Page 1

Test and Measurement

Division

Operating Manual

VECTOR NETWORK

ANALYZER

ZVR / ZVRE / ZVRL

1127.8551.61/.62

1127.8551.51/.52

1127.8551.41

ZVC / ZVCE

1127.8600.60/.61/.62

1127.8600.50/.51/.52

ZVM

1127.8500.60

ZVK

1127.8651.60

Volume 1

Operating Manual consists of 2 volumes

Printed in the Federal

Republic of Germany

1127.8700.12-03- 1

Page 2

Page 3

ZVx Tabbed Divider Overview

Volume 1 Volume 2

Contents Contents

Index Index

Data Sheet

Supplements

Safety Instructions Safety Instructions

Certificate of Quality Certificate of Quality

EC-Certificate of Conformity EC-Certificate of Conformity

Support Center Address Support Center Address

List of R&S Representatives List of R&S Representatives

Tabbed Divider Tabbed Divider

1 Preparation for Use 1 Remote Control

2 Manual Operation 2 Maintenance and Troubleshooting

3 Testing the Rated Specifications

4 Annex A: Interfaces

5 Annex B: List of Error Messages

6 Annex C: List of Commands

7 Annex D: Programming Examples

8 Annex E: Emulations

1127.8700.12 RE E-1

Page 4

Page 5

Test and Measurement

Division

Release Notes

Firmware Version 3.52

for ZVR/ZVRE/ZVRL/ZVC/ZVCE/ZVM/ZVK

1112.7990.39

Printed in the Federal

Republic of Germany

1112.8050.52-17- 1

Page 6

Page 7

ZVx Firmware Version 3.52

Contents

General Information..........................................................................................................................1

Manual for ZVR Family.................................................................................................................. 1

Update Procedure.........................................................................................................................1

Initial Steps.................................................................................................................................... 1

Documentation of Firmware Modifications.................................................................................... 1

1 Firmware Update........................................................................................................................... 2

System Requirements...................................................................................................................2

Preparations for Update................................................................................................................2

Contents of Firmware Update Kit..................................................................................................2

Update Procedure.........................................................................................................................2

2 New Features, Improvements and Modifications...........................................................5

New Features................................................................................................................................ 5

Improvements ...............................................................................................................................6

Modifications ................................................................................................................................. 6

3 Bug Fixes.........................................................................................................................................7

4 Extensions to Operating Manual............................................................................................8

5 New IEEE-Bus Commands..................................................................................................... 20

6 Special Features......................................................................................................................... 28

1112.8050.52 I.1 E-17

Page 8

Page 9

ZVx Firmware Version 3.52

General Information

Manual for ZVR Family

The analyzers of the ZVR family are supplied with the following manual:

"Operating Manual – Vector Network Analyzer" ZVR/E/L, ZVC/E, ZVM, ZVK

Order No. 1127.8700.xx-03-

where xx 11 (German)

12 (English)

13 (French)

19 (English, US letter format)

Update Procedure

The update instructions given in sec tion 1 of this release note are to the latest state; any deviating

instructions in the operating manual are to be ignored.

If you have received this document together with a new analyzer, you can skip section 1.

If you have received the document together with a firmware update kit or as a download together with

a self-extracting archive file, you should read section 1.

Initial Steps

If you work with a ZVR analyzer for the first time, it is recomm ended to read the operating m anual to

familiarize yourself with the unit.

If you are already familiar with the instrument, this document informs you about new features.

Documentation of Firmw a r e Modifications

This document covers firmware modifications that are not part of the current operating manual.

1112.8050.52 1 E-17

Page 10

Firmware Version 3.52 ZVx

1 Firmware Update

System Requirements

None

Preparations for Update

No preparations are required.

Contents of Firmware Update Kit

The update kit comprises the following:

• Five 3.5"/1.44 Mbyte disks labelled as follows:

Disk 1 : „V3.52 DISK 1“

Disk 2 : „V3.52 DISK 2“

Disk 3 : „V3.52 DISK 3“

Disk 4 : „V3.52 DISK 4“

Disk 5 : „V3.52 DISK 5“

• This document

Update Procedure

1. If you have received a self-extracting archive file per e-mail or as a download

a set of disks must first be created from the archive file.

Proceed as follows:

½ Check if you have received all files.

disk1.bin self extracting ZIP file, used to generate update disk 1

data2.cab packed contents of disk 2, automatically unpacked during FW update

data3.cab packed contents of disk 3, automatically unpacked during FW update

data4.cab packed contents of disk 4, automatically unpacked during FW update

data5.cab packed contents of disk 5, automatically unpacked during FW update

disk_d.bin this document packed

½ Keep five DOS-formatted 3.5" / 1.44 Mbyte disks ready.

½ Label disks as follows:

V3.52 DISK 1

V3.52 DISK 2

V3.52 DISK 3

V3.52 DISK 4

V3.52 DISK 5

½ Create a temporary directory on your PC (e.g. ZVRTEMP on C:\). For this you require about

3 Mbytes of free memory on your hard disk.

½ Copy file disk1.bin to this temporary directory.

½ Rename file disk1.bin to disk1.exe.

1112.8050.52 2 E-17

Page 11

ZVx Firmware Version 3.52

½ Execute disk1.exe, e.g. by using the following command sequence for Windows95/NT:

<CTRL><ESC> - RUN – C:\ ZVRTEMP \DISK1 - <ENTER> (English version) or

<CTRL><ESC> - AUSFÜHREN – C:\ ZVRTEMP \DISK1 - <ENTER> (German version).

The files are extracted.

½ Delete file disk1.exe in the temporary directory.

The temporary directory should contain the following files:

_inst32i.ex_ _isdel.exe _setup.dll _sys1.cab _user1.cab

data.tag data1.cab lang.dat layout.bin os.dat

readme.txt setup.exe setup.ini setup.ins setup.lid

½ Copy all files to update disk 1 (V3.52 DISK 1).

Check if all files are on the disk with their correct names. In particular, the underscores ("_" as in

"_inst32iex_") are essential for a successful update.

½ The contents of the other 4 disks are already in the format needed for the update. Files

data2.cab,..., data5.cab must be copied to the corresponding disks DISK2, ..., DISK5.

The disks are now ready, and you can continue with section 2 "If you have received a firmware

update kit on a disk ...".

Notes: If any error messages are output during creation of a dis k , the ins tallation proc es s for the

disk in question must be repeated. Before re-creating the disk, check if the write

protection of the disk has been removed.

File disk_d.bin contains this document in pdf format. To unpack the document proceed as follows:

½ Copy disk_d.bin to the temporary directory.

½ Rename the file to disk_d.exe.

½ Execute disk_d.exe, e.g. by using the following command sequence for Windows95/NT:

<CTRL><ESC> - RUN – C:\ ZVRTEMP \DISK_D - <ENTER> (English version)

or<CTRL><ESC> - AUSFÜHREN – C:\ ZVRTEMP \DISK_D - <ENTER> (German version)

1112.8050.52 3 E-17

Page 12

Firmware Version 3.52 ZVx

2. If you have received a firmware update kit on a disk ...

You can load the firmware directly from the disk to your network analyzer.

½ Insert the disk DISK 1 into the drive.

½ Press the SETUP key and change to the side menu by pressing ⇒ key.

½ Press the FIRMWARE UPDATE softkey.

½ Start the update by pressing the UPDATE softkey and follow the instructions on the analyzer

display.

First, the contents of the update disks are copied to the hard dis k of the instrument. Then the

files are extracted and copied in the directories accordingly. After the ex traction, the instrument

is rebooted.

The firmware update is complete.

The previous firmware version may be restored using softkey RESTORE.

3. If problems occur during the firmware update ...

The new firmware can if necessary also be loaded under NT. This should be done only with an

external keyboard and a mouse. Log-in has to be made using the ADMINISTRATOR f unction, and

the device firmware closed.

Log in as administrator.

½ Press key combination ALT SYSREQ to switch to NT screen if not yet displayed.

½ Call up the NT task bar START – SHUT DOWN.

½ Select ‘Close all programs and logon as different user’.

½ Hold the SHIFT key down and press the OK key to leave the input window until the login window

appears.

½ Release the SHIFT key as soon as the login window appears.

½ Now enter administrator as user name and 894129 as password.

Close the device firmware:

½ Press the keys CTRL ALT DEL on the external keyboard simultaneously.

½ Select the Task Manager.

½ Select the Application Rohde&Schwarz ZVR NT Interface and terminate it with End Task.

Now the new firmware can be loaded:

½ Insert DISK 1 into drive A:

½ Start the installation with START RUN A:SETUP. You will be prompted to insert the rem aining

disks one after the other.

