Rohde&Schwarz R&S®SMW200A RF Ports Alignment user manual User Manual

R&S®RFPAL, R&S®SMW-K545

RF Ports Alignment

User Manual

(;ÝC<2)

1179191202

Version 01

This manual describes the following application and software option:

●

R&S®RFPAL, version 1.0

Order number: 1414.7019.02

●

R&S®SMW-K545

Order number: 1414.6429.02

Related firmware version of the R&S®SMW200A: FW 4.80.041.xx and later

© 2020 Rohde & Schwarz GmbH & Co. KG

Mühldorfstr. 15, 81671 München, Germany

Phone: +49 89 41 29 - 0

Email: info@rohde-schwarz.com

Internet: www.rohde-schwarz.com

Subject to change – data without tolerance limits is not binding.

R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

Trade names are trademarks of the owners.

1179.1912.02 | Version 01 | R&S®RFPAL, R&S®SMW-K545

Throughout this manual, products from Rohde & Schwarz are indicated without the ® symbol.

R&S®RFPAL, R&S®SMW-K545

Contents

1 Documentation Overview......................................................................5

2 About RF Ports Alignment.................................................................... 6

3 R&S RFPAL........................................................................................... 11

4 RF Ports Alignment at the SMWs....................................................... 40

Annex.................................................................................................... 72

A Files and Data.......................................................................................72

Contents

3User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

Contents

4User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

1 Documentation Overview

This manual contains two main parts:

●

All information about the R&S RFPAL application which determines correction data

for RF ports alignment, see Chapter 3, "R&S RFPAL", on page 11

●

RF Ports alignments on the R&S SMW signal generators in a multi-instrument

setup on basis of the results of RFPAL, see Chapter 4, "RF Ports Alignment at the

SMWs", on page 40

Chapter 2, "About RF Ports Alignment", on page 6 describes the principle and com-

mon aspects of RF ports alignment.

RF ports alignment at the signal generators is embedded in the SMW's multi-instrument capabilities. See the R&S SMW200A Vector Signal Generator user manual for

comprehensive information about multi-instrument usage, general GUI and SCPI handling.

Documentation Overview

5User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

2 About RF Ports Alignment

RF ports alignment refers to test setups where the DUT gets several RF signals which

have to be coherent. The RF signals come from several R&S SMW signal generators

(multi-instrument setup). Due to own signal processing in the signal generators, the

resulting RF signals at the out ports of the instruments can differ in phase, time delay

and power in dependency to the signal frequency and power. RF ports alignment corrects such signal deviations. Consequently, the DUT receives coherent RF signals.

RF ports alignment consists of two processes:

●

Measurement of the signal deviations (or misalignments) of the RF signals from the

signal generators and creation of correction data. This task is done by

R&S RFPAL. S-parameter files (s<n>p files) are included to compensate signal

deviations by RF components in the RF paths like cables. The measurements are

carried out with the test setup for testing the DUT but with additional measurement

equipment. One signal generator is the primary instrument and its first used RF

port is the reference port. R&S RFPAL measures the signal differences between

the reference port and the other ports to calculate the required correction data.

●

Application of the correction data at the signal generators. The primary instrument

distributes correction data to the other signal generators. During test execution, the

signal generators modify their RF signals according to the correction data and

transmit the corrected signals synchronously. This functionality is enabled by the

SMW-K545 option.

Correction data is applied in real time (not by predistorting given waveforms) and

can therefore be used in real time applications such as PDW streaming.

About RF Ports Alignment

Aligned RF Signals from Coupled Signal Generators

RFPAL delivers the correction data to the primary instrument. It does not take part in

the second process. See Chapter 3, "R&S RFPAL", on page 11 for the detailed

description of the application.

When correction data has been provided to the primary instrument and the SMWKF545 option is available, the configurations for RF ports alignment are automatically

carried out. You can inspect the configurations via the primary instrument's graphical

user interface or via SCPI commands. To apply RF ports alignment, you only have to

enable it at the primary instrument. See Chapter 4, "RF Ports Alignment at the SMWs",

on page 40 for the detailed description.

2.1 Aligned RF Signals from Coupled Signal Generators

The figure shows the testing situation when alignment of the RF signals is applied by

the signal generators using the alignment data from R&S RFPAL.

6User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

Figure 2-1: Aligned RF signals

About RF Ports Alignment

Aligned RF Signals from Coupled Signal Generators

Characteristics:

●

The RF signals originate from several signal generators and are denoted by the RF

ports. Each RF port is the source for one signal path to the DUT.

