Page 1

Reversible Motor Drivers for Brush Motors

1.0A Reversible

Motor Drivers (Single Motor)

BA6956AN,BA6287F,BA6285FS,BA6285AFP-Y,BA6920FP-Y

●Description

The reversible motor driver for output 1.0A for 1 motor can set the output modes to four modes, normal, reverse, stop

(idling), and braking in accordance with logic input (2 inputs).

●Features

1) Built-in surge absorption diode

2) By built-in power save circuit, current consumption when a motor stops (idles) can be suppressed

3) Output voltage can be optionally set by reference voltage setting pin

4) Built-in thermal shutdown circuit (TSD)

●Applications

Audio-visual equipment; PC peripherals; Car audios; Car navigation systems; OA equipments

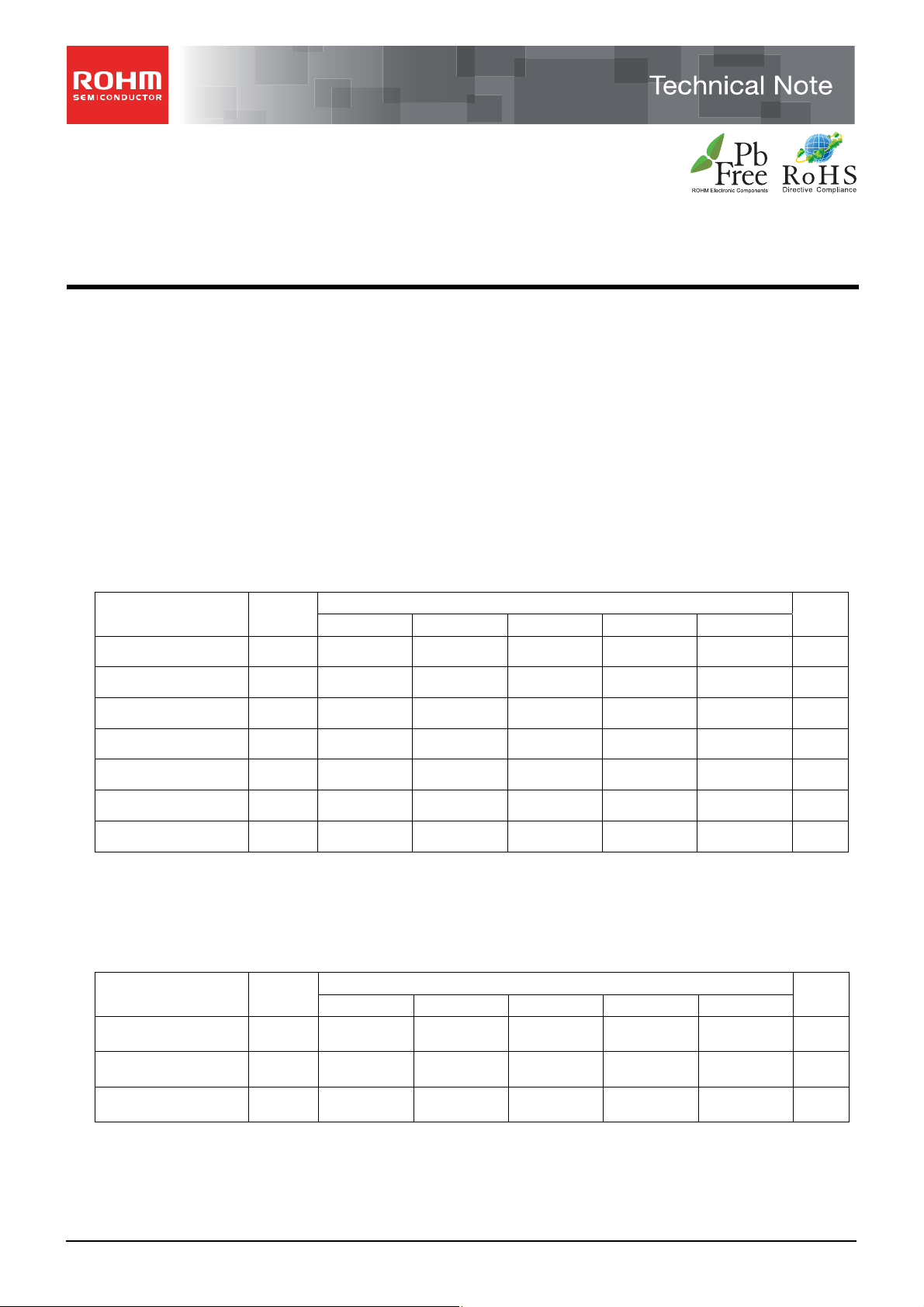

●Absolute maximum ratings (Ta=25℃, All voltages are with respect to ground)

Parameter Symbol

Supply voltage VCC 18 18 18 30 36 V

Supply voltage VM 18 18 18 30 36 V

Output current I

OMAX

BA6956AN BA6287F BA6285FS BA6285AFP-Y BA6920FP-Y

1*1 1*1 1*1 1*1 1*1 A

Ratings

No.11008EBT02

Unit

Operating temperature T

Storage temperature T

Power dissipation Pd 1.19*2 0.689*3 0.813*4 1.45*5 1.45*5 W

Junction temperature T

*1 Do not, exceed Pd or ASO.

*2 SIP9 package. Derated at 9.5mW/℃ above 25℃.

*3 SOP8 package. Mounted on a 70mm x 70mm x 1.6mm FR4 glass-epoxy board with less than 3% copper foil. Derated at 5.52mW/℃ above 25℃.

*4 SSOP-A16 package. Mounted on a 70mm x 70mm x 1.6mm FR4 glass-epoxy board with less than 3% copper foil. Derated at 6.5mW/℃ above 25℃.

*5 HSOP25 package. Mounted on a 70mm x 70mm x 1.6mm FR4 glass-epoxy board with less than 3% copper foil. Derated at 11.6mW/℃ above 25℃.

