Page 1

®

R&S

RT‑ZM

Modular Probe System

User Manual

(>COL2)

1419312802

Version 04

User Manual

Page 2

This manual describes the following R&S®RT-ZM models:

●

R&S®RT-ZM15 (1800.4700K02)

●

R&S®RT-ZM30 (1419.3005K02)

●

R&S®RT-ZM60 (1419.3105K02)

●

R&S®RT-ZM90 (1419.3205K02)

●

R&S®RT-ZM130 (1800.4500K02)

●

R&S®RT-ZM160 (1800.4600K02)

© 2019 Rohde & Schwarz GmbH & Co. KG

Mühldorfstr. 15, 81671 München, Germany

Phone: +49 89 41 29 - 0

Fax: +49 89 41 29 12 164

Email: info@rohde-schwarz.com

Internet: www.rohde-schwarz.com

Subject to change – Data without tolerance limits is not binding.

R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

Trade names are trademarks of the owners.

1419.3128.02 | Version 04 | R&S®RT‑ZM

Throughout this manual, products from Rohde & Schwarz are indicated without the ® symbol and without

product type numbers, e.g. R&S®RT-ZM15/30/60/90/130/160 is indicated as R&S RT-ZM.

Page 3

R&S®RT‑ZM

Contents

Contents

1 Product Description.............................................................. 5

1.1 Key Features and Key Characteristics............................................... 5

1.1.1 Key Characteristics................................................................................. 5

1.1.2 Key Features...........................................................................................6

1.2 Unpacking..............................................................................................7

1.2.1 Inspecting the Contents.......................................................................... 7

1.3 Description of the Probe...................................................................... 8

1.3.1 Probe Amplifier....................................................................................... 8

1.3.2 Probe Box............................................................................................... 9

1.3.3 Probe Tip Modules..................................................................................9

1.3.4 Accessories and Items..........................................................................10

2 Putting into Operation.........................................................13

2.1 Connecting the Probe to the Oscilloscope...................................... 14

2.2 Identification of the Probe..................................................................15

2.3 MultiMode............................................................................................ 15

2.4 Dynamic Range and Operating Voltage Window............................. 17

2.5 Micro Button........................................................................................18

2.6 Offset Compensation..........................................................................18

2.6.1 Differential Offset.................................................................................. 20

2.6.2 Common Mode Offset...........................................................................20

2.6.3 Positive Input Single-Ended Offset....................................................... 21

2.6.4 Negative Input Single-Ended Offset......................................................22

2.7 R&S ProbeMeter..................................................................................23

3 Connecting the Probe to the DUT...................................... 24

3.1 R&S RT-ZMA10 Tip Cable Solder-In.................................................. 25

3User Manual 1419.3128.02 ─ 04

Page 4

R&S®RT‑ZM

3.2 R&S RT-ZMA12 Tip Cable Square Pin...............................................27

3.3 R&S RT-ZMA14 Tip Cable Flex Connect........................................... 28

3.4 R&S RT-ZMA15 Tip Cable Quick Connect........................................ 29

3.5 R&S RT-ZMA30 Browser Module.......................................................30

3.6 R&S RT-ZMA40 SMA Module............................................................. 32

3.7 R&S RT-ZMA50 Extreme Temperature Kit........................................ 33

Contents

4 Maintenance and Service....................................................35

4.1 Cleaning...............................................................................................35

4.2 Contacting Customer Support...........................................................35

4.3 Returning for Servicing...................................................................... 36

4.4 Calibration Interval............................................................................. 37

4.5 Spare Parts ......................................................................................... 37

4User Manual 1419.3128.02 ─ 04

Page 5

R&S®RT‑ZM

Key Features and Key Characteristics

Product Description

1 Product Description

1.1 Key Features and Key Characteristics

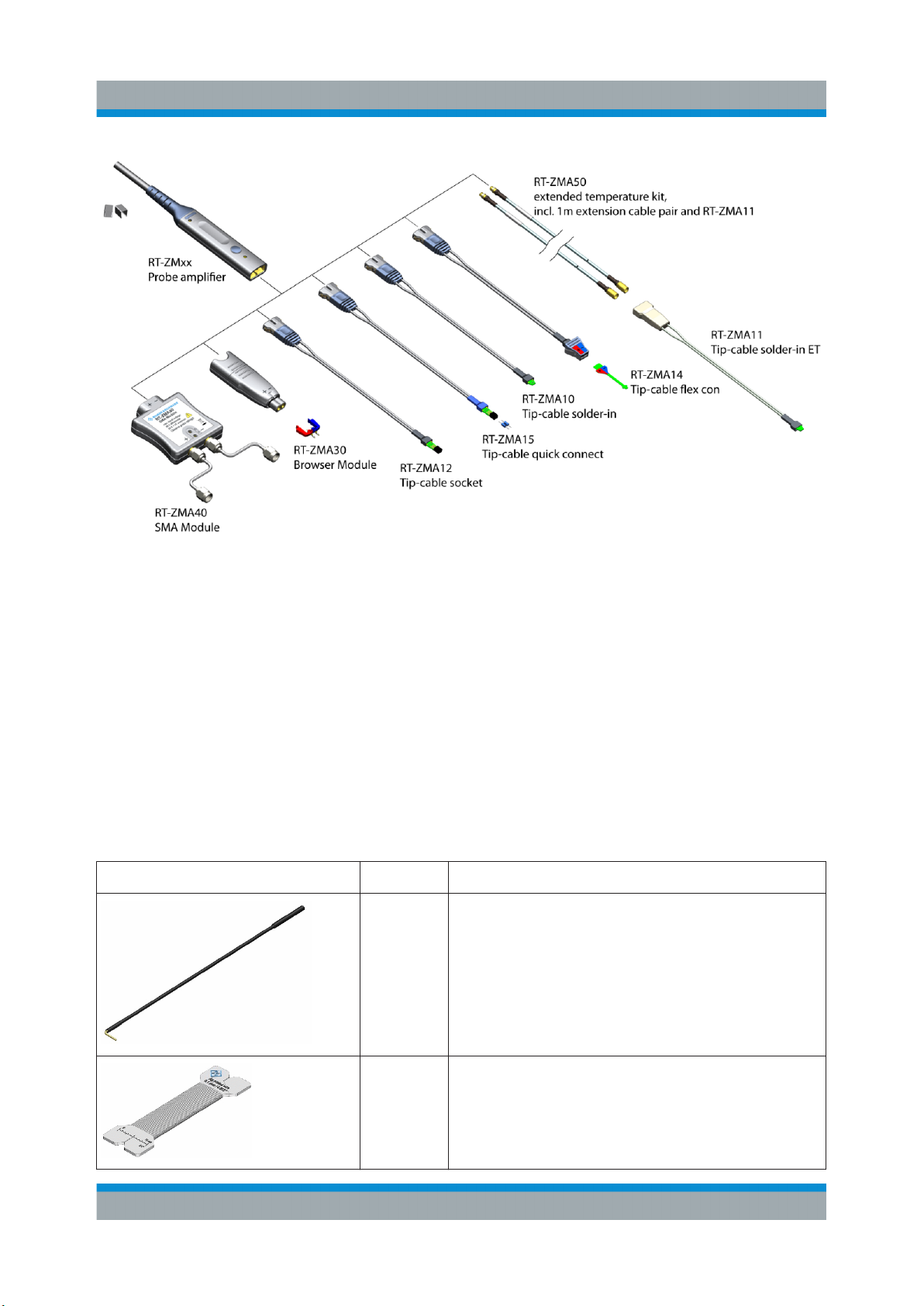

The R&S RT-ZM is a modular probe consisting of a probe amplifier and various

probe tip modules for different applications.

The R&S RT-ZM probe family features the MultiMode function which allows you

to switch between single-ended, differential and common mode measurements

without reconnecting or re-soldering the probe.

