Voltage Detector IC Series

Standard CMOS

Voltage Detector IC

BD48xxx series BD49xxx series

●General Description

ROHM’s BD48xxx and BD49xxx series are highly

accurate, low current consumption reset IC series. The

line up includes BD48xxx devices with N channel open

drain output and BD49xxx devices with CMOS output.

The devices are available for specific detection voltages

ranging from 2.3V to 6.0V in increments of 0.1V.

●Features

High accuracy detection

Ultra-low current consumption

Two output types (Nch open drain and CMOS output)

Wide Operating temperature range

Very small and low height package

Package SSOP5 is similar to SOT-23-5 (JEDEC)

Package SSOP3 is similar to SOT-23-3 (JEDEC)

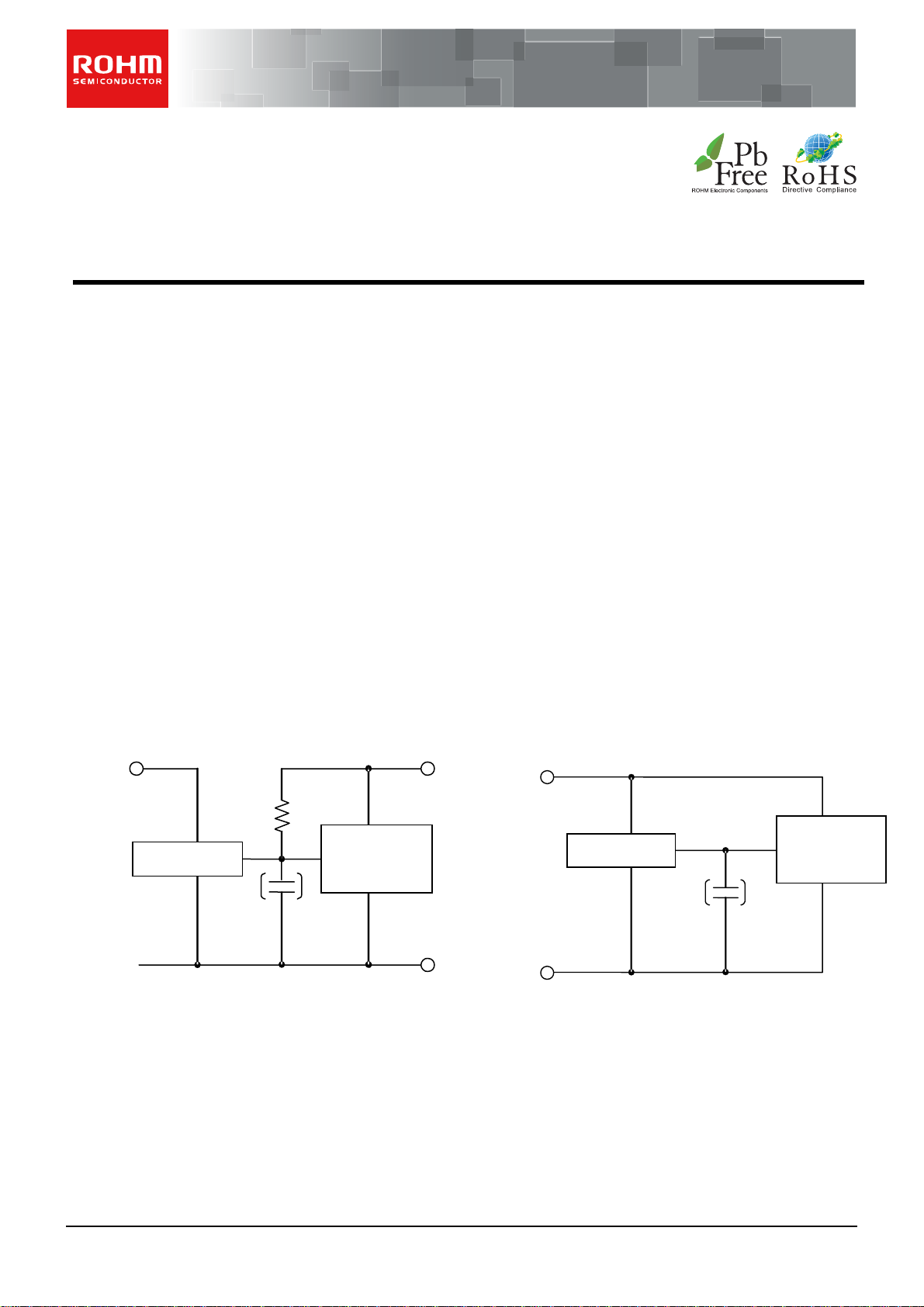

●Ty pical A pplication Circuit

Datasheet

●Key Specifications

Detection voltage: 2.3V to 6.0V (Typ.),

0.1V steps

High accuracy detection voltage: ±1.0%

Ultra-low current consumption: 0.9A (Typ.)

Operating temperature range: -40°C to +105°C

●Package

SSOP5: 2.90mm x 2.80mm x 1.15mm

SSOP3: 2.90mm x 2.80mm x 1.15mm

VSOF5: 1.60 mm x 1.60mm x 0.60mm

●Applications

Circuits using microcontrollers or logic circuits that

require a reset.

DD1

V

○Product structure:Silicon monolithic integrated circuit ○This product is not designed protection against radioactive rays.

BD48xxx

(Open Drain Output type)

BD48xxx series

L

R

R

L

C

Capacitor for

(

noise filtering

ST

)

Micro

controller

DD2

V

DD1

V

GND

GND

BD49xxx

(CMOS Output type)

BD49xxx series

R

L

C

Capacitor for

(

noise filtering

ST

)

