Rohde & Schwarz AMIQ 1110.2003.04, AMIQ 1110.2003.03, AMIQ 1110.2003.02 User Manual

Test and Measurement

Division

Operating Manual

I/Q Modulation Generator

AMIQ

1110.2003.02/03/04

Printed in the Federal

Republic of Germany

valid as of firmware version 4.00

1110.3339.12-08- 1

AMIQ Tabbed Divider Overview

Tabbed Divider Overview

Contents

Data Sheet

Safety Instructions

Certificate of Quality

EU Certificate of Conformity

List of R&S Representatives

Contents of Manuals for I/Q Modulation Generator AMIQ

Tabbed Divider

1 Chapter 1: Putting into Operation

2 Chapter 2: Getting Started

3 Chapter 3: Operation

4 Chapter 4: Functional Description

5 Chapter 5: Remote Control – Basics

6 Chapter 6: Remote Control – Commands

7 Chapter 7: Examples

8 Chapter 8: Maintenance

9 Chapter 9: Error Messages

10 Index

1110.3339.12 RE E-1

AMIQ Contents

Contents

1 Putting into Operation.........................................................................................1.1

Introduction......................................................................................................................................1.1

Front and Rear View........................................................................................................................ 1.2

Putting into Operation.....................................................................................................................1.2

Unpacking................................................................................................................................1.2

Setting Up................................................................................................................................1.3

Rackmounting................................................................................................................... .......1.3

Connection to AC Supply.........................................................................................................1.4

Power Fuses............................................................................................................................ 1.4

Power Up / Switch-on Test...................................................................................................... 1.4

Instrument Switch-off...............................................................................................................1.6

EMC Shielding Measures........................................................................................................1.6

Connection to Test Setup ...............................................................................................................1.7

Connecting the Controller........................................................................................................1.7

Software for AMIQ Control ...................................................................................................... 1.8

Signal Inputs and Outputs .......................................................................................................1.8

Connecting BER Test Signals ................................................................................................. 1.9

Connecting other Facilities .................................................................................................... 1.10

Installation of Options...................................................................................................................1.11

Option AMIQ-B1, BER Test...................................................................................................1.11

Option AMIQ-B2, Differential I/Q Outputs..............................................................................1.11

Option AMIQ-B3, Digital I/Q Output ............................................................................................. 1.12

Option AMIQB19, I/Q Rear-Panel Connection ...................................................................... 1.12

Option AMIQK11, IS-95 CDMA .............................................................................................1.12

Option AMIQK12, CDMA 2000..............................................................................................1.12

Option AMIQK13, Digital Standard W-CDMA TTD Mode (3GPP) ........................................ 1.12

Option AMIQK14, Digital Standard TD-SCDMA.................................................................... 1.12

Option AMIQK15, OFDM Signal Generation.........................................................................1.12

Option AMIQK16, Digital Standard 802.11b Wireless LAN...................................................1.13

Initial Installation or Update of AMIQ Software........................................................................... 1.13

2 Getting Started.....................................................................................................2.1

Control via Serial Interface ......................................................................................................2.1

Control via IEC/IEEE-Bus Interface......................................................................................... 2.2

Control via Floppy....................................................................................................................2.3

Switchover between Remote-Control Interfaces ..................................................................... 2.3

3 Operation .............................................................................................................3.1

Control Elements..................................................................................................................... 3.1

Indicating Elements (LEDs).....................................................................................................3.1

Calculation of I/Q Modulation Signals......................................................................................3.2

Control via WinIQSIM....................................................................................................3.2

Control via Vector Signal Generator SMIQ ...................................................................3.2

1110.3339.12 3 E-7

Contents AMIQ

4 Functional Description........................................................................................4.1

Uses .................................................................................................................................................4.1

Stress Signals for I/Q Signals..................................................................................................4.1

Special Characteristics for Use of AMIQ as I/Q Modulation Source ...................................... 4.2

Basic Operating Modes...................................................................................................................4.3

Signal Outputs .................................................................................................................................4.4

Marker Outputs........................................................................................................................4.4

Clock Output and Input.................................................................................................. 4.5

Triggering.........................................................................................................................................4.5

I/Q Signal Adjustments....................................................................................................................4.7

Adjusting the Level ..................................................................................................................4.7

Adjusting the Offset .................................................................................................................4.7

Adjusting the Delay..................................................................................................................4.7

AMIQ – Block Diagram............................................................................................................4.8

Measurement of Bit Error Rate.......................................................................................................4.9

Connector................................................................................................................................ 4.9

Signal Path and Waveform.................................................................................................... 4.10

Test Method...........................................................................................................................4.11

PRBS Polynomials................................................................................................................. 4.13

Measurement Result, Accuracy, Measurement Time...........................................................4.13

Possible Problems with BER Measurement and Related Solutions...................................... 4.14

Further Hints and Tricks ........................................................................................................4.15

Installation of Option AMIQ-B1, BER Measurement..............................................................4.16

Avoid Reflections in the BER Measurement..........................................................................4.17

Application Example for Option Differential Outputs ................................................................4.18

AMIQ Model 03 / 04........................................................................................................................4.20

Digital I/Q Output Option AMIQ-B3 .............................................................................................. 4.21

Operation of Digital I/Q Output Option (AMIQ-B3) using WinIQSIM..................................... 4.22

Pin Allocation of Digital I/Q Outputs....................................................................................... 4.23

Brief Specifications................................................................................................................4.23

Technical Details ................................................................................................................... 4.24

IEEE 488 Commands............................................................................................................ 4.25

External Clock................................................................................................................................4.26

Brief Description ....................................................................................................................4.26

Operation...............................................................................................................................4.27

IEC/IEEE-bus command........................................................................................................4.27

Multisegment Waveform ...............................................................................................................4.28

Application and structure.......................................................................................................4.28

IEC/IEEE bus commands...................................................................................................... 4.29

1110.3339.12 4 E-6

AMIQ Contents

5 Remote Control - Basics.....................................................................................5.1

Short Introduction............................................................................................................................5.1

Messages..........................................................................................................................................5.1

Interface Messages .................................................................................................................5.2

Device Messages (Commands and Device Responses)........................................................ 5.2

Structure and Syntax of the Device Messages............................................................................. 5.3

SCPI Introduction.....................................................................................................................5.3

Structure of a Command ......................................................................................................... 5.3

Structure of a Command Line..................................................................................................5.5

Responses to Queries............................................................................................................. 5.6

Parameters.............................................................................................................................. 5.6

Overview of Syntax Elements..................................................................................................5.8

Instrument Model and Command Processing .............................................................................. 5.9

Input Unit .................................................................................................................................5.9

Command Recognition.......................................................................................................... 5.10

Data Set and Instrument Hardware....................................................................................... 5.10

Status Reporting System.......................................................................................................5.10

Output Unit.............................................................................................................................5.11

Command Sequence and Command Synchronization..........................................................5.11

Status Reporting System.............................................................................................................. 5.12

Structure of an SCPI Status Register.................................................................................... 5.12

Overview of Status Registers ................................................................................................5.14

Description of the Status Registers ....................................................................................... 5.15

Status Byte (STB) and Service Request Enable Register (SRE)................................5.15

IST Flag and Parallel Poll Enable Register (PPE).......................................................5.16

Event Status Register (ESR) and Event Status Enable Register (ESE) ..................... 5.16

STATus:OPERation Register...................................................................................... 5.17

STATus:QUEStionable Register ................................................................................. 5.17

Application of the Status Reporting System .......................................................................... 5.18

