Rohde & Schwarz FSP40 1164.4391.40, FSP30 1164.4391.30, FSP13 1164.4391.13, FSP7 1164.4391.07, FSP3 1164.4391.03 User Manual

...Page 1

Test and Measurement

Division

Operating Manual

SPECTRUM ANALYZER

R&S

1164.4391.03

R&S

1164.4391.07

R&S

1164.4391.13

R&S

1164.4391.30/.39

R&S

1164.4391.40

Volume 1

This Operating Manual consists of 2 volumes

FSP3

FSP7

FSP13

FSP30

FSP40

Printed in the Federal

Republic of Germany

1164.4556.12-01- I-1

Page 2

Dear Customer,

throughout this operating manual, the abbrev iation FSP is used for your Spectrum Analyz er R&S FSP.

R&S is a registered trademar k of Rohde & Schwarz Gm bH & Co. KG

Trade names are trademar k s of the owners

1164.4556.12-01 II-2

Page 3

FSP Tabbed Divider Overview

Tabbed Divider Overview

Volume 1

Data Sheet

Safety Instructions

Certificate of Quality

EU Certificate of Conformity

List of R&S Representatives

Manuals for Spectrum Analyzer FSP

Tabbed Divider

1 Chapter 1: Putting into Operation

2 Chapter 2: Getting Started

3 Chapter 3: Operation

4 Chapter 4: Functional Description

10 Chapter 10: Index

Volume 2

Data Sheet

Safety Instructions

Manuals for Spectrum Analyzer FSP

Tabbed Divider

5 Chapter 5: Remote Control – Basics

6 Chapter 6: Remote Control – Commands

7 Chapter 7: Remote Control – Program Examples

8 Chapter 8: Maintenance and Hardware Interfaces

9 Chapter 9: Error Messages

10 Chapter 10: Index

1164.4556.12 RE E-1

Page 4

Page 5

Certificate No.: 2003-22

This is to certify that:

Equipment type Stock No. Designation

FSP3 1164.4391.03 Spectrum Analyzer

FSP7 1164.4391.07

FSP13 1164.4391.13

FSP30 1164.4391.30

FSP40 1164.4391.40

FSP-B3 1129.6491.02 Audio Modulator AM/FM

FSP-B4 1129.6740.02 OCXO 10 MHz

FSP-B6 1129.8594.02 TV-Trigger

FSP-B9 1129.6991.02 Tracking Generator

FSP-B10 1129.7246.02 External Generator Control

FSP-B15 1155.1006.02 Pulse Calibrator

FSP-B16 1129.8042.03 Lan Interface 10/1000 Base T

FSP-B20 1155.1606.02 Extended Environmental Spec

FSP-B25 1129.7746.02 Electronic Attenuator

FSP-B30 1155.1158.02 DC Power Supply

FSP-B31 1155.1258.02 NIMH Battery Pack and Charger

FSP-B32 1155.1506.02 Spare Battery Pack (NIMH)

FSP-B70 1157.0559.02 Demodulator HW and Memory Extension

EC Certificate of Conformity

complies with the provisions of the Directive of the Council of the European Union on the

approximation of the laws of the Member States

- relating to electrical equipment for use within defined voltage limits

(73/23/EEC revised by 93/68/EEC)

- relating to electromagnetic compatibility

(89/336/EEC revised by 91/263/EEC, 92/31/EEC, 93/68/EEC)

Conformity is proven by compliance with the following standards:

EN61010-1 : 1993 + A2 : 1995

EN55011 : 1998 + A1 : 1999

EN61326 : 1997 + A1 : 1998 + A2 : 2001

For the assessment of electromagnetic compatibility, the limits of radio interference for Class B

equipment as well as the immunity to interference for operation in industry have been used as a basis.

Affixing the EC conformity mark as from 2003

ROHDE & SCHWARZ GmbH & Co. KG

Mühldorfstr. 15, D-81671 München

Munich, 2003-05-28 Central Quality Management FS-QZ / Becker

1164.4391.01 CE E-2

Page 6

Page 7

Safety Instructions

This unit has been designed and tested in accordance with the EC Certificate of Conformity and has left the

manufacturer’s plant in a condition fully complying with safety standards.

To maintain this condition and to ensure safe operation, the user must observe all instructions and warnings

given in this operating manual.

Safety-related symbols used on equipment and documentation from R&S:

Observe

operating

instructions

Weight

indication for

units >18 kg

PE terminal Ground

1. The unit may be used only in the operating conditions and positions specified by the manufacturer. Unless otherwise agreed, the following

applies to R&S products:

IP degree of protection 2X, pollution severity 2

overvoltage category 2, only for indoor use, altitude max. 2000 m.

The unit may be operated only from supply networks fused with max. 16 A.

Unless specified otherwise in the data sheet, a

tolerance of ±10% shall apply to the nominal

voltage and of ±5% to the nominal frequency.

2. For measurements in circuits with voltages V

> 30 V, suitable measures should be taken to

avoid any hazards.

(using, for example, appropriate measuring

equipment, fusing, current limiting, electrical

separation, insulation).

3. If the unit is to be permanently wired, the PE

terminal of the unit must first be connected to

the PE conductor on site before any other c onnections are made. Installation and cabling of

the unit to be performed only by qualified technical personnel.

4. For permanently installed units without built-in

fuses, circuit breakers or similar protective devices, the supply circuit must be fused such as

to provide suitable protection for the users and

equipment.

5. Prior to switching on the unit, it must be ensured

that the nominal voltage set on the unit matches

the nominal voltage of the AC supply network.

If a different voltage is to be set, the power fuse

of the unit may have to be changed accordingly.

6. Units of protection class I with disconnectible

AC supply cable and appliance connector may

be operated only from a power socket with

earthing contact and with the PE conductor connected.

terminal

Danger!

Shock hazard

Warning!

Hot surfaces

Ground

7. It is not permissible to interrupt the PE conductor intentionally, neither in the incoming cable

nor on the unit itself as this may cause the unit

to become electrically hazardous.

Any extension lines or multiple socket outlets

used must be checked for compliance with relevant safety standards at regular intervals.

8. If the unit has no power switch for disconnection

from the AC supply, the plug of the connecting

cable is regarded as the disconnecting device.

In such cases it must be ensured that the power

plug is easily reachable and accessible at all

rms

times (length of connecting cable approx. 2 m).

Functional or electronic switches are not suitable for providing disconnection from the AC

supply.

If units without power switches are integrated in

racks or systems, a disconnecting device must

be provided at system level.

9. Applicable local or national safety regulations

and rules for the prevention of accidents must

be observed in all work performed.

Prior to performing any work on the unit or

opening the unit, the latter must be disconnected from the supply network.

Any adjustments, replacements of parts, maintenance or repair may be carried out only by

authorized R&S technical personnel.

Only original parts may be used for replacing

parts relevant to safety (eg power switches,

power transformers, fuses). A safety test must

be performed after each replacement of parts

relevant to safety.

(visual inspection, PE conductor test, insulationresistance, leakage-current measurement, functional test).

continued overleaf

Attention!

Electrostatic

sensitive devices require

special care

095.1000 Sheet 17

Page 8

Safety Instructions

10. Ensure that the connections with information

technology equipment comply with IEC950 /

EN60950.

11. Lithium batteries must not be exposed to high

temperatures or fire.

Keep batteries away from children.

If the battery is replaced improperly, there is

danger of explosion. Only replace the battery by

R&S type (see spare part list).

Lithium batteries are suitable for environmentally-friendly disposal or specialized recycling.

Dispose them into appropriate containers, only.

Do not short-circuit the battery.

12. Equipment returned or sent in for repair must be

packed in the original packing or in packing with

electrostatic and mechanical protection.

Electrostatics via the connectors may dam-

13.

age the equipment. For the safe handling and

operation of the equipment, appropriate

measures against electrostatics should be implemented.

14. The outside of the instrument is suitably

cleaned using a soft, lint-free dustcloth. Never

use solvents such as thinners, acetone and

similar things, as they may damage the f ront

panel labeling or plastic parts.

15. Any additional safety instructions given in this

manual are also to be observed.

095.1000 Sheet 18

Page 9

FSP Manuals

Contents of Manuals for Spectrum Analyzer FSP

Operating Manual FSP

The operating manual describes the following models and options of spectrum analyzer FSP:

• FSP3 9 kHz to 3 GHz

• FSP7 9 kHz to 7 GHz

• FSP13 9 kHz to 13.6 GHz

• FSP30 9 kHz to 30 GHz

• FSP40 9 kHz to 40 GHz

• Option FSP B3 audio demodulator

• Option FSP-B4 OCXO - reference oscillator

• Option FSP-B9 tracking generator

• Option FSP-B10 external generator control

• Option FSP-B15 pulse calibrator

• Option FSP-B16 LAN interface

• Option FSP-B25 electronic attenuator

• Option FSP-B28 trigger port

This operating manual contains information about the technical data of the instrument, the setup

functions and about how to put the instrument into operation. It inf orms about the operating c oncept

and controls as well as about the operation of the FSP via the menus and via remote control. T ypical

measurement tas ks for the FSP are explained using the f unctions of f er ed by the menus and a selection of program examples.

Additionally the operating manual includes information about maintenance of the instrument and

about error detection listing the error messages which may be output by the instrument. It is subdivided into 9 chapters:

Chapter 1 describes the control elements and connectors on the front and rear panel as well

as all procedures required for putting the FSP into operation and integration into a

test system.

Chapter 2 gives an introduction to typical measurement tasks of the FSP which are ex-

plained step by step.

Chapter 3 describes the operating principles, the struc ture of the graphical interf ace and of-

fers a menu overview.

Chapter 4 forms a reference f or manual control of the FSP and contains a detailed descr ip-

tion of all instrument f unctions and their applic ation. The c hapter also lists the remote control command corresponding to each instrument function.

Chapter 5 describes the basics for programming the FSP, command processing and the

status reporting system.

Chapter 6 lists all the remote-control commands defined for the instrument.

Chapter 7 contains program examples for a number of typical applications of the FSP.

Chapter 8 describes preventive maintenance and the characteris tics of the instrument’s in-

terfaces.

Chapter 8 gives a list of error messages that the FSP may generate.

Chapter 9 contains a list of error messages.

Chapter 10 contains an index for the operating manual.

1164.4556.12 0.1 E-1

Page 10

Manuals FSP

Service Manual - Instrument

The service manual - instrument informs on how to check compliance with rated spec ifications, on

instrument function, repair, troubleshooting and f ault elimination. It contains all information r equired

for the maintenance of FSP by exchanging modules.

1164.4556.12 0.2 E-1

Page 11

FSP Contents - Preparing for Operation

Contents - Chapter 1 " Preparing for Operation "

1 Preparing for Operation......................................................................................1.1

Description of Front and Rear Panel Views .................................................................................. 1.1

Front View................................................................................................................................1.1

Rear View................................................................................................................................1.9

Getting Started with the Instrument.............................................................................................1.14

Preparing the Instrument for Operation................................................................................. 1.14

Setting Up the Instrument...................................................................................................... 1.14

Standalone Operation..................................................................................................1.14

Safety Instruction for Instruments with Tiltable Feet ...................................................1.15

Rackmounting .............................................................................................................1.15

EMC Safety Precautions........................................................................................................ 1.16

Connecting the Instrument to the AC Supply......................................................................... 1.16

Switching the Instrument On/Off............................................................................................1.16

Switching On the Instrument ....................................................................................... 1.17

Startup Menu and Booting........................................................................................... 1.17

Switching Off the FSP ................................................................................................. 1.17

Power-Save Mode....................................................................................................... 1.18

Recalling the Most Recent Instrument Settings.....................................................................1.18

Function Test ................................................................................................................................. 1.18

Windows XP ................................................................................................................................... 1.19

Connecting an External Keyboard...............................................................................................1.20

Connecting a Mouse...................................................................................................................... 1.21

Connecting an External Monitor ..................................................................................................1.22

Connecting a Printer......................................................................................................................1.23

Selecting a Printer ................................................................................................................. 1.23

Installation of Plug&Play Printers........................................................................................... 1.26

Installation of Non-Plug&Play Printers...................................................................................1.26

Local Printer ................................................................................................................ 1.28

Configuring a Network Printer (with Option FSP-B16 only)................................................... 1.33

Connection of USB Devices .........................................................................................................1.35

Installing Windows XP Software ..................................................................................................1.37

Authorized Windows XP Software for the Instrument ...........................................................1.37

1164.4556.12 I-1.1 E-1

Page 12

Contents - Preparing for Operation FSP

7

6

5

1164.4391.30

SWEEP

CONTROL

34

2

BW SWEEP

AMPT

SPAN

FREQ

MEAS TRIG

MKR

MKR

MKR

FCTN

VARIATION

s

V

-dBm

GHz

DATA

89

7

µs

µV

ms

mV

dB

dBm

MHz

kHz

3

56

4

12

50

KEYBOARD

PROBE PO WER

ns

nV

dB..

Hz

BACK

-

.

0

AF OUTPUT

ENTER

ESC

CANCEL

TRACE

RF INPUT

EXT MIXER

LO OUT/ IF IN IF I N

GEN OUTPUT 50

DISP

LINES

MADE IN G E RMANY

MAX + 30 d Bm / 0V DC

MAX 0V DC

FILE

PREV NEXT

..

