Test and Measurement

Division

Operating Manual

SIGNAL GENERATOR

SMP

1035.5005.02/03/04/22

Printed in the Federal

Republic of Germany

1036.5015.12-08- 1

SMP Tabbed Divider Overview

Tabbed Divider Overview

Contents

Data Sheet

Safety Instructions

Certificate of quality

EC Certificate of Conformity

List of R & S Representatives

Tabbed Divider

1 Chapter 1: Preparation for Use

2 Chapter 2: Manual Operation

3 Chapter 3: Remote Control

4 Chapter 4: Maintenance

5 Chapter 5: Performance Test

6 Annex A: Interfaces

7 Annex B: List of Error Messages

8 Annex C: List of Commands (with SCPI Conformity Information)

9 Annex D: Programming Example

10 Index

1036.5015.12 RE E-1

SMP Contents

Contents

1 Preparation for Use ...........................................................................................1.1

1.1 Putting into Operation............................................................................................................ 1.1

1.1.1 Supply Voltage ..................................................................................................................1.1

1.1.2 Power Fuses .....................................................................................................................1.1

1.1.3 Switching On/Off the Instrument .......................................................................................1.1

1.1.4 Initial Status.......................................................................................................................1.2

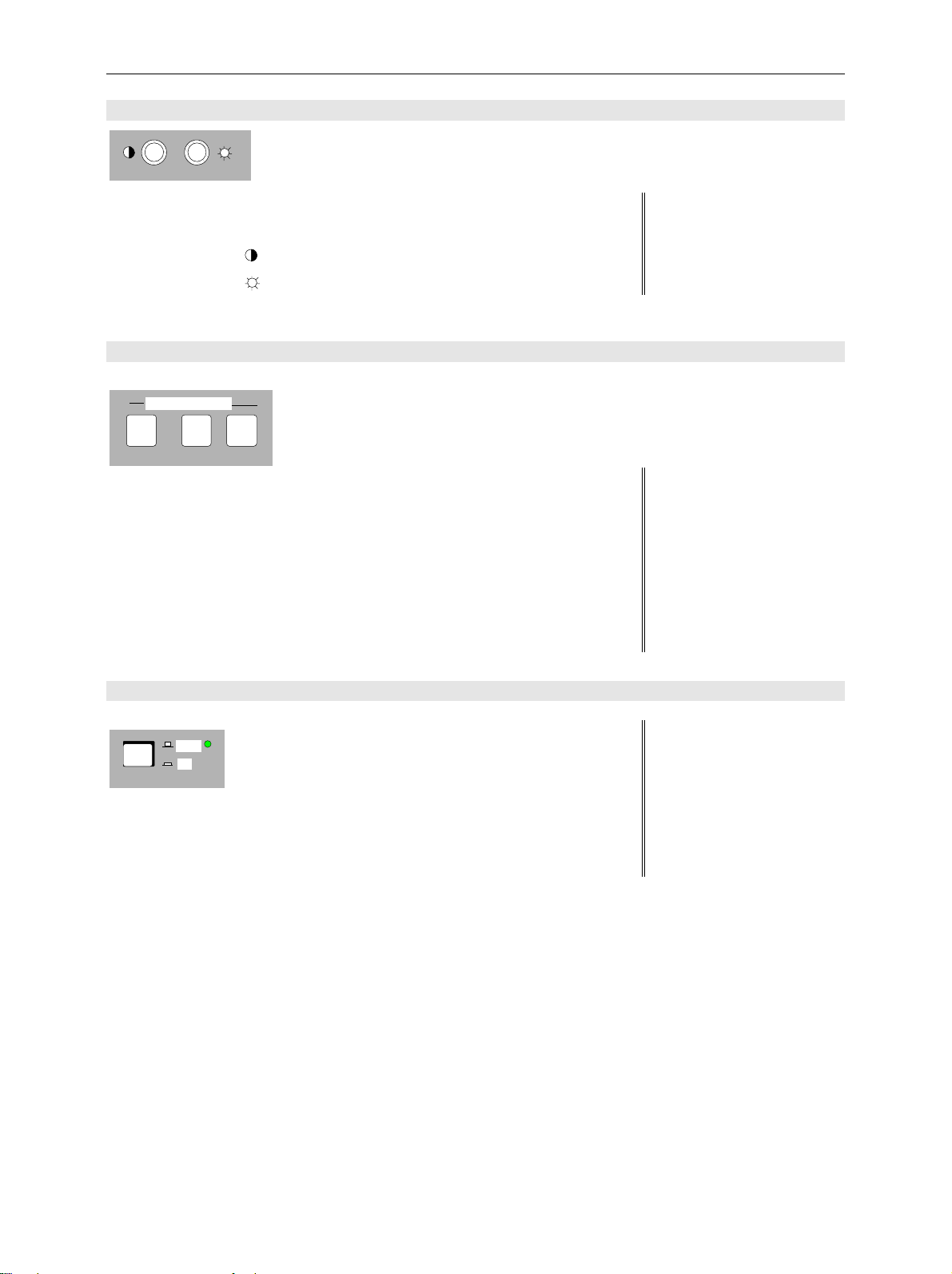

1.1.5 Setting Contrast and Brightness of the Display.................................................................1.2

1.1.6 RAM With Battery Back-Up...............................................................................................1.2

1.1.7 Preset Setting....................................................................................................................1.3

1.2 Functional Test.......................................................................................................................1.3

1.3 Fitting the Options..................................................................................................................1.4

1.3.1 Opening the Casing...........................................................................................................1.4

1.3.2 Overview of the Slots ........................................................................................................1.5

1.3.3 Option SM-B1 - Reference Oscillator OCXO ....................................................................1.5

1.3.4 Option SM-B2 - LF Generator...........................................................................................1.6

1.3.5 Option SM-B5 - FM/PM Modulator....................................................................................1.7

1.3.6 Option SMP-B11 - Frequency Range Extension 0.01 to 2 GHz........................................1.7

1.3.7 Options SMP-B12 - Pulse Modulator 2 to 20 / 2 to 27 / 2 to 40 GHz................................1.7

1.3.8 Options SMP-B13 - Pulse Modulator 0.01 to 2 GHz.........................................................1.7

1.3.9 Option SMP-B14 - Pulse Generator..................................................................................1.8

1.3.10 Options SMP-B15/B17 - Attenuator 20 GHz / 40 GHz......................................................1.8

1.3.11 Option SMP-B18 - Auxiliary Interface................................................................................1.8

1.3.12 Option SMP-B19 /SMP-B20 - Rear Panel Connections for RF and LF.............................1.9

1.4 Mounting into a 19" Rack ......................................................................................................1.9

2 Operation............................................................................................................2.1

2.1 Explanation of Front and Rear Panel....................................................................................2.1