Service Request, Making Use of the Hierarchy Structure...........................................5.18

Serial Poll ....................................................................................................................5.19

Parallel Poll..................................................................................................................5.19

Query by Means of Commands................................................................................... 5.19

Error Queue Query......................................................................................................5.19

Reset Values of the Status Reporting Systems.....................................................................5.20

Hardware Interfaces....................................................................................................................... 5.21

IEC/IEEE Bus Interface.........................................................................................................5.21

Characteristics of the Interface..............................................................................................5.21

Bus Lines...............................................................................................................................5.21

Interface Functions................................................................................................................ 5.22

Interface Messages ...............................................................................................................5.23

RS-232-C Interface......................................................................................................................... 5.24

Interface characteristics......................................................................................................... 5.24

Signal lines ............................................................................................................................5.24

Transmission parameters...................................................................................................... 5.25

Interface functions .................................................................................................................5.25

Handshake ............................................................................................................................ 5.26

1110.3339.12 5 E-7

Contents AMIQ

6 Remote Control – Commands and Data Formats.............................................6.1

Notation ...................................................................................................................................6.1

Common Commands ..............................................................................................................6.3

BERT – Bit Error Rate Tests ................................................................................................... 6.8

CALibration – Adjustment and Calibration.............................................................................6.13

DIAGnostic – Hardware Diagnosis........................................................................................6.17

MARKer – Marker Management............................................................................................6.20

MEMory/MMEMory – Waveform Management..................................................................... 6.22

OUTPut – Hardware Settings................................................................................................ 6.35

PROGram – Program Sequence Control..............................................................................6.41

SOURce – Hardware Settings...............................................................................................6.42

STATus – Status Reporting...................................................................................................6.47

SYSTem – Various Settings..................................................................................................6.50

ARM/TRIGger/ABORt – Triggering, Sequence Control.........................................................6.54

Waveform File Format...........................................................................................................6.57

Creating a Waveform File „Manually“..........................................................................6.64

Converting a Waveform File with the Application Software AMIQ-K2.........................6.66

Example of combining waveform files:........................................................................ 6.68

List of Commands..................................................................................................................6.70

Remote-control commands.........................................................................................6.70

Tags for Determining the Waveform File Formats......................................................6.73

7 Examples.............................................................................................................. 7.1

Program examples for Remote Control.........................................................................................7.1

Including IEC/IEEE-Bus Library for QuickBasic ...................................................................... 7.1

Initialization and Default Status ...............................................................................................7.2

Initializing the Controller................................................................................................7.2

Functions for Receiving and Sending Data and Commands ........................................7.2

Initializing the Instrument...............................................................................................7.2

Sending Device Setting Commands........................................................................................ 7.3

Switchover to Manual Control..................................................................................................7.3

Executing Batch Programs...................................................................................................... 7.4

Reading out Device Settings ................................................................................................... 7.4

Command Synchronization...................................................................................................... 7.5

Service Request ......................................................................................................................7.6

Selftest with Progress Indication..............................................................................................7.7

Waveform Descriptions.......................................................................................................... .......7.10

GSM Signals (GMSK)............................................................................................................7.10

GSM continuous, PRBS 9 data................................................................................... 7.10

GSM Normal Burst ......................................................................................................7.10

GSM Normal Burst, BERT PRBS 9 data.....................................................................7.11

EDGE Signals (8PSK)...........................................................................................................7.12

EDGE Normal Burst ....................................................................................................7.12

EDGE Normal Burst, BERT PRBS 9 data...................................................................7.12

GSM/EDGE (GMSK/8PSK) alternating Bursts............................................................7.13

NADC Signals........................................................................................................................7.14

NADC continuous, PRBS 9 data................................................................................. 7.14

NADC Downlink Burst .................................................................................................7.14

NADC Downlink Burst, BERT PRBS 9 data................................................................7.15

1110.3339.12 6 E-6

AMIQ Contents

DECT Signals........................................................................................................................7.16

DECT continuous, PRBS 9 data ................................................................................. 7.16

Bluetooth Signals...................................................................................................................7.17

Bluetooth continuous, PRBS 9 data............................................................................ 7.17

Bluetooth continuous, PRBS 15 data.......................................................................... 7.17

3GPP (FDD) W-CDMA Signals.............................................................................................7.18

Testmodel 1, 16 Channels .......................................................................................... 7.18

Testmodel 1, 32 Channels .......................................................................................... 7.18

Testmodel 1, 64 Channels .......................................................................................... 7.19

Testmodel 2................................................................................................................. 7.19

Testmodel 3, 16 Channels .......................................................................................... 7.20

Testmodel 3, 32 Channels .......................................................................................... 7.20

Testmodel 4................................................................................................................. 7.21

Uplink DPCH Mode, 1 DPCH (60 ksps) ......................................................................7.21

Uplink DPCH Mode, 1 DPCH (960 ksps) ....................................................................7.22

Uplink DPCH Mode, 6 DPCH (960 ksps) ....................................................................7.22

Uplink PRACH only Mode ...........................................................................................7.23

Uplink PCPCH only Mode ...........................................................................................7.23

IS95 CDMA Signals...............................................................................................................7.24

Pilot Signal...................................................................................................................7.24

Pilot Signal (with ACPR filter)...................................................................................... 7.24

9 Channels ..................................................................................................................7.25

9 Channels (with ACPR filter)......................................................................................7.25

9 Channels, worst case Crest ..................................................................................... 7.26

9 Channels, worst case Crest (with ACPR filter).........................................................7.26

64 Channels ................................................................................................................7.27

Uplink Signal (1 Access, 1 Traffic Channel)................................................................7.27

Multicarrier Signals................................................................................................................7.28

15 CW Carriers, maximum Crest................................................................................7.28

15 CW Carriers, minimum Crest.................................................................................7.28

8 GSM carriers............................................................................................................7.29

8 EDGE carriers..........................................................................................................7.29

5 NADC carriers..........................................................................................................7.29

Multicarrier Mixed Signals......................................................................................................7.30

3 WCDMA 3GPP carriers, 5 MHz spacing.................................................................. 7.30

3 WCDMA 3GPP carriers, 10 MHz spacing................................................................ 7.30

1 WCDMA 3GPP carrier + 1 EDGE carrier................................................................. 7.31

1 CDMA IS95 carrier + 1 NADC carrier....................................................................... 7.31

8 Maintenance......................................................................................................... 8.1

Mechanical and Electrical Maintenance .................................................................................. 8.1

Storing and Packing.................................................................................................................8.1

9 Error Messages ...................................................................................................9.1

Troubleshooting .............................................................................................................................. 9.1

List of Error Messages ....................................................................................................................9.2

SCPI Standard Messages ....................................................................................................... 9.2

No error.........................................................................................................................9.2

Operation complete....................................................................................................... 9.2

Query error - error upon data request ...........................................................................9.3

Device-specific error...................................................................................................... 9.3

Execution error.............................................................................................................. 9.4

Command error .............................................................................................................9.5

AMIQ-Specific Messages ........................................................................................................ 9.7

1110.3339.12 7 E-7

ContentsFigures AMIQ

Figures

Fig. 1-1 AMIQ used in a test setup..................................................................................................1.1

Fig. 1-2 AMIQ Front view.................................................................................................................1.2

Fig. 1-3 AMIQ rear view...................................................................................................................1.3

Fig. 4-1 Simplified block diagram of AMIQ...................................................................................... 4.8

Fig. 4-2 PRBS Polynomials............................................................................................................4.13

