Page 1

R&S®FPL1-K30

Noise Figure Measurements

User Manual

(;ÜR52)

1178340502

Version 08

Page 2

This manual applies to the following R&S®FPL1000 models with firmware version 1.90 and later:

●

R&S®FPL1003 (1304.0004K03) - FPL1000 with maximum frequency 3 GHz

●

R&S®FPL1007 (1304.0004K07) - FPL1000 with maximum frequency 7.5 GHz

●

R&S®FPL1014 (1304.0004K14) - FPL1000 with maximum frequency 14 GHz

●

R&S®FPL1026 (1304.0004K26) - FPL1000 with maximum frequency 26.5 GHz

The following firmware options are described:

●

R&S FPL1-K30 (1323.1760.02)

© 2021 Rohde & Schwarz GmbH & Co. KG

Mühldorfstr. 15, 81671 München, Germany

Phone: +49 89 41 29 - 0

Email: info@rohde-schwarz.com

Internet: www.rohde-schwarz.com

Subject to change – data without tolerance limits is not binding.

R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

Trade names are trademarks of the owners.

1178.3405.02 | Version 08 | R&S®FPL1-K30

Throughout this manual, products from Rohde & Schwarz are indicated without the ® symbol, e.g. R&S®FPL1000 is indicated as

R&S FPL1000.

Page 3

R&S®FPL1-K30

1 Preface.................................................................................................... 7

1.1 Documentation overview..............................................................................................7

1.1.1 Getting started manual....................................................................................................7

1.1.2 User manuals and help................................................................................................... 7

1.1.3 Service manual............................................................................................................... 7

1.1.4 Instrument security procedures.......................................................................................8

1.1.5 Printed safety instructions............................................................................................... 8

1.1.6 Data sheets and brochures............................................................................................. 8

1.1.7 Release notes and open source acknowledgment (OSA).............................................. 8

1.1.8 Application notes, application cards, white papers, etc...................................................8

1.1.9 Calibration certificate.......................................................................................................8

Contents

Contents

1.2 Conventions used in the documentation....................................................................9

1.2.1 Typographical conventions..............................................................................................9

1.2.2 Conventions for procedure descriptions..........................................................................9

1.2.3 Notes on screenshots..................................................................................................... 9

2 Welcome to the noise figure measurement application...................10

2.1 Starting the noise application....................................................................................10

2.2 Understanding the display information.................................................................... 11

3 Measurements and result displays.................................................... 14

4 Measurement basics............................................................................23

4.1 Tuning modes.............................................................................................................. 23

4.1.1 Swept measurements................................................................................................... 24

4.1.2 Frequency table measurements....................................................................................24

4.1.3 Single frequency measurements...................................................................................25

4.2 Measurement modes.................................................................................................. 25

4.3 DUT types.................................................................................................................... 27

4.3.1 Measurements on linear DUTs (direct measurement)...................................................27

4.3.2 Measurements on frequency converting DUTs............................................................. 27

4.4 Image frequency rejection..........................................................................................28

4.5 Calibration (2nd stage correction).............................................................................31

3User Manual 1178.3405.02 ─ 08

Page 4

R&S®FPL1-K30

4.6 Using smart noise sources........................................................................................ 34

4.7 Separating signals by selecting an appropriate resolution bandwidth................. 35

4.8 Analyzing several traces - trace mode......................................................................36

4.9 Using markers............................................................................................................. 36

5 Configuration........................................................................................39

5.1 Configuration overview.............................................................................................. 39

5.2 Defining the measurement frequency.......................................................................41

5.2.1 Defining a frequency set............................................................................................... 41

5.2.2 Configuring single frequency measurements................................................................44

5.2.3 Using a frequency table................................................................................................ 45

5.3 Selecting DUT characteristics................................................................................... 48

5.4 Configuring the noise source.................................................................................... 49

Contents

5.4.1 Defining the noise source characteristics......................................................................49

5.4.2 Using an ENR or temperature table.............................................................................. 53

5.5 Configuring additional loss........................................................................................57

5.5.1 Defining loss..................................................................................................................57

5.5.2 Using a loss table..........................................................................................................60

5.6 Configuring the analyzer............................................................................................ 62

5.7 Using the uncertainty calculator............................................................................... 66

5.7.1 Configuring noise source characteristics...................................................................... 67

5.7.2 Configuring DUT characteristics................................................................................... 69

5.7.3 Configuring analyzer characteristics............................................................................. 70

5.7.4 Guidelines and results...................................................................................................71

5.8 Performing measurements.........................................................................................72

5.9 Configuring inputs and outputs of the R&S FPL1000............................................. 74

5.9.1 Impedance.................................................................................................................... 74

6 Analysis................................................................................................ 75

6.1 Configuring the display.............................................................................................. 75

6.1.1 Configuring graphical results.........................................................................................75

6.1.2 Configuring numerical results........................................................................................77

6.2 Working with traces.................................................................................................... 78

6.3 Using markers............................................................................................................. 81

6.3.1 Marker configuration..................................................................................................... 81

4User Manual 1178.3405.02 ─ 08

Page 5

R&S®FPL1-K30

6.3.2 Marker positioning.........................................................................................................84

7 Remote control commands for noise figure measurements........... 87

7.1 Common suffixes........................................................................................................ 88

7.2 Introduction................................................................................................................. 88

7.2.1 Conventions used in descriptions................................................................................. 88

7.2.2 Long and short form...................................................................................................... 89

7.2.3 Numeric suffixes............................................................................................................89

7.2.4 Optional keywords.........................................................................................................90

7.2.5 Alternative keywords..................................................................................................... 90

7.2.6 SCPI parameters...........................................................................................................90

7.2.6.1 Numeric values............................................................................................................. 91

7.2.6.2 Boolean......................................................................................................................... 92

Contents

7.2.6.3 Character data.............................................................................................................. 92

7.2.6.4 Character strings...........................................................................................................92

7.2.6.5 Block data..................................................................................................................... 92

7.3 Controlling the noise figure measurement channel................................................ 93

7.4 Working with windows in the display........................................................................96

7.5 General window commands.....................................................................................103

7.6 Retrieving measurement results............................................................................. 103

7.7 Defining the measurement frequency.....................................................................105

7.8 Selecting DUT characteristics..................................................................................110

7.9 Configuring the noise source...................................................................................111

7.10 Configuring additional loss......................................................................................119

7.11 Configuring the analyzer..........................................................................................126

7.12 Using the uncertainty calculator............................................................................. 132

7.13 Performing measurements.......................................................................................142

7.14 Configuring the inputs and outputs........................................................................ 147

7.14.1 Impedance.................................................................................................................. 147

7.15 Independant CW source commands....................................................................... 147

7.16 Configuring the display............................................................................................ 149

7.17 Working with traces.................................................................................................. 152

7.18 Working with limit lines............................................................................................ 157

7.18.1 Defining general characteristics of a limit line............................................................. 158

5User Manual 1178.3405.02 ─ 08

Page 6

R&S®FPL1-K30

7.18.2 Defining horizontal data points....................................................................................159

7.18.3 Controlling lower limit lines..........................................................................................160

7.18.4 Controlling upper limit lines......................................................................................... 161

7.18.5 Managing limit lines.....................................................................................................163

7.18.6 Controlling limit checks............................................................................................... 164

7.19 Working with markers...............................................................................................166

7.19.1 Using markers............................................................................................................. 166

7.19.2 Using delta markers.................................................................................................... 169

7.19.3 Configuring markers....................................................................................................171

7.19.4 Positioning markers.....................................................................................................172

7.19.5 Positioning delta markers............................................................................................175

7.20 Using the status register.......................................................................................... 177

7.20.1 Status registers for noise figure measurements..........................................................177

Contents

7.20.1.1 STATus:OPERation register........................................................................................179

7.20.1.2 STATus:QUEStionable register................................................................................... 179

7.20.1.3 STATus:QUEStionable:LIMit register.......................................................................... 180

7.20.1.4 STATus:QUEStionable:CORRection register..............................................................180

7.20.1.5 Status register remote commands.............................................................................. 181

7.21 Deprecated remote commands for noise figure measurements.......................... 183

7.22 Programming example: measuring a noise figure.................................................184

Annex.................................................................................................. 185

A Reference: frequency table file format.............................................185

List of commands (Noise figure measurements)............................186

Index....................................................................................................191

6User Manual 1178.3405.02 ─ 08

Page 7

R&S®FPL1-K30

1 Preface

1.1 Documentation overview

1.1.1 Getting started manual

Preface

Documentation overview

This chapter provides safety-related information, an overview of the user documentation and the conventions used in the documentation.

