Rohde & Schwarz NRP 1143.8500.02 User Manual

Test and Measurement

Division

Operating Manual

Power Meter

R&S NRP

1143.8500.02

Printed in Germany

1144.1400.12-05- 1

Dear Customer,

R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. K G.

Trade names are trademarks of the owners.

1144.1400.12-05- 2

R&S NRP Supplement

Operation of the R&S NRP-Z81 wideband power sensor

on R&S NRP base unit

Dear Customer,

for proper operation of the R&S NRP-Z81 wideband power sensor, the right software is required:

Main Program (Application) 5.01

Bootloader 5.01

Keyboard Controller 3.22

The revision numbers for the software components installed in the base unit can be displayed under

menu item 'System Info', lines 'Main Program', 'Bootloader' and 'Keybd. Ctrl.'. The 'System Info' can be

found in the 'System' menu.

Please note, that the statistics capabilities of the sensor are not yet supported by these revisions.

1144.1400.12-05- Supplement 1 E-1

R&S NRP Tabbed Divider Overview

Tabbed Divider Overview

Data Sheet

Safety Instructi ons

Certificate of Quality

EU Certificate of Conformity

List of R&S Representatives

Tabbed Divider

1 Chapter 1: Putting into Operation

2 Chapter 2: Getting Started

3 Chapter 3: Operation

4 Chapter 4: Functional Description

5 Chapter 5: Remote Control – Basics

6 Chapter 6: Remote Control – Commands

7 Chapter 7: for future extensions

8 Chapter 8: Maintenance

9 Chapter 9: Error Messages

10 Chapter 10: for future extensions

1144.1400.12 RE E-1

Before putting the product into operation for

the first time, make sure to read the following

Safety Instructions

All plants and locations of the Rohde & Schwarz group of companies make every effort to keep the

safety standard of our products up to date and to offer our customers the highest possible degree of

safety. Our products and the auxiliary equipment required for them are designed and tested in

accordance with the relevant safety standards. Compliance with these standards is continuously

monitored by our quality assurance system. The product described here has been designed and tested

in accordance with the EC Certificate of Conformity and has left the manufacturer’s plant in a condition

fully complying with safety standards. To maintain this condition and to ensure safe operation, observe

all instructions and warnings provided in this manual. If you have any questions regarding these safety

instructions, the Rohde & Schwarz group of companies will be happy to answer them.

Furthermore, it is your responsibility to use the product in an appropriate manner. This product is

designed for use solely in industrial and laboratory environments or in the field and must not be used in

any way that may cause personal injury or property damage. You are responsible if the product is used

for an intention other than its designated purpose or in disregard of the manufacturer's instructions. The

manufacturer shall assume no responsibility for such use of the product.

The product is used for its designated purpose if it is used in accordance with its product documentation

and within its performance limits (see data sheet, documentation, the following safety instructions).

Using the product requires technical skills and a basic knowledge of English. It is therefore essential

that the product be used exclusively by skilled and specialized staff or thoroughly trained personnel with

the required skills. If personal safety gear is required for using Rohde & Schwarz products, this will be

indicated at the appropriate place in the product documentation.

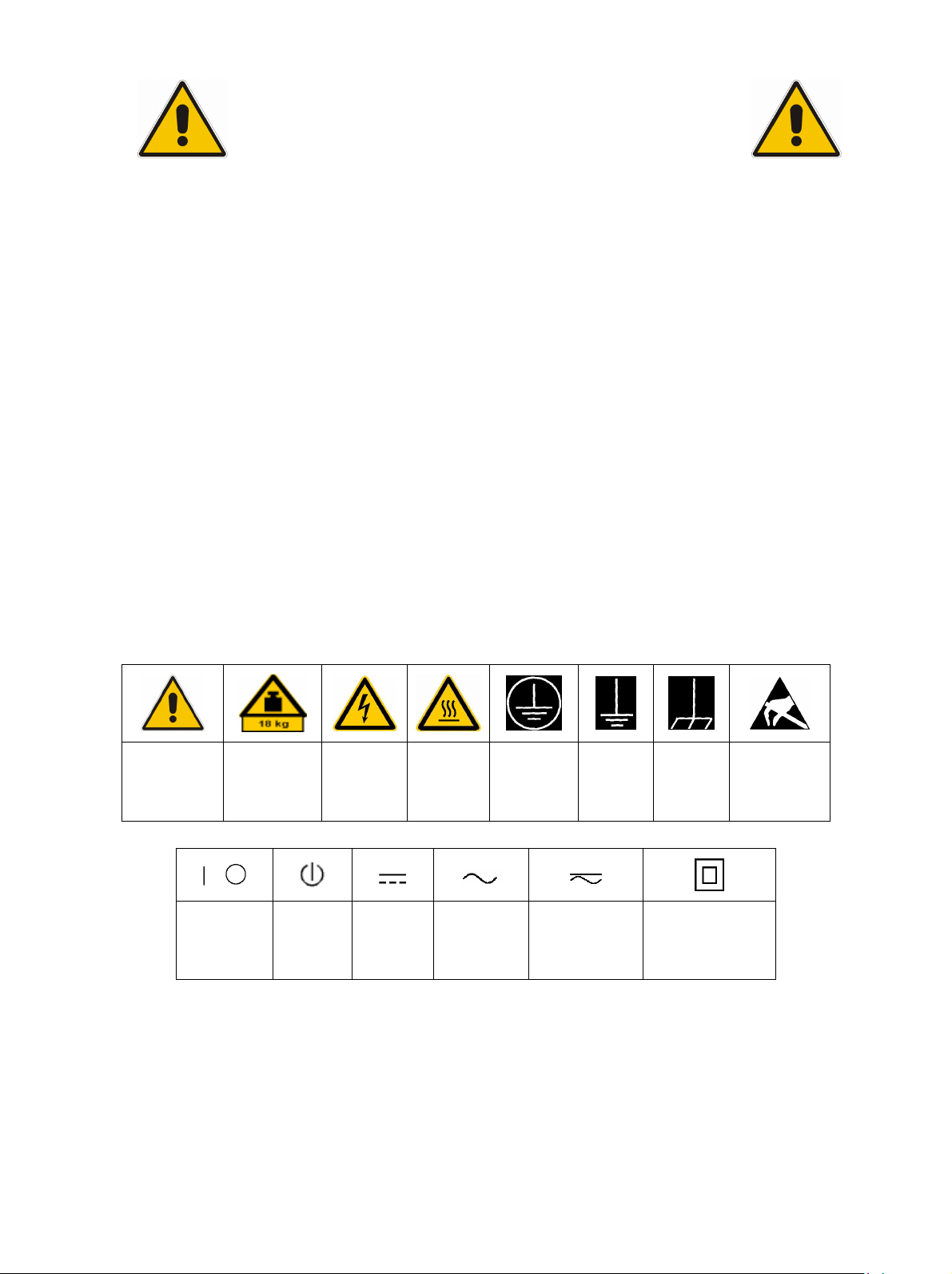

Observe

product

documentation

Supply

voltage

ON/OFF

Weight

indication for

units >18 kg

Standby

indication

Symbols and safety labels

Danger of

electric

shock

Warning!

