Page 1

PAD-T-M: 3574.3259.02

/01.00

/CI/1/EN

R&S®OSP

Open Switch and Control Unit

Operating Manual

Operating Manual

Test and Measurement

1505.3896.12 – 15

Page 2

The Operating Manual describes the following R&S®OSP models and options:

● R&S®OSP120, stock no. 1505.3009.02/.12

● R&S®OSP130, stock no. 1505.3009.03

● R&S®OSP150, stock no. 1505.3009.05/.15

● Option Module R&S®OSP-B011, stock no. 1505.4763.02

● Option Module R&S®OSP-B012, stock no. 1505.4770.02

● Option Module R&S®OSP-B101, stock no. 1505.5101.02

● Option Module R&S®OSP-B101L, stock no. 1505.5101.52

● Option Module R&S®OSP-B102, stock no. 1505.5201.02

● Option Module R&S®OSP-B102L, stock no. 1505.5201.52

● Option Module R&S®OSP-B103, stock no. 1505.5301.02

● Option Module R&S®OSP-B104, stock no. 1505.5401.02

● Option Module R&S®OSP-B106, stock no. 1505.5601.02

● Option Module R&S®OSP-B107, stock no. 1505.5901.02

● Option Module R&S®OSP-B108, stock no. 1505.5718.02

● Option Module R&S®OSP-B111, stock no. 1505.4605.02

● Option Module R&S®OSP-B111UL, stock no. 1528.1531.13/.16

● Option Module R&S®OSP-B111VL, stock no. 1515.5991.13/.16

● Option Module R&S®OSP-B112, stock no. 1505.4611.02

● Option Module R&S®OSP-B114, stock no. 1505.4711.02

● Option Module R&S®OSP-B116, stock no. 1515.5827.02

● Option Module R&S®OSP-B119, stock no. 1515.5856.02

● Option Module R&S®OSP-B121, stock no. 1515.5504.02

● Option Module R&S®OSP-B121H, stock no. 1515.5504.40

● Option Module R&S®OSP-B122, stock no. 1515.5510.02

● Option Module R&S®OSP-B122H, stock no. 1528.1525.02

● Option Module R&S®OSP-B123, stock no. 1515.5527.02

● Option Module R&S®OSP-B124, stock no. 1515.5533.02

● Option Module R&S®OSP-B125, stock no. 1515.5540.02

● Option Module R&S®OSP-B126, stock no. 1515.5556.02

● Option Module R&S®OSP-B127, stock no. 1505.4728.02

● Option Module R&S®OSP-B128, stock no. 1505.4734.02

● Option Module R&S®OSP-B129, stock no. 1517.7004.02

● Option Module R&S®OSP-B131, stock no. 1505.4740.02

● Option Module R&S®OSP-B132, stock no. 1505.4757.02

● Option Module R&S®OSP-B133, stock no. 1528.3157.02

● Option Module R&S®OSP-B136, stock no. 1522.4500.02

● Option Module R&S®OSP-B142, stock no. 1528.1048.03/.11/.12/.13

● Option Module R&S®OSP-B158, stock no. 4094.7300.02

The software contained in this product uses several valuable open source software packages. For information, see the "Open

Source Acknowledgment" on the user documentation CD-ROM (included in delivery) or at https://www.rohde-

schwarz.com/en/firmware/osp.

Rohde & Schwarz would like to thank the open source community for their valuable contribution to embedded computing.

© 2017 Rohde & Schwarz GmbH & Co. KG

Muehldorfstr. 15, 81671 Munich, Germany

Phone: +49 89 41 29 - 0

Fax: +49 89 41 29 12 164

E-mail: info@rohde-schwarz.com

Internet: http://www.rohde-schwarz.com/

Subject to change – Data without tolerance limits is not binding.

R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

Trade names are trademarks of the owners.

The following abbreviations are used throughout this manual:

R&S®OSP is abbreviated as R&S OSP

Page 3

R&S OSP Contents

Operating Manual 1505.3896.12 - 15 3

Contents

1 Documentation Overview ................................................................. 13

2 Preparing for Use .............................................................................. 15

2.1 Front Panel Tour R&S OSP120 .................................................................................15

2.1.1 Status LEDs and Standby Key ....................................................................................16

2.1.2 Front Panel Connectors ...............................................................................................16

2.2 Front Panel Tour R&S OSP130 .................................................................................17

2.2.1 Navigation Keys ...........................................................................................................18

2.2.2 Status Keys ..................................................................................................................18

2.2.3 Status Indicators ..........................................................................................................18

2.2.4 Front Panel USB Connectors ......................................................................................19

2.3 Front Panel Tour R&S OSP150 .................................................................................19

2.4 Rear Panel Tour .........................................................................................................19

2.4.1 LAN Connector ............................................................................................................20

2.4.2 CAN Bus Connector.....................................................................................................21

2.4.3 Mains Switch and Connector .......................................................................................21

2.5 Putting the Instrument into Operation .....................................................................22

2.5.1 Unpacking the Instrument and Checking the Shipment ..............................................22

2.5.2 Instrument Setup..........................................................................................................23

2.5.3 Bench Top Operation ...................................................................................................23

2.5.4 Mounting in a 19" Rack ................................................................................................23

2.5.5 EMI Protective Measures .............................................................................................23

2.5.6 Connecting the Instrument to the AC Supply ..............................................................24

2.5.7 Power on and off ..........................................................................................................24

2.5.8 Replacing Fuses ..........................................................................................................24

2.5.9 Standby and Ready State ............................................................................................25

2.6 Maintenance ...............................................................................................................25

2.6.1 Storing and Packing .....................................................................................................26

2.7 Connecting External Accessories ............................................................................26

2.7.1 Connecting a USB Flash Drive ....................................................................................26

2.7.2 Connecting a Keyboard ...............................................................................................26

2.7.3 Connecting a Monitor ...................................................................................................27

2.7.4 Connecting a LAN Cable .............................................................................................27

2.8 Starting the R&S OSP and Shutting Down ..............................................................28

2.9 Remote Operation in a LAN ......................................................................................28

Page 4

R&S OSP Contents

Operating Manual 1505.3896.12 - 15 4

2.9.1 Assigning an IP Address ..............................................................................................28

2.9.2 R&S OSP Panel ...........................................................................................................31

2.10 Linux Operating System ...........................................................................................31

2.10.1 Keyboard Properties ....................................................................................................32

2.11 Firmware Update ........................................................................................................32

2.12 Read the actual the Firmware Version ....................................................................34

2.12.1 Get Firmware Version using R&S OSP Panel .............................................................34

2.12.2 Get Firmware Version via SCPI Command .................................................................35

3 Getting Started .................................................................................. 36

3.1 Connecting R&S OSP and PC ..................................................................................37

3.2 Installing the R&S OSP Panel ...................................................................................38

3.3 R&S OSP Panel Functions ........................................................................................38

3.3.1 Configuring/Connecting R&S OSP Panel ....................................................................39

3.3.2 Addressing R&S OSP Device ......................................................................................41

3.3.3 Changing the IP address with R&S OSP Panel ..........................................................43

3.3.4 General Actions of R&S OSP Panel ............................................................................44

3.3.5 Addressing R&S OSP Modules ...................................................................................45

3.3.6 Controlling the R&S OSP-B101/-B106/-B107/-B111/-B127/-B132 ..............................46

3.3.7 Controlling the R&S OSP-B102/-B112/-B128 ..............................................................47

3.3.8 Controlling the R&S OSP-B103/-B158 ........................................................................49

3.3.9 Controlling the R&S OSP-B104/-B114 ........................................................................51

3.3.10 Controlling the R&S OSP-B108 ...................................................................................55

3.3.11 Controlling the R&S OSP-B131 ...................................................................................56

3.3.12 Controlling the R&S OSP-B116/-B136 ........................................................................56

3.3.13 Controlling the R&S OSP-B142 ...................................................................................57

3.4 Path Configuration.....................................................................................................58

3.4.1 Save a Path .................................................................................................................59

3.4.2 Switch a Path ...............................................................................................................61

3.4.3 Delete a Path ...............................................................................................................61

3.4.4 Export a Path ...............................................................................................................62

3.4.5 Import a Path ...............................................................................................................64

3.5 Sample Session .........................................................................................................65

3.5.1 Example Path Configuration ........................................................................................65

3.5.2 Manual Setting of the Paths .........................................................................................69

3.5.3 Remote Control Setting of the Path Configuration ......................................................70

3.6 Path Configuration in virtual mode ..........................................................................71

3.6.1 Simulated Module Configuration ..................................................................................71

Page 5

R&S OSP Contents

Operating Manual 1505.3896.12 - 15 5

3.6.2 Path Configuration .......................................................................................................72

3.6.3 Import of Path Configuration ........................................................................................73

3.7 GUI Info Line ...............................................................................................................73

3.7.1 Configuring the GUI Info Line ......................................................................................74

4 Manual Operation ............................................................................. 76

4.1 Manual Operation of the Modules ............................................................................76

4.2 R&S OSP Setups ........................................................................................................76

5 Instrument Functions ....................................................................... 77

5.1 R&S OSP Instrument Frame .....................................................................................77

5.1.1 R&S OSP Block Diagram ............................................................................................78

5.1.2 R&S OSP Module Slots ...............................................................................................80

5.1.3 R&S OSP120 Version12 and Module Slots .................................................................80

5.1.4 R&S OSP120 Version12 and Modules R&S OSP-B011/-B012 ..................................81

5.1.5 R&S OSP150 Version15 and Module Slots .................................................................83

5.1.6 R&S OSP150 Version15 and Modules R&S OSP-B011/-B012 ..................................85

5.2 Module Functions ......................................................................................................85

5.2.1 RF Switch Module R&S OSP-B101/-B107/-B111/-B127 .............................................85

5.2.2 RF Switch Module R&S OSP-B102/-B112/-B128 ........................................................86

5.2.3 I/O Module R&S OSP-B103 .........................................................................................88

5.2.4 I/O Module R&S OSP-B104 .........................................................................................90