With different tip modules and tip cables, the R&S RT-ZM probe can be connected to a wide variety of devices under test (DUT) and is suitable for various measurement tasks.

Provided with special features such as the R&S ProbeMeter and the micro button,

the R&S RT-ZM is designed to meet tomorrow's challenges in probing.

The probe is equipped with theRohde & Schwarz probe interface. It can be connected to any Rohde & Schwarz instrument that is compatible with this interface.

When connected to the front panel, the probe is controlled by the oscilloscope's

software. Supported oscilloscopes are listed in the data sheet.

1.1.1 Key Characteristics

The key characteristics of the probe are the following:

MultiMode feature for differential, common mode and single-ended measurements

Two different probe gain settings with 10:1 and 2:1 attenuation to achieve low system noise

Bandwidth DC to 1.5 GHz (R&S RT-ZM15)

DC to 3 GHz (R&S RT-ZM30)

DC to 6 GHz (R&S RT-ZM60)

DC to 9 GHz (R&S RT-ZM90)

DC to 13 GHz (R&S RT-ZM130)

DC to 16 GHz (R&S RT-ZM160)

Dynamic range ±2.5 V (10:1 attenuation)

±0.5 V (2:1 attenuation)

5User Manual 1419.3128.02 ─ 04

Page 6

R&S®RT‑ZM

Product Description

Key Features and Key Characteristics

Operating voltage window

(each pin to GND)

Maximum non-destructive input voltage ±30 V

Input resistance Differential: 400 kΩ

R&S ProbeMeter, measurement error <0.2 %

R&S ProbeMeter, dynamic range ±7 V

Offset capability ±16 V for compensating single-ended, differential and

Low zero and gain errors throughout the entire temperature range for all measurement modes

Micro button

Rohde & Schwarz probe interface

±7.0 V with ±16 V offset capability, DC to 100 kHz

±5.0 V with ±16 V offset capability, > 100 kHz

Single-ended: 200 kΩ

common mode DC offsets

1.1.2 Key Features

Micro button

The micro button at the probe head can remotely control different functions on the

base unit. The assigned function is configured via the base unit.

For details, see Chapter 2.5, "Micro Button", on page 18.

R&S ProbeMeter

The R&S ProbeMeter measures the DC voltage of the input signal directly at the

probe tip. It provides a continuous high-precision DC voltage measurement that is

independent of the settings of the oscilloscope and runs in parallel to the time

domain measurement. If activated on the base unit, the measured value is displayed on the screen of the Rohde & Schwarz oscilloscope.

The R&S ProbeMeter simultaneously measures both differential and common

mode DC voltages.

For details, see Chapter 2.7, "R&S ProbeMeter", on page 23.

Probe DC correction

The probe amplifier includes an integrated data memory with individually determined DC correction parameters (e.g. gain, offset). These correction parameters

are read out and processed by the Rohde & Schwarz oscilloscope. As a result,

6User Manual 1419.3128.02 ─ 04

Page 7

R&S®RT‑ZM

Product Description

Unpacking

the probe offers a very high degree of DC accuracy so that additional calibration

procedures are not required.

Probe frequency correction

The R&S RT-ZM probe amplifier includes an integrated data memory with individually measured S-parameters. These correction parameters are read out and processed by the Rohde & Schwarz oscilloscope. This leads to a more accurate

probe frequency response and an enhanced measurement accuracy.

1.2 Unpacking

The carrying case contains the following items:

●

R&S RT-ZM modular probe

●

Carrying case

●

Accessory boxes

●

User manual

●

R&S RT-ZM data sheet

●

Calibration certificate

●

Documentation of calibration values (if

ordered)

●

Foam inlay for tip cables

If R&S RT-ZMA tip modules were ordered, they come in a separate packaging

and can be inserted into the foam inlay.

1.2.1 Inspecting the Contents

●

Inspect the package for damage.

Keep the package and the cushioning material until the contents have been

checked for completeness and the device has been tested.

If the packaging material shows any signs of stress, notify the carrier and your

Rohde & Schwarz service center. Keep the package and cushioning material

for inspection.

●

Inspect the probe.

7User Manual 1419.3128.02 ─ 04

Page 8

R&S®RT‑ZM

If there is any damage or defect, or if the R&S RT-ZM modular probe does not

operate properly, notify your Rohde & Schwarz service center.

●

Inspect the accessories.

If the contents are incomplete or damaged, notify your Rohde & Schwarz service center.

Product Description

Description of the Probe

1.3 Description of the Probe

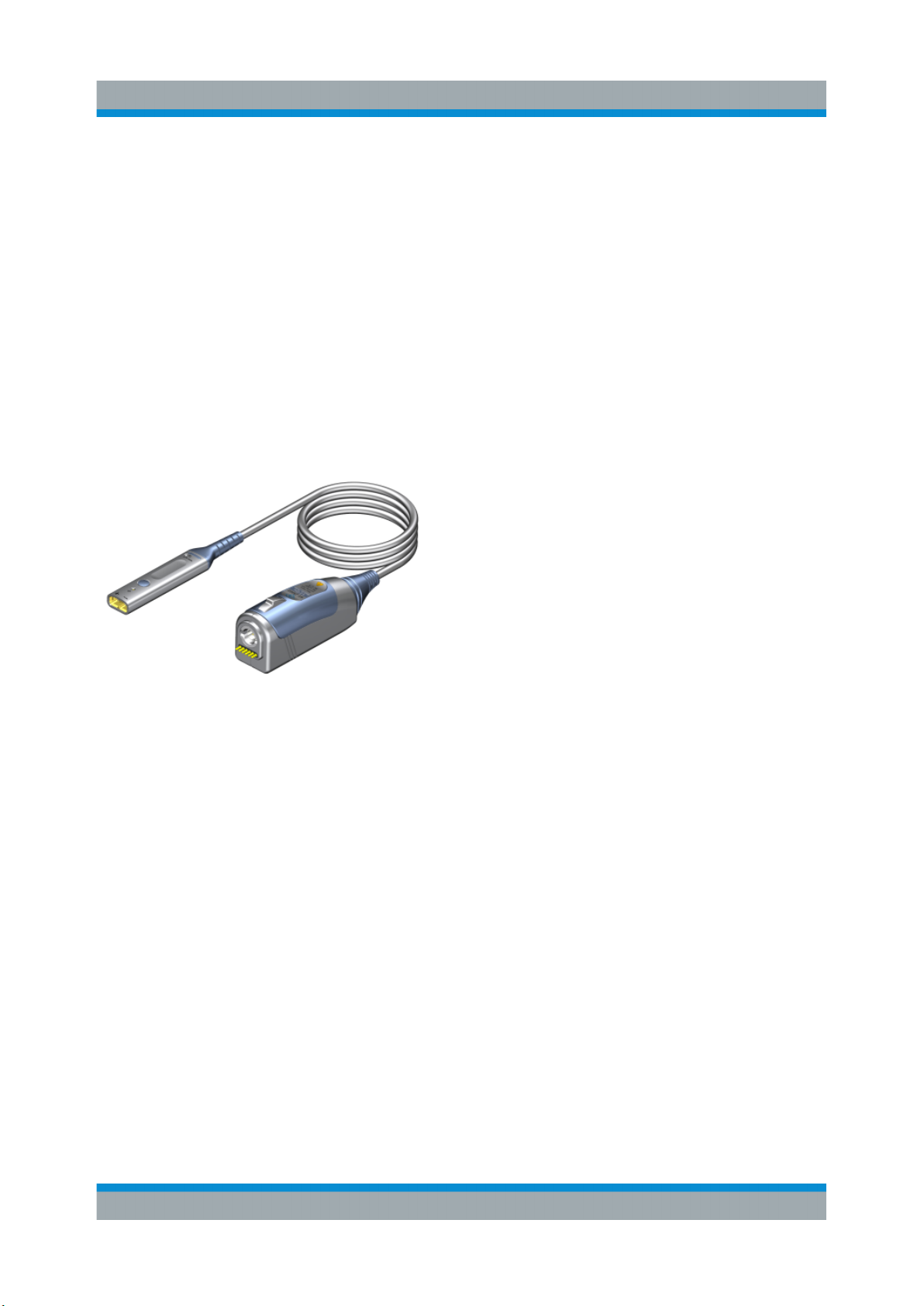

The probe consists of the active probe amplifier, the probe box for connection to

the oscilloscope, the probe cable and various probe tip modules.