After loading the software, the operating system is rebooted. T hen change bac k from administrator

to instrument (password ins trum ent) for the login. T his is done in the s ame way as changing of login

to administrator.

Note: If the firmware is installed in this way, the previous version cannot be restored.

1112.8050.52 4 E-17

Page 13

ZVx Firmware Version 3.52

2 New Features, Improvements and Modifications

New Features

• Support of waveguide calibration:

For this purpose, two new softkeys were added to the menu CAL → CAL KITS → right side menu:

WAVEGUIDE (position 6) and CUTOFF FREQUENCY (position 7)

• Deinstallation of calibration kits:

A new softkey is available in the menu CAL → CAL KITS:

UNINSTALL KITS (position 10)

• New SCPI commands:

- Reading out and modification of system error calibration and power calibration

- Support of waveguide calibration

- Query of electrical length, mechanical length and phase delay

• Support of additional, external devices:

- Generator SML (Rohde & Schwarz)

- Generator SMR30, SMR50, SMR60, SMR30B11, SMR50B11, SMR60B11 (Rohde & Schwarz)

- Generator HP8648 A/B/C/D (Agilent)

- Generator HP83650A (Agilent)

- Power Meter NRP (Rohde & Schwarz)

- Power Meter ML2438A (Anritsu)

- Power Meter E4417A (Agilent)

- Power Meter EPM-441A (Agilent)

-

1112.8050.52 5 E-17

Page 14

Firmware Version 3.52 ZVx

Improvements

• When reading and writing system error correction data and level correction data in the REAL64

format, an error message is output.

Affected IEC/IEEE bus commands:

SENSe[1..4]:CORRection:DATA

SENSe[1..4]:CORRection:POWer:DATA

SOURce[1..4]:POWer:CORRection:DATA

• If a waveguide calibration (WAVEGUIDE = ON) is performed via IEC/IEEE bus with a CUTOFF

FREQUENCY that is higher than the START FREQUENCY, an error message is now output

because this action is not permitted.

• Omission of unnecessary level calibration interpolation (improves performance especially during

operation via the IEC/IEEE bus).

• The CALC:MARK:FUNC:RES? IEC/IEEE bus query now yields 10 significant marker points

(previously only 6).

• Improvement of signal quality of R&S SMR generators (SMR20/27/30/40/50/60,

SMR20/27/30/40/50/60B11) in TTL mode.

(This requires an SMR firmware version ≥1.26.)

• Generators currently not used are switched to RF OFF. This prevents erroneous measurements

and avoids disconnecting any cables.

Examples:

- During power calibration of the internal generator, any external generators connected to the

instrument and set to REMOTE are switched to RF OFF.

- This applies analogously to the calibration of an external generator. In this case, the internal ge-

nerator (and, if available, a second external generator connec ted and set to REMOTE) is switched

to RF OFF.

- W hen a COMP/SOI/TOI, arbitrary or mixer measurem ent is switched off, the external generators

used in the measurement are set to RF OFF.

Modifications

• New softkeys or softkeys shifted to another position in menu CAL → CAL KITS:

- Softkey USER CONN NAME now at position 9 of right side menu

- Softkey USER CONN IMPEDANCE now at position 10 of right side menu

- New softkey UNINSTALL KITS at position 10 of main menu

- New softkey WAVEGUIDE at position 6 of right side menu

- New softkey CUTOFF FREQUENCY at position 7 of right side menu

1112.8050.52 6 E-17

Page 15

ZVx Firmware Version 3.52

3 Bug Fixes

• In the ACTIVE xx STANDARDS table, the entries for the OPEN standards are again available when

a calibration is performed.

• System error correction data sets generated with a version <3.50 can now be recalled again

(RECALL).

• The power correction function has been improved:

- External power calibration is reliably activated with COMP/SOI/TOI measurements.

- An existing power calibration can be used again in power sweeps and in time sweeps.

• The normal user (logged on under the name "INSTRUMENT") has write access again to the

directory AUTOKAL, so the AutoCal function works again.

• Commanding the OFFSET SHORT standards

(SENSe[1..4]:CORRection:COLLect:ACQuire:OSHORT1 or OSHORT2) in case of waveguide

calibration (WAVEGUIDE = ON) is possible again.

• Errors were corrected in the following SCPI commands:

- SENS:FUNC?

- SOURce:POWer:[LEVel]:[IMMediate]:CAMPlitude

• Softkeys that were not visible are now available again:

- Menu MEAS → USER DEF’D S-PARAMS: softkeys USER DEF’D S-PARAMS and USER DEF ACTIVE

- Menu CAL → START NEW CAL → FULL ONE PORT → BOTH PORTS: softkey 2.92 mm FEMALE

- Menu MEAS → WAVE QANTITY: softkey DRIVE PORT

1112.8050.52 7 E-17

Page 16

Firmware Version 3.52 ZVx

4 Extensions to Operating Manual

Characteristics of Calibration Standards (Re section 2.15.1.3)

The MODIFY CAL KIT softkey opens a m enu for the management of c alibration kits for the individual

connector families.

Exact knowledge of the calibration standards is a pr erequisite for a accurate system-error calibr ation.

More precisely, the calibration is based on the knowledge of those S-parameters of the standards which

are assumed to be known for the applied calibration method. These S-parameters are derived from

physical models which contain one or more par am eters ( such as the electric al length) depending on the

type of standard.

In addition to these physical parameters, there are three des cription fields for each standar d listing the

assignment of the standard and further information for the user.

1. Standard type: The type depends on the kind of standard (e.g. open c ircuit, short circuit, throughconnection) and the sex of the connectors. Example: THROUGH (MF) denotes a throughconnection with a plug at one and a socket at the other port. The standard type determines the

physical description model and therefore the param eters which can be edited. Up to four individual

standards with different param eters can be def ined for one standar d type. Only one of them can be

selected (active) at one time.

2. Calibration kit (KIT): A calibration kit is an assembly of real, physical calibration standards.

Calibration kits are supplied by Rohde & Schwarz as an accessory for network analyzers. The

parameters of the standards in a calibration kit are stored on a floppy disk which can be r ead in via

the INSTALL NEW KIT softkey. Kits for coaxial connector families usually do not contain all possible

standard types of these families but only a subset comprising the types which are most frequently

used in coaxial technology. Calibration kits can be user-defined as well. Using the ACT IVATE KIT

softkey, the standards of a calibration kit can be selected altogether by just one keystroke.

3. Serial number (SERIAL #): All st andards of a c alibration kit are f actory-labelled with the same s erial

number so they can be assigned unambiguously to this kit. The serial number helps to avoid

confusion between standards of the same type from different calibration kits which might have

different physical parameters.

1112.8050.52 8 E-17

Page 17

ZVx Firmware Version 3.52

V

N

N

ZV-Z21

ZV-Z21

ZV-Z21

ZV-Z26

ZV-Z26

ZV-Z21

ZV-Z21

ZV-Z21

ZV-Z21

ZV-Z21

ZV-Z21

ZV-Z41

ZV-Z41

OPEN PORT

OPEN PORT

CAL CAL - CAL KITS submenu:

CAL KITS

USER

ACTIVE N 50Ω STANDARDS

STANDARD TYPE

THROUGH (MM)

THROUGH (FF)

THROUGH (MF)

LINE 1 (MM)

LINE 1 (FF)

LINE 1 (MF)

LINE 2 (MM)

LINE 2 (FF)

LINE 2 (MF)

ATTENUATION (MM)

ATTENUATION (FF)

ATTENUATION (MF)

SYMM NETWORK (MM)

SYMM NETWORK (FF)

SYMM NETWORK (MF)

OPEN (M)

OPEN (F)

SHORT (M)

SHORT (F)

REFLECT (M)

REFLECT (F)

MATCH (M)

MATCH (F)

SLIDING MATCH (M)

SLIDING MATCH (F)

NOTE: The connector sex refers

to the ports of the standards!

KIT

CAL KITS

CONNECTOR

TYPE

ACTIVATE

KIT

MODIFY

STANDARDS

IEW

ACTIVE STD

CREATE

INST FILE

RESTORE

INSTD KITS

LIST

INSTD KITS

INSTALL

NEW KIT

USER CON

NAME

USER CON

IMPEDANCE

Selecting the connector families

After pressing the CAL KITS softkey, the ACTIVE XX STANDARDS selection table is

displayed, where XX denotes the connector family selected. By default, the

connector family of the test se t ports is selected. T he table gives an overview of the

active standards of the connector family:

• The STANDARD TYPE colum n lists all standard types which are required f or the

calibration procedures of the respective type of instrument.