●

To create reproducible relations between the RF signals (that nevertheless experience misalignments), the signal generators are coupled. One signal generator is

the primary instrument. The other signal generators act as secondary instruments.

The signal generators share several signals; here the primary instrument provides

them to the secondary instruments:

– Reference signal (REF)

– Baseband synchronization and trigger signal

– Local oscillator (LO)

So all instruments are synchronized using the same reference signals, trigger sig-

nals and local oscillator.

Alternatively, the reference signal and the local oscillator can be provided by external sources.

●

The first RF port of the primary instrument serves as reference port. The alignment

of the RF signals from other ports is done relative to the RF signal from the reference port.

●

The primary signal generator gets the correction data (alignment data and s<n>p

data) from RFPAL. The other signal generators get their correction data from the

primary one. Alignment data compensates misalignments between the RF signals

at the different RF ports. s<n>p data compensates signal deviations in the RF

paths caused by RF components such as cables and splitters.

7User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

2.2 Misaligned RF Signals and Alignment in Signal Generators

Alignment only works fine if the relations between the RF signals from the different RF

ports are reproducible. Therefore, trigger, clock signal and local oscillator are coupled

for the signal generators. The trigger coupling avoids trigger jitter. Misalignments still

occur regarding LO phase, time delay and signal amplitude. The figure illustrates the

different contributions to misalignments of signals and the effect of alignment with

RFPAL.

About RF Ports Alignment

Misaligned RF Signals and Alignment in Signal Generators

Figure 2-2: Contributions to misalignments and alignment effects

The table describes causes of misalignments and how misalignments are compensated in the signal generators.

Table 2-1: Causes for misalignment and their compensation

Effect Caused by Compensated by

LO phase difference Length of the cables used for the distribution of the

LO signal

Phase errors in splitters or amplifiers

Level difference Attenuation in the RF path Adjusting the RF level

Time delay Length of the cables used for the distribution of the

trigger signal

Offsetting the signal in the baseband (digital domain)

Applying I/Q delay

The compensations require different settings if carried out manually. RFPAL supports

an integrated compensation process.

Alignment over frequency and power

The phase/power/delay differences between the RF signals of the different ports

depend on the frequency and the signal power. The following figure schematically

shows the phase over frequency for two RF ports before alignment (upper left part)

and after alignment (lower left part). "bw" is the modulation bandwidth (or signal bandwidth).

8User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

Figure 2-3: Phase responses and relative compensation

RF A is the reference port. The phase values vary over frequency for both RF ports but

with different courses. Using the alignment data derived from the measurements of the

network analyzer, RF ports alignment adjusts the phase course for port RF B to that of

port RF A. This alignment is relative (as are the measurements of the network analyzer): The RF signals for RF A and RF B are in phase but no compensation is done to

get a constant phase over frequency. Power levels and delays are aligned accordingly,

that is, alignment is done relative to the reference port.

About RF Ports Alignment

Misaligned RF Signals and Alignment in Signal Generators

Also, the signal power over frequency can be measured for the reference port by a

power sensor (absolute power measurement). In this case an additional power compensation step is carried out: The power variations measured at the reference port are

compensated for the reference port and all other RF ports to get a constant power level

over frequency for all RF ports.

Figure 2-4: Power compensation with data from the power sensor

9User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

2.3 Required Options

R&S RFPAL is not related to a software option. Instead, options are required for the

R&S SMWs to interplay with RFPAL and to use the alignment data according to the following list.

●

R&S SMW-K545 (for each signal generator): RF ports alignment

●

R&S SMW-K544 (per signal path): User-defined frequency response correction

●

R&S SMW-K61 (per signal path): Multi-carrier continuous wave

●

R&S SMW-B9 (per signal path): Wideband baseband generator

●

R&S SMW-B13XT: Wideband baseband main module two I/Q paths to RF

●

R&S SMW-B90: Phase coherence

●

R&S SMW-B1003 (for example): RF frequency from 100 kHz to 3 GHz

If only standard baseband signals are required, you can use R&S SMW-B10 and R&S

SMW-B13T instead of R&S SMW-B9 and R&S SMW-B13XT.

Note that R&S RFPAL includes a QuickStep standard option to perform the alignment

procedures. For modifying the alignment procedures (only for special use cases,

expert knowledge required), the QuickStep development option (R&S QS-DEV) is

required.

About RF Ports Alignment

Required Options

10User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

R&S RFPAL

3 R&S RFPAL

3.1 About R&S RFPAL

R&S RFPAL is applicable for test scenarios where one or a few R&S SMW signal generators provide several RF signals that have to be coherent. Due to signal processing

and timing in the signal generators, the resulting RF signals at the out RF ports of the

instruments can differ in phase, time delay and power depending on the RF signal frequency and power.