Hot

surface

PE terminal Ground

Direct

current

(DC)

Alternating

current (AC)

Direct/alternating

current (DC/AC)

Ground

terminal

Device fully

protected by

double/reinforced

insulation

Attention!

Electrostatic

sensitive

devices

1171.0000.42-03.00 Sheet 1

Safety Instructions

Observing the safety instructions will help prevent personal injury or damage of any kind caused by

dangerous situations. Therefore, carefully read through and adhere to the following safety instructions

before putting the product into operation. It is also absolutely essential to observe the additional safety

instructions on personal safety that appear in relevant parts of the product documentation. In these

safety instructions, the word "product" refers to all merchandise sold and distributed by the Rohde &

Schwarz group of companies, including instruments, systems and all accessories.

Tags and their meaning

DANGER

WARNING

CAUTION This tag indicates a hazard carrying a low risk of minor or moderate

ATTENTION

NOTE

These tags are in accordance with the standard definition for civil applications in the European

Economic Area. Definitions that deviate from the standard definition may also exist in other economic

areas or military applications. It is therefore essential to make sure that the tags described here are

always used only in connection with the related product documentation and the related product. The

use of tags in connection with unrelated products or documentation can result in misinterpretation and

thus contribute to personal injury or material damage.

This tag indicates a definite hazard carrying a high risk of death or

serious injury if not avoided.

This tag indicates a possible hazard carrying a medium risk of death or

(serious) injury if not avoided

injury if not avoided.

This tag indicates the possibility of incorrect use that can cause damage

to the product.

This tag indicates a situation where the user should pay special attention

to operating the product but which does not lead to damage.

.

Basic safety instructions

1. The product may be operated only under

the operating conditions and in the

positions specified by the manufacturer. Its

ventilation must not be obstructed during

operation. Unless otherwise specified, the

following requirements apply to

Rohde & Schwarz products:

prescribed operating position is always with

the housing floor facing down, IP protection

2X, pollution severity 2, overvoltage

category 2, use only in enclosed spaces,

max. operation altitude 2000 m above sea

level, max. transport altitude 4500 m above

sea level.

Unless specified otherwise in the data

sheet, a tolerance of ±10% shall apply to

the nominal voltage and of ±5% to the

nominal frequency.

2. Applicable local or national safety

regulations and rules for the prevention of

accidents must be observed in all work

performed. The product may be opened

only by authorized, specially trained

personnel. Prior to performing any work on

the product or opening the product, the

product must be disconnected from the

supply network. Any adjustments,

replacements of parts, maintenance or

repair must be carried out only by technical

personnel authorized by Rohde & Schwarz.

Only original parts may be used for

replacing parts relevant to safety (e.g.

power switches, power transformers,

fuses). A safety test must always be

performed after parts relevant to safety

have been replaced (visual inspection, PE

conductor test, insulation resistance

measurement, leakage current

measurement, functional test).

3. As with all industrially manufactured goods,

the use of substances that induce an

allergic reaction (allergens, e.g. nickel)

such as aluminum cannot be generally

excluded. If you develop an allergic

reaction (such as a skin rash, frequent

sneezing, red eyes or respiratory

difficulties), consult a physician immediately

to determine the cause.

1171.0000.42-03.00 Sheet 2

Safety Instructions

4. If products/components are mechanically

and/or thermically processed in a manner

that goes beyond their intended use,

hazardous substances (heavy-metal dust

such as lead, beryllium, nickel) may be

released. For this reason, the product may

only be disassembled, e.g. for disposal

purposes, by specially trained personnel.

Improper disassembly may be hazardous to

your health. National waste disposal

regulations must be observed.

5. If handling the product yields hazardous

substances or fuels that must be disposed

of in a special way, e.g. coolants or engine

oils that must be replenished regularly, the

safety instructions of the manufacturer of

the hazardous substances or fuels and the

applicable regional waste disposal

regulations must be observed. Also

observe the relevant safety instructions in

the product documentation.

6. Depending on the function, certain products

such as RF radio equipment can produce

an elevated level of electromagnetic

radiation. Considering that unborn life

requires increased protection, pregnant

women should be protected by appropriate

measures. Persons with pacemakers may

also be endangered by electromagnetic

radiation. The employer/operator is

required to assess workplaces where there

is a special risk of exposure to radiation

and, if necessary, take measures to avert

the danger.

7. Operating the products requires special

training and intense concentration. Make

certain that persons who use the products

are physically, mentally and emotionally fit

enough to handle operating the products;

otherwise injuries or material damage may

occur. It is the responsibility of the

employer to select suitable personnel for

operating the products.

8. Prior to switching on the product, it must be

ensured that the nominal voltage setting on

the product matches the nominal voltage of

the AC supply network. If a different voltage

is to be set, the power fuse of the product

may have to be changed accordingly.

9. In the case of products of safety class I with

movable power cord and connector,

operation is permitted only on sockets with

earthing contact and protective earth

connection.

10. Intentionally breaking the protective earth

connection either in the feed line or in the

product itself is not permitted. Doing so can

result in the danger of an electric shock

from the product. If extension cords or

connector strips are implemented, they

must be checked on a regular basis to

ensure that they are safe to use.

11. If the product has no power switch for

disconnection from the AC supply, the plug

of the connecting cable is regarded as the

disconnecting device. In such cases, it

must be ensured that the power plug is

easily reachable and accessible at all times

(corresponding to the length of connecting

cable, approx. 2 m). Functional or

electronic switches are not suitable for

providing disconnection from the AC

supply. If products without power switches

are integrated in racks or systems, a

disconnecting device must be provided at

the system level.

12. Never use the product if the power cable is

damaged. Check the power cable on a

regular basis to ensure that it is in proper

operating condition. By taking appropriate

safety measures and carefully laying the

power cable, ensure that the cable cannot

be damaged and that no one can be hurt by

e.g. tripping over the cable or suffering an

electric shock.

13. The product may be operated only from

TN/TT supply networks fused with max.

16 A (higher fuse only after consulting with

the Rohde & Schwarz group of companies).

14. Do not insert the plug into sockets that are

dusty or dirty. Insert the plug firmly and all

the way into the socket. Otherwise, this can

result in sparks, fire and/or injuries.

15. Do not overload any sockets, extension

cords or connector strips; doing so can

cause fire or electric shocks.

16. For measurements in circuits with voltages

V

> 30 V, suitable measures (e.g.

rms

appropriate measuring equipment, fusing,

current limiting, electrical separation,

insulation) should be taken to avoid any

hazards.

17. Ensure that the connections with

information technology equipment comply

with IEC 950/EN 60950.

18. Unless expressly permitted, never remove

the cover or any part of the housing while

the product is in operation. Doing so will

expose circuits and components and can

lead to injuries, fire or damage to the

product.

1171.0000.42-03.00 Sheet 3

Safety Instructions

19. If a product is to be permanently installed,

the connection between the PE terminal on

site and the product's PE conductor must

be made first before any other connection

is made. The product may be installed and

connected only by a license electrician.

20. For permanently installed equipment

without built-in fuses, circuit breakers or

similar protective devices, the supply circuit

must be fused in such a way that suitable

protection is provided for users and

products.