This section provides an overview of the R&S FPL1000 user documentation. Unless

specified otherwise, you find the documents on the R&S FPL1000 product page at:

www.rohde-schwarz.com/manual/FPL1000

Introduces the R&S FPL1000 and describes how to set up and start working with the

product. Includes basic operations, typical measurement examples, and general information, e.g. safety instructions, etc.

A printed version is delivered with the instrument. A PDF version is available for download on the Internet.

1.1.2 User manuals and help

Separate user manuals are provided for the base unit and the firmware applications:

●

Base unit manual

Contains the description of all instrument modes and functions. It also provides an

introduction to remote control, a complete description of the remote control commands with programming examples, and information on maintenance, instrument

interfaces and error messages. Includes the contents of the getting started manual.

●

Firmware application manual

Contains the description of the specific functions of a firmware application, including remote control commands. Basic information on operating the R&S FPL1000 is

not included.

The contents of the user manuals are available as help in the R&S FPL1000. The help

offers quick, context-sensitive access to the complete information for the base unit and

the firmware applications.

All user manuals are also available for download or for immediate display on the Internet.

1.1.3 Service manual

Describes the performance test for checking compliance with rated specifications, firmware update, troubleshooting, adjustments, installing options and maintenance.

7User Manual 1178.3405.02 ─ 08

Page 8

R&S®FPL1-K30

1.1.4 Instrument security procedures

1.1.5 Printed safety instructions

1.1.6 Data sheets and brochures

Preface

Documentation overview

The service manual is available for registered users on the global Rohde & Schwarz

information system (GLORIS):

https://gloris.rohde-schwarz.com

Deals with security issues when working with the R&S FPL1000 in secure areas. It is

available for download on the Internet.

Provides safety information in many languages. The printed document is delivered with

the product.

The data sheet contains the technical specifications of the R&S FPL1000. It also lists

the firmware applications and their order numbers, and optional accessories.

The brochure provides an overview of the instrument and deals with the specific characteristics.

See www.rohde-schwarz.com/brochure-datasheet/FPL1000

1.1.7 Release notes and open source acknowledgment (OSA)

The release notes list new features, improvements and known issues of the current

firmware version, and describe the firmware installation.

The open-source acknowledgment document provides verbatim license texts of the

used open source software.

See www.rohde-schwarz.com/firmware/FPL1000

1.1.8 Application notes, application cards, white papers, etc.

These documents deal with special applications or background information on particular topics.

See www.rohde-schwarz.com/application/FPL1000

1.1.9 Calibration certificate

The document is available on https://gloris.rohde-schwarz.com/calcert. You need the

device ID of your instrument, which you can find on a label on the rear panel.

8User Manual 1178.3405.02 ─ 08

Page 9

R&S®FPL1-K30

1.2 Conventions used in the documentation

1.2.1 Typographical conventions

Preface

Conventions used in the documentation

The following text markers are used throughout this documentation:

Convention Description

"Graphical user interface elements"

[Keys] Key and knob names are enclosed by square brackets.

Filenames, commands,

program code

Input Input to be entered by the user is displayed in italics.

Links Links that you can click are displayed in blue font.

"References" References to other parts of the documentation are enclosed by quota-

All names of graphical user interface elements on the screen, such as

dialog boxes, menus, options, buttons, and softkeys are enclosed by

quotation marks.

Filenames, commands, coding samples and screen output are distinguished by their font.

tion marks.

1.2.2 Conventions for procedure descriptions

When operating the instrument, several alternative methods may be available to perform the same task. In this case, the procedure using the touchscreen is described.

Any elements that can be activated by touching can also be clicked using an additionally connected mouse. The alternative procedure using the keys on the instrument or

the on-screen keyboard is only described if it deviates from the standard operating procedures.

The term "select" may refer to any of the described methods, i.e. using a finger on the

touchscreen, a mouse pointer in the display, or a key on the instrument or on a keyboard.

1.2.3 Notes on screenshots

When describing the functions of the product, we use sample screenshots. These

screenshots are meant to illustrate as many as possible of the provided functions and

possible interdependencies between parameters. The shown values may not represent

realistic usage scenarios.

The screenshots usually show a fully equipped product, that is: with all options installed. Thus, some functions shown in the screenshots may not be available in your particular product configuration.

9User Manual 1178.3405.02 ─ 08

Page 10

R&S®FPL1-K30

2 Welcome to the noise figure measurement

Welcome to the noise figure measurement application

Starting the noise application

application

The R&S FPL1-K30 is a firmware application that adds functionality to perform "noise

figure" measurements to the R&S FPL1000.

Noise Source Control

The Noise Source Control connector on the R&S FPL1000 is a prerequisite for the

R&S FPL1 Noise Figure measurements application.

This connector is part of the "Additional Interfaces" hardware option R&S FPL1-B5.

This user manual contains a description of the functionality that the application provides, including remote control operation.

Functions that are not discussed in this manual are the same as in the Spectrum application and are described in the R&S FPL1000 user manual.

The latest versions of the manuals are available for download at the product homepage.

www.rohde-schwarz.com/manual/FPL1000

Installation

Find detailed installing instructions in the getting started or the release notes of the

R&S FPL1000.

● Starting the noise application..................................................................................10

● Understanding the display information....................................................................11

2.1 Starting the noise application

The "noise figure" measurement application adds a new type of measurement to the

R&S FPL1000.

To activate the R&S FPL1 Noise Figure measurements application

1. Select the [MODE] key.

A dialog box opens that contains all operating modes and applications currently

available on your R&S FPL1000.

2. Select the "Noise Figure" item.

The R&S FPL1000 opens a new measurement channel for the "noise figure" measurement application.

10User Manual 1178.3405.02 ─ 08

Page 11

R&S®FPL1-K30

Welcome to the noise figure measurement application

Understanding the display information

All settings specific to "noise figure" measurements are in their default state.

Multiple Channel Setups and Sequencer Function

When you activate an application, a new channel setup is created which determines

the measurement settings for that application ("Channel"). The same application can

be activated with different measurement settings by creating several "Channel"s for the

same application.

The number of channel setups that can be configured at the same time depends on the

available memory on the instrument.

Only one measurement can be performed at any time, namely the one in the currently

active channel setup. However, to perform the configured measurements consecutively, a Sequencer function is provided.

If activated, the measurements configured in the currently defined "Channel"s are performed one after the other in the order of the tabs. The currently active measurement is

indicated by a

The result displays of the individual channel setups are updated in the tabs (as well as

the "MultiView") as the measurements are performed. Sequential operation itself is

independent of the currently displayed tab.

symbol in the tab label.

For details on the Sequencer function, see the R&S FPL1000 user manual.

2.2 Understanding the display information

The following figure shows the display as it looks for "noise figure" measurements. All

different information areas are labeled. They are explained in more detail in the following sections.

11User Manual 1178.3405.02 ─ 08

Page 12

R&S®FPL1-K30

Welcome to the noise figure measurement application

Understanding the display information

1

2

3

4

4

4 4

6

Figure 2-1: Screen layout of the noise figure measurement application

1 = Toolbar

2 = Channel Setup bar

3 = Diagram header

4 = Result display

5 = Softkey bar

6 = Status bar

Channel Setup bar information

In the R&S FPL1 Noise Figure measurements application, the R&S FPL1000 shows

the following settings:

5

Ref Level Reference level of the R&S FPL1000.

