Page 1

R&S®TLx9

For information only!

This manual, dated July 9, 2018 reflects the

technical status as of that date. There may

have been technical changes since that time.

Transmitter System

System Manual

(I6ÀÊ2)

2506506002

Version 03

System Manual

Page 2

This manual describes the following R&S®TLx9 models:

●

R&S®TLx9 (2506.5001.10), 1HU, 15/10/5 W

●

R&S®TLx9 (2506.5001.20), 2HU, 200/100/50/25 W

The software contained in this product uses several valuable open source software packages. For information, see the "Open

Source Acknowledgment"

Rohde & Schwarz would like to thank the open source community for their valuable contribution to embedded computing.

on the user documentation CD-ROM (included in delivery).

© 2018 Rohde & Schwarz GmbH & Co. KG

Mühldorfstr. 15, 81671 München, Germany

Phone: +49 89 41 29 - 0

Fax: +49 89 41 29 12 164

Email: info@rohde-schwarz.com

Internet:

Subject to change – Data without tolerance limits is not binding.

R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

Trade names are trademarks of the owners.

2506.5060.02 | Version 03 | R&S®TLx9

The following abbreviations are used throughout this manual: R&S®TLx9 is abbreviated as R&S TLx9.

www.rohde-schwarz.com

Page 3

Quality management

Certied Quality System

ISO 9001

and environmental

management

Sehr geehrter Kunde,

Sie haben sich für den Kauf

eines Rohde & Schwarz Produktes entschieden. Sie erhalten

damit ein nach modernsten Fertigungsmethoden hergestelltes

Produkt. Es wurde nach den

Regeln unserer Qualitäts- und

Umweltmanagementsysteme

entwickelt, gefertigt und geprüft.

Rohde & Schwarz ist unter anderem nach den Managementsystemen ISO 9001 und ISO 14001

zertifiziert.

Der Umwelt verpflichtet

❙ Energie-efziente,

RoHS-konforme Produkte

❙ Kontinuierliche

Weiterentwicklung nachhaltiger

Umweltkonzepte

❙ ISO 14001-zertiziertes

Umweltmanagementsystem

Dear customer,

You have decided to buy a

Rohde & Schwarz product. This

product has been manufactured

using the most advanced methods. It was developed, manufactured and tested in compliance

with our quality management

and environmental management systems. Rohde & Schwarz

has been certified, for example, according to the ISO 9001

and ISO 14001 management

systems.

Environmental commitment

❙ Energy-efcient products

❙ Continuous improvement in

environmental sustainability

❙ ISO 14001-certied

environmental management

system

Certied Environmental System

ISO 14001

Cher client,

Vous avez choisi d’acheter un

produit Rohde & Schwarz. Vous

disposez donc d’un produit

fabriqué d’après les méthodes

les plus avancées. Le développement, la fabrication et les

tests de ce produit ont été effectués selon nos systèmes de

management de qualité et de

management environnemental.

La société Rohde & Schwarz a

été homologuée, entre autres,

conformément aux systèmes

de management ISO 9001 et

ISO 14001.

Engagement écologique

❙ Produits à efcience

énergétique

❙ Amélioration continue de la

durabilité environnementale

❙ Système de management

environnemental certié selon

ISO 14001

1171.0200.11 V 05.01

1171020011

Page 4

Page 5

Customer Support

Technical support – where and when you need it

For quick, expert help with any Rohde & Schwarz equipment, contact one of our Customer Support

Centers. A team of highly qualified engineers provides telephone support and will work with you to find a

solution to your query on any aspect of the operation, programming or applications of Rohde & Schwarz

equipment.

Up-to-date information and upgrades

To keep your instrument up-to-date and to be informed about new application notes related to your

instrument, please send an e-mail to the Customer Support Center stating your instrument and your wish.

We will take care that you will get the right information.