Micro

controller

www.rohm.com © 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・14・001

1/13

TSZ02201-0R7R0G300030-1-2

08.JUL.2012.Rev.006

BD48xxx series BD49xxx series

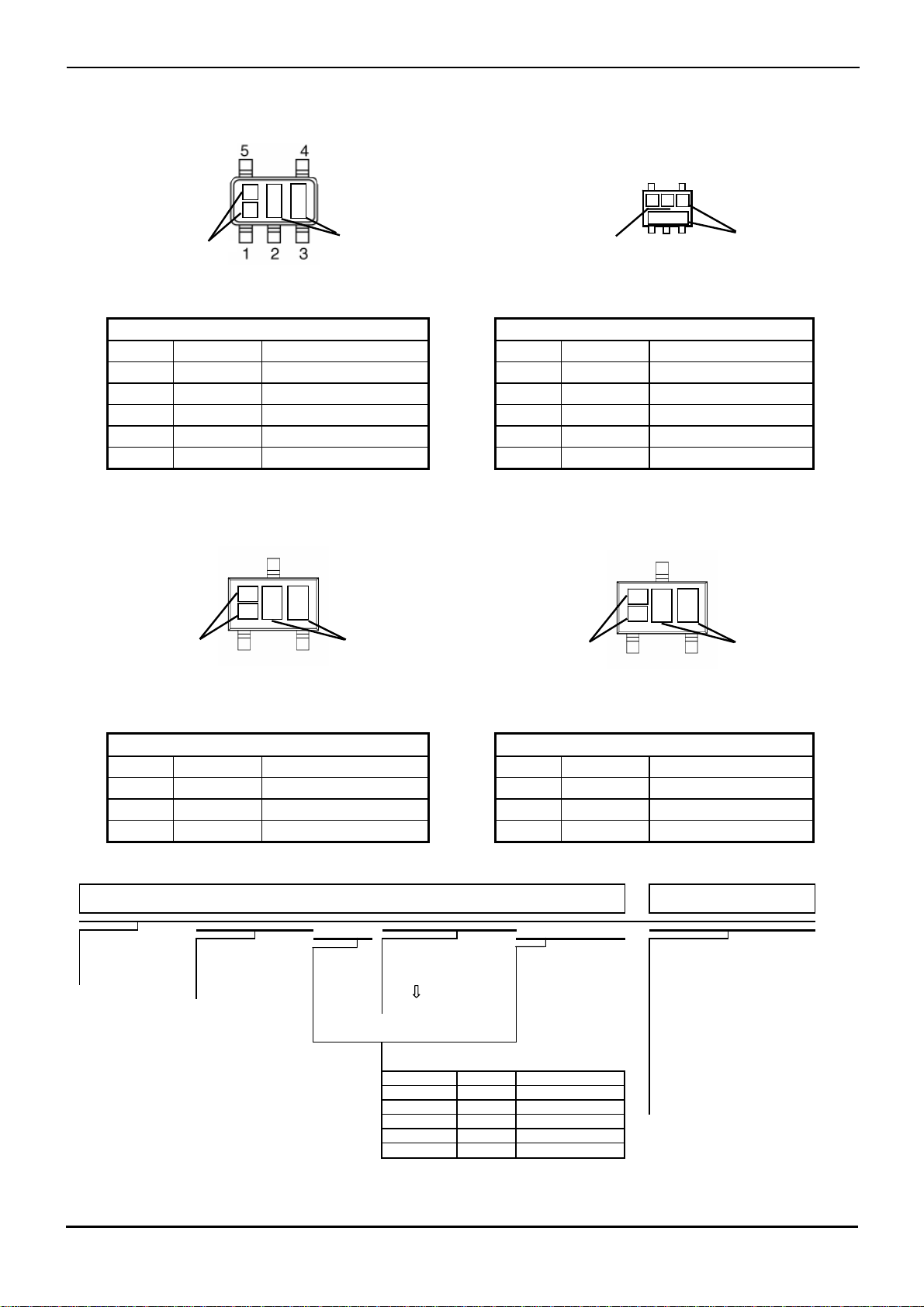

●Connection Diagram

SSOP5 VSOF5

N.C. N.C.

Datasheet

V

DD

GND

4

5

Marking

V

OUT VDD GND

TOP VIEW

Lot. No

Marking

2

3

1

OUT SUB N.C

V

TOP VIEW

Lot. No

●Pin Descriptions

SSOP5 VSOF5

PIN No. Symbol Function PIN No. Symbol Function

1 V

2 V

3 GND GND

4 N.C. Unconnected Terminal 4 GND GND

5 N.C.

*Connect the substrate to GND.

OUT Reset Output 1 VOUT Reset Output

DD Power Supply Voltage 2 SUB Substrate*

3 N.C.

Unconnected Terminal 5 V

DD Power Supply Voltage

Unconnected Terminal

SSOP3(1pin GND) SSOP3(3pin GND)

VDD

3

GND

3

Marking

1

GND

TOP VIEW

V

2

OUT

Lot. No

Marking

1

VOUT

TOP VIEW

Lot. No

2

VDD

●Pin Descriptions

SSOP3-1 SSOP3-2

PIN No. Symbol Function PIN No. Symbol Function

1 GND GND 1 V

2 V

3

OUT Reset Output 2 VDD Power Supply Voltage

DD Power Supply Voltage 3 GND GND

V

OUT Reset Output

z Ordering Information

BDx x -T Rxxx x

Part Output Type Package1 Reset Voltage Value Package2 Packageing and

Number 48 : Open Drain 23 : 2.3V forming specification

note)

49 : CMOS 0.1V step Embossed tape and reel

60 : 6.0V TR :The pin number 1is

the upper right

:SSOP5

:VSOF5

TL :The pin number 1is

Package1 Package2 Package name the upper left

E G SSOP5 :SSOP3-1

K G SSOP3(1pin GND) :SSOP3-2

L G SSOP3(3pin GND)

Blank FVE VSOF5

Blank G SSOP5

Please be new and, in hope of SSOP5, choose the package 1 by "E" and package 2" G."

www.rohm.com © 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

2/13

TSZ02201-0R7R0G300030-1-2

08.JUL.2012.Rev.006

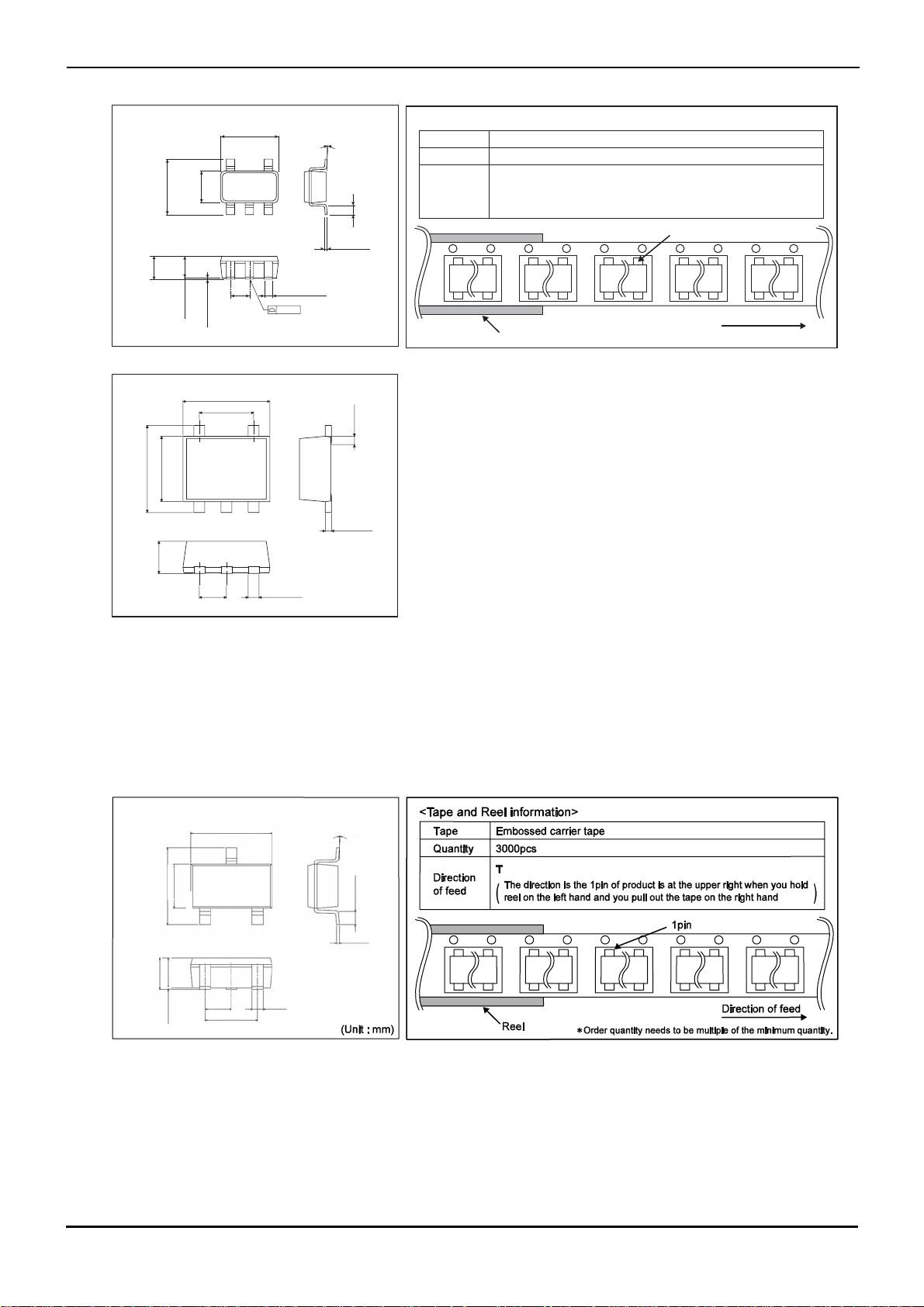

BD48xxx series BD49xxx series

SSOP3

0.45±0.1

5

5

0.95

Datasheet

SSOP5

°

2.9±0.2

5

4

+0.2

−0.1

2.8±0.2

1.6

12

3

4

0.13

+

6

°

°

−4

0.2Min.