Att Attenuation of the R&S FPL1000.

RBW Resolution bandwidth

SWT Sweep time

AVG Number of averages

ENR Excess noise ratio

For smart noise sources: also the provided temperature

2nd Stage Corr State of the 2nd stage correction.

Calibration Data Date and time of the current calibration data.

Mode Currently selected measurement mode.

Window title bar information

For each diagram, the header provides the following information:

12User Manual 1178.3405.02 ─ 08

Page 13

R&S®FPL1-K30

Welcome to the noise figure measurement application

Understanding the display information

Figure 2-2: Window title bar information for the R&S FPL1 Noise Figure measurements application

1 = Window number

2 = Window type

3 = Trace color and number

4 = Trace mode

Status bar information

Global instrument settings, the instrument status and any irregularities are indicated in

the status bar beneath the diagram. Furthermore, the progress of the current operation

is displayed in the status bar.

Risk of damaging the instrument

Make sure not to overload the input mixer during calibration and the measurement. An

overload condition can damage or destroy the input mixer.

If an overload condition occurs, the R&S FPL1000 shows a corresponding message in

the status line ("RF OVLD" or "IF OVLD").

To avoid an overload during calibration or measurement, do one or more of the following:

●

Check and adjust the DUT "gain" settings

●

Check and adjust the ENR settings

●

Increase the reference level.

13User Manual 1178.3405.02 ─ 08

Page 14

R&S®FPL1-K30

3 Measurements and result displays

Measurements and result displays

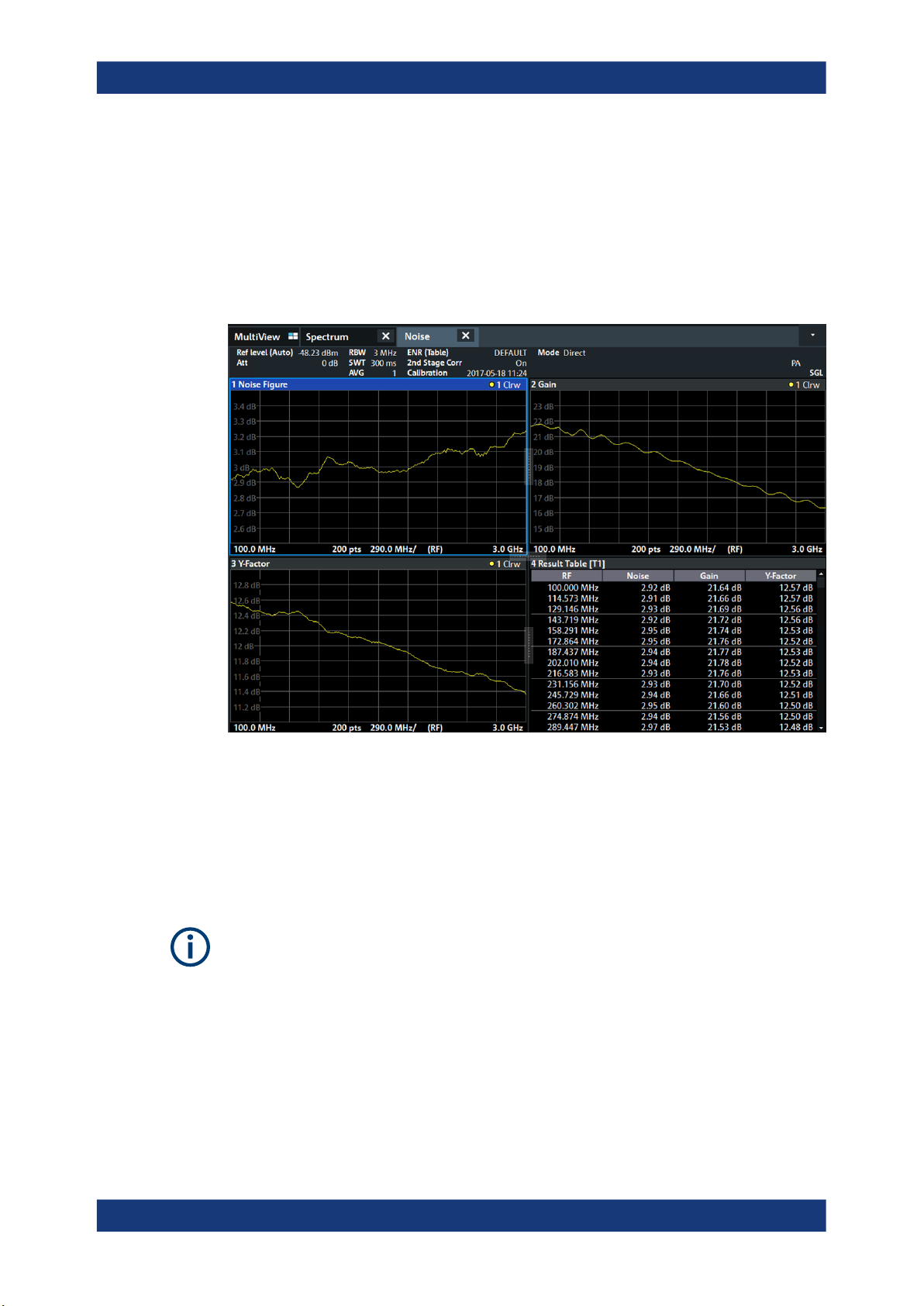

The R&S FPL1-K30 measures the "noise figure" of a DUT and displays the results

graphically and numerically. Each graphical result display shows the "noise figure" from

a different perspective. In the default configuration, the application shows the "noise

figure" of the DUT, the "gain" of the DUT and the corresponding "y-factor". In addition,

it shows the numerical results of the measurement.

The scale of the horizontal axis depends on the tuning mode.

Frequency list and swept measurements

In all graphical result displays, the horizontal axis represents the frequency. The displayed frequency is either the RF (radio frequency) or the IF (intermediate frequency).

The range depends on the frequency set you have currently defined. Because the

application only measures selected frequencies, it connects the results to draw a trace.

Negative "noise figure" and "noise temperature"

From a physical point of view, the "noise figure" and the "noise temperature" levels

have a positive range (including zero).

Due to the mathematical operations the application performs, the results can be negative. Sometimes this happens due to incorrect calibration or variance of measurement

values.

14User Manual 1178.3405.02 ─ 08

Page 15

R&S®FPL1-K30

out

in

SNR

SNR

Figure Noise

Measurements and result displays

Single frequency measurements

In all graphical result displays, the horizontal axis represents a chronological order of

measurement results for the frequency you are testing. The axis has no unit, but is

made up out of several index values that represent time. Each index value represents

one measurement point and therefore one measurement on the single frequency you

are analyzing. The size of the index (and thus number of results) depends on the number of (Measurement) Points that you have defined. Because the application only

measures at certain points in time, it connects the results to draw a trace.

The right diagram border represents the present (index = 0), values to the left represent past measurement results (index = -<x>). As soon as the application finishes a

single measurement, the measurement points are moved to the left, the new result is

added on the right. All other measurement points are moved down one position with

the most obsolete result falling out of the diagram (like in the roll mode of an oscilloscope).

Selecting the result display

►

Select the

icon in the toolbar or press the [MEAS] key.

The application enters the SmartGrid configuration mode.

For more information on the SmartGrid functionality, see the R&S FPL1000 Getting

Started.

Noise Figure..................................................................................................................15

Gain...............................................................................................................................16

Noise Temperature........................................................................................................16

Y-Factor.........................................................................................................................17

ENR Measured..............................................................................................................18

Power (Hot)...................................................................................................................19

Power (Cold)................................................................................................................. 19

Cal Y-Factor.................................................................................................................. 20

Cal Power (Hot).............................................................................................................20

Cal Power (Cold)...........................................................................................................21

Result Table.................................................................................................................. 21

Current Values...............................................................................................................21

Marker Table................................................................................................................. 22

Noise Figure

Shows the "noise figure" of the DUT.