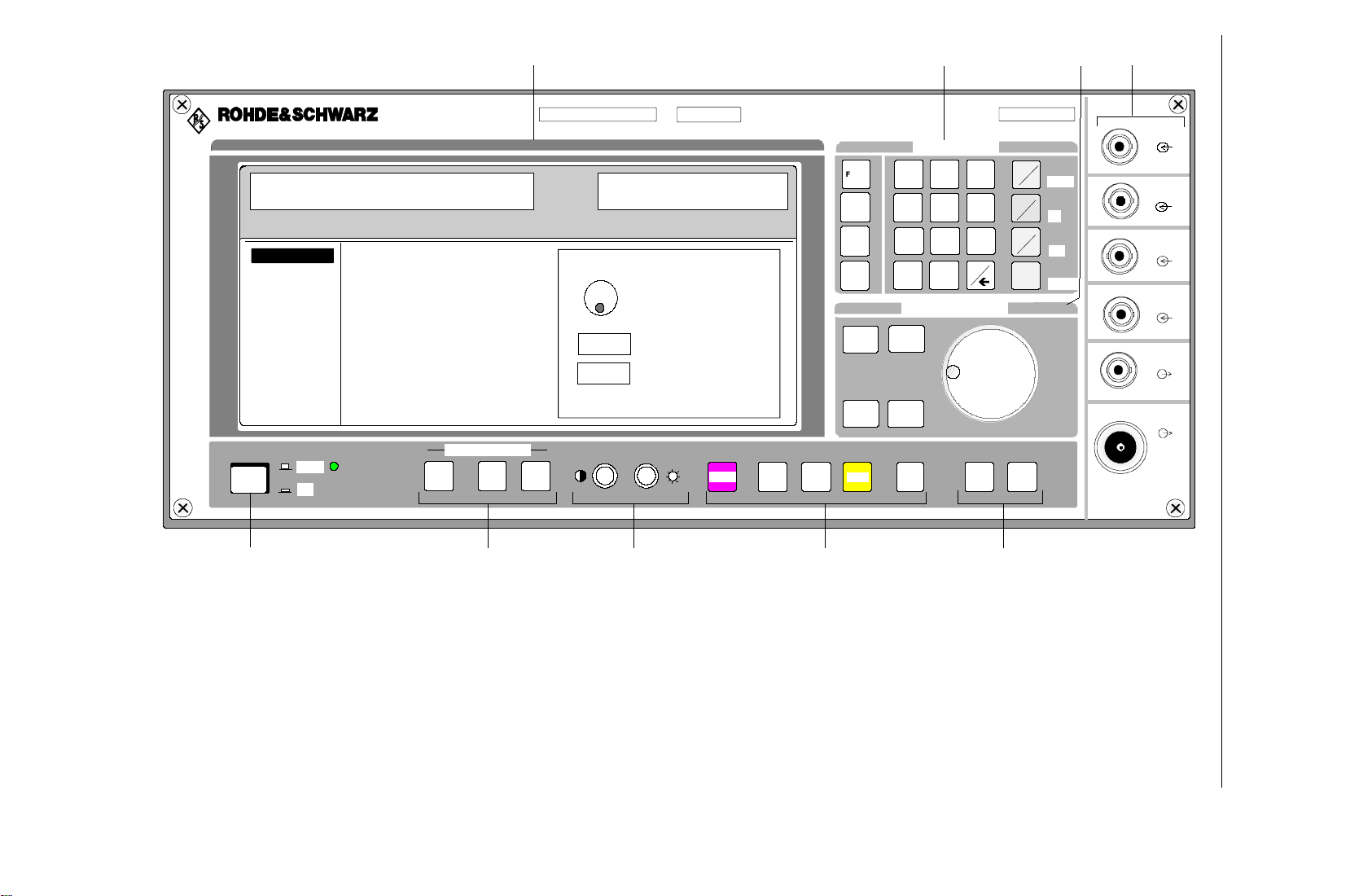

2.1.1 Elements of the Front Panel..............................................................................................2.1

2.1.1.1 Display...........................................................................................................................2.1

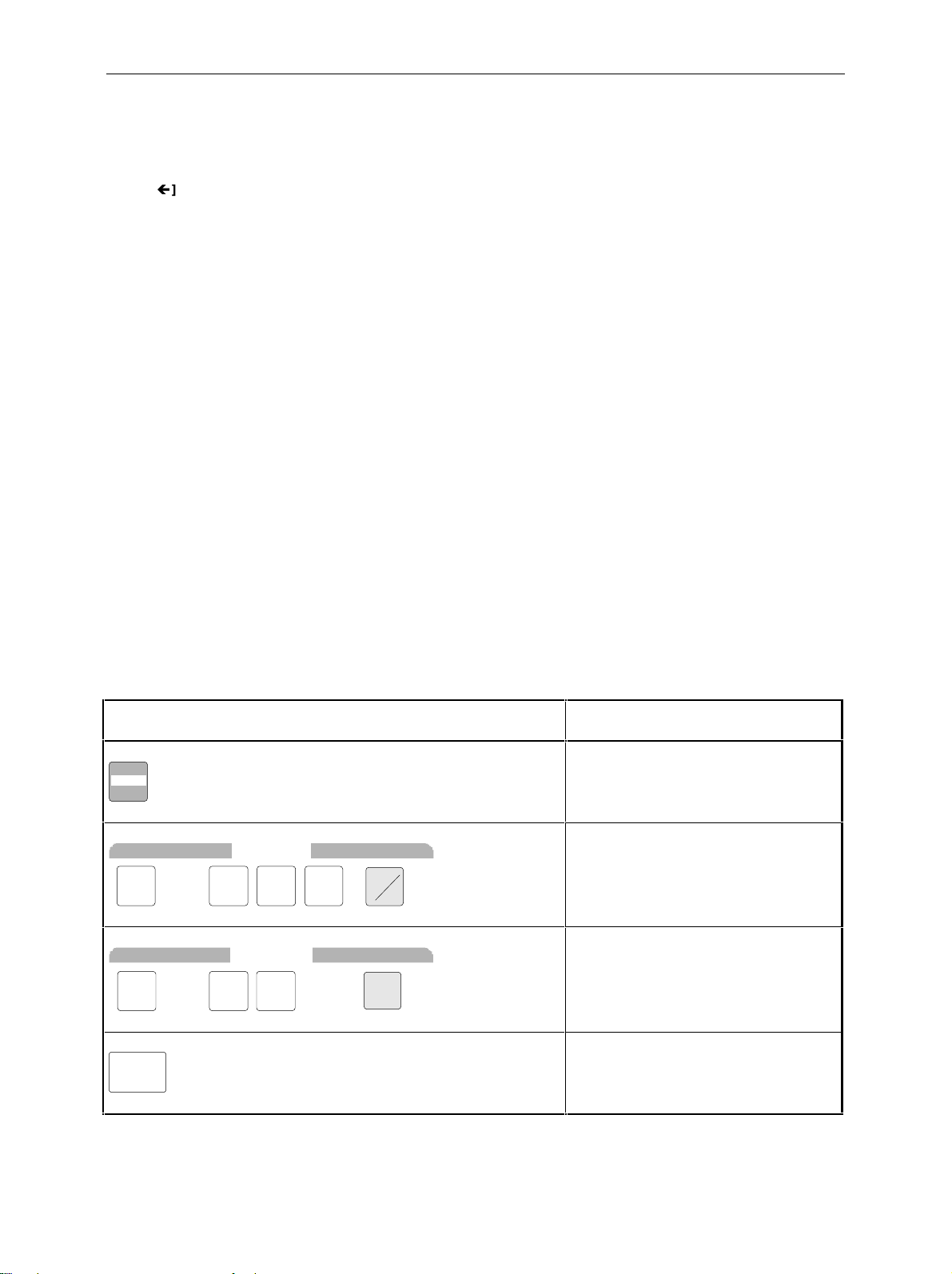

2.1.1.2 Controls .........................................................................................................................2.3

2.1.1.3 Inputs/Outputs .............................................................................................................2.11

2.1.2 Elements of the Rear Panel ............................................................................................2.13

2.2 Operating Concept............................................................................................................... 2.18

2.2.1 Display.............................................................................................................................2.18

2.2.2 Basic Operating Steps.....................................................................................................2.19

2.2.2.1 Calling the Menus........................................................................................................2.19

2.2.2.2 Selection and Change of Parameters..........................................................................2.20

2.2.2.3 Triggering Action..........................................................................................................2.21

2.2.2.4 Quick Selection of Menu (QUICK SELECT)................................................................2.21

2.2.2.5 Use of [FREQ] and [LEVEL] Keys ...............................................................................2.22

2.2.2.6 Use of [RF ON / OFF] and [MOD ON / OFF] Keys......................................................2.22

2.2.2.7 Changing Unit of Level ................................................................................................2.22

2.2.2.8 Correction of Input.......................................................................................................2.23

2.2.3 Sample Setting for First Users........................................................................................2.23

1036.5015.12 3 E-8

Contents SMP

2.2.4 List Editor ........................................................................................................................2.28

2.2.4.1 Select and Generate - SELECT LIST..........................................................................2.29

2.2.4.2 Deletion of Lists - DELETE LIST .................................................................................2.30

2.2.4.3 Edition of Lists .............................................................................................................2.31

2.2.4.4 Pattern Setting to Operate the List Editor....................................................................2.35

2.2.5 Save/Recall - Storing/Calling of Instrument Settings.....................................................2.39

2.3 Menu Summary.....................................................................................................................2.40

2.4 RF Frequency........................................................................................................................ 2.41

2.4.1 Frequency Offset and Multiplier ......................................................................................2.42

2.5 RF Level.................................................................................................................................2.43

2.5.1 Level Offset.....................................................................................................................2.45

2.5.2 Interrupt-free Level Setting..............................................................................................2.45

2.5.3 Level Control (ALC).........................................................................................................2.46

2.5.4 User Correction (UCOR).................................................................................................2.48

2.5.5 Automatic level correction...............................................................................................2.50

2.5.6 EMF.................................................................................................................................2.51

2.5.7 [RF ON / OFF]-Key..........................................................................................................2.51

2.6 Modulation ............................................................................................................................2.52

2.6.1 Modulation Sources.........................................................................................................2.52

2.6.1.1 Simultaneous Modulation ............................................................................................2.53

2.6.1.2 Alternate Switching Off of Modulations........................................................................2.53

2.6.1.3 [MOD ON/OFF] Key.....................................................................................................2.54

2.6.2 Analog Modulation...........................................................................................................2.55

2.6.2.1 LF-Generator...............................................................................................................2.55

2.6.2.2 Amplitude Modulation ..................................................................................................2.56

2.6.2.3 Frequency Modulation .................................................................................................2.57

2.6.2.4 Phase Modulation........................................................................................................2.59

2.6.2.5 Pulse Modulation .........................................................................................................2.61

2.6.3 Digital Modulation ASK and FSK.....................................................................................2.64

2.7 LF-Output..............................................................................................................................2.66

2.8 Sweep .................................................................................................................................... 2.68

2.8.1 Setting the Sweep Range (START, STOP, CENTER and SPAN)..................................2.68

2.8.2 Selecting the Sweep Run (SPACING LIN, LOG)............................................................2.69

2.8.3 Operating Modes (MODE)...............................................................................................2.69

