Motor driver ICs

FDD spindle motor driver

BA6486FS

The BA6486FS is a one-chip IC designed for driving 12V FDD spindle motors. This high-performance IC employs a

3-phase, full-wave soft switching drive system, and contains a digital servo, an index amplifier, and a power save circuit.

The compactly packaged IC reduces the number of external components required.

Applications

Floppy disk drivers

Features

1) 12V supply voltage.

2) 3-phase, full-wave soft switching drive system.

3) Digital servo circuit.

4) Power save circuit.

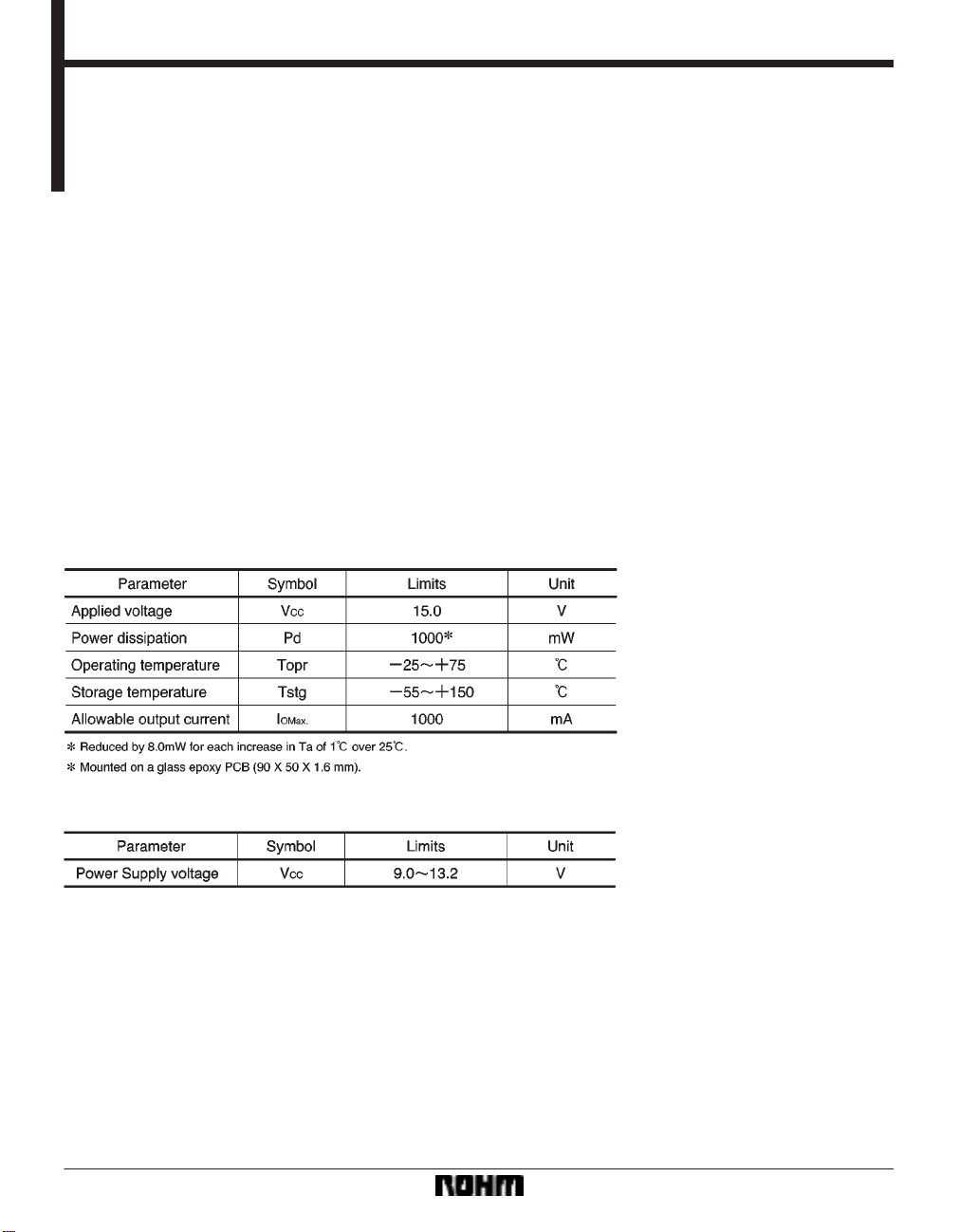

Absolute maximum ratings (Ta = 25C)

5) Hall power supply switch.