1

11 10 9 8

SPECTRUM ANALYZER 9 kHz ... 30 GHzFSP

CAL

SETUP

14

HCOPY

12

13

PRESET

16

15

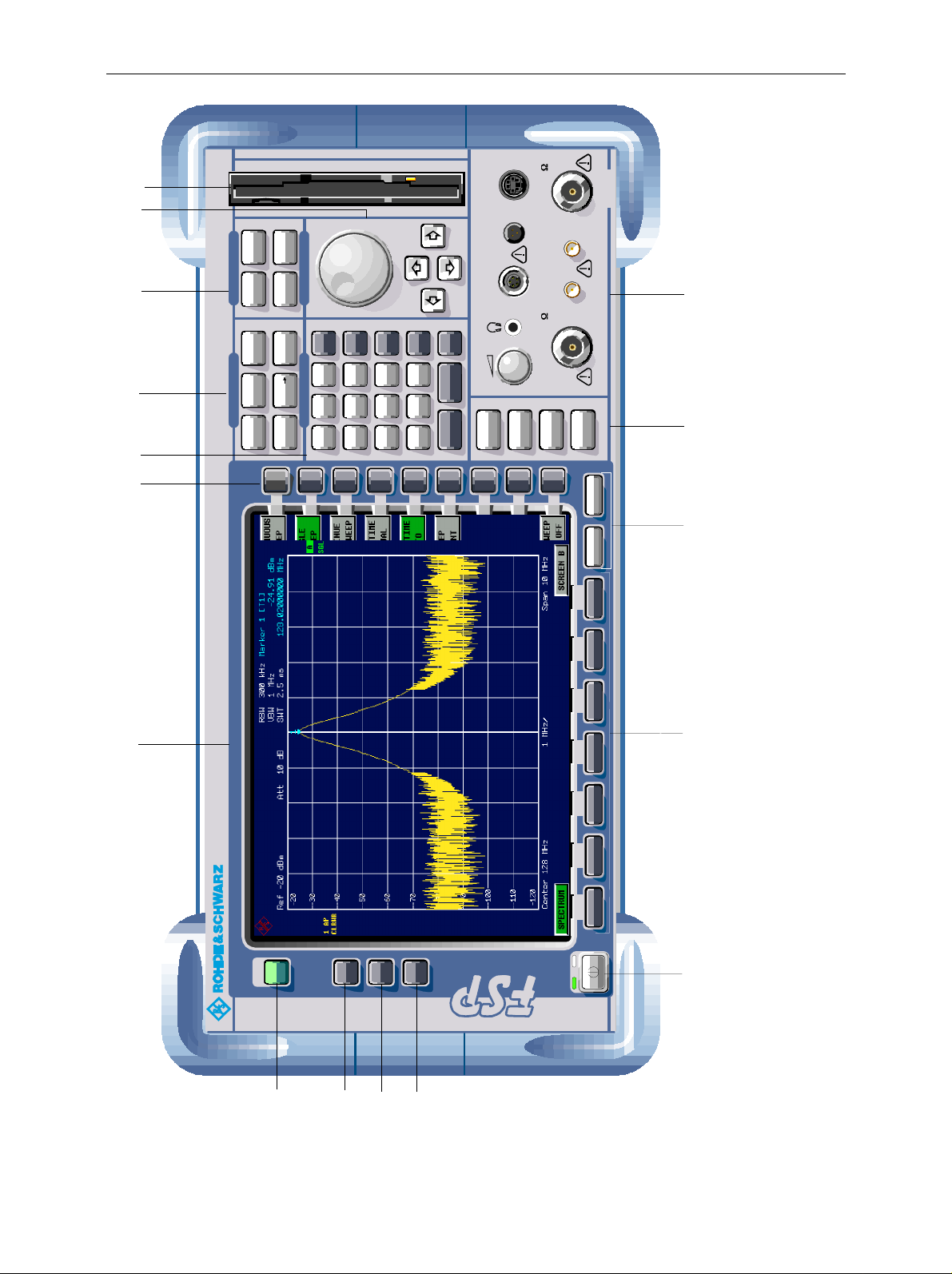

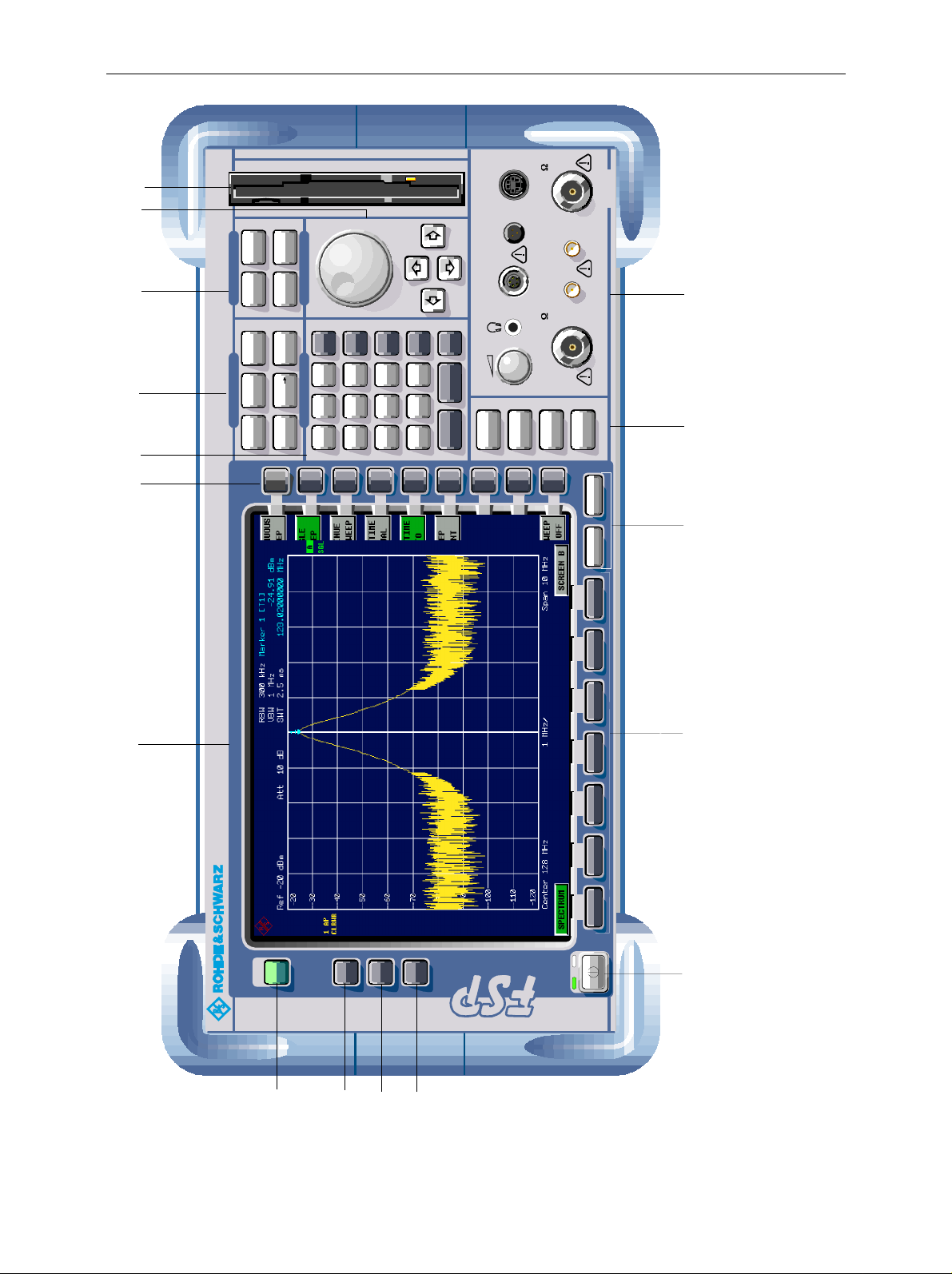

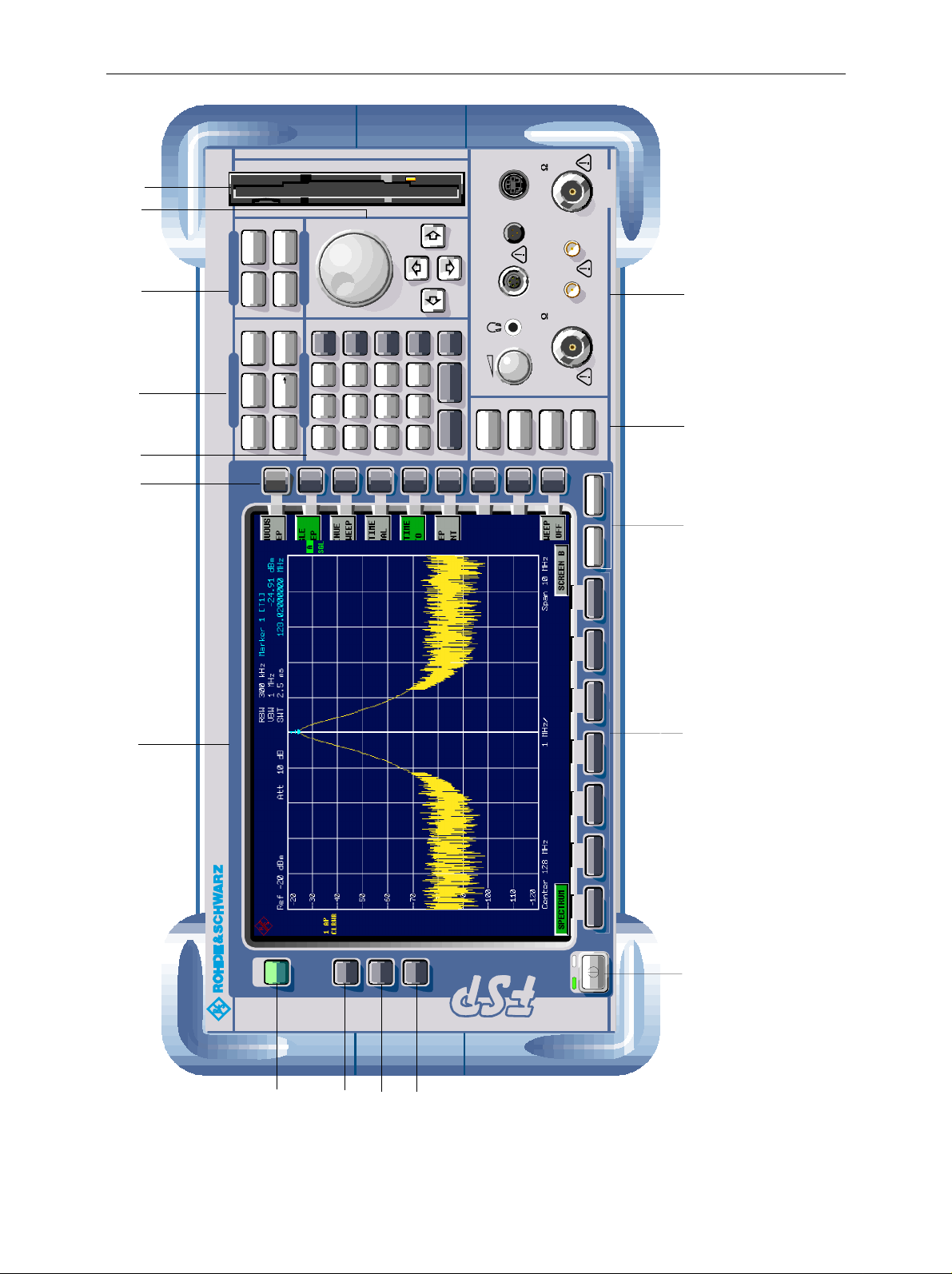

Fig. 1-1 Front View

1164.4556.12 I-1.2 E-1

Page 13

FSP Front View

1 Preparing for Operation

Chapter 1 describes the controls and c onnectors of the Spectrum Analyzer FSP by means of the f ront

and rear view. Then follows all the information that is nec essar y to put the instrument into oper ation and

connect it to the AC supply and to external devices.

A more detailed description of the hardware connectors and interfaces can be found in chapter 8.

Chapter 2 provides an introduction into the operation of the FSP by means of typical examples of

configuration and measurement; for the description of the concept for manual operation and an

overview of menus refer to chapter 3.

For a systematic explanation of all m enus, functions and par ameters and back ground inform ation refer

to the reference part in chapter 4.

For remote control of the FSP refer to the general description of the SCPI c ommands, the ins trument

model, the status reporting system, and command description in chapter 5 and 6.

Description of Front and Rear Panel Views

Front View

1

Display Screen see Chapter 3

2

Softkeys see Chapter 3

3

data input

0...9 input numbers

see Chapter 3

. input decimal point

– change sign

ESC – close input field (for uncompleted or

CANCEL already closed inputs, the original

entry is kept)

– erase the current entry in input field

(beginning of an input)

– close message window (status, error

and warning messages)

ENTER close the data input.

BACK – erase last character input for

uncompleted input

– restore previous input (undo)

1164.4556.12 1.1 E-1

Page 14

Front View FSP

7

6

5

1164.4391.30

SWEEP

CONTROL

34

2

BW SWEEP

AMPT

SPAN

FREQ

MEAS TRIG

MKR

MKR

MKR

FCTN

VARIATION

s

V

-dBm

GHz

DATA

89

7

µs

µV

ms

mV

dB

dBm

MHz

kHz

3

56

4

12

50

KEYBOARD

PROBE PO WER

ns

nV

dB..

Hz

BACK

-

.

0

AF OUTPUT

ENTER

ESC

CANCEL

TRACE

RF INPUT

EXT MIXER

LO OUT/ IF IN IF I N

GEN OUTPUT 50

DISP

LINES

MADE IN G E RMANY

MAX + 30 d Bm / 0V DC

MAX 0V DC

FILE

PREV NEXT

..

