Rohde&Schwarz R&S®ZVR-K9 User Manual

Test and

Measurement Division

Software Manual

Virtual Embedding Networks

ZVR-K9

1106.8830.02

Printed in the Federal

Republic of Germany

1106.8830.02 1 E-5

ZVR-K9 Contents

Contents

Basics.....................................................................................................................................................1

Measuring Tasks ........................................................................................................................1

Approach ....................................................................................................................................2

System Requirements......................................................................................................................3

Installation............................................................................................................................................ 4

Getting Started....................................................................................................................................5

Preparation................................................................................................................................. 5

Importing a File Generated by a CAD Program..........................................................................5

Storing the Calibration................................................................................................................ 5

Including a Network in a Calibration........................................................................................... 6

Result.......................................................................................................................................... 6

Menu Overview................................................................................................................................... 7

File ......................................................................................................................................... 7

Measure Network ..................................................................................................................... 14

Embedding................................................................................................................................ 19

De-Embedding..........................................................................................................................20

Cal Manager............................................................................................................................. 20

Info .......................................................................................................................................21

Application Examples....................................................................................................................22

Embedding: Testing SMD Components with a Virtual Matching Network................................ 22

De-Embedding: Measurement of “Embedded“ Components................................................... 23

Measuring a Microstrip Transition ............................................................................................ 24

Index......................................................................................................................................................I.1

1106.8830.02 3 E-5

Figures ZVR-K9

List of Figures

Fig. 1: Inner and outer ports of a transformation network........................................................................1

Fig. 2: Virtual impedance matching.......................................................................................................... 1

Fig. 3: Reducing the de-embedding problem to the embedding problem................................................2

Fig. 4: Scattering parameters of virtual network getstart..........................................................................6

Fig. 5: Numbering of the ports of the transformation network..................................................................8

Fig. 6: Virtual transformation network seen as the “difference“ between a test fixture with and a test

fixture without matching network................................................................................................. 22

Fig. 7: Calibration standards for measuring a transition

from printed circuit board to ceramic substrate...........................................................................24

Fig. 8: S-parameters of a transition from PCB to ceramic substrate .....................................................25