+0.05

−0.03

<Tape and Reel information>

Embossed carrier tapeTape

Quantity

Direction

of feed

3000pcs

TR

The direction is the 1pin of product is at the upper right when you hold

()

reel on the left hand and you pull out the tape on the right hand

1.25Max.

VSOF5

1.1±0.05

0.05±0.05

0.95

+0.05

0.42

−0.04

0.1

(Unit : mm)

Reel

∗

5

1.6± 0.05

1.0± 0.05

4

0.2MAX

1.2± 0.05

1.6± 0.05

(MAX 1.28 include BURR)

1

2

3

0.13± 0.05

0.6MAX

0.5

0.22± 0.05

(Unit : mm)

2.92±0.1

3

1.6±0.1

2.8±0.15

1

2

4°±4°

L

MAX

1.1±0.05

1.2

1.9±0.1

0.4±0.1

1pin

Direction of feed

Order quantity needs to be multiple of the minimum quantity.

www.rohm.com © 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

3/13

TSZ02201-0R7R0G300030-1-2

08.JUL.2012.Rev.006

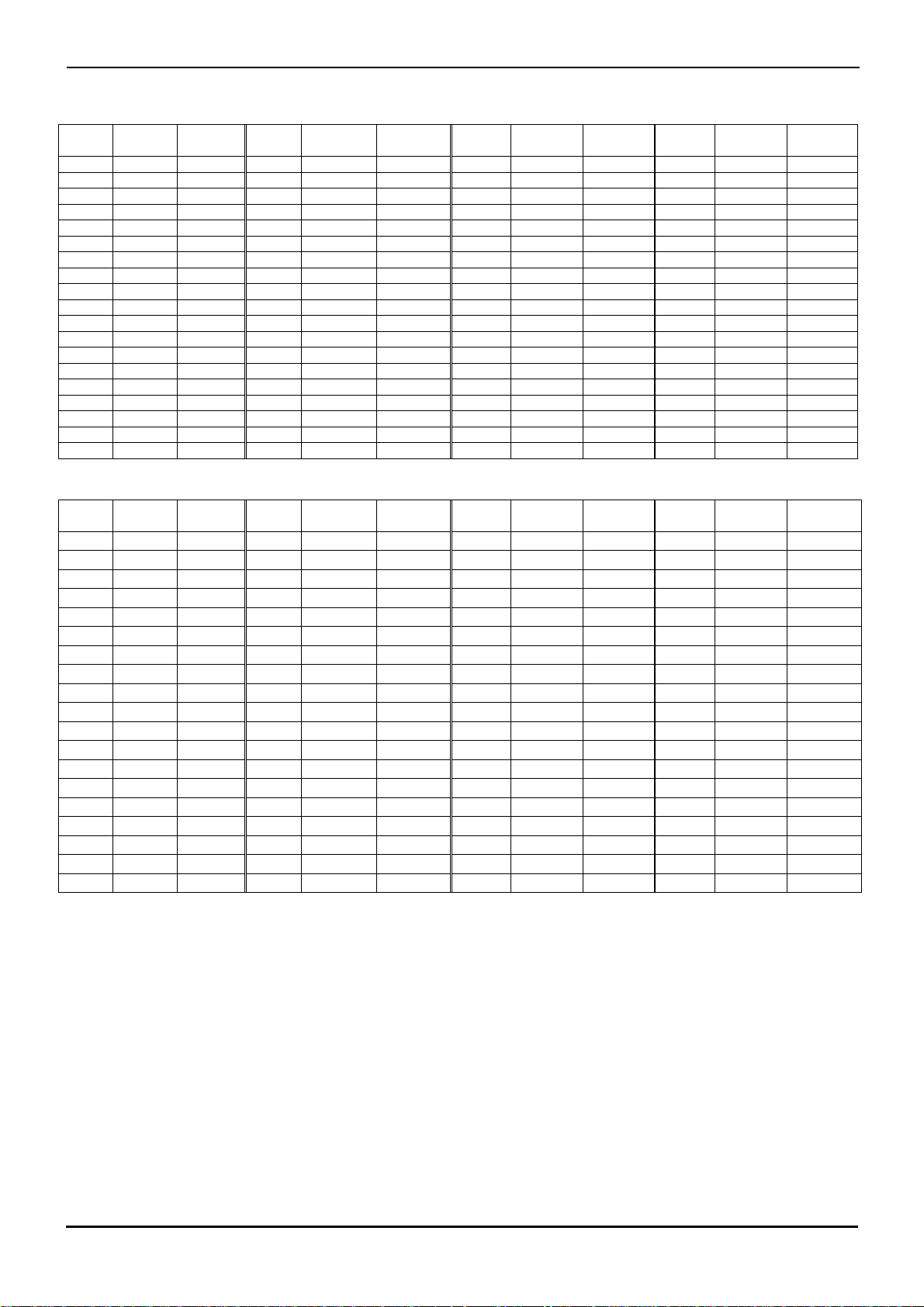

BD48xxx series BD49xxx series

Datasheet

●Lineup

Marking

Detection

Voltage

EW 6.0V BD4860 EB 4.1V BD4841 GW 6.0V BD4960 GB 4.1V BD4941

EV 5.9V BD4859 EA 4.0V BD4840 GV 5.9V BD4959 GA 4.0V BD4940

EU 5.8V BD4858 DV 3.9V BD4839 GU 5.8V BD4958 FV 3.9V BD4939

ET 5.7V BD4857 DU 3.8V BD4838 GT 5.7V BD4957 FU 3.8V BD4938

ES 5.6V BD4856 DT 3.7V BD4837 GS 5.6V BD4956 FT 3.7V BD4937

ER 5.5V BD4855 DS 3.6V BD4836 GR 5.5V BD4955 FS 3.6V BD4936

EQ 5.4V BD4854 DR 3.5V BD4835 GQ 5.4V BD4954 FR 3.5V BD4935

EP 5.3V BD4853 DQ 3.4V BD4834 GP 5.3V BD4953 FQ 3.4V BD4934

EN 5.2V BD4852 DP 3.3V BD4833 GN 5.2V BD4952 FP 3.3V BD4933

EM 5.1V BD4851 DN 3.2V BD4832 GM 5.1V BD4951 FN 3.2V BD4932

EL 5.0V BD4850 DM 3.1V BD4831 GL 5.0V BD4950 FM 3.1V BD4931

EK 4.9V BD4849 DL 3.0V BD4830 GK 4.9V BD4949 FL 3.0V BD4930

EJ 4.8V BD4848 DK 2.9V BD4829 GJ 4.8V BD4948 FK 2.9V BD4929

EH 4.7V BD4847 DJ 2.8V BD4828 GH 4.7V BD4947 FJ 2.8V BD4928

EG 4.6V BD4846 DH 2.7V BD4827 GG 4.6V BD4946 FH 2.7V BD4927

EF 4.5V BD4845 DG 2.6V BD4826 GF 4.5V BD4945 FG 2.6V BD4926

EE 4.4V BD4844 DF 2.5V BD4825 GE 4.4V BD4944 FF 2.5V BD4925

ED 4.3V BD4843 DE 2.4V BD4824 GD 4.3V BD4943 FE 2.4V BD4924

EC 4.2V BD4842 DD 2.3V BD4823 GC 4.2V BD4942 FD 2.3V BD4923

Part

Number

Marking

Detection

Voltage

Part

Number

Marking

Detection

Voltage

Part

Number

Marking

Detection

Voltage

Number

Ea

Dy

Dr

Dp

Dn

Dk

Dh

Dg

Df

De

Dd

Dc

Db

Da

Cy

Cr

Cp

Cn

Detection

Voltage

4.1V

4.0V

3.9V

3.8V

3.7V

3.6V

3.5V

3.4V

3.3V

3.2V

3.1V

3.0V

2.9V

2.8V

2.7V

2.6V

2.5V

2.4V

2.3V

Number

BD49E41

BD49E40

BD49E39

BD49E38

BD49E37

BD49E36

BD49E35

BD49E34

BD49E33

BD49E32

BD49E31

BD49E30

BD49E29

BD49E28

BD49E27

BD49E26

BD49E25

BD49E24

BD49E23

Marking

Cm

Ck

Ch

Cg

Cf

Ce

Cd

Cc

Cb

Ca

By

Br

Bp

Bn

Bm

Bk

Bh

Bg

Bf

Detection

Voltage

6.0V

5.9V

5.8V

5.7V

5.6V

5.5V

5.4V

5.3V

5.2V

5.1V

5.0V

4.9V

4.8V

4.7V

4.6V

4.5V

4.4V

4.3V

4.2V BD48E42

Part

Number

BD48E60

BD48E59

BD48E58

BD48E57

BD48E56

BD48E55

BD48E54

BD48E53

BD48E52

BD48E51

BD48E50

BD48E49

BD48E48

BD48E47

BD48E46

BD48E45

BD48E44

BD48E43

Marking

Be

Bd

Bc

Bb

Ba

Ay

Ar

Ap

An

Am

Ak

Ah

Ag

Af

Ae

Ad

Ac

Ab

Aa

Detection

Voltage

4.1V

4.0V

3.9V

3.8V

3.7V

3.6V

3.5V

3.4V

3.3V

3.2V

3.1V