Fig. 4-3 Avoid reflections in the BER measurement...................................................................... 4.17

Fig. 4-4 Application block diagram of option AMIQ-B2.................................................................. 4.18

Fig. 4-5 Pin allocation of digital I/Q outputs ...................................................................................4.23

Fig. 4-6 Technical implementation of digital I/Q outputs................................................................4.24

Fig. 4-7 Integration of the AMIQ into a system with system clock.................................................4.26

Fig. 4-8 Feeding a DUT with a spectrally pure external clock ....................................................... 4.26

Fig. 4-9 Generation of an MWV from partial traces.......................................................................4.29

Fig. 5-1 Example for the tree structure of the SCPI command systems: The SYSTem system...... 5.4

Fig. 5-2 Instrument model in the case of remote control by means of the IEC bus......................... 5.9

Fig. 5-3 The status register model................................................................................................. 5.12

Fig. 5-4 The Status registers ......................................................................................................... 5.14

Fig. 5-5 Pin Assigment of the IEC-bus interface............................................................................5.21

Fig. 5-6 Pin assigment of the RS-232-C interface.........................................................................5.24

Fig. 5-7 Null-modem connection scheme......................................................................................5.26

Tables

Table 4-1 Specifications of option AMIQ-B3 ..................................................................................4.23

Table 4-2 IEEE 488 commands for option AMIQ-B3..................................................................... 4.25

Table 5-1 Synchronization with *OPC, *OPC? and *WAI ..............................................................5.11

Table 5-2 Meaning of the bits used in the status byte.................................................................... 5.15

Table 5-3 Meaning of the bits used in the event status register.....................................................5.16

Table 5-4 Meaning of the bits used in the STATus:OPERation register........................................5.17

Table 5-5 Meaning of the bits used in the STATus:QUEStionable register................................... 5.17

Table5-6 Resetting instrument functions ...................................................................................... 5.20

Table 5-7 Interface functions.......................................................................................................... 5.22

Table 5-8 Universal Commands .................................................................................................... 5.23

Table 5-9 Addressed Commands .................................................................................................. 5.23

Table 5-10 Control strings or control characters of the RS-232-C interface....................................5.25

Table 6-1 Common commands ....................................................................................................... 6.3

Table 6-2 BERT – Bit error rate tests...............................................................................................6.9

Table 6-3 CALibration – Adjustment and calibration......................................................................6.13

Table 6-4 DIAGnostic – Hardware diagnosis................................................................................. 6.17

Table 6-5 MARKer – Marker management....................................................................................6.20

Table 6-6 MEMory – Waveform management...............................................................................6.22

Table 6-7 MMEMory – Waveform management............................................................................6.23

Table 6-8 OUTPut – Hardware settings......................................................................................... 6.35

Table 6-9 PROGram – Program sequence....................................................................................6.41

Table 6-10 SOURce – Hardware settings........................................................................................6.42

Table 6-11 Status reporting.............................................................................................................. 6.47

Table 6-12 System settings.............................................................................................................. 6.50

Table 6-13 ARM/TRIGger/ABORt – Triggering, sequence control.................................................6.54

Table 6-14 List of all remote-control commands.............................................................................. 6.70

Table 9-1 Error symptoms................................................................................................................9.1

1110.3339.12 8 E-7

Safety Instructions

Shock hazard

This unit has been designed and tested in accordance with the EC Certificate of Conformity and has left the

manufacturer’s plant in a condition fully complying with safety standards.

To maintain this condition and to ensure safe operation, the user must observe all instructions and warnings

given in this operating manual.

Safety-related symbols used on equipment and documentation from R&S:

Observe

operating

instructions

Weight

indication for

units >18 kg

PE terminal Ground

1. The unit may be used only in the operating conditions and positions specified by the manufacturer. Unless otherwise agreed, the following

applies to R&S products:

IP degree of protection 2X, Pollution severity 2,

overvoltage category 2, altitude max. 2000 m.

The unit may be operated only from supply networks fused with max. 16 A.

2. For measurements in circuits with voltages V

> 30 V, suitable measures should be taken to

avoid any hazards.

(using, for example, appropriate measuring

equipment, fusing, current limiting, electrical

separation, insulation).

3. If the unit is to be permanently wired, the PE

terminal of the unit must first be connected to

the PE conductor on site before any other c onnections are made. Installation and cabling of

the unit to be performed only by qualified technical personnel.

4. For permanently installed units without built-in

fuses, circuit breakers or similar protective devices, the supply circuit must be fused such as

to provide suitable protection for the users and

equipment.

5. Prior to switching on the unit, it must be ensured

that the nominal voltage set on the unit matches

the nominal voltage of the AC supply network.

If a different voltage is to be set, the power fuse

of the unit may have to be changed accordingly.

6. Units of protection class I with disconnectible

AC supply cable and appliance connector may

be operated only from a power socket with

earthing contact and with the PE conductor connected.

terminal

Danger!

Warning!

Ground Attention!

Hot surfaces

7. It is not permissible to interrupt the PE conductor intentionally, neither in the incoming cable

nor on the unit itself as this may cause the unit

to become electrically hazardous.

Any extension lines or multiple socket outlets

used must be checked for compliance with relevant safety standards at regular intervals.

8. If the unit has no power switch for disconnection

rms

from the AC supply, the plug of the connecting

cable is regarded as the disconnecting device.

In such cases it must be ensured that the power

plug is easily reachable and accessible at all

times (length of connecting cable approx. 2 m).

Functional or electronic switches are not suitable for providing disconnection from the AC

supply.

If units without power switches are integrated in

racks or systems, a disconnecting device must

be provided at system level.

9. Applicable local or national safety regulations

and rules for the prevention of accidents must

be observed in all work performed.

Prior to performing any work on the unit or

opening the unit, the latter must be disconnected from the supply network.

Any adjustments, replacements of parts, maintenance or repair may be carried out only by

authorized R&S technical personnel.

Only original parts may be used for replacing

parts relevant to safety (eg power switches,

power transformers, fuses). A safety test must

be performed after each replacement of parts

relevant to safety.

(visual inspection, PE conductor test, insulationresistance, leakage-current measurement, functional test).

continued overleaf

Electrostatic

sensitive devi-

ces require

special care

095.1000 Sheet 17

Safety Instructions

10. Ensure that the connections with information

technology equipment comply with IEC950 /

EN60950.

11. Lithium batteries must not be exposed to high

temperatures or fire.

Keep batteries away from children.

If the battery is replaced improperly, there is

danger of explosion. Only replace the battery by

R&S type (see spare part list).

Lithium batteries are suitable for environmentally-friendly disposal or specialized recycling.

Dispose them into appropriate containers, only.

Do not short-circuit the battery.

12. Equipment returned or sent in for repair must be

packed in the original packing or in packing with

electrostatic and mechanical protection.

Electrostatics via the connectors m ay dama-

13.

ge the equipment. For the safe handling and

operation of the equipment, appropriate measures against electrostatics should be implemented.

14. The outside of the instrument is suitably cleaned using a soft, line-free dustcloth. Never

use solvents such as thinners, acetone and

similar things, as they may damage the f ront

panel labeling or plastic parts.

15. Any additional safety instructions given in this

manual are also to be observed.