5.2.5 RF Switch Module R&S OSP-B106/-B132 ..................................................................92

5.2.6 DC MUX Module R&S OSP-B108 ...............................................................................93

5.2.7 RF Switch Module R&S OSP-B121 and R&S OSP-B121H ........................................94

5.2.8 RF Switch Modules R&S OSP-B122, OSP-B122H and OSP-B133 ............................95

5.2.9 RF Switch Module R&S OSP-B123 and R&S OSP-B124 ...........................................96

5.2.10 RF Switch Module R&S OSP-B125 and R&S OSP-B126 ...........................................99

5.2.11 Module R&S OSP-B114 for EMS application ............................................................101

5.2.12 RF Switch Module R&S OSP-B131 ...........................................................................103

5.2.13 RF Switch Module R&S OSP-B129 and R&S OSP-B119 .........................................104

5.2.14 Power Sensor Module R&S OSP-PM-I......................................................................105

5.2.15 RF Switch Module R&S OSP-B116 and R&S OSP-B136 .........................................106

5.2.16 RF Switch Module R&S OSP-B101L/-B111xL and R&S OSP-B102L .......................107

5.2.17 I/O and supply Module R&S OSP-B158 ....................................................................109

5.2.18 RF Switch Module R&S OSP-B142 ...........................................................................110

5.3 Graphical User Interface .........................................................................................112

5.3.1 Starting the R&S OSP120 .........................................................................................112

Page 6

R&S OSP Contents

Operating Manual 1505.3896.12 - 15 6

5.3.2 Starting the R&S OSP130 .........................................................................................114

5.3.3 General Navigation Operations .................................................................................115

5.3.4 Using the R&S OSP-B101/-B106/-B107/-B111 .........................................................118

5.3.5 Using the R&S OSP-B102/-B112 ..............................................................................120

5.3.6 Using the R&S OSP-B103 .........................................................................................121

5.3.7 Using the R&S OSP-B104 .........................................................................................122

5.3.8 Using the R&S OSP-B121 .........................................................................................124

5.3.9 Using the R&S OSP-B122, OSP-B122H and OSP-B133 ..........................................124

5.3.10 Using the R&S OSP-B123 to R&S OSP-B126 and R&S OSP-B129 ........................125

5.3.11 Path Configuration .....................................................................................................126

5.4 R&S OSP Switch Cycle Counter .............................................................................130

5.5 R&S OSP Selftest .....................................................................................................132

5.5.1 Selftest via R&S OSP Panel ......................................................................................132

5.6 R&S OSP Configuration Check ..............................................................................132

5.6.1 System Info via R&S OSP Panel ...............................................................................132

5.7 SCPI Read/Write .......................................................................................................133

5.7.1 R&S OSP Temperature Read Command ..................................................................134

6 Remote Control ............................................................................... 136

6.1 Remote Control Operation ......................................................................................136

6.1.1 Establishing and Testing a LAN Connection .............................................................137

6.1.2 Switchover to Remote Control ...................................................................................138

6.1.3 Return to Manual Operation ......................................................................................138

6.2 Messages ..................................................................................................................138

6.2.1 VXI-11 Interface Messages .......................................................................................138

6.2.2 Device Messages (Commands and Device Responses) ..........................................139

6.2.3 SCPI Command Structure and Syntax ......................................................................139

6.3 The R&S OSP Command Processing ....................................................................143

6.3.1 Input Unit ....................................................................................................................143

6.3.2 Command Recognition ..............................................................................................144

6.3.3 Data Base and Instrument Hardware ........................................................................144

6.3.4 Status Reporting System ...........................................................................................144

6.3.5 Output Unit .................................................................................................................145

6.4 Status Reporting System ........................................................................................145

6.4.1 Overview of Status Registers ....................................................................................146

6.4.2 Contents of the Status Registers ...............................................................................146

6.4.3 Application of the Status Reporting System ..............................................................148

6.4.4 Reset Values of the Status Reporting System ..........................................................150

Page 7

R&S OSP Contents

Operating Manual 1505.3896.12 - 15 7

7 Remote Command Reference ........................................................ 151

7.1 Special Terms and Notation ...................................................................................151

7.2 Naming Conventions ...............................................................................................152

7.3 Common Commands ...............................................................................................154

7.4 Instrument-Control Commands ..............................................................................156

7.4.1 ROUTe Commands ...................................................................................................156

7.4.2 READ Commands......................................................................................................161

7.4.3 CONFIGURE Commands ..........................................................................................165

7.4.4 MMEMory Commands ...............................................................................................166

7.4.5 DIAGnostic Commands .............................................................................................168

7.4.6 SYSTem Commands .................................................................................................169

7.5 Alphabetical List of Commands (System) .............................................................175

8 Applications .................................................................................... 176

8.1 R&S OSP and R&S EMC32 Software .....................................................................176

8.1.1 Configuration of the R&S EMC32 for R&S OSP ........................................................176

8.1.2 Defining the R&S OSP Properties in the R&S EMC32 ..............................................178

8.1.3 Setting the R&S OSP with the R&S EMC32 ..............................................................179

8.1.4 Interlock Functionality with R&S EMC32 ...................................................................179

8.2 R&S OSP Drivers .....................................................................................................182

8.3 Extending the R&S OSP System ............................................................................183

8.3.1 R&S OSP150 Extension Unit .....................................................................................183

8.3.2 Connecting the R&S OSP150 ....................................................................................184

8.3.3 How to Register the R&S OSP150 ............................................................................185

8.4 Application of Module R&S OSP-B103 ..................................................................186

8.4.1 Controlling External Relays with R&S OSP-B103 .....................................................186

8.4.2 Input Ports of R&S OSP-B103 ...................................................................................189

8.4.3 Output Ports of R&S OSP-B103 ................................................................................190

8.5 Application of Module R&S OSP-B104 ..................................................................190

8.5.1 Controlling External Power Relays with R&S OSP-B104 ..........................................190

8.5.2 Interlock Monitoring with the R&S OSP-B104 ...........................................................191

8.5.3 Input Ports of R&S OSP-B104 ...................................................................................192

8.5.4 Output Ports of R&S OSP-B104 ................................................................................193

8.6 Application of Module R&S OSP-B114 ..................................................................193

8.6.1 Switching a Signal Generator via the R&S OSP-B114 module .................................194

8.6.2 Interlock Circuitry with the R&S OSP-B114 Module ..................................................195

8.6.3 I/O Ports on the R&S OSP-B114 Module ..................................................................196

8.7 Application of Module R&S OSP-B158 ..................................................................197

Page 8

R&S OSP Contents

Operating Manual 1505.3896.12 - 15 8

8.7.1 Controlling active antennas with R&S OSP-B158 .....................................................197

9 Appendix ......................................................................................... 199

9.1 Interfaces and Connectors .....................................................................................199

9.1.1 Front Panel Connectors .............................................................................................199

9.1.2 Rear Panel Connectors .............................................................................................199

9.1.3 LAN Interface .............................................................................................................201

9.2 R&S OSP Module Interfaces ...................................................................................203

9.2.1 R&S OSP-B101/-B107/-B111/-B127 Interface ..........................................................203

9.2.2 R&S OSP-B102/-B112 Interface ................................................................................204

9.2.3 R&S OSP-B103 Interface ..........................................................................................204

9.2.4 R&S OSP-B104 Interface ..........................................................................................205

9.2.5 R&S OSP-B108 Interface ..........................................................................................207

9.2.6 R&S OSP-B106 Interface ..........................................................................................208

9.2.7 R&S OSP-B121 Interface ..........................................................................................208

9.2.8 R&S OSP-B122 Interface ..........................................................................................209

9.2.9 R&S OSP-B123 Interface ..........................................................................................209

9.2.10 R&S OSP-B124 Interface ..........................................................................................210

9.2.11 R&S OSP-B125 Interface ..........................................................................................211

9.2.12 R&S OSP-B126 Interface ..........................................................................................211

9.2.13 R&S OSP-B114 Interface ..........................................................................................211

9.2.14 R&S OSP-B128 Interface ..........................................................................................213

9.2.15 R&S OSP-B131 Interface ..........................................................................................214

9.2.16 R&S OSP-B132 Interface ..........................................................................................214

9.2.17 R&S OSP-B101L/-B111xL Interface ..........................................................................215

9.2.18 R&S OSP-B129/-B119 Interface ................................................................................216

9.2.19 R&S OSP-B142 Interface ..........................................................................................216

9.2.20 R&S OSP-PM-I Interface ...........................................................................................217

9.2.21 R&S OSP-B116/-B136 Interface ................................................................................218

9.2.22 R&S OSP-B158 Interface ..........................................................................................219

9.2.23 R&S OSP-B133 Interface ..........................................................................................220

9.2.24 R&S OSP-B122H Interface ........................................................................................220

10 Index ................................................................................................ 223

Page 9

R&S OSP Contents

Operating Manual 1505.3896.12 - 15 9

Figures

Figure 3-1: Manual operation of R&S OSP120 using GUI ........................................... 36

Figure 3-2: Manual operation of R&S OSP130 using the GUI ..................................... 36

Figure 3-3: Operation of R&S OSP120/130 by OSP Panel software or Web-GUI ....... 37

Figure 3-4: AU600 panel design ................................................................................... 51

Figure 5-1: Block Diagram R&S OSP120 ..................................................................... 78

Figure 5-2: Block Diagram R&S OSP130 ..................................................................... 79

Figure 5-3: Block Diagram R&S OSP150 ..................................................................... 79

Figure 5-4: R&S OSP Module Slots.............................................................................. 80

Figure 5-5: R&S OSP120 Version12 Module Slots at front side ................................. 80

Figure 5-6: Block Diagram R&S OSP120 Var. 12 ........................................................ 81

Figure 5-7: Block Diagram R&S OSP120 Var. 12 ........................................................ 82

Figure 5-8: R&S OSP-B011 module panel ................................................................... 82

Figure 5-9: R&S OSP-B011 module panel ................................................................... 83

Figure 5-10: R&S OSP150 Version15 Module Slots at front side ............................... 84

Figure 5-11: Block Diagram R&S OSP150 Var. 15 ...................................................... 84

Figure 5-12: Module R&S OSP-B101 ........................................................................... 85

Figure 5-13: Block Diagram Module R&S OSP-B101 .................................................. 86

Figure 5-14: Module R&S OSP-B102 ........................................................................... 87

Figure 5-15: Block Diagram Module R&S OSP-B102 .................................................. 87

Figure 5-16: Module R&S OSP-B128 ........................................................................... 88

Figure 5-17: Module R&S OSP-B103 ........................................................................... 89

Figure 5-18: Block Diagram Module R&S OSP-B103 .................................................. 89

Figure 5-19: Module R&S OSP-B104 ........................................................................... 90

Figure 5-20: Block Diagram Module R&S OSP-B104 .................................................. 91

Figure 5-21: Module R&S OSP-B106 ........................................................................... 92

Figure 5-22: Block Diagram Module R&S OSP-B106 .................................................. 93

Figure 5-23: Module R&S OSP-B108 ........................................................................... 93

Figure 5-24: Module R&S OSP-B121 ........................................................................... 94