Figure 1-1: R&S RT-ZM probe consisting of probe amplifier and probe box

1.3.1 Probe Amplifier

The probe amplifier is designed for easy handling and high performance measurements. The R&S RT-ZM probe amplifier is designed for use with the R&S RTZMA probe tip modules.

See also: Chapter 3, "Connecting the Probe to the DUT", on page 24.

8User Manual 1419.3128.02 ─ 04

Page 9

R&S®RT‑ZM

Product Description

Description of the Probe

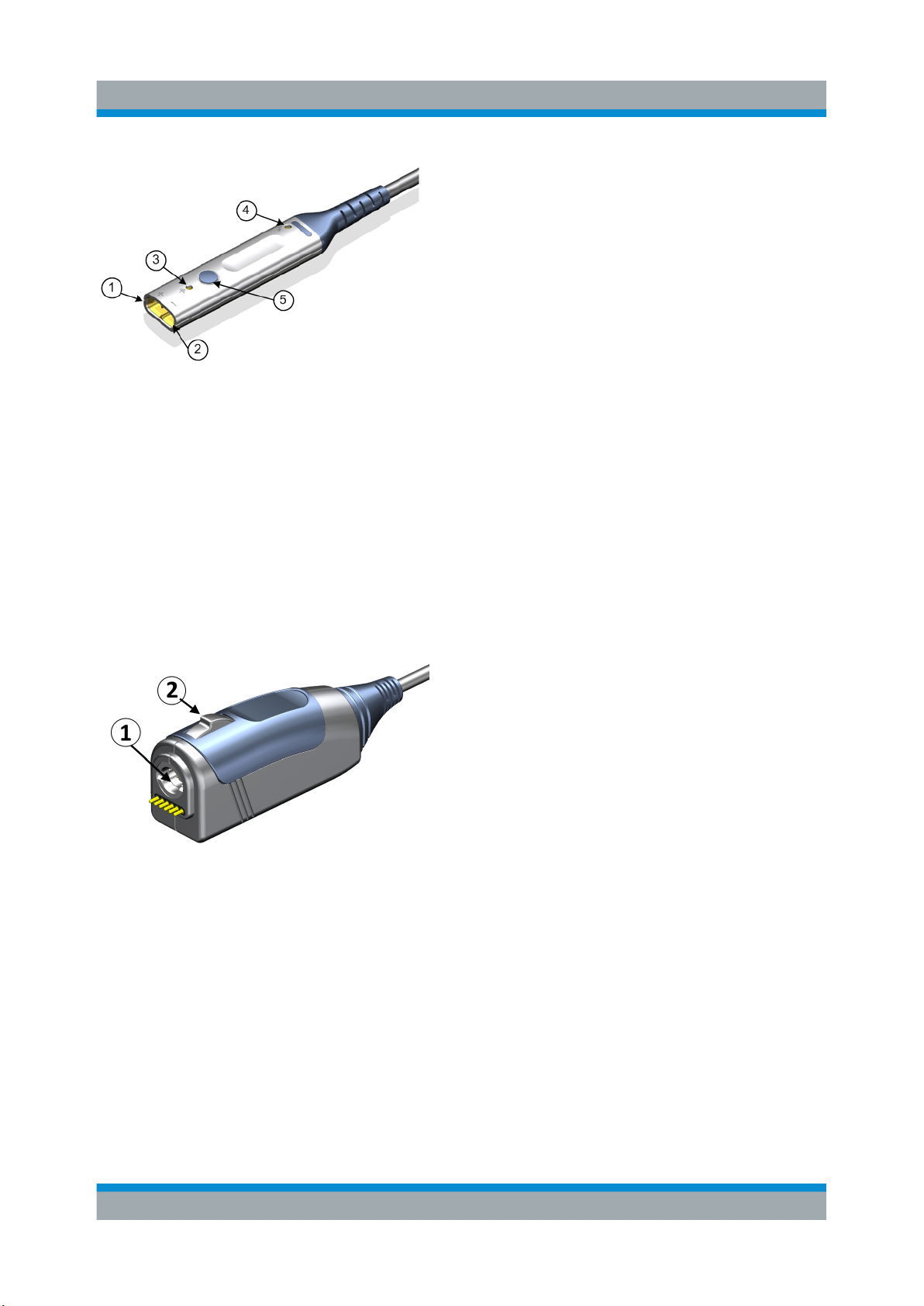

(1) Positive coaxial input

(2) Negative coaxial input

(3) Ground socket

(4) Termination voltage socket

(5) Micro button

Signal and Termination voltage sockets are

compatible with 0.64 mm (25 mil) square pins

and 0.6 mm to 0.8 mm (24 mil to 35mil) round

pins.

1.3.2 Probe Box

The probe box connects the probe and the oscilloscope via the Rohde & Schwarz

probe interface. The Rohde & Schwarz probe interface contains a male precision

7 mm (276 mil) BNC connector and six pogo pin connectors. This interface provides the required supply voltage and is also used to transmit analog signals and

digital data simultaneously. All the analog voltages required by the probe are generated in the probe box. This approach ensures that it will be possible to operate

future probes on any base unit that features a Rohde & Schwarz probe interface.

(1) Rohde & Schwarz probe interface with

7 mm (276 mil) coaxial connector and 6 pogo

pins

(2) Release knob

1.3.3 Probe Tip Modules

To use the probe for measurements, select the appropriate probe tip module and

connect it to the probe amplifier.

Figure 1-2 shows all probe tip modules are available for the R&S RT-ZM probe.

The usage of probe tip modules is described in Chapter 3, "Connecting the Probe

to the DUT", on page 24.

If you need more probe tip modules, you can order them at Rohde & Schwarz.

The order numbers are provided in the data sheet.