095.1000 Sheet 18

Certificate No.: 98034

This is to certify that:

Equipment type Order No. Designation

AMIQ 1110.2003.02/.03/.04 I/Q Modulation Generator

AMIQ-B2 1110.3700.02/.03 Differential I/Q Outputs

AMIQ-B3 1122.2103.02 Digital I/Q Output

AMIQB19 1110.3400.02 I/Q Rear Panel Connection

EC Certificate of Conformity

complies with the provisions of the Directive of the Council of the European Union on the

approximation of the laws of the Member Stat es

- relat ing to electrical equipment for use within defined voltage lim it s

(73/23/EEC revised by 93/68/EEC)

- relat ing to electromagnetic compatibility

(89/336/EEC revised by 91/263/EEC, 92/31/EEC, 93/68/ EEC)

Conformity is proven by compliance with the following standards:

EN61010-1 : 1993 + A2 : 1995

EN50081-1 : 1992

EN50082-2 : 1995

Affixing the EC confor m it y mark as from 1998

ROHDE & SCHWARZ GmbH & Co. KG

Mühldorfstr. 15, D-81671 München

Munich, 1999-09-17 Central Quality Management FS-QZ / Becker

1110.2003.02 CE E-1

AMIQ Manuals

Contents of Manuals for

I/Q Modulation Generator AMIQ

Operating Manual

The operating manual consis ting of a data sheet and 10 chapter s contains c omprehensive inf ormation on characteristics, putting into operation, operation and remote control of AMIQ:

The data sheet informs about guaranteed specifications and characteristics.

Chapter 1 describes the operating principle of AMIQ, control elements and connectors on

the front and rear panel as well as all procedures required f or putting the instrument into operation and integration into a test system.

Chapter 2 details instrument control via the remote interfaces with the aid of program ex-

amples.

Chapter 3 presents control and display elements.

Chapter 4 describes key operating modes and special characteristics of AMIQ with refer-

ence to possible applications.

Chapter 5 describes programm ing of AMIQ, comm and processing, status reporting system

and characteristics of hardware interfaces.

Chapter 6 describes the remote-control com m ands defined f or the instrum ent. At the end of

the chapter an alphabetical list of commands is given.

Chapter 7 contains program examples for a number of typical applications of AMIQ.

Chapter 8 describes preventive maintenance.

Chapter 9 gives hints on troubleshooting and contains a list of error messages.

Chapter 10 contains an index for the operating manual.

Service Manual

The service manual informs on how to check compliance with rated specifications, on instrument

function, repair, troubleshooting and fault elimination. It contains all information required for the

maintenance of AMIQ by exchanging modules.

The service manual also contains the circuit documentation for the module "IQ Analog/Digital Unit".

1110.3339.12 0.1 E-2

AMIQ Introduction

1 Putting into Operation

Introduction

Task

Operating

principle

Transmission

error

AMIQ is a modulation source for complex baseband signals of state-of-the-art

telecommunication network s. Two synchronous outputs, which are matched to each

other, and a large memory together with wide analog bandwidth make AMIQ suitable

for universal use.

AMIQ has been designed to generate I and Q signals in the baseband for present and

future types of modulation. "I" stands for the in-phase component, "Q" for the

quadrature component.

The data to be output by AMIQ are normally calculated by an external workstation ( eg

PC). To control this calculation, Rohde & Schwarz off ers two programs: WINIQ SIM

and AMIQ Control, a software for R&S vector signal generator SMIQ (see Section

"Software for AMIQ Control on page 1.8"). The desired inform ation data stream (eg a

piece of speech) is generated and a modulation mode selected. Then various

interference and distortions ( so-called impairments) are superimposed to this (ideal)

baseband signal. Thus a long sequence of sample values is obtained, which are

loaded into AMIQ (via floppy, IEC/IEEE bus or RS-232 interface). The sequence in

the AMIQ memory is then output as analog I and Q signals with the aid of f ast and

accurate D/A converters. The outputs are (normally) connected to the modulation

inputs of an I/Q modulator (eg SMIQ), which m odulates the baseband signal onto the

desired RF (Fig. 1-1).

The RF signal is transmitted via the antenna to the receiver where it is converted

back into information data. On the transmission link, errors may be caused in the

information data stream by coding, impair ments and decoding. These errors can be

detected with the aid of option AMIQ-B1 (BER measurement) and evaluated.

Test setup

AMIQ

Bit error rate test (optional)

CONTROLON

RUNNING

I/Q MODULATI ON GEN E RA T OR A MIQ

.

I Q

1110.2003. 02

MADE IN GERMANY

Device under test (DUT)

SMIQ

SMIQ

ï

ð

RF

Fig. 1-1 AMIQ used in a test setup

The four additional marker outputs and a trigger input simplify integration in a test

setup. The user-selectable positions of the marker switch points permit external,

variable amplifiers (eg for power ramping) or signalling facilities to be controlled.