1

11 10 9 8

SPECTRUM ANALYZER 9 kHz ... 30 GHzFSP

CAL

SETUP

14

HCOPY

12

13

PRESET

16

15

Fig. 1-1 Front View

1164.4556.12 1.2 E-1

Page 15

FSP Front View

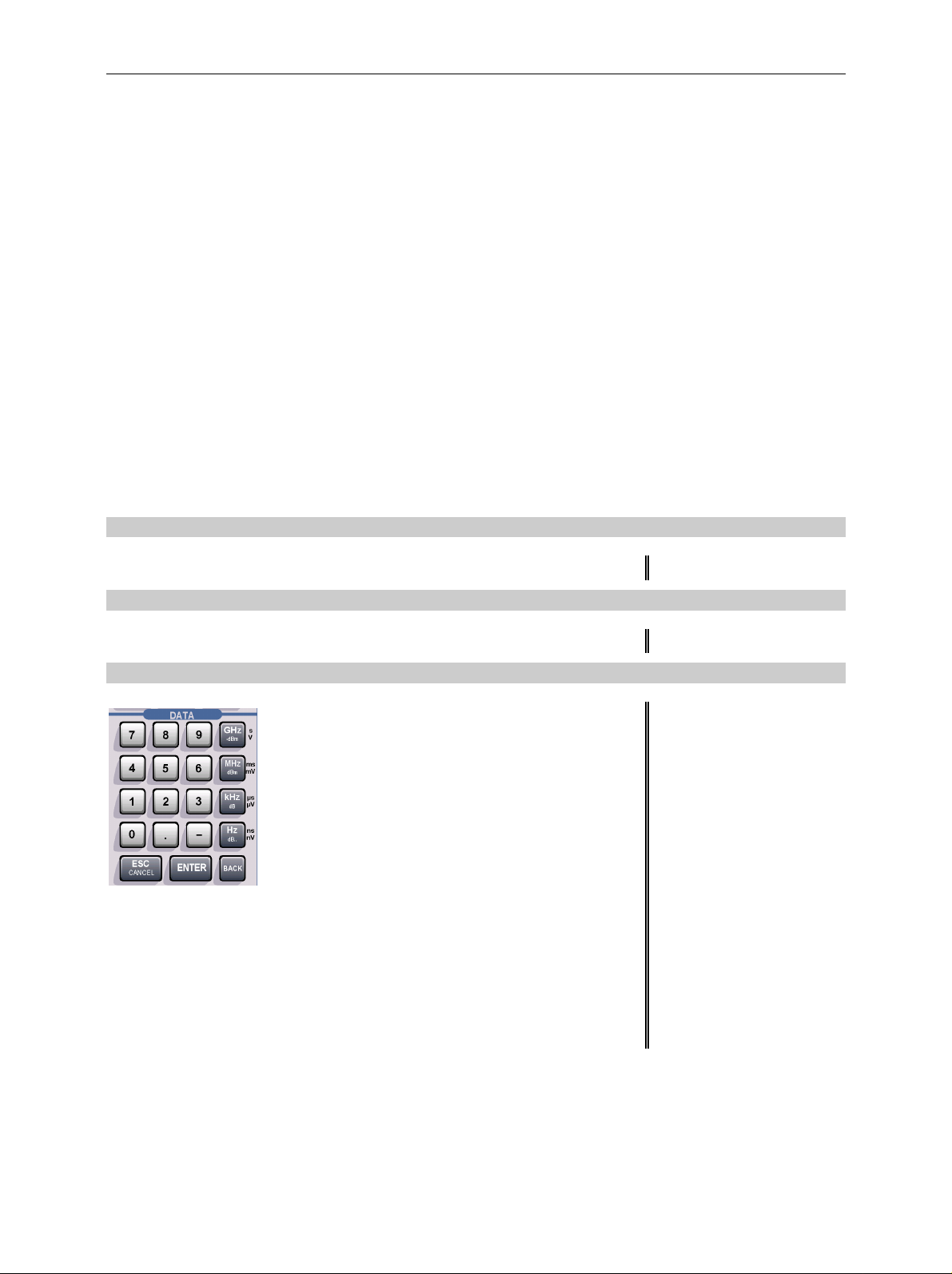

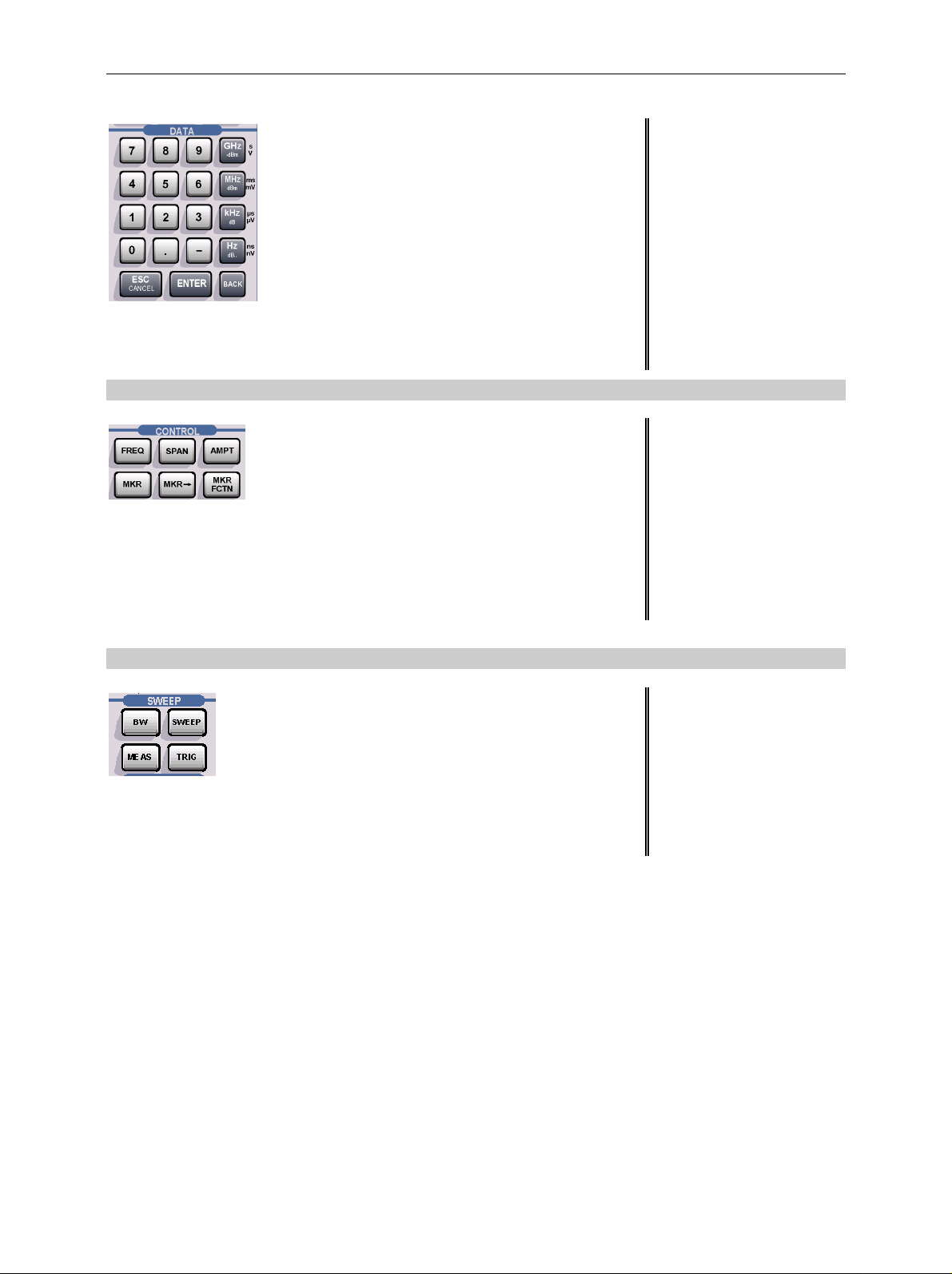

data input

GHz s The units keys close the data

-dBm V input and define the multipli-

cation factor for each basic unit.

MHz ms For dimension-less or

dBm mV alphanumeric inputs, the units

keys have weight 1.

kHz µs They behave, in this case, like the

dB µVENTER key.

Hz ns

dB.. nV

see Chapter 3

4

FREQ Set frequency axis

SPAN Set span

AMPT Set level indication and configure

RF input.

MKR Select and set standard marker and delta

marker functions.

MKR-> Change instrument settings via markers

MKR Select further marker and delta

FCTN marker functions

see Chapter 4

5

BW – Set resolution bandwidth,

video bandwidth and sweep time,

– Set coupling of these

parameters

SWEEP Select sweep

MEAS Select and set power measurements

TRIG Set trigger sources

see Chapter 4

1164.4556.12 1.3 E-1

Page 16

Front View FSP

7

6

5

1164.4391.30

SWEEP

CONTROL

34

2

BW SWEEP

AMPT

SPAN

FREQ

MEAS TRIG

MKR

MKR

MKR

FCTN

VARIATION

s

V

-dBm

GHz

DATA

89

7

µs

µV

ms

mV

dB

dBm

MHz

kHz

3

56

4

12

50

KEYBOARD

PROBE PO WER

ns

nV

dB..

Hz

BACK

-

.

0

AF OUTPUT

ENTER

ESC

CANCEL

TRACE

RF INPUT

EXT MIXER

LO OUT/ IF IN IF I N

GEN OUTPUT 50

DISP

LINES

MADE IN G E RMANY

MAX + 30 d Bm / 0V DC

MAX 0V DC

FILE

PREV NEXT

..

1

11 10 9 8

SPECTRUM ANALYZER 9 kHz ... 30 GHzFSP

CAL

SETUP

14

HCOPY

12

13

PRESET

16

15

Fig. 1-1 Front View

1164.4556.12 1.4 E-1

Page 17

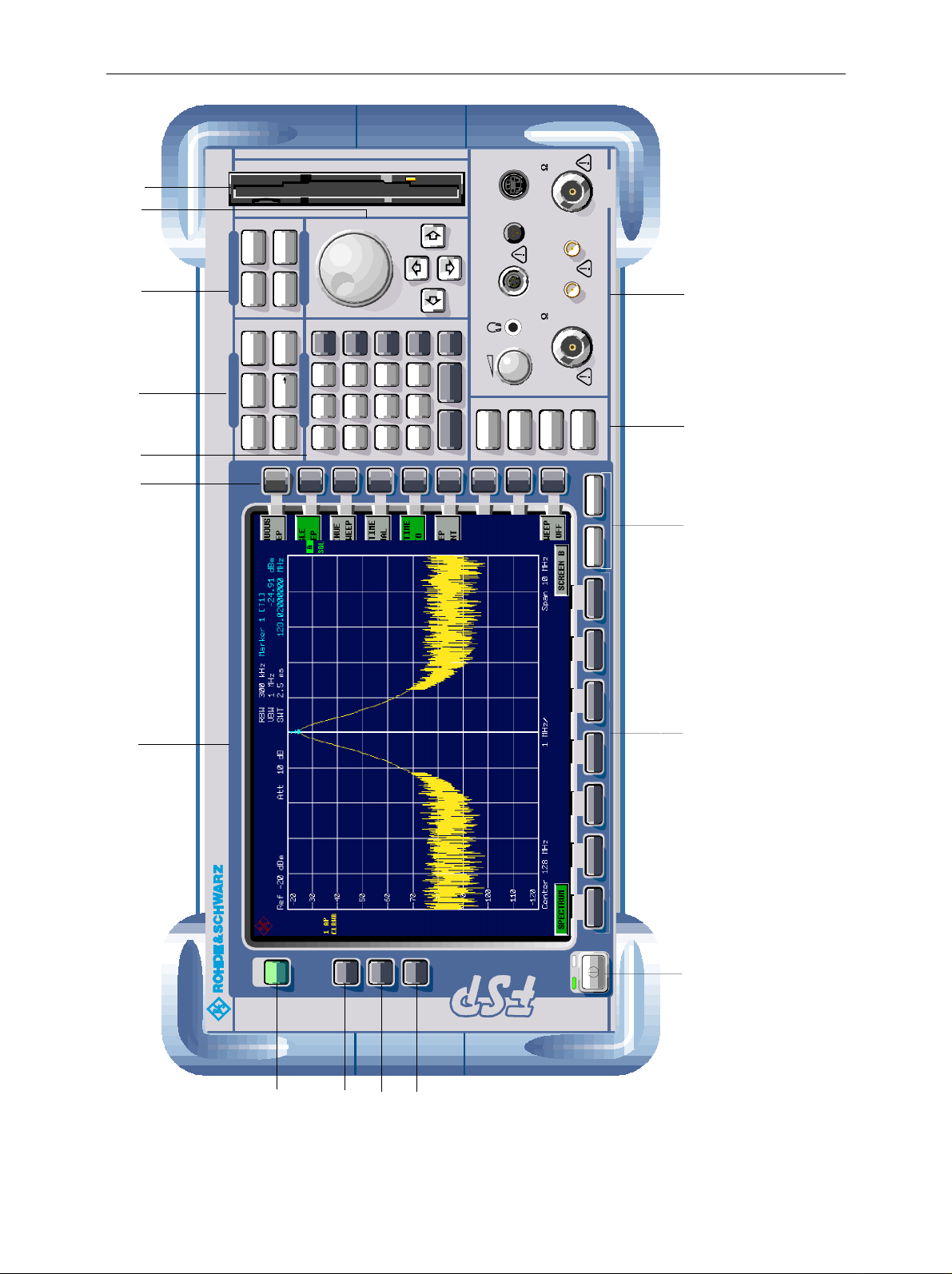

FSP Front View

≥

≥

6

Key group for entering data and for cursor movement

Cursor keys – Move the cursor within the input

fields and tables.

– Vary the input value.

– Define the direction of movement

for the roll-key.

Roll-key – Vary input values.

– Move markers and limits.

– Select letters in the help line editor.

– Move cursor in the tables

– Close data input (ENTER)

see Chapter 3

7

3 1/2" diskette drive; 1.44 MByte

8

AF OUTPUT (only with option FSP-B3)

Volume control

Head phone

connector

PROBE POWER Power supply and

coded socket

(+15 V/ -12 V) for

accessories

KEYBOARD Connector for an

external keyboard

see Chapter 8

RF INPUT RF input

Caution:

For FSP3 and FSP7 The

maximum DC voltage is 50 V,

the maximum power is

1 W (=^ 30 dBm) at

attenuation.For FSP13 and

FSP30, the maximum DC

voltage is 0 V, the maximum

power is

1 W ( 30 dBm at

attenuation)

see Chapter 8

10 dB

30 dB

1164.4556.12 1.5 E-1

Page 18

Front View FSP

7

6

5

1164.4391.30

SWEEP

CONTROL

34

2

BW SWEEP

AMPT

SPAN

FREQ

MEAS TRIG

MKR

MKR

MKR

FCTN

VARIATION

s

V

-dBm

GHz

DATA

89

7

µs

µV

ms

mV

dB

dBm

MHz

kHz

3

56

4

12

50

KEYBOARD

PROBE PO WER

ns

nV

dB..

Hz

BACK

-

.

0

AF OUTPUT

ENTER

ESC

CANCEL

TRACE

RF INPUT

EXT MIXER

LO OUT/ IF IN IF I N

GEN OUTPUT 50

DISP

LINES

MADE IN G E RMANY

MAX + 30 d Bm / 0V DC

MAX 0V DC

FILE

PREV NEXT

..