R&S RFPAL assists in providing coherent RF signals over all RF paths at the DUT: It

measures relative signal deviations between RF paths and provides correction data for

the R&S SMWs. The R&S SMWs apply the correction data to compensate the deviations. The RF signals of the different paths are aligned in this way. RFPAL is short for

RF ports alignment. For applying the correction data at the signal generators, they

have to be equipped with the SMW-K545 option.

Correction data is applied in real time (not by predistorting given waveforms) and can

therefore be used in real time applications such as PDW streaming.

About R&S

RFPAL

Figure 3-1: RF paths to be aligned

R&S RFPAL is an application that runs on a PC which is LAN-connected to the signal

generators. For alignment measurements, the test setup includes a network analyzer

and often a power sensor. R&S RFPAL controls the signal generators and the measurement instruments.

If there are other RF components in the RF paths from the RF ports to the measurement instruments than to the DUT, the measurement results of the measurement

instruments would not reflect the situation at the DUT. The different RF components

11User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

(for example splitters and cables) would cause different signal deviations. RFPAL supports compensation of such signal deviations by S-parameter files ( s<n>p files) which

have to be provided.

Without R&S RFPAL, alignment of the RF signals in a test setup with several signal

generators can be time-consuming and erroneous: First, the test and measurement

instruments have to be controlled manually in a coordinated way for the alignment

measurements. Second, the resulting corrections have to be provided manually in different parameters at the signal generators. It has to be taken care that all RF-related

parameters of the generator are maintained.

R&S RFPAL uses R&S QuickStep to control the signal generators and to perform the

alignment procedures.

Key facts

RFPAL interplays with one or several R&S SMWs, a network analyzer and optionally a

power meter.

RFPAL provides:

●

Representation of the test setup and configuration of the alignment measurements

●

Coordinated control of the R&S SMWs and measurement instruments during alignment measurements; control of an R&S OSP RF switching unit, if used, is included

●

Measurement of alignment data for correcting deviations in delay, phase, power

level (PEP)

●

Calibration support for an R&S network analyzer

●

Integration of S-parameter files (s<n>p files) for RF path components and of calibration files for R&S network analyzer and R&S OSP

●

Check of alignment results (by applying correction data)