2.8.4 Trigger Inputs..................................................................................................................2.70

2.8.5 Sweep Outputs................................................................................................................2.70

2.8.6 RF-Sweep.......................................................................................................................2.72

2.8.7 LEVEL Sw eep.................................................................................................................2.74

2.8.8 LF-Sw eep........................................................................................................................2.75

2.9 LIST Mode .............................................................................................................................2.77

2.9.1 Operating Modes (MODE)...............................................................................................2.77

2.9.2 Inputs/Outputs.................................................................................................................2.78

2.10 Memory Sequence................................................................................................................2.82

1036.5015.12 4 E-8

SMP Contents

2.11 Utilities...................................................................................................................................2.86

2.11.1 IEC-Bus Address (SYSTEM-GPIB).................................................................................2.86

2.11.2 Parameter of the RS232 Interface (SYSTEM-RS232)....................................................2.87

2.11.3 Suppressing Indications and Deleting Memories (SYSTEM-SECURITY) ......................2.88

2.11.4 Indication of the IEC-Bus Language (LANGUAGE) ........................................................2.89

2.11.5 Reference Frequency Internal/External (REF OSC).......................................................2.89

2.11.6 Phase of the Output Signal (PHASE)..............................................................................2.90

2.11.7 Password Input With Functions Protected (PROTECT) .................................................2.91

2.11.8 Calibration (CALIB) .........................................................................................................2.92

2.11.9 Indications of Module Variants (DIAG-CONFIG).............................................................2.93

2.11.10 Voltage Indication of Test Points (DIAG-TPOINT) ......................................................2.94

2.11.11 Indications of Service Data (DIAG-PARAM)................................................................2.95

2.11.12 Test (TEST).................................................................................................................2.95

2.11.13 Assigning Modulations to the [MOD ON/OFF] Key (MOD-KEY) .................................2.96

2.11.14 Setting Auxiliary Inputs/Outputs (AUX - I/O)................................................................2.97

2.11.15 Switching On/Off Beeper (BEEPER)...........................................................................2.98

2.12 The Help System................................................................................................................... 2.99

2.13 Status.....................................................................................................................................2.99

2.14 Error Messages................................................................................................................... 2.100

3 Remote Control..................................................................................................3.1

3.1 Introduction.............................................................................................................................3.1

3.2 Brief Instructions....................................................................................................................3.1

3.2.1 IEC-Bus.............................................................................................................................3.1

3.2.2 RS-232 Interface...............................................................................................................3.2

3.3 Switchover to Remote Control..............................................................................................3.2

3.3.1 Remote Control via IEC Bus .............................................................................................3.3

3.3.1.1 Setting the Device Address ...........................................................................................3.3

3.3.1.2 Indications during Remote Control ................................................................................3.3

3.3.1.3 Return to Manual Operation ..........................................................................................3.3

3.3.2 Remote Control via RS-232-Interface...............................................................................3.4

3.3.2.1 Setting the Transmission Parameters ...........................................................................3.4

3.3.2.2 Indications during Remote Control ................................................................................3.4

3.3.2.3 Return to Manual Operating ..........................................................................................3.4

3.4 Messages ................................................................................................................................3.4

3.4.1 Interface Message.............................................................................................................3.4

3.4.2 Device Messages (Commands and Device Responses)..................................................3.5

3.5 Structure and Syntax of the Device Messages....................................................................3.5

3.5.1 SCPI Introduction..............................................................................................................3.5

3.5.2 Structure of a Command...................................................................................................3.6

3.5.3 Structure of a Command Line...........................................................................................3.8

3.5.4 Responses to Queries.......................................................................................................3.8

3.5.5 Parameter..........................................................................................................................3.9

3.5.6 Overview of Syntax Elements .........................................................................................3.11

1036.5015.12 5 E-8

Contents SMP

3.6 Description of Commands................................................................................................... 3.12

3.6.1 Notation...........................................................................................................................3.12

3.6.2 Common Commands......................................................................................................3.14

3.6.3 ABORt System ................................................................................................................3.17

3.6.4 CALibration-System ........................................................................................................3.18

3.6.5 DIAGnostic-System.........................................................................................................3.19

3.6.6 DISPLAY-System............................................................................................................3.21

3.6.7 FORMat-System..............................................................................................................3.22

3.6.8 INPut-System ..................................................................................................................3.23

3.6.9 MEMory System..............................................................................................................3.23

3.6.10 OUTPut-System..............................................................................................................3.24

3.6.11 SOURce-System.............................................................................................................3.26

3.6.11.1 SOURce:AM Subsystem..........................................................................................3.26

3.6.11.2 SOURce:CORRection Subsystem...........................................................................3.28

3.6.11.3 SOURce:DM Subsystem..........................................................................................3.30

3.6.11.4 SOURce:FM Subsystem..........................................................................................3.32

3.6.11.5 SOURce:FREQuency Subsystem............................................................................3.35

3.6.11.6 SOURce:LIST Subsystem .......................................................................................3.38

3.6.11.7 SOURce:MARKer Subsystem..................................................................................3.41

3.6.11.8 SOURce:PHASe Subsystem ...................................................................................3.43

3.6.11.9 SOURce:PM Subsystem..........................................................................................3.44

3.6.11.10 SOURce:POWer Subsystem...................................................................................3.46

3.6.11.11 SOURce:PULM Subsystem.....................................................................................3.49

3.6.11.12 SOURce:PULSe Subsystem....................................................................................3.51

3.6.11.13 SOURce:ROSCillator Subsystem............................................................................3.52

3.6.11.14 SOURce:SWEep Subsystem...................................................................................3.53

3.6.12 SOURce0|2 System ........................................................................................................3.57

3.6.12.1 SOURce0|2:FREQuency Subsystem.......................................................................3.57

3.6.12.2 SOURce 0|2:FUNCtion-Subsystem.........................................................................3.59

3.6.12.3 SOURce2:MARKer-Subsystem ...............................................................................3.60

3.6.12.4 SOURce2:SWEep-Subsystem.................................................................................3.61

3.6.13 STATus-System..............................................................................................................3.63

3.6.14 SYSTem-System.............................................................................................................3.65

3.6.15 TEST-System..................................................................................................................3.70

3.6.16 TRIGger-System .............................................................................................................3.72

3.6.17 UNIT-System...................................................................................................................3.75