●Operating conditions (Ta=25℃)

Parameter Symbol

Supply voltage VCC 6.5 ~ 15 4.5 ~ 15 4.5 ~ 15 4.5 ~ 24 6.5 ~ 34 V

Supply voltage VM 6.5 ~ 15 4.5 ~ 15 4.5 ~ 15 4.5 ~ 24 6.5 ~ 34 V

VREF voltage VREF < VCC, VM < VCC, VM < VCC, VM < VCC, VM < VCC, VM V

-20 ~ 75 -20 ~ 75 -20 ~ 75 -40 ~ 85 -30 ~ 85 ℃

OPR

-55 ~ 150 -55 ~ 150 -55 ~ 150 -55 ~ 150 -55 ~ 150 ℃

STG

150 150 150 150 150 ℃

jmax

Ratings

BA6956AN BA6287F BA6285FS BA6285AFP-Y BA6920FP-Y

Unit

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

1/17

2011.05 - Rev.B

Page 2

BA6956AN,BA6287F,BA6285FS,BA6285AFP-Y,BA6920FP-Y

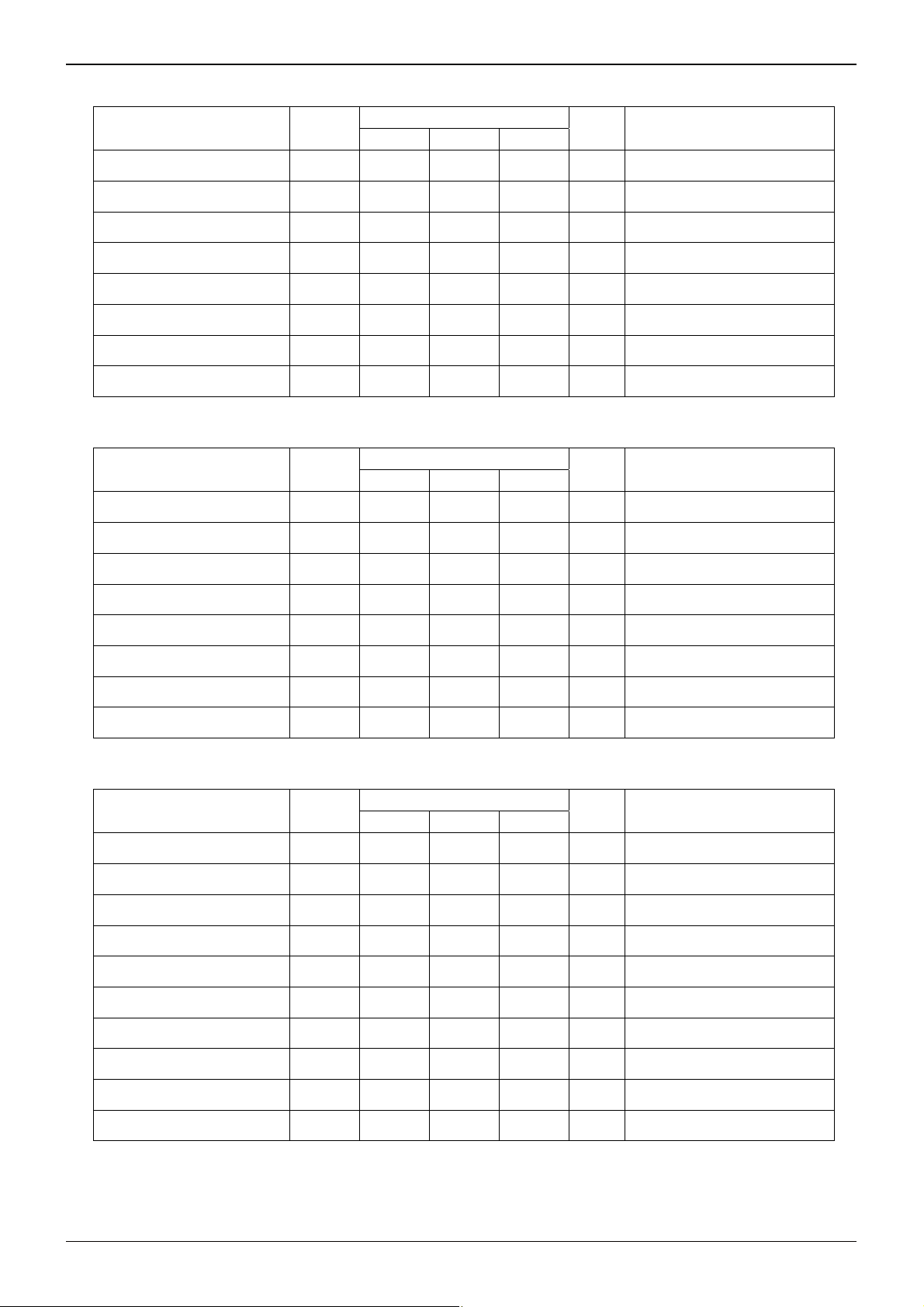

●Electrical characteristics (BA6956AN, unless otherwise specified, Ta=25℃ and VCC=9V, VM=9V)

Parameter Symbol

Min. Typ. Max.

Limits

Unit Conditions

Technical Note

Supply current 1 I

Supply current 2 I

Supply current 3 I

- 29 44 mA FWD/REV mode

CC1

- 56 80 mA Brake mode

CC2

- 0 15 µA Standby mode

CC3

Input threshold voltage H VIH 2.0 - VCC V

Input threshold voltage L VIL 0 - 0.8 V

Input bias current IIH 50 90 131 µA VIN=2V

Output saturation voltage VCE - 1.7 2.3 V IO=0.2A, vertically total

VREF bias current I

- 10 25 µA IO=0.2A, VREF=6V

REF

●Electrical characteristics (BA6287F, unless otherwise specified, Ta=25℃ and VCC=9V, VM=9V, VREF=9V)

Parameter Symbol

Supply current 1 I

Supply current 2 I

Min. Typ. Max.