1106.8830.02 4 E-5

ZVR-K9 Basics

Basics

Measuring Tasks

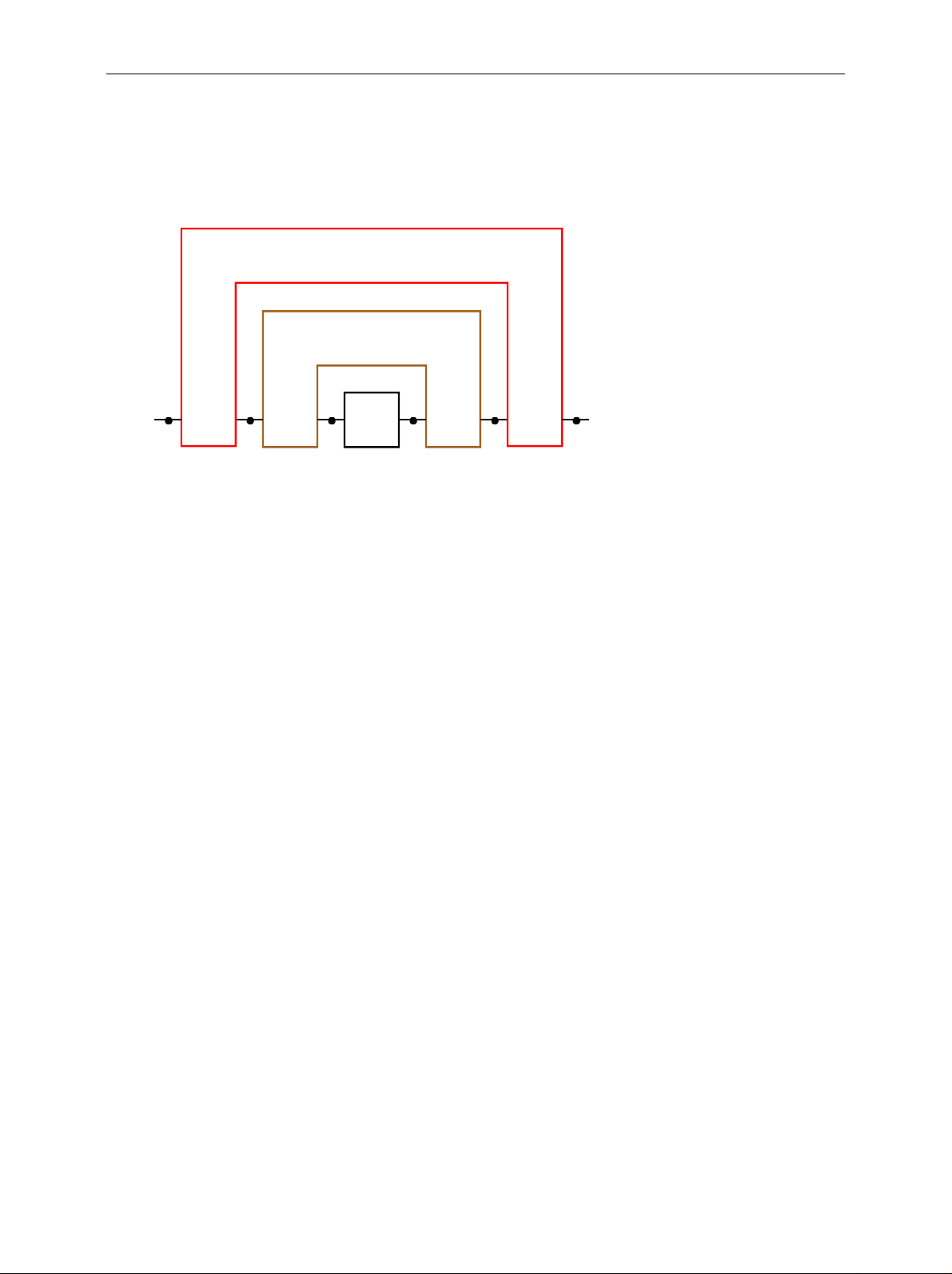

A frequently occurring category of measuring tasks in network analysis comprises the so-called

embedding and de-embedding problems. A device under test (DUT) is embedded if its ports are all

connected to a transformation network (TN) so that only the ports of the transformation network are

accessible from outside. This trans formation network may be e.g. a matching c ircuit, a test fixtur e or a

case. In general, it features twice as many ports as the DUT. The ports of the transfor mation network

which are connected to the device under test are referred to as “inner“ ports, those accessible from

outside as “outer“ ports. Fig. 1 shows an example of a two-port embedded in a trans formation network

with four ports.

TN

DUT

inner

outer

Ports of the TN

Fig. 1: Inner and outer ports of a transformation network

One possible measuring task cons ists of measuring the really existing DUT such as if it were embedded

in a transformation network , although the latter is physically not existing. In this cas e, virtual embedding

is involved. Fig. 2 shows the example of a measurement of a DUT with the input and output im pedance

, which is provided with virtual impedance transformers from Z1 to Z0 and is thus matched to the

Z

1

reference impedance Z

for the measurement.

0

NWA

(reference impedance Z

1

)

0

DUT

Z

0

Z

1

virtual impedance tran sformers Z0 : Z

Z

1

Z

0

1

Fig. 2: Virtual impedance matching

1106.8830.02 1 E-5

Basics ZVR-K9

In the opposite case, the device under test is inseparably connected with the transformation network, i.e.

the ports of the DUT are not accessible. If, nevertheles s, the S-parameters of the DUT alone are to be

determined, a “de-embedding“ problem is involved. This measuring problem can be reduced to the

embedding problem by embedding the real combination of DUT and transformation network into the

virtual inverse transformation network. The inverse and the real transformation network cancel each

other so that, viewed from outside, only the DUT is left (Fig. 3).

-1

TN (virtual)

TN (real)

DUT

Fig. 3: Reducing the de-embedding problem to the embedding problem

A third type of measuring task cons ists of the determination of the S-param eters of an unknown, but

physically existing transformation network. In the case of the two-port measurement, the difficulty is

based on the fact that the network is a four-port and, therefore, c annot directly be measured. Also the

inner and outer ports often differ in the type of transmission line (e.g. in the cas e of a test fixture f or

SMD components), which makes the calibration for a direct measurement more difficult. Measuring

tasks like that are often referred to as Unterminating problems.