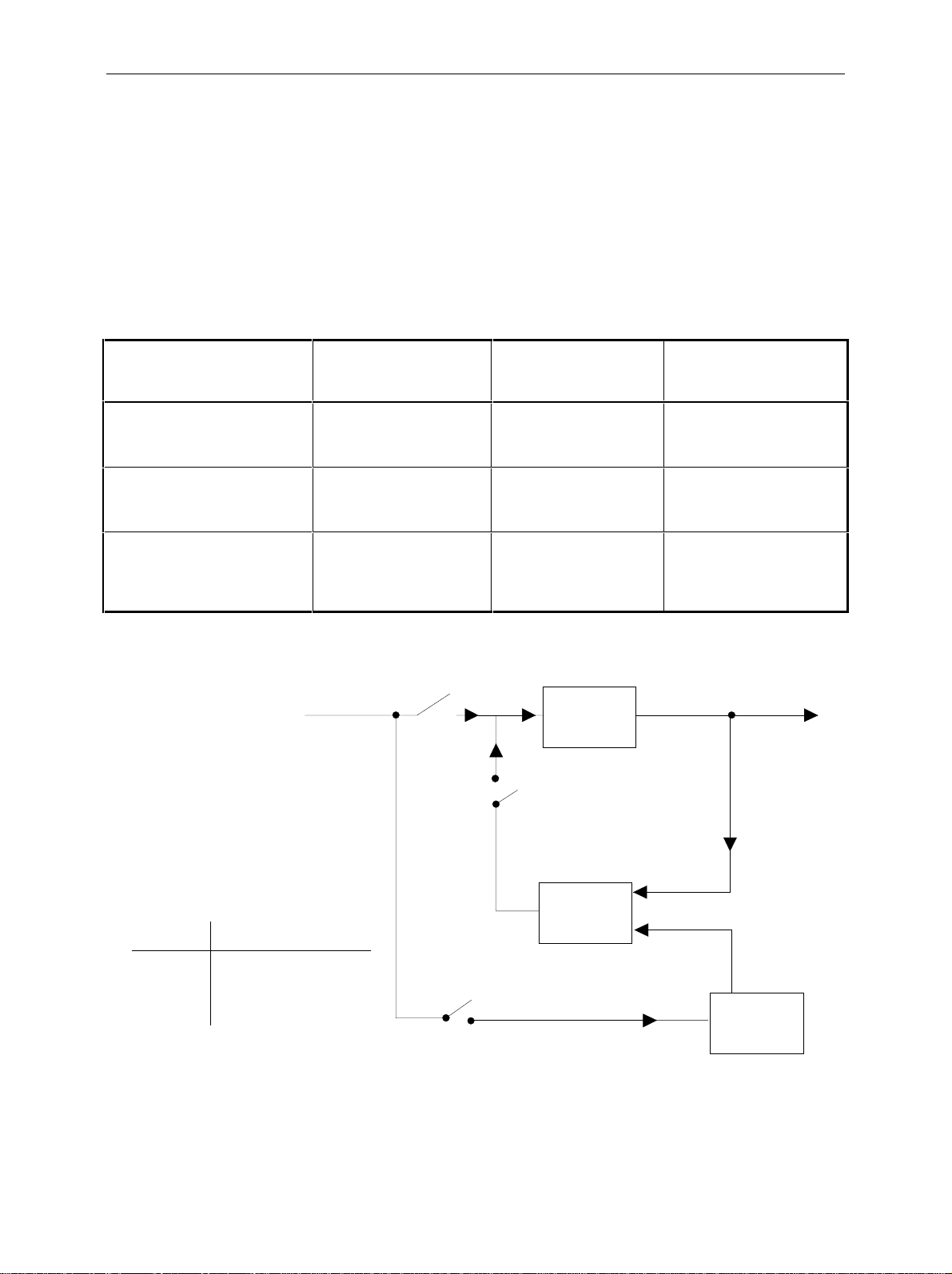

3.7 Instrument Model and Command Processing...................................................................3.76

3.7.1 Input Unit.........................................................................................................................3.76

3.7.2 Command Recognition....................................................................................................3.77

3.7.3 Data Set and Instrument Hardware.................................................................................3.77

3.7.4 Status Reporting System.................................................................................................3.77

3.7.5 Output Unit......................................................................................................................3.78

3.7.6 Command Sequence and Command Synchronization ...................................................3.78

3.8 Status Reporting System.....................................................................................................3.79

3.8.1 Structure of an SCPI Status Register..............................................................................3.79

3.8.2 Overview of the Status Registers....................................................................................3.81

3.8.3 Description of the Status Registers.................................................................................3.82

3.8.3.1 Status Byte (STB) and Service Request Enable Register (SRE) ................................3.82

3.8.3.2 IST Flag and Parallel Poll Enable Register (PPE) .......................................................3.83

3.8.3.3 Event Status Register (ESR) and Event Status Enable Register (ESE)......................3.83

3.8.3.4 STATus:OPERation Register ......................................................................................3.84

3.8.3.5 STATus:QUEStionable Register..................................................................................3.85

3.8.4 Application of the Status Reporting Systems..................................................................3.86

3.8.4.1 Service Request, Making Use of the Hierarchy Structure...........................................3.86

1036.5015.12 6 E-8

SMP Contents

3.8.4.2 Serial Poll.....................................................................................................................3.86

3.8.4.3 Parallel Poll..................................................................................................................3.87

3.8.4.4 Query by Means of Commands...................................................................................3.87

3.8.4.5 Error Queue Query......................................................................................................3.87

3.8.5 Resetting Values of the Status Reporting Systems.........................................................3.88

4 Maintenance and Troubleshooting ..................................................................4.1

4.1 Maintenance............................................................................................................................4.1

4.1.1 Cleaning the Outside.........................................................................................................4.1

4.1.2 Storage..............................................................................................................................4.1

4.1.3 Exchange of the Lithium Battery .......................................................................................4.1

4.2 Functional Test.......................................................................................................................4.4

5 Testing the Rated Specifications .....................................................................5.1

5.1 Test Instruments and Utilities...............................................................................................5.1

5.1.1 Test Setups to Measure Modulation Characteristics.........................................................5.2

5.1.1.1 Standard Test System...................................................................................................5.2

5.1.1.2 Test System for Pulse Modulation.................................................................................5.2

5.2 Test Procedures .....................................................................................................................5.3

5.2.1 Display and Keyboard .......................................................................................................5.3

5.2.2 Frequency Setting .............................................................................................................5.3

5.2.3 Reference Frequency........................................................................................................5.4

5.2.4 Suppression of Harmonics................................................................................................5.4

5.2.5 Suppression of Subharmonics ..........................................................................................5.6

5.2.6 Suppression of Nonharmonics..........................................................................................5.6

5.2.7 SSB Phase Noise..............................................................................................................5.7

5.2.8 Maximum RF Level...........................................................................................................5.8

5.2.9 RF Level Accuracy..........................................................................................................5.10

5.2.10 AM Modulation Depth Setting..........................................................................................5.11

5.2.11 AM Distortion...................................................................................................................5.11

5.2.12 AM Frequency Response................................................................................................5.12

5.2.13 Amplitude Shift Keying (ASK)..........................................................................................5.13

5.2.14 FM Deviation Setting.......................................................................................................5.13

5.2.15 FM Distortion...................................................................................................................5.15

5.2.16 FM Frequency Response................................................................................................5.16

5.2.17 Frequency Shift Keying (FSK).........................................................................................5.17

5.2.18 Pulse Modulation Rise/Fall Time.....................................................................................5.18

5.2.19 Pulse Modulation On /Off Ratio.......................................................................................5.19

5.2.20 Internal Modulation Generator.........................................................................................5.20

5.2.21 LF Generator (Option SM-B2).........................................................................................5.20

5.2.22 Pulse Generator (Option SMP-B14)................................................................................5.21

5.3 Test Report............................................................................................................................5.22

1036.5015.12 7 E-8

Contents SMP

Annex A..................................................................................................................6A.1

IEC/IEEE Bus Interface.....................................................................................................................6A.1

Characteristics of the Interface......................................................................................................6A.1

Bus Lines.......................................................................................................................................6A.1

Interface Messages .......................................................................................................................6A.3

RS-232-C Interface ...........................................................................................................................6A.4

Interface characteristics.................................................................................................................6A.4

Signal lines.....................................................................................................................................6A.4

Transmission parameters ..........................................................................................................6A.5

Interface functions .........................................................................................................................6A.5

Handshake.................................................................................................................................6A.6

Annex B............................................................................................................... 7B1.1

List of Error Messages.................................................................................................................7B1.1

SCPI-Specific Error Messages ....................................................................................................7B1.1

SMP-Specific Error Messages.....................................................................................................7B1.5

Annex C................................................................................................................. 8C.1

List of Commands (with SCPI Conformity Information)................................................................ 8C.1

Annex D................................................................................................................. 9D.1

1. Including IEC-Bus Library for QuickBasic.............................................................................. 9D.1

2. Initialization and Default Status .............................................................................................9D.1

2.1. Initiate Controller................................................................................................................ 9D.1

2.2. Initiate Instrument .............................................................................................................. 9D.1

3. Transmission of Instrument Setting Commands ...................................................................9D.2

4. Switchover to Manual Control................................................................................................ 9D.2

5. Reading out Instrument Settings ........................................................................................... 9D.2

6. List Management................................................................................................................... 9D.3

7. Command synchronization.................................................................................................... 9D.3

8. Service Request .................................................................................................................... 9D.4