9User Manual 1419.3128.02 ─ 04

Page 10

R&S®RT‑ZM

Product Description

Description of the Probe

Figure 1-2: R&S RT-ZM probing system compatibility chart

1.3.4 Accessories and Items

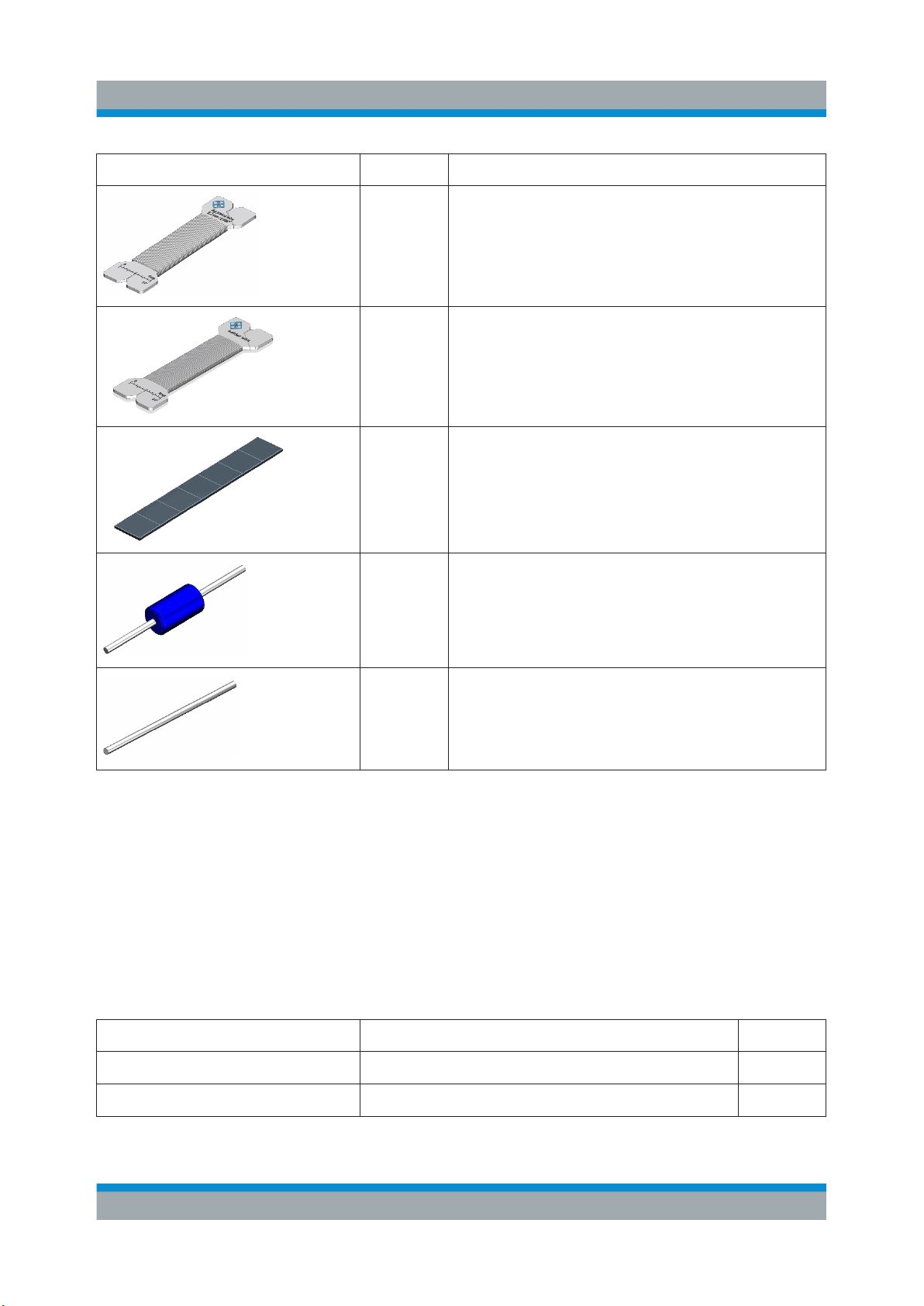

1.3.4.1 Accessories Supplied

Table 1-1 shows the accessories that are supplied with the R&S RT-ZM modular

probe.

Table 1-1: Accessories supplied

Item Quantity Description

1 Lead, 15 cm / 5.9 in

1 Solder wire 0.1mm, Ag plated, 10 m

10User Manual 1419.3128.02 ─ 04

Page 11

R&S®RT‑ZM

Item Quantity Description

1 Solder wire 0.2mm, Ag plated, 10 m

1 Solder wire, lead free, 5 m

7 Adhesive pads

Product Description

Description of the Probe

20 Solder in resistor (270 Ω) for R&S RT-ZMA15

20 Solder lead for R&S RT-ZMA12/15

For a list of spare parts, see Chapter 4.5, "Spare Parts ", on page 37.

1.3.4.2 Optional Accessories

If the delivered accessories do not meet individual customer requirements,

Rohde & Schwarz offers different accessory sets for sale. The order numbers are

provided in the data sheet.

Table 1-2: Optional accessories

Accessory set Items Quantity

R&S RT-ZA4 mini clips Mini clip 10

R&S RT-ZA5 micro clips Micro clip 4

11User Manual 1419.3128.02 ─ 04

Page 12

R&S®RT‑ZM

Product Description

Description of the Probe

Accessory set Items Quantity

R&S RT-ZA6 lead set Lead, 6 cm / 2.4 in

Lead, 15 cm / 5.9 in

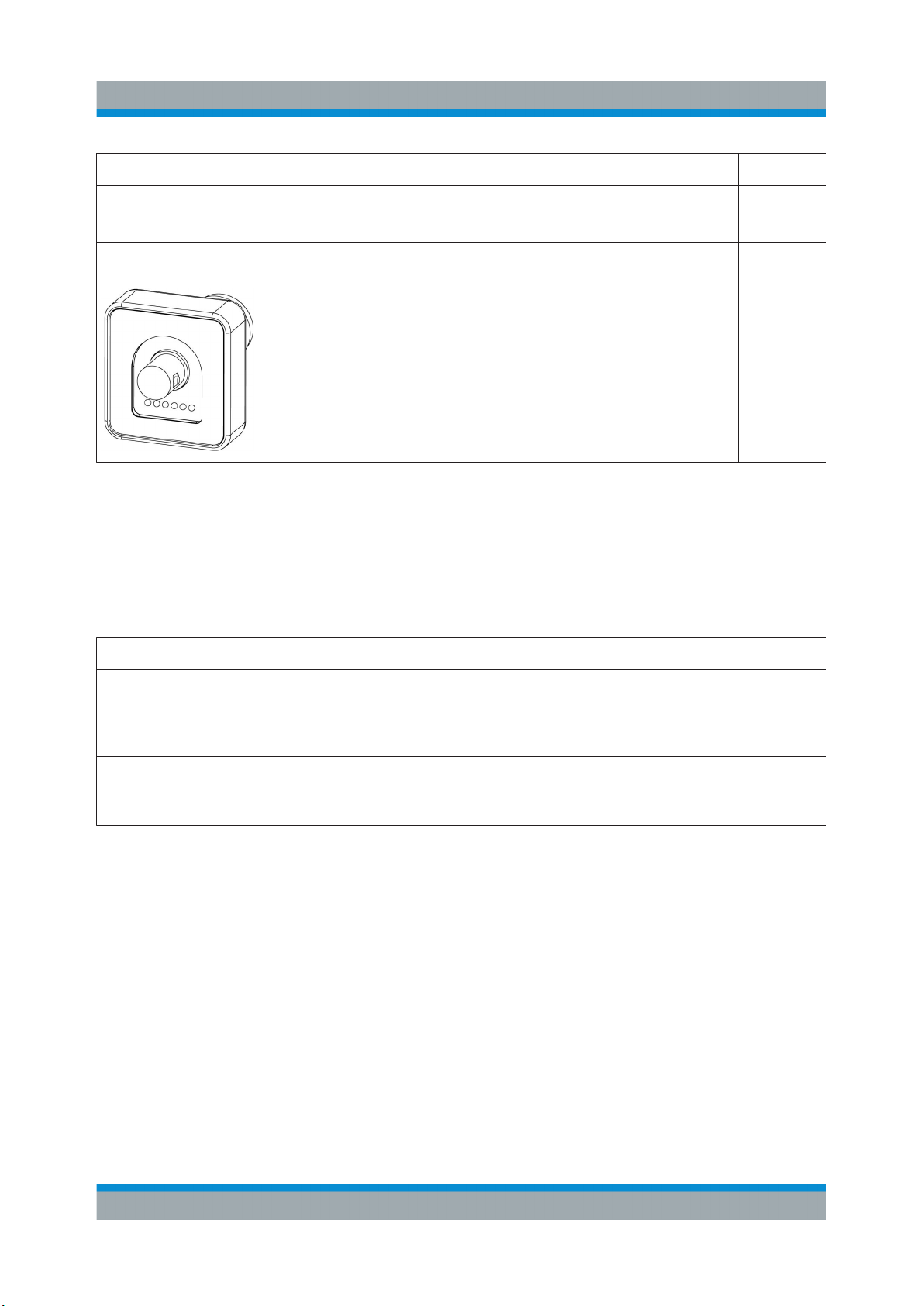

R&S RT-ZA9 probe box to

N/USB adapter

The adapter connects the R&S RT-ZM modular

probe to any other oscilloscope or any other

measurement instrument (e.g. a network or

spectrum analyzer).