1

11 10 9 8

SPECTRUM ANALYZER 9 kHz ... 30 GHzFSP

CAL

SETUP

14

HCOPY

12

13

PRESET

16

15

Fig. 1-1 Front View

1164.4556.12 1.6 E-1

Page 19

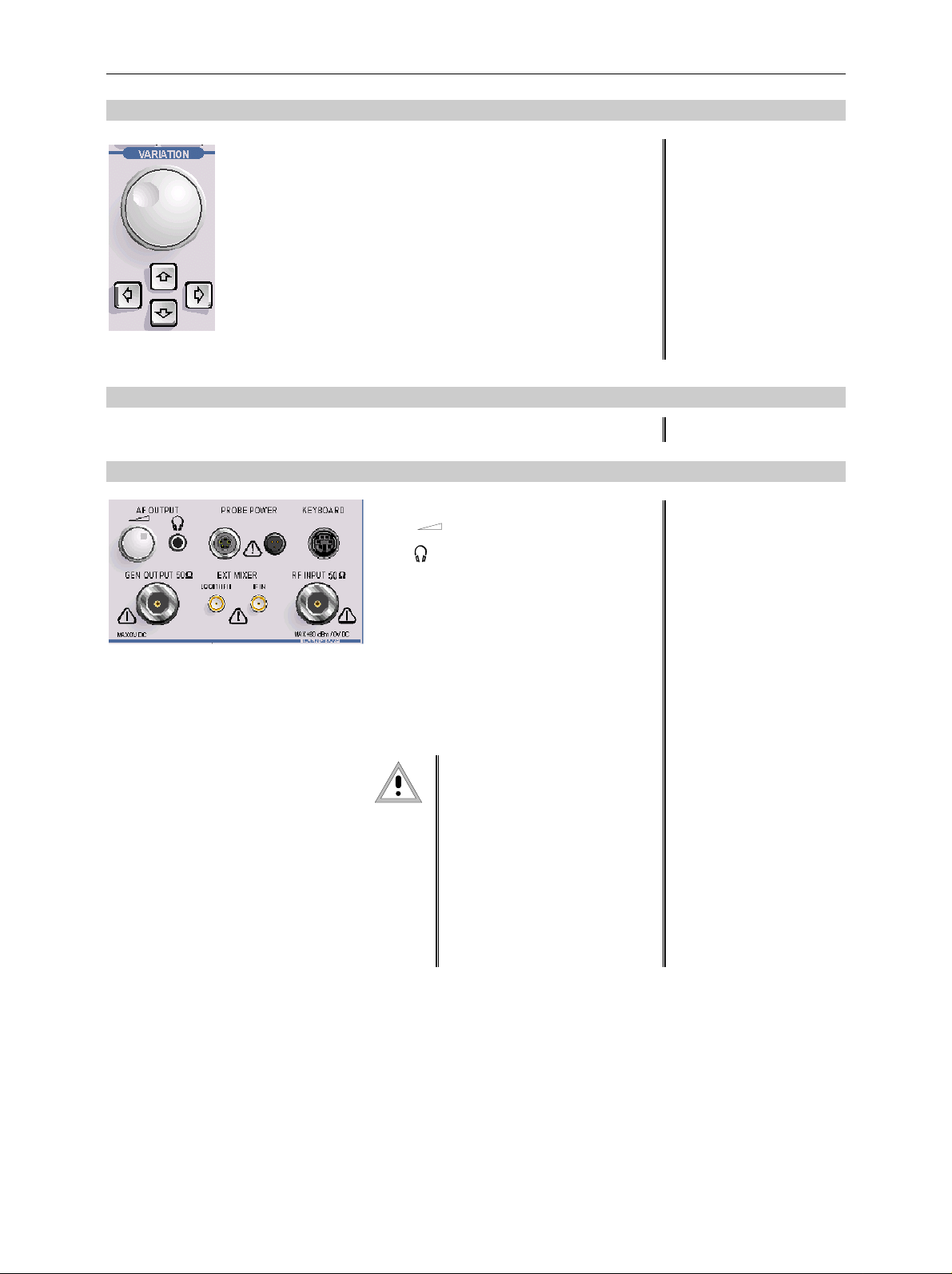

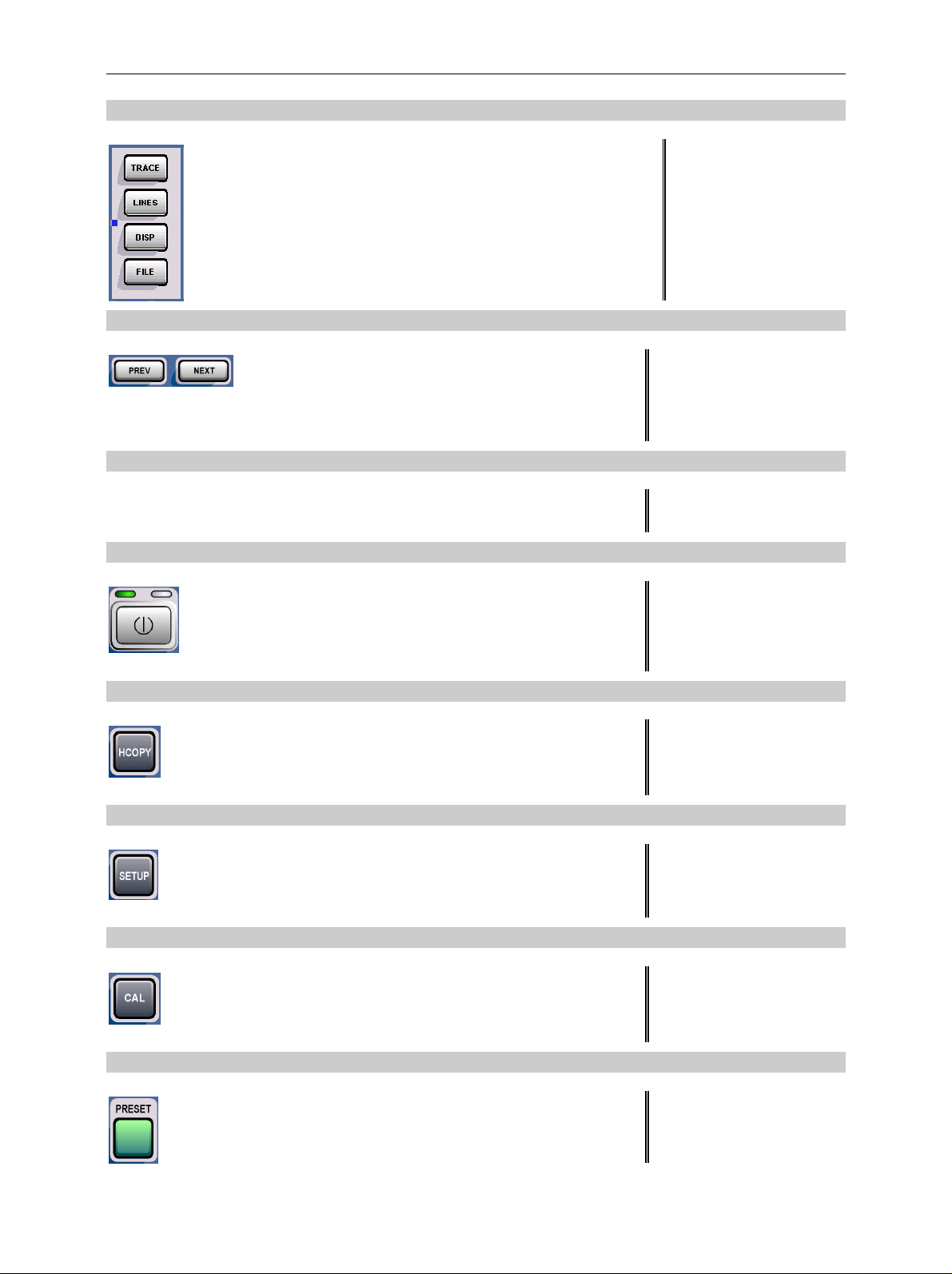

FSP Front View

9

10

11

12

TRACESelect and activate traces and detectors

LINES Set limit lines

DISP Configure display

FILE – Save and recall instrument data

– Configuration of memory media and data

Menu-change keys

NEXT Change to side menu

PREV Call main menu

Hotkeys see Chapter 3

ON/STANDBY switch see Chapter 1

see Chapter 4

see Chapter 3

13

14

15

16

Configure and start a print job see Chapters 1 and 4

Define general configuration see Chapter 4

Record correction data see Chapter 4

Call default settings see Chapter 4

1164.4556.12 1.7 E-1

Page 20

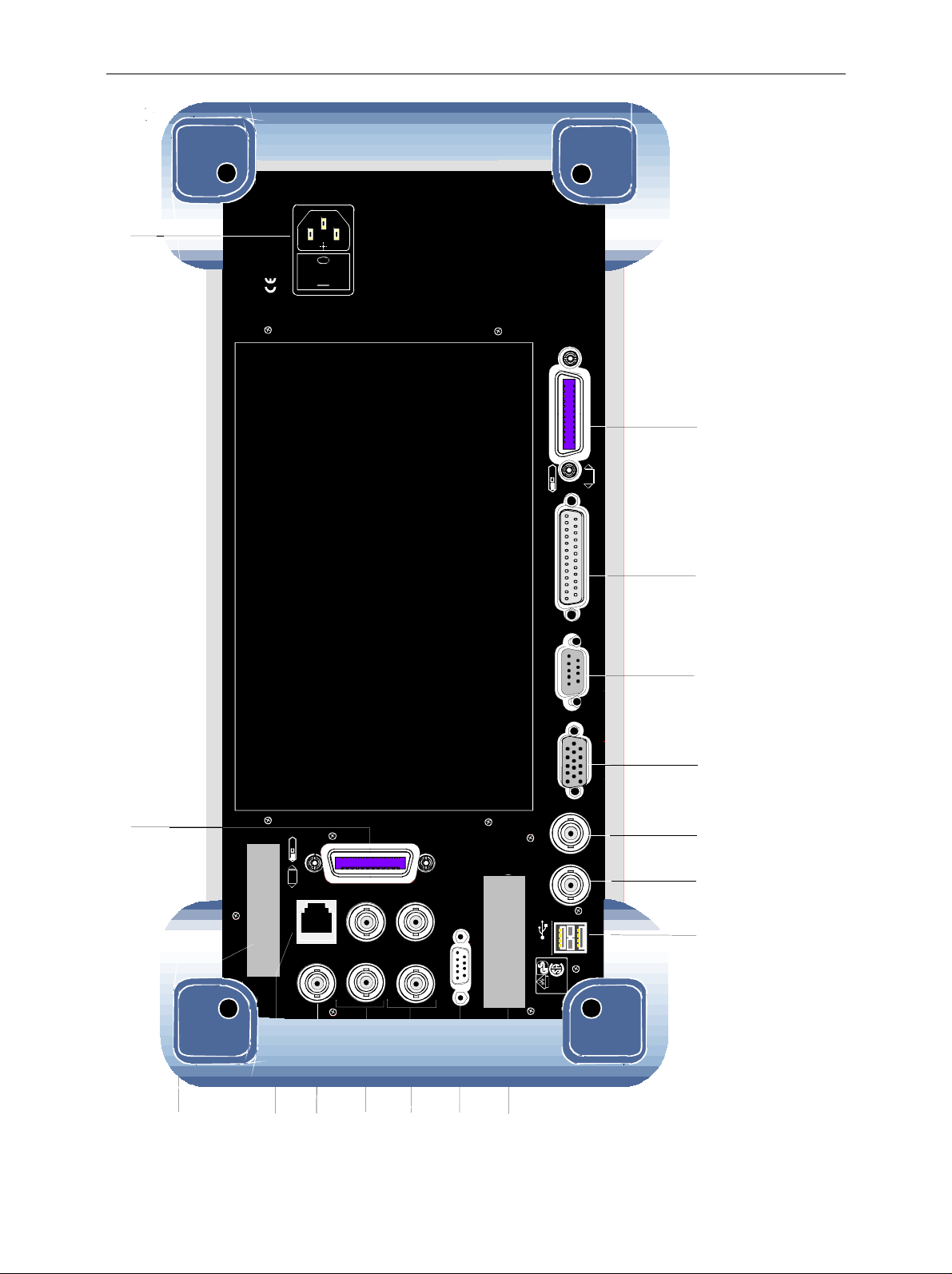

Rear View FSP

18

100 - 240 VA C

3.1 - 1.3 A

19

625

SC PI

17

20

21

MONITOR COM LPT

625

IEC 2

SC PI

SC PI

SC PI

I / Q DATA OUT

SC PI

LAN

20.4 - MHz OUT

TG Q IN

TG I IN

TG Q IN

REF OUT

USER PORT

REF IN

AUX CONTROL

NOISE

SOURC E

NOISE

GATE IN

EXT T RIG /

USB

®

US

C

LR 114 196

22

23

24

25

32

31

30

29

28

27

26

Fig. 1-1 Rear View

1164.4556.12 1.8 E-1

Page 21

FSP Rear View

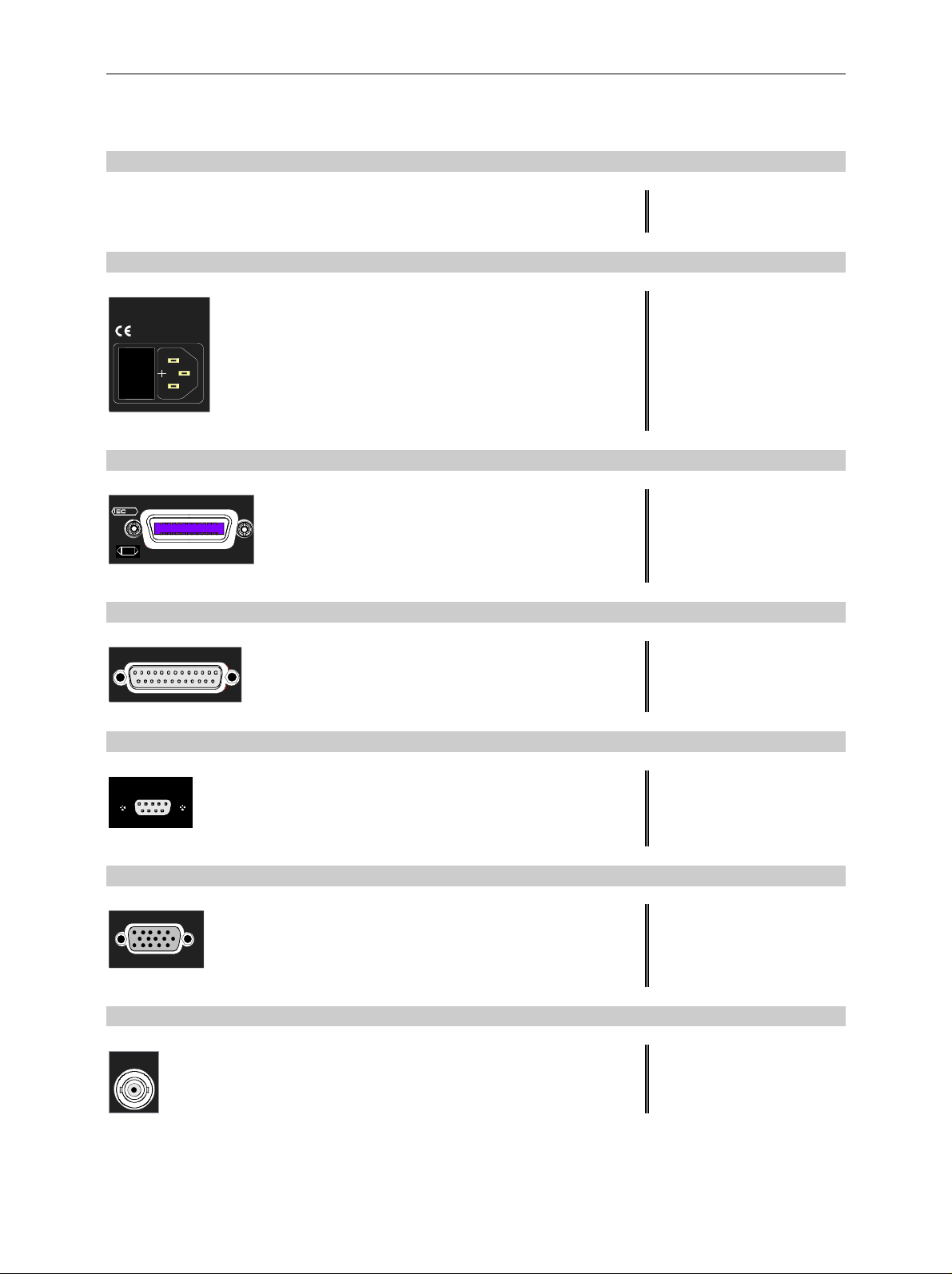

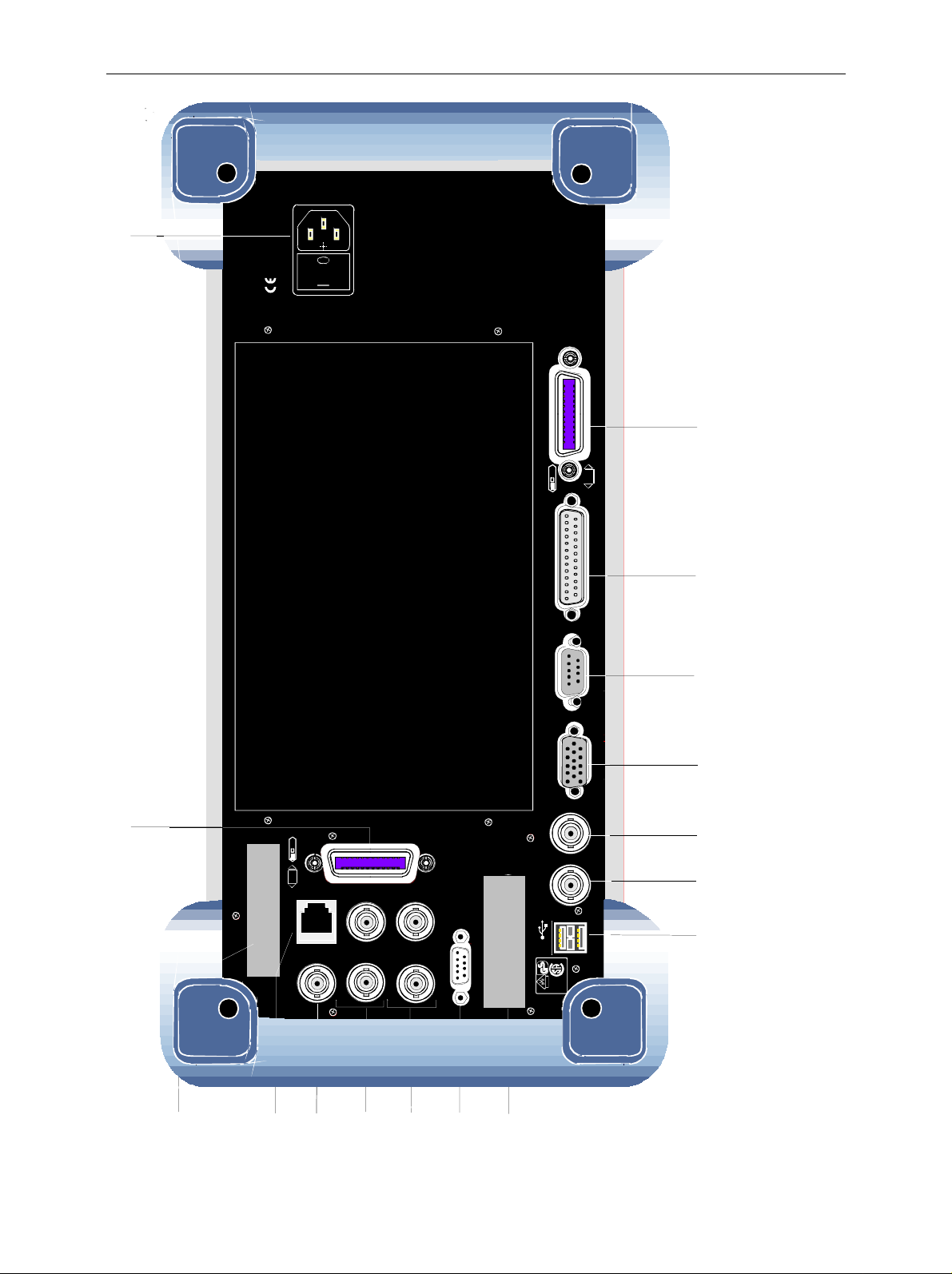

Rear View

17

Reserved for options see Chapter 8

18

100 - 240 VAC

3.1 - 1.3 A

I 0

19

625

SCPI

20

21

LPT

Power switch and AC power connector see Chapter 1

IEC/IEEE bus-connector see Chapter 8

Parallel interface connector

see Chapter 8

(printer connector)

COM

Connector for a serial interface

see Chapter 8

(9-pin socket; COM)

22

MONITOR

Connector for an external monitor see Chapter 8

23

NOISE

SOURCE

1164.4556.12 1.9 E-1

Output connector for an external noise source see Chapter 8

Page 22

Rear View FSP

18

100 - 240 VA C

3.1 - 1.3 A

19

625

SC PI

17

20

21

MONITOR COM LPT

625

IEC 2

SC PI

SC PI

SC PI

I / Q DATA OUT

SC PI

LAN

20.4 - MHz OUT

TG Q IN

TG I IN

TG Q IN

REF OUT

USER PORT

REF IN

AUX CONTROL

NOISE

SOURC E

NOISE

GATE IN

EXT T RIG /

USB

®

US

C

LR 114 196

22

23

24

25

32

31

30

29

28

27

26

Fig. 1-2 Rear View

1164.4556.12 1.10 E-1

Page 23

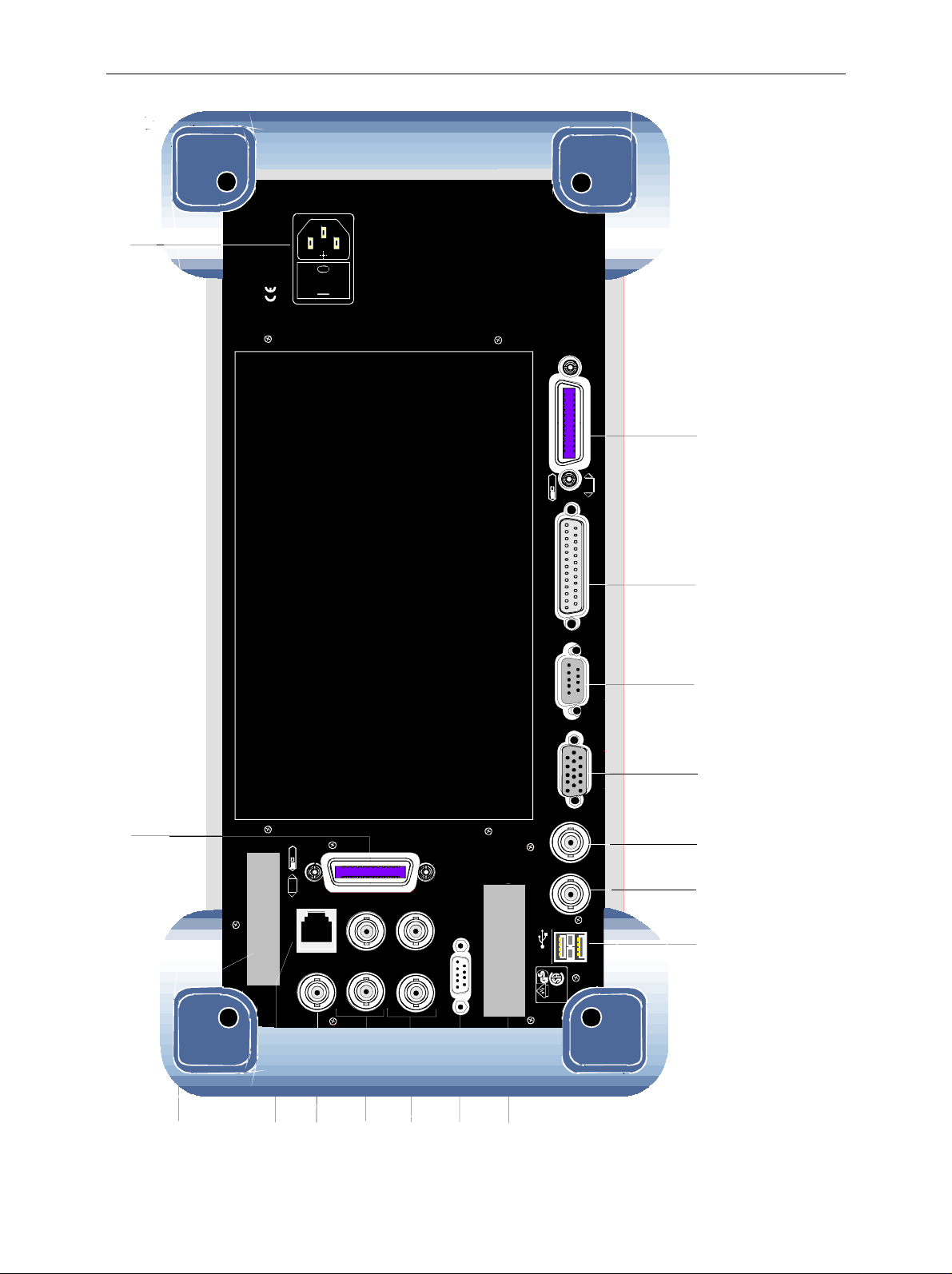

FSP Rear View

24

EXT TRIG /

GATE IN

25

Input connector for an external trigger or an

external gate signal

see Chapter 8

USB

26