The "noise figure" is the ratio of the signal-to-noise ratio at the DUT input to the signal-

to-noise ratio at the DUT output.

The vertical axis shows the level of the "noise figure" in dB. The scale depends on the

settings in the "Display Configuration" dialog box.

15User Manual 1178.3405.02 ─ 08

Page 16

R&S®FPL1-K30

Measurements and result displays

Remote command:

LAY:ADD:WIND? '2',RIGH,NOIS see LAYout:ADD[:WINDow]? on page 97

Results:TRACe<t>[:DATA]? <Trace>,NOISe

Gain

Shows the "gain" characteristics of the DUT.

The vertical axis shows the level of the "gain" in dB. The scale depends on the settings

in the "Display Configuration" dialog box.

Remote command:

LAY:ADD:WIND? '2',RIGH,GAIN see LAYout:ADD[:WINDow]? on page 97

Results:TRACe<t>[:DATA]? <Trace>,GAIN

Noise Temperature

Shows the "noise temperature" characteristics of the DUT.

16User Manual 1178.3405.02 ─ 08

Page 17

R&S®FPL1-K30

constant Boltzmannk

BandwidthB

PowerP

with

eTemperatur Noise

kB

P

off source noise with[dB] power Noise

on source noise with[dB] power Noise

with

FactorY

off

on

off

on

N

N

N

N

Measurements and result displays

The vertical axis shows the "noise temperature" in Kelvin. The scale depends on the

settings in the "Display Configuration" dialog box.

Remote command:

LAY:ADD:WIND? '2',RIGH,TEMP see LAYout:ADD[:WINDow]? on page 97

Results: TRACe<t>[:DATA]? <Trace>,TEMPerature

Y-Factor

Shows the ratio of the hot and the cold power of the DUT.

The "Y-factor" indicates the quality of measurement tolerances and uncertainties. To

get the result, the application measures the DUT power with the noise source turned

on (hot power) and the noise source turned off (cold power).

The vertical axis shows the linear relation. The scale depends on the settings in the

"Display Configuration" dialog box.

17User Manual 1178.3405.02 ─ 08

Page 18

R&S®FPL1-K30

Measurements and result displays

Remote command:

LAY:ADD:WIND? '2',RIGH,YFAC see LAYout:ADD[:WINDow]? on page 97

Results: TRACe<t>[:DATA]? <Trace>,YFACtor

ENR Measured

Shows the results of the ENR measurement.

To measure the ENR of a noise source, first attach a noise source with known ENR to

the device, enter the ENR of this noise source to the calibration ENR table and calibrate using this one. Then, attach the unknown noise source to the device and perform

a measurement ("Run Single") with this one. The graph shown in the ENR Measured

display and the results for ENR Measured in the Result Summary will be the ENR of

the noise source at the measured frequencies. The vertical axis shows the level of the

measured ENR in dB. The scale depends on the settings in the "Display Configuration"

dialog box.

18User Manual 1178.3405.02 ─ 08

Page 19

R&S®FPL1-K30

Measurements and result displays

Remote command:

LAY:ADD:WIND? '2',RIGH,ENR see LAYout:ADD[:WINDow]? on page 97

Results: TRACe<t>[:DATA]? <Trace>,ENR

Power (Hot)

Shows the absolute power characteristics at the instrument input. The noise source is

turned on.

The vertical axis shows the power in dBm. The scale depends on the settings in the

"Display Configuration" dialog box.

Remote command:

LAY:ADD:WIND? '2',RIGH,PHOT see LAYout:ADD[:WINDow]? on page 97

Results: TRACe<t>[:DATA]? <Trace>,PHOT

Power (Cold)

Shows the absolute power characteristics at the instrument input. The noise source is

turned off.

The vertical axis shows the power in dBm. The scale depends on the settings in the

"Display Configuration" dialog box.

19User Manual 1178.3405.02 ─ 08

Page 20

R&S®FPL1-K30

off source noise with[dB] power Noise

on source noise with[dB] power Noise

with

FactorY

off

on

off

on

N

N

N

N

Measurements and result displays

Remote command:

LAY:ADD:WIND? '2',RIGH,PCOL see LAYout:ADD[:WINDow]? on page 97

Results: TRACe<t>[:DATA]? <Trace>,PCOLd

Cal Y-Factor

Shows the ratio of the hot and the cold power measured during calibration.

The "Y-factor" indicates the quality of measurement tolerances and uncertainties. To

get the result, the application measures the power with the noise source turned on (hot

power) and the noise source turned off (cold power), but without the DUT inserted.

The vertical axis shows the linear relation. The scale depends on the settings in the

"Display Configuration" dialog box.

Remote command:

LAY:ADD:WIND? '2',RIGH,CYF see LAYout:ADD[:WINDow]? on page 97

Results: TRACe<t>[:DATA]? <Trace>,CYFactor

Cal Power (Hot)

Shows the absolute power characteristics at the instrument input during the calibration

measurement. The noise source is turned on, the DUT is not inserted.

The vertical axis shows the power in dBm. The scale depends on the settings in the

"Display Configuration" dialog box.

20User Manual 1178.3405.02 ─ 08

Page 21

R&S®FPL1-K30

Measurements and result displays

Remote command:

LAY:ADD:WIND? '2',RIGH,CPH see LAYout:ADD[:WINDow]? on page 97

Results: TRACe<t>[:DATA]? <Trace>,CPHot

Cal Power (Cold)

Shows the absolute power characteristics at the instrument input during the calibration

measurement. The noise source is turned off, the DUT is not inserted.

The vertical axis shows the power in dBm. The scale depends on the settings in the

"Display Configuration" dialog box.

Remote command:

LAY:ADD:WIND? '2',RIGH,CPC see LAYout:ADD[:WINDow]? on page 97

Results: TRACe<t>[:DATA]? <Trace>,CPCold

Result Table

Shows the measurement results in numerical form in a table.

The contents of the table depend on the "Display Settings". By default it shows the

"noise figure", "gain" and "y-factor" results. Each row represents one measurement

point. Each column represents one result type. The first column shows the measurement frequency.

The result table shows either the RF or the IF, depending on your selection.

For more information, see Chapter 6.1.2, "Configuring numerical results", on page 77.

Remote command:

LAY:ADD:WIND? '2',RIGH,RES see LAYout:ADD[:WINDow]? on page 97

Results: TRACe<n>[:DATA]? on page 103

Table items: DISPlay[:WINDow<n>]:TABLe:ITEM on page 149

Current Values

Shows the result at the current measurement point.

21User Manual 1178.3405.02 ─ 08

Page 22

R&S®FPL1-K30

Measurements and result displays

The contents of the "Current" result display are updated as soon as a new measurement point is analyzed.

The result types shown in the table depend on the "Display Settings". By default it

shows the results for the "Noise Figure", "Gain" and "Y-Factor" result type. Each row

represents one result type. The first column shows the result type, the second column

shows the result.

For more information, see Chapter 6.1.2, "Configuring numerical results", on page 77.

Marker Table

Shows the marker characteristics in numerical form in a table.

The size of the table depends on the number of active markers and the way you have

configured the table in the "Result Config" dialog box. For more information, see Chap-

ter 6.3, "Using markers", on page 81 and Chapter 6.1.2, "Configuring numerical

results", on page 77.

The first four columns of the table are fix.

●

Type

Shows the marker type. 'M' represents a normal marker, 'D' represents a delta

marker.

●

Ref

Shows the reference marker for relative delta markers.

●

Trc

Shows the trace that the marker is positioned on.

●

X-value

Shows the horizontal position (frequency) of the marker.