1110.3339.12 1.1 E-6

Front and Rear View AMIQ

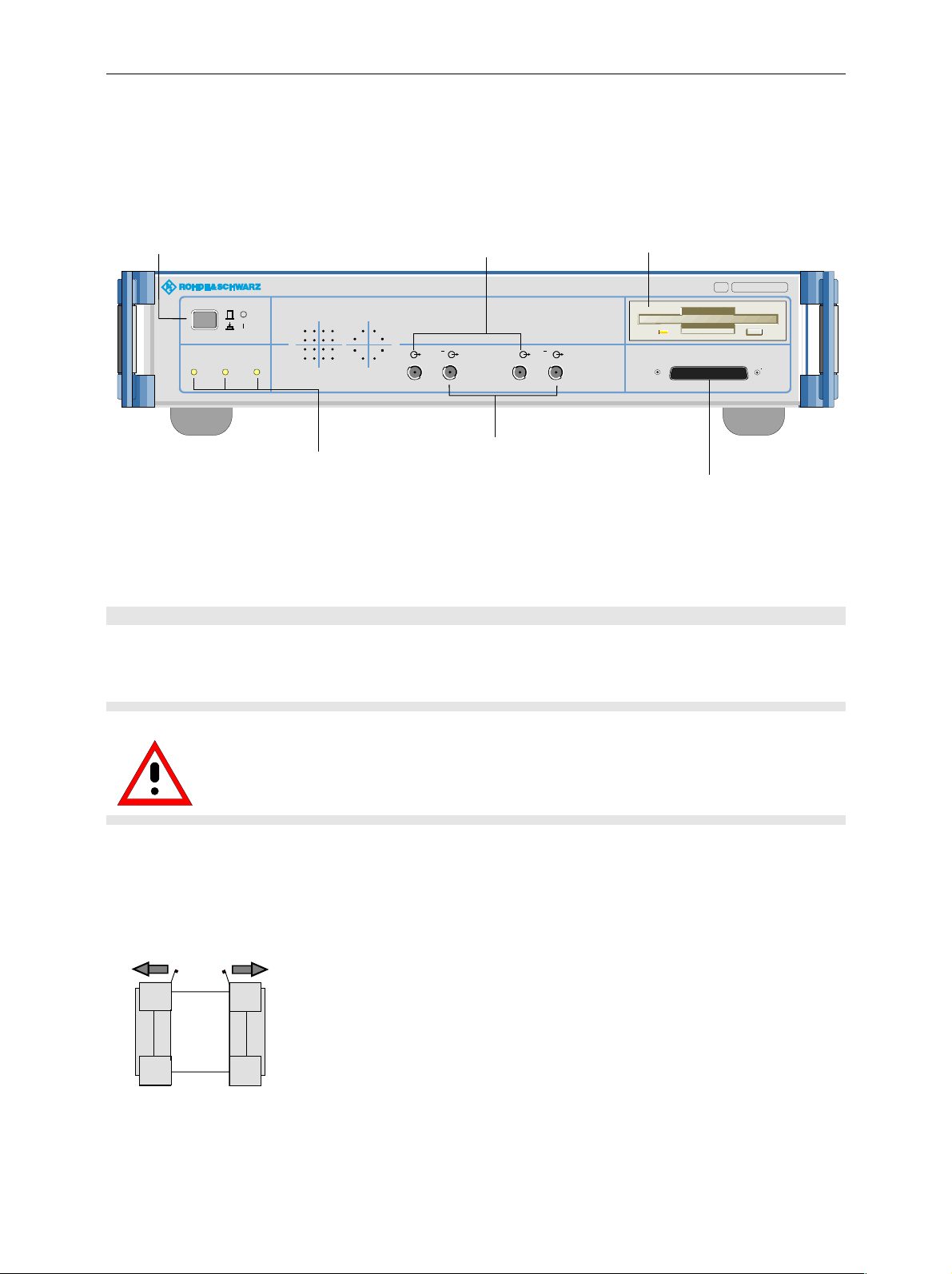

Front and Rear View

Power swi tch

preset in as long

as Instrument is on

I/Q MODULATI O N GENERATOR AMIQ

CONTRO LON

RUNNING

3 LEDs indicating the instrument status

ON AMIQ ready for operation

CONTROL Remote control active

RUNNING Wa veform in output memory in triggered

Chapter 1

.

"Power up / Switch-onTest"

.

Additional outputs T and Q with option

Differential I/Q Outputs installed

Fig. 1-2 AMIQ Front view

I In-phase component

Q Quadrature component

Chapter 1 "Introd uction"

.

I QI Q

3,5''-disk drive

Refer to "Installation of Options"

in chapter 1 when exchanging

data and ins trument so ftware

03

1110.2003.

DIGITAL OUTPUT

MADE IN GERMANY

Option Digital I/Q Output AMIQ-B 3

Putting into Operation

Caution!

The following instructions should be strictly observed, in particular when putting the

instrument into operation for the first time, to avoid damage to the instrument and

hazards to persons.

Unpacking

After unpacking the instrument, check for completeness according to the delivery note and the

accessory lists for the individual items.

Remove the two protective covers from the front and rear of

the AMIQ and carefully check the instrum ent for any damage.

In case of any damage you should immediately inform the

responsible transport agent and keep all pack ing material not

to forfeit your claims.

Remove protective covers

The original packing should also be used for any later transport or s hipment of AMIQ . You should keep

at least the two protective covers for the front and rear of the instrument.

1110.3339.12 1.2 E-6

AMIQ Putting into Operation

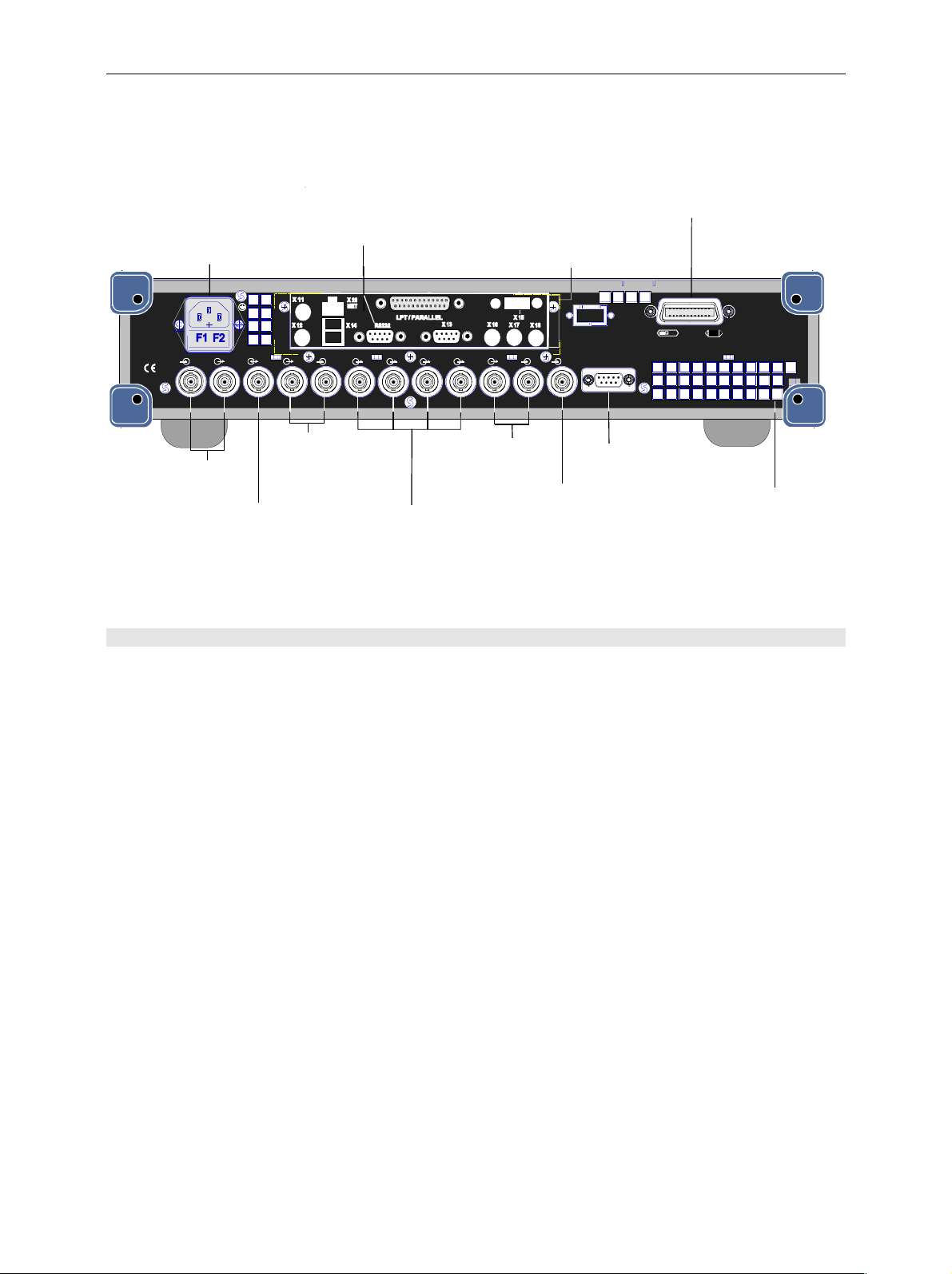

IEC/IEEE-bus interface

Power connector

with 2 fuses (F)

"Connection to AC

Supply" in cha pte r 1

RS-232 interface

"Connecting the

Controller" in chapter 1

Connector for servicing

and extensions

"Connecting other

Facilities" in chap ter 1

"Connection the Controller"

in chapter 1

100... 120 / 200...240 V

50...60 Hz 150 VA

F 1 / F 2 :

IEC 127 - T 2.5 H / 250 V

AUTO POW ER SELECTION

REF REF CLK Q Q I I TRIG BER

Reference frequency

Input / Output

Clock inpu t/output

FILT

Q filter, input

and output

1234

MARK

4marker outputs

FILTMARK

I filt e r, input

and output

Trigger input

X 10

BER input

"Connecting BER

Test Signals" in chapter 1

625

SCPI

IEEE 488

With option "Rear IQ outp ut s (AMIQ-B19)

installed, MARK 3 willl become Q and MARK 4 I.