Figure 5-25: Block diagram Module R&S OSP-B121 ................................................... 94

Figure 5-26: Module R&S OSP-B122 ........................................................................... 95

Figure 5-27: Block diagram Module R&S OSP-B122 ................................................... 96

Figure 5-28: Module R&S OSP-B123 ........................................................................... 97

Figure 5-29: Module R&S OSP-B124 ........................................................................... 97

Figure 5-30: Block diagram Module R&S OSP-B123 ................................................... 98

Figure 5-31: Block diagram Module R&S OSP-B124 ................................................... 99

Figure 5-32: Module R&S OSP-B125 ........................................................................... 99

Figure 5-33: Module R&S OSP-B126 ......................................................................... 100

Figure 5-34: Block diagram Module R&S OSP-B125 ................................................. 100

Figure 5-35: Block diagram Module R&S OSP-B126 ................................................. 101

Figure 5-36: Module R&S OSP-B114 ......................................................................... 102

Figure 5-37: Block diagram Module R&S OSP-B114 ................................................. 102

Figure 5-38: Module R&S OSP-B131 ......................................................................... 103

Figure 5-39: Block diagram Module R&S OSP-B131 ................................................. 103

Figure 5-40: Module R&S OSP-B119 and R&S OSP-B129 ....................................... 104

Figure 5-41: Block diagram Module R&S OSP-B129 ................................................. 105

Figure 5-42: Module R&S OSP-PM-I .......................................................................... 106

Figure 5-43: Block diagram Module R&S OSP-PM-I .................................................. 106

Page 10

R&S OSP Contents

Operating Manual 1505.3896.12 - 15 10

Figure 5-44: Block diagram Module R&S OSP-B116 ................................................. 107

Figure 5-45: Module R&S OSP-B116 and R&S OSP-B136 ....................................... 107

Figure 5-46: Module R&S OSP-B101L and R&S OSP-B102L ................................... 108

Figure 5-47: Module R&S OSP-B158 ......................................................................... 109

Figure 5-48: Block Diagram Module R&S OSP-B158 ................................................ 110

Figure 5-49: Module R&S OSP-B142 (variant .03 with 3 DP3T switches) ................. 111

Figure 8-1: Example of LabWindows/CVI Driver ........................................................ 182

Figure 8-2: Example of IVI Driver ............................................................................... 182

Figure 8-3: Connecting Diagram for BN 64 00 75 to R&S OSP-B104 ....................... 191

Figure 8-4: Connecting Diagram for BN 51 26 70 to R&S OSP-B104 ....................... 191

Figure 8-5: Interlock Monitoring with Module R&S OSP-B104 ................................... 192

Figure 8-6: Example for an EMS Tests system setup with Module R&S OSP-B114 194

Figure 8-7: Switching of Signal Generator with Module R&S OSP-B114................... 195

Figure 8-8 Interlock wiring with Module R&S OSP-B114 .......................................... 196

Figure 8-9: Block Diagram R&S OSP-B158 Application ............................................. 197

Figure 9-1: Pin Assignment CAN Bus Connector ....................................................... 200

Figure 9-2: Example for OSI Reference Model .......................................................... 201

Figure 9-3: VXI–11 Channels between Instrument and Controller ............................. 202

Figure 9-4: Remote control via LAN from Several Controllers ................................... 202

Figure 9-5: Layout RF Connectors of R&S OSP-B101............................................... 203

Figure 9-6: Layout RF Connectors of R&S OSP-B102............................................... 204

Figure 9-7: Pin Assignment R&S OSP-B103 Input ..................................................... 205

Figure 9-8: Pin Assignment R&S OSP-B103 Output .................................................. 205

Figure 9-9: Pin Assignment R&S OSP-B104 Relay Control ....................................... 206

Figure 9-10: Pin Assignment R&S OSP-B104 Input/Output ....................................... 206

Figure 9-11: Pin Assignment R&S OSP-B108 INPUT ................................................ 207

Figure 9-12: Pin Assignment R&S OSP-B108 Output ................................................ 207

Figure 9-13: Layout RF Connectors of R&S OSP-B106............................................. 208

Figure 9-14: Layout RF Connectors of R&S OSP-B121............................................. 209

Figure 9-15: Layout RF Connectors of R&S OSP-B122............................................. 209

Figure 9-16: Layout RF Connectors of R&S OSP-B123............................................. 210

Figure 9-17 Layout RF Connectors of R&S OSP-B124.............................................. 210

Figure 9-18: Layout RF Connectors of R&S OSP-B125............................................. 211

Figure 9-19: Layout RF Connectors of R&S OSP-B126............................................. 211

Figure 9-20: Layout the Connectors of R&S OSP-B114 ............................................ 212

Figure 9-21: R&S OSP-B114 Connector IN Pin designation ...................................... 212

Figure 9-22: R&S OSP-B114 Connector OUT Pin designation .................................. 213

Figure 9-23: Layout RF Connectors of R&S OSP-B128............................................. 213

Figure 9-24: Layout RF Connectors of R&S OSP-B131............................................. 214

Figure 9-25 Layout RF Connectors of R&S OSP-B132.............................................. 214

Figure 9-26: Layout RF Connectors of R&S OSP-B101L .......................................... 215

Figure 9-27: Layout RF Connectors of R&S OSP-B129/-B119 .................................. 216

Figure 9-28: Layout RF Connectors of R&S OSP-B142............................................. 217

Figure 9-29: Layout Connectors of R&S OSP-PM-I .................................................. 218

Figure 9-30: Layout Connectors of R&S OSP-B116 and R&S OSP-B136................ 219

Figure 9-31: Pin Assignment R&S OSP-B158 SUPPLY ............................................ 219

Figure 9-32: Pin Assignment R&S OSP-B158 OUT ................................................... 219

Figure 9-33: Pin Assignment R&S OSP-B158 IN ....................................................... 220

Figure 9-34: Layout RF Connectors of R&S OSP-B133............................................. 220

Page 11

R&S OSP Contents

Operating Manual 1505.3896.12 - 15 11

Figure 9-35: Layout RF Connectors of R&S OSP-B122H .......................................... 221

Page 12

Page 13

R&S OSP Documentation Overview

Operating Manual 1505.3896.12 - 15 13

1 Documentation Overview

The user documentation for the R&S OSP describes the following models and options:

R&S OSP120, stock no. 1505.3009.02/.12

R&S OSP130, stock no. 1505.3009.03

R&S OSP150, stock no. 1505.3009.05/.15

Option Module R&S OSP-B011, stock no. 1505.4763.02

Option Module R&S OSP-B012, stock no. 1505.4770.02

Option Module R&S OSP-B101, stock no. 1505.5101.02

Option Module R&S OSP-B101L, stock no. 1505.5101.52

Option Module R&S OSP-B102, stock no. 1505.5201.02

Option Module R&S OSP-B102L, stock no. 1505.5201.52

Option Module R&S OSP-B103, stock no. 1505.5301.02

Option Module R&S OSP-B104, stock no. 1505.5401.02

Option Module R&S OSP-B106, stock no. 1505.5601.02

Option Module R&S OSP-B107, stock no. 1505.5901.02

Option Module R&S OSP-B108, stock no. 1505.5718.02

Option Module R&S OSP-B111, stock no. 1505.4605.02

Option Module R&S OSP-B111UL, stock no. 1528.1531.13/.16

Option Module R&S OSP-B111VL, stock no. 1515.5991.13/.16

Option Module R&S OSP-B112, stock no. 1505.4611.02

Option Module R&S OSP-B114, stock no. 1505.4711.02

Option Module R&S OSP-B116, stock no. 1515.5827.02

Option Module R&S OSP-B119, stock no. 1515.5856.02

Option Module R&S OSP-B121, stock no. 1515.5504.02

Option Module R&S OSP-B121H, stock no. 1515.5504.40

Option Module R&S OSP-B122, stock no. 1515.5510.02

Option Module R&S OSP-B122H, stock no. 1528.1525.02

Option Module R&S OSP-B123, stock no. 1515.5527.02

Option Module R&S OSP-B124, stock no. 1515.5533.02

Option Module R&S OSP-B125, stock no. 1515.5540.02

Option Module R&S OSP-B126, stock no. 1515.5556.02

Option Module R&S OSP-B127, stock no. 1505.4728.02

Option Module R&S OSP-B128, stock no. 1505.4734.02

Option Module R&S OSP-B129, stock no. 1517.7004.02

Option Module R&S OSP-B131, stock no. 1505.4740.02

Option Module R&S OSP-B132, stock no. 1505.4757.02

Option Module R&S OSP-B133, stock no. 1528.3157.02

Page 14

R&S OSP Documentation Overview

Operating Manual 1505.3896.12 - 15 14

Option Module R&S OSP-B136, stock no. 1522.4500.02

Option Module R&S OSP-B142, stock no. 1528.1048.03/.11/.12/.13

Option Module R&S OSP-B158, stock no. 4094.7300.02

Page 15

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 15

2 Preparing for Use

General Safety Instructions

Please make sure to observe the instructions of the following sections so that you

cannot cause damage to the instrument or endanger people. This is of particular

importance when you use the instrument for the first time. Also observe the general

safety instructions at the beginning of this manual.

