Page 1

R&S®LCX Series

LCR Meter

User Manual

(;ÝFÊ2)

1179226002

Version 02

Page 2

This manual describes the instruments of the R&S®LCX Series, including options and measurement

accessories:

●

R&S®LCX100 LCR Meter(3629.8856.02)

●

R&S®LCX200 LCR Meter (3629.8856.03)

●

R&S®NG-B105 Option IEE 488 (GPIB) interface (5601.6000.02)

●

R&S®LCX-K106 Option advanced analysis (3630.1922.03)

●

R&S®LCX-K107 Option digital I/O ports and binning (3660.7741.03)

●

R&S®LCX-K108 Option extended bias (3692.9791.03)

●

R&S®LCX-K201 Option frequency upgrade 1 MHz (3630.1880..03)

●

R&S®LCX-K210 Option frequency upgrade 10 MHz (3630.1900.03)

●

R&S®LCX-Z1 Accessory test fixture for axial/radial lead type components (3639.2296.02)

●

R&S®LCX-Z2 Accessory Kelvin clip lead (3638.6446.02)

●

R&S®LCX-Z3 Accessory test fixture for SMD components (3639.2509.02)

●

R&S®LCX-Z4 Accessory test tweezers for SMD components (3639.2515.02)

●

R&S®LCX-Z5 Accessory transformer test cables (3639.2521.02)

●

R&S®LCX-Z11 Accessory BNC-to-BNC extension (1m) (3639.2538.02)

© 2022 Rohde & Schwarz GmbH & Co. KG

Muehldorfstr. 15, 81671 Muenchen, Germany

Phone: +49 89 41 29 - 0

Email: info@rohde-schwarz.com

Internet: www.rohde-schwarz.com

Subject to change – data without tolerance limits is not binding.

R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

Trade names are trademarks of the owners.

1179.2260.02 | Version 02 | R&S®LCX Series

Throughout this manual, products from Rohde & Schwarz are indicated without the ® symbol, and the instruments of the R&S®LCX

series are abbreviated as R&S LCX. For example, R&S®LCX200 is indicated as R&S LCX.

Page 3

R&S®LCX Series

1 Safety and regulatory information........................................................9

1.1 Safety instructions........................................................................................................9

1.2 Labels on the R&S LCX.............................................................................................. 11

1.3 Warning messages in the documentation................................................................ 12

1.4 Korea certification class A......................................................................................... 12

2 Welcome............................................................................................... 13

2.1 Key features.................................................................................................................13

3 Documentation overview.....................................................................14

3.1 Getting started manual............................................................................................... 14

3.2 User manual.................................................................................................................14

Contents

Contents

3.3 Tutorials....................................................................................................................... 14

3.4 Service manual............................................................................................................14

3.5 Instrument security procedures................................................................................ 14

3.6 Printed safety instructions.........................................................................................15

3.7 Data sheets and brochures........................................................................................ 15

3.8 Release notes and open-source acknowledgment (OSA).......................................15

3.9 Application notes, application cards, white papers, etc......................................... 15

3.10 Remote control driver.................................................................................................15

4 Getting started......................................................................................16

4.1 Preparing for use........................................................................................................ 16

4.1.1 Lifting and carrying........................................................................................................16

4.1.2 Unpacking and checking............................................................................................... 16

4.1.3 Choosing the operating site.......................................................................................... 16

4.1.4 Setting up the R&S LCX................................................................................................17

4.1.5 Considerations for test setup........................................................................................ 18

4.1.6 Connecting to power..................................................................................................... 19

4.1.7 Connecting to LAN........................................................................................................ 21

4.1.8 Connecting USB devices.............................................................................................. 22

4.1.9 Connecting a test fixture............................................................................................... 23

4.1.10 Switching on or off.........................................................................................................25

3User Manual 1179.2260.02 ─ 02

Page 4

R&S®LCX Series

4.2 Instrument tour............................................................................................................25

4.2.1 Front panel tour.............................................................................................................26

4.2.2 Rear panel tour............................................................................................................. 29

4.3 Trying out the instrument...........................................................................................32

4.4 Instrument control...................................................................................................... 35

4.4.1 Ways to operate the instrument.................................................................................... 35

4.4.2 Means of manual interaction......................................................................................... 35

4.4.3 Remote control..............................................................................................................46

5 Measurement basics............................................................................47

5.1 Impedance measurement parameters in general.....................................................47

5.2 Impedance measurement parameters of the R&S LCX........................................... 48

5.3 Considerations on measurement accuracy..............................................................50

Contents

6 Measurement setups........................................................................... 52

6.1 About test fixtures...................................................................................................... 52

6.1.1 Test fixture for axial/radial lead type components......................................................... 52

6.1.2 Kelvin clip lead.............................................................................................................. 53

6.1.3 Test fixture for SMD components..................................................................................54

6.1.4 Test tweezers for SMD components............................................................................. 54

6.1.5 Test fixture with cables for transformer components.....................................................55

6.1.6 BNC-to-BNC extension................................................................................................. 57

6.2 Configuring the test signal.........................................................................................57

6.3 Configuring BIAS........................................................................................................ 59

6.3.1 Internal bias voltage...................................................................................................... 59

6.3.2 External voltage bias.....................................................................................................60

6.3.3 Current bias...................................................................................................................61

7 Performing measurements..................................................................63

8 Instrument functions........................................................................... 67

8.1 Measurement mode.................................................................................................... 67

8.1.1 Measurement mode settings.........................................................................................67

8.1.2 Working with the measurement modes.........................................................................68

8.2 Display mode...............................................................................................................69

8.2.1 Display mode settings................................................................................................... 69

4User Manual 1179.2260.02 ─ 02

Page 5

R&S®LCX Series

8.2.2 Configuring the main view.............................................................................................70

8.3 Measurement functions..............................................................................................70

8.4 Test signal functions...................................................................................................71

8.4.1 Test signal settings........................................................................................................71

8.5 Measurement control functions.................................................................................72

8.6 Measurement parameters...........................................................................................73

8.6.1 Measurement parameter settings................................................................................. 75

8.6.2 Open/short/load correction settings.............................................................................. 78

8.6.3 Setting measurement parameters.................................................................................80

8.7 Configuration preset...................................................................................................82

8.7.1 Configuration preset settings........................................................................................ 83

8.7.2 Using the configuration preset function.........................................................................84

8.8 Specific instrument functions....................................................................................85

Contents

8.8.1 Live chart viewer........................................................................................................... 86

8.8.2 Logging chart viewer..................................................................................................... 89

8.8.3 Logging......................................................................................................................... 94

8.8.4 Dynamic impedance measurement...............................................................................98

8.8.5 Binning........................................................................................................................ 102

9 General instrument settings..............................................................111

9.1 File and data management....................................................................................... 112

9.1.1 File manager settings.................................................................................................. 113

9.1.2 Using the file manager.................................................................................................114

9.1.3 Data and file types.......................................................................................................116

9.2 Interfaces................................................................................................................... 116

9.2.1 Interface settings......................................................................................................... 117

9.2.2 Configuring interfaces..................................................................................................118

9.3 User button................................................................................................................ 118

9.3.1 User button settings.....................................................................................................118

9.3.2 Using the user button function.....................................................................................119

9.4 Screenshot.................................................................................................................119

9.4.1 Screenshot settings.....................................................................................................120

9.4.2 Using the screenshot function.....................................................................................120

9.5 CSV settings.............................................................................................................. 122

5User Manual 1179.2260.02 ─ 02

Page 6

R&S®LCX Series

9.5.1 Settings for CSV data..................................................................................................122

9.5.2 Configuring CSV data................................................................................................. 123

9.6 Date & time................................................................................................................ 123

9.7 Appearance................................................................................................................124

9.8 Sound......................................................................................................................... 125

9.9 Licenses.....................................................................................................................126

9.9.1 Licenses settings.........................................................................................................126

9.9.2 Managing licenses...................................................................................................... 127

9.10 Device information....................................................................................................129

9.10.1 Device information settings......................................................................................... 129

9.10.2 Using the dump file function........................................................................................130

9.11 Update device............................................................................................................131

9.11.1 Update device settings................................................................................................131

Contents

9.11.2 Updating the instrument software............................................................................... 132

9.12 Save/recall................................................................................................................. 133

9.12.1 Save/recall settings..................................................................................................... 133

9.12.2 Using the save/recall function..................................................................................... 134

9.13 Customizing general instrument settings.............................................................. 136

10 Network operation and remote control............................................ 139

10.1 Overview of remote access modes......................................................................... 140

10.2 Remote control interfaces and protocols............................................................... 141

10.2.1 LAN interface.............................................................................................................. 142

10.2.2 USB interface.............................................................................................................. 144

10.2.3 GPIB interface (IEC/IEEE bus interface).....................................................................145

10.2.4 Status reporting system.............................................................................................. 146

10.3 Remote access settings........................................................................................... 149