Approach

The solution to embedding and de-embedding problems known so far consists of importing the Sparameters of the really existing DUT measured with a network analyzer into a CAD program and

embedding them there in a simulated circuit environment. In addition to the network analyzer, a

controller on which the CAD program runs is generally required. T he data transm is sion is in m os t c ases

effected via IEC bus. This proc edur e can har dly be performed in automatic mode, s ince eac h s imulation

requires manual user operations. Due to the data transmission and computing times, a real-time

indication, e.g. for adjustment of the DUT, is not possible.

In this case, the Software Option ZVR-K9 of the Network Analyzer ZVR offers clear advantages. The

idea is to consider the virtual transf ormation network in the system error correction data of the network

analyzer. Since a system error correction is performed anyway for almost all measuring tasks, no

additional stage of processing is required. Besides, there is no data transmission to an external

controller. Thus, the m easurement with a virtual transf ormation network is as fast as the measur ement

without one, real-time adjustment of the DUT is possible.

The S-parameters of the transformation network originate either from a CAD program or from a

measurement. The transformation network is not directly measured, but by forming the difference

between calibrations at the inner and outer ports. This avoids the through-c onnection between ports of

different types of transmission lines which would be required in the calibration for a direct measurement.

1106.8830.02 2 E-5

ZVR-K9 System Requirements

System Requirements

In order to use all features of the software option ZVR-K9, Virtual Embedding Networks, a Network

Analyzer ZVR, ZVC ZVM or ZVK is required. This manual only refers to the m odel ZVR, however, all

that is said also applies to ZVC, ZVM and ZVK. ZVR-K9 version 2.1 runs under Micr osof t Windows

or NT 4.0, for version 3.1 Windows NT 4.0 is required. On older instruments ZVR with stock no.

1043.0009.xx and ZVC with stock no. 1106.9020.xx, Windows 3.1 is part of the option ZVR-B15

(Controller). Connection of an external keyboard to the ZVR is necessary, a mouse considerably

facilitates operation as with all Windows applications. For W indows 3.1, the version num ber of the ZVR

firmware must be 1.70 or higher, for Windows NT it m ust be 3.04 or higher. T he vers ion num ber can be

polled via INFO: FIRMWARE VERSIONS.

If one ist only interested in the functions of the File m enu, that is import, export and administration of

transformation networks, one may, as well, install ZVR-K9 version 3.1 on a PC under Windows

95/98/NT4.0.

Important Note:

If ZVR-K9 runs under Windows 3.1, the files

D:\RUNTIME\RSIB\RSlB.DLL and

D:\RUNTIME\RSIB\RSDDE.DLL

3.1

must be copied to the directory

C:\WINDOWS\SYSTEM

before starting the application for the first time!

1106.8830.02 3 E-5

Installation ZVR-K9

Installation

The software option ZVR-K9 is s upplied on two installation disks. For an ins tallation on a ZVR, the k ey

code number, which can be found on the sheet “s oftware installation”, is additionally required. You may

also obtain this number from your R&S representative.

1. (only for installation on a ZVR) Enter the key sequence SETUP: OPTIONS: ENABLE NEW OPTION

on the ZVR. The input field for optional key codes will then be opened. Enter the key code number

for the option ZVR-K9. If the input is correct, the mess age “OPTION KEY OK“ will appear, otherwise

"OPTION KEY INVALID“.

2. (only for installation on a ZVR) Switch the ZVR from measurement screen to PC screen by

simultaneously pressing the keys Alt and Sys Rq on the external keyboard.

3. Insert installation disk no. 1 into the disk drive.

Windows 3.1 (only in the case of installation on a ZVR):

4. Start Windows by entering WIN.

5. Select the command Run from the File menu in the Windows program manager.

6. Enter the following text in the command line: a:\setup

Windows NT:

4. Select the command Run from the Windows Start menu.

5. Enter the following text in the Open field: a:\setup

7. Select OK.

8. Follow the instructions on the screen.

The Setup program autom atically creates all the nec essar y directories. You m ay determine the nam e of

the program group for ZVR-K9 and the de-installation program. After the installation has been

terminated, this program group is in the foreground.

1106.8830.02 4 E-5

ZVR-K9 Getting Started

Getting Started

For installation of the Software ZVR-K9, a virtual transformation network generated with the aid of a

CAD program is included. This network perm its to illus trate som e of the num erous possible applic ations

of this software option.

Preparation

Reset the ZVR to a predefined default status using PRESET and perform a full two-port user calibration

according to the TOM method over the com plete f requency range. After c alibration, establis h a throughconnection (THROUGH) between the test ports PORT 1 and PORT 2. Use the k ey combination Alt +

Sys Rq to switch over to PC operation and start W indows. Then start the application ZVR-K9 in the

program group with the same name.