The following topics will help you to get familiar with the instrument and perform the

first steps:

● Front Panel Tour R&S OSP120 or Front Panel Tour R&S OSP130 or Front Panel

Tour R&S OSP150

● Rear Panel Tour

● Putting the Instrument into Operation

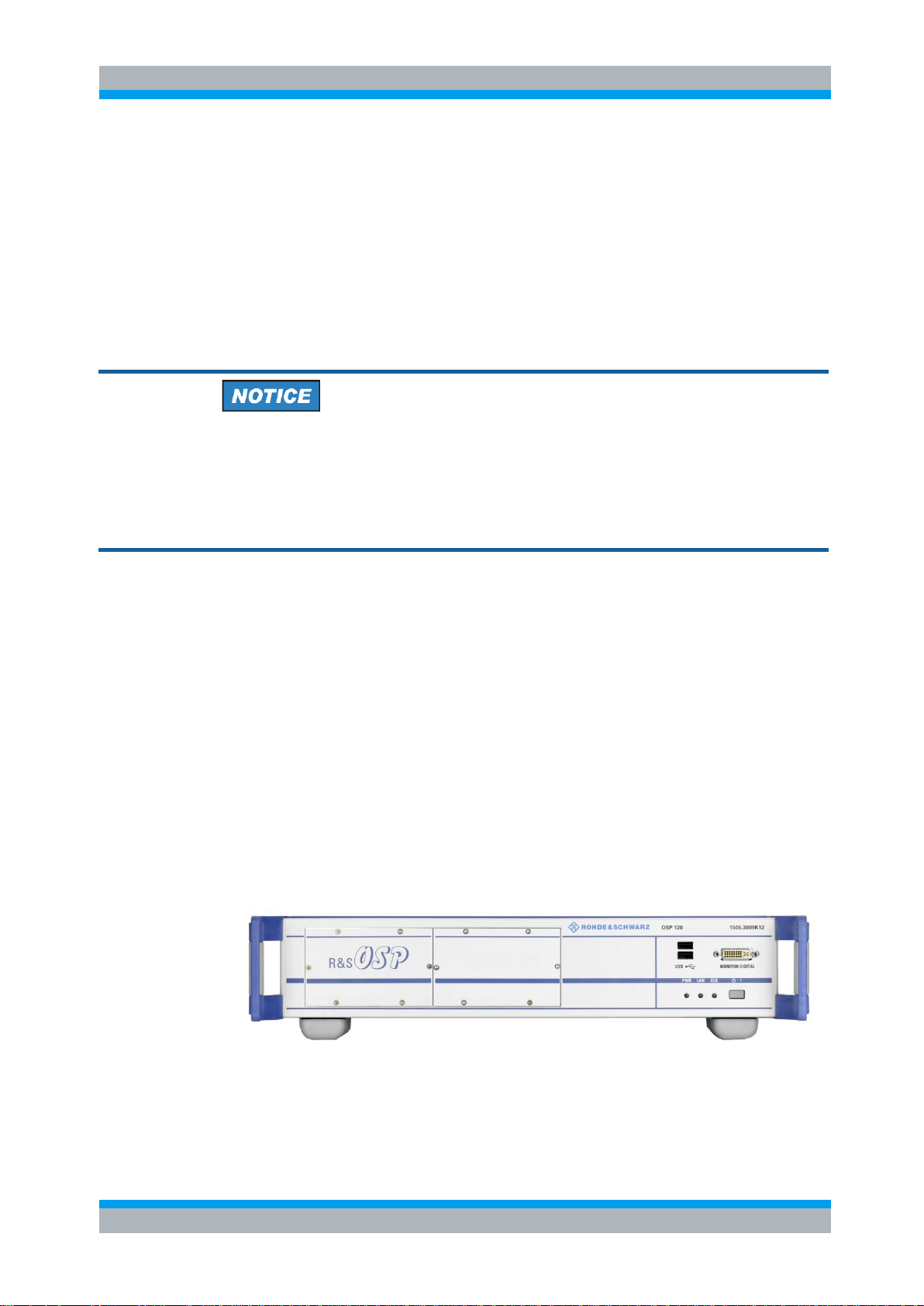

2.1 Front Panel Tour R&S OSP120

This chapter gives an overview of the front panel controls and connectors of the

R&S OSP120 and gives all information that is necessary to put the instrument into

operation and connect external devices. Notes on reinstallation of the instrument

software appear at the end of the chapter.

Chapter 3.3, R&S OSP Panel Functions, of this manual provides an introduction to the

operation of the instrument by means of the control program OSP Panel. For a

description of the operating concept and an overview of the instrument’s capabilities

refer to the Instrument Functions (chapter 5).

The front panel of the R&S OSP120 consists of STANDBY switch, Status LEDs and

connectors. Brief explanations on the function of these items and the rear panel can

be found on the next pages.

Page 16

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 16

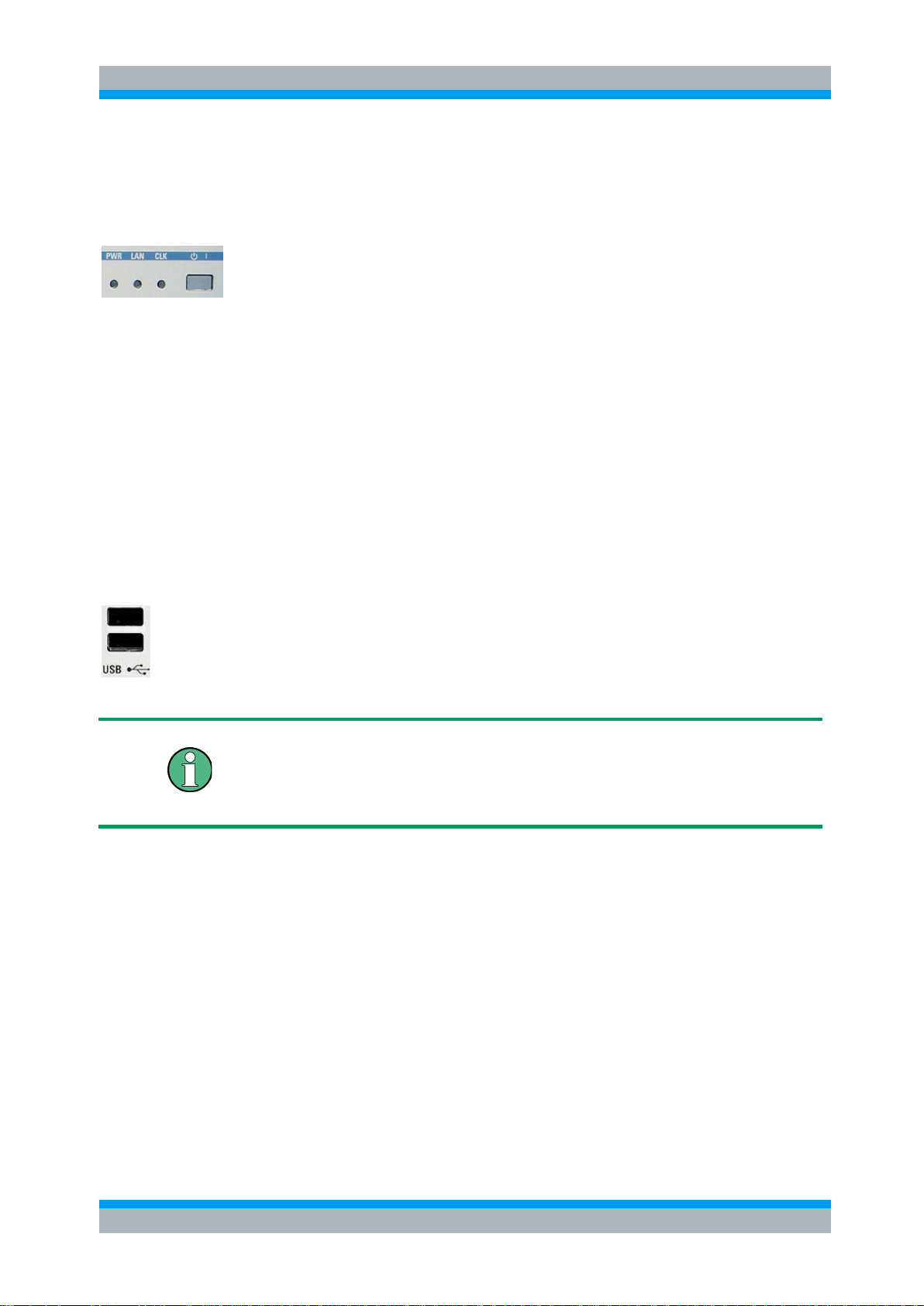

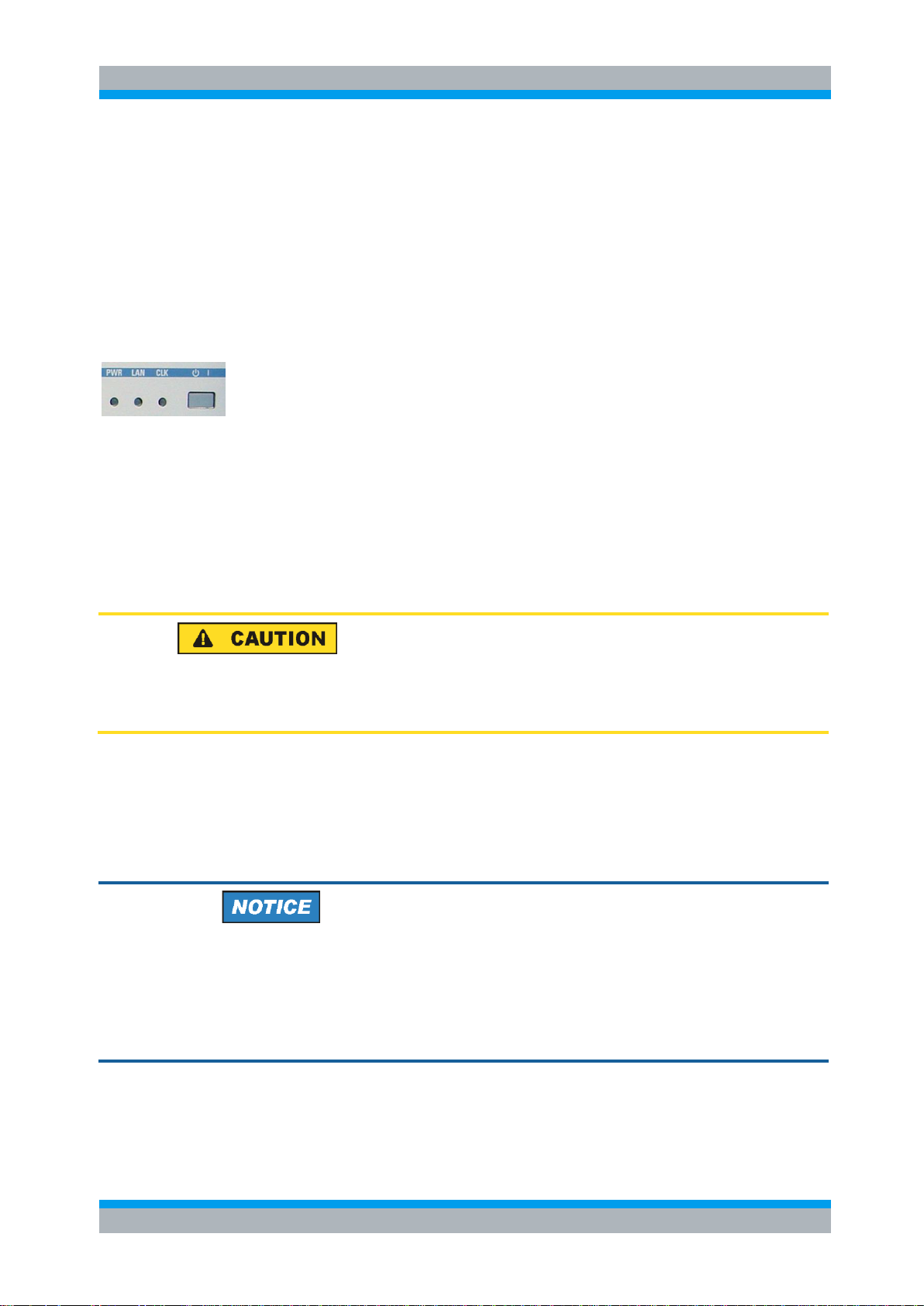

2.1.1 Status LEDs and Standby Key

The status LEDs light to indicate the following instrument states:

PWR: shows standby (yellow LED) and ready state (green LED).