6) Motor speed changeable.

7) Index amplifier.

Recommended operating conditions (Ta = 25C)

544

Motor driver ICs BA6486FS

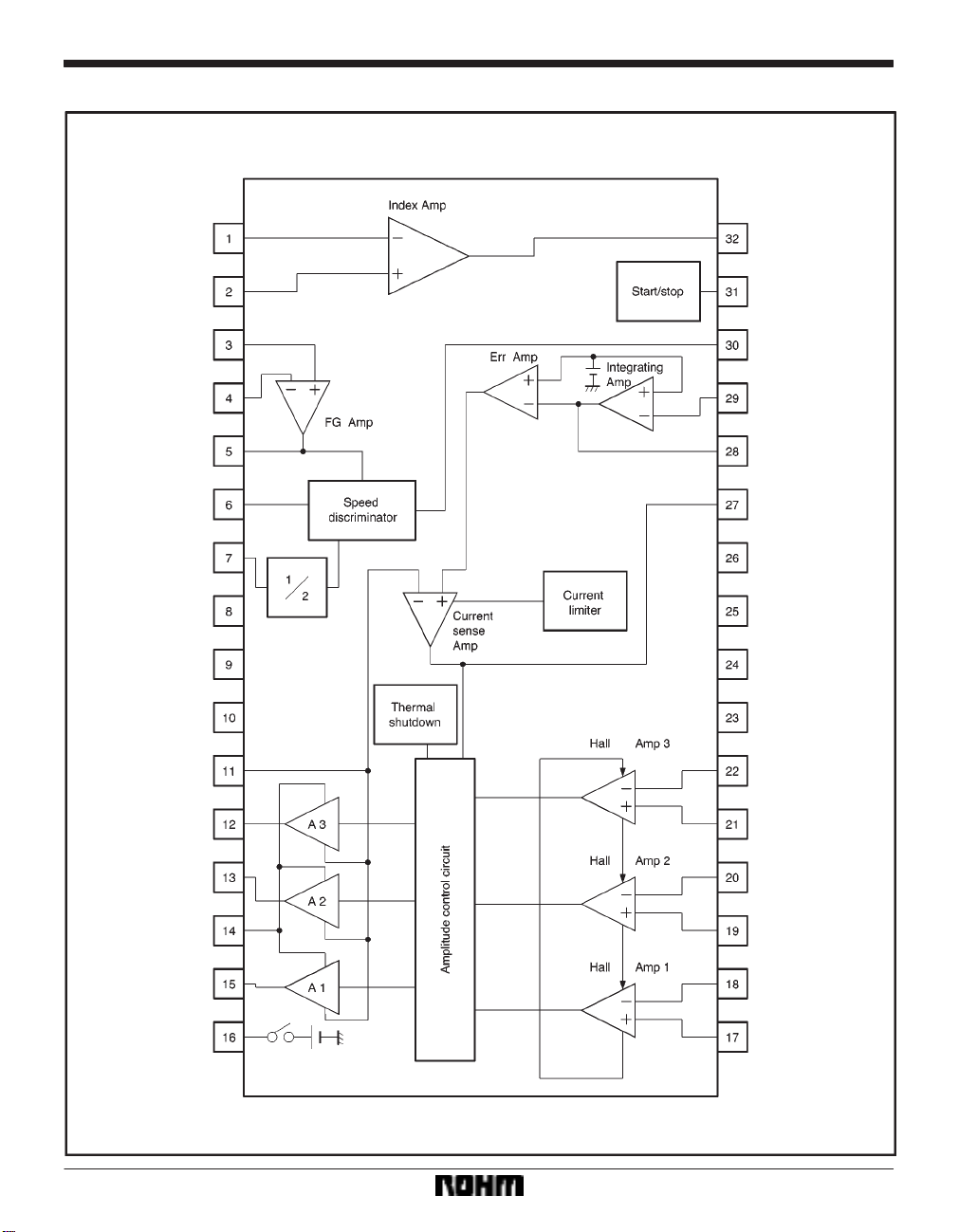

Block diagram

545

Motor driver ICs BA6486FS

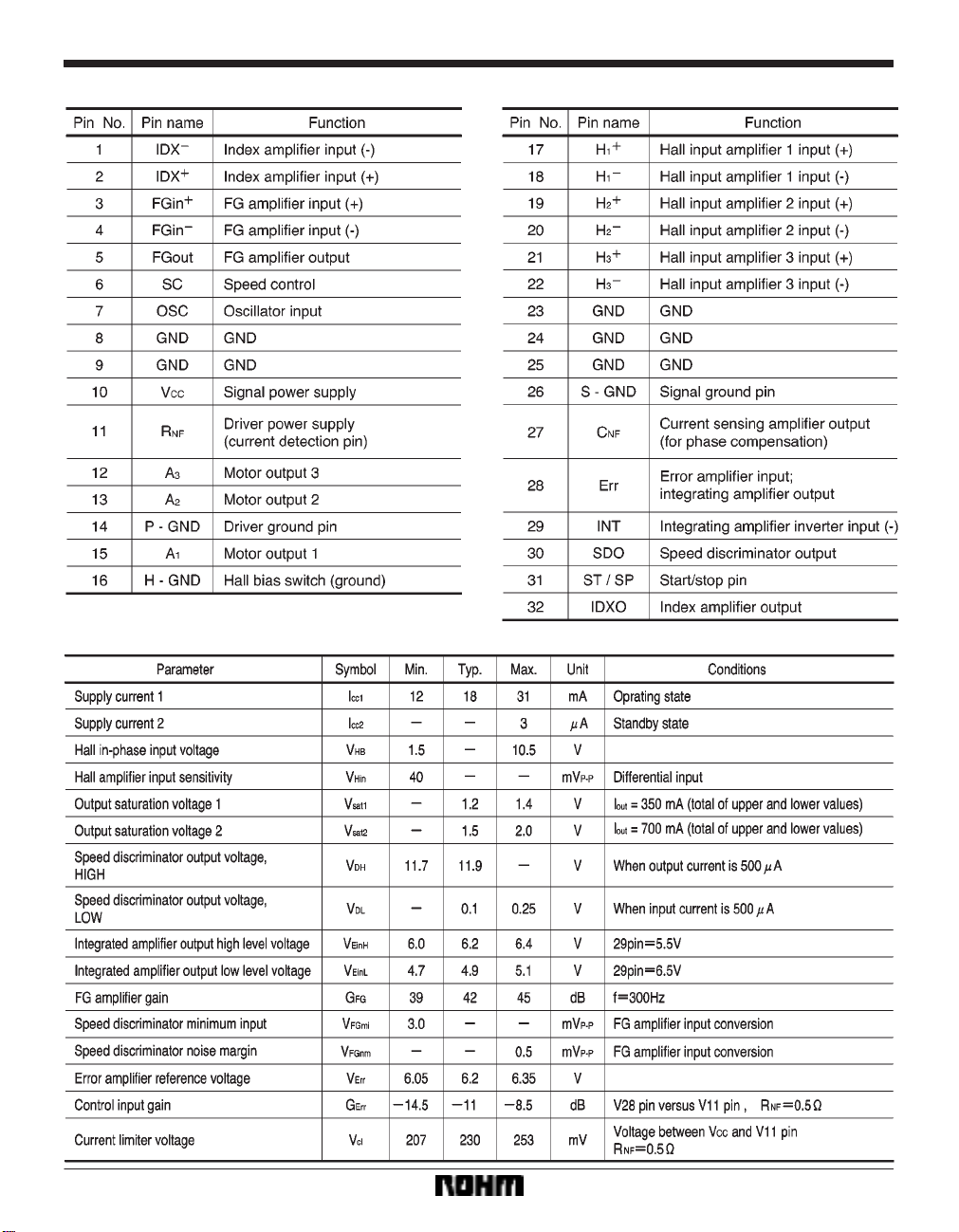

Pin descriptions

Electrical characteristics (unless otherwise noted, Ta = 25C, V

546

CC = 12V)

Motor driver ICs BA6486FS

Circuit operation

(1) Motor drive circuit

The motor driver is based on a 3-phase, full-wave soft

switching, current drive system in which the position of

rotor is sensed by Hall elements. The total drive current

of motor is sensed by a small resistor (R

NF) and regulated

through a voltage comparison. The IC consists of Hall

amplifiers, an amplitude control circuit, a driver, an error

amplifier, and current feedback ampifier (Fig. 1).

The waveforms of different steps along the signal path

from the Hall elements to the motor driver output are

shown in Fig. 2. The Hall amplifiers receive the Hall elements voltage signals as differential signals. Next, by deducting the voltage signal of Hall elements 2 from the

voltage signal of Hall elements 1, current signal H1,

which has a phase 30 degrees ahead of Hall element 1,

is created. Current signals H2 and H3 are created likewise. The amplitude control circuit then amplifies the H1,

H2, and H3 signal according to the current feedback amplifier signal. Then, drive current signals are produced at

A1, A2, and A3 by applying a constant magnification factor. Because a soft switching system is employed, the

drive current has low noise and a low total current ripple.