10.3.1 Network settings..........................................................................................................149

10.3.2 LAN settings................................................................................................................151

10.3.3 VNC settings............................................................................................................... 153

10.3.4 FTP settings................................................................................................................ 154

10.3.5 USB settings............................................................................................................... 156

10.3.6 GPIB settings.............................................................................................................. 157

10.4 Connecting the R&S LCX for remote access......................................................... 158

6User Manual 1179.2260.02 ─ 02

Page 7

R&S®LCX Series

10.5 Adjusting interface addresses.................................................................................159

10.6 Operating the R&S LCX remotely............................................................................ 163

10.6.1 Controlling the R&S LCX over LAN.............................................................................164

10.6.2 Accessing the file system of the R&S LCX using FTP................................................ 167

11 Remote control commands...............................................................171

11.1 Conventions used in SCPI command description.................................................171

11.2 Programming examples........................................................................................... 172

11.3 Common commands.................................................................................................172

11.4 Test signal commands..............................................................................................175

11.5 BIAS subsystem........................................................................................................178

11.6 CORRection subsystem........................................................................................... 180

11.7 DATA subsystem.......................................................................................................186

Contents

11.8 DIMeasure subsystem.............................................................................................. 188

11.9 DISPLay subsystem..................................................................................................192

11.10 FUNCtion subsystem................................................................................................194

11.11 HANDler subsystem..................................................................................................198

11.12 LOG subsystem.........................................................................................................200

11.13 Measurement commands.........................................................................................204

11.14 STATus subsystem....................................................................................................208

11.14.1 Status operation register............................................................................................. 208

11.14.2 Status questionable register........................................................................................210

11.15 SYSTem subsystem.................................................................................................. 211

12 Troubleshooting................................................................................. 222

12.1 Displaying status information..................................................................................222

12.2 Problems during firmware update...........................................................................222

12.3 Cannot establish a LAN connection........................................................................223

12.4 Contacting customer support..................................................................................223

13 Transporting.......................................................................................224

14 Maintenance, storage and disposal................................................. 225

14.1 Cleaning..................................................................................................................... 225

14.2 Changing fuses......................................................................................................... 225

14.3 Storage.......................................................................................................................225

7User Manual 1179.2260.02 ─ 02

Page 8

R&S®LCX Series

14.4 Disposal..................................................................................................................... 225

Contents

Glossary: List of the often used terms and abbreviations.............227

List of commands.............................................................................. 230

Index....................................................................................................233

8User Manual 1179.2260.02 ─ 02

Page 9

R&S®LCX Series

1 Safety and regulatory information

Safety and regulatory information

Safety instructions

The product documentation helps you use the product safely and efficiently. Follow the

instructions provided here and in the following chapters.

Intended use

The product is intended for the development, production and verification of electronic

components and devices in industrial, administrative, and laboratory environments.

Use the product only for its designated purpose. Observe the operating conditions and

performance limits stated in the data sheet.

Where do I find safety information?

Safety information is part of the product documentation. It warns you of potential dangers and gives instructions on how to prevent personal injury or damage caused by

dangerous situations. Safety information is provided as follows:

●

In Chapter 1.1, "Safety instructions", on page 9. The same information is provided in many languages as printed "Safety Instructions". The printed "Safety

Instructions" are delivered with the product.

●

Throughout the documentation, safety instructions are provided when you need to

take care during setup or operation.

1.1 Safety instructions

Products from the Rohde & Schwarz group of companies are manufactured according

to the highest technical standards. To use the products safely, follow the instructions

provided here and in the product documentation. Keep the product documentation

nearby and offer it to other users.

Use the product only for its intended use and within its performance limits. Intended

use and limits are described in the product documentation such as the data sheet,

manuals and the printed "Safety Instructions". If you are unsure about the appropriate

use, contact Rohde & Schwarz customer service.

Using the product requires specialists or specially trained personnel. These users also

need sound knowledge of at least one of the languages in which the user interfaces

and the product documentation are available.

Never open the casing of the product. Only service personnel authorized by

Rohde & Schwarz are allowed to repair the product. If any part of the product is damaged or broken, stop using the product. Contact Rohde & Schwarz customer service at

http://www.customersupport.rohde-schwarz.com.

Lifting and carrying the product

The maximum weight of the product is provided in the data sheet. To move the product

safely, you can use lifting or transporting equipment such as lift trucks and forklifts. Follow the instructions provided by the equipment manufacturer.

9User Manual 1179.2260.02 ─ 02

Page 10

R&S®LCX Series

Safety and regulatory information

Safety instructions

Choosing the operating site

Only use the product indoors. The product casing is not waterproof. Water that enters

can electrically connect the casing with live parts, which can lead to electric shock,

serious personal injury or death if you touch the casing. If Rohde & Schwarz provides

accessories designed for your product, e.g. a carrying bag, you can use the product

outdoors.

Unless otherwise specified, you can operate the product up to an altitude of 2000 m

above sea level. The product is suitable for pollution degree 2 environments where

nonconductive contamination can occur. For more information on environmental conditions such as ambient temperature and humidity, see the data sheet.

Setting up the product

Always place the product on a stable, flat and level surface with the bottom of the product facing down. If the product is designed for different positions, secure the product so

that it cannot fall over.

If the product has foldable feet, always fold the feet completely in or out to ensure stability. The feet can collapse if they are not folded out completely or if the product is

moved without lifting it. The foldable feet are designed to carry the weight of the product, but not an extra load.

If stacking is possible, keep in mind that a stack of products can fall over and cause

injury.

If you mount products in a rack, ensure that the rack has sufficient load capacity and

stability. Observe the specifications of the rack manufacturer. Always install the products from the bottom shelf to the top shelf so that the rack stands securely. Secure the

product so that it cannot fall off the rack.

Connecting to power

The product is an overvoltage category II product. Connect the product to a fixed

installation used to supply energy-consuming equipment such as household appliances and similar loads. Keep in mind that electrically powered products have risks, such

as electric shock, fire, personal injury or even death.

Take the following measures for your safety:

●

Before switching on the product, ensure that the voltage and frequency indicated

on the product match the available power source. If the power adapter does not

adjust automatically, set the correct value and check the rating of the fuse.

●

If a product has an exchangeable fuse, its type and characteristics are indicated

next to the fuse holder. Before changing the fuse, switch off the instrument and disconnect it from the power source. How to change the fuse is described in the product documentation.

●

Only use the power cable delivered with the product. It complies with country-specific safety requirements. Only insert the plug into an outlet with protective conductor terminal.

●

Only use intact cables and route them carefully so that they cannot be damaged.

Check the power cables regularly to ensure that they are undamaged. Also ensure

that nobody can trip over loose cables.

10User Manual 1179.2260.02 ─ 02

Page 11

R&S®LCX Series

Safety and regulatory information

Labels on the R&S LCX

●

If the product needs an external power supply, use the power supply that is delivered with the product or that is recommended in the product documentation or a

power supply that conforms to the country-specific regulations.

●

Only connect the product to a power source with a fuse protection of maximum

20 A.

●

Ensure that you can disconnect the product from the power source at any time.

Pull the power plug to disconnect the product. The power plug must be easily

accessible. If the product is integrated into a system that does not meet these

requirements, provide an easily accessible circuit breaker at the system level.

Cleaning the product

Use a dry, lint-free cloth to clean the product. When cleaning, keep in mind that the

casing is not waterproof. Do not use liquid cleaning agents.