12 24 36 mA FWD/REV mode

CC1

29 48 67 mA Brake mode

CC2

Limits

Unit Conditions

Standby current IST - 0 15 µA Standby mode

Input threshold voltage H VIH 2.0 - VCC V

Input threshold voltage L VIL 0 - 0.8 V

Input bias current IIH 45 90 135 µA VIN=2V

Output saturation voltage VCE - 1.0 1.5 V IO=0.2A, vertically total

VREF bias current I

6 12 18 mA IO=0.2A, FWD or REV mode

REF

●Electrical characteristics (BA6285FS, unless otherwise specified, Ta= 25℃ and VCC=9V, VM=9V, VREF=9V)

Parameter Symbol

Supply current 1 I

Supply current 2 I

Min. Typ. Max.

12 24 36 mA FWD/REV mode

CC1

29 48 67 mA Brake mode

CC2

Limits

Unit Conditions

Standby current IST - 0 15 µA Standby mode

Input threshold voltage H VIH 2.0 - VCC V

Input threshold voltage L VIL 0 - 0.8 V

Input bias current IIH 45 90 135 µA VIN=2V

Power save on voltage V

Power save off voltage V

2.0 - VCC V Standby mode

PSON

0 - 0.8 V Operation

PSOFF

Output saturation voltage VCE - 1.0 1.5 V IO=0.2A, vertically total

VREF bias current I

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

6 12 18 mA IO=0.2A, FWD or REV mode

REF

2/17

2011.05 - Rev.B

Page 3

BA6956AN,BA6287F,BA6285FS,BA6285AFP-Y,BA6920FP-Y

Technical Note

●Electrical characteristics (BA6285AFP-Y, unless otherwise specified, Ta=25℃ and VCC=9V, VM=9V, VREF=9V)

Parameter Symbol

Min. Typ. Max.

Limits

Unit Conditions

Supply current 1 I

Supply current 2 I

10 20 30 mA FWD/REV mode

CC1

21 42 63 mA Brake mode

CC2

Standby current IST - 0 15 µA Standby mode

Input threshold voltage H VIH 2.0 - VCC V

Input threshold voltage L VIL 0 - 0.8 V

Input bias current IIH 40 80 120 µA VIN=2V

Power save on voltage V

Power save off voltage V

- - 0.8 V Operation

PSON

2.0 - VCC V Standby mode

PSOFF

Output saturation voltage VCE - 1.0 1.5 V IO=0.2A, vertically total

VREF bias current I

9 15 21 mA IO=0.2A, FWD or REV mode

REF

●Electrical characteristics (BA6920FP-Y, unless otherwise specified, Ta=25℃ and VCC=12V, VM=12V)

Parameter Symbol

Supply current 1 I

Supply current 2 I

Min. Typ. Max.