The total drive current is controlled by the error amplifier

input voltage. The error amplifier has a voltage gain of

about –1 1dB (a factor of 0.28). The current feedback am

plifier regulates the total drive current, so that the error

amplifier output voltage (V1) is equal to the VR

NF voltage,

which has been voltage-converted from the total drive

current through the R

iter voltage (V

dence, and a current limit is applied at the level of V

NF pin. If V1 exceeds the current lim-

cl), the constant voltage Vcl takes prece-

cl/RNF.

The current feedback amplifier tends to oscillate because it receives all the feedback with a gain of 0dB. To

prevent this oscillation, connect an external capacitor to

NF pin for phase compensation and for reducing the

the C

high frequency gain.

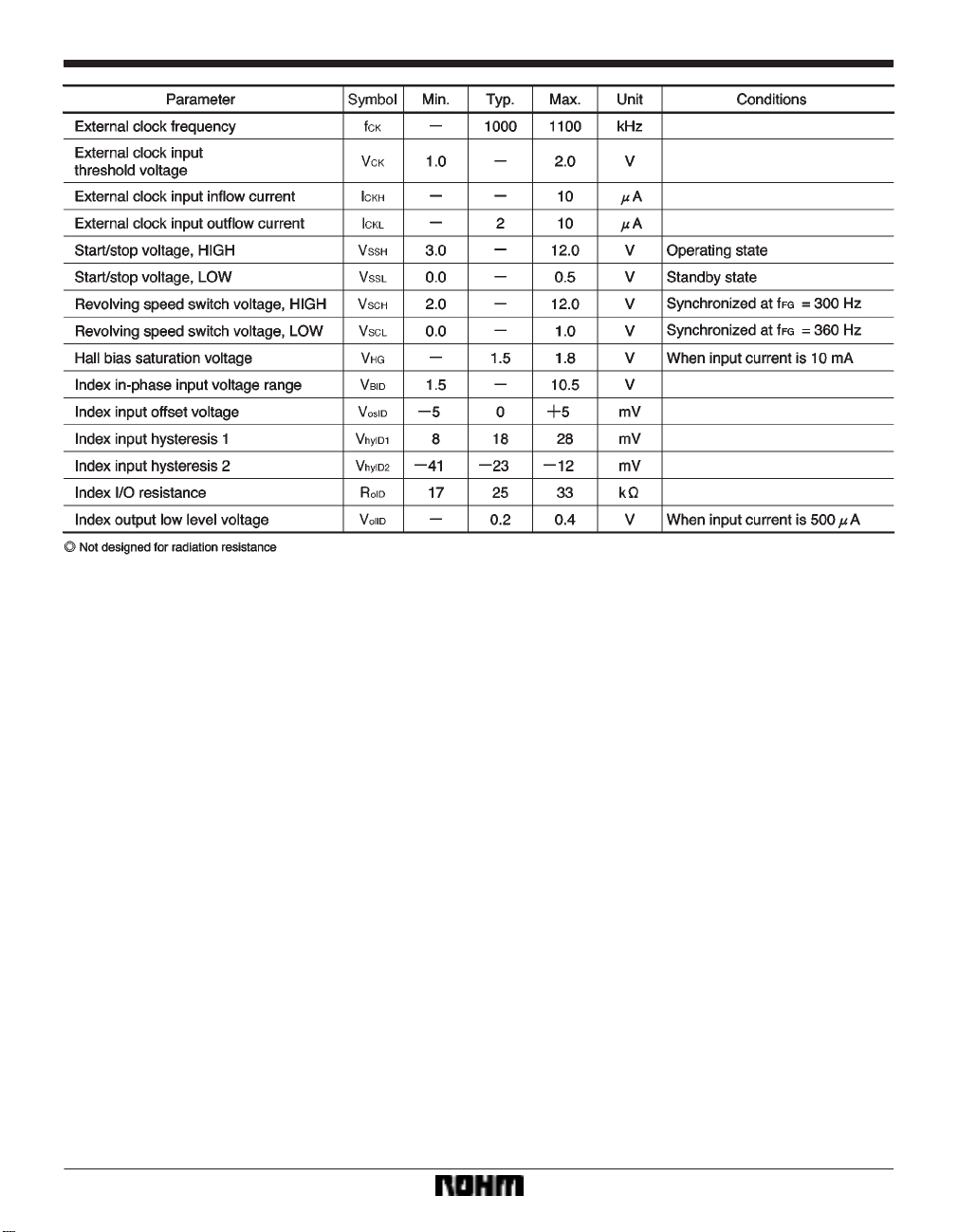

(2) Speed control circuit

The speed control circuit is a non-adjustable digital servo

system that uses a frequency locked loop (FLL). The circuit consists of an 1/2 frequency divider, an FG amplifier ,