Europe, Africa, Middle East

North America

Latin America

Asia/Pacific

China

Phone +49 89 4129 12345

customersupport@rohde-schwarz.com

Phone 1-888-TEST-RSA (1-888-837-8772)

customer.support@rsa.rohde-schwarz.com

Phone +1-410-910-7988

customersupport.la@rohde-schwarz.com

Phone +65 65 13 04 88

customersupport.asia@rohde-schwarz.com

Phone +86-800-810-8228 /

+86-400-650-5896

customersupport.china@rohde-schwarz.com

1171.0200.22-06.00

Page 6

Page 7

Page 8

Page 9

R&S®TLx9

2.3.1.1 AC Power Supply.......................................................................................................... 17

2.3.1.2 Changing Fuses............................................................................................................ 17

Contents

Contents

1 Information about this Manual..............................................................7

2 Safety Instructions.................................................................................9

2.1 Safety Instructions for Transmitter Systems and Equipment...................................9

2.2 General Safety Instructions....................................................................................... 10

2.2.1 Basic Safety Instructions...............................................................................................10

2.3 Special Hazard Information........................................................................................17

2.3.1 Hazards from AC Supply Voltage..................................................................................17

2.3.2 Hazards from High‑Energy Electric Circuits..................................................................17

2.3.3 Hazards from RF Radiation...........................................................................................18

2.3.3.1 Obligation to Instruct Personnel.................................................................................... 18

2.3.3.2 RF Shielding..................................................................................................................18

2.3.3.3 Rules When Operating an Amplifier..............................................................................18

2.3.3.4 Rules When Working on an Open Amplifier..................................................................19

3 Transmitter System R&S TLx9............................................................21

3.1 Design and Function – R&S TLx9..............................................................................21

3.1.1 Rack Design..................................................................................................................22

3.1.2 TLx9 system applications..............................................................................................23

3.1.3 TLx9 redundancy systems............................................................................................ 25

3.1.4 Modules and devices.................................................................................................... 29

3.1.4.1 Overview....................................................................................................................... 29

3.1.4.2 Inside View (1HU)......................................................................................................... 30

3.1.4.3 Replaceable Modules (1HU)......................................................................................... 30

3.1.4.4 Inside View (2HU)......................................................................................................... 32

3.1.4.5 Replaceable Modules (2HU)......................................................................................... 33

3.1.4.6 Option Keys...................................................................................................................34

3.1.4.7 Material Number Assignment........................................................................................35

3.1.4.8 Option Boards............................................................................................................... 36

3.1.4.9 Backplane..................................................................................................................... 36

3.1.4.10 Exciter Board.................................................................................................................37

3System Manual 2506.5060.02 ─ 03

Page 10

R&S®TLx9

3.1.4.11 GapFiller Board............................................................................................................. 38

Contents

3.1.4.12 TSP901 (T

3.1.4.13 TSP901 (Transmitter Status Panel) of 2HU device.......................................................40

3.1.4.14 TDU901 (Transmitter Display Unit)............................................................................... 41

3.1.4.15 Power Amplifier Module................................................................................................ 42

3.1.4.16 Power Supplies............................................................................................................. 43

3.1.4.17 Capacitor Backup Battery............................................................................................. 43

3.1.4.18 IPM2/4 Processor Board............................................................................................... 43

3.1.4.19 ASI Distribution Board...................................................................................................44

3.1.4.20 DVB-T/T2 Receiver....................................................................................................... 45

3.1.4.21 DVB-S/S2 Receiver.......................................................................................................45

3.1.4.22 Mini LAN Switch Board................................................................................................. 46

3.1.4.23 LAN Switch Board......................................................................................................... 47

3.1.4.24 Local LAN2 Board......................................................................................................... 47

3.1.4.25 RF Switch Board........................................................................................................... 48

GapFiller Redundancy 1+1 Antenna Redundancy........................................................48

GapFiller Redundancy in 1+1 Systems with Single Antenna........................................ 48

ransmitter Status Panel) of 1HU device ......................................................39

1+1 RF Switch for 15W Backup TX Systems ...............................................................49

3.1.4.26 GapFiller 1+1 15W Redundancy System with RF Switching........................................ 50

3.1.5 Specifications................................................................................................................ 51

3.1.5.1 General Data.................................................................................................................51

3.1.5.2 Inputs............................................................................................................................ 55

3.1.5.3 Quality........................................................................................................................... 56

3.2 Installation R&S TLx9................................................................................................. 56

3.2.1 Unpacking and Setting Up............................................................................................ 56

3.2.1.1 Equipment Supplied...................................................................................................... 56

3.2.1.2 Unpacking Instrument................................................................................................... 57