5 8 12 mA FWD/REV mode

CC1

3 5 8 mA Brake mode

CC2

Limits

Unit Conditions

Standby current IST - 0 15 µA Standby mode

Input threshold voltage H VIH 3.0 - VCC V

Input threshold voltage L VIL 0 - 0.8 V

Input bias current IIH 100 200 300 µA VIN=3V

Power save on voltage V

Power save off voltage V

2.0 - VCC V Standby mode

PSON

- - 0.8 V Operation

PSOFF

Output saturation voltage VCE - 2.2 3.3 V IO=0.2A, vertically total

VREF bias current I

- 12 35 µA IO=0.1A, VREF=6V

REF

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

3/17

2011.05 - Rev.B

Page 4

BA6956AN,BA6287F,BA6285FS,BA6285AFP-Y,BA6920FP-Y

Technical Note

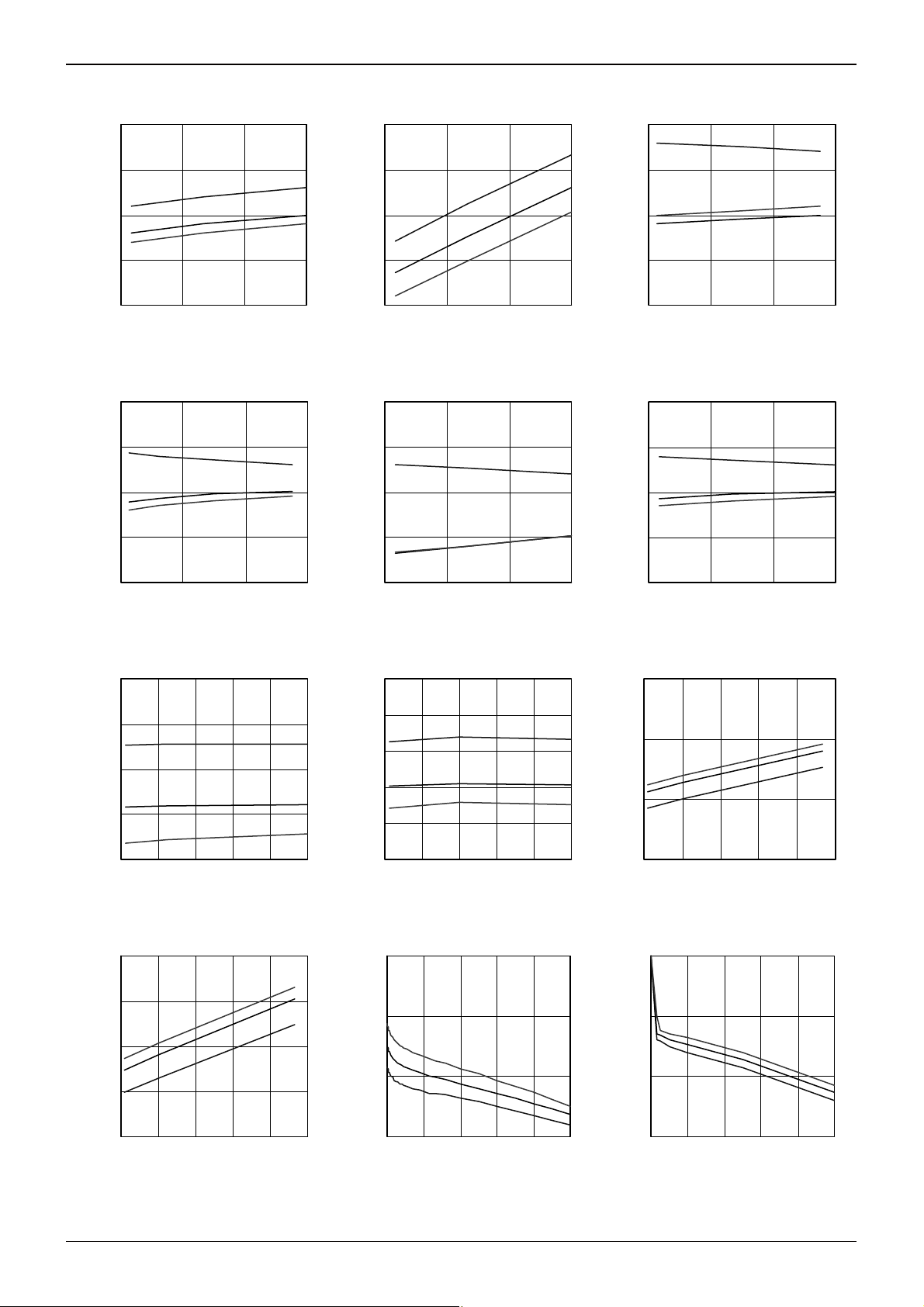

●Electrical characteristic curves (Reference data)

40

80

30

35

70

25

30

60

20

25

Supply Current: Icc1 [mA] _

20

6 9 12 15

Supply Voltage: Vcc [V]

Fig.1 Supply current 1 (forward) Fig.2 Supply current 2 (brake) Fig.3 Supply current 1 (forward)

(BA6956AN) (BA6956AN) (BA6287F)

60

-20°C

25°C

75°C

50

Circuit Current: Icc2 [mA] _

40

6 9 12 15

Supply Voltage: Vcc [V]

40

55

35

-20°C

25°C

75°C

-20°C

25°C

75°C

15

Circuit Current: Icc1 [mA] _

10

4 8 12 16

Supply Voltage: Vcc [V]

60

55

-20°C

25°C

75°C

50

45

Supply Current: Icc2 [mA] _

40

4 8 12 16

Supply Voltage: Vcc [V]

Fig.4 Supply current 2 (brake) Fig.5 Supply current 1 (forward) Fig.6 Supply current 2 (brake)

(BA6287F) (BA6285FS) (BA6285FS)

35

30

25

-20°C

25°C

75°C

-40°C

25°C

85°C

20

Circuit Current: Icc1 [mA] _

30

25

Circuit Current: Icc1 [mA] _

20

6 9 12 15

Supply Voltage: Vcc [V]

70

60

50

40

Circuit Current: Icc2 [mA] _

30

-40°C

25°C

85°C

50

45

Supply Current: Icc2 [mA] _

40

6 9 12 15

Supply Voltage: Vcc [V]

8

6

4

Circuit Current: Icc1 [mA] _

-25°C

25°C

75°C

-30°C

25°C

85°C

15

4 8 12 16 20 24

Supply Voltage: Vcc [V]

Fig.7 Supply current 1 (forward) Fig.8 Supply current 2 (brake) Fig.9 Supply current 1 (forward)

(BA6285AFP-Y) (BA6285AFP-Y) (BA6920FP-Y)

20

4 8 12 16 20 24

Supply Voltage: Vcc [V]

2

6 1218243036

Supply Voltage: Vcc [V]

12

10

8

8.5

75°C

25°C

-20°C

8.0

9.0

75°C

25°C

-20°C

8.5

6

Circuit Current: Icc2 [mA] _

4

6 1218243036

Supply Voltage: Vcc [V]

Fig.10 Supply current 2 (brake) Fig.11 Output high voltage Fig.12 Output high voltage

(BA6920FP-Y) (BA6956AN) (BA6287F)

-30°C

25°C

85°C

7.5

Output High Voltage: VOH [V] _

7.0

0 0.2 0.4 0.6 0.8 1

Output Current: Iout [A]

8.0

Output High Voltage: VOH [V] _

7.5

0 0.2 0.4 0.6 0.8 1

Output Current: Iout [A]

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

4/17

2011.05 - Rev.B

Page 5

BA6956AN,BA6287F,BA6285FS,BA6285AFP-Y,BA6920FP-Y

Technical Note

●Electrical characteristic curves (Reference data) - Continued

9.0

8.5

75°C

25°C

-20°C

8.0

Output High Voltage: VOH [V] _

7.5

0 0.2 0.4 0.6 0.8 1

Output Current: Iout [A]

Fig.13 Output high voltage Fig.14 Output high voltage Fig.15 Output high voltage

(BA6285FS) (BA6285AFP-Y) (BA6920FP-Y)

1.0

75°C

0.8

25°C

-20°C

9.0

8.5

8.0

Output High Voltage: VOH [V] _

7.5

0 0.2 0.4 0.6 0.8 1

Output Current: Iout [A]

1.0

0.8

85°C

25°C

-40°C

9.0

8.5

8.0

7.5

Output High Voltage: VOH [V] _

7.0

0 0.2 0.4 0.6 0.8 1

Output Current: Iout [A]

1.0

0.8

85°C

25°C

-30°C

0.6

0.4

0.2

Output Low Voltage: VOL [V] _

0.0

0 0.2 0.4 0.6 0.8 1

Output Current: Iout [A]

Fig.16 Output low voltage Fig.17 Output low voltage Fig.18 Output low voltage

(BA6956AN) (BA6287F) (BA6285FS)