27

AUX CONTROL

28

REF IN REF OUT

Connector for USB see Chapter 8

Reserved for options

Connector to control an external generator ((only

with option FSP-B10)

REF IN Input connector for an external

see Chapter 4

reference (10 MHz)

REF OUT Output connector for an internal

reference (10 MHz)

1164.4556.12 1.11 E-1

Page 24

Rear View FSP

18

100 - 240 VAC

3.1 - 1.3 A

19

625

SC PI

17

20

21

MONITOR COM LPT

625

IEC 2

SCP I

SCP I

SCP I

I / Q DATA OUT

SCP I

LAN

20.4 - MHz OUT

TG Q IN

TG I IN

TG Q IN

REF OUT

USER PORT

REF IN

AUX CONTROL

NOISE

SOURC E

NOISE

GATE IN

EXT TRI G /

USB

®

US

C

LR 114 196

22

23

24

25

32

31

30

29

28

27

26

Bild 1-2 Rear View

1164.4556.12 1.12 E-1

Page 25

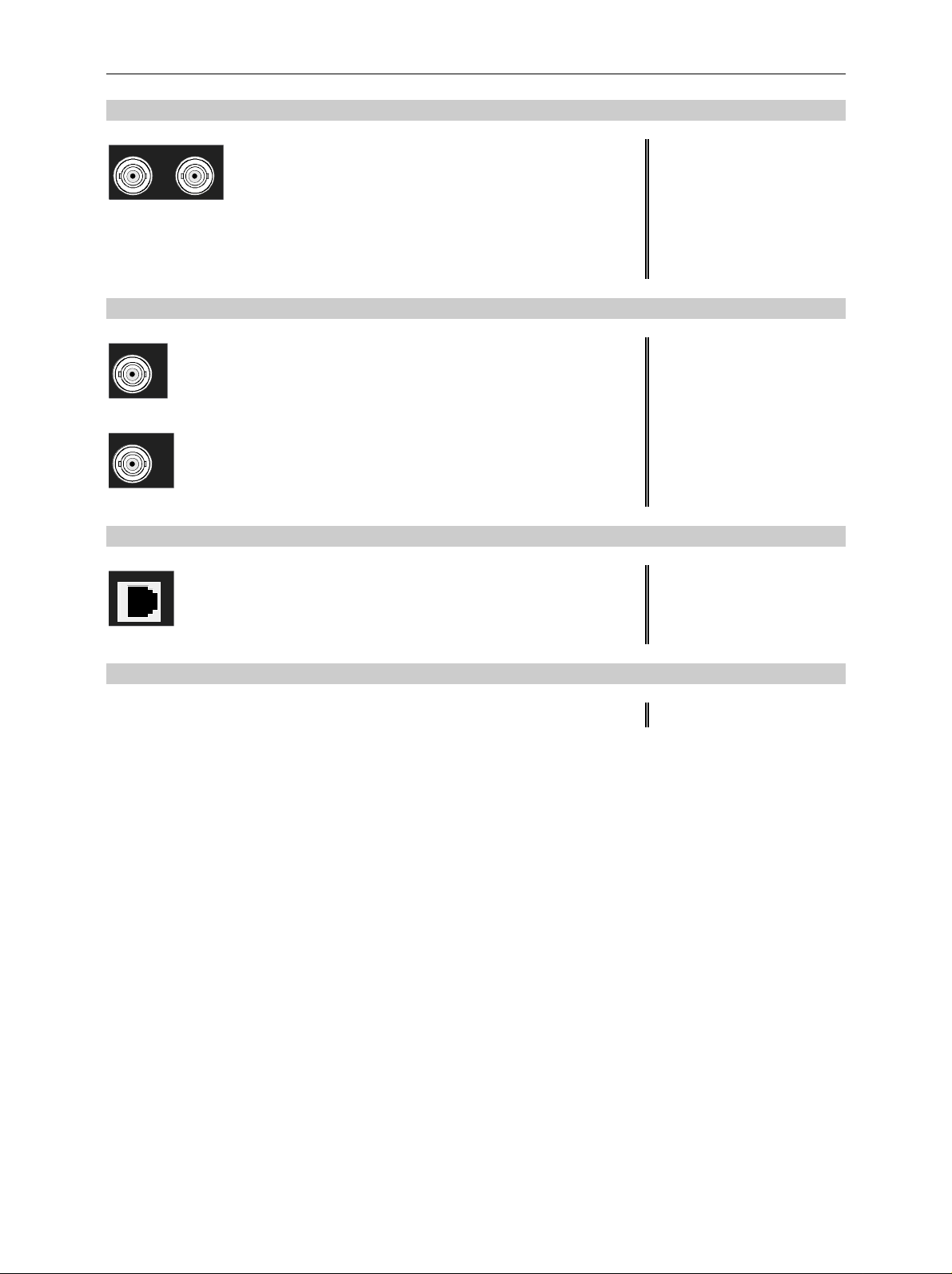

FSP Rear View

29

TG I IN TG Q IN

30

20.4 - MHz OUT

CVS IN/OUT

31

LAN

TG IN Signal input connector for external

modulation of Tracking Generator

(option FSP-B9)

TG Q IN Signal input connector for external

modulation of Tracking Generator

(option FSP-B9)

Output connector for 20.4 MHz IF

see Chapter 8

(replaced by CCVS IN OUT if option FSP-B6 is

built in)

Selectable CCVS input/output

see Chapter 4 and 8

(only if option FSP-B6 is built in)

LAN Interface (option FSP-B16) see Chapter 4

32

Reserved for options

1164.4556.12 1.13 E-1

Page 26

Getting Started with the Instrument FSP

Getting Started with the Instrument

The following section describes how to activate the instrument and how to connect external devices

such as printer and monitor.

Chapter 2 explains the operation of the instrument using simple measurement examples.

Important:

Prior to switching on the instrument, make sure that the following conditions are fulfilled:

• The instrument cover is in place and tightly screwed on

• Fan openings are not obstructed

• Signal levels at the inputs are within specified limits

• Signal outputs are connected correctly and not overloaded.

Any non-compliance may cause damage to the instrument .

Preparing the Instrument for Operation

Ø Take the instrument out of the packaging and check whether the

items listed in the pack ing list and in the lists of acces sories are all

included.

Ø Remove the two protective covers from the front and rear of the FSP

and carefully check the instrument for damage.

remove protective caps

Ø Should the instrument be damaged, immediately notify the carrier

and keep the box and packing material.