For normal markers, the position is an absolute value. The position of delta markers is relative to another marker.

●

<Result>

Shows the measurement result at the marker position.

For normal markers, the result is an absolute value. Results for delta markers are

relative to another marker.

Remote command:

LAY:ADD:WIND? '2',RIGH,MTAB see LAYout:ADD[:WINDow]? on page 97

Results:

CALCulate<n>:MARKer<m>:Y? on page 168

CALCulate<n>:DELTamarker<m>:Y? on page 171

22User Manual 1178.3405.02 ─ 08

Page 23

R&S®FPL1-K30

4 Measurement basics

Measurement basics

Tuning modes

The measurement basics contain background information on the terminology and principles of "noise figure" measurements.

"Noise figure" measurements determine the noise that a device under test (DUT) adds

to a signal as that signal passes through the DUT.

● Tuning modes......................................................................................................... 23

● Measurement modes.............................................................................................. 25

● DUT types............................................................................................................... 27

● Image frequency rejection.......................................................................................28

● Calibration (2nd stage correction)...........................................................................31

● Using smart noise sources......................................................................................34

● Separating signals by selecting an appropriate resolution bandwidth.................... 35

● Analyzing several traces - trace mode....................................................................36

● Using markers.........................................................................................................36

4.1 Tuning modes

Basically, the application calculates the "noise figure" of a DUT based on the characteristics of the DUT that have been measured and a noise source whose properties are

known. Therefore, the Noise Source Control connector on the R&S FPL1000 is a prerequisite for the R&S FPL1 Noise Figure measurements application.

In addition to the noise characteristics of a DUT, the application is also able to determine several more DUT characteristics like its "gain" or its "noise temperature" characteristics.

23User Manual 1178.3405.02 ─ 08

Page 24

R&S®FPL1-K30

4.1.1 Swept measurements

Measurement basics

Tuning modes

The application provides several measurement modes or tuning modes.

● Swept measurements............................................................................................. 24

● Frequency table measurements..............................................................................24

● Single frequency measurements.............................................................................25

The sweep tuning mode performs measurements on a set of discrete frequencies

based on the frequency parameters. Each measurement analyzes the noise characteristics of the corresponding frequency or measurement point.

For swept measurements, the application automatically determines the measurement

frequencies and combines them in a frequency list.

Such a frequency set is the result of the frequency and span information that you have

provided. The frequency and span information is made up out of the center frequency,

the span, the start and the stop frequency. In combination with the measurement points

or the frequency table step size, the application calculates the contents of the frequency table.

The center frequency is the frequency in the center of the frequency band you are

measuring. Thus, it is defined either by the span, or the start and stop frequencies.

The measurement points is the number of entries in a frequency list and thus the

number of measurements that the application performs during a "noise figure" measurement.

The stepsize defines the distance between two measurement points. It is constant for

all measurement points.

If the stepsize is larger than the distance between start and stop frequency, the frequency table consists of the start and stop frequencies only.

4.1.2 Frequency table measurements

The frequency table tuning mode also performs measurements on a set of frequencies based on the contents of a frequency list. Each measurement analyzes the noise

characteristics of the corresponding frequency.

Compared to a swept measurement, you can customize the contents of the frequency

list. Thus, you can add frequencies that are independent of the frequency stepsize and

the number of measurement points.

Frequency tables also allow you to define a variable RBW and sweep time, depending

on the current frequency of the sweep point (see "Variable RBW and sweep time for

low-frequency measurements" on page 35 and Chapter 5.2.3, "Using a frequency

table", on page 45).

24User Manual 1178.3405.02 ─ 08

Page 25

R&S®FPL1-K30

4.1.3 Single frequency measurements

Measurement basics

Measurement modes

The single frequency tuning mode performs one or several consecutive measurements on a single frequency. You can perform the measurement on any frequency that

is supported by the hardware you are using.

Single frequency measurements are a way to facilitate manual adjustments for "noise

figure" measurements. They also allow you to get an idea about how the "noise figure"

at a particular frequency change over time.

Note that sweep lists or frequency tables are not considered in this measurement

mode.

Single frequency measurement results

For single frequency measurements, the same set of graphical result displays is available as for frequency list measurements ("Noise Figure", "Gain" etc.). Note, however,

that the x-axis has no unit, but shows a series of results taken for a single frequency.

The number of displayed results depends on the number of measurement points you

have defined.

For more information, see Chapter 3, "Measurements and result displays", on page 14.

In addition, you can also view the results in the Result Table in numerical form.

Single frequency measurements are not available when you are using a resistor as a

noise source.

4.2 Measurement modes

In some cases, the Power (Hot) and Power (Cold) results require two different noise

sources with different temperature characteristics (cold and hot). Measurements with a

resistor noise source are such a case.

Usually, noise sources with diode characteristics are used for "Noise Figure" measurements. These noise sources have two states, on and off. When they are supplied with

power (state = on), the application measures the hot power, when they are not supplied

with power (state = off), it measures the cold power. Turning the noise source on and

off is automatically done by the application, so that you can get the hot and cold power

characteristics in a single step.

This automatic measurement mode is the default measurement mode of the R&S

FPL1 Noise Figure measurements application.

A resistor noise source, however, requires two resistors, one hot and one cold. You

have to substitute the hot resistor by the cold resistor to measure first the hot and then

the cold power. For these cases, the application provides a manual measurement

mode. This measurement mode is automatically selected when you select a "Noise

Source" on page 51 with resistor characteristics, but is not restricted to those cases.

The manual measurement mode is available for measurements and the calibration

stage.

25User Manual 1178.3405.02 ─ 08

Page 26

R&S®FPL1-K30

Measurement basics

Measurement modes

Performing a manual measurement

In manual measurement mode, you have to measure (or calibrate) the hot and cold

power characteristics of the DUT separately. When you start the measurement, the

application opens a dialog box that allows you to select the type of measurement to

perform next.

Recommended order of measurements

Note that it is recommended that you begin with the hot power measurement.

Furthermore, calibration always begins with the hot power measurement.

In case the hot power has to be measured first, the cold power measurement is

unavailable:

When the first measurement is done, you can change the test setup by connecting the

other resistor. Then start the second measurement.

In the dialog box, the measurement stage that is already done is labeled green.

In addition, the application shows the missing calibration and measurement steps in

the channel bar.

26User Manual 1178.3405.02 ─ 08

Page 27

R&S®FPL1-K30

4.3 DUT types

Measurement basics

DUT types

Clearing results

To replace the previous calibration or measurement results, clear the currently stored

data using the "Clear Calibration Results" or "Clear Measurement Results" function.

Returning to automatic measurement mode

When you are in automatic measurement mode and select a noise source with resistor

characteristics, the application automatically selects the manual measurement mode.

When you are in manual measurement mode and select a noise source with diode

characteristics, you have to select the automatic measurement mode deliberately in

the "Sweep" menu.

"Noise figure" measurements are possible on DUTs with a wide variety of characteristics. The DUT characteristics not only affect the test setup, but also determine the way

the application populates the frequency list for swept measurements.

The R&S FPL1 Noise Figure measurements application supports measurements on

DUTs that work on a fixed frequency as well as measurements on frequency-converting DUTs.

● Measurements on linear DUTs (direct measurement).............................................27

● Measurements on frequency converting DUTs....................................................... 27

4.3.1 Measurements on linear DUTs (direct measurement)

For a linear DUT, the RF frequency remains the same between its input and output.

For measurements on such DUTs, it is sufficient to measure the signal's RF frequency

without any additional equipment (like a local oscillator). A typical linear DUT is an

amplifier, for example.

The test setup for measurements on such DUTs usually consists of the noise source,

the DUT and an analyzer. If necessary, the measurement also considers loss that

occurs somewhere in the measurement path.

For linear DUTs, the contents and layout of the "Overview" dialog box represents the

configuration of a typical test setup.