3.2.1.3 Setting Up Instrument................................................................................................... 57

3.2.2 Connecting Cables........................................................................................................57

3.2.2.1 Overview of Connectors................................................................................................58

3.2.2.2 Connecting Input Signals.............................................................................................. 60

3.2.2.3 Connecting External Reference Sources...................................................................... 60

3.2.2.4 Connecting Antenna System.........................................................................................61

4System Manual 2506.5060.02 ─ 03

Page 11

R&S®TLx9

3.2.2.5 Preparing RF Carrier Loop............................................................................................61

Contents

3.2.2.6 Connecting User Interface

3.2.2.7 Connecting AC Power Supply.......................................................................................62

3.3 Commissioning R&S TLx9......................................................................................... 62

............................................................................................ 61

Annex.................................................................................................... 63

A R&S TLx9 Interface Description......................................................... 63

A.1 Base unit and Exciter / GapFiller Board Interfaces..................................................63

A.1.1 Overview....................................................................................................................... 63

A.1.2 Description.................................................................................................................... 64

A.2 Option Board Interfaces............................................................................................. 70

A.2.1 LAN Switch....................................................................................................................70

A.2.2 Local LAN2 Board......................................................................................................... 73

A.2.3 DVB-T/T2 RX................................................................................................................ 74

A.2.4 DVB-S/S2 RX................................................................................................................75

A.2.5 1+1 ASI Distribution Board............................................................................................80

A.2.6 RF Switch Board........................................................................................................... 82

5System Manual 2506.5060.02 ─ 03

Page 12

R&S®TLx9

Contents

6System Manual 2506.5060.02 ─ 03

Page 13

R&S®TLx9

Information about this Manual

1 Information about this Manual

This manual is part of the documentation for the R&S TLx9 transmitter family from

Rohde & Schwarz. The individual manuals for the transmitter family have a modular

structure and complement each other

Structure

The system manual, which is the central and overarching part of the overall documentation, describes all the steps involved in installing a transmitter.

Operation of the transmitter system after installation and the steps required to put the

system into operation are described in the Tx9 operating manual.

The TLx9 service manual describes all maintenance, troubleshooting and service tasks

that customers can carry out themselves. At certain points in the transmitter manual,

the reader is referred to the appropriate operating manual or service manual.

Contents

.

The manuals for the transmitter family describe all activities required for installation,

startup, operation, maintenance, troubleshooting and servicing of the transmitter and

its component parts. The appendix contains the interface descriptions and the technical documentation.

Safety

All skilled personnel working with a transmitter or its components have a duty to read

the associated manuals and to follow the safety measures described in the section

"Safety" and given at appropriate points in the manual. It must be ensured that the

transmitter and the individual components of the transmitter are used only for their

intended use. All activities connected with the transmitter or individual transmitter components must be carried out by skilled personnel. If activities require additional skills

and qualifications, this is indicated at the appropriate points in the manual.

Symbols and notation

The "warning triangle" symbol refers the reader to potential hazards. The degree of

danger is indicated by different signal words next to the warning symbol.

Instructions are given in numbered steps. All other formatting options are intended to

improve clarity and are self‑explanatory.

7System Manual 2506.5060.02 ─ 03

Page 14

R&S®TLx9

Information about this Manual

8System Manual 2506.5060.02 ─ 03

Page 15

R&S®TLx9

Safety Instructions

Safety Instructions for Transmitter Systems and Equipment

2 Safety Instructions

2.1 Safety Instructions for Transmitter Systems and Equipment

Compliance with safety regulations

The safety regulations specified in this manual must always be complied with.

The following points require special attention:

●

Only qualified technicians are allowed to install and wire the electrical equipment.

●

National and international safety rules and regulations must be observed when

equipping operating facilities and during the assembly and operation of electrical

systems.

These include, for example:

– Protective measures to prevent accidents

Protection against overvoltage

–

– Isolation of electrical systems

– Grounding of electrical systems

– Physical properties and laying of electrical lines and cables

– Regulations that apply to factories, work areas and special systems

●

When installing transmitter racks, it is important to observe national accident prevention regulations, for example, with regard to:

– Crushing hazard when working beneath suspended loads

– Fall hazards when working on ladders

– Risk of injury when lifting heavy loads

●

Personal protective equipment (PPE) must be used when installation or repair work

is being carried out. Depending on the type of work, it may be necessary to wear

protective clothing such as hard hats, safety gloves, eye protection, etc.