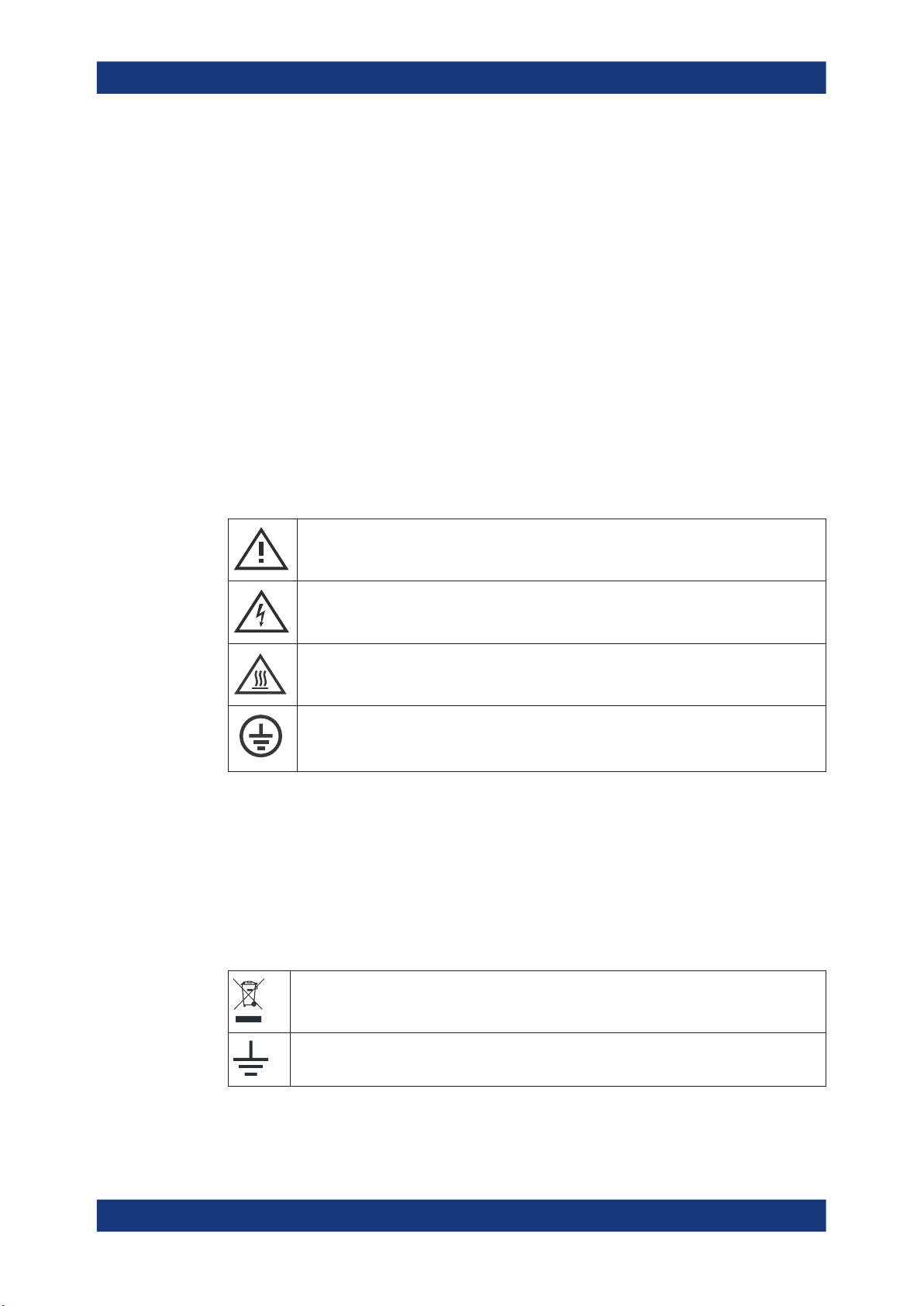

Meaning of safety labels

Safety labels on the product warn against potential hazards.

Potential hazard

Read the product documentation to avoid personal injury or product damage.

Electrical hazard

Indicates live parts. Risk of electric shock, fire, personal injury or even death.

Hot surface

Do not touch. Risk of skin burns. Risk of fire.

Protective conductor terminal

Connect this terminal to a grounded external conductor or to protective ground. This connec-

tion protects you against electric shock if an electric problem occurs.

1.2 Labels on the R&S LCX

Labels on the casing inform about:

●

Personal safety, see "Meaning of safety labels" on page 11.

●

Product and environment safety, see Table 1-1.

Table 1-1: Labels regarding R&S

LCX and environment safety

Labeling in line with EN 50419 for disposal of electrical and electronic equipment after the product has come to the end of its service life. For more information, see "Disposing electrical and

electronic equipment" on page 226.

Grounding connection

11User Manual 1179.2260.02 ─ 02

Page 12

R&S®LCX Series

1.3 Warning messages in the documentation

Safety and regulatory information

Korea certification class A

Chassis grounding connection

Noiseless ground.

The input signal at these connectors must be free from external voltages. The measurement

results are otherwise incorrect.

A warning message points out a risk or danger that you need to be aware of. The signal word indicates the severity of the safety hazard and how likely it will occur if you do

not follow the safety precautions.

DANGER

Imminently hazardous situation. Will result in death or serious injury if not avoided.

WARNING

Potentially hazardous situation. Could result in death or serious injury if not avoided.

CAUTION

Potentially hazardous situation. Could result in minor or moderate injury if not avoided.

NOTICE

Potential risks of damage. Could result in damage to the supported product or to other

property.

1.4 Korea certification class A

이 기기는 업무용(A급) 전자파 적합기기로서 판매자 또는 사용자는 이 점을 주의하시기

바라며, 가정외의 지역에서 사용하는 것을 목적으로 합니다.

12User Manual 1179.2260.02 ─ 02

Page 13

R&S®LCX Series

2 Welcome

2.1 Key features

Welcome

Key features

The R&S LCX LCR Meter sets standards in analyzing passive components. It provides

the full range of measurements to characterize resistors, capacitors and inductors, and

displays results as absolute, relative or average values.

Outstanding key features are:

●

Frequency range: 4 kHz to 300 kHz (R&S LCX100), and up to 10 MHz

(R&S LCX200)

●

Measurement functions: L, C, R, |Z|, X, |Y|, G, B, D, Q, Φ, ∆, M, N

●

Basic accuracy: 0.05 %

●

Continuous, manual or external control via interface, binning interface or trigger

●

Digital I/O ports and binning function for automatic sorting of components (option

R&S LCX-K107)

●

LAN, USB interface for remote control, optionally IEEE-488 (GPIB) bus interface

(option R&S NG-B105)

For details on the specification, see the data sheet.

13User Manual 1179.2260.02 ─ 02

Page 14

R&S®LCX Series

3 Documentation overview

3.1 Getting started manual

3.2 User manual

Documentation overview

Instrument security procedures

This section provides an overview of the R&S LCX user documentation. Unless specified otherwise, you find the documents on the R&S LCX product page at:

www.rohde-schwarz.com/manual/lcx

Introduces the R&S LCX and describes how to set up and start working with the product. Includes basic operations, typical measurement examples, and general information, e.g. safety instructions, etc. A printed version is delivered with the instrument.

The user manual contains the description of all instrument modes and functions. It also

provides an introduction to remote control, a complete description of the remote control

commands with programming examples, and information on maintenance, instrument

interfaces and error messages. Includes the contents of the getting started manual.

The user manual is also available for download or for immediate display on the Internet.

3.3 Tutorials

Tutorials offer guided examples and demonstrations on operating the R&S LCX. They

are provided on the product page of the internet.

3.4 Service manual

Describes the performance test for checking compliance with rated specifications, firmware update and maintenance.

The service manual is available for registered users on the global Rohde & Schwarz

information system (GLORIS): https://gloris.rohde-schwarz.com

3.5 Instrument security procedures

Deals with security issues when working with the R&S LCX in secure areas. It is available for download on the Internet.

14User Manual 1179.2260.02 ─ 02

Page 15

R&S®LCX Series

3.6 Printed safety instructions

3.7 Data sheets and brochures

3.8 Release notes and open-source acknowledgment

Documentation overview

Remote control driver

Provides safety information in many languages. The printed document is delivered with

the product.

The data sheet contains the technical specifications of the R&S LCX. It also lists the

firmware applications and their order numbers, and optional accessories.

The brochure provides an overview of the instrument and deals with the specific characteristics.

See www.rohde-schwarz.com/brochure-datasheet/lcx

(OSA)

The release notes list new features, improvements and known issues of the current

firmware version, and describe the firmware installation.

The open-source acknowledgment document provides verbatim license texts of the

used open source software.

See www.rohde-schwarz.com/firmware/lcx

3.9 Application notes, application cards, white papers, etc.

These documents deal with special applications or background information on particular topics.

See www.rohde-schwarz.com/application/lcx

3.10 Remote control driver

The instrument drivers enable remote control via the corresponding interfaces. The

drivers and installation instructions are available for download on the product page at

www.rohde-schwarz.com/driver/lcx.

15User Manual 1179.2260.02 ─ 02

Page 16

R&S®LCX Series

4 Getting started

4.1 Preparing for use

4.1.1 Lifting and carrying

4.1.2 Unpacking and checking

Getting started

Preparing for use

This chapter contains the same information as the getting started manual.

Here, you can find basic information about setting up the product for the first time.

See "Lifting and carrying the product" on page 9.

1. Unpack the R&S LCX carefully.

2. Retain the original packing material. Use it when transporting or shipping the

R&S LCX later.

3. Using the delivery notes, check the equipment for completeness.

4. Check the equipment for damage.

If the delivery is incomplete or equipment is damaged, contact Rohde & Schwarz.

See also: Chapter 13, "Transporting", on page 224.

4.1.3 Choosing the operating site

Specific operating conditions ensure proper operation and avoid damage to the product and connected devices. For information on environmental conditions such as ambient temperature and humidity, see the data sheet.

See also "Choosing the operating site" on page 10.

Electromagnetic compatibility classes

The electromagnetic compatibility (EMC) class indicates where you can operate the

product. The EMC class of the product is given in the data sheet under "General data".

