

100

90

80

70

60

50

40

EFFICIENC Y (% )

30

20

10

0

0246

OUTPUT POWER (W/ch)

Fig. 21 Output Power - Supply Voltage Fig. 22 Efficiency - Output Power

RL=6Ω

14

fin=1kHz

12

10

8

6

4

OUTPUT POW ER (W)

2

0

4681012

THD=10%

Fig. 23 Efficiency - Output Power Fig. 24 Efficiency - Output Power

100

90

80

70

60

50

40

EFFICIENCY (%)

Vcc=9V

R

=6Ω

L

fin=1kHz

30

20

10

0

0246

OUTPUT POWER (W/ch)

Vcc=10.5V

R

=6Ω

L

fin=1kHz

100

90

80

70

60

50

40

EFFICIENC Y (% )

VCC (V)

30

20

10

0

0246

OUTPUT POWER (W/ch)

Vcc=6V

R

=6Ω

L

fin=1kHz

2

Vcc=9V

1

ICC (A)

0

Vcc=6V

051015

TOTAL OUTPUT POWER (W)

Fig. 25 Current Consumption - Output Power

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

Vcc=10.5

RL=6Ω

fin=1kHz

7/14

2010.05 - Rev.B

BD5413EFV

●Pin Assignment Diagram

Technical Note

Top View

1

GNDA

2

FIL

VCCA

3

4

TEST

VCCP1P

OUT1P

GNDP1

GNDP1

OUT1N

VCCP1N

ERR

VCCD

5

6

7

8

9

10

11

12

●Outer Dimensions and Inscriptions

(Maximum size including burr: 6.15) (5.0)

Fig. 27 Outer Dimensions and Inscriptions of the HTSSOP-B24 Package

FIL

N.C .

DRIVER

1P

DRIVER

1N

ERROR

High Temperature Protection

Fig. 26 Pin Assignment

D5413EFV

PWM1

Protections & Logic

Power - off Detector

Output Short Protection

PWM2

Soft

Shutdown

DRIVER

2P

DRIVER

2N

Sampling

Frequency

Control

Shutdown

Control

Type

Lot No.

24

23

22

21

20

19

18

17

16

15

14

13

IN1

IN2

TS

VCCP 2P

OUT 2P

GNDP 2

GNDP 2

OUT2N

VCCP 2N

FC

SDX

GNDD

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

8/14

2010.05 - Rev.B

BD5413EFV

●Pin configuration (Pin Voltage: Typical Value)

No. Symbol Pin voltage Pin description Internal equalizing circuit

3

ch1: Analog signal input pin

24

23

IN1

IN2

1/2V

CC

ch2: Analog signal input pin

23/2 4

20

k

Input an audio signal via a capacitor.

Technical Note

5 VCCP1P Vcc ch1: Positive power system power supply pin

6 OUT1P Vcc to 0V

ch1: Positive PWM signal output pin

Make connection to the output LPF.

7, 8 GNDP1 0V ch1: Power GND pin

9 OUT1N Vcc to 0V

ch1: Negative PWM signal output pin

Make connection to the output LPF.

10 VCCP1N Vcc ch1: Negative power system power supply pin

Error output pin

Pin for notifying an operation error

H: Error

11 ERROR

H: 5V

L: 0V

L: Normal operation

1

12

11

7 , 8

7 , 8

5

6

10

9

100

ON /OFF

300k

12 VCCD VCC Control power supply pin

13 GNDD 0V Control GND pin

Shut-down control pin

14 SDX -

H: Shut-down OFF

L: Shut-down ON

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

9/14

13

12

225k

14

13

175k

2010.05 - Rev.B

BD5413EFV

●Pin configuration - Continued

No. Symbol Pin voltage Pin description

Technical Note

Internal equalizing circuit

4 TEST VCC

Keep this pin open or connect it to VCC for

regular use.

Shut-down ON/OFF

Do not use the TEST pin.

22 TS 0 to 4V

Constant setting pin

Connect a capacitor.

16 VCCP2N Vcc ch2: Negative power system power supply pin

17 OUT2N Vcc to 0V

18,

GNDP2 0V ch2: Power GND pin

19

ch2: Negative PWM signal output pin

Make connection to the output LPF.

12

22

13

18 , 19

100

16

17

21

20 OUT2P Vcc to 0V

ch2: Positive PWM signal output pin

Make connection to the output LPF.

21 VCCP2P Vcc ch2: Positive power system power supply pin

3 VCCA Vcc Analog system power supply pin

Analog signal system bias pin

2 FILA 1/2VCC

Connect a capacitor.