Using the USB interface of the adapter, the

probe can be powered and controlled from any

conventional PC. However, full software functionality is only provided by the supported oscilloscopes (see data sheet).

5

5

1

1.3.4.3 Service Accessories

To order accessories for servicing the probe, contact your Rohde & Schwarz service center. The following accessories are available:

Table 1-3: Service accessories

Item Description

R&S RT-ZK3 The service kit is used to calibrate the probe, to do perform-

ance tests, and for servicing. The service kit includes all

adapters and accessories to connect the probe to the

required measuring instruments.

R&S RT-ZM Service Manual The service manual contains a detailed description of the

performance test to verify the specifications, and other

important service procedures.

12User Manual 1419.3128.02 ─ 04

Page 13

R&S®RT‑ZM

Putting into Operation

2 Putting into Operation

The probe is designed for usage with oscilloscopes that have a Rohde & Schwarz

probe interface. Supported Rohde & Schwarz oscilloscopes are listed in the probe's data sheet.

Read and observe the printed "Basic Safety Instructions" that are delivered with

the probe. Also, read and observe the safety instructions of the oscilloscope the

probe is connected to.

Maximum non-destructive input voltage

The maximum non-destructive input voltage is ±30 V. A higher input voltage

can destroy the probe.

Risk of device damage

The R&S RT-ZM can withstand a moderate amount of physical and electrical stress. To avoid damage, treat the probe with care:

●

Do not exceed the specified voltage limits.

●

Connect the R&S RT-ZM only to an instrument with Rohde & Schwarz

probe interface. Never connect it to a usual BNC jack. Although the

7 mm coaxial connector looks like a standard BNC connector, it is constructed differently and does not fit to the standard BNC jack. The interface of the R&S RT-ZM can withstand a higher frequency limit.

●

Handle the probe by the probe tip module or probe box.

●

Handle the probe by the probe head or probe box. Avoid excessive

strain on the probe cable, and kinking.

●

Prevent the probe from receiving mechanical shock.

●

Do not spill liquids on the probe.

●

Store the probe in a shock-resistant case, e.g. in the foam-lined shipping case.

13User Manual 1419.3128.02 ─ 04

Page 14

R&S®RT‑ZM

Connecting the Probe to the Oscilloscope

During usage, the probe slightly heats up. Warming is normal behavior and not a

sign of malfunction.

Putting into Operation

2.1 Connecting the Probe to the Oscilloscope

1. If your DUT is floating and not grounded, connect the DUT ground to the oscilloscope ground before connecting any probe tip module to your DUT.

2. Connect the probe box (1) to the Rohde & Schwarz probe interface of the

oscilloscope (2).

The probe snaps in when connected properly to the port.

Figure 2-1: Connecting the probe to the Rohde & Schwarz oscilloscope

► To disconnect the probe:

a) Press and hold the release button (3).

b) Pull the probe box away from the oscilloscope.

14User Manual 1419.3128.02 ─ 04

Page 15

R&S®RT‑ZM

Putting into Operation

MultiMode

2.2 Identification of the Probe

When the probe is connected to the oscilloscope, the oscilloscope recognizes the

probe and reads out the probe-specific parameters.

The complete probe information is shown in the probe settings dialog. For more

information, refer to the user manual of your oscilloscope.

2.3 MultiMode

The R&S RT-ZM probe family features the MultiMode function which allows you

to switch between single-ended, differential and common mode measurements

without reconnecting or resoldering the probe.

Four different input voltages can be measured with the MultiMode feature:

●

P-Mode: (pos.) Single-ended input voltage (Vp)

Voltage between the positive input terminal and ground

●

N-Mode: (neg.) Single-ended input voltage (Vn)

Voltage between the negative input terminal and ground

●

DM-Mode: Differential mode input voltage (Vdm)

Voltage between the positive and negative input terminal

●

CM-Mode: Common mode input voltage (Vcm)

Mean voltage between the positive and negative input terminal vs. ground

In the N-Mode, the signal at negative input terminal is not inverted.

15User Manual 1419.3128.02 ─ 04

Page 16

R&S®RT‑ZM

Figure 2-2: Input voltage at probe tip

Putting into Operation

MultiMode

The R&S RT-ZM probes have three input terminals: the positive signal input (+),

the negative signal input (-), and ground.

Figure 2-3: Displayed voltage on oscilloscope screen

The setting of the probe mode is part of the probe settings of the channel to which

the probe is connected. You can also configure the micro button at the probe

amplifier to select the "Probe Mode". For more details, see the oscilloscope's user

manual.

The MultiMode feature is not supported by R&S RT-ZMA30 browser module

because there is no ground connection.

16User Manual 1419.3128.02 ─ 04

Page 17

R&S®RT‑ZM

Putting into Operation

Dynamic Range and Operating Voltage Window

2.4 Dynamic Range and Operating Voltage Window

Two separate specifications are necessary to characterize the permissible input

voltage range of a R&S RT-ZM MultiMode probe.

Measurement mode Single-Ended P, Single-Ended N, or Common Mode

Dynamic Range ±2.50 V at 10:1 attenuation

±0.50 V at 2:1 attenuation

The dynamic range for single-ended (P-Mode, N-Mode) or common mode (CMMode) measurements designates the maximum voltage (Vp, Vn) that can occur

between each of the two input terminals (Vp, Vn) and ground at the probe tip.

Differential measurement mode

Dynamic Range ±2.50 V at 10:1 attenuation

±0.50 V at 2:1 attenuation

Operating voltage window

(each pin to ground)

●

The dynamic range for differential measurement (DM-Mode) designates the

±7.0 VDC to 100 kHz

±5.0 V > 100 kHz at 10:1 attenuation

±1.0 V > 100 kHz at 2:1 attenuation

maximum differential voltage Vdm that can occur between the positive and

negative signal terminal at the probe tip.

●

At the same time, the two voltage values at each of the two signal terminals V

and Vn referenced to the common ground must not exceed a specific limit

value. This limitation is referred to as the operating voltage window (some

manufacturers also use the less precise term "common mode range" for the

same parameter).

●

If one of these ranges is exceeded, an unwanted signal clipping can occur.

When measuring differential signals, frequently change to common mode

measurement to check for unallowed common mode signals.

p

●

The attenuation is automatically selected by the oscilloscope's "V/div" setting

17User Manual 1419.3128.02 ─ 04

Page 18

R&S®RT‑ZM

Figure 2-4: Operating voltage window for differential measurement mode DM at 10:1

attenuation for all offset settings at 0 V

Putting into Operation

Offset Compensation

2.5 Micro Button

The micro button provides easy and quick access to important functions of the

Rohde & Schwarz oscilloscope. After a function has been assigned, pressing the

micro button remotely controls this specific function on the base unit. For example, "Run continuous" or "Run single" are often assigned to the micro button.

The configuration of the micro button is part of the probe settings of the channel

to which the probe is connected. For more details, see the oscilloscope's user

manual.

2.6 Offset Compensation

The R&S RT-ZM probe features the most comprehensive offset compensation

function. The compensation of DC components directly at the probe tip even in

front of the active probe amplifier is possible with an extremely wide compensation range of ±16 V.