●

Class B equipment is suitable for use in:

– Residential environments

– Environments that are directly connected to a low-voltage supply network that

supplies residential buildings

16User Manual 1179.2260.02 ─ 02

Page 17

R&S®LCX Series

4.1.4 Setting up the R&S LCX

4.1.4.1 Placing the R&S LCX on a bench top

Getting started

Preparing for use

●

Class A equipment is intended for use in industrial environments. It can cause

radio disturbances in residential environments due to possible conducted and radiated disturbances. It is therefore not suitable for class B environments.

If class A equipment causes radio disturbances, take appropriate measures to

eliminate them.

See also:

●

"Setting up the product" on page 10

●

"Intended use" on page 9

To place the product on a bench top

1. Place the product on a stable, flat and level surface. Ensure that the surface can

support the weight of the product. For information on the weight, see the data

sheet.

CAUTION! Foldable feet can collapse. See "Setting up the product" on page 10.

2.

Always fold the feet completely in or out. With folded-out feet, do not place anything on top or underneath the product.

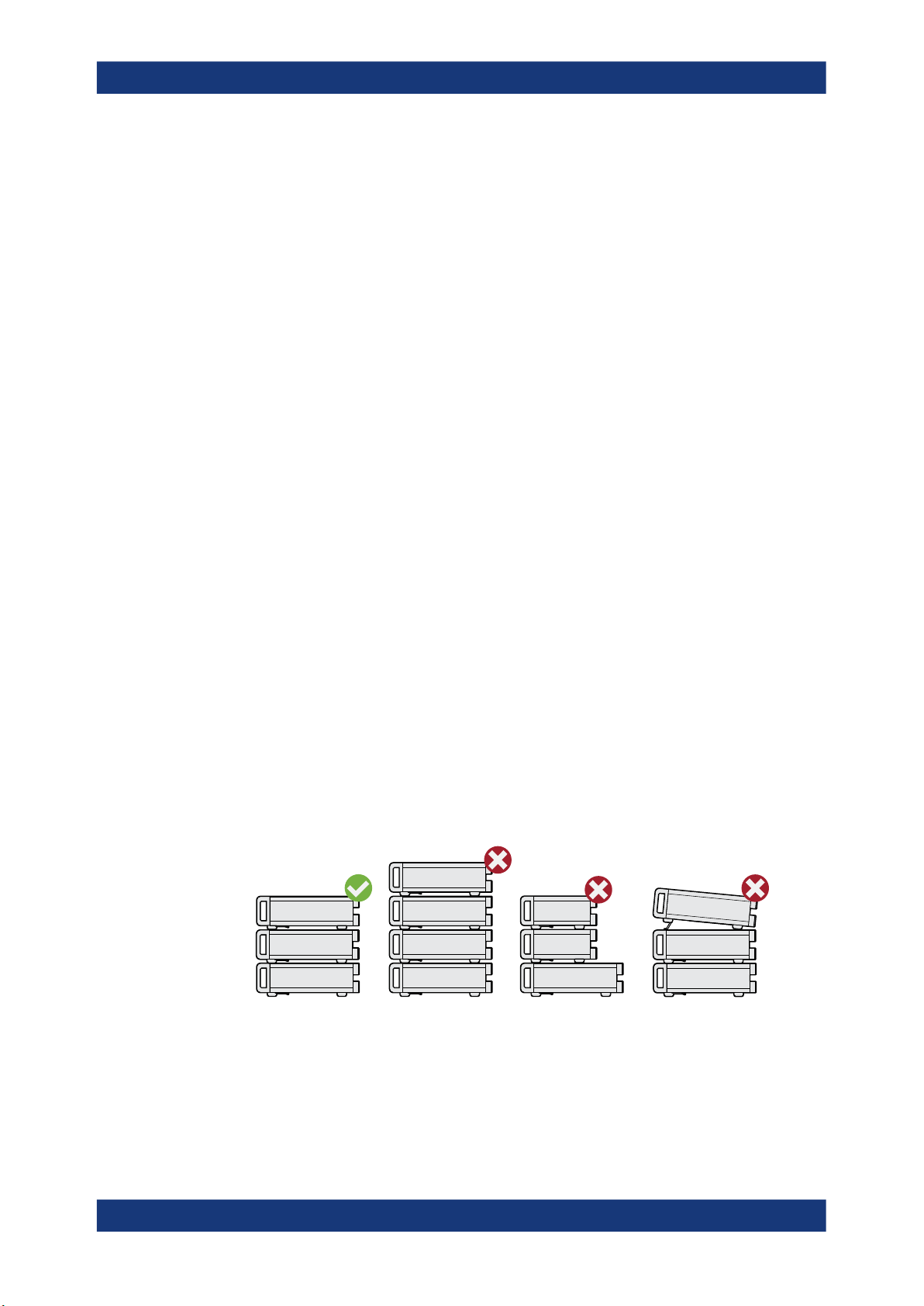

WARNING! A stack of products can fall over and cause injury. Never stack more

3.

than three products on top of each other. Instead, mount them in a rack.

Stack as follows:

● If the products have foldable feet, fold them in completely.

● All products must have the same dimensions (width and length).

● Do not exceed a total load of 50 kg placed on the product at the bottom of the

stack.

Left

Middle left = Stacked incorrectly, too many products

Middle right = Stacked incorrectly, different dimensions

Right = Stacked incorrectly, different dimensions, folded-out feet

NOTICE! Overheating can damage the product.

4.

= Stacked correctly

Prevent overheating as follows:

17User Manual 1179.2260.02 ─ 02

Page 18

R&S®LCX Series

4.1.4.2 Mounting the R&S LCX in a rack

Getting started

Preparing for use

● Keep a minimum distance of 10 cm between the fan openings of the product

and any object in the vicinity.

● Do not place the product next to heat-generating equipment such as radiators

or other products.

To prepare the rack

1. Observe the requirements and instructions in "Setting up the product" on page 10.

NOTICE! Insufficient airflow can cause overheating and damage the product.

2.

Design and implement an efficient ventilation concept for the rack.

Mounting the R&S LCX in a rack

To mount the R&S LCX in a rack:

1. Use an adapter kit that fits the dimensions of the R&S LCX to prepare the

R&S LCX for rack mounting.

a) Order the rack adapter kit designed for the R&S LCX. For the order number,

see the data sheet.

b) Mount the adapter kit. Follow the assembly instructions provided with the

adapter kit.

2. Lift the R&S LCX to shelf height.

3. Push the R&S LCX onto the shelf until the rack brackets fit closely to the rack.

4. Tighten all screws at the rack brackets with a tightening torque of 1.2 Nm to secure

the R&S LCX at the rack.

Unmounting the R&S LCX from a rack

To unmount the R&S LCX from a rack:

1. Loosen the screws at the rack brackets.

2. Bring the lifting equipment to shelf height.

3. Remove the R&S LCX from the rack.

4. If placing the R&S LCX on a bench top again, unmount the adapter kit from the

R&S LCX. Follow the instructions provided with the adapter kit.

4.1.5 Considerations for test setup

Cable selection and electromagnetic interference (EMI)

Electromagnetic interference (EMI) can affect the measurement results.

18User Manual 1179.2260.02 ─ 02

Page 19

R&S®LCX Series

Getting started

Preparing for use

To suppress electromagnetic radiation during operation:

●

Use high-quality shielded cables, especially for the following connector types:

– Connectors for external devices

Double-shielded data cables. The length of data cables must not exceed 3 m.

– Connectors for signal transmission

Shielded coaxial cables. The length of signal cables must not exceed 1 m.

We recommend that you use the R&S LCX-Z11 BNC-to-BNC extension (1 m)

from Rohde & Schwarz.

– BNC

Double-shielded BNC cables.

– USB

Double-shielded USB cables. The length of passive USB cables must not

exceed 1 m.

– LAN

At least CAT6+ cables

– IEEE-488 (GPIB)

Double-shielded cables. We recommend that you use the double-shielded

cable "R&S HZ72" from Rohde & Schwarz.

●

Always terminate open cable ends.

●

Ensure that connected external devices comply with EMC regulations.

Signal input and output levels

Information on signal levels is provided in the data sheet. Keep the signal levels within

the specified ranges to avoid damage to the product and connected devices.

4.1.6 Connecting to power

For safety information, see "Connecting to power" on page 10.

When using the R&S LCX the first time, you can skip Replacing the external bias fuse

and Replacing the line fuse.

If there are any problems during power-on or malfunction of the bias, check the condition of the mains fuse. Also check the fuse for the external bias input as described in

these instructions. They explain how to check and change the protective fuses, if necessary.

Replacing the external bias fuse

The bias voltage input of the R&S LCX is protected by a fuse of type IEC 60127-2/5F0.5L/250V (order no. 0009.5463.00). The externally accessible fuse is at the rear

panel.

To check and exchange the external bias fuse:

NOTICE! Risk of instrument damage. Malfunction of the fuse that protects the bias

1.

voltage input from overload can damage the circuitry of the instrument.