Ø For further transport or shipm ent of the FSP, the original packing

should be used. It is recommended to keep at least the two

protective covers of the front and rear panels in order to prevent

damage to the controls and connectors.

Setting Up the Instrument

Standalone Operation

The instrument is designed for use under general laboratory conditions. The ambient conditions required

at the site of operation are as follows:

• The am bient tem per ature m ust be in the range spec ified in

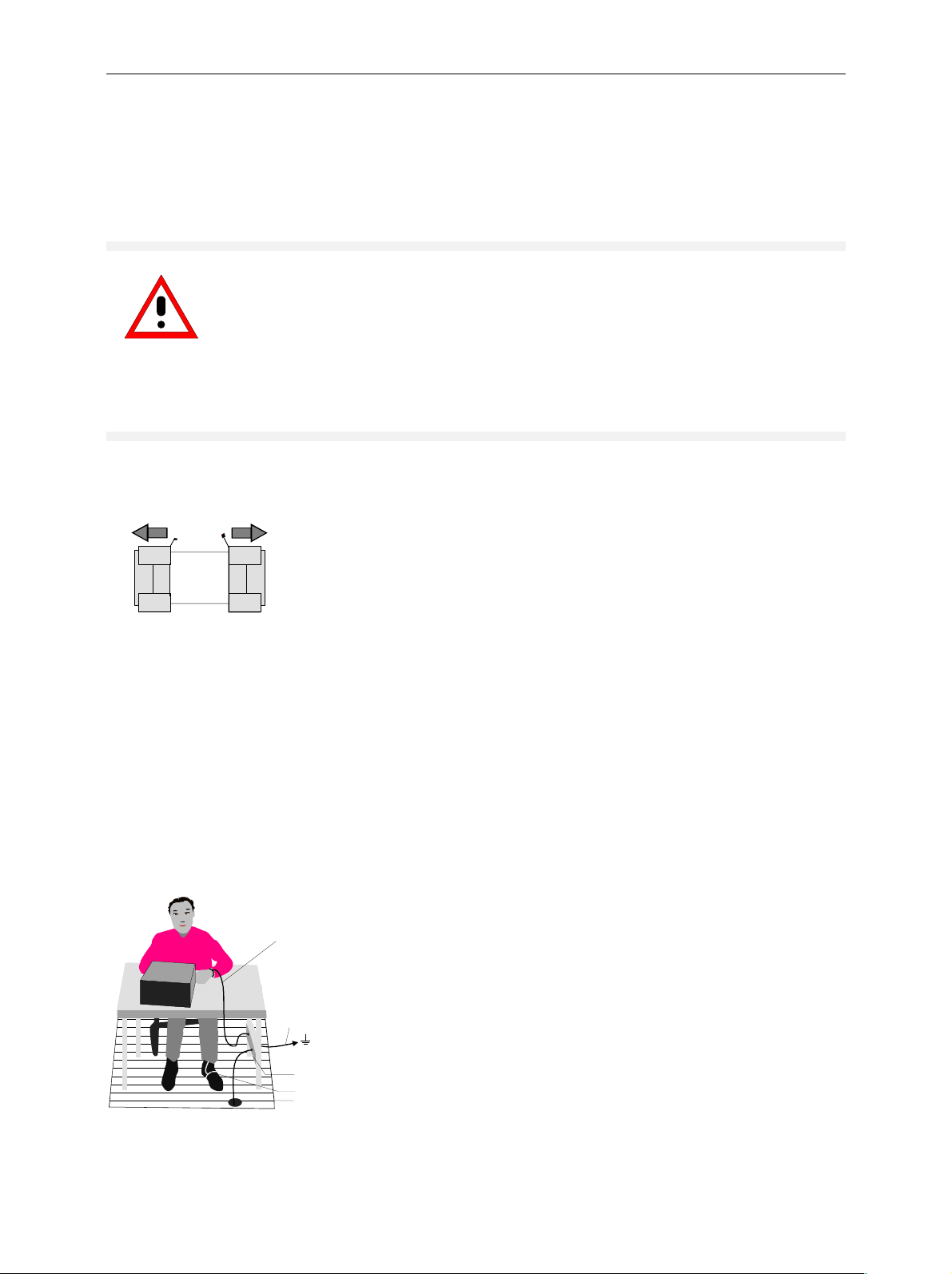

Wrist strap with cord

Building ground

Ground connection

of operational site

Heel strap

Floor mat

the data sheet.

• All fan openings must be unobstructed and the air flow at

the rear panel and at the side-panel perforations must be

unimpeded. The distance to the wall should be at least

10 cm.

• The mounting surface should be flat.

• To avoid damage of electronic components of the DUT

due to electrostatic discharge on manual touch, protective

measures against electrostatic discharge are

recommended.

1164.4556.12 1.14 E-1

Page 27

FSP Getting Started with the Instrument

Safety Instruction for Instruments with Tiltable Feet

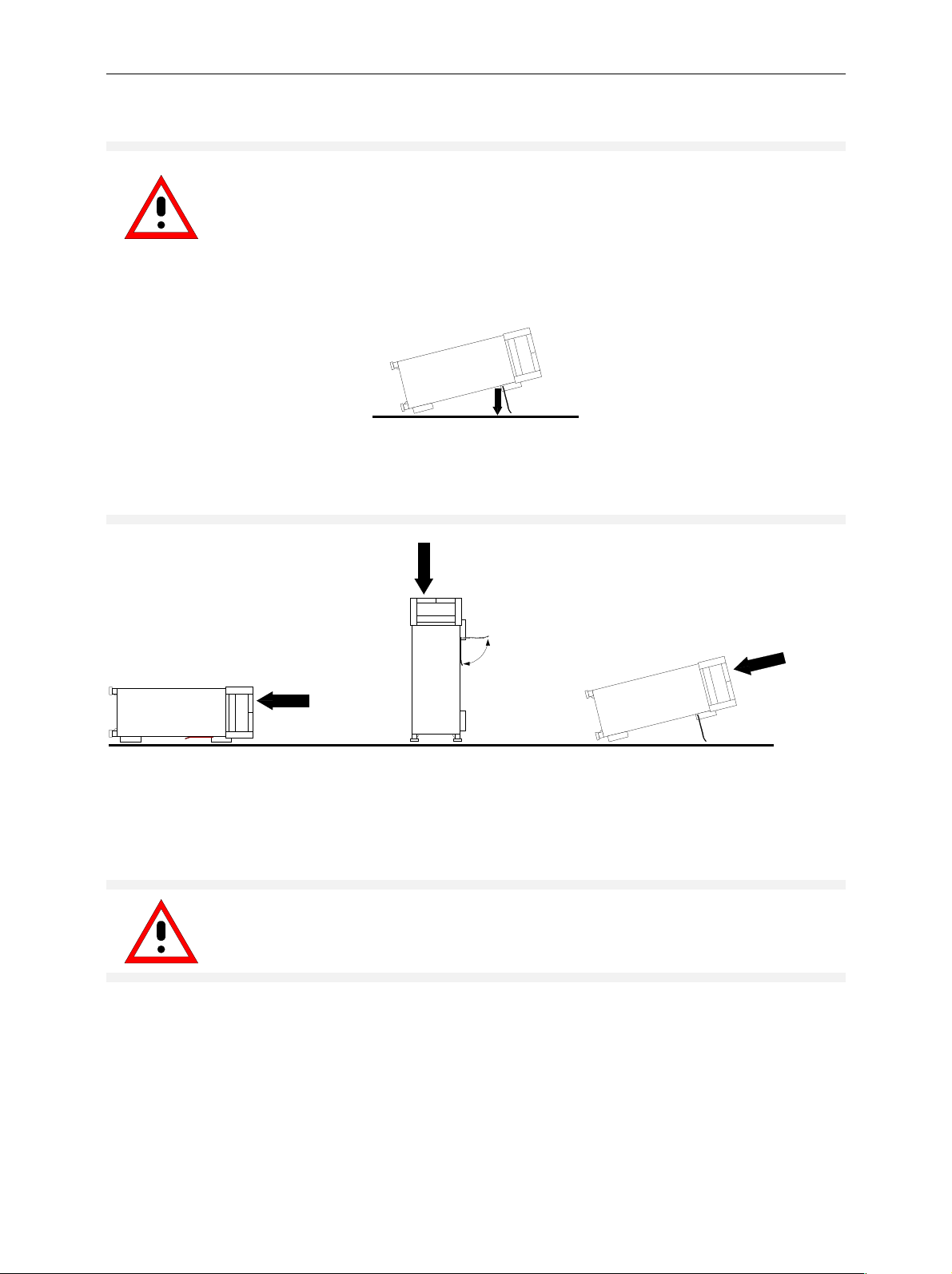

Warning

The feet must be fully folded in or out. Only in this way can the stability of the

instrument be guaranteed and reliable operation be ensured. W ith the feet out, the

total load for the feet must not exceed 500 N (own weight and additional units put

onto the instrument). These units must be sec ured against slipping (e.g. by locking

the feet of the unit at the top side of the enclosure).

<500N

When shifting the instrument with the feet out, the feet might c ollapse and fold in. To

avoid injuries, the instrument must therefore not be shifted with the feet out.

The instrument can be operated in any position.

Rackmounting

Important:

For rack installation, ensure that the air flow at the s ide-panel per for ations and the air

exhaust at the rear panel are not obstructed.

The instrument may be installed in a 19" rack by using a rack adapter kit (Order No. see data sheet).

The installation instructions are part of the adapter kit.

1164.4556.12 1.15 E-1

Page 28

Getting Started with the Instrument FSP

EMC Safety Precautions

In order to avoid electromagnetic interference (EMI), the instrument may be operated only with all covers

closed. Only adequately shielded signal and control cables may be used (see recommended

accessories).

Connecting the Instrument to the AC Supply

The FSP is equipped with an AC voltage selection feature and will automatically adapt itself to the

applied AC voltage (range: 100 to 240 V AC, 40 to 400 Hz). External voltage selection or adaptation of

the fuses are not necessary. The AC power connector is located on the rear panel (see below).

Ø Connect the instrument to the AC power source using the AC

I

o

Power connector

power cable delivered with the instrument.

As the instrument is designed according to the regulations for

safety class EN61010, it must be connected to a power outlet

with earthing contact.

Switching the Instrument On/Off

Caution:

Do not power down during booting. Such a switch-off may lead to corr uption of

the hard disk files.

AC power switch on the rear panel

Power switch

Power connec tor

I 0

Power switch

Position I = ON

In the I position, the instrument is in st andby mode or in

operation, depending on the position of the

ON/STANDBY key at the front of the instrument.

Note:

The AC power switch may remain ON continuously.

Switching to OFF is only required when the instrument

must be completely removed from the AC power source.

Position O = OFF

The 0 position implies an all-pole disconnection of the

instrument from the AC power source.

1164.4556.12 1.16 E-1

Page 29

FSP Getting Started with the Instrument

ON/STANDBY switch on the front panel

ON STANDBY

Caution:

In standby mode, the AC

power voltage is present

within the instrument

Standby switch

The ON/STANDBY switch activates two different oper ating

modes indicated by coloured LEDs:

Operation ON - ON/STANDBY is depressed

The green LED (ON) is illuminated. The instrument is

ready for operation. All modules within the instrument are

supplied with power.

STANDBY - ON/STANDBY switch is not pressed.

The yellow LED (STANDBY) is illuminated. Only the

power supply is supplied with power and the quartz oven

is maintained at normal operating temperature.

Switching On the Instrument

Ø In order to switch on the FSP, set the power switch on the rear panel to position I.

Ø Set the F SP to operating mode by pressing the ON/STANDBY key on the front panel. The green

LED must be illuminated.

Startup Menu and Booting

After switching on the instrum ent, a message indicating the ins talled BIOS version (e.g. Analyzer BIOS

Rev. 1.2) appears on the screen for a few seconds.

Subsequently Windows XP is booted fir st and after that the instrument firm ware will boot. As soon as

the boot process is finished the ins trument will start measuring. T he settings used will be the one that

was active when the instrument was previously switched off, provided no other device c onf igur ation than

FACTORY had been selected with STARTUP RECALL in the FILE menu.

Switching Off the FS P

Ø Switch the ON/STANDBY key on the front panel to standby mode by pressing it once.

The yellow LED must be illuminated.

Only when removing the FSP completely from t h e A C p o w e r so u r ce :

Ø Set the power switch at the rear panel to position 0.

1164.4556.12 1.17 E-1

Page 30

Function Test FSP

Power-Save Mode

Display:

The FSP offers the possibility of switching on a power-save mode for the screen display. The

backlighting will be switched off if no entry is made on the front panel (key, softkey or hotkey as well as

spinwheel) during the selected response time.

In order to switch on the power-save mode:

1. Call the DISPLAY - CONFIG DISPLAY submenu to configure the screen display:

Ø Press DISP key

Ø Press CONFIG DISPLAY softkey

2. Activate the save mode

Ø Press DISPLAY PWR SAVE softkey.

The softkey is highlighted in colour, thus indicating that the power-save mode is on. At the

same time the data entry for the delay time is opened.

3. Define the delay time

Ø Enter the required response time in minutes and confirm the entry using the ENTER key.

The screen will be blanked out after the selected time period has elapsed.

A power-save mode is preset f or the built-in hard disk which is automatic ally closed down 15 minutes

after the last access.

Recalling the Most Recent Instrument Settings

The FSP stores its current inst rument settings onto the hard disk every time it is switched of f via the

ON/STANDBY key. After each power-on, the FSP is reloaded with the operational parameters which

were active just prior to the last power-off (STANDBY or AC power OFF) or were set with ST ARTUP

RECALL (see Chapter 4 "Saving and Recalling Data Sets").

Note: Storing the current instrument settings is not possible if the ins trument is s witched off us ing

the POWER ON switch at the rear panel or when unplugging the mains cord. After poweron the instrument settings stored previously on the hard disk will be loaded in this case.

Function Test

After turning on the AC power, the FSP will display the following message on the display screen:

Rohde & Schwarz GmbH & Co. KG

Analyzer BIOS Vx.y

After appearance of the above message, a selftest of the controller hardware is performed.

Subsequently, the Windows NT controller boots and the measurement screen will appear.

The system self- alignment is activated via CAL key, CAL TOTAL softkey. The individual res ults of the

self-alignment (PASSED / FAILED) can be displayed in the CAL menu (CAL RESULTS).

With the aid of the built-in selftest functions (SETUP key, SERVICE, SELFTEST soft keys), the

functional integrity of the instrument can be verified and/or defective modules can be localized.

1164.4556.12 1.18 E-1

Page 31

FSP Windows NT

Windows XP

Caution:

The drivers and programs used under Windows XP are adapted to the measuring

instrument. In order to prevent the instrument functions from damage, the settings

should only be modified as described below.

Existing software may only be modified using update software released by Rohde &

Schwarz.

Additionally only programs authorized by Rohde & Schwarz for use on the FSP may

be run on the instrument.

Do not power down during booting. Such a switch-off may lead to corruption of

the hard disk files.