21. Do not insert any objects into the openings

in the housing that are not designed for this

purpose. Never pour any liquids onto or into

the housing. This can cause short circuits

inside the product and/or electric shocks,

fire or injuries.

22. Use suitable overvoltage protection to

ensure that no overvoltage (such as that

caused by a thunderstorm) can reach the

product. Otherwise the operating personnel

will be endangered by electric shocks.

23. Rohde & Schwarz products are not

protected against penetration of water,

unless otherwise specified (see also safety

instruction 1.). If this is not taken into

account, there exists the danger of electric

shock for the user or damage to the

product, which can also lead to personal

injury.

24. Never use the product under conditions in

which condensation has formed or can form

in or on the product, e.g. if the product was

moved from a cold to a warm environment.

25. Do not close any slots or openings on the

product, since they are necessary for

ventilation and prevent the product from

overheating. Do not place the product on

soft surfaces such as sofas or rugs or

inside a closed housing, unless this is well

ventilated.

26. Do not place the product on heatgenerating devices such as radiators or fan

heaters. The temperature of the

environment must not exceed the maximum

temperature specified in the data sheet.

27. Batteries and storage batteries must not be

exposed to high temperatures or fire. Keep

batteries and storage batteries away from

children. Do not short-circuit batteries and

storage batteries.

If batteries or storage batteries are

improperly replaced, this can cause an

explosion (warning: lithium cells). Replace

the battery or storage battery only with the

matching Rohde & Schwarz type (see

spare parts list). Batteries and storage

batteries must be recycled and kept

separate from residual waste. Batteries and

storage batteries that contain lead, mercury

or cadmium are hazardous waste. Observe

the national regulations regarding waste

disposal and recycling.

28. Please be aware that in the event of a fire,

toxic substances (gases, liquids etc.) that

may be hazardous to your health may

escape from the product.

29. The product can be very heavy. Be careful

when moving it to avoid back or other

physical injuries.

30. Do not place the product on surfaces,

vehicles, cabinets or tables that for reasons

of weight or stability are unsuitable for this

purpose. Always follow the manufacturer's

installation instructions when installing the

product and fastening it to objects or

structures (e.g. walls and shelves).

31. Handles on the products are designed

exclusively for personnel to hold or carry

the product. It is therefore not permissible

to use handles for fastening the product to

or on means of transport such as cranes,

fork lifts, wagons, etc. The user is

responsible for securely fastening the

products to or on the means of transport

and for observing the safety regulations of

the manufacturer of the means of transport.

Noncompliance can result in personal injury

or material damage.

32. If you use the product in a vehicle, it is the

sole responsibility of the driver to drive the

vehicle safely. Adequately secure the

product in the vehicle to prevent injuries or

other damage in the event of an accident.

Never use the product in a moving vehicle if

doing so could distract the driver of the

vehicle. The driver is always responsible for

the safety of the vehicle. The manufacturer

assumes no responsibility for accidents or

collisions.

33. If a laser product (e.g. a CD/DVD drive) is

integrated in a Rohde & Schwarz product,

do not use any other settings or functions

than those described in the product

documentation. Otherwise this may be

hazardous to your health, since the laser

beam can cause irreversible damage to

your eyes. Never try to take such products

apart, and never look into the laser beam.

1171.0000.42-03.00 Sheet 4

DIN EN ISO 9001 : 2000

DIN EN 9100 : 2003

DIN EN ISO 14001 : 1996

DQS REG. NO 001954 QM/ST UM

Certified Quality System

Sehr geehrter Kunde,

Sie haben sich für den Kauf eines

Rohde & Schwarz-Produktes entschieden. Hiermit erhalten Sie ein nach

modernsten Fertigungsmethoden

hergestelltes Produkt. Es wurde nach

den Regeln unseres Managementsystems entwickelt, gefertigt und

geprüft.

Das Rohde & Schwarz Managementsystem ist zertifiziert nach:

DIN EN ISO 9001:2000

DIN EN 9100:2003

DIN EN ISO 14001:1996

Dear Customer,

you have decided to buy a Rohde &

Schwarz product. You are thus assured of receiving a product that is

manufactured using the most modern

methods available. This product was

developed, manufactured and tested

in compliance with our quality management system standards.

The Rohde & Schwarz quality management system is certified according to:

DIN EN ISO 9001:2000

DIN EN 9100:2003

DIN EN ISO 14001:1996

Cher Client,

vous avez choisi d‘acheter un produit

Rohde & Schwarz. Vous disposez

donc d‘un produit fabriqué d‘après

les méthodes les plus avancées. Le

développement, la fabrication et les

tests respectent nos normes de gestion qualité.

Le système de gestion qualité de

Rohde & Schwarz a été homologué

conformément aux normes:

DIN EN ISO 9001:2000

DIN EN 9100:2003

DIN EN ISO 14001:1996

QUALITÄTSZERTIFIKAT CERTIFICATE OF QUALITY CERTIFICAT DE QUALITÉ

1171.0200.11-01.00

Certificate No.: 2002-36, page 1

EC Certificate of Conformity

This is to certify that:

Equipment type

Stock No. Designation

NRP 1143.8500.02 Power Meter

NRP-B1 1146.9008.02 Sensor Check Source

NRP-B2 1146.8801.02 Second Sensor Input

NRP-B3 1146.8501.02 Battery Supply

NRP-B4 1146.9308.02 Ethernet Lan-Interface

NRP-B5 1146.9608.02 3rd und 4th Sensor

NRP-B6 1146.9908.02 Rear-Panel Sensor

complies with the provisions of the Directive of the Council of the European Union on the

approximation of the laws of the Member States

- relating to electrical equipment for use within defined voltage limits

(73/23/EEC revised by 93/68/EEC)

- relating to electromagnetic compatibility

(89/336/EEC revised by 91/263/EEC, 92/31/EEC, 93/68/EEC)

Conformity is proven by compliance with the following standards:

EN61010-1 : 2001-12

EN55011 : 1998 + A1 : 1999, Class B

EN61326 : 1997 + A1 : 1998 + A2 : 2001 + A3 : 2003

For the assessment of electromagnetic compatibility, the limits of radio interference for Class

B equipment as well as the immunity to interference for operation in industry have been used

as a basis.