First, only the main menu and the status line are visible at the lower edge of the screen. The lef t-hand

field of the status line displays the currently active input function or the current action of the program, the

right-hand field indicates the user prompts.

Importing a File Generated by a CAD Program

The demo network is provided in the data base format of Ansoft (e.g. Serenade) under the name

GETSTART in the directory c:\rsapplic\demo. To be able to use it, import and save it in the s pecif ic data

format of the Sof tware ZVR-K9. For this purpose, use the c om m and Import Network in the File menu. It

opens a window having the same name. Within the frame Select File on the left-hand side, select the file

GETSTART.FLP. Then click on the box TN1 THROUGH in the graph. The box will turn red and the

frame Select Action will appear below. In the fram e, select Insert Selected File. Now the for mat of the

import file will be checked. The following question may be answered by YES or NO, since the right

subnetwork TN2 of GETSTART.FLP is just an ideal through, too. Now the box TN1 displays the file

name instead of THROUGH. Clic k on Import Network( s). T hen follows the window Save Trans formation

Network for entering the name of the network and an optional com ment with up to 256 characters . The

Network List indicates all networks stored so f ar for inf o. By clicking on OK, the new network file will be

stored in the ZVR-K9 format, thus completing the file import.

Storing the Calibration

Next, the imported network is to be considered in the previously created user calibration, i.e. the latter is

modified. It is recom m ended to store the original c alibration status if you intend to reuse it later. For the

management of c alibration data, the c ommand Cal Manager is provided in the main menu, calling up an

interactive window. The keypad Append Active Cal to List permits to store the currently active user

calibration in the Cal List. You may define a name with a length of up to 8 characters for this calibr ation.

Vice versa, a calibration can be reactivated from the Cal List via Set Cal Active. In addition, the Cal

Manager permits you to determine in which calibration (Bas e Cal) a network is to be considered. The

current setting is indicated on the left side in the frame Bas e Cal for (De-) Embedding. You may define

either the current calibration or the one selected in the Cal List as Base Cal. Even if you have

transferred the previously created user calibration into the Cal List, it remains active and you may

maintain the default setting of the f rame Base Cal for De-( Embedding). The key Close permits to leave

the Cal Manager.

1106.8830.02 5 E-5

Getting Started ZVR-K9

Including a Networ k in a Calibration

Call up the command Embedding in the m ain menu. T he window displayed shows you the frame Base

Cal with the base calibration set in the Cal Manager, into which the network is embedded. The Network

List in the lower half of the screen lis ts all currently stored network s. Next to the nam e, you can see the

most important data at a glance, such as date, comment, point grid and frequency range. If the list

contains many entries, you will be able find the desired network f aster with these additional pieces of

information. If you have installed the Software ZVR-K9 and per formed all steps described so far, the

network list only contains the previously imported getstart. Select this network by click ing on the r elevant

line. The name will then appear in the fram e Embedding Network and the key Modify Base Cal can be

operated. Click on this key. After successful termination of embedding an appropriate message will

appear. Confirm this message and return to the main menu.

Result

You may have noticed in the last step that the status LED REM(OTE) was switched on as long as the

window Embedding was open. This LED indicates that the ZVR is under the control of the Software

ZVR-K9. In the main menu, however, this LED is always switched off. You may then switch over to

measurement s creen and operate the ZVR via the f ront panel. Switch to meas urem ent screen now and

activate the four-channel display (DISPLAY: QUAD CHAN QUAD SPLIT). You will then see all the four

S-parameters of your device under test - the through-connection - as if it were embedded into a virt ual

network. This virtual network consists of an ideal bandpass filter at PORT 1 and an ideal throughconnection at PORT 2. Thus, only the S-param eters of the bandpass filter with a pas sband of 1.2 to 1.5

GHz take effect (Fig. 4).

Fig. 4: Scattering parameters of virtual network getstart

When the base calibration is modified, frequency range and point grid of the virtual network are adopted.

This is why the frequency range has also changed compared with the previous status after PRESET.

Further important functions are the measurem ent of a transformation network and the data export in

CAD file format. T his will be explained in more detail in the sections "Menu Overview" or "Application

Examples".

1106.8830.02 6 E-5

Loading...

Loading...