• The KIT column indicates to which calibra tion kit the currently selected physical

standard belongs. By default, for standard types contained in the calibration kits

offered by Rohde & Schwarz, the designation of the corresponding kit is also

displayed. Although typical parameter values are pre- defined f or these s tandards ,

the individual parameters for eac h calibration kit, which are supplied on a floppy,

should be read in for the sake of maximum accuracy (see INSTALL NEW KIT

softkey). The predefined standards without calibration kit assignment are

assumed to be ideal.

1112.8050.52 9 E-17

Page 18

Firmware Version 3.52 ZVx

The cursor can be used to select the standard type the softkeys MODIFY

STANDARDS and VIEW ACTIVE STD refer to.

For polarized connector families, three types exist for each two-port standard,

namely male/male (MM), female/female (FF), and male/female (MF). One-port

standards are provided as male (M) and female ( F). For non-polarized connectors,

such as PC 7, all standards are contained only once in the table.

If a calibration method requires to measure two standards with the same polarity

simultaneously, their characteristics are assumed to be identical. This applies, e.g.,

to the TOM-X calibration method if the OPEN BOTH PORTS measurement is

performed.

The following types of standards are provided for the various types of network analyzers. Due to the

restricted calibration facilities of the Z VRE, ZVCE and ZVRL c ompared to the ZVR, ZVC, ZVK and ZVM,

a reduced set of standards is required only.

Table: Standard types for the network analyzers

ZVR, ZVC, ZVK, ZVM ZVRE, ZVCE, ZVRL

THROUGH THROUGH through-connection

LINE 1 line 1 for TRL calibration procedure

LINE 2 line 2 for TRL calibration procedure

ATTENUATION unknown matched attenuator

SYMMETRIC NETWORK unknown mismatched reflection-symmetric

OPEN OPEN open circuit

SHORT SHORT short circuit

OFFSET SHORT OFFSET SHORT additional short circuit for waveguide calibration

REFLECT unknown mismatched one-port standard

MATCH MATCH broadband termination

SLIDING MATCH SLIDING MATCH sliding load

two-port standard

1112.8050.52 10 E-17

Page 19

ZVx Firmware Version 3.52

V

N

N

CAL CAL - MODIFY CAL KIT - SELECT KIT submenu:

CAL KITS

CONNECTOR

TYPE

ACTIVATE

KIT

MODIFY

STANDARDS

IEW

ACTIVE STD

RESTORE

INSTD KITS

LIST

INSTD KITS

INSTALL

NEW KIT

USER CON

NAME

USER CON

IMPEDANCE

CONNECTOR

TYPE

Ω

Ν 50

Ω

Ν 75

PC 7

SMA

PC 3.5

SEXLESS

USR CONN 1

USR CONN 2

The CO NNECTOR TYPE softkey calls a m enu for selecting the

connector family shown in the ACTIVE XX STANDARDS table.

The type and order of the connectors shown in this menu are

different for the different models of the Z Vx family. The connec tor

types used for the instrument test ports always come at the

uppermost position. This is also the default setting.

The following connector families are provided:

• N 50 Ω,

• N 75 Ω,

• PC 7,

• SMA,

• PC 3.5,

• 2.92 mm.

In addition two connector families can be arbitrarily defined,

namely:

• SEXLESS USR CONN 1

• USR CONN 2

Only the two user-defined connector families can be configured

for waveguide calibration.

Ω

Ν 50

Ν 75 Ω

PC 7

SMA

PC 3.5

The N 50 Ω softkey displays the table ACTIVE N 50 Ω STANDARD .

The N 75 Ω softkey displays the table ACTIVE N 75 Ω STANDARDS.

The PC 7 softkey displays the table ACTIVE PC 7 STANDARDS.

The SMA softkey displays the table ACTIVE SMA STANDARDS.

The PC 3.5 softkey displays the table ACTIVE PC 3.5 STANDARDS.

1112.8050.52 11 E-17

Page 20

Firmware Version 3.52 ZVx

SEXLESS

USR CONN 1

The SEXLESS USR CONN 1 softkey displays the table ACTIVE USER CONN 1

STANDARDS. The connector family SEXLESS USR CONN 1 which can be user-

defined is not polarized (similar to PC 7) and particularly suited for non-coaxial cable

systems such as microstr ip.

The two user-defined connector f amilies SEXLESS USR CONN 1 and USR CONN 2

can also be used for waveguide calibration (refer to WAVEGUIDE softkey

description). As waveguides are as a rule not polar ized, SEXLESS USR CONN 1 is

to be preferred to USR CONN 2.

The name of this c onnector family (USER CONN 1 by default) can be modified via

the USER CONN NAME softkey.

USR CONN 2

The USR CONN 2 softk ey displays the table ACTIVE USER CONN 2 STANDARDS.

Unlike SEXLESS USR CONN 1, this us er-defined connector fam ily is polarized and

therefore suited for the coaxial connectors that are not pre-defined in the

CONNECTOR TYPE menu. The connector family USR CONN 2 can also be used

for waveguide calibration.

The name of this c onnector family (USER CONN 2 by default) can be modified via

the USER CONN NAME softkey.

CAL CAL - CAL KITS submenu:

ACTIVATE

KIT

The ACTIVATE KIT softkey displays the selection table ACTIVATE KIT.

ACTIVATE KIT

OPEN PORT

ZCAN

ZV-Z21

ZV-Z26

ZV-Z28

ZV-Z41

This table lists all calibration kit names defined for the connector family currently

selected. All standards including the ones that are currently not active are

considered.

The cursor k eys move the c ur sor within the table. A k it is s elec ted via the units pr ef ix

key. A checkmark displayed for a short time indicates that a kit has been selected.

All standards with the selected kit name are set active.

1112.8050.52 12 E-17

Page 21

ZVx Firmware Version 3.52

Modifying the standards

The MODIFY STANDARDS softkey calls the MODIFY XX YY STANDARDS table.

In the four quadrants of this table, the parameters of the four individual standards of

a single type are displayed. The type is selected in the ACTIVE XX STANDARDS

table. The parameters describe the physical model of this standard type. All

displayed parameters can be edited, even if the corresponding standard is currently

not set. The upper five param eter s ar e available f or all s tandard types, the remaining

ones depend on the kind of model applied.

If a parameter in this table is changed, an as terisk (*) is appended to the calibr ation

kit name (KIT) of the corresponding standard.

ACTIVE Standard active

A checkmark in the table row ACTIVE indicates which one of the individual

standards is currently active. If a definite standard type, e.g. an OPEN (F), is

measured in a calibration, the calibr ation algor ithm uses the parameter s of the active

individual standard of this type.

KIT Designation of the calibration k it

The calibration kit name can be entered here. It comprises a maximum of 10

characters and appears in the ACTIVE XX STANDARDS table if the standard

activated.

Some softk ey functions access the calibration kit nam e as well. The standar ds with

the same kit name can be activated altogether via ACTIVATE KIT. The softkey

RESTORE INSTD KITS restores the original param eters of the calibration data s ets

which were installed from floppy disk. LIST INST D KITS list all calibration data of a

connector type installed from floppy disk.

1112.8050.52 13 E-17

Page 22

Firmware Version 3.52 ZVx

An asterisk (*) as the last character of the kit name indicates that the preset values

or the values installed from f loppy of one or several par ameters of the c orr es ponding

individual standard were changed. If an attempt is made to enter a calibration kit

name which is already present twice (e.g. once in the original f or m and once labelled

as user-defined, i.e. with an asterisk), an exclamation m ark and an asterisk will be

appended to the name.

SERIAL # Serial number of the standard

Besides the calibration kit name, the serial number (max. 15-digit) is a further

individual attribute for the standards. It is used especially to distinguish standards

from calibration k its of the same type. For the calibration kits offered by Rohde &

Schwarz, the same serial number is used throughout the whole kit. This number is

assigned to every single standard when the kit is installed. Standards purchased

later as spare parts have another serial number of course.

MIN FREQ – minimum frequency of the standard

The sliding load, e.g., is a standard with minim um frequency since it can be used

above 2 GHz only.

MAX FREQ – maximum frequency of the standard

For each standard, a max imum f requency is defined. The physical model des cribed

by the subsequent parameters is valid up to this maximum frequency.

LENGTH – electrical length of the standard

The electrical length of the standar d can be entered for OPEN, SHORT, OFFSET

SHORT (short with length offset) , REFLECT, THROUGH, LINE 1 and LINE 2 and

SYMMETRIC NETWORK. The default unit of the electrical length is mm. For

REFLECT and SYMMETRIC NETWORK, the electrical length must be specified only

if it causes a phase deviation of more than 90° from the assumed approximation

(APPROX field) in the frequency range to be calibrated.

Note: For one-port standards , only the single length (length offset) is to be enter ed,

too.

LOSS – losses

The losses of the standard are entered in this field. It is assumed that they are

resistive line losses whose value (in dB) inc reases proportionally with the root of the

frequency due to the skin effect. T he attenuation is thus entered in units of dB/GHz.