LAN: shows if data are received via LAN network; see Remote Control (chapter 6).

CLK: is flashing if data are transferred via CAN bus.

On an R&S OSP150, the logic is inverted: the CLK indicator goes off shortly during

CAN bus activity.

The STANDBY key serves the following purpose:

Toggle between standby and ready state (indicated by the yellow and green PWR

LED, respectively).

Single Universal Serial Bus connectors of type A (master USB), used to connect a

keyboard or flash drive. All front panel USB connectors comply with standard USB 2.0;

refer to the "Specifications".

USB Connection

The length of passive connecting USB cables should not exceed 1 m. The maximum

current per USB port is 500 mA. It is recommended to use double-shielded USB

cables.

The status LEDs and the standby toggle switch are located in the bottom right corner

of the front panel. See also chapter 2.5.9.

2.1.2 Front Panel Connectors

2.1.2.1 USB Connectors

Page 17

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 17

2.1.2.2 Monitor Connector

An external monitor with a digital interface can be connected to the MONITOR

DIGITAL connector on the front panel of the R&S OSP120. An external monitor,

together with a keyboard, is a prerequisite for manual intervention in order to define

the LAN configuration or in case of service to have access to the Linux Operating

system.

Monitor connection:

Before the external monitor is connected, the instrument must be switched off

(standby mode) to prevent damage to the monitor and the R&S OSP120. After

connection, the external monitor is detected when the instrument is started. The Linux

Operating system menu of the R&S OSP is then displayed on the external monitor.

Further settings are not required.

It is recommended to use a double-shielded monitor cable equipped with ferrites at

each end.

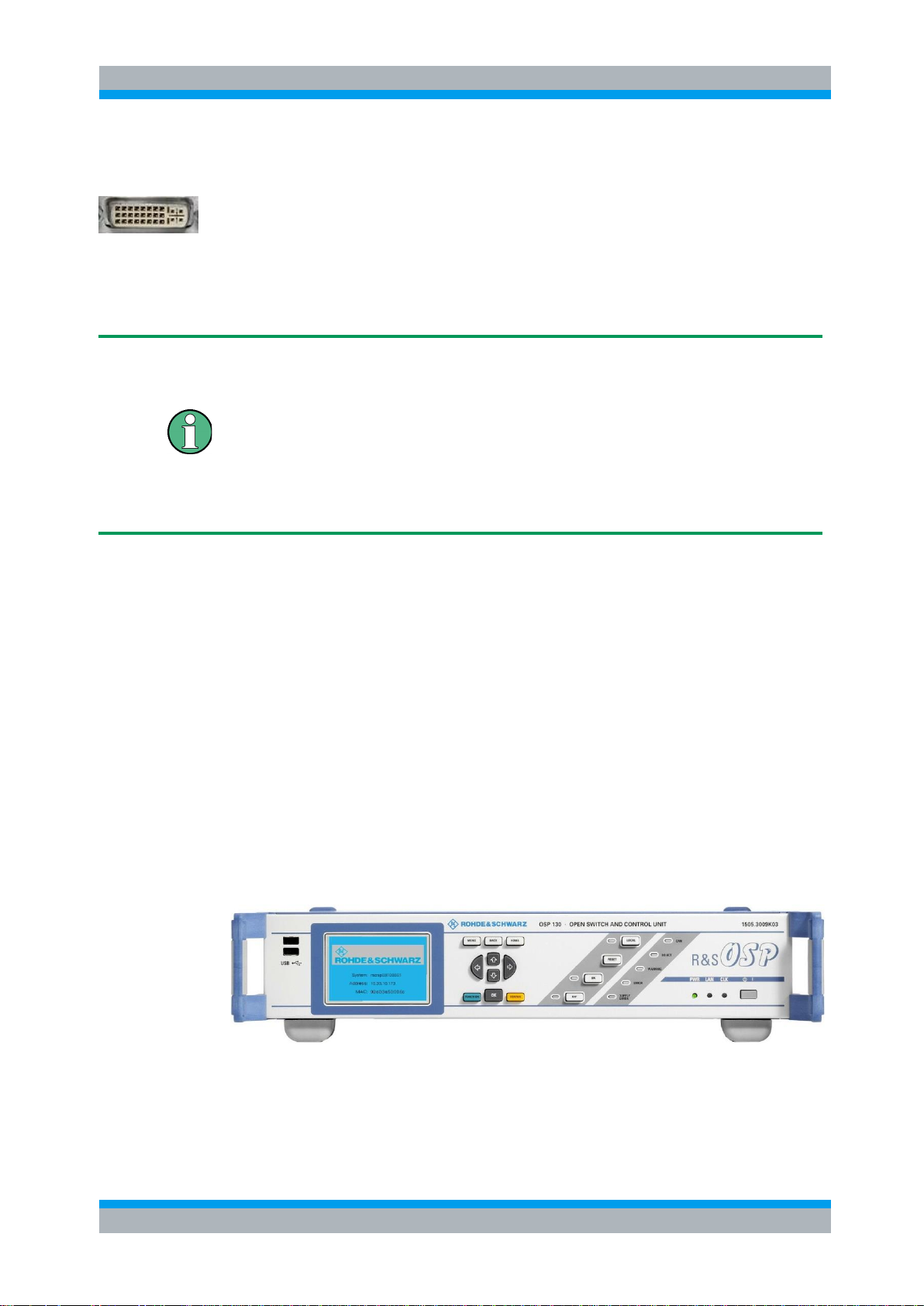

2.2 Front Panel Tour R&S OSP130

This chapter gives an overview of the front panel controls and connectors of the

R&S OSP130 and gives all information that is necessary to put the instrument into

operation and connect external devices. Notes on reinstallation of the instrument

software appear at the end of the chapter.

The chapter Getting Started of this manual provides an introduction to the operation of

the instrument by means of the control program OSP Panel. For a description of the

operating concept and an overview of the instrument’s capabilities refer to the

Instrument Functions (chapter 5). The graphical user interface on the instrument is

explained in chapter 5.3.

The front panel of the R&S OSP130 has the same STANDBY key and Status LEDs as

the R&S OSP120. See the corresponding sections in chapter 2.1.1 for details. There is

no connector for an external monitor.

Page 18

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 18

2.2.1 Navigation Keys

In the top row next to the screen there are three keys to quickly access different

hierarchy levels in the menus.

pressing the key MENU activates the top level menu.

pressing the key BACK moves up in hierarchy by one menu level.

pressing the key HOME leaves the menu and displays the Main menu screen

In the top row next to the screen there are three keys to quickly access different

hierarchy levels in the menus.

With the cursor keys the focus is moved within the screen elements; see a detailed

description in chapter 5.3.

In the top row next to the screen there are three keys to quickly access different

hierarchy levels in the menus.

pressing the key FUNCTION executes a switching action, if applicable.

pressing the key OK confirms a selection, for example for going to the next menu

level.

pressing the key STATUS displays status information for the chosen item (device or

module) or changes the selection of a switch for path configuration.

The OFF key is not used at the moment.

The ON key is not used at the moment.

Pressing the RESET key leaves the menu and displays the Main menu screen.

The LOCAL key is not used at the moment.

Error in supply voltage, please contact service.

General error condition. Please note any additional information what could have led to

this condition and contact R&S if the error is reproducible.

The navigation keys allow access to the various functions of the graphical user

interface. They can be subdivided into three groups.

2.2.2 Status Keys

The status keys serve the following purposes:

2.2.3 Status Indicators

The status indicators have the following meaning:

Page 19

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 19

General warning condition. Not used at the moment.

Indicates communication via the CAN interface.

Indicates communication via the CAN interface as well.

2.2.4 Front Panel USB Connectors

Single Universal Serial Bus connectors of type A (master USB), used to connect a

keyboard or flash drive. All front panel USB connectors comply with standard USB 2.0;

refer to the "Specifications".

USB Connection

The length of passive connecting USB cables should not exceed 1 m. The maximum

current per USB port is 500 mA. It is recommended to use double-shielded USB

cables.

2.3 Front Panel Tour R&S OSP150

This chapter gives an overview of the front panel controls of the R&S OSP150. The

front panel of the R&S OSP150 is similar to the front panel of the R&S OSP120 having

the Standby key and the three status LEDs but does not have any connector. See

chapter 2.1.1 for the description of the front panel elements.

Please notice that the operation of the CLK LED is different to OSP120 and OSP130.