3.0V

2.9V

2.8V

2.7V

2.6V

2.5V

2.4V

2.3V

Part

Number

BD48E41

BD48E40

BD48E39

BD48E38

BD48E37

BD48E36

BD48E35

BD48E34

BD48E33

BD48E32

BD48E31

BD48E30

BD48E29

BD48E28

BD48E27

BD48E26

BD48E25

BD48E24

BD48E23

Marking

Ff

Fe

Fd

Fc

Fb

Fa

Ey

Er

Ep

En

Em

Ek

Eh

Eg

Ef

Ee

Ed

Ec

Eb

Detection

Voltage

6.0V

5.9V

5.8V

5.7V

5.6V

5.5V

5.4V

5.3V

5.2V

5.1V

5.0V

4.9V

4.8V

4.7V

4.6V

4.5V

4.4V

4.3V

4.2V

Part

Number

BD49E60

BD49E59

BD49E58

BD49E57

BD49E56

BD49E55

BD49E54

BD49E53

BD49E52

BD49E51

BD49E50

BD49E49

BD49E48

BD49E47

BD49E46

BD49E45

BD49E44

BD49E43

BD49E42

Marking

Dm

Part

Part

www.rohm.com © 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

4/13

TSZ02201-0R7R0G300030-1-2

08.JUL.2012.Rev.006

BD48xxx series BD49xxx series

Marking

Cm

Ck

Ch

Cg

Cf

Ce

Cd

Cc

Cb

Ca

By

Br

Bp

Bn

Bm

Bk

Bh

Bg

Bf

Detection

Voltage

6.0V BD48K60

5.9V BD48K59

5.8V BD48K58

5.7V BD48K57

5.6V BD48K56

5.5V BD48K55

5.4V BD48K54

5.3V BD48K53

5.2V BD48K52

5.1V BD48K51

5.0V BD48K50

4.9V BD48K49

4.8V BD48K48

4.7V BD48K47

4.6V BD48K46

4.5V BD48K45

4.4V BD48K44

4.3V BD48K43

4.2V BD48K42

Part Number Marking

Be

Bd

Bc

Bb

Ba

Ay

Ar

Ap

An

Am

Ak

Ah

Ag

Af

Ae

Ad

Ac

Ab

Aa

Detection

Voltage

4.1V BD48K41

4.0V BD48K40

3.9V BD48K39

3.8V BD48K38

3.7V BD48K37

3.6V BD48K36

3.5V BD48K35

3.4V BD48K34

3.3V BD48K33

3.2V BD48K32

3.1V BD48K31

3.0V BD48K30

2.9V BD48K29

2.8V BD48K28

2.7V BD48K27

2.6V BD48K26

2.5V BD48K25

2.4V BD48K24

2.3V BD48K23

Marking

Kb

Ka

Hy

Hr

Hp

Hn

Hm

Hk

Hh

Hg

Hf

He

Hd

Hc

Hb

Ha

Gy

Gr

Gp

Detection

Voltage

6.0V BD48L60

5.9V BD48L59

5.8V BD48L58

5.7V BD48L57

5.6V BD48L56

5.5V BD48L55

5.4V BD48L54

5.3V BD48L53

5.2V BD48L52

5.1V BD48L51

5.0V BD48L50

4.9V BD48L49

4.8V BD48L48

4.7V BD48L47

4.6V BD48L46

4.5V BD48L45

4.4V BD48L44

4.3V BD48L43

4.2V BD48L42

Part Number Marking

Gn

Gm

Gk

Gh

Gg

Gf

Ge

Gd

Gc

Gb

Ga

Fy

Fr

Fp

Fn

Fm

Fk

Fh

Fg

Detection

Voltage

4.1V BD48L41

4.0V BD48L40

3.9V BD48L39

3.8V BD48L38

3.7V BD48L37

3.6V BD48L36

3.5V BD48L35

3.4V BD48L34

3.3V BD48L33

3.2V BD48L32

3.1V BD48L31

3.0V BD48L30

2.9V BD48L29

2.8V BD48L28

2.7V BD48L27

2.6V BD48L26

2.5V BD48L25

2.4V BD48L24

2.3V BD48L23

Part Number Marking

Ff

Fe

Fd

Fc

Fb

Fa

Ey

Er

Ep

En

Em

Ek

Eh

Eg

Ef

Ee

Ed

Ec

Eb

Part Number Marking

Np

Nn

Nm

Nk

Nh

Ng

Nf

Ne

Nd

Nc

Nb

Na

My

Mr

Mp

Mn

Mm

Mk

Mh

Detection

Voltage

6.0V BD49K60

5.9V BD49K59

5.8V BD49K58

5.7V BD49K57

5.6V BD49K56

5.5V BD49K55

5.4V BD49K54

5.3V BD49K53

5.2V BD49K52

5.1V BD49K51

5.0V BD49K50

4.9V BD49K49

4.8V BD49K48

4.7V BD49K47

4.6V BD49K46

4.5V BD49K45

4.4V BD49K44

4.3V BD49K43

4.2V BD49K42

Detection

Voltage

6.0V BD49L60

5.9V BD49L59

5.8V BD49L58

5.7V BD49L57

5.6V BD49L56

5.5V BD49L55

5.4V BD49L54

5.3V BD49L53

5.2V BD49L52

5.1V BD49L51

5.0V BD49L50

4.9V BD49L49

4.8V BD49L48

4.7V BD49L47

4.6V BD49L46

4.5V BD49L45

4.4V BD49L44

4.3V BD49L43

4.2V BD49L42

Part

Number

Part

Number

Marking

Ea

Dy

Dr

Dp

Dn

Dm

Dk

Dh

Dg

Df