19User Manual 1179.2260.02 ─ 02

Page 20

R&S®LCX Series

Getting started

Preparing for use

Do not use either fuse type other than specified, nor a defective fuse, and never

short-circuit the fuse.

Make sure that you have disconnected the R&S LCX from the mains.

2. Check the condition of the external bias fuse.

3. If necessary, install the fuse type required for the external bias voltage.

a) Unscrew the fuse holder with a suitable screwdriver.

b) Pull out the fuse holder.

c) Replace the fuse by a fuse of the specified type.

d) Insert the fuse holder into the external bias inlet.

When inserting the fuse holder, press it slightly and tighten it.

Replacing the line fuse

The product is protected by one fuse of type IEC 60127-2/5-T2.0H/250V

(order no. 0020.7546.00). The externally accessible fuse is part of the IEC socket of

the power supply at the rear panel.

To exchange the line fuse:

1. Check the available supply voltage.

The mains voltage must be within the voltage range as denoted on the instrument.

The label is at the rear panel, on the left of the "AC power" connector and power

switch.

The power supply module covers a wide power supply range and normally does

not require adjustment.

2. If the power supply exceeds the permissible range, contact Rohde & Schwarz customer service.

WARNING! The fuse is part of the main power supply. Handling the fuse while the

3.

power is on can lead to electric shock.

If necessary, exchange the fuse required for the supply voltage.

4. Before changing the fuse:

a) Set the switch on the power supply to position [0].

b) Disconnect the R&S LCX from the power source.

5. Replace the line fuse.

a) Unplug the power cable.

b) Press the plastic lock on the bottom of the fuse holder inwards using a screw-

driver (with a blade width of approximately 2 mm).

A narrow guide on the bottom of the fuse holder denotes the insertion point.

When unlocking the mechanism, compression springs automatically push the

fuse holder outwards.

c) Pull out the fuse holder.

d) Check the condition of the fuse.

20User Manual 1179.2260.02 ─ 02

Page 21

R&S®LCX Series

Getting started

Preparing for use

e) Replace the fuse by a fuse of the specified type.

A label next to the fuse holder also indicates the fuse type and its characteris-

tics.

f) Note: The protruding contact springs must not be deformed. Align the fuse

holder with the guide bar facing the socket.

Carefully slide the fuse holder against the spring pressure into the slot until the

plastic lock latches.

Connecting to power

To connect the instrument to the mains:

1. Check the available supply voltage.

The mains voltage must be within the voltage range as denoted on the instrument.

The label is at the rear panel, on the left of the "AC power" connector and power

switch.

The power supply module covers a wide power supply range and normally does

not require adjustment.

2. If the power supply exceeds the permissible range, contact Rohde & Schwarz customer service.

3.

If necessary, ground the instrument using the grounding connection

A ground connector socket is at the front panel to connect a ground cable with a

banana plug.

As an alternative, a ground terminal at the rear panel enables you to connect a

ground cable firmly with a screw:

a) At the rear panel, unscrew the screw of the ground terminal using a cross-

recess screw driver.

b) Attach a ground cable with a ring terminal and pass the screw through it.

c) Fasten the screw.

d) Connect the cable to ground.

4. Plug the AC power cable into the "AC power" connector.

The power supply switch connector is at the rear panel. Only use the power cable

delivered with the R&S LCX.

5. Plug the AC power cable into a power outlet with ground contact.

The required ratings are listed next to the AC connector and in the data sheet.

4.1.7 Connecting to LAN

.

Establishing the LAN connection

The R&S LCX provides Ethernet (LAN) connectivity. Provided the corresponding rights

are assigned, you can use these interfaces for remote control and data transfer from a

controller PC. The controller PC must also be connected in the network.

The "LAN" connector is at the rear panel.

21User Manual 1179.2260.02 ─ 02

Page 22

R&S®LCX Series

Getting started

Preparing for use

To connect the R&S LCX to the LAN:

1. Connect the "LAN" socket using an RJ-45 cable to the LAN.

By default, the R&S LCX configuration uses DHCP that assigns the IP address

automatically.

NOTICE! If the R&S LCX cannot obtain an IP address automatically, or cannot

2.

establish the connection, the icon in the status bar turns red.

Possible reasons are that the LAN does not support DCHP or requires a specific

TCP/IP configuration, or that the connection is missing.

To troubleshoot the problem, proceed as follows:

a) Check if you have connected both, the R&S LCX and the controller PC to the

LAN.

b) Consult your network administrator to request support and an IP address, if

necessary.

c) If necessary, assign the IP address manually as described in "Assigning the

LAN interface addresses manually" on page 159.

If switched on and connected, the R&S LCX indicates the address information and

LAN parameters in the "Ethernet Settings dialog".

Figure 4-1: LAN settings dialog

4.1.8 Connecting USB devices

The "USB A" connector is at the front panel. You can connect or disconnect all USB

devices from the R&S LCX during operation. But do not remove an external USB memory stick while the instrument is saving data, since it leads to loss of data.

22User Manual 1179.2260.02 ─ 02

Page 23

R&S®LCX Series

Getting started

Preparing for use

To connect USB storage devices

USB storage devices, such as memory sticks, allow easy data transfer from or to the

R&S LCX. You can also use them for firmware updates.

► Connect the USB storage device to the "USB A" connector.

If you use the front panel connectors, connect the USB storage device directly,

without connecting cable. Connecting cables can cause electromagnetic radiation

and impair the measurement result.

To connect USB devices with external power supply

If you need more power for the external bias, you can use an USB device with external

power supply.

NOTICE! Connected devices with external power supply can feed back current into

1.

the 5 V power supply of the USB interface and thus damage the R&S LCX.

Make sure that there is no connection between the positive pole of the power supply and the +5 V power pin of the USB interface (VBUS).

2. Connect the USB storage device to the "USB A" connector at the front panel.

4.1.9 Connecting a test fixture

The R&S LCX enables you to measure passive components like capacitors, coils,

resistors, transformers. To measure such components requires the use of suitable

measurement adapters, in this context considered as test fixtures.

For information on the test fixtures available for the R&S LCX, see Measurement Set-

ups > About Test Fixtures.

The test fixtures are connected firmly to the four BNC connectors H POT (high potential), H CUR (high current), L POT low potential) and L CUR (low current) at the front

panel.

The following instructions describe the mechanical connection of the adapter only.

Before starting a measurement, consider the prerequisites and steps to be performed

before as described in Chapter 4.3, "Trying out the instrument", on page 32.

Connecting a test fixture to the instrument

To connect a 4-terminal test fixture to the R&S LCX:

NOTICE! Check all terminals to make sure that they are not damaged.

1.

NOTICE! Before connecting, discharge all components. Externally supplied voltage

can damage the BNC connectors of the R&S LCX.

Turn the levers at the "BNC" connectors of the test fixture to the left to release the

lock (1).

23User Manual 1179.2260.02 ─ 02

Page 24

R&S®LCX Series

Getting started

Preparing for use

2

1

Figure 4-2: Connecting a test fixture

2. Carefully plug the test fixture to the four "BNC" measurement connectors of the

R&S LCX (2).

3. Turn all levers to the right to tighten the connection (3).

3

Figure 4-3: Fastening the test fixture

The mechanical test setup is ready for operation.

Connecting a test fixture with the BNC-to-BNC extension

If you are using the BNC-to-BNC extension (option R&S LCX-Z11), you can connect all

devices as described in Connecting a test fixture to the instrument. We recommend

that you keep the order as follows:

1. Connect the BNC-to-BNC to the R&S LCX.

Proceed as described in step 1.

2. Connect the test fixture to the extension.

24User Manual 1179.2260.02 ─ 02

Page 25

R&S®LCX Series

4.1.10 Switching on or off

Getting started

Instrument tour

Switching on the product

The product is off but connected to power.

1. Set the switch on the power supply to position [I].

The power supply switch connector is on the rear panel.

The R&S LCX starts, and the front panel keys light up briefly.

2. Press the power key for a second.

The power is on the front panel.

The instrument checks the system, boots the operating system, and then starts the

R&S LCX firmware.

The power lights green.

When starting for the first time, the R&S LCX starts with the default settings. When

restarting the instrument, the settings depend on the instrument configuration

before shut-down.

Shutting down the product

► Press the power key.

All current settings are saved and the operating system shuts down.

The power changes to gray (off).

To disconnect from power

The product is in the standby state.

NOTICE! Risk of data loss. If you disconnect the product from power when it is in

1.

the ready state, you can lose settings and data. Shut it down first.

Set the switch on the power supply to position [0].

2. Disconnect the product from the power source.

4.2 Instrument tour

The following topics help you to get familiar with the instrument and perform the first

steps:

●

Front panel tour

●

Rear panel tour

The sections explain the controls and connections at the front and back of the

R&S LCX. For specifications of the interfaces, see the data sheet.