●

Provision of correction data (alignment data and s<n>p files) to the primary

R&S SMW

R&S RFPAL

About R&S RFPAL

12User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

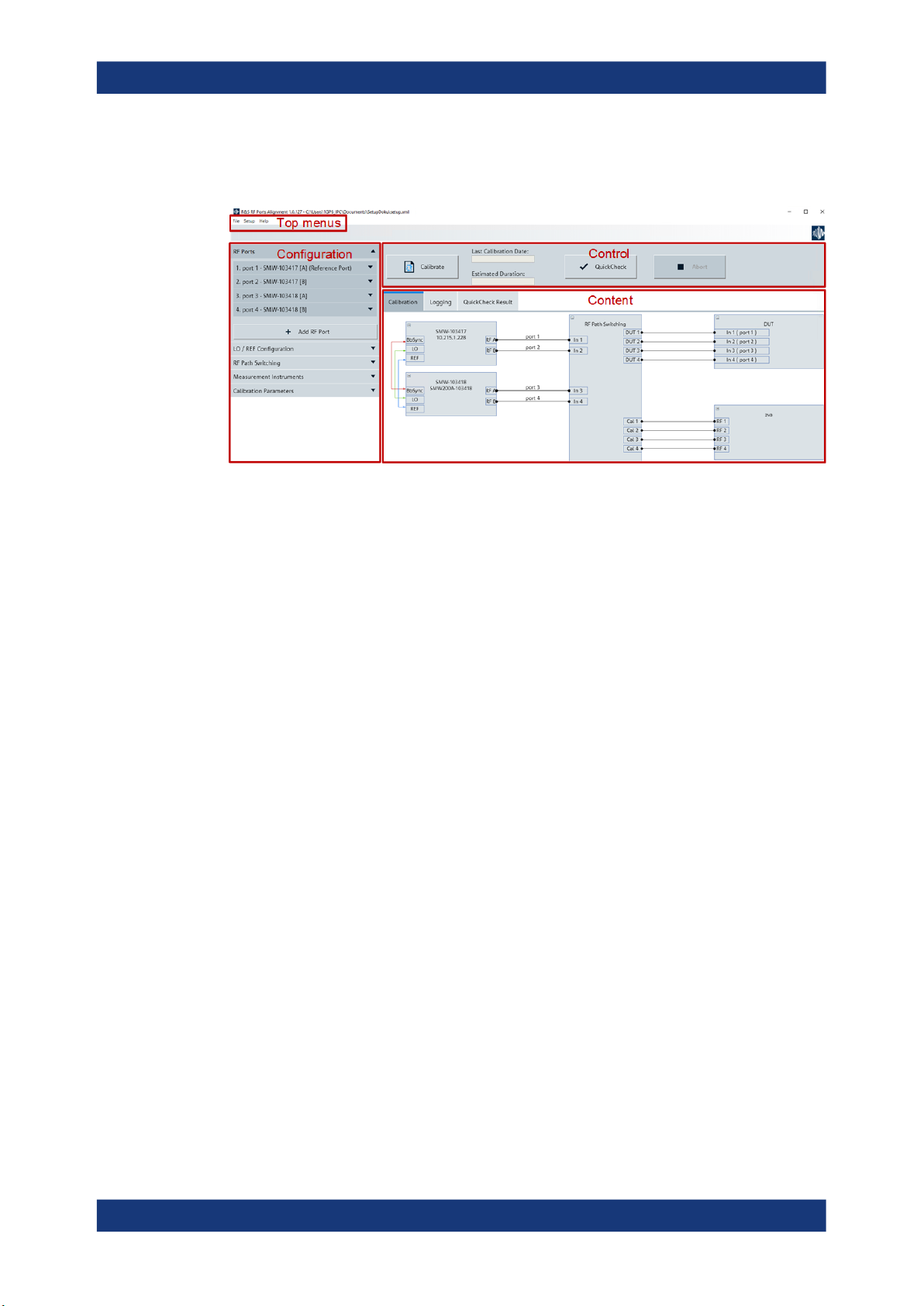

3.2 GUI Overview

Figure 3-2: GUI overview

R&S RFPAL

GUI Overview

The graphical user interface is structured in three major areas:

●

Configuration

●

Control

●

Content

In the configuration area, you configure the setup for alignment measurements. The

settings can be saved via the top menu "File > Save Setup" or previous settings can be

loaded via "File > Load Setup".

You start and control the alignment measurements via "Calibrate" in the control area.

The information in the content area is distributed in several tabs:

●

The "Calibration" tab shows a graphical representation of the setup as configured

in the configuration area and used for the alignment measurements.

●

The "Logging" tab contains processing and status information and event reports.

You see what is going on. If errors occur, the information in this tab helps you to

understand the problem and how to solve it.

●

The "QuickCheck Result" displays charts for magnitude/phase/delay errors detected with a "QuickCheck" action. The "QuickCheck" runs the signal generators with

correction data applied and measures the remaining misalignments.