"Signal Inputs and Outputs" in chapter 1

Fig. 1-3 AMIQ rear view

Setting Up

Permissible setup positions for AMIQ:

• Flat.

• Upright standing on its rear. In this case an angular AC supply connector should be used.

Air vents

Note: To ensure problem-free operation of the instrument the following should be observed:

•

Do not obstruct air vents at the rear and sides.

•

Observe the permissible ambient temperature specified in the data sheet.

•

Avoid condensation. Allow instrument with condensation to dry before switching on.

Rackmounting

Adapter ZZA-211 (Order No. 1096.3260.00) allows the AMIQ to be mounted in 19" racks. Rackmounting

is described in the installation instructions of the rack adapter.

For rackmounting it is recom mended to fit the option AMIQB19 (I/Q Rear -Panel Connection) (O rder No.

1110.3400.02), which changes I and Q connectors from the front to the rear.

Note: To ensure problem-free operation of the instrument the following should be observed:

•

Provide for sufficient air flow in the rack.

•

Make sure that there is sufficient space between air vents and rack.

1110.3339.12 1.3 E-6

Putting into Operation AMIQ

Connection to AC Supply

Caution!

Allow instrument with condensation to dry before switching on.

Observe permissible ambient temperatures -10°C to +45°C.

Do not cover up air vents.

AMIQ may be connected to a single-phase AC supply with a rated voltage from 100 V to 240 V and

rated frequency from 50 Hz to 60 Hz.

Note: AMIQ automatically sets itself to the local AC supply voltage. There is no need for

external switchover or exchanging fuses.

Use the power cord supplied with the AMIQ for

connection to the AC supply. Since the AMIQ is

designed in line with protection class I requirements

← AC supply connector

← Power fuses

to EN61010 it may only be connected to an earthingcontact type connector. As soon as the connection

has been established, AMIQ outputs a beep and the

ON LED lights with slightly reduced brightness. After

the start-up is completed, the ON LED is fully on.

Power Fuses

AMIQ is fully fused by two fuses IEC127-T4.0H /250 V. T he fuses are accommodated in the pull-out

fuse holder below the power connector. Before replac ing the fuses , disconnect the power cord from the

AMIQ. Use a screwdriver to lift the f use holder below the power connector and pull it out. Us e only fuses

of the above type.

Power Up / Switch-on Test

Ø Press switch-on key on the AMIQ front panel.

Note: No floppy should be in the drive when AMIQ is switched on. If

this happens nonetheless, one of the actions stored on the

floppy may be executed (see sections "New installation of

AMIQ software" and "Changing the IEC/IEEE-bus address in

this chapter).

Start-up procedure

Test of controller

hardware

After power-up the system is started, the c ontroller short test is perform ed

and the operating system DOS and the remote-c ontrol software are loaded

from the integrated hard disk. During this time the ON LED lights with

reduced intensity.

First the switch-on test for the integrated controller is perf ormed. Since at

this stage the LEDs are not driven, no inform ation can be obtained on the

device status. If a fault occurs, AMIQ outputs a sequence of beeps, the

meaning of which can be seen in the enclos ed main board manual. If a fault

occurs, the switch-on procedure is normally aborted.

1110.3339.12 1.4 E-6

AMIQ Putting into Operation

Short test of functional

hardware

LEDs after the short test

Error messages

The AMIQ hardware is then set to operating state and tes ted. Any error is

signalled by two short successive beeps provided the built-in louds peaker

was not switched off with the IEC/IEEE-bus comm and :SYST:BEEP:STAT

OFF. At the end of the selftest a single beep is output. After this the

instrument is ready for operation.

Further information on er ror can be obtained by a repeated readout of the

error queue using IEC/IEEE-bus queries :SYST:ERR?.

Even if an error occurs, the s witch-on proc edure is in most cases continued

so that the error queue can be read out. The instrum ent may not be fully

functional however.

If an error is detected in the short test, the ON LED flashes.

With the short test completed successfully, the last active setup is

automatically loaded from the hard disk and the instrument is set to the

operating status before switch-off. The currently selected waveform is

loaded together with this complete setup. For a curve with 4.000.000

samples and with AMIQ 03, this may take up approx. 20 seconds. With

AMIQ 04 and its quadrupled mem or y capacity, the loading time increases to

approx. 80 s.

If no further errors oc curred, the ON and the CONTROL LEDs briefly light.

Afterwards, the ON and RUN LEDs come fully on.

If an error is detected the error message is entered in plain text into the

error queue of AMIQ and ON LED flashes. This is why after restart the

AMIQ control program in the host c omputer should read out the error queue

by means of the comm and SYST:ERR? until it is empty, i.e., until the entry

0,"No Error" is read. Depending on the error detected, AMIQ will

usually respond to commands tr ansmitted via IEEE-bus or RS-232 interface

but may not be fully functioning. The ON LED lights steadily at full

brightness.

Note

If ON LED flash fast, it is only a hint that AMIQ does not generate any c urv e

at the moment. It appears whenever a curve was stored directly to the

AMIQ’s SDRAM to save time before switching off AMIQ by means of the

MEM:DATA RAM, <binary block data> command (e.g. with

WinIQSIM via the settings Transmission, Force internal, Destination

AMIQ-RAM). This can be suppressed by loading curves via a waveform file

using the command MMEM:LOAD RAM, 'filename.WV'; such a curve is

available immediately after switching on the instrument.

Ø If AMIQ does not start as described above, check the AC supply

connection and, if required, replace the two power fuses (see section

"Power fuses" in this chapter).

Ø A complete self test of AMIQ’s hardware com ponents can be star ted with

the common command *TST?. Furthermore, the command

DIAG:SELF:SDRAM? can be used to test the whole SDRAM of AMIQ in

detail, see Sections „Common Commands“ and „DIAGnostic – Hardware

Diagnosis“ in Chapter 6.

1110.3339.12 1.5 E-6

Putting into Operation AMIQ

Instrument Switch-off

Ø Wait until the hard disk or the floppy disk drive are no longer accessed

Ø Remove floppy from the disk drive

Ø Press power switch on the front panel. All instrument settings are

retained.

EMC Shielding Measures

To avoid electromagnetic interference, the instr ument must always be closed when in operation. Use

only appropriate, shielded signalling lines and control cables. Particularly the line connec ted to the cloc k

output should be double-shielded and terminated.

1110.3339.12 1.6 E-6

AMIQ Connection to Test Setup

Connection to Test Setup

Connecting the Controller

AMIQ has no user interface of its own. An external controller is therefore required for operating AMIQ

which can be performed in two ways:

Connection via IEC/IEEE

bus

Connection via the serial

interface

Serial interface

AMIQ is simply connected to the IEC/IEEE bus. Upon delivery the bus

address is 6. If the bus address has been changed, e.g. by a previous

control comm and, or if the bus address has to be c hanged, proceed as

described in section "Changing the IEC/IEEE-bus address" on page 1.7.

AMIQ is connected to the serial interface of a PC by means of a null

modem cable. Connect the cable to the 9-contact sub-D connector of the

AMIQ labeled RS232. Use the COM1 or COM2 connector of the PC

which may be a 25-contact or 9-contact connector. Suitable adapters

may have to be used.

The serial interface is c onfigured for 9600 Baud, 8 data bits, no parity.

When the W inIQSIM software is used, which is recom mended by R&S,

the interface of the PC is automatically configured with the AMIQ

settings. However, the interface used has to be set in the menu first.

Pin assignment and wiring of the null modem cable are described in

section "Handshake" of chapter 5.