and a speed discriminator (Fig. 14).

An internal reference is generated from an external clock

signal input. The 1/2 frequency divider reduces the frequency of the OSC signal. The FG amplifier amplifies the

minute voltage generated by the motor FG pattern and

produces a rectangular-shaped speed signal. The FG

amplifier gain (G

FG = 42dB, typical) is determined by the

internal resistance ratio.

547

Motor driver ICs BA6486FS

For noise filtering, a high-pass filter is given by C3 and a

resistor of 1.6kΩ (typical), and a low-pass filter is given

by C4 and a resistor of 200kΩ (typical). The cutoff frequencies of high-pass and low-pass filters (f

H and fL, re-

spectively) are given by:

f

H=

2π 1.6kΩ C3

1

fL=

2π 200kΩ C4

1

The C3 and C4 capacitances should be set so as to satisfy the following relationship:

f

HfFGfL

where fFG is the FG frequency . Note that the FG amplifier

inputs have a hysteresis.

The speed discriminator divides the reference clock and

compares with the reference frequency , and then outputs

an error pulse according to the frequency difference. The

motor rotational speed N is given in the following formula.

fosc

1

(1)N=60 S

S

n

z

fosc is the reference clock frequency,

n is (speed discriminator count) 2,

z is the FG tooth number.

The discriminator count depends on the speed control

pin voltage.

The integrator flattens out the error pulse of the speed

discriminator and creates a control signal for the motor

drive circuit (Fig. 15).

(3) Index amplifier

The index amplifier is a hysteresis amplifier with a typical

hysteresis width of +18mV and –22mV. The input pin is

not biased internally.

(4) Other circuits

S Start/stop circuit

The start /stop circuit puts the IC to the operating state

when the control pin is LOW, and to the standby state (circuit current is nearly zero) when the control pin is HIGH.

The Hall device bias switch, which is linked to the

start/stop circuit, is turned off during the standby state,

so that the Hall device current is shut down.

S Thermal shutdown circuit

This circuit shuts down the IC currents when the chip

junction temperature is increased to about 175_C (typical). The thermal shutdown circuit is deactivated when

the temperature drops to about 155_C (typical).

548

Motor driver ICs BA6486FS

549

Motor driver ICs BA6486FS

550

Motor driver ICs BA6486FS

Operation notes

(1) Thermal shutdown circuit

This circuit shuts down all the IC currents when the chip

junction temperature is increased to about 175C (typical). The thermal shutdown circuit is deactivated when

the temperature drops to about 155C (typical).

(2) Hall elements connection

Hall elements can be connected in either series or parallel. When connecting in series, care must be taken not to

allow the Hall output to exceed the Hall common-mode

input range.

(3) Hall input level

Switching noise may occur if the Hall input voltage (pins

1722) is too high. Differential inputs of about 100m V

are recommended.

Input/output circuits

(1) Index input (1, 2 pin)

(4) Driver ground pin (14 pin)

Pin 14, which is the motor current ground pin, is not connected to the signal ground pin (26 pin). Design a proper

conductor pattern in consideration of the motor current

that flows through pin 14.

(5) External clock

Make sure that the pin 7 voltage is always less than V

and more than the ground voltage.

p-p

CC

(2) FG amplifier (35 pin)

(3) Speed control (6 pin) (4) External clock input (7 pin)

551

Motor driver ICs BA6486FS

(5) Motor output (1115 pin) (6) Hall bias (16 pin)

(7) Hall input (1722 pin) (8) Integrating amplifier (28, 29 pin)

(9) Speed discriminator output (30 pin) (10) Start/stop (31 pin) (11) Index output (32 pin)

552

Motor driver ICs BA6486FS

Application example

553

Motor driver ICs BA6486FS

Electrical characteristic curves

External dimensions (Units: mm)

554

Loading...

Loading...