De

Dd

Dc

Db

Da

Cy

Cr

Cp

Cn

Marking

Mg

Mf

Me

Md

Mc

Mb

Ma

Ky

Kr

Kp

Kn

Km

Kk

Kh

Kg

Kf

Ke

Kd

Kc

Datasheet

Detection

Voltage

4.1V BD49K41

4.0V BD49K40

3.9V BD49K39

3.8V BD49K38

3.7V BD49K37

3.6V BD49K36

3.5V BD49K35

3.4V BD49K34

3.3V BD49K33

3.2V BD49K32

3.1V BD49K31

3.0V BD49K30

2.9V BD49K29

2.8V BD49K28

2.7V BD49K27

2.6V BD49K26

2.5V BD49K25

2.4V BD49K24

2.3V BD49K23

Detection

Voltage

4.1V BD49L41

4.0V BD49L40

3.9V BD49L39

3.8V BD49L38

3.7V BD49L37

3.6V BD49L36

3.5V BD49L35

3.4V BD49L34

3.3V BD49L33

3.2V BD49L32

3.1V BD49L31

3.0V BD49L30

2.9V BD49L29

2.8V BD49L28

2.7V BD49L27

2.6V BD49L26

2.5V BD49L25

2.4V BD49L24

2.3V BD49L23

Number

Number

Part

Part

www.rohm.com © 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

5/13

TSZ02201-0R7R0G300030-1-2

08.JUL.2012.Rev.006

BD48xxx series BD49xxx series

●Absolute Maximum Ratings (Ta=25°C)

Parameter Symbol Limits Unit

Power Supply Voltage VDD-GND -0.3 to +10 V

Output Voltage

Dissipation

Nch Open Drain Output GND-0.3 to +10

CMOS Output

SSOP5

VSOF5

*1*3

*2*3

V

OUT

540 Power

Pd

GND-0.3 to V

210

DD

+0.3

mW

Operating Temperature Topr -40 to +105 °C

Ambient Storage Temperature Tstg -55 to +125 °C

*1 Use above Ta=25°C results in a 5.4mW loss per degree.

*2 Use above Ta=25°C results in a 2.1mW loss per degree.

*3 When a ROHM standard circuit board (70mm×70mm×1.6mm glass epoxy board) is mounted.

●Electrical Characteristics (Unless Otherwise Specified Ta=-40 to 105°C)

Parameter Symbol Condition

Detection Voltage V

Output Delay Time “LÆH” tPLH

Circuit Current when ON ICC1 VDD=V

Circuit Current when OFF ICC2 VDD=V

Operating Voltage Range VOPL

‘Low’Output Current (Nch) IOL

‘High’Output Current (Pch)

(BD49xxx Series)

Leak Current when OFF

(BD48xxx Series)

Detection Voltage

Temperature coefficient

Hysteresis Voltage V

V

(T) : Standard Detection Voltage(2.3V to 6.0V, 0.1V step)

DET

RL: Pull-up resistor to be connected between VOUT and power supply.

RL=470k, VDD=HÆL

DET

CL=100pF RL=100k

Vout=GNDÆ50%

V

DET

V

DET

DET

-0.2V

+2.0V

*1

*1

DET

V

DET

V

DET

V

DET

V

DET

V

DET

V

DET

VOL0.4V, Ta=25 to 105°C, RL=470k 0.95 - -

V

OL0.4V, Ta=-40 to 25°C, RL=470k 1.20 - -

VDS=0.5V, VDD=1.5V, V

V

DS=0.5V, VDD=2.4V, V

VDS=0.5V, VDD=4.8V, V

IOH

I

V

DET

VDS=0.5V, VDD=6.0V, V

DS=0.5V, VDD=8.0V, V

V

VDD=VDS=10V

leak

Ta=-40°C to 105°C

/T

(Designed Guarantee)

VDD=LÆHÆL V

DET

=2.3-6.0V 0.4 1.0 -

DET

=2.7-6.0V 2.0 4.0 -

DET

=2.3-4.2V 0.7 1.4 -

DET

=4.3-5.2V 0.9 1.8 -

DET

=5.3-6.0V 1.1 2.2 -

DET

Min. Typ. Max.

V

(T)

DET

*1

×0.99

*2

- - 100 µs

=2.3-3.1V - 0.51 1.53

=3.2-4.2V - 0.56 1.68

=4.3-5.2V - 0.60 1.80

=5.3-6.0V - 0.66 1.98

=2.3-3.1V - 0.75 2.25

=3.2-4.2V - 0.80 2.40

=4.3-5.2V - 0.85 2.55

=5.3-6.0V - 0.90 2.70

*1

- - 0.1 µA

- ±100 ±360 ppm/°C

×0.03 V

DET

Limit

V

DET

×0.05 V

DET

CL: Capacitor to be connected between VOUT and GND.

Designed Guarantee. (Outgoing inspection is not done on all products.)

*1 Guarantee is Ta=25°C.

*2 t

PLH:VDD=(V

typ.-0.5V)Æ(V

DET

typ.+0.5V)

DET

V

(T)

Datasheet

V

(T)