4.3.2 Measurements on frequency converting DUTs

A frequency converting DUT converts the RF frequency to an intermediate frequency

(IF) using the local oscillator (LO). A frequency-converting DUT either converts the RF

frequency to a lower IF (down-conversion) or a higher IF (up-conversion).

27User Manual 1178.3405.02 ─ 08

Page 28

R&S®FPL1-K30

Measurement basics

Image frequency rejection

If you have selected a frequency-converting DUT measurement mode, the layout of the

"Overview" dialog box adds the local oscillator to the test setup.

The local oscillator can have a fixed or a variable frequency. If the LO frequency is

fixed, the intermediate frequency (IF) resulting from the conversion process is variable

(depending on the input signal). If the LO frequency is variable, the IF has to be fixed.

The R&S FPL1 Noise Figure measurements application supports only the fixed LO frequency measurement method.

Fixed LO frequency

If you select one of the fixed LO measurement modes, the LO frequency is the same

for all entries in the frequency list. The IF frequency for each entry is variable and is the

result of the equation the selected mode is based on.

●

fRF + fLO for up-converters

●

fRF - fLO for down-converters

The fixed LO measurement modes are, for example, required for measurements on

satellite converters.

4.4 Image frequency rejection

Frequency converting DUTs convert a radio frequency (RF) to an intermediate frequency (IF). The IF is lower than the RF for down-converting DUTs, and higher than

the RF for up-converting DUTs.

In a basic test setup, the image frequency of the RF signal is also converted to the IF.

Depending on the DUT, this effect can be wanted or even necessary, or not. To avoid

measurement errors of the "noise figure" and "gain" of up to 3 dB, make sure to use

the appropriate measurement configuration.

Basically, you can distinguish between single sideband (SSB) mixers, double sideband

(DSB) mixers, and mixers that partly suppress a sideband. If a sideband is not needed

or only partly needed, you can reject the image frequency. If you do so, the application

activates a filter that suppresses the image frequency to a certain extent.

The following illustrations help you configure the measurement correctly.

For more information on how to configure image rejection, see "Image Rejection"

on page 48.

28User Manual 1178.3405.02 ─ 08

Page 29

R&S®FPL1-K30

Measurement basics

Image frequency rejection

Double sideband measurements

Double sideband mixers use both sidebands to the same extent. Both RF and image

frequency are converted. In that case, turn off image rejection.

fLO= frequency of the local oscillator

fIF= intermediate frequency = fRF ± f

fRF= lower sideband = fLO - f

f

= upper sideband = fLO + f

image

LO

IF

IF

If image rejection is on, the results have a 3 dB error. That means "noise figure" results

are 3 dB lower than they should be. "Gain" results are 3 dB higher.

Single sideband measurements

Single sideband mixers use a single sideband only. In that case, you have to suppress

the sideband that is not required. If you do so, the measurement is like on an amplifier.

To suppress a sideband completely, it is best to set the image rejection to the maximum amount possible (999.99 dB).

Partial sideband suppression

For measurements on mixers with a low image frequency rejection, there are two test

scenarios.

●

Mixers whose image rejection is known.

●

Mixers whose image rejection is unknown.

29User Manual 1178.3405.02 ─ 08

Page 30

R&S®FPL1-K30

Measurement basics

Image frequency rejection

For mixers whose image rejection is known, define the magnitude of image rejection in

dB as accurately as possible. Otherwise, measurement results ("noise figure" and

"gain") deviate between 0 dB to 3 dB.

If you do not know the image rejection characteristics of a mixer, use a custom test

setup including an additional filter. You also have to know the "gain" characteristics of

the DUT.

(1)

= Test setup for calibration

(2) = Test setup for "noise figure" measurement

In the test setup shown above, a lowpass filter prevents unwanted noise from being fed

in at the image frequency.

Depending on the position of the frequency bands, you might need a highpass or

bandpass filter for the RF frequency instead of the lowpass filter. The important point is

that unwanted noise is not converted by a further receive path of the mixer. The

unwanted noise at the receive frequency must not be reduced. The insertion loss must

be considered, if applicable.

With this test setup, the measurement on a mixer without sideband suppression is the

same as SSB measurements.

To take the characteristics of the filter into account, include the insertion loss of the filter at the RF. To consider the actual filter suppression at the image frequency, include

the actual attenuation for the image rejection.

Harmonics mixer measurement

For a harmonics mixer, the input signals are not only converted to the IF by the wanted

harmonic. The harmonic of the LO signal produced in the mixer is also converted.

Often, the mixer even features a lower conversion loss for unwanted harmonics. For

measurements on this type of mixer, you have to use a bandpass filter. The filter

ensures that there is only noise at the desired frequency at the input of the DUT. This

30User Manual 1178.3405.02 ─ 08

Page 31

R&S®FPL1-K30

4.5 Calibration (2nd stage correction)

Measurement basics

Calibration (2nd stage correction)

measurement is similar to measurements on a mixer with an average sideband suppression.

The calibration procedure of the application measures the inherent noise of the

R&S FPL1000 you are using. Performing calibration is therefore recommended, as it

increases the accuracy of measurement results. The results get more accurate

because the application takes the inherent noise of the analyzer into account while it

calculates the results.

Calibration for "noise figure" measurements is also known as 2nd stage correction.

This term is used because in a typical "noise figure" test setup, the DUT represents the

first stage and the analyzer the second stage in the test setup.

The 2nd stage correction is a calibration that is specific to "noise figure" measurements. It is independent of the overall calibration state of the analyzer and does not

calibrate the analyzer.

For successful calibration, you need additional equipment.

●

Noise source

The noise source is like a calibration standard. It provides a reference with known

noise characteristics that allows the application to determine the inherent noise of

the analyzer you are using.

During the calibration, the application measures the inherent noise characteristics of

the analyzer at the set of measurement frequencies.

Thus, the 2nd stage correction is valid for a particular instrument configuration, the

room temperature and the instrument temperature. As long as this configuration stays

the same, calibration data remains valid.

Calibrating single frequency measurements

Like for all other measurements of the R&S FPL1 Noise Figure measurements application, perform a calibration before a single frequency measurement for increased accuracy.

There is an easy way to calibrate single frequency measurements, if you already calibrated the application for swept or list measurements. If the single frequency is part of

the frequency list, the measurement is already calibrated for that frequency and no further steps are necessary. The application recalls the last calibration values when you

switch back to sweep mode or frequency table mode.

Only if you use a single frequency that is not part of the frequency list, you must calibrate this frequency point first.

●

Interpolation

31User Manual 1178.3405.02 ─ 08

Page 32

R&S®FPL1-K30

Measurement basics

Calibration (2nd stage correction)

If you change the frequency, while the frequency span stays the same or is

reduced, the application interpolates the correction data for the new measurement

points. A new calibration is not required.

However, measurements based on interpolated data can result in an increased

measurement uncertainty. Highly accurate measurements that are conform to the

values specified in the data sheet are only possible at calibrated measurement

points.

Note that useful interpolation is possible only if essential calibration parameters

(e.g. impedance or attenuation) change only slightly. This is the case if the distance

between the original calibration points is sufficiently small.

If the span increases compared to the span during calibration, a new calibration is

necessary.

If the application interpolates the calibration data, it shows a corresponding label in

the channel bar and a warning message in the status bar.

●

Invalid calibration

If you change one of the amplitude parameters (e.g. the attenuation), calibration is

labeled invalid. In that case, calibration is not accurate, because the settings are

not in line with the settings at the time the R&S FPL1000 has been calibrated. If

calibration is invalid, repeat the calibration or restore the settings as they were during the calibration.

Saving calibration data

If you save the current configuration or measurement results to a data set, calibration

data is part of that data set.

For more information on saving and restoring data sets, see the "Storing and Recalling

Instrument Settings and Measurement Data" chapter in the R&S FPL1000 user manual.