The meanings of the labels on the R&S LCX are described in Chapter 1.2, "Labels on

the R&S LCX", on page 11.

25User Manual 1179.2260.02 ─ 02

Page 26

R&S®LCX Series

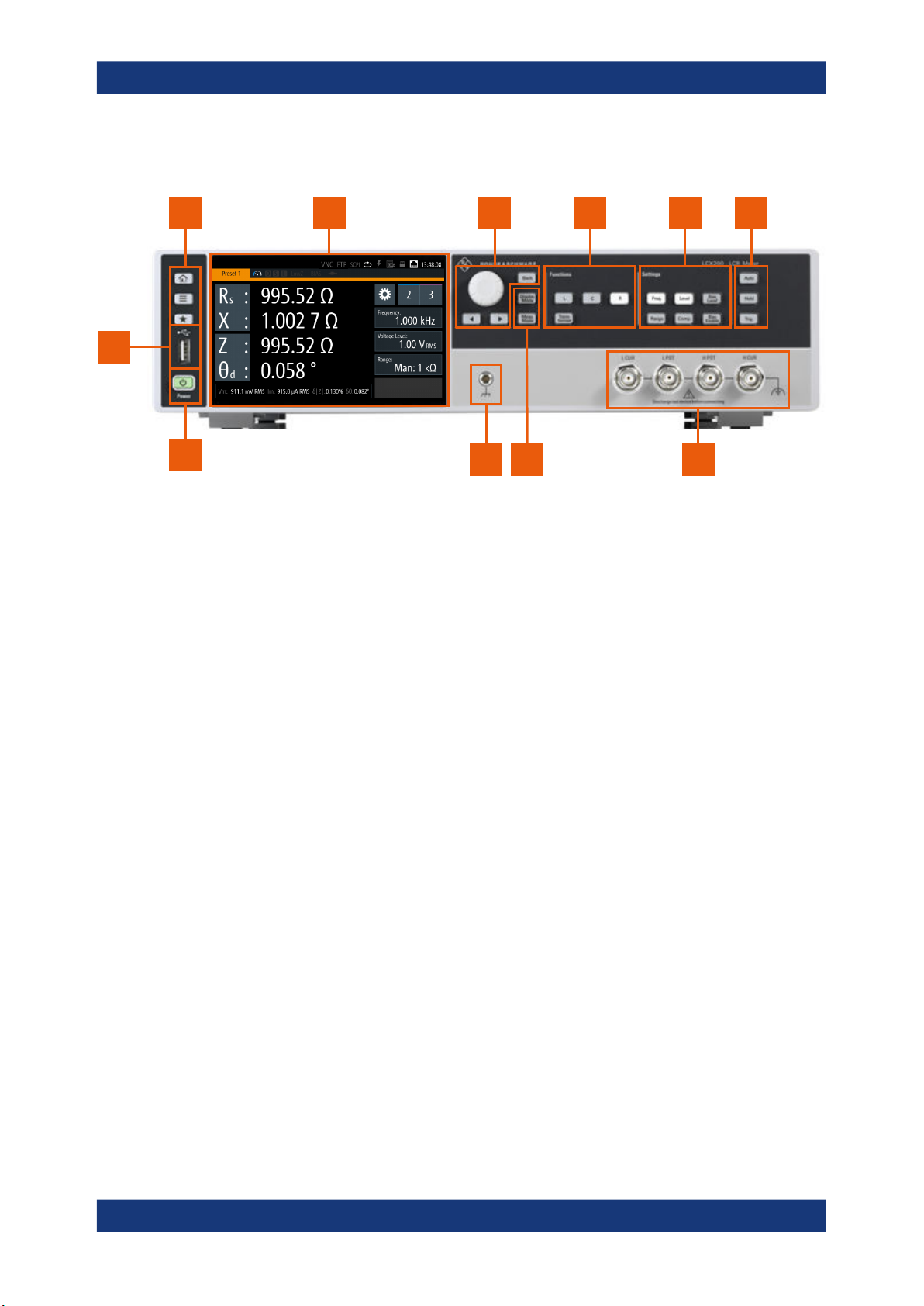

4.2.1 Front panel tour

1 2 3 4 5 6

11

Getting started

Instrument tour

10

Figure 4-4: R&S LCX front panel

1 = Basic display keys, see "Basic display keys" on page 27

2 = Touchscreen display, see Chapter 4.2.1.1, "Touchscreen display", on page 26

3 = Navigation controls, see "Navigation controls" on page 27

4 = Function keys, see "Function keys" on page 28

5 = Setting keys, see "Settings keys" on page 28

6 = Measurement control keys, see "Measurement control keys" on page 28

7 = BNC measurement connectors, see "L CUR, L POT, H CUR, H POT" on page 29

8 = Measurement mode keys, see "Measurement mode keys" on page 28

9 = Ground connector, see "Ground socket" on page 29

10 = POWER key, see "POWER On/Standby key" on page 29

11 = USB host connector

4.2.1.1 Touchscreen display

The color TFT touchscreen at the front panel is the graphical user interface. It shows

the measurement readings, status information and settings, and provides access to

settings dialogs.

8

79

26User Manual 1179.2260.02 ─ 02

Page 27

R&S®LCX Series

Getting started

Instrument tour

Figure 4-5: Touchscreen display

For details on the screen display, see Chapter 4.4.2.1, "Understanding the display

information", on page 36.

The touch-sensitive panel provides an alternative means of user interaction for quick

and easy handling of the instrument, see Chapter 4.4.2, "Means of manual interaction",

on page 35.

4.2.1.2 Keys

This section introduces the functionality of the hardkeys at the front panel. These controls lead you to menus and dialogs displayed on the screen. For information on how to

operate the instrument, see Chapter 4.4.2, "Means of manual interaction",

on page 35.

Basic display keys

The utility keys arrange different windows on the display.

Table 4-1: Display keys

Display key Assigned functions

[home] Returns to the initial feature screen.

[settings] Displays a menu list for accessing general instrument functions.

[★ (User)] Executes a previously assigned user action.

Press and hold accesses the favorites menu for assigning a user action.

Navigation controls

The navigation controls include a rotary knob and navigation keys. They allow you to

navigate within the display or within dialogs, see Chapter 4.4.2, "Means of manual

interaction", on page 35.

27User Manual 1179.2260.02 ─ 02

Page 28

R&S®LCX Series

Getting started

Instrument tour

Table 4-2: Navigation controls

Key Assigned functions

[Rotary knob] Selects, activates or confirms settings.

[◀] / [▶] Moves the cursor in entry fields.

[Back] Returns to a previous level in menus, or closes a view.

Measurement mode keys

The measurement controls enable you to select the measurement mode and view of

the representation of the measurement readings.

Table 4-3: Measurement mode controls

Key Assigned functions

[Meas. Mode] Selects either continuous or manually triggered measurement mode.

[Display Mode] Selects the display of measurement readings.

Function keys

The keys in the function panel select the parameters for the measurement.

Table 4-4: Measurement function controls

Key Assigned functions

[L] Selects the function for measuring inductance.

[C] Selects the function for capacity measurement.

[R] Selects the measurement for a resistor.

[Transformer] Selects the transformer measurement.

Settings keys

The keys in the settings panel enable you to select measurement ranges and additional parameters for executing the measurement.

Table 4-5: Measurement function controls

Key Assigned functions

[Freq.] Sets the signal frequency.

[Range] Selects the impedance range.

[Level] Sets the level.

[Comp.] Opens the "Open/Short/Load Correction" dialog for quick access.

[Bias Level] Sets the bias voltage and current.

[Bias Enable] Activates internal or external bias.

Measurement control keys

These keys provide control during the measuring procedure.

28User Manual 1179.2260.02 ─ 02

Page 29

R&S®LCX Series

4.2.1.3 Connectors

Getting started

Instrument tour

Table 4-6: Navigation controls

Key Assigned functions

[Auto] Activates the automatic selection of the measurement function.

[Hold] Freezes the measurement range, on the screen indicated with prefix "Hold:"

at the range value.

[Trig.] Triggers a measurement manually.

POWER On/Standby key

The [On/Standby] key switches the instrument from the standby to the ready state or

vice versa.

The [On/Standby] lights green when the instrument is switched on, see Chapter 4.1.10,

"Switching on or off", on page 25.

The measurement input connectors and the USB connector are on the front panel.

L CUR, L POT, H CUR, H POT

Four BNC sockets:

●

"L CUR" (low current): signal output for series measurements (signal generator).

●

"L POT" (low potential): signal input for parallel measurement (voltage measurements).

●

"H CUR" (high current): signal input for series measurements (current measurements).

●

"H POT" (high potential): signal input and output for parallel measurements (measurement bridge).

Ground socket

Protective ground socket (4 mm banana socket) to secure the R&S LCX, e.g. with a

grounded external conductor.

The front panel ground socket is directly connected to the mains safety ground by the

line cord.

See Table 1-1.