DET

×1.01

×0.08 V

DET

Unit

V

µA

µA

V

mA

mA

www.rohm.com © 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

6/13

TSZ02201-0R7R0G300030-1-2

08.JUL.2012.Rev.006

BD48xxx series BD49xxx series

●Block Diagrams

Vref

VDD

Vref

Fig.1 BD48xxx series

VDD

Fig.2 BD49xxx series

GND

GND

OUT

V

VOUT

Datasheet

www.rohm.com © 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

7/13

TSZ02201-0R7R0G300030-1-2

08.JUL.2012.Rev.006

BD48xxx series BD49xxx series

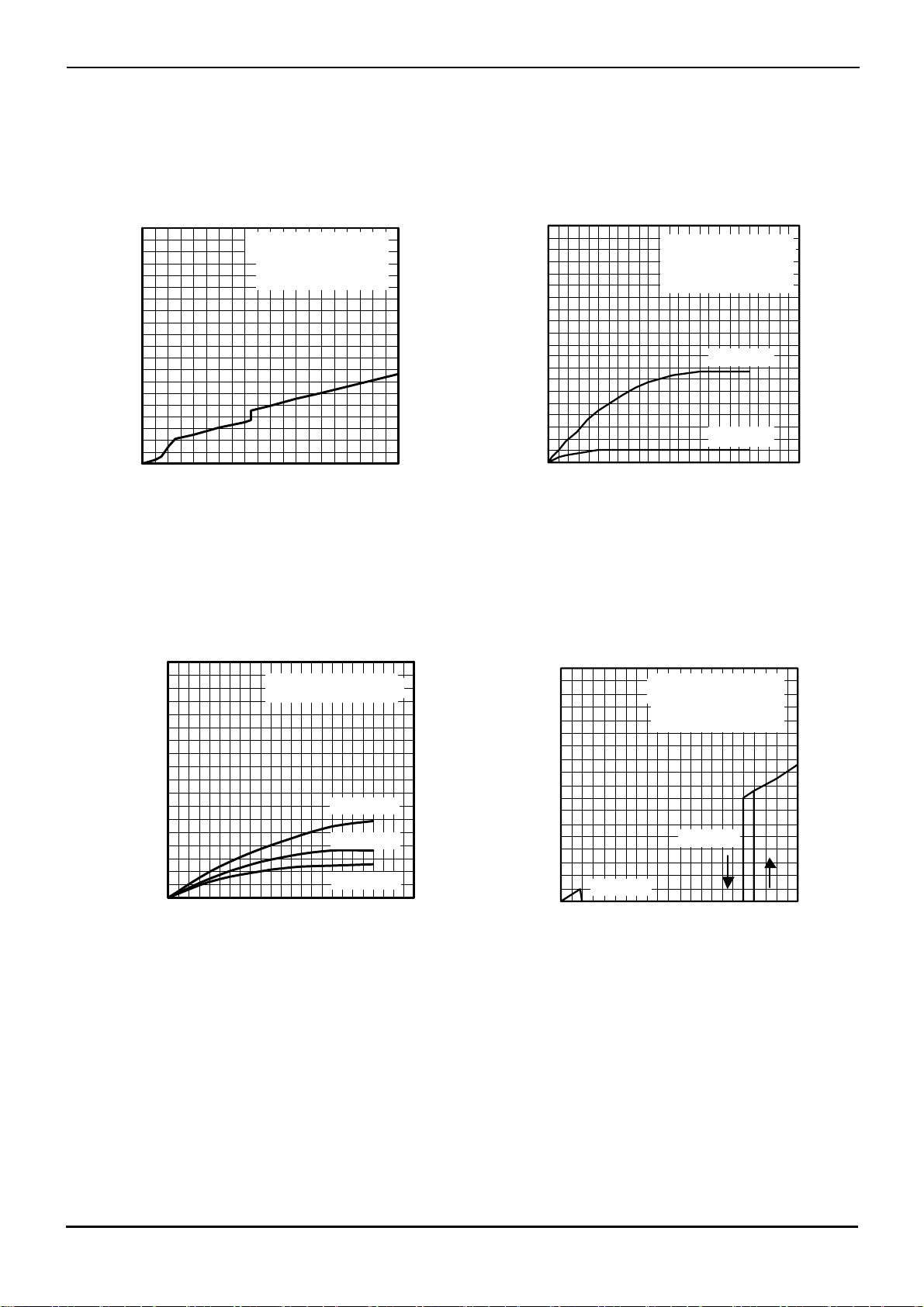

●Typical Performance Curves

Datasheet

2.0

【BD48x42】

BD4842G/FVE

【

[A]

DD

1.5

I

:

【BD49x42】

1.0

0.5

CIRCUIT CURRENT

0.0

012345678910

DD

SUPPLY VOLTAGE :VDD[V]

V

Fig.3 Circuit Current

45

BD4942G/FVE

40

[mA]

OH

I

35

:

【

【BD49x42】

30

25

20

VDD=8.0V

15

10

5

0

"HIGH" OUTPUT CURRENT

VDD=6.0V

VDD=4.8V

0123456

DRAIN-SOURCE VOLTAGE : V

20

】

[mA]

OL

I

:

15

BD4842G/FVE

【BD48x42】

【

【BD49x42】

】

10

VDD=2.4V

5

VDD=1.2V

0

"LOW" OUTPUT CURRENT

0.0 0.5 1.0 1.5 2.0 2.5

DRAIN-SOURCE VOLTAGE : V

DS

[V]

Fig.4 “Low” Output Current

9

】

[V]

OUT

V

:

8

7

6

BD4842G/F VE

【BD48x42】

【

【BD49x42】

】

5

4

3

Ta=25

℃

DS

[V]

2

OUTPUT VOLTAGE

1

Ta=25

0

00.5 11.522.5 33.544.5 55.5

℃

VDD SUPPLY VOLTAGE :VDD[V]

Fig.5 “High” Output Current

www.rohm.com © 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

8/13

Fig.6 I/O Characteristics

TSZ02201-0R7R0G300030-1-2

08.JUL.2012.Rev.006

BD48xxx series BD49xxx series

Datasheet

OUTPUT VOLTAGE

A]

μ

[

DD1

I

:

[V]

OUT

V

:

1.0

0.8

0.6

0.4

0.2

0.0

1.5

1.0

【BD48x42】

BD4842G/FVE

【

【

【BD49x42】

0

0.5

1

1.5

SUPPLY VOLTAGE :

Fig.7 Operating Limit Voltage

BD4842G/F VE

【

【

【BD48x42】

【BD49x42】

BD48x42x

2

[V]

BD48x42x

】

】

5.4

】

[V]

DET

V

5.0

Low to High(V

4.6

4.2

2.5

3.8

DETECTION VOLTAGE:

3.4

~

~

3.0

-40 0 40 80

High to Low(V

TEMPERATURE

BD4842G/FVE

【BD48x42】

BD48x42x

【

【

【BD49x42】

+ΔV

)

:

Ta[ ℃]

】

】

)

Fig.8 Detection Voltage

Release Voltage

1.5

A]

】

μ

[

DD2

I

:

BD48x42x

BD4842G/F VE

【

【

【BD48x42】

【BD49x42】

】

】

1.0

0.5

0.0

CIRCUIT CURRENT WHEN ON

-40 -20 0 20 40 60 80 100

TEMPERATURE : Ta[℃]

Fig.9 Circuit Current when ON

www.rohm.com © 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

9/13

0.5

0.0

CIRCUIT CURRENT WHEN OFF

-40 -20 0 20 40 60 80 100

TEM PERATURE : Ta[℃]

Fig.10 Circuit Current when OFF

TSZ02201-0R7R0G300030-1-2

08.JUL.2012.Rev.006

BD48xxx series BD49xxx series

1.5

BD48x42x

BD4842G/FVE

[V]

OPL

V

:

【

【

【BD48x42】

【BD49x42】

1.0

0.5

MINIMUM OPERATION VOLTAGE

0.0

-40 -20 0 20 40 60 80 100

TEMPERATURE : Ta[℃]

Fig.11 Operating Limit Voltage

】

Datasheet

】

www.rohm.com © 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

10/13

TSZ02201-0R7R0G300030-1-2

08.JUL.2012.Rev.006

BD48xxx series BD49xxx series

Datasheet

●Application Information

Explanation of Operation

For both the open drain type (Fig.12) and the CMOS output type (Fig.13), the detection and release voltages are used as

threshold voltages. When the voltage applied to the V

pins reaches the applicable threshold voltage, the V

DD

OUT

voltage switches from either “High” to “Low” or from “Low” to “High”. Please refer to the Timing Waveform and Electrical

Characteristics for information on hysteresis.

or another

DD

Because the BD48xxx series uses an open drain output type, it is possible to connect a pull-up resistor to V

power supply [The output “High” voltage (V

R1

Vref

R2

R3

) in this case becomes VDD or the voltage of the other power supply].