The offset compensation feature is available for every MultiMode setting:

18User Manual 1419.3128.02 ─ 04

Page 19

R&S®RT‑ZM

Putting into Operation

Offset Compensation

MultiMode

setting

DM-Mode Differential DC voltage ±16 V Probing single-ended signals with the

CM-Mode Common mode DC

P-Mode DC voltage at positive

N-Mode DC voltage at nega-

Offset compensation Offset com-

pensation

range

±16 V Measurements of signals with high

voltage

±24 V Measurement of single-ended AC sig-

input terminal

±24 V Measurement of single ended AC sig-

tive input terminal

Application

R&S RT-ZMA30 browser module, e.g.

power rails with high DC component

and small AC signal.

common mode levels, e.g. current measurements with a shunt resistor.

nals with high superimposed DC component at the positive input terminal.

Note: The maximum voltage difference

between the positive and negative input

terminals is 16 V.

nals with high superimposed DC component at the negative input terminal.

Note: The maximum voltage difference

between the positive and negative input

terminals is 16 V.

You can set the offset compensation at the oscilloscope in various ways:

●

Use the vertical [Position] knob. Before adjusting the offset, make sure that

the function of the knob is set to "Offset".

●

Use the probe settings menu of the channel to which the probe is connected.

●

Use the micro button to compensate the DC component of the measurement

signal, which is very helpful during measurements of input signals with different DC offsets. Therefore, assign "Set offset to mean" to the micro button

function.

Setting an offset compensation voltage and then switching the probe measurement mode does not affect the offset settings.

For example, you can measure a differential signal superimposed with a high DC

common mode component. First switch to CM-mode and compensate the common mode offset using the vertical [Position] knob until the measurement trace is

in the center of the oscilloscope screen. Then switch back to DM-mode to measure the differential signal.

For more details on setting the offset compensation voltage, refer to the user

manual of your Rohde & Schwarz oscilloscope.

19User Manual 1419.3128.02 ─ 04

Page 20

R&S®RT‑ZM

Putting into Operation

Offset Compensation

2.6.1 Differential Offset

The differential offset function can compensate a DC voltage applied between the

positive (Vp) and the negative (Vn) input terminal at the probe tip. Setting a differ-

ential offset compensation in DM measurement mode is directly visible on the

oscilloscope screen as a voltage offset of the measured waveform.

Figure 2-5: Differential offset compensation for a single-ended measurement (negative

input connected to ground) using an R&S RT‑ZM15/30/60/90/130/160

2.6.2 Common Mode Offset

The common mode offset function can compensate a DC voltage applied to both

input terminals at the probe tip (referenced to ground). Setting a common mode

offset compensation in CM measurement mode is directly visible on the oscilloscope screen as a voltage offset of the measured waveform.

20User Manual 1419.3128.02 ─ 04

Page 21

R&S®RT‑ZM

Putting into Operation

Offset Compensation

Figure 2-6: Common mode (CM) offset compensation for a differential measurement

2.6.3 Positive Input Single-Ended Offset

The P offset function can compensate a DC voltage applied to the positive input

terminal (Vp) at the probe tip (referenced to ground). Setting a P offset compensa-

tion in single-ended P measurement mode is directly visible on the oscilloscope

screen as a voltage offset of the measured waveform.

This function is useful when measuring single-ended AC signals with high superimposed DC component at the positive input terminal referenced to ground.

21User Manual 1419.3128.02 ─ 04

Page 22

R&S®RT‑ZM

Putting into Operation

Offset Compensation

Figure 2-7: P offset compensation for a single-ended measurement at the positive input

terminal

2.6.4 Negative Input Single-Ended Offset

The N offset function can compensate a DC voltage applied to the negative input

terminal (Vn) at the probe tip (referenced to ground). Setting an N offset compen-

sation in single-ended N measurement mode is directly visible on the oscilloscope

screen as a voltage offset of the measured waveform.

This function is useful when measuring single-ended AC signals with high superimposed DC component at the negative input terminal referenced to ground.

Figure 2-8: N offset compensation for a single-ended measurement at the negative input

terminal

22User Manual 1419.3128.02 ─ 04

Page 23

R&S®RT‑ZM

Putting into Operation

R&S ProbeMeter

2.7 R&S ProbeMeter

The R&S ProbeMeter is an integrated voltmeter that measures DC voltages with

higher precision compared to the oscilloscope's DC accuracy. The DC measurement is performed continuously and in parallel to the time domain measurement

of the oscilloscope.

High-precision measurements are achieved through immediate digitization of the

measured DC voltage at the probe tip.

The R&S ProbeMeter measures the differential and common mode DC voltages

simultaneously, and independently of the MultiMode setting.

When the R&S ProbeMeter is active, the measured values are displayed on the

oscilloscope. The R&S ProbeMeter state is part of the probe settings of the channel to which the probe is connected. For details, refer to the user manual of the

Rohde & Schwarz oscilloscope.

Advantages of the R&S ProbeMeter:

●

Measures DC voltages of different levels, no need to adjust the measurement

range of the oscilloscope.

●

True DC measurement (integration time > 100 ms), not mathematical average

of displayed waveform.

●

High measurement accuracy and low temperature sensitivity.

●

Simple means of setting the oscilloscope's trigger level and vertical scaling if a

waveform is not visible.

●

Independent of oscilloscope settings for offset, position, vertical scale, horizontal scale, and trigger.

●

Independent of probe settings for measurement mode and gain.

●

Unique way to detect unexpected or inadmissible common mode voltages,

e.g. bias points - measurement of common mode DC voltages without reconnecting the probe.

●

Differential measurement range ±2.5 V + offset compensation setting.

Common mode measurement range ±7 V + common mode offset compensation setting.

23User Manual 1419.3128.02 ─ 04

Page 24

R&S®RT‑ZM

Connecting the Probe to the DUT

3 Connecting the Probe to the DUT

This chapter describes how to connect the probe to the DUT using different

R&S RT-ZMA tip modules offered for the R&S RT-ZM probe family. The various

tip modules are described and their use is explained. Note that you always need

a tip module, measurements without any tip module are not possible.

The recommended configurations are designed to give the best probe performance for different probing situations, to measure with confidence in the performance and signal fidelity. Using the recommended connection configurations is

your key to making accurate oscilloscope measurements with known performance levels.

Probe frequency correction

For R&S RT-ZMAxx probe tip modules, typical S-parameters are determined and

stored in the oscilloscope. When the connected R&S RT-ZMA tip module is

selected in the oscilloscope probe menu, the appropriate correction parameters

are automatically processed by the Rohde & Schwarz oscilloscope. Correction

leads to a more accurate probe frequency response and an enhanced measurement accuracy.

Supported oscilloscopes are listed in the data sheet.

Damage caused by electrostatic discharge

Electrostatic discharge (ESD) can damage the electronic components of the

probe and the instrument, and also the device under test (DUT). Electrostatic discharge is most likely to occur when you connect or disconnect a

DUT or test fixture to the probe and to the instrument's test ports. To prevent electrostatic discharge, use a wrist strap and cord and connect yourself to the ground, or use a conductive floor mat and heel strap combination. Discharge cables and probe tips before you connect them.

24User Manual 1419.3128.02 ─ 04

Page 25

R&S®RT‑ZM

Risk of damaging the device

To avoid damage to the device, take the following precautions:

●

Only connect the probe tip module to the probe amplifier if the probe

amplifier is connected to the oscilloscope channel. This ensures that the

amplifier is grounded.

●

Always disconnect the probe tip module from the probe amplifier before

unsoldering or disconnecting it, moving it to a new position and resoldering or reconnecting it.

●

Be careful when handling the probe amplifier connection pins:

– When connecting a tip module to the probe amplifier, push it straight

in.

– When disconnecting a tip module from the probe amplifier, pull the

tip module connectors straight out of the sockets.

Connecting the Probe to the DUT

R&S RT-ZMA10 Tip Cable Solder-In

– Never bend the probe tip module to pop it loose from the amplifier.

– Do not wiggle the probe tip module up and down or twist it to remove

the connector from the probe amplifier.

Protect the probe amplifier against excess heat. When using the probe

amplifier with tip modules that can withstand extreme temperatures, do not

subject the probe amplifier to temperatures outside of its operating range of

0 °C to 40 °C.