Affixing the EC conformity mark as from 2002

ROHDE & SCHWARZ GmbH & Co. KG

Munich, 2006-11-23 Central Quality Management FS-QZ / Radde

1143.8500.02 –s1- CE E-10

Mühldorfstr. 15, D-81671 München

Certificate No.: 2002-36, page 2

EC Certificate of Conformity

This is to certify that:

Equipment type

Stock No. Designation

NRP-Z3 1146.7005.02 USB Adapter

NRP-Z4 1146.8001.02/.04 USB Adapter

NRP-Z11 1138.3004.02/.04 Average Power Sensor

NRP-Z21 1137.6000.02 Average Power Sensor

NRP-Z22 1137.7506.02 Average Power Sensor

NRP-Z23 1137.8002.02 Average Power Sensor

NRP-Z24 1137.8502.02 Average Power Sensor

NRP-Z27 1169.4102.02 Power Sensor Module

NRP-Z37 1169.3206.02 Power Sensor Module

NRP-Z51 1138.0005.02 Thermal Power Sensor

NRP-Z55 1138.2008.02 Thermal Power Sensor

NRP-Z81 1137.9009.02 Wideband Power Sensor

NRP-Z91 1168.8004.02/.04 Average Power Sensor

complies with the provisions of the Directive of the Council of the European Union on the

approximation of the laws of the Member States

- relating to electrical equipment for use within defined voltage limits

(73/23/EEC revised by 93/68/EEC)

- relating to electromagnetic compatibility

(89/336/EEC revised by 91/263/EEC, 92/31/EEC, 93/68/EEC)

Conformity is proven by compliance with the following standards:

EN61010-1 : 2001-12

EN55011 : 1998 + A1 : 1999, Class B

EN61326 : 1997 + A1 : 1998 + A2 : 2001 + A3 : 2003

For the assessment of electromagnetic compatibility, the limits of radio interference for Class

B equipment as well as the immunity to interference for operation in industry have been used

as a basis.

Affixing the EC conformity mark as from 2002

ROHDE & SCHWARZ GmbH & Co. KG

Munich, 2006-11-23 Central Quality Management FS-QZ / Radde

1143.8500.02 -s2- CE E-10

Mühldorfstr. 15, D-81671 München

Customer Support

Technical support – where and when you need it

For quick, expert help with any Rohde & Schwarz equipment, contact one of our

Customer Support Centers. A team of highly qualified engineers provides telephone

support and will work with you to find a solution to your query on any aspect of the

operation, programming or applications of Rohde & Schwarz equipment.

Up-to-date information and upgrades

To keep your Rohde & Schwarz equipment always up-to-date,

please subscribe to our electronic newsletter at

http://www.rohde-schwarz.com/www/response.nsf/newsletterpreselection

or request the desired information and upgrades via email from your Customer Support

Center (addresses see below).

Feedback

We want to know if we are meeting your support needs. If you have any comments

please email us and let us know CustomerSupport.Feedback@rohde-schwarz.com.

USA & Canada

East Asia

Rest of the World

Monday to Friday (except US public holidays)

8:00 AM – 8:00 PM

Tel. from USA 888-test-rsa (888-837-8772) (opt 2)

From outside USA +1 410 910 7800 (opt 2)

Fax +1 410 910 7801

E-mail Customer.Support@rsa.rohde-schwarz.com

Monday to Friday (except Singaporean public holidays)

8:30 AM – 6:00 PM Singapore Time (SGT)

Tel. +65 6 513 0488

Fax +65 6 846 1090

E-mail Customersupport.asia@rohde-schwarz.com

Monday to Friday (except German public holidays)

08:00 – 17:00 Central European Time (CET)

Tel. from Europe +49 (0) 180 512 42 42

From outside Europe +49 89 4129 13776

Fax +49 (0) 89 41 29 637 78

Eastern Standard Time (EST)

1171.0200.22-01.00

E-mail CustomerSupport@rohde-schwarz.com

12

Address List

Headquarters, Plants and Subsidiaries

Headquarters

ROHDE& SCHWARZ GmbH & Co. KG

Mühldorfstraße 15 · D-81671 München

P.O.Box 80 14 69 · D-81614 München

Plants

ROHDE& SCHWARZ Messgerätebau GmbH

Riedbachstraße 58 · D-87700 Memmingen

P.O.Box 16 52 · D-87686 Memmingen

ROHDE& SCHWARZ GmbH & Co. KG

Werk Teisnach

Kaikenrieder Straße 27 · D-94244 Teisnach

P.O.Box 11 49 · D-94240 Teisnach

ROHDE& SCHWARZ závod

Vimperk, s.r.o.

Location Spidrova 49

CZ-38501 Vimperk

ROHDE& SCHWARZ GmbH & Co. KG

Dienstleistungszentrum Köln

Graf-Zeppelin-Straße 18 · D-51147 Köln

P.O.Box 98 02 60 · D-51130 Köln

Subsidiaries

R&S BICK Mobilfunk GmbH

Fritz-Hahne-Str. 7 · D-31848 Bad Münder

P.O.Box 20 02 · D-31844 Bad Münder

ROHDE& SCHWARZ FTK GmbH

Wendenschloßstraße 168, Haus 28

D-12557 Berlin

ROHDE& SCHWARZ SIT GmbH

Am Studio 3

D-12489 Berlin

R&S Systems GmbH

Graf-Zeppelin-Straße 18

D-51147 Köln

GEDIS GmbH

Sophienblatt 100

D-24114 Kiel

HAMEG Instruments GmbH

Industriestraße 6

D-63533 Mainhausen

Fax +49 (89) 41 29-121 64

info.rs@rohde-schwarz.com

Phone +49 (83 31) 1 08-0

info.rsmb@rohde-schwarz.com

Phone +49 (99 23) 8 50-0

info.rsdts@rohde-schwarz.com

Phone +420 (388) 45 21 09

Fax +49 (22 03) 49 51-229

info.rsdc@rohde-schwarz.com

service.rsdc@rohde-schwarz.com

Phone +49 (50 42) 9 98-0

info.bick@rohde-schwarz.com

Phone +49 (30) 658 91-122

info.ftk@rohde-schwarz.com

info.sit@rohde-schwarz.com

Phone +49 (22 03) 49-5 23 25

Fax +49 (22 03) 49-5 23 36

info.rssys@rohde-schwarz.com

Phone +49 (431) 600 51-0

Phone +49 (89) 41 29-0

+49 (83 31) 1 08-1124

Fax +49 (99 23) 8 50-174

Fax +420 (388) 45 21 13

Phone +49 (22 03) 49-0

Fax +49 (50 42) 9 98-105

Fax +49 (30) 655 50-221

Phone +49 (30) 658 84-0

Fax +49 (30) 658 84-183

Fax +49 (431) 600 51-11

sales@gedis-online.de

Phone +49 (61 82) 800-0

Fax +49 (61 82) 800-100

info@hameg.de

Locations Worldwide

Please refer to our homepage: www.rohde-schwarz.com

◆ Sales Locations

◆ Service Locations

◆ National Websites

12

1171.0200.42-02.00

R&S NRP Table of Contents Chapter 1

Table of Contents

1 Putting into Operation ......................................................................................................1.1

Notes on putting into operation......................................................................................................1.1

Unpacking the meter...................................................................................................................1.1

Setting up the meter ...................................................................................................................1.2

Front and rear views ........................................................................................................................1.3

Front panel..................................................................................................................................1.3

Rear panel ..................................................................................................................................1.5

Installation in a 19" rack ..................................................................................................................1.7

AC supply voltage ............................................................................................................................1.7

AC supply fuses ...............................................................................................................................1.7

EMC....................................................................................................................................................1.7

Switching the meter on/off ..............................................................................................................1.8

Welcome screen and function test .............................................................................................1.8

Resetting and setting brightness and contrast .........................................................................1.10

ON state....................................................................................................................................1.10

Preset...............................................................................................................................................1.11

1144.1400.12 I-1.1 E-3

R&S NRP Notes on putting into operation

1 Putting into Operation

This Chapter describes putting into operation (unpacking, AC supply connection, switching the meter on

and off), function testing and installing the meter, the preset or default settings and also contains front

and rear views of the meter.