13User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

3.3 Concepts

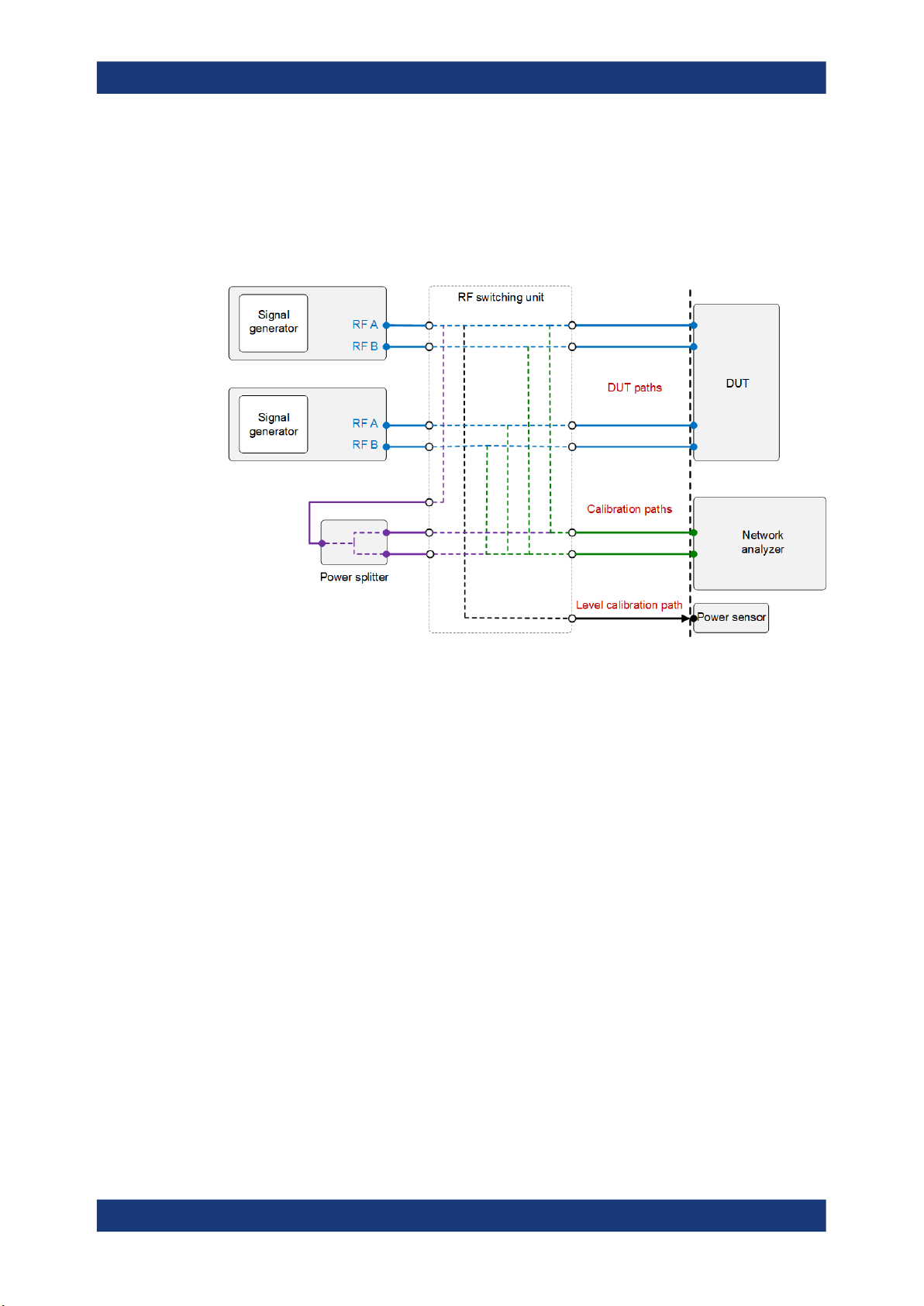

3.3.1 Test Setup for Alignment Measurements

R&S RFPAL

Concepts

Figure 3-3: Test setup including an RF switching unit and relevant paths

The figure shows a useful instrument setup for RFPAL alignment measurements.

Characteristics:

●

The measurements instruments, a network analyzer and a power sensor, are

embedded in the test setup that is used for executing tests after alignment. No test

setup changes are required after alignment.

●

Optionally, an RF switching unit connects the RF signal path sections at the signal

generator side and the signal path sections at the DUT side. RFPAL controls the

switching unit. It can select the paths to be used for measurements, so the paths

are switched automatically during RFPAL operations. A configuration file is

required at the switching unit that defines the required paths.

If no switching unit is used, the required connections between RF ports and network analyzer have to be established manually (assisted by dialogs) during the

measurement procedures.

●

The components in the RF signal paths to the DUT can differ from the components

to the measurement instruments. So, DUT paths are distinguished from the corresponding calibration paths to the network analyzer and from the level calibration

path (corresponding paths: same signal generator's RF port). See in Integration of

S-Parameter Files how the different path types are used.

Tip: Use cables of the same length and type for corresponding paths and all RF

ports. Consequently, the relative signal deviations are minimized.

●

The power sensor is used for measuring the RF signal power at the reference port.

14User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

●

For calibration of the network analyzer, a power splitter can be integrated in the

test setup. If an RF switching unit is used, the in port and the out ports of the power

splitter are connected to the switching unit, and the configuration file for the switching unit defines the RF paths through the power splitter. RFPAL commands the unit

to select the right RF paths to and from the power splitter for the calibration of the

network analyzer. So, no change of the test setup and no manual connection

establishment is required when proceeding from network analyzer calibration to

alignment measurements.

3.3.2 Integration of S-Parameter Files

The network analyzer carrying out the alignment measurements experiences the same

misalignments as the DUT if the DUT paths and the corresponding calibration paths

are equivalent. This is the case if the RF connections to both devices consist of the

same RF components (for example cables of the same type and lengths are used). So

the alignment measurements match the situation at the DUT, and applying RF port

alignment with the produced alignment data exactly aligns the RF signals at the DUT.

In other words, alignment is required at the DUT reference plane (see the figure), and

the measurement plane of the network analyzer matches the DUT reference plane.

R&S RFPAL

Concepts

Figure 3-4: Equivalent DUT and calibration paths

The DUT paths and calibration paths often contain different RF components, which

cause different signal deviations. These deviations have to be compensated for matching the situations at the measurement reference plane and the DUT reference plane.