1 GNDA 0V Analog signal system GND pin

18 , 19

20

3

2

1

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

10/14

2010.05 - Rev.B

BD5413EFV

●Application Circuit Diagram

(1)Application Circuit Diagram with a Load of 8Ω for Stereo Operation

・Vcc=6V to 10.5V

SP ch1

(8Ω)

GNDA

C7

0.47µ

VCC

C2

10µ

33µH

C6

0.1µ

C8

0.1µ

33µH

L1

L2

C1

47µ

VCCP1

10µ

+

GNDP1

C3

0.1µ

C9

0.1µ

C4C5

0.1µ

1

FIL

2

3

TEST

4

PWM1

5

6

DRIVER

1P

7

8

9

DRIVER

1N

10

Protections & Logic

Power-of f Detector

Output Short Protection

High Temperature Prot ecti on

ERROR OUTPUT

VCC GNDD

11

12

ERROR

PWM2

Soft

Shutdown

DRIVER

2P

DRIVER

2N

Sampling

Frequency

Control

Shutdown

Control

24

23

22

21

20

19

18

17

16

15

14

13

C19

0.47µ

C18

0.47µ

C17

2.2µ

VCCP2

C16

0.1µ

GNDP2

C11

0.1µ

INPUT

ch-1

INPUT

ch-2

GNDD

C12

+

10µ

300kHz

250kHz

200kHz

SHUTDOWN

Technical Note

L4

33µH

C15

0.1µ

C14

0.47µ

C13

0.1µ

L3

33µH

SP ch2

(8Ω)

0.1µ

C10

Fig.28 Circuit Diagram with a Load of 8Ω for Stereo Operation

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

11/14

2010.05 - Rev.B

BD5413EFV

(2)BOMs of Boards for Stereo Operation

Table 1 BOMs of Boards with Loads of 8Ω, 6Ω and 16Ω for Stereo Operation

No. Item Part Number Vendor

1 IC BD5413EFV ROHM HTSSOP-B24 - - - - 1 IC1

2 C GRM32EB31A476KE20 MURATA 3225 1210 47µF 10V ±10% ±10% 1 C1

3 C GRM21BB31C106KE15 MURATA 2012 0805 10µF 16V ±10% ±10% 1 C2

4 C GRM188B11C104KA01 MURATA 1608 0603 0.1µF 16V ±10% ±10% 6 C3, C4, C9, C10, C11, C16

5 C GRM188B30J225KE18 MURATA 1608 0603 2.2µF 6.3V ±10% ±10% 1 C17

6 C GRM188B11C474KA87 MURATA 1608 0603 0.47µF 16V ±10% ±10% 2 C18, C19

7 C EMZA350ADA100ME61G CHEM1-00N 5.3×5.3 10µF 35V ±20% +20%, -25% 2 C5, C12

BOM of Board with a Load Resistance of 8Ω

No. Item Part Number Vendor

8 C GRM188B11C104KA01 MURATA 1608 0603 0.1µF 16V ±10% ±10% 4 C6, C8, C13, C15

9 C GRM188B11C474KA87 MURATA 1608 0603 0.47µF 16V ±10% ±10% 2 C7, C14

No. Item Part Number Vendor

10 L TSL0808RA-330K1R4-PF TDK

BOM of Board with a Load Resistance of 6Ω

No. Item Part Number Vendor

8 C GRM188B11C474KA87 MURATA 1608 0603 0.47µF 16V ±10% ±10% 4 C6, C8, C13, C15

9 C GRM188B11C474KA87 MURATA 1608 0603 0.47µF 16V ±10% ±10% 2 C7, C14

No. Item Part Number Vendor

10 L TSL0808RA-220K1R7-PF TDK

BOM of Board with a Load Resistance of 16Ω

No. Item Part Number Vendor

8 C GRM188B11C104KA01 MURATA 1608 0603 0.01µF 16V ±10% ±10% 4 C6, C8, C13, C15

9 C GRM188B11C224KA01 MURATA 1608 0603 0.22µF 16V ±10% ±10% 2 C7, C14

No. Item Part Number Vendor

10 L TSL0808RA-680K1R0-PF TDK

Configuration

mm inch

Configuration

mm inch

Configuration

mm

,8.3

Ф8.5

Configuration

mm inch

Configuration

mm

,8.3

Ф8.5

Configuration

mm inch

Configuration

mm

,8.3

Ф8.5

Technical Note

Value

Value

Value Tolerance

33µH ±10% 92mΩmax 1.4A max 4 L1, L2, L3, L4

Value

Value Tolerance

22µH ±10% 70mΩmax 1.7A max 4 L1, L2, L3, L4

Value

Value Tolerance

68µH ±10% 160mΩmax 1A max 4 L1, L2, L3, L4

Rated

voltage

Rated

voltage

Rated

voltage

Rated

voltage

Tolerance

Tolerance

DC

Resistance

Tolerance

DC

Resistance

Tolerance

DC

Resistance

Temperature

characteristics

Temperature

characteristics

Rated

DC Current

Temperature

characteristics

Rated

DC Current

Temperature

characteristics

Rated

DC Current

Quantity Reference

Quantity Reference

Quantity Reference

Quantity Reference

Quantity Reference

Quantity Reference

Quantity Reference

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

12/14

2010.05 - Rev.B

BD5413EFV

●Notes for use

1. About absolute maximum ratings

If an applied voltage or an operating temperature exceeds an absolute maximum rating, it may cause destruction of a

device. A result of destruction, whether it is short mode or open mode, is not predictable. Therefore, provide a physical

safety measure such as fuse, against a special mode that may violate conditions of absolute maximum ratings.