1.0

85°C

0.8

0.6

0.4

25°C

-40°C

0.2

Output Low Voltage: VOL [V] _

0.0

0 0.2 0.4 0.6 0.8 1

Output Current: Iout [A]

Fig.19 Output low voltage Fig.20 Output low voltage Fig.21 Thermal derating curve

(BA6285AFP-Y) (BA6920FP-Y) (SIP9)

0.6

0.4

0.2

Output Low Voltage: VOL [V] _

0.0

0 0.2 0.4 0.6 0.8 1

Output Current: Iout [A]

1.5

1.2

0.9

0.6

0.3

Output Low Voltage: VOL [V] _

0.0

0 0.2 0.4 0.6 0.8 1

Output Current: Iout [A]

75°C

25°C

-20°C

85°C

25°C

-30°C

0.6

0.4

0.2

Output Low Voltage: VOL [V] _

0.0

0 0.2 0.4 0.6 0.8 1

Output Current: Iout [A]

1.5

i) 1.19W

1.0

Pd [W]

0.5

0.0

0 25 50 75 100 125 150

AMBIENT TEMPERATURE [°C]

i) Package only

75°C

25°C

-20°C

1.5

Pd [W]

ii) Mounted on ROHM standard PCB

(70mm x 70m m x 1.6mm FR4 gl ass-epoxy board)

i) Package only

1.0

ii) 0.689W

0.5

i) 0.563W

1.5

ii) Mounted on ROHM standard PCB

(70mm x 70mm x 1.6mm FR4 glass-epoxy board)

i) Package only

1.0

ii) 0.813W

Pd [W]

0.5

i) 0.625W

3

ii) Mounted on ROHM standard PCB

(70mm x 70m m x 1. 6m m FR4 gl ass-epoxy board)

i) Package only

2

Pd [W]

1

ii)1.45W

i)0.85W

0.0

0 25 50 75 100 125 150

AMBIENT TEMPERATURE [°C]

Fig.22 Thermal derating curve Fig.23 Thermal derating curve Fig.24 Thermal derating curve

(SOP8) (SSOP-A16) (HSOP25)

0.0

0 25 50 75 100 125 150

AMBIENT TEMPERATURE [°C]

0

0 25 50 75 100 125 150

AMBIENT TEMPERATURE [°C]

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

5/17

2011.05 - Rev.B

Page 6

BA6956AN,BA6287F,BA6285FS,BA6285AFP-Y,BA6920FP-Y

●Block diagram and pin configuration

BA6956AN

TSD

VCC

FIN

RIN

VREF

7

9

1

CTRL

R2

R3

8

GND

4

OUT1

C2

Fig.25 BA6956AN

Table 1 BA6956AN

Pin Name Function

1 VREF Reference voltage setting pin

2 OUT2 Driver output

3 RNF Power ground

4 OUT1 Driver output

5 VM Power supply (driver stage)

6 VCC Power supply (small signal)

7 FIN Control input (forward)

8 GND GND

9 RIN Control input (reverse)

Technical Note

VM

R1

5

VCC

6

C1

RNF

3

2

OUT2

M

C3

VM

FIN

RNF

VREF

OUT2

OUT1

RIN

VCC

GND

Fig.26 BA6956AN (SIP9)

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

6/17

2011.05 - Rev.B

Page 7

BA6956AN,BA6287F,BA6285FS,BA6285AFP-Y,BA6920FP-Y

●Block diagram and pin configuration

BA6287F

R1

C1

VM

VCC

FIN

RIN

2

3

TSD

4

5

CTRL

1

OUT1

C2

M

Fig.27 BA6287F

Table 2 BA6287F

Pin Name Function

1 OUT1 Driver output

2 VM Power supply (driver stage)

3 VCC Power supply (small signal)

4 FIN Control input (forward)

5 RIN Control input (reverse)

6 VREF Reference voltage setting pin

7 OUT2 Driver output

8 GND GND

VCC

VREF

6

GND

8

7

OUT2

C3

OUT1

VM

VCC

FIN

Fig.28 BA6287F (SOP8)

Technical Note

R2

ZD

GND

OUT2

VREF

RIN

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

7/17

2011.05 - Rev.B

Page 8

BA6956AN,BA6287F,BA6285FS,BA6285AFP-Y,BA6920FP-Y

●Block diagram and pin configuration

BA6285FS

R1

C1

VM

VCC

FIN

RIN

SAVE

POWER

11

4

5

6

8

TSD

CTRL

1

GND

3

OUT1 OUT2

M

C2

Fig.29 BA6285FS

Table 3 BA6285FS

Pin Name Function

1 GND GND

2 NC NC

3 OUT1 Driver output

4 VM Power supply (driver stage)

5 VCC Power supply (small signal)

6 FIN Control input (forward)

7 NC NC

8 PS Power save enable pin

9 NC NC

10 NC NC

11 RIN Control input (reverse)

12 VREF Reference voltage setting pin

13 NC NC

14 OUT2 Driver output

15 NC NC

16 RNF Power ground

Technical Note

VCC

R2

VREF

12

RNF

16

14

C3

GND

NC

OUT1

VM

VCC

FIN

NC

PS

Fig.30 BA6285FS (SSOP-A16)