OUT

Q1

V

DD

R

L

V

OUT

GND

Vref

R1

R2

R3

Q2

Q1

Fig.12 (BD48xxx series Internal Block Diagram) Fig.13 (BD49xxx series Internal Block Diagram)

Reference Data

Examples of Leading (t

Part Number t

) and Falling (t

PLH

) Output

PHL

(s) t

PLH

PHL

(s)

BD48x45 39.5 87.8

BD49x45 32.4 52.4

V

=4.3VÆ5.1V VDD=5.1VÆ4.3V

DD

*This data is for reference only.

The figures will vary with the application, so please confirm actual operating conditions before use.

Timing Waveform

Example: the following shows the relationship between the input voltages VDD and the output voltage V

input power supply voltage V

is made to sweep up and sweep down (the circuits are those in Fig.12 and 13).

DD

when the

OUT

1

When the power supply is turned on, the output is unsettled from

VDD

VDET+ΔVDET

V

OUT

0V

VOH

VOL

VDET

VOPL

tPHL

tPLH

tPHL

①

②

③ ④

Fig.14 Timing Waveform

⑤

tPLH

after over the operating limit voltage (V

possible that the reset signal is not valid when the rise time of V

DET

PHL

+ V

.

but less than the reset release

OPL

), the output voltages will switch to Low.

DET

faster than t

2

When VDD is greater than V

voltage (V

3

If VDD exceeds the reset release voltage (V

V

switches from L to H.

OUT

4

If VDD drops below the detection voltage (V

supply is powered down or when there is a power supply fluctuation,

switches to L (with a delay of t

V

OUT

5

The potential difference between the detection voltage and the

PHL

release voltage is known as the hysteresis width (V

system is designed such that the output does not flip-flop with power

).

OPL

) until t

DET

. Therefore it is

PHL

+ V

DET

) when the power

supply fluctuations within this hysteresis width, preventing

malfunctions due to noise.

terminal

V

DD

V

OUT

GND

DD

), then

DET

). The

DET

is

www.rohm.com © 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

11/13

TSZ02201-0R7R0G300030-1-2

08.JUL.2012.Rev.006

BD48xxx series BD49xxx series

●Circuit Applications

Examples of a common power supply detection reset circuit.

DD1

V

L

R

BD48xxx

C

L

capacitor is for

(

noise filtering

R

ST

Micro

controller

)

Fig.15 Open Drain Output Type

DD1

V

BD49xxx

C

capacitor is for

(

filtering

ST

R

L

)

GND

Fig.16 CMOS Output Type

DD2

V

GND

Micro

controller

Datasheet

Application examples of BD48xxx series (Open Drain

output type) and BD49xxx series (CMOS output type) are

shown below.

CASE1: the power supply of the microcontroller (V

differs from the power supply of the reset detection (V

Use an open drain output type (BD48xxx) device with a

load resistance R

CASE2: the power supply of the microcontroller (V

same as the power supply of the reset detection (V

Use a CMOS output type (BD49xxx) device or an open

drain device with a pull up resistor between output and

VDD1.

When a capacitance C

the V

pin (the reset signal input terminal of the

OUT

microcontroller), please take into account the waveform of

the rise and fall of the output voltage (V

The Electrical characteristics were measured using

= 470k and CL = 100pF.

R

L

attached as shown in figure 15.

L

for noise filtering is connected to

L

).

OUT

DD1

DD1

DD1

).

DD2

).

) is

)

www.rohm.com © 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

12/13

TSZ02201-0R7R0G300030-1-2

08.JUL.2012.Rev.006

BD48xxx series BD49xxx series

Datasheet

●Operational Notes

1 . Absolute maximum range

Absolute Maximum Ratings are those values beyond which the life of a device may be destroyed. We cannot be defined the

failure mode, such as short mode or open mode. Therefore a physical security countermeasure, like fuse, is to be given when

a specific mode to be beyond absolute maximum ratings is considered.

2 . GND potential

GND terminal should be a lowest voltage potential every state.

Please make sure all pins, which are over ground even if, include transient feature.

3 . Electrical Characteristics

Be sure to check the electrical characteristics that are one the tentative specification will be changed by temperature, supply

voltage, and external circuit.

4 . Bypass Capacitor for Noise Rejection

Please put into the capacitor of 1F or more between V

pin and GND, and the capacitor of about 1000pF between V

DD

OUT

and GND, to reject noise. If extremely big capacitor is used, transient response might be late. Please confirm sufficiently for the

point.

5 . Short Circuit between Terminal and Soldering

Don’t short-circuit between Output pin and V

pin, Output pin and GND pin, or VDD pin and GND pin. When soldering the IC

DD

on circuit board, please be unusually cautious about the orientation and the position of the IC. When the orientation is

mistaken the IC may be destroyed.

6 . Electromagnetic Field

Mal-function may happen when the device is used in the strong electromagnetic field.

7 . The V

line inpedance might cause oscillation because of the detection current.

DD

8. A V

-GND capacitor (as close connection as possible) should be used in high VDD line impedance condition.

DD

9 . Lower than the mininum input voltage makes the V

OUT high impedance, and it must be VDD in pull up (VDD) condition.

10. This IC has extremely high impedance terminals. Small leak current due to the uncleanness of PCB surface might cause

unexpected operations. Application values in these conditions should be selected carefully. If the leakage is assumed

between the V

terminal and the GND terminal, the pull-up resistor should be less than 1/10 of the assumed leakage

OUT

resistance.

11. External parameters

The recommended parameter range for R

is 10k to 1M. There are many factors (board layout, etc) that can affect

L

characteristics. Please verify and confirm using practical applications.

12. Power on reset operation

Please note that the power on reset output varies with the V

rise up time. Please verify the actual operation.

DD

13. Precautions for board inspection

Connecting low-impedance capacitors to run inspections with the board may produce stress on the IC. Therefore, be certain

to use proper discharge procedure before each process of the test operation.

To prevent electrostatic accumulation and discharge in the assembly process, thoroughly ground yourself and any

equipment that could sustain ESD damage, and continue observing ESD-prevention procedures in all handing, transfer and

storage operations. Before attempting to connect components to the test setup, make certain that the power supply is OFF.

Likewise, be sure the power supply is OFF before removing any component connected to the test setup.

14. When the power supply, is turned on because of in certain cases, momentary Rash-current flow into the IC at the logic

unsettled, the couple capacitance, GND pattern of width and leading line must be considered.

pin

Status of this document

The Japanese version of this document is formal specification. A customer may use this translation version only for a reference

to help reading the formal version.

If there are any differences in translation version of this document formal version takes priority.

www.rohm.com © 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

13/13

TSZ02201-0R7R0G300030-1-2

08.JUL.2012.Rev.006

Datasheet

Datasheet

Notice

●General Precaution

1) Before you use our Products, you are requested to carefully read this document and fully understand its contents.

ROHM shall not be in any way responsible or liable for failure, malfunction or accident arising from the use of any

ROHM’s Products against warning, caution or note contained in this document.

2) All information contained in this document is current as of the issuing date and subject to change without any prior

notice. Before purchasing or using ROHM’s Products, please confirm the latest information with a ROHM sales

representative.