See the figure for typical conditions.

15User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

R&S RFPAL

Concepts

Figure 3-5: Different DUT paths and calibration paths that require S-parameter compensation

RFPAL integrates compensation of signal deviations from RF components in the RF

paths by S-parameter files (s<n>p files). The different RF path types are handled as

follows:

●

Calibration path: Gets the S-parameter files for the components in the RF signal

path between RF port and network analyzer, particularly for the switching unit.

RFPAL uses these S-parameter files for compensating deviations in these paths

during the alignment measurements. So alignment data is produced as if the measurements were carried out in the RF ports reference plane. Applying the S-parameter files shifts the measurement reference plane to the RF ports reference plane.

●

DUT path: Gets the S-parameter files for cables, splitters and other components in

that path. RFPAL forwards these calibration files to the primary signal generator

after the alignment measurements. They are applied by the signal generators to

compensate the signal deviations in the DUT paths. In combination with alignment

data related to the RF ports reference plane, the DUT gets aligned RF signals.

Applying the S-parameter files can be seen as deembedding of the DUT: By

removing the signal deviations between the RF ports of the signal generators and

the DUT, the reference plane where the RF signals are aligned is shifted from the

RF ports reference plane to the DUT reference plane.

●

Level calibration path: Gets the S-parameter files for the components in the RF signal path between reference port and power sensor. RFPAL uses these S-parameter files in the same way as those for the calibration paths.

Measuring the frequency responses of the RF components in the different RF paths is

not part of RFPAL. Usually, the frequency responses of the RF components are known

and s<n>p calibration files for them are already available.

16User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

3.3.3 Alignment Measurements

The figure shows schematically how misalignments between two RF ports of one or

two signal generators are measured with a network analyzer.

R&S RFPAL

Concepts

Figure 3-6: Alignment measurement for RF A and RF B

With connections between the reference port and a second RF port to the network

analyzer established, RFPAL commands the signal generators to generate appropriate

RF signals. Instead of continuous-wave signals to be swept over the signal bandwidth,

multi-carrier continuous wave (MCCW) signals are used. The network analyzer measures the differences between the RF signals over the frequencies and over signal

power levels as configured in RFPAL.

Afterwards, if more than two RF ports have to be aligned, the second RF port is

changed and the same alignment measurement is carried out for the new pair of reference port and second RF port, and so on for all RF ports to be aligned. So, the reference port is always connected to the same input port of the network analyzer and the

second port changes for each measurement. The connection to the next RF port is

changed either automatically via RF switching box under control of RFPAL or manually.

Power measurement with the power sensor is performed only for the reference port

(relative power differences between the reference port and the other RF ports are

already covered by the network analyzer measurements).

3.3.4 Calibration of the Network Analyzer

RFPAL supports calibration of the network analyzer. Two ports of the network analyzer

are used to measure the signal differences of two RF ports of the signal generators.

Calibration of the network analyzer makes sure that any differences in the frequency

responses of the receivers behind the ports are compensated and do not influence the

alignment measurements. For determining the differences of frequency responses in

17User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

the network analyzer, the same RF signal is fed to the two ports. The network analyzer

measures and evaluates the differences between the responses.

If direct receiver access is enabled for the network analyzer, its "Ref" and "Meas" connectors can alternatively be used (there is a receiver behind "Ref" and one behind

"Meas"). Notice that when using direct receiver access, the standard calibration of the

network analyzer is no more valid.

Two methods for calibration of the network analyzer are supported:

●

Power splitter method: The primary signal generator generates appropriate RF signals and transmits them to a power splitter where they are split. The resulting two

identical RF signals are fed to the two network analyzer receivers to be calibrated.

RFPAL controls both the primary signal generator and the network analyzer and

applies the s<n>p calibration file of the power splitter. This method fits to the test

setup that is later used for testing. Only the power splitter is added to the test setup

and its connections have to be established.

R&S RFPAL

Concepts

Figure 3-7: Calibration of network analyzer with power splitter and signal generator

Use the power splitter method for the R&S ZVA. The following method is not valid

for this instrument.

●

TOSM method: This calibration type yields the most accurate calibration results

(reflection and transmission measurements; 12-term error correction model). It

relies on automatic calibration procedures of the network analyzer. Equivalent VNA

standard calibration is also possible.