The instrument runs under the operating system Windows XP Embedded. The com puter c an be used to

install and configure device drivers that were authorized by Rohde & Schwarz. Any further use of the

computer function is only allowed under the conditions described in this operating manual.

Login

Windows XP requires a login process , during which the user is asked for identif ication by entering his

name and password. As a factory default the instrum ent is configured for Auto Login, i.e. the login is

performed automatic ally and in the background. The user name used f or this is "instrument" and the

password is also "instrument" (in small letters).

Administrator level

The NT user account used for the autologin function has administrator access rights.

Windows XP Service Packs

The Windows XP Embedded system installed on the instrument includes Service Pack 1 for XP

Embedded.

Any service pack not approved by Rohde & Schwarz must not be installed since malfunctions

may occur. These malfunctions could impair measurements that are correctly performed on the

instrument and necessitate a repair.

The user is especially warned against using Service Pack s of Windows XP Hom e or of the Pr ofes sional

Edition, since these Service Packs are not compatible with Windows XP Embedded.

Calling the Windows XP start menu

The Windows NT start menu is called using the key combination <CTRL> <ESC>. It is possible to

access the required subm enus f rom the star t m enu by means of the m ouse or the cur sor k eys. In order

to return to the measurement screen the button "R&S Analyzer Interface" in the W indows NT task bar

can be used.

1164.4556.12 1.19 E-1

Page 32

Connecting an External Keyboard FSP

Connecting an External Keyboard

Caution:

Connect the keyboard only when the instrument is switched off

(STANDBY). Otherwise, proper functioning cannot be ens ured due to interactions with

the firmware.

The FSP allows an external PC keyboard to be connected to the 6-pin PS/2 connector labelled

KEYBOARD on the front panel or to the USB interface on the rear panel.

KEYBOARD

USB

The keyboard makes it easier to enter comments, file names, etc, when measurements are performed.

If the keyboard is to be connected to the PS/2 connector, the PSP-Z2 keyboard (Order No.

1091.4100.02, English) is recomm ended. This keyboard includes not only the PC keyboard but also a

trackball for controlling the mouse.

Keyboards and mouse devices in line with the USB standard 1.1 are suitable f or connection to the USB

interface.

The keyboard (except for PSP-Z2, see above) will automatically be recognized after connection. The US

keyboard assignment is the default setting. Special settings such as ref resh rate can be performed in

the Windows XP menu START - SETTINGS - CONTROL PANEL - KEYBOARD.

Chapter 8 contains the interface description for the connectors.

1164.4556.12 1.20 E-1

Page 33

FSP Connecting an External Keyboard

Connecting a Mouse

To make Windows XP operation easier, the allows a mouse to be connected to the PS/2 mouse

interface or to the USB interface on the rear panel.

To make Windows XP operation easier, the F SP allows a mouse to be connec ted to the USB interface

on the rear panel.

USB

Microsoft and Logitech mouse types are supported.

Note. The recommended keyboard PSP-Z2 is equipped with a track ball for mouse c ontr ol. Connecting

an additional mouse will cause interface conflicts and lead to malfunctions of the instrument.

After connection the mouse is automatically recognized. Special settings suc h as mouse cursor s peed

etc, can be performed in the Windows XP menu START - SETTINGS - CONTROL PANEL - MOUSE.

Chapter 8 contains the interface description for the connector.

1164.4556.12 1.21 E-1

Page 34

Connecting an External Monitor FSP

Connecting an External Monitor

Caution:

The monitor may only be connected when the instrument is sw itched off (STANDBY).

Otherwise, the monitor may be damaged.

Do not modify the screen driver (dis play type) and display configuration since this will

severely affect instrument operation.

The instrument is equipped with a rear-panel MONITOR connector for the connection of an external

monitor.

MONITOR

After connecting the external monitor the instrument needs to be rebooted in order to recognize the

monitor. After that the measurement screen is displayed on both the external monitor and the

instrument. Further settings are not necessary.

1164.4556.12 1.22 E-1

Page 35

FSP Connecting a Printer

Connecting a Printer

A printer can be connected while the instrument is running.

The FSP allows two different printer c onfigurations for printing a hardc opy to be created plus s witchover

between these two configurations. The DEVICES table in the HCOPY menu shows the available

selection of installed printers (see section 4.4 "Documentation of Measurement Results").

The interfaces for connecting printers are on the rear panel:

LPT

USB

Chapter 8 contains the interface description for the connectors.

Selecting a Printer

Before a hardcopy can be printed, the printer has to be selected from the "HCOPY" menu.

In the following example, an HP DeskJet 660C printer that was preinstalled for LPT1 is selected as

DEVICE2 for hardcopies of the screen content.

Ø Press the HCOPY key.

The HCOPY menu will open.

HCOPY

DEVICE

SETUP

DEVICE

12

COLORS

DEVICE

12

Ø Press the DEVICE 1/2 softkey.

Device 2 will become the active output

unit.

Note:

If the printer is to be operated as device 1,

this step can be omitted.

1164.4556.12 1.23 E-1

Page 36

Connecting a Printer FSP

DEVICE

SETUP

Ø Press the DEVICE SETUP softkey.

The HARDCOPY SETUP table opens and

displays the selection of output formats.

The current selection "Clipboard" is

highlighted and marked with a dot in the

option button.

Ø Use the cursor key

to move the

selection bar to "Printer" and press

ENTER.

Windows for selecting a printer (Name),

printing to file (Print to File) and selecting

printout orientation (Orientation) are

displayed.

Ø Use the cursor key to set the selection

bar to "Name" and press ENTER .

The list of available printer types appears.

Ø Use the cursor key

/ or the

spinwheel to move the selection bar to the

"HP DeskJet 660C" printer and press

ENTER.

The list closes and the selected printer

appears in the "Name" field.

Note:

If the desired printer is not available in the

selection list, its driver must first be

installed.

For further information, see sections

"Installation of Plug&Play Printers",

"Installation of Non-Plug&Play Printers"

and "Installation of Network Printers".

1164.4556.12 1.24 E-1

Page 37

FSP Connecting a Printer

VARIATION

Ø Press the cursor key or turn the

spinwheel until the "Close" button is

reached.

Further settings can still be made:

"Print to File" redirects printing to a f ile. In

this case, the system prompts you for a file

name when printing is started.

Ø The selection is activated by pressing

ENTER or the spinwheel.

"Orientation" is used to switch between

portrait and landscape format.

Ø To change the selection, open the list by

pressing ENTER and select the desired

orientation with the cursor key

/ . To

close the list, press ENTER again.

The "Close" button is used to complete the

setup.

Ø Press ENTER as soon as the "Close"

button is available.

The dialog closes. Printing will now be

performed according to the selected settings.

PRINT

SCREEN

Start printing

Ø Press the PRINT SCREEN softkey.

A hardcopy of the screen contents will be

printed.

1164.4556.12 1.25 E-1

Page 38

Connecting a Printer FSP

The factory setting for DEVICE 2 is "Clipboard". In this case, the printout will be copied to the

Windows XP clipboard which is supported by most Windows applications. The contents of the

clipboard can be pasted directly into a document via EDIT - PASTE.

Table 1-1 Factory settings for DEVICE 1 and DEVICE 2 in the HCOPY menu shows the factory

settings for the two output devices.

Table 1-1 Factory settings for DEVICE 1 and DEVICE 2 in the HCOPY menu

Setting Selection in

configuration table

Output device DEVICE WINDOWS METAFILE CLIPBOARD

Output PRINT TO FILE YES ---

Orientation ORIENTATION --- ---

Setting for DEVICE 1 Setting for DEVICE 2

Installation of Plug&Play Printers

The installation of Plug&Play printers under Windows XP is quite simple:

After the printer is connected and s witched on, Windows XP autom atically recognizes it and installs its

driver, provided the driver is included in the XP installation.

If the XP printer driver is not f ound, Windows XP prom pts you to enter the path f or the corresponding

installation files. In addition to pre-installed driver s, a number of other printer drivers can be f ound in

directory D:\I386.

Note: When installing new printer dr ivers, you will be prompted to indicate the path of the new

driver. This path may be on a disk in dr ive A. Alternatively, the driver can be loaded via a

memory stick or USB CD-ROM drive (see section "Connection of USB Devices").

Installation of Non-Plug&Play Printers

Note: The dialogs below can be controlled either from the front panel or via the mouse and

keyboard (see sections "Connec ting a Mouse" and "Connecting a Keyboard"). Mouse and

PC keyboard are absolutely essential for configuring network printers.

A new printer is installed with the INSTALL PRINTER softkey in the HCOPY menu.

Ø Press the HCOPY key.

The HCOPY menu will open.

HCOPY

DEVICE

SETUP

DEVICE

12

COLORS

1164.4556.12 1.26 E-1

Page 39

FSP Connecting a Printer

NEXT

INSTALL

PRINTER

Ø Press the NEXT key to open the side

menu.

Ø Press INSTALL PRINTER to open the

Printers and Faxes dialog window.

Ø Select Add Printer in the list using the

spinwheel.

Ø Highlight the selected item with CURSOR

RIGHT and press ENTER or the

spinwheel to confirm the selection.

The Add Printer Wizard is displayed.

Ø Select NEXT with the spinwheel and press

the spinwheel for confirmation.

Local or Network Printer can be selected.

1164.4556.12 1.27 E-1

Page 40

Connecting a Printer FSP

Ø To install a local printer, select Local

printer attached to this computer with the

spinwheel. Press the spinwheel for

confirmation and continue with the "Local

Printer" section.

Ø To install a network printer, select A

network printer or a printer attached to

another computer. Press the spinwheel for

confirmation and continue with the

"Network Printer" section.

Local Printer

In the following example, a Star LC24 printer is connected to the LPT1 interface and configured as

DEVICE2 for hardcopies of screen contents. The Add Printer Wizard has already been opened as

described in the section "Starting the Add Printer Wizard" .

Ø To select the USB interface, open the list

of ports by clicking the spinwheel.

Select the printer port with

spinwheel/arrow keys and confirm by

pressing the spinwheel. The selection lis t

is closed again.

Ø To select the LPT connec tor, the selection

list need not be opened.

Ø Place the cursor on the Next button and

confirm by pressing the spinwheel.

The "Install Printer Software" dialog is

opened.

1164.4556.12 1.28 E-1

Page 41

FSP Connecting a Printer

Ø Select the desired manufac turer ( "Star") in

the Manufacturer table using the up / down

keys.

Ø Go to the Printers list with the spinwheel.

Ø Select the desired printer type (Star LC24-

200 Colour) using the up / down k eys and

confirm with ENTER.

Note:

If the desired printer type is not in the list, the

respective driver is not installed yet. In this

case click the HAVE DISK button with the

mouse key. You will be prompted to ins ert a

disk with the corresponding printer driver.

Press OK and select the desired printer

driver.

Ø The printer name can be changed as

required in the Printer name entry field

(max. 60 characters). A PC keyboard is

required in this case.

Ø Use the spinwheel to select Yes or No for

the default printer.

Ø Choose the desired status with the up

/down keys.

Ø Confirm with ENTER.

The Printer Sharing dialog is opened.

1164.4556.12 1.29 E-1

Page 42

Connecting a Printer FSP

Ø Exit the dialog with ENTER.

The Print Test Page dialog is opened.

Ø Exit the dialog with ENTER.

The Completing the Add Printer Wizard

dialog is opened.

Ø Check the displayed settings and exit the

dialog with ENTER.

The printer is installed. If Windows finds

the required driver files, the installation is

completed without any further queries.

If W indows cannot find the required driver

files, a dialog is opened where the path for

the files can be entered.

1164.4556.12 1.30 E-1

Page 43

FSP Connecting a Printer

Ø Select the Browse button with the

spinwheel and confirm with by pressing

the spinwheel.

The Locate File dialog is opened.

Ø Turn the spinwheel to select the directory

and path D:\I386 and press it to confirm

the selection.

If the selected item is not pr inted on a blue

background, it must be marked with the

cursor up / down keys before it can be

activated by pressing the spinwheel.

Ø Select the driver file with the spinwheel

and confirm by pressing the spinwheel.

The file is included in the Files Needed

dialog.

Note:

If the desired file is not in the D:\I386

directory, a disk with the driver file is

needed. In this case, exit the dialog with

ESC and repeat the selection starting from

the "Files needed" dialog.

1164.4556.12 1.31 E-1

Page 44

Connecting a Printer FSP

Ø Select the OK button with the spinwheel

and press the spinwheel to confirm.

The installation is completed.

Finally, the instrument must be configured for printout with this printer using the softkeys DEVICE

SETUP and DEVICE 1/2 in the hardcopy main menu (see section "Selecting a printer").

1164.4556.12 1.32 E-1

Page 45

FSP Connecting a Printer

Configuring a Network Printer (with Option FSP-B16 only)

Ø To select a network printer, click the option

"A network printer or a printer attached to

another computer".

Continue with Next.

Ø Click Browse for a printer and then Next.

A list of selectable printers is displayed.

Ø Mark the desired printer and select it with

OK.

1164.4556.12 1.33 E-1

Page 46

Connecting a Printer FSP

Ø Confirm the subsequent prom pt to install a

suitable printer driver with "OK".

The list of available printer drivers is

displayed.

The manufacturers are listed in the lefthand table, the available printer drivers in

the right-hand table.

Ø Select the manufacturer from the

Manufacturers table and then the printer

driver from the Printers table.

Note:

If the desired type of output device is not

shown in the list, the driver has not yet been

installed. In this case, click the "HAVE DISK"

button. You will be prompted to insert a disk

with the corresponding printer driver. Insert

the disk, select "OK" and then choose the

desired printer driver.

Ø Click Next.

If one or more printers have already been

installed, this window queries whether the

printer last installed is to be used as the

default printer for the Windows XP

applications. The default selection is No.

Ø Start the printer driver installation with

Finish.

Finally, the instrument has to be configured for printout with this printer using the softkeys DEVICE

SETUP and DEVICE 1/2 in the hardcopy menu (see section "Selection of a Printer").

1164.4556.12 1.34 E-1

Page 47

FSP Connecting an Output Device

Connection of USB Devices

Up to two USB devices can be directly connected to the analyzer via the USB interface on the rear of the

FSP. This number can be increased as required by interconnecting USB hubs.

Owing to the wide variety of available USB devices, the FSP can be expanded with almost no

limitations. The following list shows a selection of USB devices suitable for the FSP:

• Power Sensor R&S NRP-Z11 or R&S NRP-Z21 (Adapter Cable R&S NRP-Z4 required)

• Pendrive (memory stick) for easy data transfer from/to the PC (e.g. firmware updates)

• CD-ROM drive for easy installation of firmware applications

• PC keyboard for entering comments, file names, etc

• Mouse for easy operation of Windows dialogs

• Printer for documentation of measurement results

• Modem for remote control of the FSP over great distances

The installation of USB devices is quite simp le under Windows XP since all USB devic es are Plug&Play.

Apart from the keyboard and the mouse, all USB devices can be connected to or disconnec ted fr om the

FSP while the instrument is running.