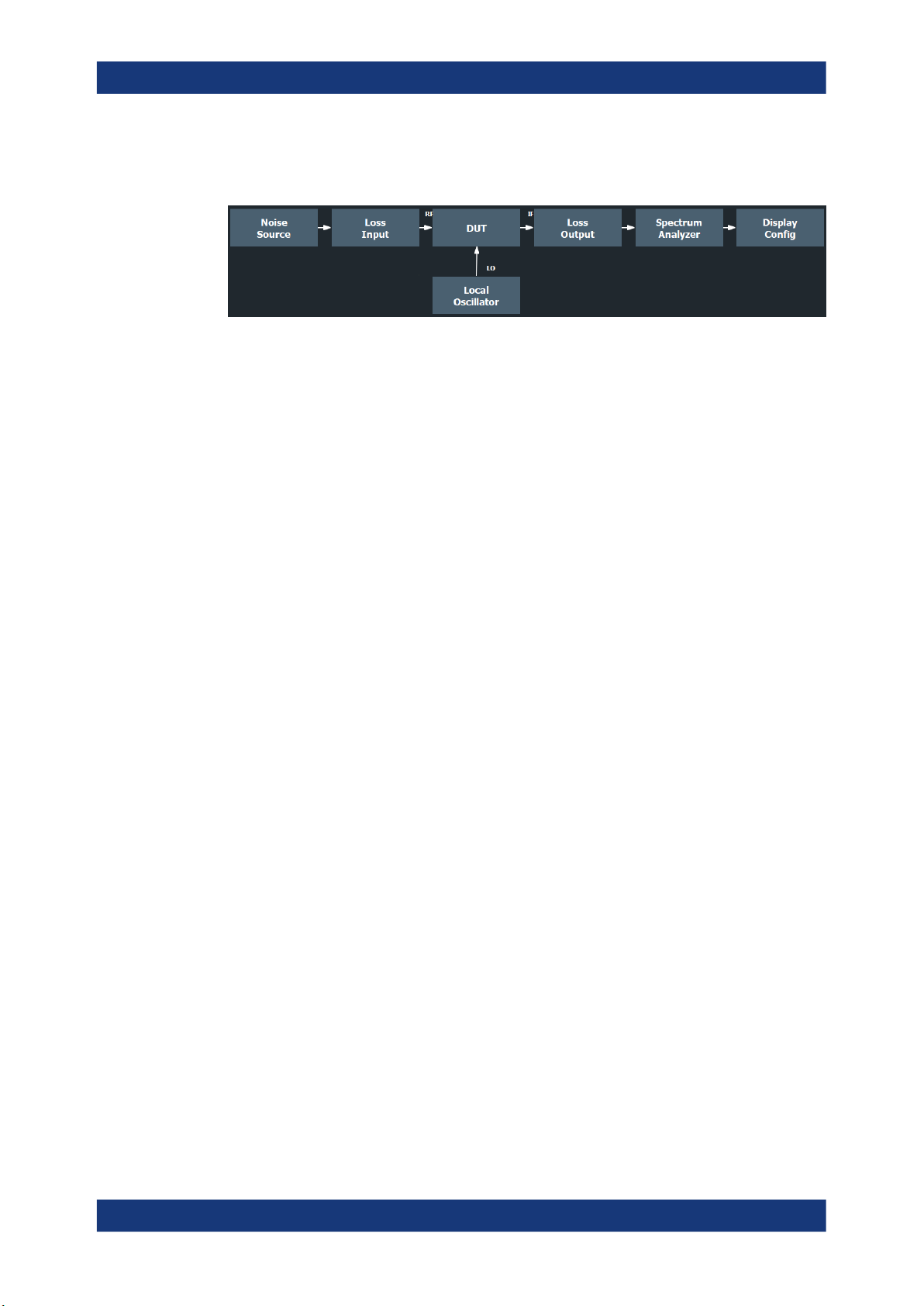

The picture below shows a typical calibration setup that includes a noise source.

32User Manual 1178.3405.02 ─ 08

Page 33

R&S®FPL1-K30

Measurement basics

Calibration (2nd stage correction)

Figure 4-1: Noise figure calibration setup

1. Connect the noise source directly and without a cable to the RF input of the analyzer.

2. Connect the noise source to the +28 V voltage supply (Noise Source Control connector) on the back of the R&S FPL1000.

To connect the noise source to the voltage supply, you need a coaxial cable.

After you have set up calibration, there are several ways to start calibration.

●

In the "Noise Overview" dialog box, press the "Calibrate" button.

●

In the "Sweep" menu, press the "Calibrate" softkey.

Calibration Save

If the user has performed a valid calibration on the instrument, the calibration results

can be saved by using the "Calibration Save" button in the "Export" dialog. This provides the possibility to use once stored calibration results at a later point.

Remote command:

[SENSe:]CORRection:SAVE on page 128

Calibration Recall

Calibration results that have been stored once on the instrument can be recalled by

using the "Calibration Recall" button in the "Import" dialog.

33User Manual 1178.3405.02 ─ 08

Page 34

R&S®FPL1-K30

Measurement basics

Using smart noise sources

To achieve a valid calibration by importing a saved one, all parameters of

R&S FPL1000-K30 must match exactly to the ones that have been used for the calibration. At the import of a calibration, a preview dialog is shown which contains all relevant parameters of the calibration to be imported and an indication (green / red) if they

match to the current instrument and option settings. Only if the calibration context summary is green, the calibration import can be done. If the calibration context summary is

red, importing the calibration results would lead to an invalid calibration status for the

current settings. Thus the calibration results cannot be imported in this case. If the calibration context summary is green but some of the individual entries are red (i.e. they

differ from the current settings), the calibration results still can be imported. The import

will then overwrite the red marked settings with the ones from the stored calibration to

ensure the settings match.

Remote command:

[SENSe:]CORRection:RECall on page 128

4.6 Using smart noise sources

A smart noise source (SNS) provides its own ENR and uncertainty tables and a temperature value from an internal measurement. Thus, accuracy is improved and less

configuration efforts are required.

When you connect a smart noise source, the R&S FPL1000 automatically loads its

ENR table and stores it for future measurements. The ENR table remains stored on the

instrument even after the noise source is disconnected. If the table already exists on

the R&S FPL1000, the contents are updated, if necessary. The contents of the most

recently loaded SNS ENR table are also stored as the "default" ENR table. Thus, they

remain available even if the noise source type is changed, for example to "noise

diode". The ENR tables for smart noise sources are shown for reference only and can-

34User Manual 1178.3405.02 ─ 08

Page 35

R&S®FPL1-K30

4.7 Separating signals by selecting an appropriate reso-

Measurement basics

Separating signals by selecting an appropriate resolution bandwidth

not be edited in the R&S FPL1 Noise Figure measurements application. The name of

each ENR table contains the serial number of the SNS.

Test Setup

Connect the smart noise source to the Lemosa Power Sensor / Noise Source Control

connector on the R&S FPL1000. (For models without a Lemosa connector, connect the

SNS to the BNC Noise source control connector and a USB connector on the

R&S FPL1000.) Then connect the SNS output to the DUT or the RF Input connector on

the R&S FPL1000. Only one SNS can be active on the R&S FPL1000 at any time.

The identification and setup procedure after connecting the FS-SNS may take up to 10

seconds.

lution bandwidth

The resolution bandwidth defines the 3 dB bandwidth of the resolution filter to be used.

An RF sinusoidal signal is displayed according to the passband characteristic of the

resolution filter (RBW), i.e. the signal display reflects the shape of the filter.

The highest sensitivity is obtained at the smallest bandwidth (1 Hz). If the bandwidth is

increased, the reduction in sensitivity is proportional to the change in bandwidth.

Increasing the bandwidth by a factor of 3 increases the displayed noise by approx. 5

dB (4.77 dB precisely). If the bandwidth is increased by a factor of 10, the displayed

noise increases by a factor of 10, i.e. 10 dB.