Notes on putting into operation

Before putting the R&S NRP into operation, ensure that

• the sensor inputs are not overloaded,

• the meter’s outputs are not overloaded or wrongly connected,

• the ventilation holes are not obstructed.

The meter may be damaged if these precautions are not observed.

Unpacking the meter

When you have removed the meter from its packing, check that nothing is missing using the delivery

note and the accessory lists.

If there is any damage, contact the carrier. Keep all the packing to support any claims for compensation.

It is also best to use the original packing if the meter has to be shipped or transported at a later date.

1144.1400.12 1.1 E-3

Notes on putting into operation R&S NRP

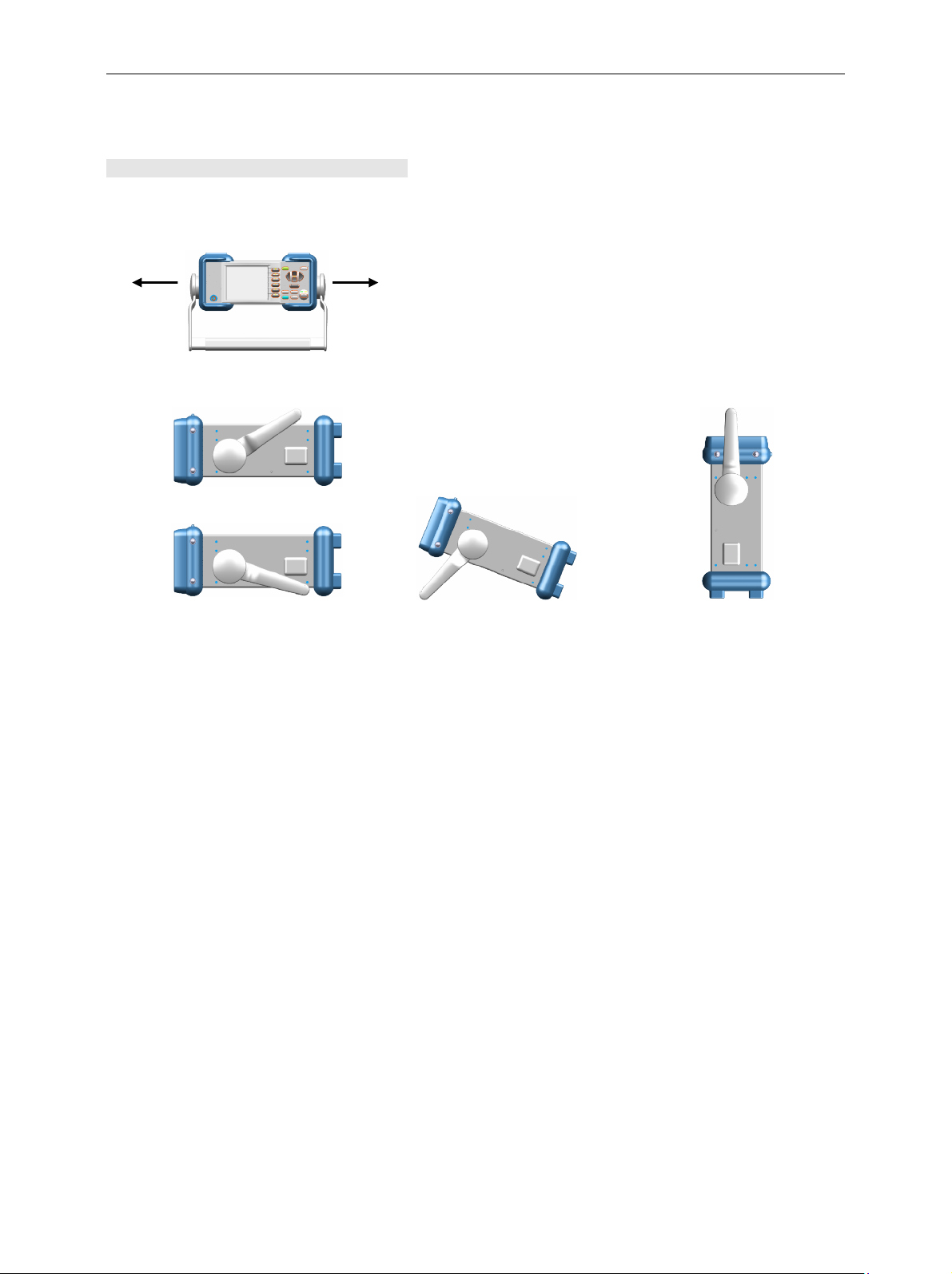

Setting up the meter

Carrying handle

If the R&S NRP is not installed in a rack, it should be set up

so that the viewing angle for the display is optimal. The

carrying handle can be locked in a variety of positions to

act as a stand.

To adjust the handle, pull the two side-pieces of the handle

outwards so that the handle can be rotated.

The handle locks at angles which are multiples of 60°.

1144.1400.12 1.2 E-3

R&S NRP Front and rear views

Front and rear views

.

NRP POWER METER

MENU

TRIGDEL/1

Front panel

Sensor connector

E

SC LOCAL

(

PRE SET

F

/

REQ

)

ZERO CAL

/

The front panel accommodates a maximum of two sensor

connectors (for sensors A and B). The power sensors are

connected by inserting the male connector. To disconnect

hold the connector by its sleeve. Pulling on the sensor cable will not release the sensor connector.

Test generator

POW ER REF

The test generator connector (option R&S NRP-B1) provides a high-precision, unmodulated sine signal with a

power of 1 mW and a frequency of 50 MHz for checking

the sensors.

The generator is turned on and off from the

System menu

(see Chapter 4.6 System Settings).

1144.1400.12 1.3 E-3

Front and rear views R&S NRP

eypad

K

See Chapter 3 (Manual Operation).

M

ENU

ESC LOCAL

/

()