●

Instruments and systems must not be operated unless their cabinets are closed.

Observe the appropriate safety instructions when opening cabinets for maintenance or repair work.

●

Isolate all poles when disconnecting instruments and systems from the AC supply.

In addition, disconnect all external sources of power, i.e. all measuring cables,

extension cables and multipoint connectors (except for special service connectors).

Then wait approx. 5 minutes to ensure that the capacitors in the system are sufficiently discharged.

●

Additional information on liquid‑cooled transmitters: When installing the cooling

system and filling it with coolant (pump and heat exchanger), the applicable regula-

9System Manual 2506.5060.02 ─ 03

Page 16

R&S®TLx9

tions on working with hazardous products (coolant) must be observed; see the section "Material Safety Data Sheets" under "EC Safety Data Sheet – Antifrogen".

2.2 General Safety Instructions

This section contains general safety instructions applying to all products manufactured

or sold by Rohde & Schwarz.

In line with IEC215 or EN60215, transmitter systems and their add‑on equipment must

be operated under the responsibility of qualified technicians only. The minimum

requirements for qualified electricians are also defined in the standard "Safety requirements for radio transmitting equipment".

Compliance with all legal and regulatory requirements is a precondition for operating

radio equipment and systems. The operator and/or the operator's authorized representative is responsible for ensuring compliance with these requirements. They must additionally ensure that the training of the operating personnel satisfies the specific requirements of the respective country

. This includes any periodic training that is necessary.

Safety Instructions

General Safety Instructions

2.2.1 Basic Safety Instructions

It is essential to read and observe the following instructions and safety information.

All plants and locations of the Rohde & Schwarz group of companies make every effort

to keep the safety standards of our products up to date and to offer our customers the

highest possible degree of safety. Our products and the auxiliary equipment that they

require are manufactured and tested in line with the applicable safety standards. Compliance with these standards is continuously monitored by our Quality Assurance

department. The product described here has been manufactured and tested in accordance with the enclosed EC Certificate of Conformity and left the manufacturer's plant in

a condition fully complying with the relevant safety standards. To maintain this condition and to ensure safe operation, you must observe all information, warnings and

instructions provided in this manual. Please do not hesitate to contact the

Rohde & Schwarz group of companies if you have any queries regarding these safety

instructions.

Furthermore, it is your responsibility to use the product in an appropriate manner. This

product is designed for use solely in industrial and laboratory environments or, if

expressly permitted, also in the field and must not be used in any way that may cause

personal injury or property damage. You are responsible if the product is used for any

purpose other than its designated purpose or in disregard of the manufacturer's

instructions. The manufacturer shall not be liable for any consequences resulting from

the product being used for purposes other than those for which it is intended.

The product is used for its designated purpose if it is used in accordance with its product documentation and within its performance limits (see data sheet, documentation

and the following safety instructions). Using the product requires technical skills and a

10System Manual 2506.5060.02 ─ 03

Page 17

R&S®TLx9

Safety Instructions

General Safety Instructions

basic knowledge of English. It must therefore be ensured that only skilled and specialized staff or thoroughly trained personnel with the required skills are allowed to use the

product. If personal protective equipment is required for using Rohde & Schwarz products, this will be indicated at the appropriate place in the product documentation. Keep

the basic safety instructions and the product documentation in a safe place and pass

them on to other users of the product.

Observance of the safety instructions is intended to prevent injury or damage resulting

from hazards of all types. T

fully read and fully understand the following safety instructions prior to and during use

of the product. It is also essential to observe all other safety instructions (e.g. relating

to personnel protection) which are given at appropriate points in the product documentation. In these safety instructions, the term "product" refers to all articles sold and distributed by the Rohde & Schwarz group of companies; these include instruments, systems and all accessory items.

Signal words and their meaning

The following signal words are used in the product documentation to warn of risks and

hazards.

o this end, persons who are to use the product must care-

indicates an immediate high-risk hazard which will result in death or serious injury if it

is not avoided.

indicates a potential medium-risk hazard which can result in death or (serious) injury if

it is not avoided.

indicates a low-risk hazard which could result in minor or moderate injury if it is not

avoided.

indicates possible incorrect operation which could result in damage to the product.