Some solder-in accessories are very fine and sensitive. Stabilize the probe

using appropriate means (e.g. adhesive pads, probe positioner) in order to

protect the solder joint from excessive mechanical stress.

3.1 R&S RT-ZMA10 Tip Cable Solder-In

The R&S RT-ZMA10 tip cable solder-in is a semi-permanent solder-in connection

that supports the full bandwidth of the probe amplifier.

25User Manual 1419.3128.02 ─ 04

Page 26

R&S®RT‑ZM

Connecting the Probe to the DUT

R&S RT-ZMA10 Tip Cable Solder-In

The R&S RT-ZMA10 tip cable solder-in is well

suited for creating solid contact with test points

that are hard to reach (e.g. IC pins).

Bandwidth: up to 16 GHz

MultiMode compatible

Length: 15 cm

Variable span range of the leads: 0 mm to

5 mm (0 mil to 200 mil).

Temperature range: -30 °C to +80 °C

For measurements with MultiMode functionality, solder both signal leads (P,N) in front and

both ground wires (GND) at the outside of the

tip board to the DUT. In this configuration, you

can measure single-ended, differential and

common mode signals without resoldering the

tip cable.

If you want to use the DM Mode only for differential measurements, you do not have to solder the ground wires (GND). Leave ground

vias open and only solder both signal leads

(P,N) to your DUT.

Always keep soldered leads as short as possible for best performance and signal integrity

Risk of damaging the probe due to excess heat

Do not leave the soldering iron in contact with the probe tip for more than a

few seconds at a time. Excess heat may damage the probe.

26User Manual 1419.3128.02 ─ 04

Page 27

R&S®RT‑ZM

Connecting the Probe to the DUT

R&S RT-ZMA12 Tip Cable Square Pin

3.2 R&S RT-ZMA12 Tip Cable Square Pin

The R&S RT-ZMA12 tip cable square pin is used to plug onto pins and make a

connection to the DUT that is easy to plug and remove.

The R&S RT-ZMA12 tip cable square pin is

well suited for creating contact with soldered in

test leads. It can also be used to plug onto pin

strips with a pitch of 1.27 mm (50 mil).

Bandwidth: up to 6 GHz

MultiMode compatible

Length: 15 cm

Distance range: 1.27 mm (50 mil)

Temperature range: -30°C to +80°C

Permanently solder 2 signal (P,N) and ground

wires (GND) to your DUT and effortlessly connect or reconnect your socket head to your

measurement point. In this configuration, you

can measure single-ended, differential and

common mode signals.

However, if you are making only differential

measurements you do not have to connect the

GND lead (GND).

Always keep soldered or connected pins as

short as possible for best performance and

signal integrity.

27User Manual 1419.3128.02 ─ 04

Page 28

R&S®RT‑ZM

Connecting the Probe to the DUT

R&S RT-ZMA14 Tip Cable Flex Connect

3.3 R&S RT-ZMA14 Tip Cable Flex Connect

The R&S RT-ZMA14 tip cable flex connect makes an easy to clamp and remove

connection onto solder-in flex tips soldered directly to the DUT, and supports the

full bandwidth of the probe amplifier.

The R&S RT-ZMA14 tip cable flex connector is

suited for contacting with soldered-in flex tips.

Solder as many flex tips onto your DUT as

needed and easily connect and reconnect different test points using the clamp connector of

the tip cable.

Bandwidth: up to 16 GHz

MultiMode compatible

Length: 15 cm

Variable span range of the leads: 0 mm to 5

mm (0 mil to 200 mil)

Temperature range: -30°C to +80°C

Permanently solder the flex tips and ground

wire (GND) to your DUT and effortlessly connect or reconnect your RT-ZMA14 tip cable

using its clamp connector.

In this configuration, you can measure singleended, differential and common mode signals.

However, if you are making only differential

measurements you do not have to solder the

ground wires (GND) to the two ground vias at

both sides of the flex tips. For differential measurements only, optionally cut off the ground

vias to reach smaller probing areas.

Always keep soldered pins and resistors as

short as possible for best performance and

signal integrity.

Risk of damaging the probe due to excess heat

Do not leave the soldering iron in contact with the probe tip for more than a

few seconds at a time. Excess heat may damage the probe.

28User Manual 1419.3128.02 ─ 04

Page 29

R&S®RT‑ZM

R&S RT-ZMA15 Tip Cable Quick Connect

Risk of damaging the accessories

Always mechanically strain-relieve the flex tip using adhesive pads or lowtemperature hot glue to protect your probe accessories and DUT from damage.

Risk of damaging the clamp connector

During soldering always disconnect the flex tip from the R&S RT-ZMA14 tip

cable to prevent damaging the clamp connector.

Connecting the Probe to the DUT

3.4 R&S RT-ZMA15 Tip Cable Quick Connect

The R&S RT-ZMA15 tip cable quick connect makes an easy to plug and remove

connection onto resistors soldered directly to the DUT, and supports the full bandwidth of the probe amplifier.

29User Manual 1419.3128.02 ─ 04

Page 30

R&S®RT‑ZM

Connecting the Probe to the DUT

R&S RT-ZMA30 Browser Module

The R&S RT-ZMA15 tip cable quick connect is

suited for creating contact with soldered-in

270 Ω resistors, and easily reconnecting different test points.

Only use the 270 Ω resistors from the

R&S RT-ZMA accessories set for optimal flatness and bandwidth

Bandwidth: up to 12 GHz

MultiMode compatible

Length: 15 cm

Distance range: 1.27 mm (50 mil)

Temperature range: -30°C to +80°C

Permanently solder the 270 Ω resistors (P,N)

and ground wire (GND) to your DUT and

effortlessly connect or reconnect your socket

head to your measurement point. In this configuration, you can measure single-ended, differential and common mode signals.

However, if you are making only differential

measurements you do not have to solder the

ground wire (GND) between the two resistors.

Always keep soldered pins and resistors as

short as possible for best performance and

signal integrity.

3.5 R&S RT-ZMA30 Browser Module

The R&S RT-ZMA30 browser module allows handheld probing with maximum

convenience at the DUT and supports the full bandwidth of the probe amplifier.

30User Manual 1419.3128.02 ─ 04

Page 31

R&S®RT‑ZM

Connecting the Probe to the DUT

R&S RT-ZMA30 Browser Module

Risk of injuries

The included browser pins are exceptionally sharp and must be handled

with extreme care. To prevent injuries, always use tweezers when inserting

or removing pins.

The R&S RT-ZMA30 browser module has

spring-loaded pins with damping resistors

close to the test point.

The pin distance can be set by turning the levers.

Bandwidth: up to 16 GHz

Distance range: 0.5 mm to 8 mm (20 mil to

315 mil)

Axial travel: 0.5 mm (20 mil)

Not MultiMode compatible, the module has no

ground connector.

Using the R&S RT-ZMA30 browser module

sets the probe amplifier to DM mode.

To measure differential signals, connect both

pins to the differential pair at the DUT.

To probe single-ended signals, connect the

positive pin to the signal and the negative pin

to the ground.

31User Manual 1419.3128.02 ─ 04

Page 32

R&S®RT‑ZM

Risk of damage due to excess force

To avoid damaging the browser’s pins, do not apply a side load to the

browser.

Connecting the Probe to the DUT

R&S RT-ZMA40 SMA Module

Replaceable parts, spring-loaded resistor tips

Do not apply too much force when browsing. The weight of the probe in

your hand should be sufficient.

Always remove the browser from the DUT before disconnecting the probe amplifier from the oscilloscope.

3.6 R&S RT-ZMA40 SMA Module

The R&S RT-ZMA40 SMA module allows you to connect two 2.92 mm, 3.5 mm,

or SMA cables to make a MultiMode measurement on a single oscilloscope channel. It supports the full bandwidth of the probe amplifier.