P

RE SET

FREQ

ZERO CAL

/

TRIGDEL/1

1144.1400.12 1.4 E-3

R&S NRP Front and rear views

means of PC downloads (for more information, see the

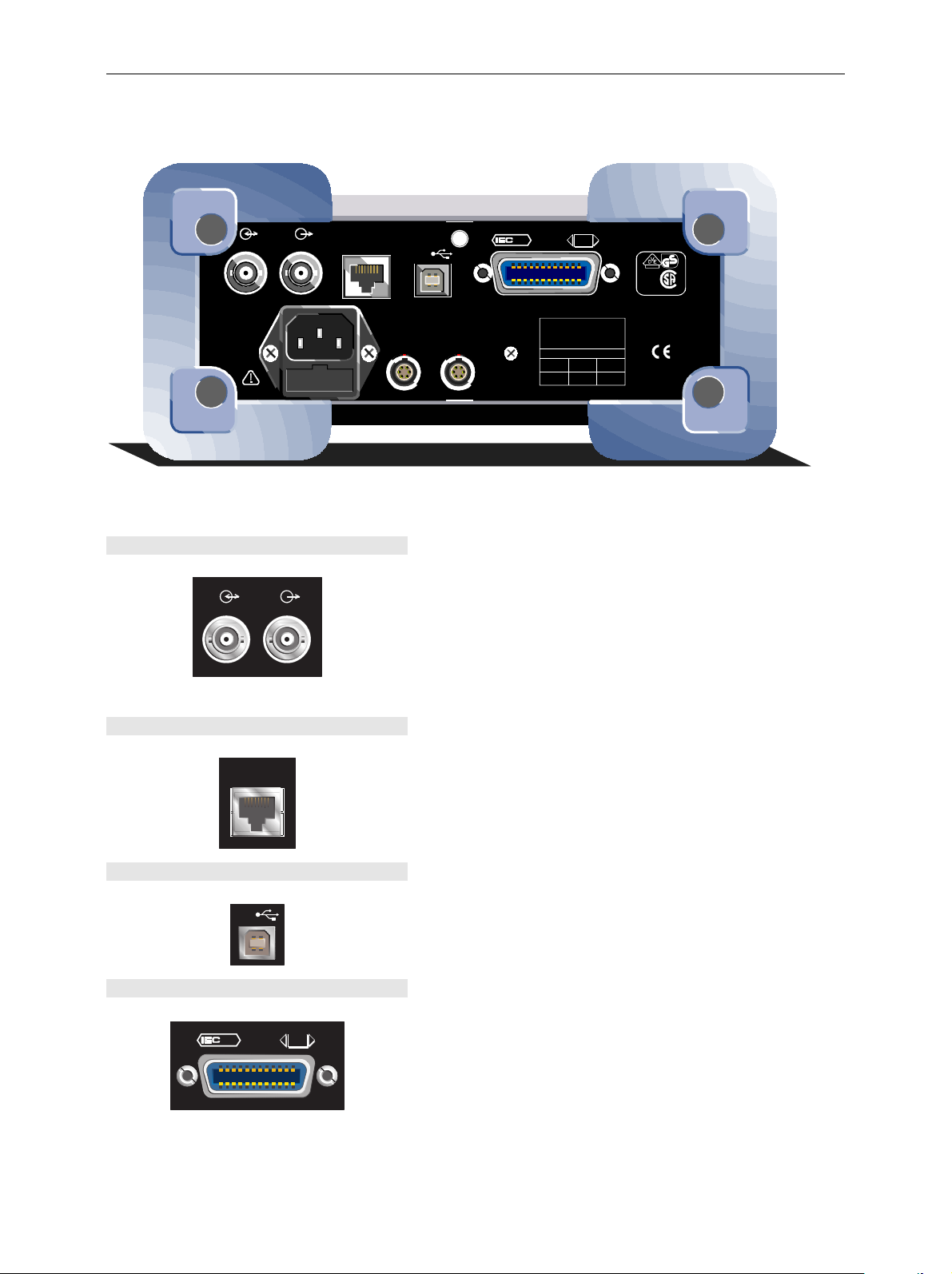

Rear panel

6

TRIG / OUT 2

AUTOMATIC POWER SELECTI ON

100 ... 120 V 50 .. . 400 Hz

220 ... 240 V 50 .. . 60 Hz

80 VA

1/F2: IEC 127

F

2.0 H / 250 V

T

ETHERNETOUT 1

USB

SENSOR INPUT

D (B)C (A)

25

IEEE 488

SC PI

OPTION I NCL.

R114 196

L

C®U

S

OUT1 and TRIG / OUT2

TRIG / OUT 2

Ethernet

Ethernet

USB

USB

IEC/IEEE bus

625

IEEE 488

OUT 1

SCPI

The BNC connector OUT1 outputs an analog signal with a

voltage between 0V and 3.3 V. It can be used to output a

voltage that is proportional to the measured value (e.g. for

level regulation) or a digital signal for threshold monitoring.

The BNC connector TRIG / OUT2 can be used either as an

external trigger input or as a second analog output.

System

The inputs/outputs are configured from the

menu

(see Chapter 4.6 System Settings).

The Ethernet connector (option R&S NRP-B4) is an RJ45

socket for remote controlling the R&S NRP via a network.

The type-B USB connector is used to update firmware by

service manual, Chapter 4).

The IEC/IEEE bus connector to IEEE488 is used to remote

control the R&S NRP.

1144.1400.12 1.5 E-3

Front and rear views R&S NRP

C supply connector

A

The AC supply connector comprises a standard, IEC lowtemperature connector and contains a fuse holder for two

miniature fuses. The fuse holder can be taken out with a

screwdriver.

See AC supply voltage on page 1.7 for more on connecting the AC supply.

Sensor connectors

S

ENSO R INPUT

Sensor connectors A and B (option R&S NRP-B6) or C and

D (option R&S NRP-B5) can be accommodated on the rear

panel.

D (B )C (A )

1144.1400.12 1.6 E-3

R&S NRP Installation in a 19" rack

Installation in a 19" rack

Caution

If the meter is rack-mounted ensure there is a free flow of air through the holes in the

The R&S NRP can be installed in 19" racks using a variety of rack adapters (see data sheet for order

Nos.). The installation instructions come with the adapter.

side panels.

AC supply voltage

The R&S NRP can be operated from AC lines with a voltage range of 100 V to 240 V and a frequency

range of 50 Hz to 60 Hz. Note that a restricted voltage range (100 V to 120 V) applies to 400 Hz networks. The AC supply connector is at the rear of the meter. The meter sets itself automatically to the

applied voltage if it is in range.

AC supply fuses

The R&S NRP has two fuses as indicated by the type plate. The fuses are accommodated in a fuse

holder in the AC supply connector. The holder can be pulled out to insert fuses. The power supply has

its own fuse.

Caution

Only the service department may replace the internal fuse.

AC supply connector

Fuse holder

AC supply connector at the rear of the meter

EMC

To prevent EMI, the meter must always be installed to meet the relevant EMC standards. Never operate

the instrument with its enclosure removed. Only use shielded signal and control cables that meet the

relevant EMC standards.