These signal words correspond to the standard definitions for civil applications in the

European Economic Area. Definitions that deviate from the standard definition may

also exist in other economic areas or military applications. It is therefore essential to

make sure that the signal words described here are always used only in connection

with the related product documentation and the related product. The use of signal

11System Manual 2506.5060.02 ─ 03

Page 18

R&S®TLx9

Safety Instructions

General Safety Instructions

words in connection with unrelated products or documentation can result in misinterpretation and in personal injury or material damage.

Operating conditions, operating positions and operating locations

The product may be operated only under the operating conditions, in the operation

positions and at the operating locations specified by the manufacturer, without the product's ventilation being obstructed. If the manufacturer's specifications are not

observed, this can result in electric shock, fire and/or serious personal injury or death.

Applicable local or national safety regulations and rules for the prevention of accidents

must be observed in all work performed.

Unless otherwise specified, the following requirements apply to Rohde & Schwarz

1.

products:

a) Operating position: housing base at bottom

b) IP degree of protection: 2X

c) Degree of fouling: 2

d) Overvoltage category: 2

e) For indoor use only

f) Operation up to 2000 m above sea level

g) Transport up to 4500 m above sea level

h) Tolerance for nominal voltage: ±10 %

i) Tolerance for nominal frequency: ±5 %

2. Do not place the product on surfaces, vehicles, shelves or tables that for reasons

of weight or stability are unsuitable for this purpose. Always follow the manufacturer's installation instructions when installing the product and fastening it to objects or

structures (e.g. walls and shelves). Installing the product in a manner that does not

comply with the product documentation could result in personal injury or even

death.

3. Do not place the product on heat‑generating devices (e.g. radiators or fan heaters).

The ambient temperature must not exceed the maximum temperature specified in

the product documentation or in the data sheet. Product overheating can cause

electric shock, fire and/or serious personal injury or even death.

Electrical safety

If the information on electrical safety is not observed either at all or to the extent necessary, electric shock, fire and/or serious personal injury or even death may occur.

1. Prior to switching on the product, always ensure that the nominal voltage set on the

product matches the nominal voltage of the mains supply. If a different voltage is to

be set, the mains fuse of the product may have to be changed accordingly.

2. In the case of products with degree of protection I with movable power feed line

and connector, operation is permitted only at sockets with protective conductor

contact and connected protective conductor.

12System Manual 2506.5060.02 ─ 03

Page 19

R&S®TLx9

Safety Instructions

General Safety Instructions

3. Intentional interruption of the protective conductor either along the feed line or in

the product itself is not permitted. Doing so can result in the danger of an electric

shock from the product. If extension cables or multipoint connectors are used, they

must be checked on a regular basis to ensure that they are safe to use.

4. If the product does not have a mains switch for disconnecting the product from the

power supply

, the plug attached to the connecting cable must be used as a disconnect device. In such cases, it must be ensured that the power plug is within easy

reach and accessible at all times (length of connecting cable approx. 2 m). Functional switches or electronic switches are not suitable for disconnecting the product

from the power supply. If products without mains switches are integrated in racks or

systems, a disconnect device must be provided at the system level.

5. Never use the product if the power cable is damaged. Check the power cable on a

regular basis to ensure that it is in proper operating condition. Take appropriate

safety measures and lay the power cable carefully to ensure that the cable will not

be damaged and that no one can be hurt by, for example, suffering an electric

shock or tripping over the cable.

6. Operation is only permitted in TN/TT supply networks which are fuse-protected with

max. 16 A (higher fuse ratings should only be used after consultation with the

Rohde & Schwarz group of companies).

7. Do not insert the plug into sockets that are dusty or dirty. Insert the plug firmly and

completely into the socket provided. Disregard of these points can lead to sparks,

fire and/or injury.

8. Do not overload the sockets, extension cables or multipoint connectors as this can

cause fire or electric shocks.

9. For measurements in electric circuits with voltages V

> 30 V, suitable measures

rms

(e.g. appropriate measuring equipment, fusing, current limiting, electrical separation, insulation) must be taken to avoid any hazards.