Losses are indicated only for OPEN, SHORT , OFFSET SHORT (short with length

offset), THROUGH and LINE. For one-port standards, the total loss, i.e., the return

loss must be entered.

1112.8050.52 14 E-17

Page 23

ZVx Firmware Version 3.52

C0... C3 – polynomial coefficients for parasitic capacitance

For OPEN, as well as for REFLECT and SYMMETRIC NETWORK with APPROX =

OPEN selected, the parasitic capacitance at the open end of the line can be

described by a third-order frequency polynomial. C0 denotes the constant par t, C1 to

C3 the polynomial coefficients of the corresponding powers of the frequency. The

unit of the coefficient Cn is thus fF/GHz

For REFLECT and SYMMETRIC NETWORK, specification of the coefficients is

required only if the latter cause a phase deviation of more than 90° from the

assumed OPEN approximation in the frequency range to be calibrated.

L0... L3 – polynomial coefficients for parasitic inductance

For OPEN, as well as for REFLECT and SYMMETRIC NETWORK with APPROX =

SHORT selected, the parasitic inductance can be described by a third-order

frequency polynomial. L0 denotes the constant part, L1 to L3 the polynomial

coefficients of the cor responding powers of the f requency. The unit of the coef ficient

Ln is thus pH/GHz

n

(n=0,..., 3).

For REFLECT and SYMMETRIC NETWORK, specification of the coefficients is

required only if the latter cause a phase deviation of more than 90° from the

assumed SHORT approximation in the frequency range to be calibrated.

APPROX – approximate modelling

n

(n=0,..., 3).

VIEW

ACTIVE STD

When a reflection standard (REFLECT) or a reflection-symmetric network

(SYMMETRIC NETWORK) is selected, it must be indicated, whether the unknown

reflection coefficient can be approximately modelled as a short or an open circuit.

This information is required only to exclude a sign ambiguity when the reflection

coefficient is determined implicitly. If the length offset or parasitic reactances cause a

rotation of the phase of the unknown reflection coefficient of more than 90

respect to the approximate phas e (0

0

for APPROX = OPEN, 1800 for SHORT), these

0

with

parameters must be specified as well.

The VIEW ACTIVE STD softkey displays the ACTIVE XX YY table, where XX

denotes the connector family and YY the standard type, e.g. ACTIVE N 50 Ω OPEN

(F).

This table can not be edited. It shows the parameters of the currently active

individual standard of the type that was selected in the ACTIVE XX STANDARDS

table. If a certain standard type, e.g. an OPEN (F) is m easured during a c alibration,

the calibration algorithm uses the par am eters of the active individual s tandard of this

type. For a description of the table rows refer to softkey MODIFY STANDARDS.

1112.8050.52 15 E-17

Page 24

Firmware Version 3.52 ZVx

CREATE

INST FILE

RESTORE

INSTD KITS

The C REATE INST FILE softk ey creates an installation file for a calibration kit. This

function is useful, e.g., if an updated installation file for the entire calibration kit is

needed after exchange of an individual calibra tion standard, or if calibration k it data

entered via MODIFY STANDARDS are to be transferred to other instruments. The

SELECT KIT table shows all calibration kits of the connector type currently selected.

Once the desired kit has been selected and c onfirmed via the ENT ER key, an input

field for the path and name of the installation file is displayed. The default entries

correspond to the current path for SAVE / EDIT and the name of the selected

calibration kit with the extension *.chk . Upon entering the name the ins tallation file is

written to the specified directory.

To create an updated installation file for the entir e calibration k it after exc hanging an

individual calibration standard, the file supplied with the replacement standard is

installed first. During installation, only the data pertaining to this standard are

overwritten in the corresponding calibration k it f ile. Af ter wards, the des ir ed f ile f or the

entire kit can be created via CREATE INST FILE .

To create an installation file f or calibration kits from other manuf acturers, the data

describing the different st andards is entered via MODIFY STANDARDS; the entire

data is assigned to the same calibr ation kit. After wards, CREATE INST FILE is used

to create the installation file.

The RESTORE INSTD KITS s oftkey resets the parameters of all standards to the

values defined in the instrument firmware. Exceptions are calibration kits installed

from floppy disk (or from another st orage medium) . Those are r eset to their or iginal

state after the installation.

LIST

INSTD KITS

The softkey also activates the s am e standards which were active in the pr eset state.

Besides that, the default values of the name and reference impedance of the

connector families which can be user-defined (SEXLESS USR CONN 1 and USR

CONN 2) are restored. This function is used to c ancel all user entr ies, especially the

ones made by mistake.

The LIST INSTD KITS softkey displays the INSTALLED CAL KITS table.

This table can not be edited. It shows all calibration k its which were installed from

floppy disk (or from another storage m edium ) or which were generated by modifying

an originally installed calibration kit. Preinstalled kits or kits generated by modification

of an originally preinstalled kit are not listed.

INSTALLED CAL KITS

CONNECTOR KIT SERIAL #

Ν 50 Ω

ZV-Z21 123456/001

CONNECTOR Connector family

The CONNECTOR column shows the connector family of the calibration kit.

The meaning of the two columns KIT and SERIAL # is as explained under softk ey

MODIFY STANDARDS. If the standards of a kit have different serial numbers

VARIOUS is indicated in the SERIAL # column.

1112.8050.52 16 E-17

Page 25

ZVx Firmware Version 3.52

INSTALL

NEW KIT

UNINSTALL

KITS

The INSTALL NEW KIT softkey allows the user to install calibration kits from a floppy

disk or another storage medium.

If a floppy containing a single calibration kit file (this applies to all f loppies provided

with the calibration kits from Rohde & Schwarz) is inserted into the disk drive a

message window indicating the connector type and the kit designation is displayed

after a short time. In this window, installation of the new kit mus t be confir med. The

calibration kit is read in and a new message indicates that the installation was

successfully completed.

If several calibration kit f iles (file extension *.ck) are stored on the floppy, or if no

floppy is in the disk drive, the input field EDIT CAL KIT PATH is invok ed where the

path and file name of the desired calibration kit file can be entered. The further

procedure is as described above.

The UNINSTALL KITS softkey allows the user to delete the user- installed calibration

kits for a connector family.

User-installed calibration kits are meant to include calibration kits read in from a

storage medium by means of the INSTALL NEW KIT function. They do not mean to

include the preinstalled kits contained in the instrument firm ware. Please note that

this function deletes all user-installed calibration kits for the connector family

selected in the CONNECTOR TYPE menu (e.g. PC 3.5).

To preserve particular user-installed calibration kits, they must first be saved by

means of the CREATE INST FILE function.

1112.8050.52 17 E-17

Page 26

Firmware Version 3.52 ZVx

π

WAVEGUIDE

The connector families SEXLESS USR CONN 1 and USR CONN 2 can also be

configured for waveguide calibration by means of the WAVEGUIDE softk ey. If this

softkey is activated, the instrument takes into account the nonlinear relationship

between the phase of the S-parameters and the frequency, which prevails in

waveguides. This effect is also known as dispersion.

At the frequency f, the transmission phase ϕ, e.g. of a THROUGH or a LINE

standard of the length l, is not governed by the relationship

2

f

l

ϕ

⋅=

but by

c

2

f

π

2

ϕ

l

c

where f

mode).

When the WAVEGUIDE softkey is activated, the CUTOFF FREQUENCY softkey for

entering the cutoff frequency is available too.

The OPEN standard is unsuitable with waveguide calibration bec ause in this case it

does not provide total reflection but radiates like an antenna. Therefore, if the

WAVEGUIDE softkey is switched on, the OPEN standards ar e replac ed by SHORTS

(for standards table see CAL CAL - CAL KITS submenu). The latter must have a

length offset different from the existing SHORTS and are for this reason referred to

as OFFSET SHORTS. At frequencies at which the length difference between the

SHORT and the OFFSET SHO RT equals a m ultiple of λ/2, s ingularities occur since

the shorts have identical reflection coefficients in this c ase. To avoid this, the length

offset of the OFFSET SHORT should be s elected to obtain a length dif ferenc e of λ/4

between the SHORT and the OFFSET SHORT in the middle of the m easurement

frequency range. The associated reflec tion coefficients are then exactly opposite in

phase. As the frequency range is normally not larger than the single-mode range of

the waveguide, i.e. max. one octave, singularities do not occur at the range limits

either if the length offset is selected as described.

is the cutoff frequency of the waveguide mode used (normally the basic

c

f

1

c

−⋅⋅=

,

f

The SHORT of a waveguide calibr ation kit is us ually in the form of a plate, i.e. it has

no electrical length. The effects of attenuation and leakage inductance can be

neglected in practice. The OFF SET SHORT is in m ost cases realized by a SHORT

to which a piece of line (λ/4) (shim ) is added. The electr ical length of this added line

is entered as the length offset f or the OFFSET SHORT. The eff ects of attenuation

and leakage inductance can usually also be neglected for the OFFSET SHORT.