USB A

Female USB (universal serial bus) connector of type A (host USB). You can connect a

USB memory stick, e.g., to record and export measurement data, to capture screenshots, or to update the firmware.

How to: Chapter 4.1, "Preparing for use", on page 16

4.2.2 Rear panel tour

This section provides an overview of the connectors at the rear panel of the instrument.

For technical data of the connectors, see the data sheet.

29User Manual 1179.2260.02 ─ 02

Page 30

R&S®LCX Series

Getting started

Instrument tour

1 2

345678910

Figure 4-6: R&S LCX rear panel

1 = IEEE-488 interface, see "IEC 625/IEEE 488" on page 30

2 = Kensington lock, see "Kensington lock" on page 30

3 = AC power connector and power switch, see "AC power supply" on page 30

4 = Ground terminal, see "Ground terminal" on page 31

5 = D-sub connector, see "Digital I/O" on page 31

6 = Bias connectors and fuse holder, see "External Voltage Bias" on page 31, "BIAS Fuse" on page 31

7 = Trigger input connector, see "Trigger Input" on page 31

8 = USB host connector, see "USB A" on page 29

9 = USB device connector, see "USB B" on page 31

10 = Ethernet (LAN) interface connector, see "LAN" on page 31

IEC 625/IEEE 488

Option: R&S NG-B105

General purpose interface bus (GPIB) interface to connect a computer for remote con-

trol of the R&S LCX.

See "Establishing the GPIB remote control connection" on page 158.

Kensington lock

Flat key security slot to prevent the instrument from removal.

The locking system consists of a small, metal-reinforced hole with a metal anchor and

a rubberized metal cable that is secured with a key lock. The loop at the end of the

cable allows you to tie the unit to a fixed object.

AC power supply

Mains power supply with power switch, fuse holder and IEC socket.

●

Mains power switch:

Switch for connecting and disconnecting the internal power supply from the power

source, see Chapter 4.1.10, "Switching on or off", on page 25.

●

Fuse holder

Socket for the fuse securing the line voltage. Depending on the power supply system, the corresponding fuse must be plugged before connecting to power. See

"Connecting to power" on page 21.

●

IEC socket

30User Manual 1179.2260.02 ─ 02

Page 31

R&S®LCX Series

Getting started

Instrument tour

Power supply connector for connecting the R&S LCX to the mains., see Chap-

ter 4.1.6, "Connecting to power", on page 19.

Ground terminal

Protective ground terminal to secure the R&S LCX, e.g. with a grounded external conductor, see Table 1-1.

Digital I/O

15-pole D-Sub socket to connect the binning interface.

External Voltage Bias

4 mm safety sockets for external bias voltage.

Note: External BIAS requires constant voltage.

Before applying the voltage, make sure that you have set the constant voltage mode in

the supplying instrument. Refer to the user manual of the power supply.

The External Voltage Bias socket is not directly connected to ground.

Indirectly, there is a connection to ground with low impedance over the "H CUR" output

buffer.

When the bias voltage is turned on, the potential to ground deviates only by a maxi-

mum of ±18 V. Without external bias, make sure that the voltage at the two sockets

does not exceed the safety extra low voltage or the specified 40 V DC.

BIAS Fuse

Socket for the fuse securing the external bias voltage.

Trigger Input

BNC socket for external trigger signal.

The trigger input is directly connected to the mains safety ground by the line cord.

USB A

Female USB (universal serial bus) connector of type A (host USB). You can connect a

USB memory stick, e.g., to record and export measurement data, to capture screenshots, or to update the firmware.

How to: Chapter 4.1, "Preparing for use", on page 16

USB B

Female USB (universal serial bus) type B connector. This interface provides remote

control of the instrument from a controller PC.

See "Establishing a USB remote control connection" on page 158.

LAN

RJ-45 socket to connect the R&S LCX to a LAN for remote control, remote operation,

and data transfer.

How to: Chapter 4.1.7, "Connecting to LAN", on page 21

31User Manual 1179.2260.02 ─ 02

Page 32

R&S®LCX Series

4.3 Trying out the instrument

Getting started

Trying out the instrument

As a brief introduction, the following example describes the basic steps to be taken

when setting up a measurement. The instructions guide you through the measurement

of a resistor.

Further test setups and measurement methods are described in the user manual, see

Chapter 6, "Measurement setups", on page 52.

The test setup uses the R&S LCX-Z3 SMD test fixture connected to the R&S LCX for

measuring wireless components.

If necessary, you can connect the R&S LCX-Z11 BNC-to-BNC extension between the

R&S LCX and the test fixture, e.g., to make it easier to pick and place the DUTs.

Basic measurement steps

The R&S LCX LCR meter measures the impedance and phase angle with an AC signal, and derives the required characteristics.

As the equivalent circuit of each DUT contains capacitive, real and conductive parts,

the characteristics of passive components vary dependent on frequency, level, temperature and additional bias. Even the test equipment can impact the measurement

results. Therefore, we recommend that you use the test fixture that fits best for your

application, and align the instrument on all frequencies. Keep the order as given to

minimize parasitic parts and thus to optimize the measurement accuracy.

1. Select the test fixture that fits best for your application.

2. After power-on set the R&S LCX to an initial state, see "Setting the initial state"

on page 32.

3. Connect the test fixture, see Chapter 4.1.9, "Connecting a test fixture", on page 23.

4. Configure the test signal, see "Setting up the test signal" on page 33.

5. Align the instrument on all frequencies, see "Aligning the instrument on all frequen-

cies" on page 34.

6. Start a resistor measurement "Measuring a resistor" on page 34.

Setting the initial state

NOTICE! Check all terminals to make sure that they are not damaged.

1.

Power on the R&S LCX, as described in Chapter 4.1.6, "Connecting to power",

on page 19.

2. Switch on the R&S LCX, see Chapter 4.1.10, "Switching on or off", on page 25.

NOTICE! Risk of measurement inaccuracy. Measurements can be inaccurate, if

3.

performed when the instrument is not warmed-up. Wait until the instrument has

reached its operating temperature before you start the measurement procedure.

The warm-up time is up to 30 minutes.

To start from an initial state, set the instrument to default:

32User Manual 1179.2260.02 ─ 02

Page 33

R&S®LCX Series

Getting started

Trying out the instrument

a) Press the [settings] key at the front panel.

On the front panel, press the [settings] button.

b) In the "Device" tab, select "Save/Recall Device Settings".

c) Select "Default Settings".

The instrument prompts you to confirm the operation.

d) Confirm with "Ok".

The R&S LCX resets all parameters except for system settings.

e)

Select

Connecting the test fixture

The figure shows schematically the elements to be connected.

► To connect the test fixture, proceed as described in Chapter 4.1.9, "Connecting a

test fixture", on page 23.

Setting up the test signal

To configure the test signal:

to return to the settings menu.

1. To set the frequency:

a) On the screen, select "Frequency".

b) Enter, e.g. 10 kHz using the keypad on the screen.

c)

Confirm with

2. To select the level parameter:

Before setting the test signal level, you can select either the signal voltage, or the

signal current for the level setting:

a) Press the [settings] at the front panel.

b) Select the "Measurement" tab.

c) Select "Test Signal Level".

d) Select, e.g. "Voltage".

e) Confirm with "Set".

f) Press the [home] key to return to the measurement window.

The R&S LCX provides the selected parameter for the level setting on the screen.

3. To set the test signal level:

a) On the screen, select "Level".

b) Enter, e.g. 1.3 VRMS.

c)

Confirm with

4. If you know the expected range, set the range as follows.

Otherwise skip this step and proceed with step 5:

.

.

a) Select "Range".

b) In the "Select Measurement Range" dialog, select the expected impedance,

e.g. 10 kΩ.

c) Confirm with "Set".

33User Manual 1179.2260.02 ─ 02

Page 34

R&S®LCX Series

Getting started

Trying out the instrument

5. On the front panel, press the [Auto] key to activate automatic detection of the measurement function according to the component type of the DUT.

Aligning the instrument on all frequencies

To align the R&S LCX on all frequencies:

1. Press the [Comp.] key at the front panel.

The "Open/Short/Load Correction" dialog opens.

2. Perform a short correction, in this example described for the SMD test fixture

(R&S LCX-Z3):

a) Short-circuit the contact devices, i.e. the clamps or pins, according to the used

test fixture.

b) Set "Short Correction Enabled" > "ON".

The short correction takes about 2 minutes.

3. Perform an open correction:

a) Open the contact devices.

Depending on the test fixture, take care that you set the required position.

For example, Kelvin clamps require the same position as expected for the measurement, or the spacing between SMD pins must correspond to the size of the

measurement sample.

b) Set "Open Correction Enabled" > "ON".

The open correction also lasts for about 2 minutes.

Note: For information on corrections with other test fixtures, see Chapter 6.1,

"About test fixtures", on page 52.