Changing the IEC/IEEE-bus Address

Upon delivery the instrument is set to address 6. If for any reason this address is not available, the

setting can be changed as follows:

Ø Generate a file on a PC, which contains only the following line:

:SYST:COMM:GPIB:ADDR x

with x being the desired address. Add an empty line.

Ø Copy this file under the name AUTOEXEC.IEC into the main memory of a 3.5" floppy.

Ø Insert the floppy in the AMIQ, switch AMIQ off and on again.

1110.3339.12 1.7 E-6

Connection to Test Setup AMIQ

Software for AMIQ Control

AMIQ can only be remote-controlled. To simplify operation, Rohde & Schwarz offers two different

software programs for the control of AMIQ:

• W inIQSIM: This software permits calculation of complex I/Q signals, controls the trans fer of these

signals to the AMIQ via IEEE-bus or RS-232 interface and determines how the signals are output.

• AMIQ control software m enu for SMIQ: In this case AMIQ is controlled f rom SMIQ. Control is s imilar

to that of the SMIQ options but I/Q signals cannot be generated. It is possible, however, to load I/Q

signals that have been generated on an external PC.

Signal Inputs and Outputs

I

Q Q

Pin 35

Pin 1

Digital Output

I

Analog I/Q output:

The loaded waveforms are output at two BNC connectors I and Q on

the front panel (four BNC connectors I and I, Q andQ if option

Differential Outputs (AMIQ-B2) is fitted). The output is determined by

the trigger conditions and depends on the applied trigger signals (see

section "Triggering" in chapter 4) . If the trace output is not active, an

idle-channel signal is output (see section "ARM/TRIGger/ABORt Triggering, Sequence control" in chapter 6).

If option AMIQ-B2 is not fitted the I/Q outputs on the front panel can be

taken to the rear with option I/Q Rear-Panel Connection (AMIQB19).

This simplifies wiring particularly when the AMIQ is rack-mounted.

Note: When the I/Q outputs are taken to the rear, marker outputs 3

and 4 (BNC connectors) are used. This means that marker

outputs 3 and 4 are no longer available.

Upon delivery and after an *RST, the I and Q outputs are

switched off. Use commands OUTPUT:I FIX and OUTPUT:Q

FIX to reactivate the channels.

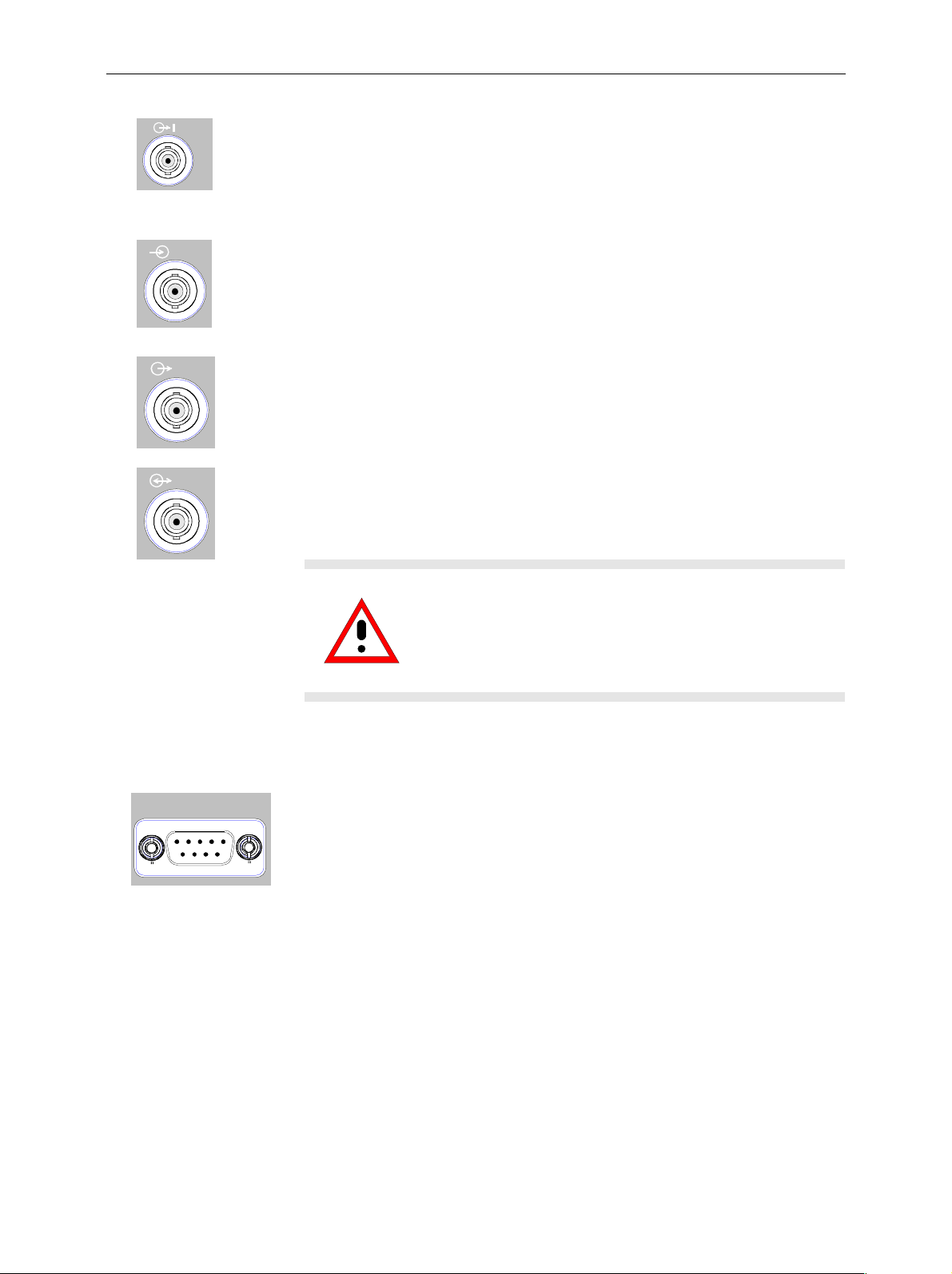

Digital I/Q output:

Pin 68

Option AMIQ-B3, Digital I/Q Output, provides the 16 bit wide data bus for

both I and Q channels via a 68-pole SCSI socket at the front panel of the

AMIQ. See section "Option "Digital I/Q Output AMIQ-B3" below.

Pin 34

TRIG

Trigger input (TRIG):

Rear BNC connector (fem ale). The output of the stored waveform can be star ted

or enabled with a TTL signal applied to this connector. Trigger condition and

polarity are user-selectable.

1

MARK

Marker outputs (MARK):

Four BNC connectors (female) at the rear. These outputs (TTL level, can be

terminated with 50 Ω) are used for the control of further instruments, e.g. an

oscilloscope or variable amplifiers (power ramping). (See "Marker outputs" in

chapter 4).

1110.3339.12 1.8 E-6

AMIQ Connection to Test Setup

REF

REF

CLK

FILT

I/Q filter (input and output):

Here an external passband filter (e.g. f or anti-aliasing) can be looped in for the I

and Q path instead of the internal filters. The outputs have a nom inal impedance

of 50 Ω and yield a peak voltage of 0.5 V into 50 Ω when driven at full scale. T he

filter attenuation in the passband range should be 0 dB.

Reference clock input (REF):

Input for an external 10 MHz reference clock; V

= 0.1 V to 2 V, input

rms

impedance 50 Ω.