After the instrument is connected to the USB interface, Windows XP automatically searches for a

suitable device driver.

If Windows XP does not find a suitable driver, you will be prompted to specify a directory where the

driver software can be found. If the driver software is on a CD, a USB CD-ROM should first be

connected to drive to the FSP.

As soon as the connection between the FSP and the USB device is interrupted, Windows XP will again

recognize the modified hardware configuration and will deactivate the corresponding device driver.

Example:

Connecting a pendrive (memory stick) to the FSP:

1. After the pendrive is connected to the USB interface, Windows XP will recognize the newly

connected hardware:

2. Windows XP installs the corresponding driver.

After successful installation, XP signals that the unit is ready for operation:

3. The pendrive is now available as a new drive and is displayed in Windows Explorer:

1164.4556.12 1.35 E-1

Page 48

Connecting an Output Device FSP

The pendrive can be used as a normal drive to load or save files.

4. If the pendrive is no longer required or if files are to be transferred to another computer, the

pendrive is simply disconnected. Windows XP will then deactivate the driver.

If the corresponding drive is still selected in Explorer, an error message will be displayed indicating

that the drive is no longer available.

1164.4556.12 1.36 E-1

Page 49

FSP Installing Windows NT Software

Installing Windows XP Software

Authorized Windows XP Softw ar e for the Instrument

The driver software and the system s ettings of Windows XP are adapted to the m easurem ent f unctions

of the instrument. Correc t operation of the instrument c an therefore be guaranteed only if the software

and hardware used are authorized or supplied by Rohde & Schwarz.

The following program pac kages have been successfully tested for com patibility with the instrument's

software:

• FS-K3 – software for measuring noise factor and gain

• FS-K4 – software for measuring phase noise

• R&S Power Viewer

(virtual power sensor for displaying the results of Power Sensors NRP-Z11 and -Z21)

• Windows XP remote desktop

• FileShredder – for deleting files from the hard disk

• Symantec Norton AntiVirus – software for protection against viruses

The use of other software or hardware may cause failures in the functions of the FSP.

A current list of the software author ized for use on the FSP c an be obtained fr om your nearest Rohde &

Schwarz agency (see list of addresses).

1164.4556.12 1.37 E-1

Page 50

Page 51

FSP Contents– Getting Started

Contents - Chapter 2 "Getting Started"

2 Getting Started..................................................................................................... 2.1

Level and Frequency Measurements............................................................................................. 2.1

Measurement Example 1 – Measuring Frequency and Level using Markers ........................ 2.1

Measurement Example 2 – Measuring Frequency with the Frequency Counter...................2.3

Measurement of Harmonics............................................................................................................2.5

Measuring Harmonics with Frequency Sweeps....................................................................... 2.7

Measurement Example – Measuring the distance between fundamental wave

and the 2

High-Sensitivity Harmonics Measurements........................................................................... 2.10

Measurement Example ...............................................................................................2.10

Measuring the Spectra of complex Signals ................................................................................2.13

Separating Signals by Selecting an Appropriate Resolution Bandwidth...................................... 2.13

Measurement Example - Resolving two signals with a level of –30 dBm each and a

frequency difference of 30 kHz.................................................................................... 2.14

Intermodulation Measurements.............................................................................................2.17

Measurement Example – Measuring the FSP’s intrinsic intermodulation distance.....2.19

nd

and 3

rd

harmonics of the internal reference signal ................................... 2.7

Measuring Signals in the Vicinity of Noise .................................................................................2.23

Measurement example – Measuring the level of the internal reference generator

at low S/N ratios .......................................................................................................... 2.25

Noise Measurements..................................................................................................................... 2.28

Measuring noise power density.............................................................................................2.28

Measurement example – Measuring the intrinsic noise power density of the

FSP at 1 GHz and calculating the FSP’s noise figure................................................2.28

Measurement of Noise Power within a Transmission Channel.............................................2.31

Measurement Example – Measuring the intrinsic noise of the FSP at 1 GHz in a

1.23 MHz channel bandwidth with the channel power function...................................2.31

Measuring Phase Noise........................................................................................................ 2.35

Measurement Example -

Measuring the phase noise of a signal generator at a carrier offset of 10 kHz..................... 2.35

Measurements on Modulated Signals ......................................................................................... 2.37

Measurements on AM signals ............................................................................................... 2.37

Measurement Example 1 –

Displaying the AF of an AM signal in the time domain................................................2.37

Measurement Example 2 - .................................................................................................

Measuring the modulation depth of an AM carrier in the frequency domain.............. 2.39

Measurements on FM Signals............................................................................................... 2.40

Measurement Example - Displaying the AF of an FM carrier ..................................... 2.40

Measuring Channel Power and Adjacent Channel Power.....................................................2.43

Measurement Example 1 - ACPR measurement on an IS95 CDMA Signal...............2.44

Measurement Example 2 – Measuring the adjacent channel power of an

IS136 TDMA signal .....................................................................................................2.48

Measurement Example 3 - Measuring the Modulation Spectrum

in Burst Mode with the Gated Sweep Function ........................................................... 2.51

Measurement Example 4 - Measuring the Transient Spectrum in Burst Mode

with the Fast ACP function..........................................................................................2.53

Measurement Example 5 - Measuring adjacent channel power of a

W-CDMA uplink signal................................................................................................2.55

1164.4556.12 I-2.1 E-1

Page 52

Contents – Getting Started FSP

Amplitude distribution measurements ................................................................................... 2.58

Measurement Example – Measuring the APD and CCDF of white noise

generated by the FSP..................................................................................................2.58

Time Domain Measurements........................................................................................................2.61

Power measurements............................................................................................................ 2.61

Measurement Example – Measuring the power of a GSM burst

during the switch-on phase .........................................................................................2.61

Power Ramping Measurement for Burst Signals...................................................................2.63

Measurement Example – Measurements on GSM burst edges using a high time

resolution.....................................................................................................................2.63

Measuring the S/N Ratio of Burst Signals .............................................................................2.65

Measurement Example - S/N ratio of a GSM signal ...................................................2.65

1164.4556.12 I-2.2 E-1

Page 53

FSP Level and Frequency Measurements

2 Getting Started

Chapter 2 explains how to operate the FSP using typical measurements as examples. Chapter 3

describes the basic operating steps such as selecting the m enus and setting param eters, and explains

the screen structure and displayed function indicators.

Chapter 4 describes all the menus and FSP functions.

All of the following examples are bas ed on the standard settings of the analyzer. These are set with the

PRESET key. A complete listing of the standard settings can be found in chapter 4, section "Pr eset

settings of the FSP – PRESET key".

Level and Frequency Measurements

Measuring the frequency and level of a signal is one of the m ost common purposes for the use of a

spectrum analyzer. For unknown signals, the spectrum analyzer default settings (PRESET) are a good

starting point for the measurement.

If signal levels at the RF input are expected to be above 30 dBm (= 1 W), a power attenuator must be

connected to the RF input of the spectrum analyzer. Please note that the total powar of all applied

signals must be tak en into account concerning this limit. If a power attenuator is not used, signal levels

above 30 dBm can destroy the RF attenuator or the input mixer.

Measurement Example 1 – Measuring Frequency and Level using

Markers

It is easy to measure the level and frequency of a sinewave carrier with the marker function. At the

marker pos ition, the FSP indicates the s ignal’s am plitude and frequenc y. The accur acy of the fr equency

measurement is determined by the FSP reference frequency, the resolution of the marker frequency

display and the resolution of the screen.

In the example, the frequency of the 128-MHz internal reference generator is displayed using the

marker.

1. Set the spectrum analyzer to its default settings.

Ø Press the PRESET key.

2. Connect the test signal to the RF INPUT on the instrument front panel.

3. Switch on the internal reference generator.

Ø Press the SETUP key.

The SETUP menu opens.

Ø Press the SERVICE softkey.

The SETUP - SERVICE menu opens.

Ø Press the INPUT CAL softkey.

The internal reference generator is turned on.

The FSP’s RF input is turned off.

4. Set the center frequency to 128 MHz.

Ø Press the FREQ key.

Ø The entry field for the center frequency is displayed on the screen.

Ø Enter 128 from the numeric keypad and terminate the entry with the MHz key.

5. Reduce the measurement frequency range (SPAN) to 1 MHz.

1164.4556.12 2.1 E-1

Page 54

Level and Frequency Measurements FSP

Ø Press the SPAN key.

Ø Enter 1 from the numeric keypad and terminate the entry with the MHz key.

Note: If the SPAN is changed, the resolution bandwidth (RES BW), the video bandwidth

(VIDEO BW) and the sweep time (SW EEP TIME) are also set to new values bec ause

they are defined as coupled functions in the standard PRESET settings.

6. Measure the level and frequency using the marker and read off the results from the screen.

Ø Press the MKR key.

The marker is switched on and automatically jumps to the trace peak.

Note: When a mark er is switched on for the first time, it automatically per forms the PEAK

SEARCH function (as in this example).

If a marker is already active, the PEAK softkey in the MKR-> menu must be pressed in

order to set the currently active marker onto the displayed signal maximum.

The level and frequency indicated by the marker are displayed in the marker info field at the upper

edge of the screen. These are the measurement results.

The info-field header indicates the number of the marker (MARKER 1) and the number of the

trace on which the marker is positioned ([T1] = Trace 1).

Increasing the Frequency Resolution During a Frequency Measurement with a Marker

The frequency resolution of the marker is determined by the pixel resolution of the trace. The FSP uses

501 pixels for a trace, i.e. at a frequency span of 1 MHz each pixel corresponds to a frequency range of

approx. 2 kHz. This gives a maximum error of 1 kHz.

To increase the pixel resolution of the trace, the frequency span has to be reduced.

7. Reduce the frequency span to 10 kHz.

Ø Press the SPAN key.

Ø Enter 10 from the numeric keypad and terminate the entry with the kHz key.

Note: If the SPAN is changed, the resolution bandwidth (RES BW), the video bandwidth

(VIDEO BW) and the sweep time (SW EEP TIME) are also set to new values bec ause

they are defined as coupled functions in the standard PRESET settings.

The internal reference signal is measured with a span of 10 kHz. The pixel resolution of the trace

is now approx. 20 Hz (10 kHz span / 501 pixel), i.e. the accuracy of the marker frequency display

is increased to approx. 10 Hz.

8. Switch on the RF input again for normal operation of the analyzer.

Ø Press the PRESET key or press the SETUP key and the SERVICE softkey.

Ø Press the INPUT RF softkey.

The internal signal path of the FSP is switched back to the RF input in order to resume normal

operation.

1164.4556.12 2.2 E-1

Page 55

FSP Level and Frequency Measurements

Measurement Example 2 – Measuring Frequency with the Frequency

Counter

With the internal frequency counter, frequencies can be measured more accurately than with the

marker. The fr equenc y sweep is stopped at the marker position and the FSP measures the f requenc y of

the corresponding signal. If an analog bandwidth (≥300 kHz) is used, the frequency is measured by

counting the zero-crossings of the last IF . With digital resolution bandwidths (10 Hz to 100 kHz), the

frequency measurement is performed in the IQ baseband by a special approximation algorithm.

The resolution range for the frequency measurement is 0.1 Hz to 10 kHz. At bandwidths ≥300 k Hz, the

time required for the FSP to perform the f requency measurem ent is dependent on the selected counter

resolution (1/(frequency resolution in Hz)). The digital frequency approximation takes about 30 ms to

perform a frequency measurement irrespective of the selected resolution.

The frequency measurement accuracy is determined by the reference frequency of the FSP and the

selected counter resolution.

In the example, the frequency of the 128-MHz internal reference generator is displayed with the marker.

1. Set the spectrum analyzer to the default settings.

Ø Press the PRESET key.

The FSP is in its default state.

2. Switch on internal reference generator

Ø Press the SETUP key.

Ø Press the softkeys SERVICE - INPUT CAL.

The internal 128 MHz reference generator is now on. The FSP’s RF input is turned off.

3. Set the center frequency and the frequency span

Ø Press the FREQ key and enter 128 MHz.

The FSP center frequency is set to 128 MHz.

Ø Press the SPAN softkey and enter 1 MHz.

The FSP frequency span is set to 1 MHz.

4. Switch on the marker

Ø Press the MKR key.

The marker is switched on and set to the signal maximum. The level and the frequency at the

marker are displayed in the marker-info field.

5. Switch on the frequency counter.

Ø Press the SIGNAL COUNT softkey in the marker menu.

The frequency count is displayed in the marker field at the top of the screen along with the set

resolution (1 kHz is the default setting ).

The sweep stops at the marker position and the FSP measures the frequency of the

corresponding signal. The frequency is output in the marker info field. To distinguish the signal

count result from the normal marker frequency display, the marker is labeled with CNT.

1164.4556.12 2.3 E-1

Page 56

Level and Frequency Measurements FSP

6. Set the resolution of the frequency counter to 1 Hz.

Ø Press the NEXT key.

Ø Press the CNT RESOL 1 Hz softkey.

Fig. 2-1 Frequency measurement with a frequency counter

Note: The frequency measurement with the integral frequency counter only gives correct

results for RF sinewaves or discrete spectral lines. To meet the specified

measurement accuracy, the marker should be more than 25 dB above noise.

7. Switch on the RF input again for normal operation of the analyzer.

Ø Press the PRESET key or press the SETUP key and the SERVICE softkey.

Ø Press the INPUT RF softkey.

The internal signal path of the FSP is switched back to the RF input in order to resume normal

operation.

Hint: For bandwidths between 300 kHz and 10 MHz, the FSP uses a frequenc y counter at an IF

of 20.4 MHz. The time for m easuring the frequency is, therefore, inversely proportional to

the selected resolution, i.e. at a resolution of 1 Hz a gate tim e of 1 s econd is r equired f or the

counter. For digital bandwidths below 300 kHz, the frequency is measured in the baseband

by digital frequency approximation. The time required for measuring the frequency is

approx. 30 ms irrespective of the selected resolution.

When measuring the frequency of a sinewave carrier at a high resolution it is , ther ef ore, best

to set a resolution bandwidth of 100 kHz or less. The measurement time will then be

reduced to a minimum.

1164.4556.12 2.4 E-1

Page 57

FSP Measurement of Harmonics

Measurement of Harmonics

Measuring the harmonics of a s ignal is a frequent problem which can be solved best by means of a

spectrum analyzer. In general, every signal contains harmonics which ar e larger than other s. Harmonics

are particularly critical regarding high-power transmitters s uch as trans ceivers bec ause large harm onics

can interfere with other radio services.

Harmonics are produced by nonlinear characteristics. They can often be reduced by lowpass filters.

Since the spectrum analyzer has a nonlinear characteristic, e.g. in its first mixer, measures must be

taken to ensure that harmonics produced in the analyzer do not cause spurious results. If necessary, the

fundamental wave must be selectively attenuated with respect to the other harm onics with a highpass

filter.

When harm onics are being measured, the obtainable dynamic range depends on the K2 intercept of

the spectrum analyzer. The K2 intercept is the virtual input level at the RF input mixer at which the level