λ

Note: The

calibration.

CUTOFF

FREQUENCY

1112.8050.52 18 E-17

The CUTOFF FREQUENCY softkey opens an input field for entering the cutoff

frequency for the waveguide mode for which calibration is to be made. This is usually

the basic mode of the waveguide.

The waveguide mode cannot propagate below the cutoff frequency, which means

that system error correction is not possible below this point. The cutoff frequency,

therefore, represents the minimum start f requency for measurem ent and calibration.

If the start frequency of the calibration range is lower than the entered cutoff

frequency (e.g. after a PRESET), an error message is output.

/4 line can also be used as a LINE standard, for example for TRL

Page 27

ZVx Firmware Version 3.52

USER CONN

NAME

USER CONN

IMPEDANCE

The USER CONN NAME softkey activates the entry of a name comprising up to 11

characters for the connec tor families SEXLESS USR CONN 1 and USR CONN 2.

The name refer s to the fam ily selected in the CONNECTOR TYPE menu. In the title

of the tables ACTIVE XX STANDARDS, MODIFY XX YY STANDARDS and ACTIVE

XX YY, it replaces the character str ing XX. The name of the cor responding sof tkeys

in the CONNECTOR TYPE submenu, however, can not be overwritten.

The default names are USER CONN 1 and USER CONN 2.

The USER CONN IMPEDANCE softkey activates the entry of the reference

impedance for the connector SEXLESS USR CONN 1 or USR CONN 2. The

impedance refers to the family selected in the CONNECTOR TYPE menu. The

default value is 50 Ω.

Note: Only a constant reference impedance can be entered v ia this softkey. While

the characteristic impedance of a waveguide is highly frequency-dependent, the

conversion of reflection coefficients to impedances or the calculation of Z parameters

in the waveguide are irrelevant in practice.

1112.8050.52 19 E-17

Page 28

Firmware Version 3.52 ZVx

5 New IEEE-Bus Commands

CALCulate:MARKer Subsystem (Re section 3.6.3.5)

The CALCulate:MARKer subsystem controls the marker functions.

COMMAND PARAMETER UNIT COMMENT

CALCulate<1..4>

:MARKer<1...8>

[:STATe]

:AOFF

:MODE

:COUPled

[:STATe]

:X

:MODE

:Y?

:FORMat

:TRANsform

:COMPlex

:TRACe

:SEARch

[:IMMediate]

:NEXT

:RIGHt

:LEFT

:TRACking

:MAXimum

:MINimum

:FUNCtion

[:SELect]

:BWIDth

:MODE

:QFACtor

:SFACtor

:TARGet

:RESULT?

:EDELay

:VALue?

:DELTa

:STATe

:REFerence

<Boolean>

CONTinuous | DISCrete

<Boolean>

<numeric_value>

ABS | REL

-MLINear | MDB | PHASe |

REAL | IMAGinary | SWR |

GDELay | MLPHase | MDPHase |

COMPlex | L | C | RLC

S | SINV | Z | ZREL | Y | YREL

CHDATA | CHMEM

--

--

--

-<Boolean>

--

--

MAXimum | MINimum |

TARGet | BFILter

<numeric_value>

BPASs | BSTop

-<numeric_value>,<numeric_value>

<numeric_value>

TIME | DISTance | ELENgth | OFF

<Boolean>

MARKER1 | MARKER2 |

MARKER3 | MARKER4 |

MARKER5 | MARKER6 |

MARKER7 | MARKER8 | FIXed

--

--

HZ | S | DBM

--

--

--

--

--

--

--

--

--

DB

--

--

-DBM|DB

--

no query

query only

no query

no query

no query

no query

-no query

no query

query only

query only

1112.8050.52 20 E-17

Page 29

ZVx Firmware Version 3.52

COMMAND PARAMETER UNIT COMMENT

:RPOSition

[:CARTesian]

POLar

:PTPeak

:STATe

:RESult?

:CENTer

:STARt

:STOP

:REFerence

CALCulate[1...4]:MARKer[1...8]:FUNCtion:EDELay

This comm and switches on or off the display of the electrical or the mec hanical length or the phase

delay. The suffix of MARKer has no meaning. The parameter information means the following:

ELENgth = electrical length

DISTance = mechanical length

TIME = phase delay

OFF = display switched off

Syntax:

Example:

Features:

CALCulate[1...4]:MARKer[1...8]:FUNCtion:EDELay TIME | DISTance |

"CALC:MARK:FUNC:EDEL TIME"

*RST value:

SCPI:

<numeric_value>,<numeric_value>

<numeric_value>,<numeric_value>,

<numeric_value>

<Boolean>

[ALL]

OFF

device-specific

HZ | S | DBM,DB

HZ | S | DBM,DB,

DB

-query only

no query

no query

no query

no query

ELENgth | OFF

CALCulate[1...4]:MARKer[1...8]:FUNCtion:EDELay:VALue?

This command queries the value of the electrical or the mechanical length or the phase delay.

The format of the return value must be selected beforehand with CALC:MARK:FUNC:EDEL.

The suffix of MARKer has no meaning.

Syntax:

Example:

Features:

CALCulate[1...4]:MARKer[1...8]:FUNCtion:EDELay:VALue?

"CALC:MARK:FUNC:EDEL:VAL?"

*RST value:

SCPI:

-device-specific

This command is a query only and therefore has no *RST value.

1112.8050.52 21 E-17

Page 30

Firmware Version 3.52 ZVx

SENSe:CORRection Subsystem (Re section 3.6.14.3)

The SENSe:CORRection subsystem controls the system error correction and the recording of the

individual correction values.

COMMAND PARAMETER UNIT COMMENT

:CORRection

[:STATe]

:DATA

:DATE?

:INTerpolate

[:STATe]

:AKAL

:SELect

:EXPort

:IMPort

:CLEar

:REName

:COLLect

[:ACQuire]

:METHod

:SAVE

:CONNection<1|2>

:CKIT

:INSTall

:N<50|75>

:SELect

<Boolean>

<string>,<block> | <numeric_value>...

<Boolean>

<string>

<string>

<string>

<string>

<string>,<string>

THRough | OPEN1 | OPEN2 |

OPEN12 | SHORT1 | SHORT2 |

MATCH1 | MATCH2 |

MATCH12 | NET | ATT |

IMATCH12 | REFL1 | REFL2 |

SLIDE1 | SLIDE2 | SLIDE12 |

LINE1 | LINE2 |

M1O2 | O1M2 | OSHORT1 | OSHORT2 |

AKAL

FTRans | RTRans | FRTRans |

TOM | TRM | TRL | TNA |

TOMX | TOSM |

FUNDAMENTAL |

FOPORT1 | FOPORT2 | FOPORT12 |

FOPTport | ROPTport |

REFL1 | REFL2 | REFL12 |

TPORT | FTREF1 | RTREF2

N50FEMALE | N50MALE | N75FEMALE |

N75MALE | PC7 | SMAFEMALE |

SMAMALE | PC35FEMALE | PC35MALE |

PC292FEMALE | PC292MALE |

UFEMALE1 | UMALE1 | UFEMALE2 |

UMALE2

N50 | N75 | SMA | PC7 | PC35 | PC292 |

USER1 | USER2

<string>

MMTHrough | MFTHrough | FFTHrough |

MMLINE1 | MFLINE1 | FFLINE1 |

MMLINE2 | MFLINE2 | FFLINE2 |

MMATten | MFATten | FFATten |

MMSNetwork | MFSNetwork |

FFSNetwork |

MOPen | FOPen |

MSHort | FSHort |

MREFlect | FREFlect |

MMTCh | FMTCh |

MSMatch | FSMatch[,<string>]

<string>

query only

no query

no query

no query

no query

no query

no query

[SENSe<1...4>]

:CORRection

:CKIT

1112.8050.52 22 E-17

Page 31

ZVx Firmware Version 3.52

COMMAND PARAMETER UNIT COMMENT

:USER<1|2>

:SELect

:IMPedance

:WGUide

[:STATe]

:CFRequency

:MMTHrough

:MFTHrough

:FFTHrough

:MMLINE<1|2>

:MFLINE<1|2>

:FFLINE<1|2>

:MMATten

:MFATten

:FFATten

MMTHrough | MFTHrough | FFTHrough |

MMLINE1 | MFLINE1 | FFLINE1 |

MMLINE2 | MFLINE2 | FFLINE2 |

MMATten | MFATten | FFATten |

MMSNetwork | MFSNetwork |

FFSNetwork |

MOPen | FOPen | MSHort | FSHort |

OSHort | FOSHort | MOSHort |

MREFlect | FREFlect |

MMTCh | FMTCh |

MSMatch | FSMatch[,<string>]