10. In the case of connections to IT equipment (e.g. PCs or industrial computers), it

must be ensured that such connections satisfy the IEC60950‑1/EN60950‑1 or

IEC61010‑1/EN61010‑1 standards that apply in each case.

11. Unless expressly permitted, never remove the cover or any part of the housing

while the product is in operation. Doing so would expose electrical lines and components and could lead to injuries, fire or damage to the product.

12. If a product is to be permanently installed, the connection between the protective

conductor terminal on site and the product's protective conductor must be made

first before any other connection is made. The product may be installed and connected only by a qualified electrician.

13. For permanently installed equipment without built‑in fuses, circuit breakers or similar protective devices, the supply circuit must be fused in such a way that anyone

who has access to the product, as well as the product itself, is adequately protected from injury or damage.

13System Manual 2506.5060.02 ─ 03

Page 20

R&S®TLx9

Safety Instructions

General Safety Instructions

14. Use suitable overvoltage protection to ensure that no overvoltage (such as that

caused by a bolt of lightning) can reach the product. Otherwise the person operating the product will be exposed to the danger of an electric shock.

15. Do not insert foreign objects into the housing openings. Doing so can cause short

circuits inside the product and/or electric shocks, fire or injuries.

Unless otherwise specified, products are not protected against the penetration of

16.

fluids; see also the section "Operating conditions, operating positions and operating locations", item 1. The instruments must therefore be protected against the

penetration of fluids. Failure to observe this point may result in the user suffering

an electric shock or the product being damaged, which in turn can endanger personnel.

17. Never use the product under conditions in which condensation has formed or can

form in or on the product, e.g. if the product has been moved from a cold to a warm

environment. Penetration by water increases the risk of electric shock.

18. Prior to cleaning the product, disconnect it completely from the power supply

(e.g. mains or battery). Clean instruments using a damp, soft, lint-free paper towel

or cotton cloth. Warm water or a mild cleaner (good results have been achieved

using glass cleaner (Mat. No. 0041.5336.00)) is recommended as a cleaning

agent. If any other cleaning agent is to be used, it must be checked beforehand

whether the cleaning agent is compatible with the surface to be cleaned.

Operation

1. Operating the product requires special training and intense concentration. It must

be ensured that persons who operate the product are fit to do so from a physical,

intellectual and mental viewpoint, otherwise there is a risk of injury or damage. It is

the responsibility of the employer/operator to select suitable personnel for operating the product.

2. Before moving or transporting the product, read and observe the information in the

section "Transport" on page 16.

3. As with all industrially manufactured goods, it is not possible to completely rule out

the use of materials which cause allergies, i.e. "allergens" (e.g. nickel). If, when

using Rohde & Schwarz products, allergic reactions occur (e.g. skin rash, frequent

sneezing, red eyes or respiratory problems), consult a doctor immediately in order

to determine the cause and to prevent health problems.

4. Before mechanically and/or thermally processing or dismantling the product, it is

essential to refer to the section "Disposal" on page 16, item 1.

5. Depending on the function, certain products such as RF radio systems can produce an elevated level of electromagnetic radiation. In order to protect unborn life,

pregnant women must be protected by means of suitable measures. Electromagnetic radiation also poses a risk to persons with pacemakers. The employer/operator is obliged to assess and identify workplaces where there is a particular risk of

exposure to radiation, and to take precautions to prevent potential hazards.

14System Manual 2506.5060.02 ─ 03

Page 21

R&S®TLx9

Safety Instructions

General Safety Instructions

6. In the event of fire, toxic substances (gases, fluids, etc.) can be discharged from

the product and damage the health of personnel. If a fire occurs, appropriate measures must therefore be taken (e.g. breathing masks and protective clothing).

7. If a laser product is integrated in a Rohde & Schwarz product (e.g. CD/DVD drive),

no settings or functions other than those described in the product documentation

should be used in order to prevent injury (e.g. from the laser beam).

Repair and service

The product may be opened only by authorized, specially trained personnel. Before

1.

any work is performed on the product or before the product is opened, it must be

disconnected from the supply voltage, otherwise there is a risk of electric shock.