Measuring a resistor

1. To select the resistor measurement (DUT component type), press the [R] key.

2. To select the parameters for measurement results display:

a) Select the softkey in the upper left corner, to open the selection editor.

b) Select the parameters "R-X" (resistance, reactance).

c) Repeat the steps to select the second parameters, e.g. select "Z-Θ" (impe-

dance, phase angle).

3. Insert the sample resistor in the test fixture as follows:

a) To open the contact pins, relax and hold the lever to the left.

b) Carefully position the sample between the contacts in the center.

c) Release the lever to fix the sample.

The measurement starts and you can see the readings on the screen.

34User Manual 1179.2260.02 ─ 02

Page 35

R&S®LCX Series

4.4 Instrument control

4.4.1 Ways to operate the instrument

Getting started

Instrument control

This chapter provides an overview on how to work with the R&S LCX. It introduces the

possibilities for operating the instrument and describes the basic functionality of the

control elements. If a measurement configuration requires specific operating steps, the

corresponding settings description in the user manual points it out separately.

● Ways to operate the instrument.............................................................................. 35

● Means of manual interaction...................................................................................35

● Remote control........................................................................................................46

You can operate an R&S LCX in two ways:

●

Manual operation

Use the touchscreen and the front panel controls to configure general and measurement settings.

See Chapter 4.4.2, "Means of manual interaction", on page 35 for basic information on manual operation of the instrument.

●

Remote control

Create programs to automatize repeating settings, tests and measurements. A

controller PC with remote access to the instrument runs the programs.

See Chapter 4.4.3, "Remote control", on page 46 for an overview of the interfaces

provided for remote control.

4.4.2 Means of manual interaction

For manual interaction of the R&S LCX, use the touchscreen and front panel controls,

see front panel. The display shows the current settings, menus and dialogs, when you

perform your settings.

For the manual interaction with the R&S LCX, you have several methods that you can

use as an alternative to perform a task:

●

Touchscreen

Touchscreen operation is the most direct way to interact with the instrument.

Almost all control elements and actions on the screen are based on the standard

operating system concept. You can tap any user interface element to set parameters in dialogs, enter data, or scroll within a dialog.

Using various finger gestures you can select any user interface element, set

parameters in dialogs, enter data using online keypads, or scroll within a dialog.

– Tapping

Touch quickly: selects a parameter or provokes an action.

– Swiping

35User Manual 1179.2260.02 ─ 02

Page 36

R&S®LCX Series

Getting started

Instrument control

Touch and swipe: Scrolls through the contents of a display element larger than

the screen, e.g. a menu list.

– Dragging

Touch and drag: Shifts the contents from one position to another on the display.

By dragging your finger over a diagram, you can pan the displayed area of the

diagram to show results that were previously out of view.

●

System, measurement and function keys

The front panel hardkeys provide nearly all functions and controls to operate the

instrument in the classic way, without touchscreen.

You can access the main functions and parameters, measurement and display

modes and configure general instrument settings. When selected, i.e. a function is

active, the corresponding function key lights up white.

●

Navigation controls

The navigation controls include a [rotary knob] and right [▶], left [◀] keys.

The rotary knob allows you to navigate on the home screen or in dialogs, and to

set parameters. The [◀] [▶] move the cursor in entry fields.

This manual describes the manual interaction with the instrument using the touchscreen. It mentions the alternative methods using the keys on the instrument or the onscreen keypads if it deviates from the standard operating procedures.

Throughout the manual, the term "select" refers to any of the described methods, i.e.

using a finger on the touchscreen or a key on the instrument or on a keyboard.

For basic instructions on how to control the R&S LCX, see Chapter 4.4.2.2, "Accessing

the functionality", on page 43.

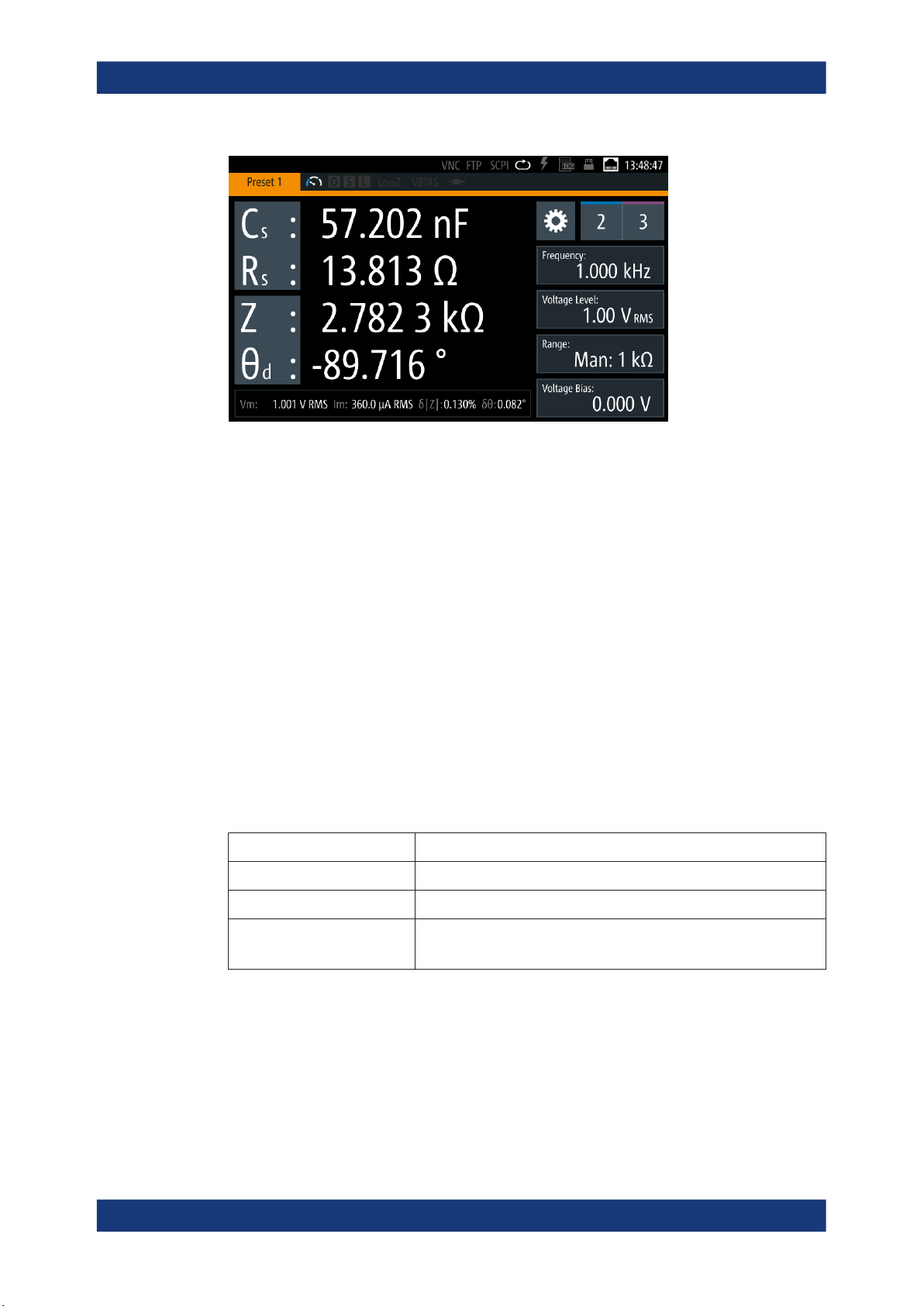

4.4.2.1 Understanding the display information

The initial display screen shows the measurement result window, status information

and general settings at the top. The main area displays the measurement results,

depending on the selected measurement and display mode.

For detailed information, see Chapter 8.2, "Display mode", on page 69.

36User Manual 1179.2260.02 ─ 02

Page 37

R&S®LCX Series

Getting started

Instrument control

21

3

6

4

5

Figure 4-7: Example of screen display

1 = Configuration preset indicator, see "Configuration preset indicator" on page 37

2 = Status bars, see "Status bar" on page 37

3 = Settings softkey and configuration preset softkeys, see "Settings softkey" on page 40, "Configuration

preset softkeys" on page 40

4 = Signal parameters, see "Signal parameters" on page 40

5 = Test signal monitor, see "Test signal monitor" on page 40

6 = Measurement parameters and results, see "Measurement parameters and results" on page 41

The following sections explain the information areas as labeled.

Configuration preset indicator

The R&S LCX enables you to set up to three different measurement configurations and

assign them as favorites with the "Configuration preset softkeys" on page 40. The

indicator displays the currently active preset configuration.

(Preset 1/2/3) displays the currently active preset configuration.

Status bar

You can see two status bar lines. The status bar in the upper line on the right, referred

to as instrument status bar, indicates icons which represent the states of connections,

remote control communication and operating modes. The status bar to the right of

"Preset", is referred to as measurement status bar. Its icons indicate measurement

modes and states.

Instrument status bar