<string>

<numeric_value>

<Boolean>

<numeric_value>

<string>,

<string>,

<numeric_value>,

<numeric_value>,

<numeric_value>,

<numeric_value>

<string>,

<string>,

<numeric_value>,

<numeric_value>,

<numeric_value>,

<numeric_value>

<string>,

<string>,

<numeric_value>,

<numeric_value>,

<numeric_value>,

<numeric_value>

<string>,

<string>,

<numeric_value>,

<numeric_value>,

<numeric_value>,

<numeric_value>

<string>,

<string>,

<numeric_value>,

<numeric_value>,

<numeric_value>,

<numeric_value>

<string>,

<string>,

<numeric_value>,

<numeric_value>,

<numeric_value>,

<numeric_value>

<string>,

<string>,

<numeric_value>,

<numeric_value>

<string>,

<string>,

<numeric_value>,

<numeric_value>

<string>,

<string>,

<numeric_value>,

<numeric_value>

OHM

HZ

,

,

HZ,

HZ,

m,

,

,

HZ,

HZ,

m,

,

,

HZ,

HZ,

m,

,

,

HZ,

HZ,

m,

,

,

HZ,

HZ,

m,

,

,

HZ,

HZ,

m,

,

,

HZ,

HZ

,

,

HZ,

HZ

,

,

HZ,

HZ

1112.8050.52 23 E-17

Page 32

Firmware Version 3.52 ZVx

[SENSe[1...4]:]CORRection:CKIT:USER<1|2>:WGUIde[:STATe]

This command switches on or off waveguide calibration for the respective calibration kit.

The suffix of SENSe has no meaning.

Syntax:

Example:

Features:

[SENSe[1...4]:]CORRection:CKIT:USER<1|2>:CFRequency

This command sets the cutoff frequency for the USER calibration kit.

Syntax:

Example:

Features:

[SENSe[1...4]:]CORRection:DATA

This comm and is used for reading and writing system error cor rection values. The data s et contains

a complex value (real and imaginar y component) for each tes t point. The data can be transmitted

either in ASCII format, or in binary REAL32 format. Transmission in REAL64 format is not possible.

The <string> parameter may assume the following values:

"SCORR1" Directivity, port 1

"SCORR2" Source match, port 1

"SCORR3" Reflection tracking, port 1

"SCORR4" Forward isolation

"SCORR5" Load match, port 1

"SCORR6" Forward transmission tracking

"SCORR7" Directivity, port 2

"SCORR8" Source match, port 2

"SCORR9" Reflection tracking, port 2

"SCORR10" Reverse isolation

"SCORR11" Load match, port 2

"SCORR12" Reverse transmission tracking

"E11" to "E22" Elements of E matrix (15-term method)

"G11" to "G22" Elements of G matrix (7-term and 15-term methods)

"H11" to "H22" Elements of H matrix (7-term and 15-term methods)

"F11", "F21", "F12" Elements of F matrix (15-term method)

Syntax:

Example:

Features:

[SENSe[1...4]:]CORRection:CKIT:USER<1|2>:WGUide[:STATe] ON | OFF

"CORR:CKIT:USER:WGU ON"

*RST value:

SCPI:

[SENSe[1...4]:]CORREction:CKIT:USER<1|2>: CFRequency <numeric_value>

"CORR:CKIT:USER2:CFR 1 GHz

*RST value:

SCPI:

[SENSe[1...4]:]CORRection:DATA

"CORR:DATA "SCORR1",<block_data>"

*RST value:

SCPI:

OFF

device-specific

0 Hz

device-specific

<string>,<block> | <numeric_value>...

device-specific

1112.8050.52 24 E-17

Page 33

ZVx Firmware Version 3.52

The table below shows the correction terms available for the calibration methods:

Calibration Method Available Correction Terms

Trans Norm Forward

Trans Norm Reverse

Trans Norm both Directions SCORR6, SCORR12

Refl Norm P1

Refl Norm P2

Refl Norm both Ports SCORR3, SCORR9

Trans+Refl Norm Forward

Trans+Refl Norm Reverse

Trans+Refl Norm both Ports SCORR3, SCORR6, SCORR9, SCORR12

Full One Port P1

Full One Port P2

Full One Port both Ports SCORR1 to SCORR3, SCORR7 to SCORR9

One Path Two Port Forward

One Path Two Port Reverse

TOM, TRM, TNA, TRL G11 to G22 and H11, H12, H22 (H21 = 1);

TOSM SCORR1 to SCORR12

TOM-X

SCORR6

SCORR12

SCORR3

SCORR9

SCORR3, SCORR6

SCORR9, SCORR12

SCORR1 to SCORR3

SCORR7 to SCORR9

SCORR1 to SCORR3, SCORR6

SCORR7 to SCORR9, SCORR12

Gxx is normalized to H21

E11 to E22, G11 to G22, H11 to H22, F11, F21, F12

[SENSe[1...4]:]CORRection:POWer:DATA

This comm and is used for reading and writing power correction values for a receiver channel. The

data can be transmitted either in ASCII for mat, or in binary REAL32 format. Trans mission in REAL64

format is not possible.

The <string> parameter may assume the following values:

"B1" Correction data for wave b1 at port 1

"INPUTB1" Correction data for wave b1 at input b1

"B2" Correction data for wave b2 at port 2

"INPUTB2" Correction data for wave b2 at input b2

"IFREF" Correction data for reference input a1 on rear panel

"A1REF" Correction data for reference input a1 (ZVM and ZVK only)

"A2REF" Correction data for reference input a2 (ZVM and ZVK only)

Syntax:

Example:

Features:

[SENSe[1...4]:]CORRection:POWer:DATA <string>,<block> |

<numeric_value>...

"CORR:POW:DATA "B1",<block>"

*RST value:

SCPI:

device-specific

1112.8050.52 25 E-17

Page 34

Firmware Version 3.52 ZVx

SOURce Subsystem (Re section 3.6.15)

COMMAND PARAMETER UNIT COMMENT

SOURce<1...4>

:POWer

[:LEVel]

[:IMMediate]

[:AMPLitude]

:CAMPlitude

:A<1|2>

:ESRC<1|2>

:SLOPe

:EXTernal<1|2>

[:AMPLitude]

:SLOPe

:ALC

[:STATe]

:NLINear

:COMP

:RANGe

:UPPer

:LOWer

:SOI

:RANGe

:UPPer

:LOWer

:TOI

:RANGe

:UPPer

:LOWer

:CENTer

:SPAN

:STARt

:STOP

:CORRection

:DATA

:EXT<1|2>

:SWEep

:NREadings

[:ACQuire]

:LLISt

:STATE

<numeric_value>

<numeric_value>

<numeric_value>

<numeric_value>

<numeric_value>

<numeric_value>

<Boolean>

<numeric_value>

<numeric_value>

<numeric_value>

<numeric_value>

<numeric_value>

<numeric_value>

<numeric_value>

<numeric_value>

<numeric_value>

<numeric_value>

<string>,

<block> | <numeric_value>. ..

<numeric_value>,

<numeric_value>,

<numeric_value>,

LIN | LOG

<numeric_value>

A1 | A2 | ESRC1 | ESRC2

<numeric_value>,

<numeric_value>,

<numeric_value> ...

<Boolean>

DBM

DBM

DBM

DB/GHZ

DBM

DB/GHZ

dBm

dBm

dBm

dBm

dBm

dBm

dBm

dB

dBm

dBm

HZ,

HZ,

,

no query

,

HZ,

dB

1112.8050.52 26 E-17

Page 35

ZVx Firmware Version 3.52

COMMAND PARAMETER UNIT COMMENT

:FREQuency

[:CW]

:FIXED

:CONVersion

:ARBitrary

:IFRequency

:EFRequency<1|2>

:NLINear

:COMP

:SOI

:OFFSet

:TOI

:OFFSet

<numeric_value>

<numeric_value>

<numeric_value>,

<numeric_value>,

<numeric_value>,

CW | FIXed | SWEep

<Boolean>,

<numeric_value>,

<numeric_value>,

<numeric_value>,

CW | FIXed | SWEep

INT | ESRC1 | ESRC2

IESRC1 | IESRC2 | ESRC12

<numeric_value>

IESRC1 | IESRC2 | ESRC12

<numeric_value>

HZ

HZ

,

,

HZ,

,

,

,

HZ,

HZ

HZ

SOURce[1...4]:POWer:CORRection:DATA

This comm and is used f or reading and writing power correction values for a generator channel. The

data can be transmitted either in ASCII for mat, or in binary REAL32 format. Trans mission in REAL64

format is not possible.