9. Operating the Generator in the IEC-Bus Controller Mode..................................................... 9D.6

1036.5015.12 8 E-8

SMP Contents

TABLES

Table 2-1 Input sockets for the different types of modulation 2.52

Table 2-2 Status messages in the case of a deviation 2.53

Table 2-3 Modulations which cannot be operated simultaneously 2.54

Table 2-4 Modulation generators as component parts 2.55

Table 2-5 Parameters for the various frequency modulation modes 2.57

Table 2-6 LIST mode; Example of a list 2.77

Table 2-7 MEMORY SEQUENCE; Example of a list 2.82

Table 3-1 Common Commands 3.14

Table 3-2 Device Response to *OPT? 3.15

Table 3-3 Synchronization with *OPC, *OPC? and *WAI 3.78

Table 3-4 Meaning of the bits used in the status byte 3.82

Table 3-5 Meaning of the bits used in the event status register 3.83

Table 3-6 Meaning of the bits used in the STATus:OPERation register 3.84

Table 3-7 Meaning of the bits used in the STATus:QUEStionable register 3.85

Table 3-8 Resetting instrument functions 3.88

FIGURES

Fig. 1-1 SMP, View from the top 1.5

Fig. 2-1 Front panel view 2.2

Fig. 2-2 Rear panel view 2.12

Fig. 2-3 Design of the display 2.18

Fig. 2-4 MODULATION-AM menu 2.19

Fig. 2-5 Display after AM setting 2.25

Fig. 2-6 Display after pattern setting 2.27

Fig. 2-7 OPERATION page of the MEM SEQ menu 2.28

Fig. 2-8 SELECT-LIST-selection window 2.29

Fig. 2-9 DELETE-LIST selection window 2.30

Fig. 2-10 Edit function EDIT/VIEW 2.31

Fig. 2-11 Block function FILL: Input window 2.32

Fig. 2-12 Edit function INSERT: Input window 2.34

Fig. 2-13 Edit function DELETE: Input window 2.35

Fig. 2-14 Starting point of the pattern setting 2.36

Fig. 2-15, a to c Pattern setting - Edition of a list 2.38

Fig. 2-16 Menu FREQUENCY 2.41

Fig. 2-17 Example of a circuit with frequency offset or multiplier 2.42

Fig. 2-18 Menu LEVEL 2.43

Fig. 2-19 Example of a circuit with level offset 2.45

Fig. 2-20 Basic principle of level control of the SMP 2.46

Fig. 2-21 Example of external power control using a power meter 2.46

Fig. 2-22 Menu LEVEL - ALC 2.47

Fig. 2-23 Menu LEVEL - UCOR - OPERATION page 2.48

Fig. 2-24 Menu UCOR - LEVEL-EDIT page 2.49

Fig. 2-25 a Automatic level correction 2.50

Fig. 2-25 b Measurement 2.50

Fig. 2-26 Menu LEVEL-EMF 2.51

Fig. 2-27 Menu MODULATION-AM 2.56

Fig. 2-28 Operating modes for frequency modulation 2.57

Fig. 2-29 Menu MODULATION-FM 2.58

Fig. 2-30 Menu MODULATION - PM fitted with option SM-B2,

LF-generator (LFGEN2), and option SM-B5, FM/PM-modulator 2.60

Fig. 2-31 Signal example 1: single pulse, TRIGGER MODE = AUTO 2.61

Fig. 2-32 Signal example 2: double pulse 2.62

1036.5015.12 9 E-8

Contents SMP

Fig. 2-33 Menu MODULATION-PULSE 2.62

Fig. 2-34 Menu DIGITAL MOD-ASK 2.64

Fig. 2-36 Menu LF OUTPUT 2.66

Fig. 2-37 Signal example sweep 0 to 20 GHz: 2.71

Fig. 2-38 Signal example sweep: MODE = SINGLE, BLANK TIME = LONG 2.72

Fig. 2-39 Menu SWEEP - FREQ 2.72

Fig. 2-40 Menu SWEEP - LEVEL 2.74

Fig. 2-41 Menu SWEEP - LF GEN 2.75

Fig. 2-42 Signal example LIST mode: MODE = EXT-STEP 2.79

Fig. 2-43 Menu LIST - OPERATION page 2.79

Fig. 2-44 Menu List - EDIT page 2.81

Fig. 2-45 Menu MEM SEQ -OPERATION-page (preset setting) 2.84

Fig. 2-46 Menu MEM SEQ - EDIT page 2.85

Fig. 2-47 Menu UTILITIES -SYSTEM -GPIB 2.86

Fig. 2-48 Menu UTILITIES - SYSTEM - RS232 2.87

Fig. 2-49 Menu UTILITIES - SYSTEM-SECURITY 2.88

Fig. 2-50 Menu UTILITIES - REF OSC (preset setting) 2.89

Fig. 2-51 Menu UTILITIES - PHASE (preset setting) 2.90

Fig. 2-52 Menu UTILITIES - PROTECT (preset setting) 2.91

Fig. 2-53 Menu UTILITIES - CALIB - PULSE GEN 2.92

Fig. 2-54 Menu UTILITIES - DIAG - CONFIG 2.93

Fig. 2-55 Menu UTILITIES - DIAG - TPOINT 2.94

Fig. 2-56 Menu UTILITIES - DIAG - PARAM 2.95

Fig. 2-57 Menu UTILITIES - MOD KEY (preset setting) 2.96

Fig. 2-58 Menu UTILITIES - AUX I/O 2.97

Fig. 2-59 Menu UTILITIES - BEEPER 2.98

Fig. 2-60 Menu STATUS page 2.99

Fig. 2-61 ERROR page 2.100

Fig. 3-1 Tree structure of the SCPI command systems 3.6

Fig. 3-2 Instrument model in the case of remote control 3.76

Fig. 3-3 The status -register model 3.79

Fig. 3-4 Overview of the status register 3.81

Fig. 4-1 Shielding cover of controller and front panel modulel 4.3

Fig. 4-2 Position of the RAM battery on the PCB 4.3

Fig. 4-3 UTILITIES-TEST menu, 4.4

1036.5015.12 10 E-8

Before putting the product into operation for

the first time, make sure to read the following

Safety Instructions

Rohde & Schwarz makes every effort to keep the safety standard of its products up to date and to offer

its customers the highest possible degree of safety. Our products and the auxiliary equipment required

for them are designed and tested in accordance with the relevant safety standards. Compliance with

these standards is continuously monitored by our quality assurance system. This product has been

designed and tested in accordance with the EC Certificate of Conformity and has left the manufacturer’s

plant in a condition fully complying with safety standards. To maintain this condition and to ensure safe

operation, observe all instructions and warnings provided in this manual. If you have any questions

regarding these safety instructions, Rohde & Schwarz will be happy to answer them.

Furthermore, it is your responsibility to use the product in an appropriate manner. This product is

designed for use solely in industrial and laboratory environments or in the field and must not be used in

any way that may cause personal injury or property damage. You are responsible if the product is used

for an intention other than its designated purpose or in disregard of the manufacturer's instructions. The

manufacturer shall assume no responsibility for such use of the product.

The product is used for its designated purpose if it is used in accordance with its operating manual and

within its performance limits (see data sheet, documentation, the following safety instructions). Using

the products requires technical skills and knowledge of English. It is therefore essential that the

products be used exclusively by skilled and specialized staff or thoroughly trained personnel with the

required skills. If personal safety gear is required for using Rohde & Schwarz products, this will be

indicated at the appropriate place in the product documentation.

Observe

operating

instructions

Supply

voltage

ON/OFF

Weight

indication for

units >18 kg

Standby

indication

Symbols and safety labels

Danger of

electric

shock

Direct

current

(DC)

Warning!

Hot

surface

PE terminal Ground

Alternating

current (AC)

Direct/alternating

current (DC/AC)

Ground

terminal

Device fully

protected by

double/reinforced

insulation

Attention!

Electrostatic

sensitive

devices

1171.0000.42-02.00 Sheet 1

Safety Instructions

Observing the safety instructions will help prevent personal injury or damage of any kind caused by

dangerous situations. Therefore, carefully read through and adhere to the following safety instructions

before putting the product into operation. It is also absolutely essential to observe the additional safety

instructions on personal safety that appear in other parts of the documentation. In these safety

instructions, the word "product" refers to all merchandise sold and distributed by Rohde & Schwarz,

including instruments, systems and all accessories.

Tags and their meaning

DANGER

WARNING

CAUTION This tag indicates a safety hazard with a low potential of risk for the user

ATTENTION

NOTE

These tags are in accordance with the standard definition for civil applications in the European

Economic Area. Definitions that deviate from the standard definition may also exist. It is therefore

essential to make sure that the tags described here are always used only in connection with the

associated documentation and the associated product. The use of tags in connection with unassociated

products or unassociated documentation can result in misinterpretations and thus contribute to personal

injury or material damage.

This tag indicates a safety hazard with a high potential of risk for the

user that can result in death or serious injuries.

This tag indicates a safety hazard with a medium potential of risk for the

user that can result in death or serious injuries.

that can result in slight or minor injuries.

This tag indicates the possibility of incorrect use that can cause damage

to the product.

This tag indicates a situation where the user should pay special attention

to operating the product but which does not lead to damage.

Basic safety instructions

1. The product may be operated only under

the operating conditions and in the

positions specified by the manufacturer. Its

ventilation must not be obstructed during

operation. Unless otherwise specified, the

following requirements apply to

Rohde & Schwarz products:

prescribed operating position is always with

the housing floor facing down, IP protection

2X, pollution severity 2, overvoltage

category 2, use only in enclosed spaces,

max. operation altitude max. 2000 m.

Unless specified otherwise in the data

sheet, a tolerance of ±10% shall apply to

the nominal voltage and of ±5% to the

nominal frequency.

2. Applicable local or national safety

regulations and rules for the prevention of

accidents must be observed in all work

performed. The product may be opened

only by authorized, specially trained

personnel. Prior to performing any work on

the product or opening the product, the

product must be disconnected from the

supply network. Any adjustments,

replacements of parts, maintenance or

repair must be carried out only by technical

personnel authorized by Rohde & Schwarz.

Only original parts may be used for

replacing parts relevant to safety (e.g.

power switches, power transformers,

fuses). A safety test must always be

performed after parts relevant to safety

have been replaced (visual inspection, PE

conductor test, insulation resistance

measurement, leakage current

measurement, functional test).

3. As with all industrially manufactured goods,

the use of substances that induce an

allergic reaction (allergens, e.g. nickel)

such as aluminum cannot be generally

excluded. If you develop an allergic

reaction (such as a skin rash, frequent

sneezing, red eyes or respiratory

difficulties), consult a physician immediately

to determine the cause.

1171.0000.42-02.00 Sheet 2

Safety Instructions

4. If products/components are mechanically

and/or thermically processed in a manner

that goes beyond their intended use,

hazardous substances (heavy-metal dust

such as lead, beryllium, nickel) may be

released. For this reason, the product may

only be disassembled, e.g. for disposal

purposes, by specially trained personnel.