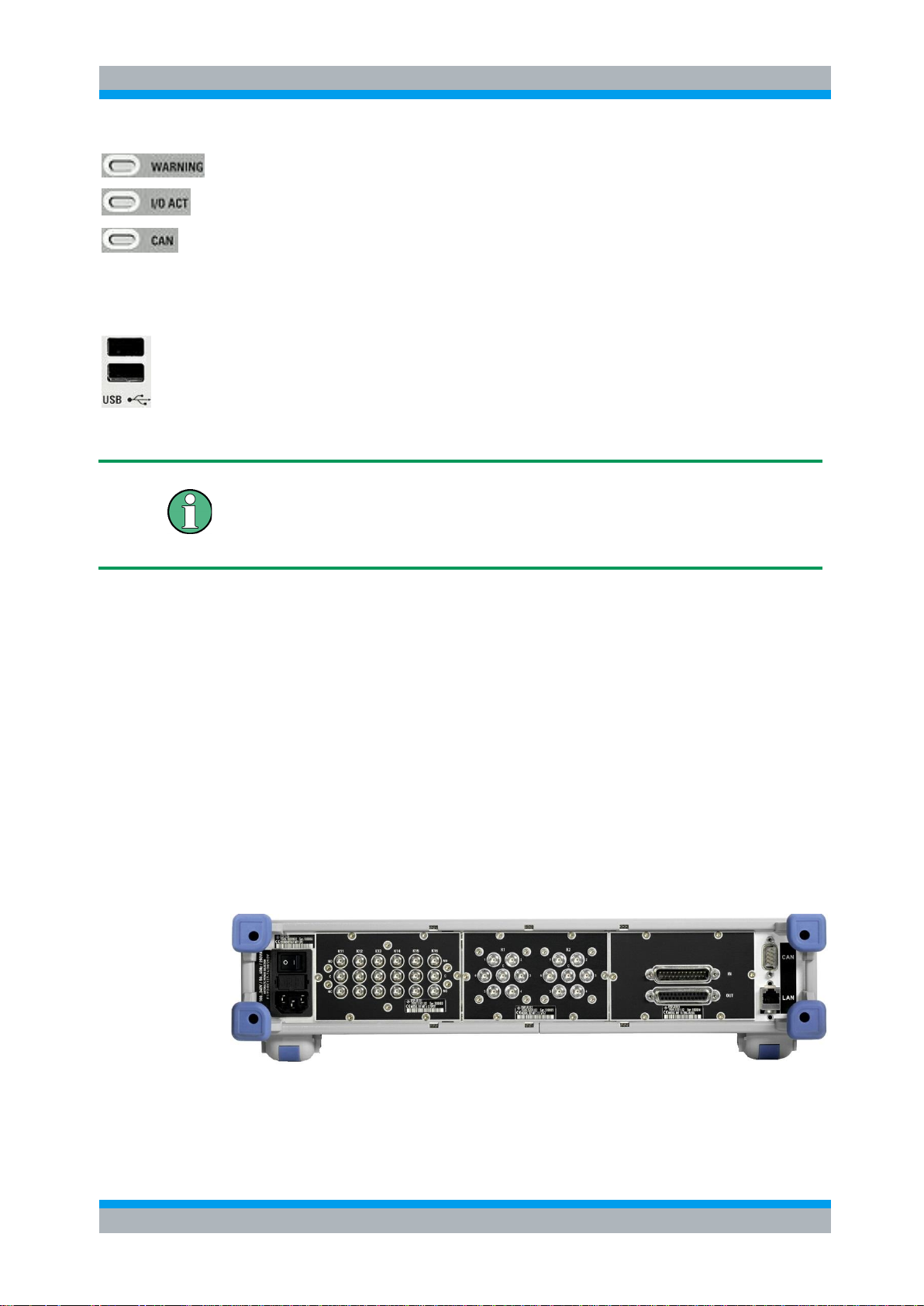

2.4 Rear Panel Tour

This section gives an overview of the rear panel connectors of the R&S OSP120. The

rear panels of the R&S OSP130 and of the R&S OSP150 are almost identical to it.

The rear connectors and interfaces are described in detail in the complete operating

manual. The following connectors are available on the instruments:

Page 20

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 20

LAN connector (RJ-45) is used to integrate the instrument to a Local Area Network,

8-pin LAN connector RJ-45 used to connect the R&S OSP120 or OSP130 to a Local

Area Network (LAN). Refer to Remote Operation in a LAN.

LAN Connection

Depending on the connection (a non-dedicated network connection or dedicated

connection to a single controller) a standard RJ-45 cable or cross-over RJ-45 cable is

required. See chapter 2.9.1 for further information.

It is recommended to use double-shielded LAN cables of category 6 (SSTP).

primarily for remote control purposes. This connector is not available on the

R&S OSP150.

CAN bus connector (D-Sub, 9 pin) is a control port to connect one or several extension

units R&S OSP150.

The R&S OSP owns three slots which can be configured with the options available for

the R&S OSP. The above configuration shows the following options:

Option R&S OSP-B101: Relay module consisting of six coaxial relays of SPDT type;

the RF coaxial connectors are SMA type

Option R&S OSP-B102: Relay module consisting of two coaxial relays of SP6T type;

the RF coaxial connectors are SMA type

Option R&S OSP-B103: I/O module with 16 Bit input / output ports; the connectors are

D-Sub types, 25 pin, female for output and male for input

In case of the options which can be installed in the R&S OSP, the connectors related

to each option are described in detail in chapter 9.2, R&S OSP Module Interfaces.

2.4.1 LAN Connector

Page 21

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 21

2.4.2 CAN Bus Connector

9-pin connector D-Sub male used to connect the R&S OSP120 or R&S OSP130 to

extension units R&S OSP150. Refer to Instrument Functions in chapter 5.

Maximum input levels

The maximum input levels and voltages of the input connectors at the front and rear

panel must not be exceeded.

Supply Voltage over CAN bus

In some CAN bus applications the R&S OSP120, OSP130 or OSP150 is required to

deliver the supply voltage to an external device. An example for this is the connection

of the fiber-optic extender R&S OSP-Z104. Using the cable OSP-Z106 is

recommended for this case.

However, when connecting an R&S OSP150 to an OSP120 or OSP130, this supply

voltage line must not be present. Using the connecting cables R&S OSP-Z101 or

R&S OSP-Z102 is recommended. Not observing these precautions may damage the

power supplies in the R&S OSP.

See also chapter 9.1.2.1 for the pinout of the CAN bus connector.

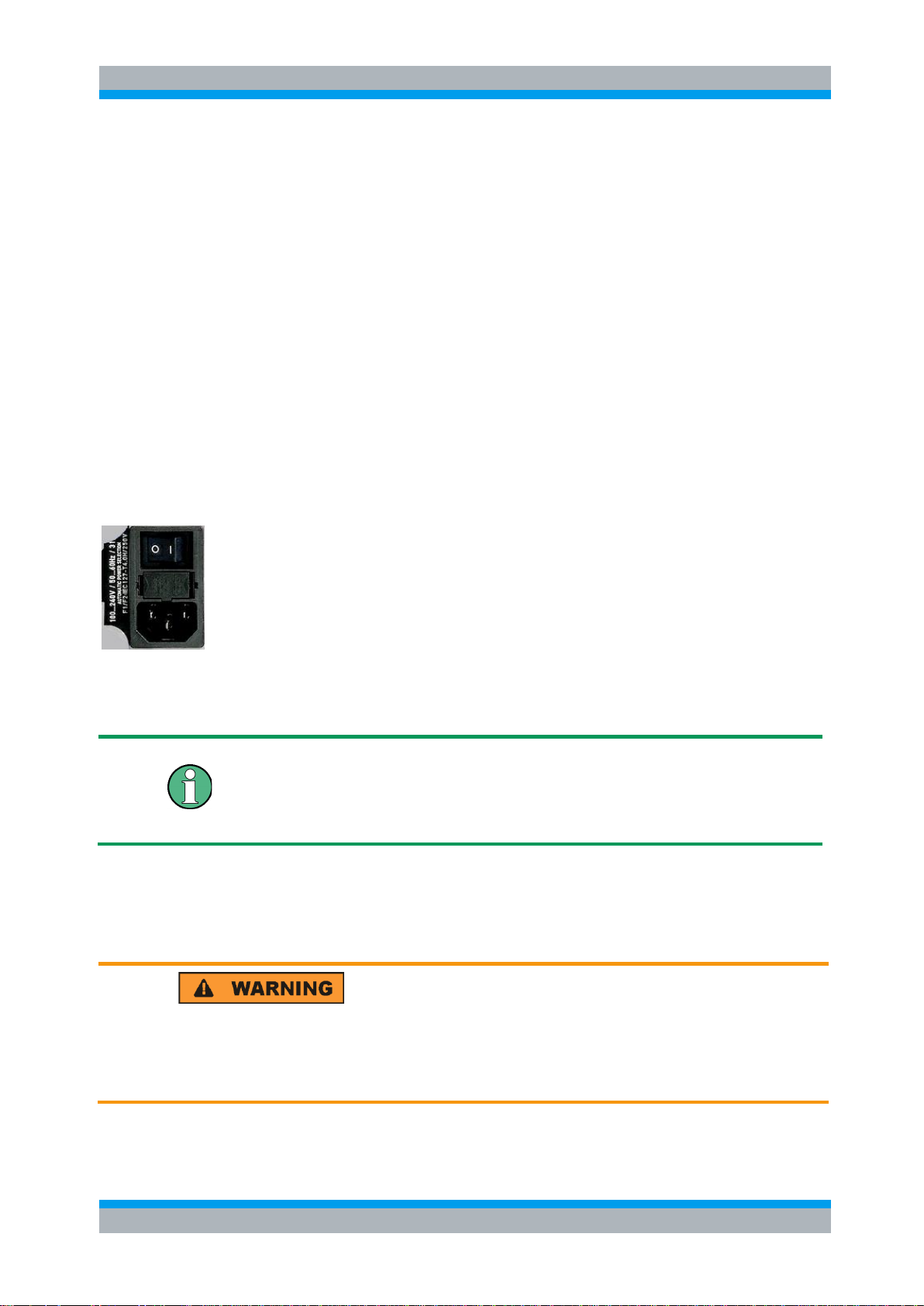

The mains connector is located at the bottom left corner of the rear panel.

Next to the connector is a mains fuse, and above the fuse the mains switch. With the

positions “0” the instrument is disconnected from mains, and in position “1” it is

connected. See chapters 2.5.6 and 2.5.7 for more information.

2.4.3 Mains Switch and Connector

Page 22

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 22

2.5 Putting the Instrument into Operation

Instrument setup

Before turning on the instrument, please make sure that the following conditions are

fulfilled:

Instrument covers are in place and all fasteners are tightened.

Fan openings are unobstructed.

Signal levels at the input connectors are all within the specified ranges.

Signal outputs are correctly connected and not overloaded.

The instrument is dry and shows no condensation.

Non-observance may cause damage to the instrument or other devices in the test

setup.

This section describes the basic steps to be taken when setting up the R&S OSP for

the first time.

2.5.1 Unpacking the Instrument and Checking the Shipment

Remove the instrument from its packaging and check the equipment for completeness

using the delivery note and the accessory lists for the various items.

First, pull off the polyethylene protection pads from the instrument's rear feet and then

carefully remove the pads from the instrument handles at the front.

Pull off the corrugated cardboard cover that protects the rear of the instrument.

Carefully unthread the corrugated cardboard cover at the front that protects the

instrument handles and remove it.

Check the instrument for any damage. If there is damage, immediately contact the

carrier who delivered the instrument. In this case, make sure not to discard the box

and packing material.

It is advisable to keep the original packing material in order to prevent control elements

and connectors from being damaged in case the instrument is to be transported or

shipped at a later date.

Page 23

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 23

2.5.2 Instrument Setup

Allow for sufficient air supply in the rack.

Make sure that there is sufficient space between the ventilation holes and the rack

casing.

The R&S OSP is designed for use under laboratory conditions, either on a bench top

or in a rack. The general ambient conditions required at the operating site are as

follows:

The ambient temperature must be in the ranges specified for operation and for

compliance with specifications (see "Specifications").