TOSM (Through – Open – Short – Match) calibration can be done in two ways. For

both, the network analyzer generates RF signals, transmits them to and through

standard units, measures the responses and evaluates the differences between

generated RF signals and responses:

– Using a calibration kit for the network analyzer: The Short, Open and Match

standard from the kit are connected to one port, the Through standard is put

between this port and the second one. See the network analyzer's documentation. RFPAL is not involved. This calibration must be done at the network analyzer before RFPAL is used. RFPAL just gets the name of the resulting calibration file.

– Using a calibration unit: It replaces the standards from a calibration kit, and full

automation is possible. See again the network analyzer's documentation.

Though the calibration procedures are carried out completely at the network

analyzer, RFPAL assists for this type of calibration: If the calibration unit is inte-

18User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

grated in the test setup at RFPAL, RFPAL can control not only the network analyzer but also the calibration unit and the calibration. The results of the calibration are stored in a calibration file which the user has to specify in RFPAL. Later

on, RFPAL loads this file onto the network analyzer.

3.3.5 Delivery of Correction Data

Having completed the alignment measurements, RFPAL delivers the alignment data

and s<n>p files for the DUT paths for all RF ports to the primary signal generator (via

*.rfsa archive file). The combination of alignment and s<n>p data is called correction

data. Further distribution of the correction data and application of the correction data,

which aligns the RF signals, is done at the signal generators without participation of

RFPAL.

3.3.6 QuickStep Behind the Scene

R&S QuickStep is an application that configures test procedures, runs test plans –

sequences of individual tests together with scheduling and execution information – and

evaluates the results. During test execution, R&S QuickStep controls the test equipment via SCPI commands. R&S QuickStep also provides the calibration and alignment

procedures.

R&S RFPAL

Preparing for Use

The alignment procedures cover the typical use cases. To adapt the alignment procedures for special test scenarios, it is possible to modify the alignment procedures.

Therefore, the R&S QuickStep development option is required.

3.4 Preparing for Use

3.4.1 Preliminaries

3.4.1.1 Required Hardware

RFPAL is intended to be used on a PC. No special hardware and other software is

required. The tool runs on Windows 7 or 10.

3.4.1.2 Required Options

R&S RFPAL is not related to a software option. Instead, options are required for the

R&S SMWs to interplay with RFPAL and to use the alignment data, particularly R&S

SMW-K545 RF ports alignment.

Note that R&S RFPAL includes a QuickStep standard option to perform the alignment

procedures. For modifying the alignment procedures (only for special use cases,

19User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

expert knowledge required), the QuickStep development option (R&S QS-DEV) is

required.

3.4.2 Installing and Starting RFPAL

Installing RFPAL

The tool is provided as .exe installation file. You install the tool on the PC that controls

the alignment procedures.

1. Download the installation file from the following destination.

https://www.rohde-schwarz.com/software/rfpal

2. Double-click the file.

An installation dialog guides you through the installation process.

3. Accept the license conditions and click "Next".

RFPAL is installed on your PC. An "R&S RFPAL" icon is added on the desktop for

starting the tool.

R&S RFPAL

Operation

Starting the tool

► Double-click the "R&S RFPAL" icon on the desktop.

The application starts and its graphical user interface opens with a start page.

Either click "New setup" to create a setup file that has only some default settings

and that you fill with configuration data. Or click "Load setup" to load a setup file

from an earlier RFPAL session. Then, the actual RFPAL GUI is opened representing the settings stored in the setup file.

3.5 Operation

RFPAL is operated by a sequence of steps.

●

Configure the Setup

●

Configure RF Path Switching and the Measurement Instruments

●

Configure the Alignment Measurements

●

Execute the Measurements and Transfer Correction Data

Prerequisites

Before applying the following procedures:

●

Make sure that the cabling connections have been established. Particularly, RFPAL

needs LAN connections to the instruments to be controlled.

●

Switch on the instruments.

20User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

Set up all instruments at once in the connection configuration dialog when opening it

the first time during the RFPAL configuration (see Connection configuration dialog).

Then, you only have to select the right instruments in the later RFPAL configuration

steps.

3.5.1 Configure the Setup

The setup of the signal generators and the connections is configured by parameters in

the "RF Ports" and "LO/REF Configuration" sections of the configuration area on the

left side. After saving the configuration, the "Calibration" tab displays a schematic diagram of the instruments and paths as configured.

Use case

No setup is loaded. Instead, a new setup is built by configurations in the "Calibration"

area.

Prerequisites

R&S RFPAL

Operation

●

S-parameter files for the components in the RF paths (between RF ports and the

DUT and the measurement instruments) are available if needed (see Integration of

S-Parameter Files).

To configure the RF ports (including signal generators and RF paths)

1. Select "File > New Setup" from the top menu, enter a filename for the .xml file that

describes the setup and store the file.