Reference clock output (REF):

Output of 10 MHz reference clock; V

= 0.5 V, output impedance 50 Ω.

rms

Clock input/output (CLK):

Output with the actual clock rate; V

= 0.5 V, output impedance 50 Ω.

rms

Input for external clock (TTL signal).

Caution!

Connecting BER Test Signals

BER

AMIQ comprises a programmable facility for bit error rate (BER)

measurements . The required signals have to be applied to the AMIQ via the

BER input with TTL level. The signals to be applied depend on the test

method used and are described in the manual for option AMIQ-B1 (see

section "BER measurement" in chapter 4).

Because of the high clock rates at the clock output, a

double-screened cable should be used to keep within

permissible EMI limits. The line should in all cases be

terminated with 50

Ω

.

1110.3339.12 1.9 E-6

Connection to Test Setup AMIQ

Connecting other Facilities

The connectors labeled LPT /PARALLEL, X10, X11, X12 and X13 are used

for servicing or for extensions.

Note: In normal operation these connectors must be open.

1110.3339.12 1.10 E-6

AMIQ Installation of Options

Installation of Options

The following options are available for AMIQ:

BER Measurement AMIQ-B1 1110.3500.02

Differential I/Q Outputs AMIQ-B2 1110.3700.02

Digital I/Q Output AMIQ-B3 1122.2103.02

Rear I/Q Outputs AMIQB19 1110.3400.02

IS-95 CDMA AMIQK11 1122.2003.02

CDMA 2000 AMIQK12 1122.2503.02

Digital Standard W-CDMA TTD Mode (3GPP) AMIQK13 1122.2603.02

TD-SCDMA AMIQK14 1122.2703.02

OFDM Signal Generation AMIQK15 1122.2803.02

Option Digital Standard 802.11b Wireless LAN AMIQK16 1122.2903.02

AMIQ is supplied with the options already fitted. For a subsequent installation of options refer to the

fitting instructions supplied with the options or refer to chapter 4 of the Service Manual.

Software options AMIQ-B1, AMIQK11, AMIQK12, AMIQK13, AMIQK14, AMIQK15 and AMIQK16

can be activated by the customer. No extra test equipment is needed for t he installation. Since

the option is activated by means of an enable code, the unit need not be opened. Proceed

according to the instructions supplied with the option.

Installation of a software option is desc ribed at the end of c hapter 4 us ing AMIQ- B1 as an example. The

IEC/IEEE bus command to enable a software option is:SYSTem:OPTion <name>, <key>, see

chapter 6.

In order to fit one of the hardware options AMIQ-B2, AMIQ-B3 or AMIQB19 the casing of the

instrument must be opened. This will break the calibration seal so that the calibration is no

longer valid. Therefore, these options should be installed by an R&S service representative.

Important: The components used in the instrument are sensitive to electrostatic charges

and should therefore be handled according to ESD regulations.

Option AMIQ-B1, BER Test

AMIQ-B1 is a software option which can be installed without opening the instrum ent. For the installation

proceed as described in the instructions supplied with the option.

For a description of the BER test refer to chapter 4.

Option AMIQ-B2, Differential I/Q Outputs

To fit this hardware option the instrument must be opened. Therefore, it must be retrofitted by an

authorized service representative. Control of the diff erential outputs of AMIQ by means of W inIQSIM is

supplied starting with version 2.10.

For an application example for option Differential Outputs refer to chapter 4.

1110.3339.12 1.11 E-6

Option AMIQ-B3, Digital I/Q Output AMIQ

Option AMIQ-B3, Digital I/Q Output

Retrofitting the hardware option AMIQ-B3 requires the instr ument to be opened. Therefore, it m ust be

done by an authorized service representative. The Digital I/Q Output can be controlled by WinIQSIM

version 3.10 and higher.

An application example for option Digital I/Q Output is given in chapter 4.

Option AMIQB19, I/Q Rear-Panel Connection

This option can be fitted only if option Differential Outputs (AMIQ-B2) is not installed. Retrofitting the

option requires the instrument to be opened. Therefore, this must be done by an authorized service

representative. W ith option AMIQB19 fitted, marker outputs 3 and 4 are no longer available as these

connectors are used as Q and I signal outputs (i.e. the I output is connected to mark er output 4, the Q

output is connected to marker output 3).

Option AMIQK11, IS-95 CDMA

Software option for interpreting a waveform file generated acc ording to IS95 by W inIQSIM, version 2.10

or higher. These CDMA signals comply with the IS-95A and J-STD-008 mobile radio standards.

Option AMIQK12, CDMA 2000

Software option for interpreting a waveform file gener ated in WinIQSIM vers. 3.20 ac cording to CDMA

2000. These CDMA signals comply with the IS-2000 mobile radio standard. T he 1X and the 3X modes

(multi carrier and direct spread) can be simulated at the physical layer.

Option AMIQK13, Digital Standard W-CDMA TTD Mode (3GPP)

Software option to interpret a waveform file generated in WinIQSIM as of version 3.60.

3GPP TDD (3rd Generation Partnership Project Time Division Duplex) refers to a mobile radio

transmission method defined by 3GPP (http://www.3GPP.org).

Option AMIQK14, Digital Standard TD-SCDM A

Software option to interpret a waveform file generated in WinIQSIM as of version 3.50.

TD-SCDMA (time-division synchronous CDMA) designates a mobile-radio transmission method

developed by the China Wireless Telecommunication Standard Group (CWTS, http://www.cwts.org).

This standard is similar to the 3GPP TDD proposal, but with greater emphasis placed on GSM

compatibility and with a chip rate limited to 1.28 Mcps.

Option AMIQK15, OFDM Signal Generati on

Software option for interpreting a waveform file generated in WinIQOFDM with the aid of W inIQSIM

Vers. 3.40. Special emphasis is plac ed on the generation of signals conforming to HIPERLAN/2 or IEEE

802.11a (WinIQOFDM is a PC software that generates OFDM-modulated signals from binary data

streams, these signals are then read by WinIQSIM via the DDE interface for further processing).

1110.3339.12 1.12 E-6

AMIQ Initial Installation or Update of AMIQ Software

Option AMIQK16, Digital Standard 802.11b Wireless LAN

Software option to interpret a waveform file generated in WinIQSIM as of version 3.80.

The 802.11b wireless LAN standard is a packet-oriented method for data transmission. The data

packets are transmitted and received on the same frequenc y in time division duplex (TDD), but without

a fixed timeslot raster.

Initial Installation or Update of AMIQ Software

For initial installation of the AMIQ sof tware, a program disk (3.5") is needed. The dis k is available from

your local sales engineer. It usually contains two files: AMIQxxx.DAT and README.TXT. "xxx" stands

for the firmware version number; AMIQ304.DAT means firmware version 3.04, for example.

In AMIQxxx.DAT, over 40 files required for the firmware update are packed in compressed form.

Insert the disk into the AMIQ floppy disk drive. Then switch the unit off and on again. On switch-on, the

unit automatically checks whether an update disk is inserted in the drive. If this is the case, the c omplete

new firmware is loaded from the disk. The download takes approx. 4 minutes and is indicated by a

green LED on the floppy disk drive. When the LED goes out, AMIQ is ready for operation.

In the event that the firmware is not loaded, a fault may be in the controller which can only be eliminated

with the aid of a graphics card (ISA or PCI bus) when the instrument is open and a keyboard is

connected (see Service Manual).

1110.3339.12 1.13 E-6

Loading...

Loading...