All fan openings including the rear panel perforations must be unobstructed. The

distance to the wall should be at least 10 cm.

2.5.3 Bench Top Operation

If the R&S OSP is operated on a bench top, the surface should be flat.

The instrument is used in horizontal position, standing on its feet.

2.5.4 Mounting in a 19" Rack

The instrument can be mounted in 19" racks using a ZZA-211 adapter (order number

1096.3260.00). Please note the mounting instructions supplied with the rack adapter.

2.5.5 EMI Protective Measures

In order to avoid electromagnetic interference (EMI), the instrument may only be

operated when it is closed and with all shielding covers fitted. Only appropriate

shielded signal and control cables may be used.

Page 24

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 24

2.5.6 Connecting the Instrument to the AC Supply

To turn the power on or off, press the AC power switch to position I (On) or 0 (Off).

See also Replacing Fuses.

After power-on, the R&S OSP instrument is in ready state after about 30 seconds.

The STANDBY key at the front panel of the instrument is used to toggle between

standby and ready state. The AC power switch can be permanently on.

Switching off is required only if the instrument must be completely removed from the

AC power supply but may be used in order to reduce power consumption when not in

use.

Extension units

If communication between OSP120 or OSP130 and any extension unit OSP150

connected via CAN bus cannot be established properly, try to turn on the extension

unit(s) first before turning on the OSP120 or OSP130.

Shock hazard

For fuse replacement, ensure that the instrument is switched off and disconnected

from the power supply by removing the plug from the AC power connector.

The R&S OSP is automatically adapted to the AC supply voltage supplied. The supply

voltage must be between 100 V and 240 V with frequencies ranging from 50 Hz to

60 Hz (see also the tolerances quoted in the "Specifications"). The mains connector is

located in the lower left corner of the rear panel.

► Connect the instrument to the AC power source using the AC power cable

delivered with the instrument.

The maximum power consumption of the instrument depends on the installed options.

The typical power consumption is also listed in the "Specifications".

The R&S OSP is protected by two fuses located in the fuse holder below the AC power

switch; see Replacing Fuses.

2.5.7 Power on and off

The mains connector is located at the bottom left corner of the rear panel.

2.5.8 Replacing Fuses

The instrument is protected by two fuses (IEC 127- T4.0H/250V, stock no.

0020.7600.00) located in the fuse holder below the AC power switch on the rear panel.

To replace the fuses

Page 25

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 25

1. Open the lid of the AC power connector.

After switching on the AC power, the R&S OSP is in ready mode after about

30 seconds.

Press the STANDBY key on the front panel briefly to switch the R&S OSP from the

standby to ready state or vice versa.

Shock hazard

The instrument is still power-supplied while it is in standby mode.

Instrument damage caused by cleaning agents

Cleaning agents contain substances that may damage the instrument, e.g. solvent-

containing cleaning agents may damage the front panel labeling or plastic parts. Never

use cleaning agents such as solvents (thinners, acetone, etc), acids, bases, or other

substances.

2. Lift the fuse holder out of its slot.

3. Exchange the fuses.

4. Put the fuse holder back in its slot and close the lid.

2.5.9 Standby and Ready State

The STANDBY toggle switch is located in the bottom right corner of the front panel.

In standby state, the left PWR LED is yellow. The standby power only supplies the

power switch circuits. In this state it is safe to switch off the AC power and disconnect

the instrument from the power supply.

After Power On or when changing from Standby to Ready state, the left PWR LED is

immediately switched to green and all modules are power-supplied. Please note that

the Linux operating system of R&S OSP takes about 30 seconds to start up. After this

time the R&S OSP is ready for operation.

2.6 Maintenance

The R&S OSP does not require any special maintenance. Make sure that the air vents

are not obstructed. The outside of the instrument is suitably cleaned using a soft, nonfluffy dust cloth.

For our support center address and a list of useful R&S contact addresses refer to the

pages at the beginning of this manual.

Page 26

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 26

2.6.1 Storing and Packing

A USB flash drive can be connected to one of the USB Connectors on the front panel

of the R&S OSP120 or OSP130.

The flash drive is detected automatically when it is connected.

A keyboard can be connected to one of the USB Connectors on the front panel of the

R&S OSP120.

The keyboard is detected automatically when it is connected. The default input

language is English – US. Refer to chapter 2.10.1 for changing the keyboard

properties.

Keyboard configuration

The keyboard configuration already is pre-configured.

Operating the R&S OSP120 does not require a keyboard. Usually all essential

functions can be controlled via LAN interface.

The R&S OSP can be stored at the temperature range quoted in the data sheet. When

it is stored for a longer period of time the instrument should be protected against dust.

The original packing should be used, particularly the protective caps at the front and

rear, when the instrument is to be transported or dispatched. If the original packing is

no longer available, use a sturdy cardboard box of suitable size and carefully wrap the

instrument to protect it against mechanical damage.

2.7 Connecting External Accessories

The LAN interface at the rear panel of the R&S OSP120 or OSP130 is used for remote

control of the instrument:

● A LAN connection can be established in order to remotely control the instrument

from an external PC (see Connecting a LAN Cable).

In addition the R&S OSP120 provides interfaces for monitor connection and USB

connection:

● An external monitor shows the menus of the Linux Operating System, if any

access or setup within the Linux Operating System should be necessary.

● A keyboard simplifies the entry of data (see Connecting a Keyboard).

● A flash drive supports the firmware update (see Connecting a USB Flash Drive).

2.7.1 Connecting a USB Flash Drive

2.7.2 Connecting a Keyboard

Page 27

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 27

2.7.3 Connecting a Monitor

A standard monitor can be connected to the DVI-D connector on the front panel of the

R&S OSP120.

Monitor configuration

There is no particular configuration of the monitor required.

Operating the R&S OSP120 does not require a monitor. Usually all essential functions

can be control via LAN interface.

Monitor connection

The monitor must be connected while the instrument is switched off (in standby mode).

Otherwise correct operation can not be guaranteed.

A LAN cable can be connected to the LAN connector on the rear panel of the

R&S OSP120 or OSP130. To establish a LAN connection proceed as follows:

Refer to chapter Assigning an IP Address and learn how to avoid connection errors.

Connect an appropriate LAN cable to the LAN port. Use a commercial RJ-45 cable to

establish a non-dedicated network connection, or a cross-over RJ-45 cable to

establish a dedicated connection between the instrument and a single PC.

The monitor displays the menus of the Linux Operating System which is integral part of

the R&S OSP120. The monitor together with keyboard is required if any setups /

changes have to be done in the Linux operating system.

2.7.4 Connecting a LAN Cable

Dedicated vs. non-dedicated network connections

There are two methods to establish a LAN connection of the R&S OSP:

● A non-dedicated network (Ethernet) connection from the instrument to an existing

network made with an ordinary RJ-45 network cable. The instrument is assigned an

IP address and can coexist with a computer and with other hosts on the same

network.

● A dedicated network connection between the instrument and a single computer

made with a cross-over RJ-45 network cable. The computer must be equipped

with a network adapter and is directly connected to the instrument. The use of

hubs, switches, or gateways is not needed, however, data transfer is still made

using the TCP/IP protocol.

Page 28

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 28

2.8 Starting the R&S OSP and Shutting Down

Standby state

It is recommended to switch the R&S OSP to standby state before disconnecting it

from the AC supply.

To start the R&S OSP, proceed as follows:

● Make sure that the instrument is connected to the AC power supply and switch

the power switch (see chapter 2.5.7) on the rear panel to position I (On). All

modules of the R&S OSP are powered (the left PWR LED is green) and after

about 30 seconds the instrument is in ready state.

● If necessary, press the STANDBY toggle switch (see chapter 2.5.9) on the front

panel to switch the instrument to ready state (the left PWR LED is green).

● In ready state, the instrument already has booted the Linux Operating System

(see chapter 2.10) and started the R&S OSP application. Independent of the last

setup, the R&S OSP always starts with the default conditions, i.e. all relays in

reset condition.

To shut down the R&S OSP, proceed as follows:

● Press the STANDBY key, which will shut down the Linux operating system and

set the instrument to standby state.

● If desired, set the AC power switch to position 0 (Off).

2.9 Remote Operation in a LAN

A LAN connection is used to integrate the R&S OSP (not the OSP150) into a

home/company network. The LAN connection is required for:

● Remote control operation of the R&S OSP120 or OSP130.

● Manual control of the R&S OSP from a remote computer using the "OSP Panel"

application.

To establish the connection proceed as follows:

● Assign an IP address to the R&S OSP following the directions below and connect

the instrument to the network as described in chapter 2.7.4, Connecting a LAN

Cable.

2.9.1 Assigning an IP Address

There are two different modes for the OSP LAN configuration. The OSP as it is

delivered works in the LAN configuration as described in chapter 2.9.1.1.

With OSP firmware version 2.51 onwards, the OSP LAN configuration can be setup as

described in chapter 2.9.1.2.

Page 29

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 29

The actual LAN configuration can be read out from the OSP by the following SCPI

Valid IP addresses

If your network does not support DHCP, or if you choose to disable dynamic TCP/IP

configuration, you must assign valid address information before connecting the

R&S OSP to the LAN. Contact your network administrator to obtain a valid IP address,

because connection errors can affect the entire network.

command:

SYSTem:NETWork:MODe?

2.9.1.1 Default mode of LAN Configuration

The actual LAN configuration is set to mode -> DHCP_AUTO

Depending on the network capacities, the IP address information for the R&S OSP120

or R&S OSP130 can be obtained in different ways.

● If the network supports dynamic TCP/IP configuration using the Dynamic Host

Configuration Protocol (DHCP), all address information can be assigned

automatically.

● If the network does not support DHCP, or if the instrument is set to use alternate

TCP/IP configuration, a static IP address is used.

By default, the R&S OSP is configured either to use:

● A dynamic TCP/IP configuration and obtain all address information automatically.

This means that it is safe to establish a physical connection to the LAN without

any previous R&S OSP configuration.

(Priority 1)

● A user defined static IP address. This address can be defined (but must not) in

addition to the default address. See chapter 3.3.3 for information how to configure

the user defined IP address via the OSP Panel application.

(Priority 2)

● A static default IP address. Per default, the R&S OSP is set to the IP address

192.168.48.147. See also chapter 3.1.

(Priority 3)

Please note the priorities shown above which is related to IP address handling done

by the OSP.