ZD

RNF

NC

OUT2

NC

VREF

RIN

NC

NC

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

8/17

2011.05 - Rev.B

Page 9

BA6956AN,BA6287F,BA6285FS,BA6285AFP-Y,BA6920FP-Y

●Block diagram and pin configuration

BA6285AFP-Y

R1

C1

VM

VCC

FIN

RIN

POWER

SAVE

16

17

18

20

19

TSD

CTRL

7

FIN

8

GND GND

9

OUT1 OUT2

M

C2

Fig.31 BA6285AFP-Y

Table 4 BA6285AFP-Y

Pin Name Function

1 NC NC

2 NC NC

3 NC NC

4 NC NC

5 OUT2 Driver output

6 RNF Power ground

7 GND GND

8 GND GND

9 OUT1 Driver output

10 NC NC

11 NC NC

12 NC NC

13 NC NC

14 NC NC

15 NC NC

16 VM Power supply (driver stage)

17 VCC Power supply (small signal)

18 FIN Control input (forward)

19 PS Power save enable pin

20 RIN Control input (reverse)

21 VREF Refere nce voltage setting pin

22 NC NC

23 NC NC

24 NC NC

25 NC NC

FIN GND GND

Technical Note

VCC

R2

VREF

21

RNF

6

5

C3

NC

NC

NC

NC

OUT2

RNF

GND

GND

GND

OUT1

NC

NC

NC

NC

Fig.32 BA6285AFP-Y (HSOP25)

ZD

NC

NC

NC

NC

VREF

RIN

GND

PS

FIN

VCC

VM

NC

NC

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

9/17

2011.05 - Rev.B

Page 10

BA6956AN,BA6287F,BA6285FS,BA6285AFP-Y,BA6920FP-Y

●Block diagram and pin configuration

BA6920FP-Y

TSD

FIN

RIN

POWER

SAVE

18

20

19

CTRL

8

FIN

GND

9

OUT1

C2

5

M

Fig.33 BA6920FP-Y

Table 5 BA6920FP-Y

Pin Name Function

1 NC NC

2 NC NC

3 NC NC

4 NC NC

5 OUT2 Driver output

6 RNF Power ground

7 NC NC

8 GND GND

9 OUT1 Driver output

10 NC NC

11 NC NC

12 NC NC

13 NC NC

14 NC NC

15 NC NC

16 VM Power supply (driver stage)

17 VCC Power supply (small signal)

18 FIN Control input (forward)

19 PS Power save enable pin

20 RIN Control input (reverse)

21 VREF Reference voltage setting pin

22 NC NC

23 NC NC

24 NC NC

25 NC NC

FIN GND GND

Technical Note

NC

NC

NC

NC

NC

NC

NC

NC

NC

R2

R3

R1

C1

NC

NC

NC

NC

VREF

RIN

GND

PS

FIN

VCC

VM

NC

NC

VM

16

VCC

17

VREF

21

RNF

6

OUT2

C3

OUT2

RNF

GND

GND

OUT1

Fig.34 BA6920FP-Y (HSOP25)

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

10/17

2011.05 - Rev.B

Page 11

BA6956AN,BA6287F,BA6285FS,BA6285AFP-Y,BA6920FP-Y

Technical Note

●External application components

1) Resistor for the current limitation, R1

This is a current limiting resistor for collector loss reduction and at the time of short-circuited output. It depends o n the

power supply voltage used, etc., but choose resistance of about 5 to 10Ω. In addition, set resistance with utmost care

to voltage drop caused by inrush current that flows when the motor is started.

2) Resistors and zener diode for the output high voltage setting, R2, R3 and ZD

These are the resistors and zener diode used when output high voltage is set. As for the voltage, only ( V

lower than the VREF pin voltage for BA6287F, BA6285FS and BA6285AFP-Y. (Reference values; V

SAT

≈ 0.25V, VF ≈

SAT

0.75V) Zener diode ZD is recommended to be used instead of resistor R3 when the power supply voltage is unstable

for BA6956AN and BA6920FP-Y.

3) Stabilization capacitor for the power supply line, C1

Please connect the capacitor of 1μF to 100μF for the stabilization of the power supply line, and confirm the motor

operation.

4) Phase compensating capacitor, C2, C3

Noise is generated in output pins or oscillation results in accord with the set mountin g state such as power supply

circuit, motor characteristics, PCB pattern artwork, etc. As noise oscillation measures, connect 0.01μF to 0.1μF

capacitors.

●Functional descriptions

1) Operation modes

Table 6 Logic table

IN1 IN2 OUT1 OUT2 Operation

L L OPEN* OPEN* Stop (idling)

H L H L Forward (OUT1 > OUT2)

L H L H Reverse (OUT1 < OUT2)

H H L L Brake (stop)

* OPEN is the off state of all output transistors. Please note that this is the state of the connected diodes, which differs from that of the mechanical relay.

** Output OUT1 and OUT2 become OPEN regardless of the input logic of FIN and RIN when switching to the power save mode with the POWERSAVE pin.

a) Stand-by mode

In stand-by mode, all output power transistors are turned off, and the motor output goes to high impedance.

b) Forward mode

This operating mode is defined as the forward rotation of the motor when the OUT1 pin is high and OUT2 pin is

low. When the motor is connected between the OUT1 and OUT2 pins, the current flows from OUT1 to OUT2.

c) Reverse mode

This operating mode is defined as the reverse rotation of the motor when the OUT1 pin is low and OUT2 pin is

high. When the motor is connected between the OUT1 and OUT2 pins, the current flows from OUT2 to OUT1.

d) Brake mode

This operating mode is used to quickly stop the motor (short circuit brake).

Note) Switching of rotating direction (FWD/REV)

When the rotating direction is changed over by the motor rotating condition, switch the d irection after the motor is

temporarily brought to the BRAKE condition or OPEN condition. It is recommended to keep the relevant conditi ons

as follows:

via BRAKE: Longer than braking time*. (* the time required for the output L terminal to achieve potential below GND when brake is activated.)

via OPEN: The time longer than 1 ms is recommended.

+ VF )

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

11/17

2011.05 - Rev.B

Page 12

BA6956AN,BA6287F,BA6285FS,BA6285AFP-Y,BA6920FP-Y

2) Output high voltage setting

This function optionally sets output voltage by the output high voltage setting pin and controls the motor rotating speed.