When connecting the SMA module to the output sockets of the DUT, use the Sshaped semi-rigid cables supplied with the SMA module. Change the angle of the

S-shaped semi-rigid cables to adjust the distance of the input sockets. The S-shaped semi-rigid cables are phase-matched to prevent unwanted signal conversion

and assure best signal integrity.

Always remove the SMA module from the DUT before disconnecting the probe

amplifier from the oscilloscope.

32User Manual 1419.3128.02 ─ 04

Page 33

R&S®RT‑ZM

Connecting the Probe to the DUT

R&S RT-ZMA50 Extreme Temperature Kit

Bandwidth: up to 16 GHz

MultiMode compatible

Termination voltage range: ±4V with a maxi-

mum current of ±40 mA

Distance range: up to 65 mm (2560 mil)

The R&S RT-ZMA40 SMA module applies a

termination voltage (±4 V) to the DUT to

enable measurements against a common

mode DC voltage instead of ground, which is

required for many digital signal standards.

The termination voltage can be controlled by

the oscilloscope. Therefore, connect the supplied red DC lead to the VT terminal of the

R&S RT-ZM probe amplifier to the VT terminal

of the R&S RT-ZMA40 SMA module. Neces-

sary termination voltage is detected automatically, but can also be set manually.

3.7 R&S RT-ZMA50 Extreme Temperature Kit

The R&S RT-ZMA50 extreme temperature kit contains a R&S RT-ZMA11 solderin tip cable and a pair of matched extension cables for measurements in extreme

temperature environments.

Risk of damaging the probe due to excess heat

Do not leave the soldering iron in contact with the probe tip for more than a

few seconds at a time. Excess heat may damage the probe.

33User Manual 1419.3128.02 ─ 04

Page 34

R&S®RT‑ZM

Connecting the Probe to the DUT

R&S RT-ZMA50 Extreme Temperature Kit

The R&S RT-ZMA50 extreme temperature kit is

well suited for creating solid contact with test

points in extreme temperature areas, e.g. temperature chambers.

Note: The R&S RT-ZM probe amplifier always

remains outside the temperature chamber and

has a specified operating temperature range

from 0°C to 40°C.

Bandwidth: up to 12 GHz

MultiMode compatible

Length: 115 cm

Variable span range of the leads: 0 mm to 5 mm

(0 mil to 200 mil)

Temperature range: -55° C to +125° C

The R&S RT-ZMA11 tip cable solder-in ET cannot be plugged directly into the probe amplifier.

Always connect the R&S RT-ZMA11 tip cable

solder-in ET to the 1-m extension cable pair and

connect the other end of the extension cable

pair to the R&S RT-ZM probe amplifier.

For measurements with MultiMode functionality,

solder both signal wires (P,N) and both ground

wires (GND) at the outside of the tip board to the

DUT.

In this configuration, you can measure singleended, differential and common mode signals.

If you want to use the DM mode only for differential measurements, you do not have to solder

the ground wires (GND).

Always keep soldered leads as short as possible

for best performance and signal integrity.

34User Manual 1419.3128.02 ─ 04

Page 35

R&S®RT‑ZM

Maintenance and Service

Contacting Customer Support

4 Maintenance and Service

Like all Rohde & Schwarz products, Rohde & Schwarz probes and adapters are

of high quality and require only minimum service and repair. However, if service

or calibration is needed, contact your Rohde & Schwarz service center. Return a

defective product to the Rohde & Schwarz service center for diagnosis and

exchange.

4.1 Cleaning

To clean the exterior of the product, use a soft cloth moistened with either distilled

water or isopropyl alcohol. Before using the product again, make sure to dry it

completely. Never use cleaning agents such as solvents (thinners, acetone, etc.),

acids, bases or other substances.

4.2 Contacting Customer Support

Technical support – where and when you need it

For quick, expert help with any Rohde & Schwarz equipment, contact one of our

Customer Support Centers. A team of highly qualified engineers provides telephone support and will work with you to find a solution to your query on any

aspect of the operation, programming or applications of Rohde & Schwarz equipment.

Up-to-date information and upgrades

To keep your instrument up-to-date and to be informed about new application

notes related to your instrument, please send an e-mail to the Customer Support

Center stating your instrument and your wish. We will take care that you will get

the right information.

Europe, Africa, Middle East

Phone +49 89 4129 12345

customersupport@rohde-schwarz.com

35User Manual 1419.3128.02 ─ 04

Page 36

R&S®RT‑ZM

North America

Phone 1-888-TEST-RSA (1-888-837-8772)

customer.support@rsa.rohde-schwarz.com

Latin America

Phone +1-410-910-7988

customersupport.la@rohde-schwarz.com

Asia/Pacific

Phone +65 65 13 04 88

customersupport.asia@rohde-schwarz.com

China

Maintenance and Service

Returning for Servicing

Phone +86-800-810-8228 / +86-400-650-5896

customersupport.china@rohde-schwarz.com

4.3 Returning for Servicing

Use the original packaging to return your R&S RT-ZM to your Rohde & Schwarz

service center. A list of all service centers is available on:

www.services.rohde-schwarz.com

If you cannot use the original packaging, consider the following:

1. Use a sufficiently sized box.

2. Protect the product from damage and moisture (e.g. with bubble wrap).

3. Use some kind of protective material (e.g. crumpled newspaper) to stabilize

the product inside the box.

4. Seal the box with tape.

5. Address the package to your nearest Rohde & Schwarz service center.

36User Manual 1419.3128.02 ─ 04

Page 37

R&S®RT‑ZM

Maintenance and Service

Spare Parts

4.4 Calibration Interval

The recommended calibration interval for R&S RT-ZM modular probe is two

years. For servicing, send the probe to your nearest Rohde & Schwarz service

center (see Chapter 4.3, "Returning for Servicing", on page 36).

4.5 Spare Parts

The following accessories can be ordered at the Rohde & Schwarz service center. Use the order numbers provided in the following table.

Table 4-1: Accessories for R&S RT-ZM

Pos Item Description Material number

1 Adhesive pads 1800.4268.00

2 Cable marker 1800.4245.00

3 Lead wire black (ground) 1800.4222.00

4 Solder wire 0.2mm Ag

plated

1800.4074.00

5 Solder wire 0.1mm Ag

plated

1800.4051.00

37User Manual 1419.3128.02 ─ 04

Page 38

R&S®RT‑ZM

Maintenance and Service

Spare Parts

Pos Item Description Material number

6 Spool solder wire 1800.4097.00

7 Solder in resistor 270 Ω 3623.2791.00

8 Solder lead 3623.2791.00

9 SMP bullet 1419.3386.00

10 SMP bullet removal tool 1800.4451.00

11 Pogo pin Pogo pin connector, 6 pins 3584.6396.00

12 R&S RT-ZK3 R&S RT-ZK3 service kit 1419.3934.02

Table 4-2: Accessories for R&S RT-ZMA14

Pos Item Description Material number

1 10 Flex Tips 332 Ohm sol-

der-in

1337.9781.02

38User Manual 1419.3128.02 ─ 04

Page 39

R&S®RT‑ZM

Maintenance and Service

Spare Parts

Table 4-3: Accessories for R&S RT-ZMA30

Pos Item Description Material number

1 Browser pins 1800.4416.00

1800.4422.00

Table 4-4: Accessories for R&S RT-ZMA40

Pos Item Description Material number

1 Semi rigid cable 1419.4276.00

2 Lead wire red (termination

voltage)

Table 4-5: Parts for ESD prevention

Pos. Item Material number

1 ESD wrist strap 0008.9959.00

2 ESD grounding cable 1043.4962.00

1800.4239.00

39User Manual 1419.3128.02 ─ 04

Loading...

Loading...