Improper disassembly may be hazardous to

your health. National waste disposal

regulations must be observed.

5. If handling the product yields hazardous

substances or fuels that must be disposed

of in a special way, e.g. coolants or engine

oils that must be replenished regularly, the

safety instructions of the manufacturer of

the hazardous substances or fuels and the

applicable regional waste disposal

regulations must be observed. Also

observe the relevant safety instructions in

the product documentation.

6. Depending on the function, certain products

such as RF radio equipment can produce

an elevated level of electromagnetic

radiation. Considering that unborn life

requires increased protection, pregnant

women should be protected by appropriate

measures. Persons with pacemakers may

also be endangered by electromagnetic

radiation. The employer is required to

assess workplaces where there is a special

risk of exposure to radiation and, if

necessary, take measures to avert the

danger.

7. Operating the products requires special

training and intense concentration. Make

certain that persons who use the products

are physically, mentally and emotionally fit

enough to handle operating the products;

otherwise injuries or material damage may

occur. It is the responsibility of the

employer to select suitable personnel for

operating the products.

8. Prior to switching on the product, it must be

ensured that the nominal voltage setting on

the product matches the nominal voltage of

the AC supply network. If a different voltage

is to be set, the power fuse of the product

may have to be changed accordingly.

9. In the case of products of safety class I with

movable power cord and connector,

operation is permitted only on sockets with

earthing contact and protective earth

connection.

10. Intentionally breaking the protective earth

connection either in the feed line or in the

product itself is not permitted. Doing so can

result in the danger of an electric shock

from the product. If extension cords or

connector strips are implemented, they

must be checked on a regular basis to

ensure that they are safe to use.

11. If the product has no power switch for

disconnection from the AC supply, the plug

of the connecting cable is regarded as the

disconnecting device. In such cases, it

must be ensured that the power plug is

easily reachable and accessible at all times

(length of connecting cable approx. 2 m).

Functional or electronic switches are not

suitable for providing disconnection from

the AC supply. If products without power

switches are integrated in racks or systems,

a disconnecting device must be provided at

the system level.

12. Never use the product if the power cable is

damaged. By taking appropriate safety

measures and carefully laying the power

cable, ensure that the cable cannot be

damaged and that no one can be hurt by

e.g. tripping over the cable or suffering an

electric shock.

13. The product may be operated only from

TN/TT supply networks fused with max.

16 A.

14. Do not insert the plug into sockets that are

dusty or dirty. Insert the plug firmly and all

the way into the socket. Otherwise this can

result in sparks, fire and/or injuries.

15. Do not overload any sockets, extension

cords or connector strips; doing so can

cause fire or electric shocks.

16. For measurements in circuits with voltages

V

> 30 V, suitable measures (e.g.

rms

appropriate measuring equipment, fusing,

current limiting, electrical separation,

insulation) should be taken to avoid any

hazards.

17. Ensure that the connections with

information technology equipment comply

with IEC 950/EN 60950.

18. Never remove the cover or part of the

housing while you are operating the

product. This will expose circuits and

components and can lead to injuries, fire or

damage to the product.

1171.0000.42-02.00 Sheet 3

Safety Instructions

19. If a product is to be permanently installed,

the connection between the PE terminal on

site and the product's PE conductor must

be made first before any other connection

is made. The product may be installed and

connected only by a skilled electrician.

20. For permanently installed equipment

without built-in fuses, circuit breakers or

similar protective devices, the supply circuit

must be fused in such a way that suitable

protection is provided for users and

products.

21. Do not insert any objects into the openings

in the housing that are not designed for this

purpose. Never pour any liquids onto or into

the housing. This can cause short circuits

inside the product and/or electric shocks,

fire or injuries.

22. Use suitable overvoltage protection to

ensure that no overvoltage (such as that

caused by a thunderstorm) can reach the

product. Otherwise the operating personnel

will be endangered by electric shocks.

23. Rohde & Schwarz products are not

protected against penetration of water,

unless otherwise specified (see also safety

instruction 1.). If this is not taken into

account, there exists the danger of electric

shock or damage to the product, which can

also lead to personal injury.

24. Never use the product under conditions in

which condensation has formed or can form

in or on the product, e.g. if the product was

moved from a cold to a warm environment.

matching Rohde & Schwarz type (see

spare parts list). Batteries and storage

batteries are hazardous waste. Dispose of

them only in specially marked containers.

Observe local regulations regarding waste

disposal. Do not short-circuit batteries or

storage batteries.

28. Please be aware that in the event of a fire,

toxic substances (gases, liquids etc.) that

may be hazardous to your health may

escape from the product.

29. Please be aware of the weight of the

product. Be careful when moving it;

otherwise you may injure your back or other

parts of your body.

30. Do not place the product on surfaces,

vehicles, cabinets or tables that for reasons

of weight or stability are unsuitable for this

purpose. Always follow the manufacturer's

installation instructions when installing the

product and fastening it to objects or

structures (e.g. walls and shelves).

31. Handles on the products are designed

exclusively for personnel to hold or carry

the product. It is therefore not permissible

to use handles for fastening the product to

or on means of transport such as cranes,

fork lifts, wagons, etc. The user is

responsible for securely fastening the

products to or on the means of transport

and for observing the safety regulations of

the manufacturer of the means of transport.

Noncompliance can result in personal injury

or material damage.

25. Do not close any slots or openings on the

product, since they are necessary for

ventilation and prevent the product from

overheating. Do not place the product on

soft surfaces such as sofas or rugs or

inside a closed housing, unless this is well

ventilated.

26. Do not place the product on heatgenerating devices such as radiators or fan

heaters. The temperature of the

environment must not exceed the maximum

temperature specified in the data sheet.

27. Batteries and storage batteries must not be

exposed to high temperatures or fire. Keep

batteries and storage batteries away from

children. If batteries or storage batteries are

improperly replaced, this can cause an

explosion (warning: lithium cells). Replace

the battery or storage battery only with the

1171.0000.42-02.00 Sheet 4

32. If you use the product in a vehicle, it is the

sole responsibility of the driver to drive the

vehicle safely. Adequately secure the

product in the vehicle to prevent injuries or

other damage in the event of an accident.

Never use the product in a moving vehicle if

doing so could distract the driver of the

vehicle. The driver is always responsible for

the safety of the vehicle; the manufacturer

assumes no responsibility for accidents or

collisions.

33. If a laser product (e.g. a CD/DVD drive) is

integrated in a Rohde & Schwarz product,

do not use any other settings or functions

than those described in the documentation.

Otherwise this may be hazardous to your

health, since the laser beam can cause

irreversible damage to your eyes. Never try

to take such products apart, and never look

into the laser beam.

Por favor lea imprescindiblemente antes de

la primera puesta en funcionamiento las

siguientes informaciones de seguridad

Informaciones de seguridad

Es el principio de Rohde & Schwarz de tener a sus productos siempre al día con los estandards de

seguridad y de ofrecer a sus clientes el máximo grado de seguridad. Nuestros productos y todos los

equipos adicionales son siempre fabricados y examinados según las normas de seguridad vigentes.

Nuestra sección de gestión de la seguridad de calidad controla constantemente que sean cumplidas

estas normas. Este producto ha sido fabricado y examinado según el comprobante de conformidad

adjunto según las normas de la CE y ha salido de nuestra planta en estado impecable según los

estandards técnicos de seguridad. Para poder preservar este estado y garantizar un funcionamiento

libre de peligros, deberá el usuario atenerse a todas las informaciones, informaciones de seguridad y

notas de alerta. Rohde&Schwarz está siempre a su disposición en caso de que tengan preguntas

referentes a estas informaciones de seguridad.

Además queda en la responsabilidad del usuario utilizar el producto en la forma debida. Este producto

solamente fue elaborado para ser utilizado en la indústria y el laboratorio o para fines de campo y de

ninguna manera deberá ser utilizado de modo que alguna persona/cosa pueda ser dañada. El uso del

producto fuera de sus fines definidos o despreciando las informaciones de seguridad del fabricante

queda en la responsabilidad del usuario. El fabricante no se hace en ninguna forma responsable de

consecuencias a causa del maluso del producto.

Se parte del uso correcto del producto para los fines definidos si el producto es utilizado dentro de las

instrucciones del correspondiente manual del uso y dentro del margen de rendimiento definido (ver

hoja de datos, documentación, informaciones de seguridad que siguen). El uso de los productos hace

necesarios conocimientos profundos y el conocimiento del idioma inglés. Por eso se deberá tener en

cuenta de exclusivamente autorizar para el uso de los productos a personas péritas o debidamente

minuciosamente instruidas con los conocimientos citados. Si fuera necesaria indumentaria de

seguridad para el uso de productos de R&S, encontrará la información debida en la documentación del

producto en el capítulo correspondiente.

Símbolos y definiciones de seguridad

Ver manual

de

instrucciones

del uso

Informaciones

para

maquinaria

con uns peso

de > 18kg

Peligro de

golpe de

corriente

¡Advertencia!