The <string> parameter is used for selecting the correction data set as follows:

"A1" Generator output a1

"A2" Generator output a2

"ESRC1" External generator 1

"ESRC2" External generator 2

Syntax:

SOURce[1...4]:POWer:CORRection:DATA <string>,

<block> | <numeric_value>...

Example:

Features:

"SOUR:POW:CORR:DATA "A1",<block>"

*RST value:

SCPI:

device-specific

1112.8050.52 27 E-17

Page 36

Firmware Version 3.52 ZVx

6 Special Features

The format of the system error calibrat ion (SFK) files and the calibration kit (CalKit) files was

changed for version 3.50. The files from older firm ware versions are therefore converted to the new

data format. The change concerns files with the extension "CAC", "CA1" to "CA4", "CK", "CKD" and

"DAT". The old files are not deleted but r enamed, i.e. an additional ex tens ion – ".BC350" – is appended.

For example, "FACTORY.CAC" is renamed to "FACTORY.CAC.BC350".

Note:

There is no conversion if version 3.50 is updated to version 3.52.

The new data format cannot be processed by older firmware versions.

The following procedure should be adopted, therefore, when restoring a previous firmware version

(e.g. V 3.40):

½ Restore the old firmware version as usual by means of SETUP → FIRMWARE UPDATE →

RESTORE.

½ Terminate the firmware.

½ In the Explorer, change to the "C:\R_S\INSTR\CAL" directory.

½ Each file for which a file of identical name but with the additional extension ".BC350" exists,

must be renamed, for example by appending the additional extension ".V350".

For example, "N50.CKD" must be renamed to "N50.CKD.V350".

Note:

If a file with the name "CK_INST.DAT" exists, it must in any case be renamed to

"CK_INST.DAT.V350“, no matter whether or not a file "CK_INST.DAT.BC350" exists.

½ All files with the additional extension ".BC350" must be renamed, i.e. the extension has to be

removed.

For example, "N50.CKD.BC350" has to be renamed to "N50.CKD".

½ Start the firmware by means of START → START INSTRUMENT.

The SFK and CalKit files that were available prior to the update to vers ion 3.50 or 3.52 are now fully

available again. New files added through the version 3.50 or 3.52 update cannot be used however.

As an alternative to the above procedure, the com plete "C:\R_S\INSTR\CAL" directory can be saved,

for example under "C:\R_S\INSTR\CAL.BC350", before the update to version 3.50 or 3.52 is made.

After restoring the old firmware version, this directory must be renamed to "C:\R_S\INSTR\CAL".

1112.8050.52 28 E-17

Page 37

ZVx Contents

Contents

1 Preparation for Use................................................................................................................... 1.1

1.1 Introduction............................................................................................................................1.1

1.2 Legend for Front and Rear View.......................................................................................... 1.1

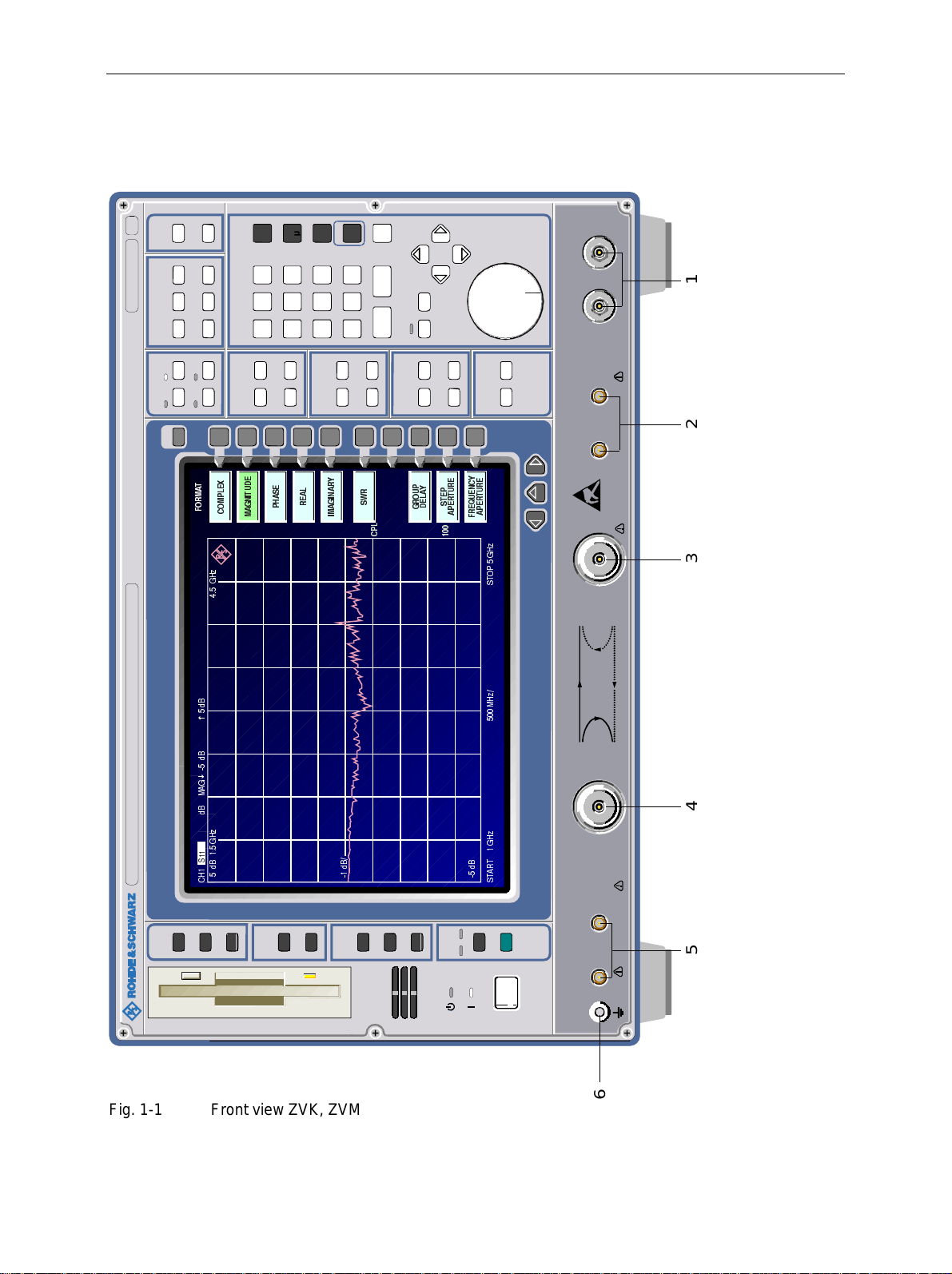

1.2.1 Front View ZVR, ZVK and ZVM..................................................................................... 1.1

1.2.1.1 Front View ZVR................................................................................................1.1

1.2.1.2 Front View ZVK, ZVM..................................................................................... 1.13

1.2.2 Rear View ZVR, ZVK and ZVM................................................................................... 1.15

1.3 Start-Up.................................................................................................................................1.20

1.3.1 Unpacking the Instrument ........................................................................................... 1.20

1.3.2 Instrument Setup......................................................................................................... 1.20

1.3.2.1 Stand-alone Operation ................................................................................... 1.20

1.3.2.2 19" Rack Installation.......................................................................................1.21

1.3.3 EMI Protection Measures............................................................................................ 1.21

1.3.4 Connecting to AC Power............................................................................................. 1.21

1.3.5 AC Power Line Fuses..................................................................................................1.21

1.3.6 Battery-Powered Memory............................................................................................1.22

1.4 Controller Function.............................................................................................................1.23

1.5 Connecting a Mouse........................................................................................................... 1.25

1.6 Connecting an External Keyboard..................................................................................... 1.25

1.7 Connecting an External Monitor........................................................................................ 1.26

1.8 Connecting an Output Device............................................................................................ 1.28

1.9 Connecting a CD-ROM Drive..............................................................................................1.35

1.10 Firmware Update .................................................................................................................1.37

1.11 Installing Windows NT Software........................................................................................ 1.38

1.12 Options................................................................................................................................. 1.39

1.12.1Option FSE-B17 – Third IEC/IEEE Interface...............................................................1.39

1.12.1.1 Installing the software................................................................... 1.39

1.12.1.2 Operation...................................................................................... 1.42

1.12.2Option FSE-B16 – Ethernet Adapter........................................................................... 1.43

1.12.2.1 Hardware Installation.................................................................... 1.43

1.12.2.2 Software Installation ..................................................................... 1.44

1.12.2.3 Operation...................................................................................... 1.48

1127.8700.12 3 E-3

Page 38

Contents ZVx

2 Manual Operation......................................................................................................................2.1