●Precaution on using ROHM Products

1) Our Products are designed and manufactured for application in ordinary electronic equipments (such as AV equipment,

OA equipment, telecommunication equipment, home electronic appliances, amusement equipment, etc.). If you

intend to use our Products in devices requiring extremely high reliability (such as medical equipment, transport

equipment, traffic equipment, aircraft/spacecraft, nuclear power controllers, fuel controllers, car equipment including car

accessories, safety devices, etc.) and whose malfunction or failure may cause loss of human life, bodily injury or

serious damage to property (“Specific Applications”), please consult with the ROHM sales representative in advance.

Unless otherwise agreed in writing by ROHM in advance, ROHM shall not be in any way responsible or liable for any

damages, expenses or losses incurred by you or third parties arising from the use of any ROHM’s Products for Specific

Applications.

2) ROHM designs and manufactures its Products subject to strict quality control system. However, semiconductor

products can fail or malfunction at a certain rate. Please be sure to implement, at your own responsibilities, adequate

safety measures including but not limited to fail-safe design against the physical injury, damage to any property, which

a failure or malfunction of our Products may cause. The following are examples of safety measures:

[a] Installation of protection circuits or other protective devices to improve system safety

[b] Installation of redundant circuits to reduce the impact of single or multiple circuit failure

3) Our Products are designed and manufactured for use under standard conditions and not under any special or

extraordinary environments or conditions, as exemplified below. Accordingly, ROHM shall not be in any way

responsible or liable for any damages, expenses or losses arising from the use of any ROHM’s Products under any

special or extraordinary environments or conditions. If you intend to use our Products under any special or

extraordinary environments or conditions (as exemplified below), your independent verification and confirmation of

product performance, reliability, etc, prior to use, must be necessary:

[a] Use of our Products in any types of liquid, including water, oils, chemicals, and organic solvents

[b] Use of our Products outdoors or in places where the Products are exposed to direct sunlight or dust

[c] Use of our Products in places where the Products are exposed to sea wind or corrosive gases, including Cl

2S, NH3, SO2, and NO2

H

[d] Use of our Products in places where the Products are exposed to static electricity or electromagnetic waves

[e] Use of our Products in proximity to heat-producing components, plastic cords, or other flammable items

[f] Sealing or coating our Products with resin or other coating materials

[g] Use of our Products without cleaning residue of flux (even if you use no-clean type fluxes, cleaning residue of

flux is recommended); or Washing our Products by using water or water-soluble cleaning agents for cleaning

residue after soldering

[h] Use of the Products in places subject to dew condensation

4) The Products are not subject to radiation-proof design.

5) Please verify and confirm characteristics of the final or mounted products in using the Products.

6) In particular, if a transient load (a large amount of load applied in a short period of time, such as pulse) is applied,

confirmation of performance characteristics after on-board mounting is strongly recommended. Avoid applying power

exceeding normal rated power; exceeding the power rating under steady-state loading condition may negatively affect

product performance and reliability.

7) De-rate Power Dissipation (Pd) depending on Ambient temperature (Ta). When used in sealed area, confirm the actual

ambient temperature.

8) Confirm that operation temperature is within the specified range described in the product specification.

9) ROHM shall not be in any way responsible or liable for failure induced under deviant condition from what is defined in

this document.

2,

Notice - Rev.003

© 2012 ROHM Co., Ltd. All rights reserved.

Datasheet

●Precaution for Mounting / Circuit board design

1) When a highly active halogenous (chlorine, bromine, etc.) flux is used, the residue of flux may negatively affect product

performance and reliability.

2) In principle, the reflow soldering method must be used; if flow soldering method is preferred, please consult with the

ROHM representative in advance.

For details, please refer to ROHM Mounting specification

●Precautions Regarding Application Examples and External Circuits

1) If change is made to the constant of an external circuit, please allow a sufficient margin considering variations of the

characteristics of the Products and external components, including transient characteristics, as well as static

characteristics.

2) You agree that application notes, reference designs, and associated data and information contained in this document

are presented only as guidance for Products use. Therefore, in case you use such information, you are solely

responsible for it and you must exercise your own independent verification and judgment in the use of such information

contained in this document. ROHM shall not be in any way responsible or liable for any damages, expenses or losses

incurred by you or third parties arising from the use of such information.

●Precaution for Electrostatic

This Product is electrostatic sensitive product, which may be damaged due to electrostatic discharge. Please take proper

caution in your manufacturing process and storage so that voltage exceeding the Products maximum rating will not be

applied to Products. Please take special care under dry condition (e.g. Grounding of human body / equipment / solder iron,

isolation from charged objects, setting of Ionizer, friction prevention and temperature / humidity control).

●Precaution for Storage / Transportation

1) Product performance and soldered connections may deteriorate if the Products are stored in the places where:

[a] the Products are exposed to sea winds or corrosive gases, including Cl2, H2S, NH3, SO2, and NO2

[b] the temperature or humidity exceeds those recommended by ROHM

[c] the Products are exposed to direct sunshine or condensation

[d] the Products are exposed to high Electrostatic

2) Even under ROHM recommended storage condition, solderability of products out of recommended storage time period

may be degraded. It is strongly recommended to confirm solderability before using Products of which storage time is

exceeding the recommended storage time period.

3) Store / transport cartons in the correct direction, which is indicated on a carton with a symbol. Otherwise bent leads

may occur due to excessive stress applied when dropping of a carton.

4) Use Products within the specified time after opening a humidity barrier bag. Baking is required before using Products of

which storage time is exceeding the recommended storage time period.

●Precaution for Product Label

QR code printed on ROHM Products label is for ROHM’s internal use only.

●Precaution for Disposition

When disposing Products please dispose them properly using an authorized industry waste company.

●Precaution for Foreign Exchange and Foreign Trade act

Since our Products might fall under controlled goods prescribed by the applicable foreign exchange and foreign trade act,

please consult with ROHM representative in case of export.

●Precaution Regarding Intellectual Property Rights

1) All information and data including but not limited to application example contained in this document is for reference

only. ROHM does not warrant that foregoing information or data will not infringe any intellectual property rights or any

other rights of any third party regarding such information or data. ROHM shall not be in any way responsible or liable

for infringement of any intellectual property rights or other damages arising from use of such information or data.:

2) No license, expressly or implied, is granted hereby under any intellectual property rights or other rights of ROHM or any

third parties with respect to the information contained in this document.

Datasheet

Notice - Rev.003

© 2012 ROHM Co., Ltd. All rights reserved.

Datasheet

●Other Precaution

1) The information contained in this document is provided on an “as is” basis and ROHM does not warrant that all

information contained in this document is accurate and/or error-free. ROHM shall not be in any way responsible or

liable for any damages, expenses or losses incurred by you or third parties resulting from inaccuracy or errors of or

concerning such information.

2) This document may not be reprinted or reproduced, in whole or in part, without prior written consent of ROHM.

3) The Products may not be disassembled, converted, modified, reproduced or otherwise changed without prior written

consent of ROHM.

4) In no event shall you use in any way whatsoever the Products and the related technical information contained in the

Products or this document for any military purposes, including but not limited to, the development of mass-destruction

weapons.

5) The proper names of companies or products described in this document are trademarks or registered trademarks of

ROHM, its affiliated companies or third parties.

Datasheet

Notice - Rev.003

© 2012 ROHM Co., Ltd. All rights reserved.

Loading...

Loading...