Superficie

caliente

Conexión a

conductor

protector

Conexión

a tierra

Conexión

a masa

conductora

¡Cuidado!

Elementos de

construción

con peligro de

carga

electroestática

El aparato está

protegido en su

totalidad por un

aislamiento de

doble refuerzo

potencia EN

MARCHA/PARADA

Indicación

Stand-by

Corriente

continua

DC

Corriente

alterna AC

Corriente

continua/alterna

DC/AC

1171.0000.42-02.00 página 1

Informaciones de seguridad

Tener en cuenta las informaciones de seguridad sirve para tratar de evitar daños y peligros de toda

clase. Es necesario de que se lean las siguientes informaciones de seguridad concienzudamente y se

tengan en cuenta debidamente antes de la puesta en funcionamiento del producto. También deberán

ser tenidas en cuenta las informaciones para la protección de personas que encontrarán en otro

capítulo de esta documentación y que también son obligatorias de seguir. En las informaciones de

seguridad actuales hemos juntado todos los objetos vendidos por Rohde&Schwarz bajo la

denominación de „producto“, entre ellos también aparatos, instalaciones así como toda clase de

accesorios.

Palabras de señal y su significado

PELIGRO Indica un punto de peligro con gran potencial de riesgo para el

ususario.Punto de peligro que puede llevar hasta la muerte o graves

heridas.

ADVERTENCIA Indica un punto de peligro con un protencial de riesgo mediano para el

usuario. Punto de peligro que puede llevar hasta la muerte o graves

heridas .

ATENCIÓN Indica un punto de peligro con un protencial de riesgo pequeño para el

usuario. Punto de peligro que puede llevar hasta heridas leves o

pequeñas

CUIDADO Indica la posibilidad de utilizar mal el producto y a consecuencia

dañarlo.

INFORMACIÓN Indica una situación en la que deberían seguirse las instrucciones en el

uso del producto, pero que no consecuentemente deben de llevar a un

daño del mismo.

Las palabras de señal corresponden a la definición habitual para aplicaciones civiles en el ámbito de la

comunidad económica europea. Pueden existir definiciones diferentes a esta definición. Por eso se

debera tener en cuenta que las palabras de señal aquí descritas sean utilizadas siempre solamente en

combinación con la correspondiente documentación y solamente en combinación con el producto

correspondiente. La utilización de las palabras de señal en combinación con productos o

documentaciones que no les correspondan puede llevar a malinterpretaciones y tener por

consecuencia daños en personas u objetos.

Informaciones de seguridad elementales

1. El producto solamente debe ser utilizado

según lo indicado por el fabricante referente

a la situación y posición de funcionamiento

sin que se obstruya la ventilación. Si no se

convino de otra manera, es para los

productos R&S válido lo que sigue:

como posición de funcionamiento se define

principialmente la posición con el suelo de la

caja para abajo , modo de protección IP 2X,

grado de suciedad 2, categoría de

sobrecarga eléctrica 2, utilizar solamente en

estancias interiores, utilización hasta 2000 m

sobre el nivel del mar.

A menos que se especifique otra cosa en la

hoja de datos, se aplicará una tolerancia de

±10% sobre el voltaje nominal y de ±5%

sobre la frecuencia nominal.

2. En todos los trabajos deberán ser tenidas en

cuenta las normas locales de seguridad de

trabajo y de prevención de accidentes. El

producto solamente debe de ser abierto por

personal périto autorizado. Antes de efectuar

trabajos en el producto o abrirlo deberá este

ser desconectado de la corriente. El ajuste,

el cambio de partes, la manutención y la

reparación deberán ser solamente

efectuadas por electricistas autorizados por

R&S. Si se reponen partes con importancia

para los aspectos de seguridad (por ejemplo

el enchufe, los transformadores o los

fusibles), solamente podrán ser sustituidos

por partes originales. Despues de cada

recambio de partes elementales para la

seguridad deberá ser efectuado un control de

1171.0000.42-02.00 página 2

Informaciones de seguridad

seguridad (control a primera vista, control de

conductor protector, medición de resistencia

de aislamiento, medición de medición de la

corriente conductora, control de

funcionamiento).

3. Como en todo producto de fabricación

industrial no puede ser excluido en general

de que se produzcan al usarlo elementos

que puedan generar alergias, los llamados

elementos alergénicos (por ejemplo el

níquel). Si se producieran en el trato con

productos R&S reacciones alérgicas, como

por ejemplo urticaria, estornudos frecuentes,

irritación de la conjuntiva o dificultades al

respirar, se deberá consultar inmediatamente

a un médico para averigurar los motivos de

estas reacciones.

4. Si productos / elementos de construcción son

tratados fuera del funcionamiento definido de

forma mecánica o térmica, pueden generarse

elementos peligrosos (polvos de sustancia

de metales pesados como por ejemplo

plomo, berilio, níquel). La partición elemental

del producto, como por ejemplo sucede en el

tratamiento de materias residuales, debe de

ser efectuada solamente por personal

especializado para estos tratamientos. La

partición elemental efectuada

inadecuadamente puede generar daños para

la salud. Se deben tener en cuenta las

directivas nacionales referentes al

tratamiento de materias residuales.

5. En el caso de que se produjeran agentes de

peligro o combustibles en la aplicación del

producto que debieran de ser transferidos a

un tratamiento de materias residuales, como

por ejemplo agentes refrigerantes que deben

ser repuestos en periodos definidos, o

aceites para motores, deberan ser tenidas en

cuenta las prescripciones de seguridad del

fabricante de estos agentes de peligro o

combustibles y las regulaciones regionales

para el tratamiento de materias residuales.

Cuiden también de tener en cuenta en caso

dado las prescripciones de seguridad

especiales en la descripción del producto.

6. Ciertos productos, como por ejemplo las

instalaciones de radiación HF, pueden a

causa de su función natural, emitir una

radiación electromagnética aumentada. En

vista a la protección de la vida en desarrollo

deberían ser protegidas personas

embarazadas debidamente. También las

personas con un bypass pueden correr

peligro a causa de la radiación

electromagnética. El empresario está

comprometido a valorar y señalar areas de

trabajo en las que se corra un riesgo de

exposición a radiaciones aumentadas de

riesgo aumentado para evitar riesgos.

7. La utilización de los productos requiere

instrucciones especiales y una alta

concentración en el manejo. Debe de

ponerse por seguro de que las personas que

manejen los productos estén a la altura de

los requerimientos necesarios referente a

sus aptitudes físicas, psíquicas y

emocionales, ya que de otra manera no se

pueden excluir lesiones o daños de objetos.

El empresario lleva la responsabilidad de

seleccionar el personal usuario apto para el

manejo de los productos.

8. Antes de la puesta en marcha del producto

se deberá tener por seguro de que la tensión

preseleccionada en el producto equivalga a

la del la red de distribución. Si es necesario

cambiar la preselección de la tensión

también se deberán en caso dabo cambiar

los fusibles correspondientes del prodcuto.

9. Productos de la clase de seguridad I con

alimentación móvil y enchufe individual de

producto solamente deberán ser conectados

para el funcionamiento a tomas de corriente

de contacto de seguridad y con conductor

protector conectado.

10. Queda prohibida toda clase de interrupción

intencionada del conductor protector, tanto

en la toma de corriente como en el mismo

producto ya que puede tener como

consecuencia el peligro de golpe de corriente

por el producto. Si se utilizaran cables o

enchufes de extensión se deberá poner al

seguro, que es controlado su estado técnico

de seguridad.

11. Si el producto no está equipado con un

interruptor para desconectarlo de la red, se

deberá considerar el enchufe del cable de

distribución como interruptor. En estos casos

deberá asegurar de que el enchufe sea de

fácil acceso y nabejo (medida del cable de

distribución aproximadamente 2 m). Los

interruptores de función o electrónicos no

son aptos para el corte de la red eléctrica. Si

los productos sin interruptor están integrados

en construciones o instalaciones, se deberá

instalar el interruptor al nivel de la

instalación.

1171.0000.42-02.00 página 3

Informaciones de seguridad

12. No utilice nunca el producto si está dañado el

cable eléctrico. Asegure a través de las

medidas de protección y de instalación

adecuadas de que el cable de eléctrico no

pueda ser dañado o de que nadie pueda ser

dañado por él, por ejemplo al tropezar o por

un golpe de corriente.

13. Solamente está permitido el funcionamiento

en redes de distribución TN/TT aseguradas

con fusibles de como máximo 16 A.

14. Nunca conecte el enchufe en tomas de

corriente sucias o llenas de polvo. Introduzca

el enchufe por completo y fuertemente en la

toma de corriente. Si no tiene en

consideración estas indicaciones se arriesga

a que se originen chispas, fuego y/o heridas.

15. No sobrecargue las tomas de corriente, los

cables de extensión o los enchufes de

extensión ya que esto pudiera causar fuego

o golpes de corriente.