1144.1400.12 1.7 E-3

Switching the meter on/off R&S NRP

Switching the meter on/off

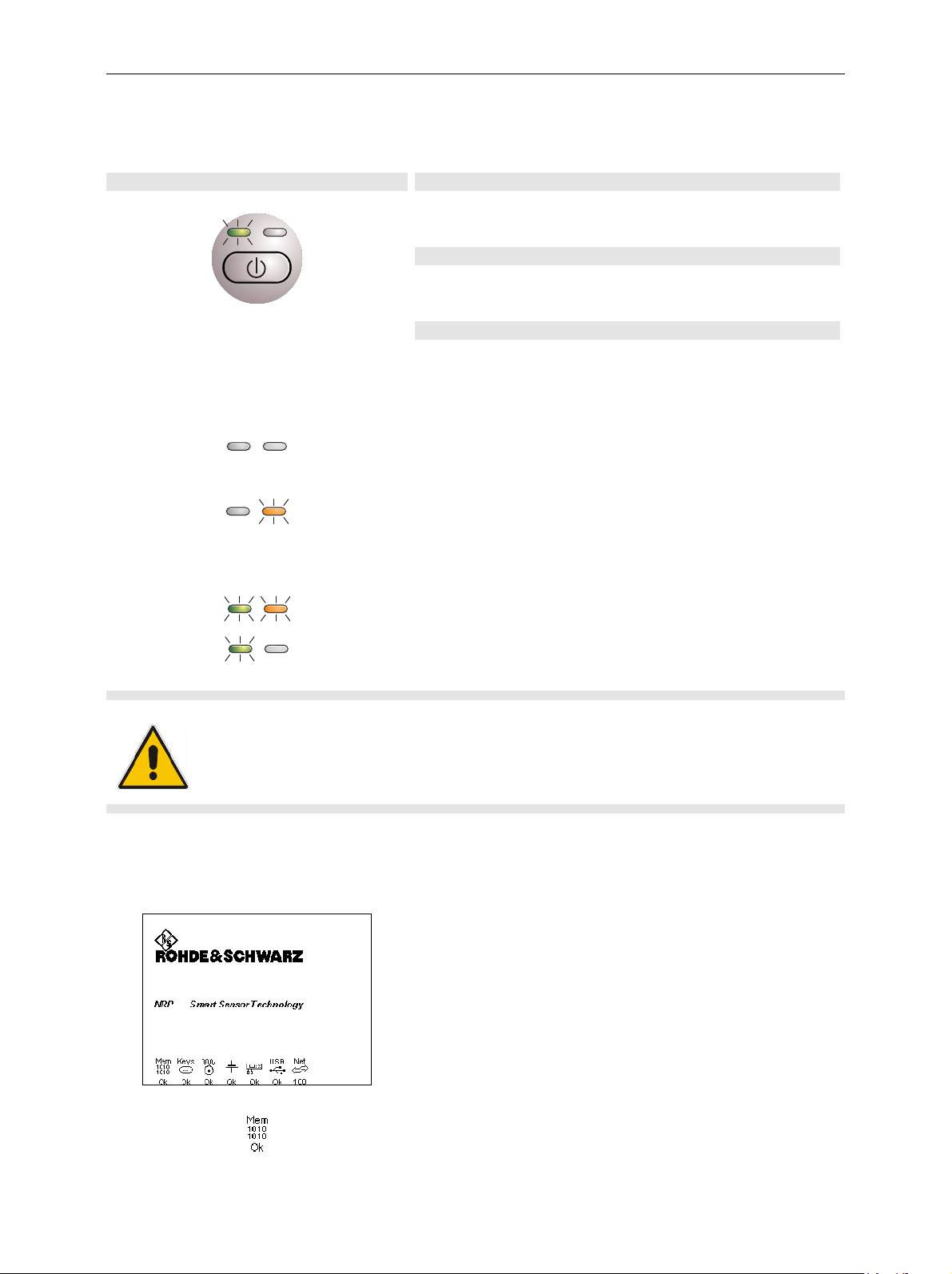

ON/STANDBY key

The following are, therefore, the possible operating states:

( Ø ) key

The ON/STANDBY key is used to toggle between the on

and standby states.

Yellow LED (AC supply)

The yellow LED indicates that the AC supply is connected

to the R&S NRP.

Green LED (ON)

The green LED indicates when the meter is on.

The meter is off and disconnected from the AC supply.

The meter is on standby. The AC supply is connected and

the power supply is operating correctly.

If option R&S NRP-B3 (battery) has been installed, automatic charging will be started if the battery is low.

The meter is on and is being powered from the AC supply.

The meter is on and is being battery powered (only applies

if option R&S NRP-B3 has been installed).

Caution

If you want to completely isolate the meter from the AC supply, pull out the AC supply

plug. Selecting the standby mode does not disconnect the AC supply.

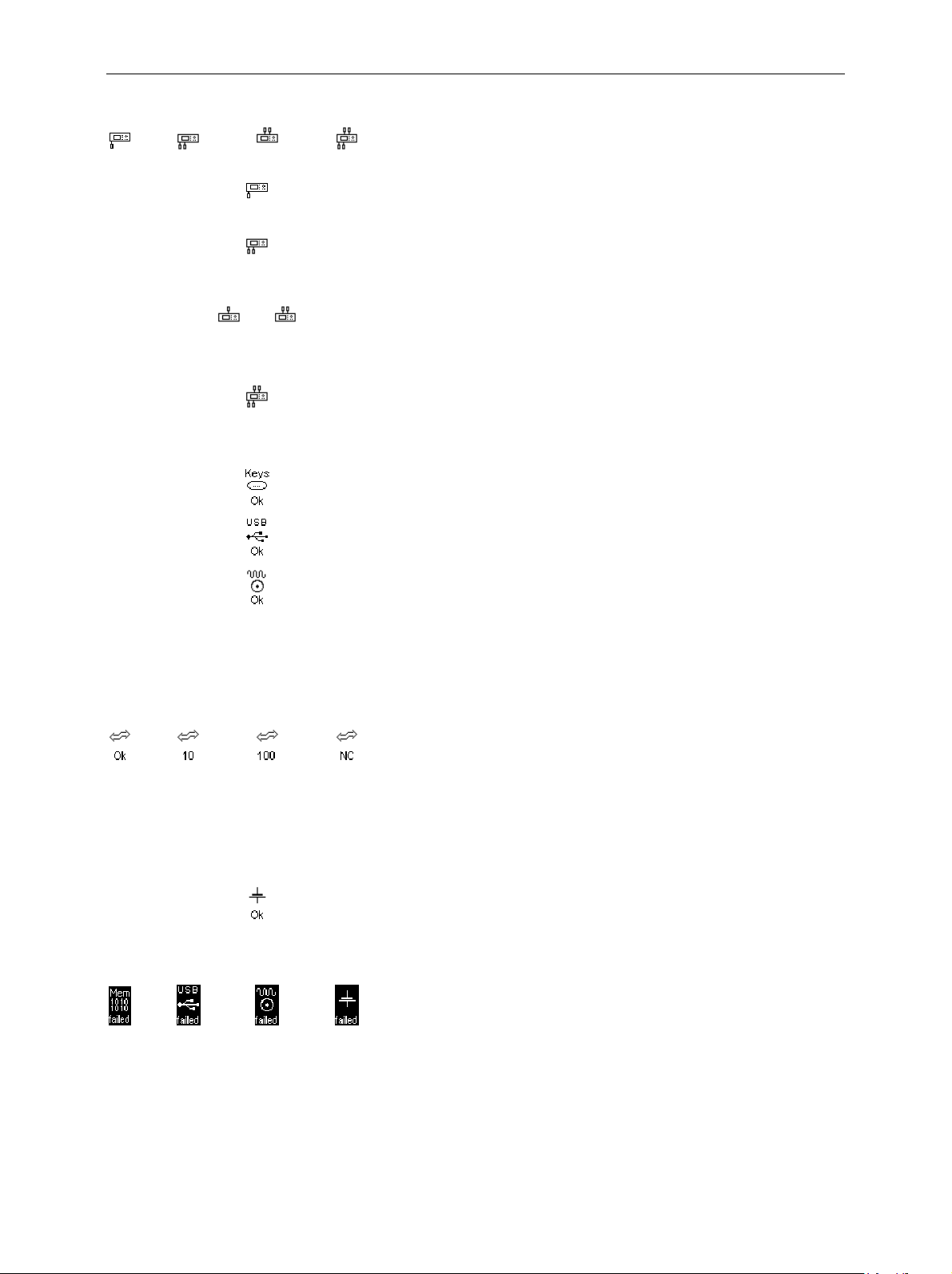

Welcome screen and function test

After switch-on, the R&S NRP performs a selftest. The contents of all non-volatile memories, the RAM and the addressability of all interfaces is checked. Messages indicate

which options have been installed.