However, when the output high voltage is set to a low level, consumption at IC increases. Carry out thermal design with

sufficient margin incorporated with the power dissipation (Pd) under the actual application condition taken into account.

a) BA6287F, BA6285FS, BA6285AFP-Y

The circuit diagram associated with the output high voltage setting

VREF pin is as per shown on the right. The output high and low

voltages V

and VOL are expressed by:

OH

VOH = VREF - ( V

V

OL

= V

SAT(Q3)

(Reference values; V

+ V

SAT(Q1)

F(Q2)

≈ 0.15V, VF ≈ 0.7V)

SAT

)

In addition, the relation of VREF voltage to output voltage is expressed by:

( V

SAT(Q1)

+ V

) < VREF < VM - V

F(Q2)

SAT(Q2)

+ V

F(Q2)

+ V

SAT(Q1)

Therefore, when the VREF voltage condition is as follows, the

output high voltage is restricted.

VREF > VM - V

= VM - V

V

OH

SAT(Q2)

SAT(Q2)

+ V

SAT(Q1)

+ V

F(Q2)

b) BA6956AN, BA6920FP-Y

The circuit diagram associated with the output high

voltage setting VREF pin is as per shown on the right.

The output high and low voltages VOH and VOL are

expressed by:

V

= VREF + ( V

OH

≈ VREF

V

OH

V

= V

OL

SAT(Q6)

= V

V

OL

SAT(Q7)

(Reference values; V

(BA6956AN)

+ V

+ V

F(Q5)

F(Q6)

F(Q4)

(BA6920FP-Y)

≈ 0.15V, VF ≈ 0.7V)

SAT

) - ( V

F(Q2)

+ V

F(Q3)

)

VREF

Fig.36 BA6956AN Fig.37 BA6920FP-Y

The output high voltage controllable range is expressed by:

VREF < VCC - V

VREF < VM - ( V

VREF < VM - V

SAT(Q1)

SAT(Q2)

SAT(Q3)

- V

+ V

+ ( V

F(Q4)

F(Q3)

F(Q2)

- V

F(Q5)

) + ( V

+ V

F(Q3)

F(Q2)

) - ( V

+ V

F(Q3)

F(Q4)

) - ( V

+ V

+ V

F(Q4)

F(Q5)

F(Q5)

) (BA6920FP-Y)

When the VREF voltage condition is as follows, the output high voltage is restricted.

- V

- V

VREF > VCC - V

VREF > VM - ( V

VREF > VM - V

SAT(Q1)

SAT(Q2)

SAT(Q3)

+ V

+ ( V

F(Q4)

F(Q3)

F(Q2)

F(Q5)

) + ( V

+ V

F(Q3)

F(Q2)

) - ( V

+ V

F(Q3)

F(Q4)

) - ( V

+ V

+ V

F(Q4)

F(Q5)

F(Q5)

) (BA6920FP-Y)

VOH = VCC - V

V

= VM - V

OH

= VM - V

V

OH

- V

SAT(Q1)

- V

SAT(Q2)

(BA6920FP-Y)

SAT(Q3)

- V

F(Q2)

(BA6956AN)

F(Q3)

F(Q3)

Technical Note

VM

VREF

Q1

Q2

OUT

Q3

RNF

(GND, BA6287F)

Fig.35 BA6287F, BD6285FS, BA6285AFP-Y

VM

VCC

Q3

OUT

Q6

RNF

Q1

Q2

Q4

Q5

Q3

Q6

) (BA6956AN)

) (BA6956AN)

VM

VCC

OUT

RNF

VREF

Q1

Q4

Q5

Q2

Q7

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

12/17

2011.05 - Rev.B

Page 13

BA6956AN,BA6287F,BA6285FS,BA6285AFP-Y,BA6920FP-Y

●Interfaces

FIN

RIN

POWER

SAVE

(BA6285FS, BA6285AFP-Y, BA6920FP-Y)

Fig. 38 FIN, RIN Fig.39 POWER SAVE

VM

VCC

VM

VREF

VREF

OUT1

OUT2

OUT1

OUT2

VREF

RNF

RNF

(GND, BA6287F)

(BA6956AN) (BA6287F, BA6285FS, BA6285AFP-Y) (BA6920FP-Y)

Fig. 40 VCC, VM, OUT1, OUT2, VREF, RNF, GND

Technical Note

VM

VCC

OUT1

OUT2

RNF

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

13/17

2011.05 - Rev.B

Page 14

BA6956AN,BA6287F,BA6285FS,BA6285AFP-Y,BA6920FP-Y

●Notes for use

1) Absolute maximum ratings

Devices may be destroyed when supply voltage or operating temperature exceeds the absolute maximum rating.

Because the cause of this damage cannot be identified as, for e xample, a short circuit or an o pen circuit, it is important

to consider circuit protection measures – such as adding fuses – if any value in excess of absolute maximum ratings i s

to be implemented.

2) Connecting the power supply connector backward

Connecting the power supply in reverse polarity can damage the IC. Take precautions against reverse polarity when

connecting the power supply lines, such as adding an external direction diode.

3) Power supply lines

Return current generated by the motor’s Back-EMF require s countermeasures, such as providing a return curr ent path

by inserting capacitors across the power supply and GND (10µF, ceramic capacitor is recommended). In this case, it is

important to conclusively confirm that none of the negative effects sometimes seen with electrolytic capacitors –

including a capacitance drop at low temperatures - occurs. Also, the connected power supply must have sufficient

current absorbing capability. Otherwise, the regenerated current will increase voltage on the power supply line, which

may in turn cause problems with the product, including peripher al circuits exceeding the absolute maximum ratin g. To

help protect against damage or degradation, physical safety measures should b e taken, such as providing a voltage

clamping diode across the power supply and GND.

4) Electrica l p otential at GND

Keep the GND terminal potential to the minimum potential under any operating condition. In addition, check to

determine whether there is any terminal that provides voltage below GND, including the voltage during transient

phenomena. When both a small signal GND and high current GND are present, single-point groundi ng (at the set’s

reference point) is recommended, in order to separate the small signal and high current GND, and to ensure that

voltage changes due to the wiring resistance and high current do not affect the voltage at the small signal GND. In the

same way, care must be taken to avoid changes in the GND wire pattern in any external connected component.