16. En las mediciones en circuitos de corriente

con una tensión de entrada de Ueff > 30 V se

deberá tomar las precauciones debidas para

impedir cualquier peligro (por ejemplo

medios de medición adecuados, seguros,

limitación de tensión, corte protector,

aislamiento etc.).

17. En caso de conexión con aparatos de la

técnica informática se deberá tener en

cuenta que estos cumplan los requisitos de

la EC950/EN60950.

18. Nunca abra la tapa o parte de ella si el

producto está en funcionamiento. Esto pone

a descubierto los cables y componentes

eléctricos y puede causar heridas, fuego o

daños en el producto.

19. Si un producto es instalado fijamente en un

lugar, se deberá primero conectar el

conductor protector fijo con el conductor

protector del aparato antes de hacer

cualquier otra conexión. La instalación y la

conexión deberán ser efecutadas por un

electricista especializado.

20. En caso de que los productos que son

instalados fijamente en un lugar sean sin

protector implementado, autointerruptor o

similares objetos de protección, deberá la

toma de corriente estar protegida de manera

que los productos o los usuarios estén

suficientemente protegidos.

21. Por favor, no introduzca ningún objeto que

no esté destinado a ello en los orificios de la

caja del aparato. No vierta nunca ninguna

clase de líquidos sobre o en la caja. Esto

puede producir corto circuitos en el producto

y/o puede causar golpes de corriente, fuego

o heridas.

22. Asegúrese con la protección adecuada de

que no pueda originarse en el producto una

sobrecarga por ejemplo a causa de una

tormenta. Si no se verá el personal que lo

utilice expuesto al peligro de un golpe de

corriente.

23. Los productos R&S no están protegidos

contra el agua si no es que exista otra

indicación, ver también punto 1. Si no se

tiene en cuenta esto se arriesga el peligro de

golpe de corriente o de daños en el producto

lo cual también puede llevar al peligro de

personas.

24. No utilice el producto bajo condiciones en las

que pueda producirse y se hayan producido

líquidos de condensación en o dentro del

producto como por ejemplo cuando se

desplaza el producto de un lugar frío a un

lugar caliente.

25. Por favor no cierre ninguna ranura u orificio

del producto, ya que estas son necesarias

para la ventilación e impiden que el producto

se caliente demasiado. No pongan el

producto encima de materiales blandos como

por ejemplo sofás o alfombras o dentro de

una caja cerrada, si esta no está

suficientemente ventilada.

26. No ponga el producto sobre aparatos que

produzcan calor, como por ejemplo

radiadores o calentadores. La temperatura

ambiental no debe superar la temperatura

máxima especificada en la hoja de datos.

1171.0000.42-02.00 página 4

Informaciones de seguridad

27. Baterías y acumuladores no deben de ser

expuestos a temperaturas altas o al fuego.

Guardar baterías y acumuladores fuera del

alcance de los niños. Si las baterías o los

acumuladores no son cambiados con la

debida atención existirá peligro de explosión

(atención celulas de Litio). Cambiar las

baterías o los acumuladores solamente por

los del tipo R&S correspondiente (ver lista de

piezas de recambio). Baterías y

acumuladores son deshechos problemáticos.

Por favor tirenlos en los recipientes

especiales para este fín. Por favor tengan en

cuenta las prescripciones nacionales de cada

país referente al tratamiento de deshechos.

Nunca sometan las baterías o acumuladores

a un corto circuito.

28. Tengan en consideración de que en caso de

un incendio pueden escaparse gases tóxicos

del producto, que pueden causar daños a la

salud.

29. Por favor tengan en cuenta que en caso de

un incendio pueden desprenderse del

producto agentes venenosos (gases, líquidos

etc.) que pueden generar daños a la salud.

30. No sitúe el producto encima de superficies,

vehículos, estantes o mesas, que por sus

características de peso o de estabilidad no

sean aptas para él. Siga siempre las

instrucciones de instalación del fabricante

cuando instale y asegure el producto en

objetos o estructuras (por ejemplo paredes y

estantes).

31. Las asas instaladas en los productos sirven

solamente de ayuda para el manejo que

solamente está previsto para personas. Por

eso no está permitido utilizar las asas para la

sujecion en o sobre medios de transporte

como por ejemplo grúas, carretillas

elevadoras de horquilla, carros etc. El

usuario es responsable de que los productos

sean sujetados de forma segura a los medios

de transporte y de que las prescripciones de

seguridad del fabricante de los medios de

transporte sean tenidas en cuenta. En caso

de que no se tengan en cuenta pueden

causarse daños en personas y objetos.

32. Si llega a utilizar el producto dentro de un

vehículo, queda en la responsabilidad

absoluta del conductor que conducir el

vehículo de manera segura. Asegure el

producto dentro del vehículo debidamente

para evitar en caso de un accidente las

lesiones u otra clase de daños. No utilice

nunca el producto dentro de un vehículo en

movimiento si esto pudiera distraer al

conductor. Siempre queda en la

responsabilidad absoluta del conductor la

seguridad del vehículo y el fabricante no

asumirá ninguna clase de responsabilidad

por accidentes o colisiones.

33. Dado el caso de que esté integrado un

producto de laser en un producto R&S (por

ejemplo CD/DVD-ROM) no utilice otras

instalaciones o funciones que las descritas

en la documentación. De otra manera pondrá

en peligro su salud, ya que el rayo laser

puede dañar irreversiblemente sus ojos.

Nunca trate de descomponer estos

productos. Nunca mire dentro del rayo laser.

1171.0000.42-02.00 página 5

DIN EN ISO 9001 : 2000

DIN EN 9100 : 2003

DIN EN ISO 14001 : 1996

DQS REG. NO 001954 QM/ST UM

Certified Quality System

Sehr geehrter Kunde,

Sie haben sich für den Kauf eines

Rohde & Schwarz-Produktes entschieden. Hiermit erhalten Sie ein nach

modernsten Fertigungsmethoden

hergestelltes Produkt. Es wurde nach

den Regeln unseres Managementsystems entwickelt, gefertigt und

geprüft.

Das Rohde & Schwarz Managementsystem ist zertifiziert nach:

DIN EN ISO 9001:2000

DIN EN 9100:2003

DIN EN ISO 14001:1996

Dear Customer,

you have decided to buy a Rohde &

Schwarz product. You are thus assured of receiving a product that is

manufactured using the most modern

methods available. This product was

developed, manufactured and tested

in compliance with our quality management system standards.

The Rohde & Schwarz quality management system is certified according to:

DIN EN ISO 9001:2000

DIN EN 9100:2003

DIN EN ISO 14001:1996

Cher Client,

vous avez choisi d‘acheter un produit

Rohde & Schwarz. Vous disposez

donc d‘un produit fabriqué d‘après

les méthodes les plus avancées. Le

développement, la fabrication et les

tests respectent nos normes de gestion qualité.

Le système de gestion qualité de

Rohde & Schwarz a été homologué

conformément aux normes:

DIN EN ISO 9001:2000

DIN EN 9100:2003

DIN EN ISO 14001:1996

QUALITÄTSZERTIFIKAT CERTIFICATE OF QUALITY CERTIFICAT DE QUALITÉ

Certificate No.: 9502006

This is to certify that :

Equipment type Order No. Designation

SMP02 1035.5005.02 Signal Generator

SMP03 1035.5005.03

SMP04 1035.5005.04

SMP22 1035.5005.22

SMP-B11 1036.6240.02 Frequency Extension

SMP-B12 1036.5750.02/.03/.04 Pulse Modulator

SMP-B13 1036.7147.02 Pulse Modulator

SMP-B14 1036.7347.02 Pulse Generator

SMP-B15 1036.5250.02 RF Attenuator

SMP-B17 1036.5550.02 RF Attenuator

SMP-B18 1036.8920.02 Auxiliary Interface

EC Certificate of Conformity

complies with the provisions of the Directive of the Council of the European Union on the

approximation of the laws of the Member States

- relating to electrical equipment for use within defined voltage limits

(73/23/EEC revised by 93/68/EEC)

- relating to electromagnet ic com patibility

(89/336/EEC revised by 91/263/EEC, 92/31/EEC, 93/ 68/ EEC)

Conformity is proven by compliance with the following standards:

EN61010-1 : 1991

EN50081-1 : 1992

EN50082-1 : 1992

Affixing the EC conformity mark as from 1995

ROHDE & SCHWARZ GmbH & Co. KG

Mühldorfstr. 15, D-81671 München

Munich, 1997-08-26 Central Quality Management FS-QZ / Becker

1035.5005.02 CE E-3

Customer Support

Technical support – where and when you need it

For quick, expert help with any Rohde & Schwarz equipment, contact one of our

Customer Support Centers. A team of highly qualified engineers provides telephone

support and will work with you to find a solution to your query on any aspect of the

operation, programming or applications of Rohde & Schwarz equipment.

Up-to-date information and upgrades

To keep your Rohde & Schwarz equipment always up-to-date,

please subscribe to our electronic newsletter at