The higher spectral resolution with smaller bandwidths is won by longer sweep times

for the same span. The sweep time has to allow the resolution filters to settle during a

sweep at all signal levels and frequencies to be displayed.

If the RBW is too large, signal parts that are very far away (e.g. from a different signal)

are considered in the measurement and distort the results. The displayed noise increases.

If the RBW is too small, the measurement time increases.

Variable RBW and sweep time for low-frequency measurements

Usually, a constant RBW and sweep time is used for the entire measurement. However, for low-frequency measurements (under 10 MHz), smaller bandwidths and longer

sweep times are required to improve accuracy of the results. Using a small RBW and

long sweep time for the entire span would increase measurement time significantly. In

this case, a variable RBW and sweep time can be defined for lower frequencies,

depending on the current frequency of the sweep point. The variable RBW and sweep

times are defined in the frequency table (see Chapter 5.2.3, "Using a frequency table",

on page 45). The defined RBW and sweep times are also included in a table export.

In the channel bar, the bandwidth and sweep time range of the variable values is indicated.

35User Manual 1178.3405.02 ─ 08

Page 36

R&S®FPL1-K30

4.8 Analyzing several traces - trace mode

Measurement basics

Using markers

The trace mode determines the way the data is processed and displayed. The application provides the following trace modes.

Table 4-1: Overview of available trace modes

Trace Mode Description

Blank Hides the selected trace.

Clear Write Overwrite mode: the trace is overwritten by each sweep. This is the default setting.

View The current contents of the trace memory are frozen and displayed.

Each time the trace mode is changed, the selected trace memory is cleared.

The default trace mode for the first trace is Clear/Write. For trace 2-4, the default trace

mode is "Blank". If you require another mode, you have to set it manually.

As you can have up to four traces simultaneously, you can compare the results with

different measurement configurations. For example, freeze a trace and use it as a reference trace.

If you change the scaling of the y-axis, the R&S FPL1000 automatically adapts the

trace data to the changed display range. Thus, you can perform an amplitude zoom

after the measurement to show details of the trace.

4.9 Using markers

Markers are used to mark points on traces, to read out the results of a particular measurement point or compare results of different traces. The noise application provides

four markers.

When you activate a marker, the application automatically positions it on the first measurement point (left border of the diagram) of trace 1, regardless of how many traces

36User Manual 1178.3405.02 ─ 08

Page 37

R&S®FPL1-K30

Measurement basics

Using markers

are active. A marker is always positioned on the same horizontal position in all active

measurement windows. If you change the position of a marker in one window, the

application adjusts the position of that marker in all other measurement windows. Thus,

the marker results for a specific marker are always for the same frequency, which

makes it easier to compare results.

Markers in single frequency mode

When you use a marker for single frequency measurements, the marker is positioned

on a particular index value and not a particular measurement point. This means that

during continuous measurements, the marker remains on the index value you have put

it on. It does not move down the line with the results.

To move a marker, you can use several methods.

●

Enter a particular measurement frequency in the input field that opens when you

activate a marker.

●

Move the marker around with the rotary knob or the cursor keys.

●

Drag the marker around using the touchscreen.

All markers can be used either as normal markers or delta markers. A normal marker

indicates the absolute signal value at the defined position in the diagram. A delta

marker indicates the value of the marker relative to the specified reference marker (by

default marker 1).

The application always positions the marker on the trace with the lowest number that is

in Clear/Write trace mode. To set the marker on another trace, use the "Marker to

Trace" function. With this function, you can also position a marker on a trace that is in

"View" trace mode, e.g. to compare measurement results. Note that at least one active

marker has to be a normal marker.

37User Manual 1178.3405.02 ─ 08

Page 38

R&S®FPL1-K30

Measurement basics

Using markers

The application shows the results at the marker position directly in the diagram area

(up to two markers) or in the marker table (if you use more than two markers).

Marker information in diagram area

By default, the results of the last two markers or delta markers that were activated are

displayed in the diagram area.

The following information is displayed there:

●

The marker type (M for normal, D for delta, or special function name)

●

The marker number (1 to 4)

●

The assigned trace number in square brackets [ ]

●

The marker value on the y-axis

●

The marker position on the x-axis

Marker information in marker table

In addition to the marker information displayed within the diagram area, a marker table

can be displayed in a separate window. For more information on the contents of the

marker table, see "Marker Table" on page 22.

38User Manual 1178.3405.02 ─ 08

Page 39

R&S®FPL1-K30

5 Configuration

Configuration

Configuration overview

"Noise figure" measurements require a special application on the R&S FPL1000, which

you activate using the [MODE] key.

The Noise Source Control connector on the R&S FPL1000 is also a prerequisite for the

R&S FPL1 Noise Figure measurements application. Without this connector, no measurement can be performed.

This connector is part of the "Additional Interfaces" hardware option R&S FPL1-B5.

When you activate a measurement channel in the R&S FPL1 Noise Figure measurements application, a measurement for the input signal is defined with the default configuration. The "Noise Figure" menu is displayed and provides access to the most

important configuration functions.

Unavailable hardkeys

Note that the [AMPT], [BW], and [TRIG] keys have no contents and no function in the

R&S FPL1 Noise Figure measurements application.

● Configuration overview............................................................................................39

● Defining the measurement frequency..................................................................... 41

● Selecting DUT characteristics.................................................................................48

● Configuring the noise source.................................................................................. 49

● Configuring additional loss......................................................................................57

● Configuring the analyzer......................................................................................... 62

● Using the uncertainty calculator..............................................................................66

● Performing measurements......................................................................................72

● Configuring inputs and outputs of the R&S FPL1000............................................. 74

5.1 Configuration overview

Throughout the measurement channel configuration, an overview of the most important

currently defined settings is provided in the "Overview". The "Overview" is displayed

when you select the "Overview" icon, which is available at the bottom of all softkey

menus.

39User Manual 1178.3405.02 ─ 08

Page 40

R&S®FPL1-K30

Configuration

Configuration overview

In addition to the main measurement settings, the "Overview" provides quick access to

the main settings dialog boxes. The individual configuration steps are displayed in the

order of the data flow. Thus, you can easily configure an entire measurement channel

from input over processing to output and analysis by stepping through the dialog boxes

as indicated in the "Overview".

In particular, the "Overview" provides quick access to the following configuration dialog

boxes (listed in the recommended order of processing):

To perform a calibration

1. Noise Source

See Chapter 5.4, "Configuring the noise source", on page 49.

2. Spectrum Analyzer

See Chapter 5.6, "Configuring the analyzer", on page 62.

3. Calibration

See "Calibrate" on page 73

To perform a measurement

1. Noise Source

See Chapter 5.4, "Configuring the noise source", on page 49.

2. Input and output losses

See Chapter 5.5, "Configuring additional loss", on page 57.

3. DUT configuration

See Chapter 5.3, "Selecting DUT characteristics", on page 48

4. Spectrum Analyzer

See Chapter 5.6, "Configuring the analyzer", on page 62.

5. Display Configuration

40User Manual 1178.3405.02 ─ 08

Page 41

R&S®FPL1-K30

Configuration

Defining the measurement frequency

See Chapter 6.1, "Configuring the display", on page 75

To configure settings

► Select any button in the "Overview" to open the corresponding dialog box.

Select a setting in the channel bar (at the top of the measurement channel tab) to

change a specific setting.

Preset Channel Setup

Select the "Preset Channel" button in the lower left-hand corner of the "Overview" to

restore all measurement settings in the current channel setup to their default values.

Note: Do not confuse the "Preset Channel" button with the [Preset] key, which restores

the entire instrument to its default values and thus closes all channel setups on the

R&S FPL1000 (except for the default channel setup)!

Remote command:

SYSTem:PRESet:CHANnel[:EXEC] on page 96

Specific Settings for

The channel setup can contain several windows for different results. Thus, the settings

indicated in the "Overview" and configured in the dialog boxes vary depending on the