Reading the IP address

When using the dynamic TCP/IP configuration, the actual IP address information will

be displayed when booting the R&S OSP. Proceed as follows:

Connect the R&S OSP via a commercial RJ-45 cable to your network supporting

DHCP

Page 30

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 30

Switch on the R&S OSP120 with Monitor and Keyboard connected (not applicable to

the OSP130)

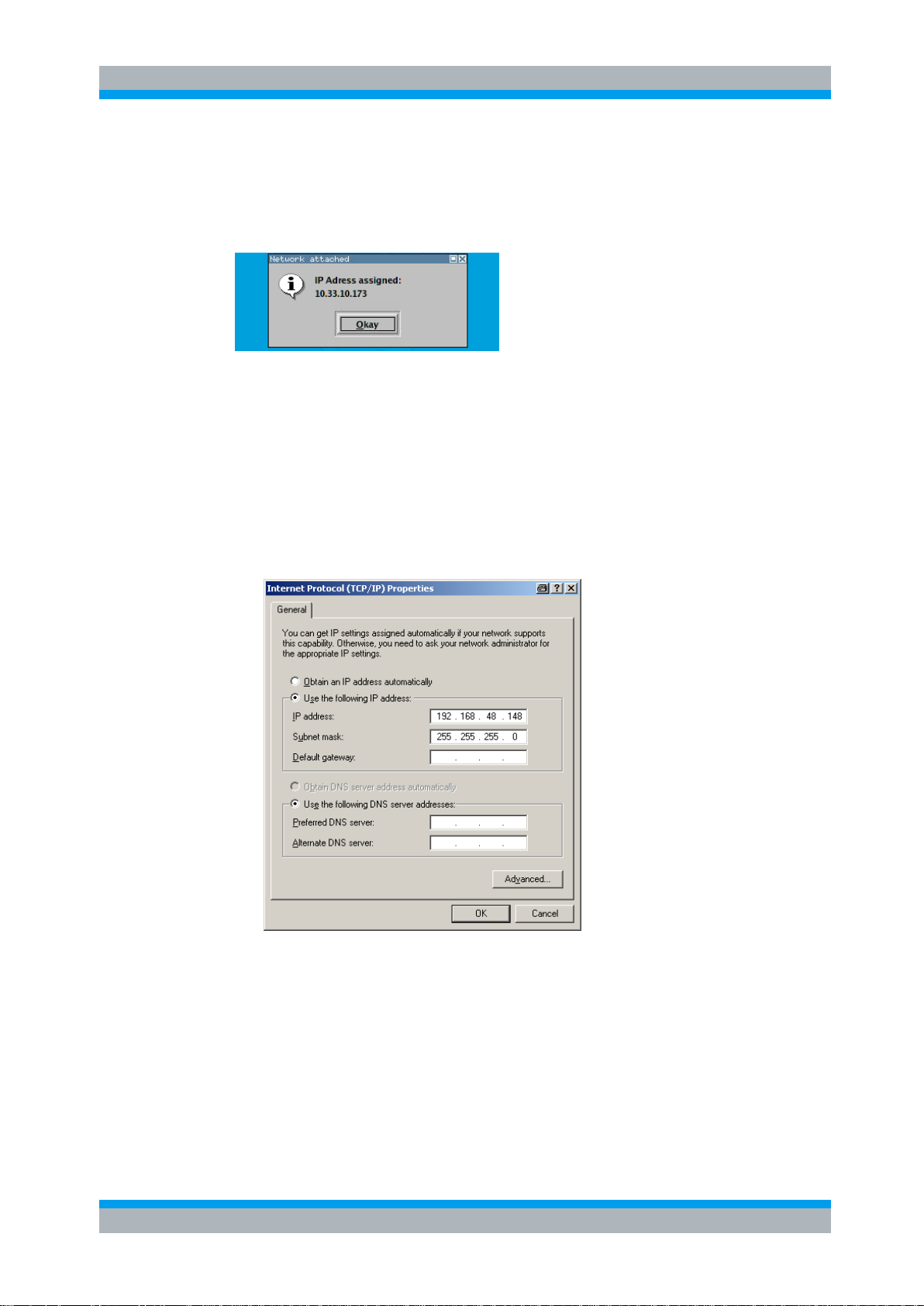

At the end of the booting process, the IP address will be displayed as shown below for

the OSP120 and the OSP130. The values of the IP address shown are only examples.

Press Okay button or the ENTER key on the keyboard (OK key for the R&S OSP130)

for confirmation and to continue the operation.

Manual TCP/IP configuration

If your network does not support DHCP, proceed as follows:

1. Connect the R&S OSP120 or OSP130 via a cross-over RJ-45 cable to your

computer (or network not supporting DHCP).

2. Set the network configuration of your computer to work with a static IP address.

The following setup is recommended:

3. Switch on the R&S OSP and wait until boot-up is finished.

The R&S OSP now can be accessed under its default IP address from your computer.

Page 31

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 31

2.9.1.2 Specific mode of LAN Configuration

The R&S OSP120 can be configured to enable gateway routing.

The actual LAN configuration is set to mode -> DHCP-STATIC

The LAN configuration can be setup using the OSP Panel application. See chapter

3.3.3.

The change over to DHCP-STATIC mode is achieved by the following SCPI command:

SYSTem:NETWork:STATic "<IpAddr>","<Netmask>","<Gateway>".

2.9.2 R&S OSP Panel

The R&S OSP120 has no elements for front panel operating. A “manual” operation is

achieved via the R&S application OSP Panel.

"OSP Panel" is a Windows application which can be used to access and control the

R&S OSP120 or the OSP130 from a remote computer through a LAN connection. The

OSP Panel allows full access to all R&S OSP functions.

To start the OSP Panel connection

4. Connect the R&S OSP to a LAN and determine its IP address; see Remote

Operation in a LAN. It is necessary to have a VISA library installed on your

computer.

5. Install the OSP Panel application on your computer (connected to the LAN). The

VISA libraries which are necessary for running the OSP Panel are available on a

separate disc (NI-VISA I/O Library)..

6. Start the OSP Panel, specify the correct IP address in the OSP Panel, and the

R&S OSP can be manually controlled.

For detailed information about OSP Panel refer to the chapter 3.3 R&S OSP Panel

Functions.

2.10 Linux Operating System

The R&S OSP is equipped with a Linux operating system which has been configured

according to the instrument's features and needs. Changes in the system configuration

can be necessary in order to

● Establish a LAN connection.

● Customize the properties of the keyboard connected to the R&S OSP120.

● Call up additional software tools.

Page 32

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 32

Configuration of the operating system, updates

The operating system is adapted to the R&S OSP. To avoid impairment of instrument

functions, only change the settings described in this manual. Existing software must be

modified only with update software released by Rohde & Schwarz. Likewise, only

programs authorized by Rohde & Schwarz for use on the instrument must be

executed.

2.10.1 Keyboard Properties

The keyboard properties can be changed via the console of the Linux Operating

System. To customize the keyboard properties, perform the following steps:

1. Switch off the R&S OSP.

2. R&S OSP120: Connect the external monitor and keyboard to the R&S OSP120

and switch on the instrument. The messages of the Linux boot process are

displayed on the monitor. Wait until the boot process is finished (takes about 30

seconds) and press the <ENTER> key.

3. R&S OSP130: Connect the external keyboard to the R&S OSP120 and switch on

the instrument. Wait until booting is complete. Change from regular display to

Linux system login by pressing the keys CTRL + ALT + F3.

4. When asked for the login, use the login name root and the password root.

To change the keyboard properties to German, type <de> and conform with the

<ENTER> key. The keyboard properties will be kept until the instrument is switched

off. After booting of the instrument, the default keyboard configuration (English US) is

set up again.

2.11 Firmware Update

This chapter contains information on firmware update and Linux operating system

update to the R&S OSP120 or OSP130.

Page 33

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 33

Possible impairment of the functioning of the instrument

The instrument is equipped with the Linux operating system. It is thus possible to install

COTS software in the instrument. The use and installation of commercial off-the-shelf

(COTS) software may impair the instrument function. For this reason, we recommend

that you only execute programs tested by Rohde & Schwarz with regard to their

compatibility with the instrument software. In certain cases, the use of these programs

can impair the performance of the instrument.

The drivers and programs used in the instrument under Linux have been adapted to

the test instrument. Existing instrument software must only be modified with update

software released by Rohde & Schwarz.

The firmware update packages for the R&S OSP120 and OSP130 are integrated in a

single setup file "OSP<xxx>.rsu" (<xxx> denotes the version of the firmware update).

Firmware updates as well as the Release Notes describing the improvements and

modifications are provided on the Internet at the download site of the R&S OSP

homepage.

The installation of a new firmware version is performed via the USB interface. A deinstallation of the old firmware is not necessary. The firmware update is performed

while the instrument is running. The new firmware will be loaded right after the update

process.

To perform a firmware update, perform the following steps.

1. The update file has to be downloaded from the Internet to a PC. From there the

file should be transferred to a USB flash drive which will later be plugged into the

USB interface of the R&S OSP.

2. Connect the external monitor and keyboard to the R&S OSP120 and switch on

the instrument. Wait until booting is complete.

3. Connect the USB flash drive to one of the two USB interfaces on the R&S OSP

front panel. If the instrument recognizes a flash drive at its USB interface, and

finds valid update versions, the Software Update Process is started. Press the

Yes button (OK key on OSP130) to continue

All update versions (files with extension .rsu) stored on the flash drive now are offered

for selection. Thus, an upgrade or downgrade of the firmware is possible at any time.

Select the required firmware update version and press the OK button.

Page 34

R&S OSP Preparing for Use

Operating Manual 1505.3896.12 - 15 34

It is recommended not to switch off the instrument or to remove the USB flash drive

while the firmware update is running.

Firmware Update:

The firmware update is not allowed to be performed running the GUI via Web-Browser

and VNC. Doing this will abort the firmware installation procedure!

If the software update is complete, the USB flash drive has to be removed. A message

box is coming up to confirm the removal of the flash drive . After confirmation the

instrument starts rebooting.

The R&S OSP is now ready to operate with the new firmware version.

Before using the R&S OSP, repeat the registration process. See chapter 3.3.2 for details.

2.12 Read the actual the Firmware Version

The currently installed firmware version of the different R&S OSP units can be read in

several ways as described in the following chapters.

2.12.1 Get Firmware Version using R&S OSP Panel

The firmware versions of all OSP models can be read using the application OSP

Panel. Start the OSP Panel and select the function >File >System Info.

This function displays the OSP System information together with the actual Firmware

version. The Firmware version is shown in the OSP Identification string as highlighted

in the following example (Version 1.5).

Page 35