2. About power supply line

As return of current regenerated by back EMF of output coil happens, take steps such as putting capacitor between

power supply and GND as a electric pathway for the regenerated current. Be sure that there is no problem with each

property such as emptied capacity at lower temperature regarding electrolytic capacitor to decide capacity value. If the

connected power supply does not have sufficient current absorption capacity, regenerative current will cause the voltage

on the power supply line to rise, which combined with the product and its peripheral circuitry may exceed the absolute

maximum ratings. It is recommended to implement a physical safety measure such as the insertion of a voltage clamp

diode between the power supply and GND pins.

3. Potential of GND (1, 7, 8, 13, 18 and 19 pins)

Potential of the GND terminal must be the lowest under any operating conditions.

4. About thermal design

Perform thermal design with sufficient margins, in consideration of maximum power dissipation Pd under actual operating

conditions. This product has an exposed frame on the back of the package, and it is assumed that the frame is used with

measures to improve efficiency of heat dissipation. In addition to front surface of board, provide a heat dissipation pattern

as widely as possible on the back also.

A class-D power amplifier has heat dissipation efficiency far higher than that of conventional analog power amplifier and

generates less heat. However, extra attention must be paid in thermal design so that a power dissipation Pdiss should not

exceed the maximum power dissipation Pd.

Maximum power dissipation

Power dissipation

PoPd

Odiss

Ta-Tjmax

θ

ja

1

1-

〔 WPP

η

〕

W

〔

〕

Tjmax: Maximum temperature junction = 150[

Ta: Operating ambient temperature [

θja: Package thermal resistance [

Po: Output power [W]

η: Efficiency

Technical Note

℃]

℃/W]

5. About operations in strong electric field

Note that the device may malfunction in a strong electric field.

6. Thermal shutdown (TSD) circuit

This product is provided with a built-in thermal shutdown circuit. When the thermal shutdown circuit operates, the output

transistors are placed under open status. The thermal shutdown circuit is primarily intended to shut down the IC avoiding

thermal runaway under abnormal conditions with a chip temperature exceeding Tjmax = 150

℃, and is not intended to

protect and secure an electrical appliance. Accordingly, do not use this circuit function to protect a customer's electrical

appliance.

7. About shorting between pins and installation failure

Be careful about direction and displacement of an IC when installing it onto the board. Faulty installation may destroy the

IC when the device is energized. In addition, a foreign matter getting in between IC pins, pins and power supply, and

pins and GND may cause shorting and destruction of the IC.

8. About power-on or power-off sequence

Set the SDX pin (pin 14) to “L” level before initiating the power-on sequence. Similarly, set the SDX pin (pin 14) to “L”

level before initiating the power-off sequence. If such a setting is made, pop reduction is achieved at power-on or poweroff sequence. In addition, note that all power supply pins shall be made active or inactive at the same time.

9. About error output pin (pin 11)

When a high temperature protection function or VCC/GND shorting protection function is activated, an error flag is output

via an error output pin. Because the error output pin is primarily intended to indicate the state of BD5413EFV and is

available only to protect BD5413EFV, it cannot be used for any other purposes.

10. About TEST pin (pin 4)

Do not use the TEST pin. Keep this pin open or connect it to VCC for regular use.

℃]

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

13/14

2010.05 - Rev.B

BD5413EFV

●Ordering part number

Technical Note

B D

Part No

BD.

HTSSOP-B24

7.6±0.2

1.0MAX

5 4 1 3

E F V

Part No.

5413

Package

EFV:HTSSOP-B24

(MAX 8.15 include BURR)

5.6±0.1

0.325

0.85±0.05

0.65

0.08±0.05

7.8±0.1

(5.0)

24 13

(3.4)

112

1PIN MARK

S

0.08

+0.05

0.24

0.08

-

0.04

4°

S

M

+

6°

−

4°

0.53±0.15

+0.05

0.17

-

0.03

(Unit : mm)

<Tape and Reel information>

Quantity

Direction

1.0±0.2

of feed

Embossed carrier tape (with dry pack)Tape

2000pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

-E 2

Packaging and forming specification

E2: Embossed tape and reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

Direction of feed

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

14/14

2010.05 - Rev.B

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other parties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

Notice

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes efforts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller, fuelcontroller or other safety device). ROHM shall bear no responsibility in any way for use of any

of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

http://www.rohm.com/contact/

R1010

A

Loading...

Loading...