2.1 Introduction: Measurement Examples and Processing of Measured Values ............... 2.1

2.1.1 Transmission Measurements – Measurement of Gain and Loss.................................. 2.2

2.1.1.1 Measurement Task........................................................................................... 2.2

2.1.1.2 Connection of the DUT.....................................................................................2.2

2.1.1.3 Preset...............................................................................................................2.2

2.1.1.4 Setting the Analyzer..........................................................................................2.3

2.1.1.5 Instrument Calibration ......................................................................................2.8

2.1.1.6 Performing the Measurement........................................................................... 2.9

2.1.1.7 Output of Measurement Results..................................................................... 2.11

2.1.2 Reflection Measurements............................................................................................ 2.12

2.1.2.1 Measurement Task......................................................................................... 2.12

2.1.2.2 Connection of the DUT...................................................................................2.12

2.1.2.3 Preset.............................................................................................................2.12

2.1.2.4 Setting the Analyzer........................................................................................2.12

2.1.2.5 Instrument Calibration ....................................................................................2.13

2.1.2.6 Performing the Measurement......................................................................... 2.14

2.1.3 Filter Measurements

2.1.3.1 Measurement Task......................................................................................... 2.17

2.1.3.2 Reset, Setting and Calibration of the Instrument............................................ 2.17

2.1.3.3 Measurement of the Filter Parameters........................................................... 2.17

2.1.4 Processing of Measured Values.................................................................................. 2.22

2.2 Menu Overview .................................................................................................................... 2.25

2.2.1 SYSTEM Key Group.................................................................................................... 2.25

2.2.2 COPY Key Group........................................................................................................ 2.29

2.2.3 MEMORY Key Group.................................................................................................. 2.30

2.2.4 USER Key ...................................................................................................................2.32

2.2.5 SWEEP Key Group..................................................................................................... 2.33

2.2.6 MARKER Key Group...................................................................................................2.35

2.2.7 LINES Key Group........................................................................................................2.37

2.2.8 RESPONSE Key Group .............................................................................................. 2.38

2.2.9 CAL Key Group ........................................................................................................... 2.41

2.3 Basic Steps of Operation.................................................................................................... 2.48

2.3.1 Screen......................................................................................................................... 2.48

2.3.1.1 The Diagram Area..........................................................................................2.49

2.3.1.2 The Softkey Area............................................................................................ 2.59

2.3.2 Subdivision of Screen - Display Modes....................................................................... 2.60

2.3.2.1 Single Channel ...............................................................................................2.60

2.3.2.2 Dual Channel Overlay Overlay....................................................................... 2.61

2.3.2.3 Dual Channel Split.......................................................................................... 2.61

2.3.2.4 Quad Channel Overlay................................................................................... 2.62

2.3.2.5 Quad Channel Dual Split................................................................................ 2.62

− Measurements of Bandwidth, Q Factor and Shape Factor.... 2.17

1127.8700.12 4 E-3

Page 39

ZVx Contents

2.3.2.6 Quad Channel Quad Split............................................................................... 2.63

2.3.2.7 Full Screen – Expand Mode ........................................................................... 2.63

2.3.3 Diagrams.....................................................................................................................2.64

2.3.3.1 Cartesian Diagrams........................................................................................ 2.64

2.3.3.2 Polar Diagrams............................................................................................... 2.68

2.3.3.3 Smith Charts................................................................................................... 2.71

2.3.3.4 Inverted Smith Charts..................................................................................... 2.72

2.3.3.5 Charter Diagrams...........................................................................................2.72

2.3.4 Display Windows......................................................................................................... 2.73

2.3.4.1 Message Fields .............................................................................................. 2.73

2.3.4.2 Markers and Marker Info Lists........................................................................ 2.73

2.3.4.3 System Messages..........................................................................................2.76

2.3.4.4 Scale Reference Fields .................................................................................. 2.77

2.3.5 Calling and Changing the Menus ................................................................................ 2.79

2.3.6 Setting the Parameters................................................................................................2.81

2.3.6.1 Numeric Keypad – DATA ENTRY Key Group................................................ 2.81

2.3.6.2 Roll-key and Cursor Keys............................................................................... 2.82

2.3.6.3 Selection of Parameters .................................................................................2.83

2.3.6.4 Editing of Numeric Parameters ...................................................................... 2.88

2.3.6.4.1 Editing With External Keyboard.................................................... 2.91

2.3.6.4.2 Editing with Auxiliary Line Editor................................................... 2.92

2.3.7 Disabling the Control Elements - HOLD Key............................................................... 2.93

2.3.8 Setting the Step size - STEP Key................................................................................ 2.94

2.3.9 Mouse and External Keyboard Control........................................................................ 2.95

2.3.9.1 External Keyboard.......................................................................................... 2.95

2.3.9.2 Mouse Control of Data Entry Windows and Tables........................................ 2.95

2.3.9.3 Mouse Control of Display Elements ...............................................................2.96

2.4 General Configuration – SYSTEM Key Group .................................................................. 2.97

2.4.1 Selection of the Operating Mode – MODE Key........................................................... 2.97

2.4.1.1 Time Domain Transformation (Option ZVR-B2)............................................. 2.98

2.4.1.1.1 Switchover between Frequency and Time Domain...................... 2.99

2.4.1.1.2 Selecting the Gate........................................................................ 2.99

2.4.1.1.3 Selecting the Transformation Type.............................................2.106

2.4.1.1.4 Defining the frequency grid.........................................................2.108

2.4.1.1.5 Scaling the Abscissa ..................................................................2.113

2.4.1.1.6 Positioning the Gate................................................................... 2.114

2.4.1.2 External Measurements................................................................................ 2.115

2.4.1.3 Measurements on Frequency-Converting DUTs (Option ZVR-B4)..............2.117

2.4.1.3.1 Harmonics Measurements ......................................................... 2.118

2.4.1.3.2 Mixer Measurements.................................................................. 2.119

2.4.1.3.3 Arbitrary Frequency Conversion................................................. 2.123

2.4.1.4 Nonlinear Measurements (Option ZVR-B5) ................................................. 2.126

2.4.1.4.1 Compression Point Measurement.............................................. 2.127

2.4.1.4.2 Measurement of the 2

nd

and 3rd Order Interc. Point (SOI, TOI).. 2.132

2.4.1.5 Sweep Modes............................................................................................... 2.138

2.4.1.6 Reference Channel Ports (Option ZVR-B6) .................................................2.140

2.4.1.7 Fast Measurement (FAST MODE)...............................................................2.140

2.4.2 Preliminary Setup and Interface Configuration – SETUP Key...................................2.141

2.4.2.1 Programming the Interface Configuration and Time .................................... 2.142

1127.8700.12 5 E-3

Page 40

Contents ZVx

2.4.2.1.1 IEC Bus Address Selection ........................................................ 2.142

2.4.2.1.2 User Port Configuration.............................................................. 2.143

2.4.2.1.3 Serial Interface Configuration..................................................... 2.144

2.4.2.1.4 Setting Date and Time................................................................ 2.147

2.4.2.1.5 Connecting the External Monitor................................................ 2.147

2.4.2.1.6 Indication of the Automatic System Error Calibration.................2.148

2.4.2.2 External Reference Oscillator....................................................................... 2.148

2.4.2.3 Enabling Firmware Options ..........................................................................2.149

2.4.2.4 Service Functions.........................................................................................2.150

2.4.3 Instrument Status and Measurement Parameters – INFO Key.................................2.151

2.4.3.1 Firmware Versions........................................................................................ 2.151

2.4.3.2 Hardware Configuration and Options ...........................................................2.152

2.4.3.3 System Messages........................................................................................2.153

2.5 Measurement Documentation – COPY Key Group ...........................................................2.155

2.5.1 Printing Data – COPY Key ........................................................................................ 2.155

2.5.2 Printing Configuration – SETTING Key..................................................................... 2.157

2.5.2.1 Selection of Displayed Elements.................................................................. 2.158

2.5.2.2 Selection of Data Medium ............................................................................2.159

2.5.2.3 Selection of Hardcopy Format......................................................................2.159

2.5.2.4 Entry of Comment Text ................................................................................2.160

2.5.2.5 Color Settings............................................................................................... 2.161

2.5.2.6 Selection and Configuration of the Output Device........................................ 2.162

2.5.2.7 Selection of Line Style.................................................................................. 2.164

2.6 Saving and Recalling Data Sets – MEMORY Key Group................................................ 2.165

2.6.1 Configuration of Memory – CONFIG Key................................................................. 2.167

2.6.2 Saving Data Sets – SAVE Key.................................................................................2.169