2. Select "RF Ports" in the configuration area on the left.

3. For each RF port in your physical test setup, add an RF port section by clicking the

"+ Add RF Port" field, and configure each section as described in the following

steps.

4. Enter an RF port name from the loaded test setup for "RF Port Name".

Note: The first RF port is always the reference port. The signal generator with that

port is the primary instrument.

5. Open the "Config" dialog, add the signal generator for the RF port (for example

with "Search Instrument" if the instrument is already connected and running in the

LAN).

6. Click "Save & Select" while the row for the signal generator is highlighted. The dia-

log is closed and the device name of the signal generator from the "Config" dialog

is displayed in the "Device Name" field.

7. Select the used "RF Port".

8. For the components in the signal path from the signal generator's RF port to the

DUT, add the related S-parameter files in the "DUT Path" section. Therefore, start

with "Add Row".

21User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

9. For the components in the signal path from the signal generator's RF port to the

calibration instrument (for example a network analyzer), add the related S-parameter files in the "Calibration Path" section. Therefore, start with "Add Row".

10. For the reference port of the primary instrument, the "Level Calibration Path" sec-

tion is available. For the components in the signal path from the reference port to

the level calibration instrument (power sensor), add the related S-parameter files in

the "Calibration Path" section. Therefore, start with "Add Row".

To configure the local oscillator and the reference signal

In this example procedure, it is assumed that the primary signal generator provides the

local oscillator and the REF signal, all secondary signal generators get the LO and

REF signals from the primary instrument.

Default settings are provided for this use case. So, if you decide to operate with this

use case, you can omit the following procedure. Nevertheless, the procedure illustrates

exemplarily how to configure in this section.

1. Select "LO / REF Configuration" in the configuration area on the left.

R&S RFPAL

Operation

2. Configure the parameters according to your physical test setup.

● Enable "LO Coupling".

● Select "Star" for the "LO Configuration".

● Select "Intern" for the "LO Source".

● Select "Intern" for the "REF Source".

To save the configuration

► Select "File > Save Setup" from the top menu.

Vice versa, you get the saved configuration via "File > Load Setup".

3.5.2 Configure RF Path Switching and the Measurement Instruments

RF path switching means changing one connection between an RF port of a signal

generator and the network analyzer (the other connection to the reference RF port is

kept).

Measurement instruments are the network analyzer and the power sensor.

To configure the RF path switching

If an RF switching unit is integrated in the test setup, you can use automatic switching:

RFPAL commands the switching unit to establish the required connections.

Else, manual switching is required where you reconnect manually.

1. Select "RF Path Switching" in the configuration area on the left.

2. Select the "Switching Mode" according to your needs.

3. In case of "Automatic" "Switching Mode":

22User Manual 1179.1912.02 ─ 01

R&S®RFPAL, R&S®SMW-K545

● Configure and select the RF switching unit via the "Config" dialog.

● Enter the name of the configuration file that defines the mapping between the

ports of the RF switching unit and the RF path sections (this file must be available on the RF switching unit).

To configure the network analyzer

Calibration of the network via power splitter is included. See Calibration of the Network

Analyzer for details.

1. Expand "Measurement Instruments" in the configuration area on the left. Make

sure that the checkbox at the "Vector Network Analyzer" field is ticked and expand

the field.

2. Get the "Device Name" of the network analyzer via the Config dialog and "Save &

Select".

If the network analyzer is not yet available in the "Config" dialog, add the instrument in the dialog and select it.

3. "Number of Ports" shows how many ports of the network analyzer are used for the

alignment measurements. This parameter is read-only.

R&S RFPAL

Operation

4. Keep "Direct Receiver Access" disabled.

5. Select "Power Splitter" for the "Calibration Mode".

A table for S-parameter files is displayed.

6. Select the S-parameter file for compensating signal deviations by the power splitter

(only for calibration).

To configure the power meter

1. Still in the "Measurement Instruments" area, make sure that the checkbox at the

"Power Meter" field is ticked and expand the field.

2. Get the "Device Name" of the power meter via the "Config" dialog and "Save &

Select".

To save the configuration

► Select "File > Save Setup" from the top menu.

3.5.3 Configure the Alignment Measurements

The configurations for the alignment measurements are done in the "Calibration

Parameters" section in the configuration area on the left.

To configure the RF signals for alignment measurements

1. Select "Calibration Parameters" in the configuration area on the left.

2. Specify the carrier frequencies used for the calibration measurements.

23User Manual 1179.1912.02 ─ 01

Loading...

Loading...