5) Thermal design

Use a thermal design that allows for a sufficient margin in light of the power d issipation (Pd) under actual operating

conditions.

6) ASO - Area of Safety Operation

When using the IC, set the output transistor so that it does not exceed absolute maximum ratings or ASO.

7) Inter-pin shorts and mounting errors

Use caution when positioning the IC for mounting on printed circuit boards. T he IC may be damaged if there is any

connection error, or if pins are shorted together.

8) Operation in strong electromagnetic fields

Using this product in strong electromagnetic fields may cause IC malfunctions. Use extreme caution with

electromagnetic fields.

9) Built-in thermal shutdown (TSD) circuit

The TSD circuit is designed only to shut the IC off to prevent thermal runaway. It is not designed to protect the IC or

guarantee its operation in the presence of extreme heat. Do not continue to use the IC after the TSD circuit is activated,

and do not operate the IC in an environment where activation of the circuit is assumed.

10) Capacitor between output and GND

In the event a large capacitor is connected between the output and GND, i f VCC and VIN are sh ort-circuited with 0V or

GND for any reason, the current charged in the capacitor flows into the output and may destroy the IC. Use a capacitor

smaller than 0.47μF between output and GND.

11) Testing on application boards

When testing the IC on an application board, connecting a capacitor to a l ow impedance pin subjects the IC to stress.

Therefore, always discharge capacitors after each process or step. Always turn the IC's power supply off before

connecting it to or removing it from the test setup during the inspection process. Ground the IC during assembly steps

as an antistatic measure. Use similar precaution when transporting or storing the IC.

Technical Note

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

14/17

2011.05 - Rev.B

Page 15

BA6956AN,BA6287F,BA6285FS,BA6285AFP-Y,BA6920FP-Y

12) Regarding the input pin of the IC

This monolithic IC contains P+ isolation and P substrate layers between adjacent elements, in order to keep them

isolated. P-N junctions are formed at the intersection of these P layers with the N layers of other elements, creating a

parasitic diode or transistor. For example, the relation between each potential is as follows:

When GND > Pin A and GND > Pin B, the P-N junction operates as a parasitic diode.

When GND > Pin B, the P-N junction operates as a parasitic transistor.

Parasitic diodes inevitably occur in the structure of the IC. The operation of parasitic diodes can result in mutual

interference among circuits, as well as operating malfunctions and physical damage. T herefor e, do not use methods b y

which parasitic diodes operate, such as applying a voltage lower than the GND (P substrate) voltage to an input pin.

Pin A

Parasitic element

N

+

P

P

P

P substrate

GND

+

Transistor (NPN)

Resistor

Pin B

B

C

Pin A

N

N N

Parasitic

element

+

P

Parasitic element

N

Appendix: Example of monolithic IC structure

E

P

P substrate

GND

Technical Note

Pin B

B C

+

P

N

GND

Other adjacent elements

E

GND

Parasitic

element

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

15/17

2011.05 - Rev.B

Page 16

BA6956AN,BA6287F,BA6285FS,BA6285AFP-Y,BA6920FP-Y

●Ordering part number

Technical Note

B A

Part No. Part No.

SIP9

SOP8

SSOP-A16

5.8±0.2

10.5±0.5

3.5±0.5

6.2±0.3

1.5±0.1

6.2± 0.3

4.4± 0.2

1.5± 0.1

0.11

1.2

1 9

(MAX 5.35 include BURR)

4.4±0.2

0.595

0.11

(MAX 6.95 include BURR)

15

2

0.8

6 2 8 5 A

6956A

6287

6285

6285A

6920

2.8±0.2

0.6

0.3±0.1

0.8

1.3

+

6

°

4

°

−4°

0.3MIN

0.9±0.15

+0.1

0.17

-

0.05

(Unit : mm)

0.3MIN

0.15± 0.1

(Unit : mm)

2.54

5.0±0.2

7

1.27

6.6± 0.2

1216 14

13

453

21.8±0.2

6

438251

0.42±0.1

11

61

0.1

S

0.1 S

9

10

87

0.36± 0.1

F P - Y E 2

Package

N : SIP9

F : SOP8

FS : SSOP-A16

FP-Y : HSOP25

<Tape and Reel information>

TubeContainer

Quantity

Direction of feed

<Tape and Reel information>

Quantity

Direction

of feed

<Tape and Reel information>

Quantity

Direction

of feed

1000pcs

Direction of products is fixed in a container tube

Embossed carrier tapeTape

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

Embossed carrier tapeTape

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

Packaging and forming specification

E2: Embossed tape and reel

None: Tube

Order quantity needs to be multiple of the minimum quantity.

∗

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

Direction of feed

Direction of feed

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

16/17

2011.05 - Rev.B

Page 17

BA6956AN,BA6287F,BA6285FS,BA6285AFP-Y,BA6920FP-Y

HSOP25

7.8 ± 0.3

1.9 ± 0.1

13.6 ± 0.2

(MAX 13.95 include BURR)

2.75 ± 0.1

25 14

5.4 ± 0.2

1

1.95 ± 0.1

0.8

0.11

12.0 ± 0.2

0.36 ± 0.1

13

0.3Min.

0.25 ± 0.1

S

0.1 S

(Unit : mm)

<Tape and Reel information>

Embossed carrier tapeTape

Quantity

Direction

of feed

2000pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

1pin

∗

Technical Note

Direction of feed

Order quantity needs to be multiple of the minimum quantity.

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

17/17

2011.05 - Rev.B

Page 18

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other parties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes efforts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injur y (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller, fuelcontroller or other safety device). ROHM shall bear no responsibility in any way for use of any

of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

Notice

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

R1120

A

Loading...

Loading...