Function test on the RAM.

1144.1400.12 1.8 E-3

R&S NRP Switching the meter on/off

Addressability check on the interfaces for the sensor channels. Only one of the icons shown on the left is displayed to

show the number of channels that have been installed.

Channel A.

Appears if the device is single-channel.

Channel A or channels A and B, fitted on the front panel.

Appears only if option R&S NRP-B2 is installed

(second measurement input).

Channels A and B, fitted on the rear panel.

Appears only if option R&S NRP-B6 is installed at the rear

(sensor connectors A (B)).

Channels A to D.

Appears only if option R&S NRP-B5 is installed

(3rd and 4th measurement input).

Addressability check on the keypad controller.

Addressability check on the USB interface at the rear of the

meter.

Addressability check on the test generator.

Appears only if option R&S NRP-B1 is installed.

(test generator).

Addressability test on the Ethernet interface. The transmission rate is displayed.

Appears only if option R&S NRP-B4 is installed

(Ethernet).

The “Ok” below the network icon indicates that the interface can be addressed.

If the R&S NRP is not connected to a network hub or if a

connection cannot be established during booting, the message NC (Not Connected) is displayed instead of OK. It is

however possible to establish a network connection later

on at any time.

Addressability check on the battery and charging regulator.

Appears only if option R&S NRP-B3 (battery) is installed.

If an error occurs when an interface test is being performed,

the message failed is displayed under the appropriate icon

and the icon is shown in inverse video. When all the tests

are completed, booting is interrupted; booting can be restarted by pressing the

continue softkey.

1144.1400.12 1.9 E-3

Switching the meter on/off R&S NRP

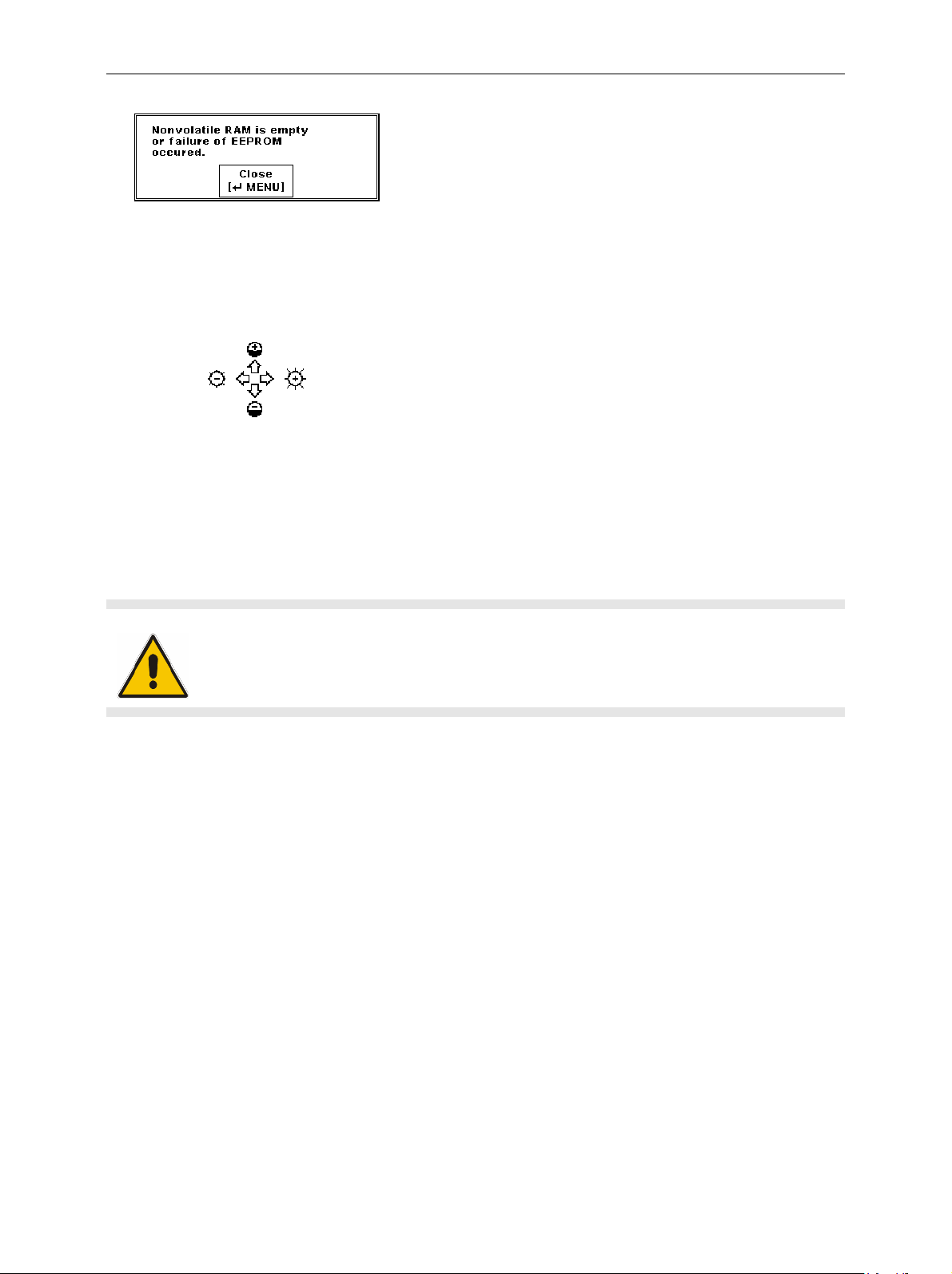

If an error is detected when the non-volatile memory containing instrument settings is checked, an error message is displayed when booting is completed. The non-volatile memory

is then re-initialized completely and the R&S NRP goes into

the preset state. All instrument settings that have been

saved are lost as a result of this procedure.

Resetting and setting brightness and contrast

If you press the (Æ) key immediately after switching on the

R&S NRP, after about 3 seconds the R&S NRP goes into a

state in which you can adjust brightness and contrast.

Initially, contrast and brightness are automatically set to

their default values. You can then make the settings you

want using the diagram on the screen.

ON state

Whenever the meter is switched off, its settings are saved. The next time it is switched on, these settings are automatically restored.

If the last setup before switch-off is to be restored, the R&S NRP must be switched off

with the standby key ( Ø ). If the meter is turned off by disconnecting the AC supply, it is

possible that the settings being used immediately beforehand are not saved.

1144.1400.12 1.10 E-3

Loading...

Loading...