2. Any adjustments, part replacements, maintenance or repairs may be performed

only by authorized Rohde & Schwarz electricians. Only original parts may be used

for replacing safety-relevant parts (e.g. mains switches, power transformers,

fuses). A safety check must be performed after safety‑relevant parts have been

replaced (visual inspection, protective conductor test, insulation resistance measurement, leaking current measurement, functional test). This ensures that the

product remains safe to use.

Batteries and accumulators/cells

If the instructions regarding batteries and accumulators/cells are not observed either at

all or to the extent necessary, product users may be exposed to the risk of explosions,

fire and/or serious personal injury and even death. Batteries and accumulators with

alkaline electrolytes (e.g. lithium cells) must be handled in line with EN 62133.

1. Cells must not be disassembled, opened or crushed.

2. Cells and batteries must not be exposed to heat or fire. Storage in direct sunlight

must be avoided. Keep cells and batteries clean and dry. Clean soiled terminals

using a dry, clean cloth.

3. Cells and batteries must not be short-circuited. Cells or batteries must not be

stored in a box or in a drawer where they can short‑circuit each other, or where

they can be short‑circuited by other conductive materials. A cell or battery should

only be taken out of its original packaging when it is to be used.

4. Keep cells and batteries out of the reach of children. If a cell or battery has been

swallowed, seek medical assistance immediately.

5. Cells and batteries must not be subjected to severe mechanical jolts or impacts.

6. If a cell develops a leak, the fluid must not come into contact with the skin or eyes.

If contact occurs, wash the affected area with plenty of water and seek medical

assistance.

7. There is a risk of explosion if cells or batteries containing alkaline electrolyte

(e.g. lithium cells) are replaced or charged incorrectly. To ensure that the product

15System Manual 2506.5060.02 ─ 03

Page 22

R&S®TLx9

Safety Instructions

General Safety Instructions

remains safe to use, always replace cells or batteries with the appropriate

Rohde & Schwarz type (see the replacement parts list).

8. Cells and batteries must be recycled and kept separate from residual waste. Accumulators and batteries that contain lead, mercury or cadmium must be disposed of

as hazardous waste. Observe the national regulations regarding waste disposal

and recycling.

ransport

T

1. The product may be extremely heavy. Therefore, the product must be handled with

care. In some cases, the user may require a suitable means of lifting or moving the

product (e.g. with a lift truck) to avoid back or other physical injuries.

2. Handles on the products are designed exclusively to enable personnel to transport

the product. The handles are not to be used for securing the product to or on transport equipment (e.g. cranes, forklift trucks, carts, etc.). It is your responsibility to

ensure that the products are attached securely to or on suitable transport or lifting

equipment. Observe the safety regulations from the manufacturer of the used

transport or lifting equipment in order prevent injury to personnel and damage to

the product.

3. If you use the product in a vehicle, it is the responsibility of the driver to drive the

vehicle in a safe and appropriate manner. The manufacturer shall not accept liability for accidents or collisions. Never use the product in a moving vehicle if there is a

risk that this could distract the vehicle driver. Make sure that the product is adequately secured in order to prevent injury or other damage in the event of an accident.

Disposal

1. If products or their components are processed mechanically and/or thermally

beyond the scope of the operating conditions for which they were intended, hazardous materials (dust containing heavy metals such as lead, beryllium, nickel) can

be released. For this reason, the product may only be disassembled by specially

trained personnel. Improper disassembly may be hazardous to your health.

National waste disposal regulations must be observed.

2. If, when handling the product, hazardous materials or operating fluids are encountered which must be disposed of separately (e.g. coolant or engine oils that have to

be changed at regular intervals), the safety instructions from the manufacturer of

these hazardous materials and operating fluids, and the applicable local disposal

regulations must be observed. Also observe any additional relevant safety instructions in the product documentation. Incorrect disposal of hazardous materials or

operating fluids can result in damage to health and the environment.

16System Manual 2506.5060.02 ─ 03

Page 23

R&S®TLx9

2.3.1 Hazards from AC Supply Voltage

2.3.1.1 AC Power Supply

2.3 Special Hazard Information

All voltages of Urms > 30 V AC or U > 60 V DC must be regarded as constituting a

shock hazard. When working with voltages that constitute a shock hazard, appropriate

measures must be taken to prevent exposure to danger

nents. Work on live parts should only be performed in exceptional cases and only if

special safety precautions are taken.

●

Before connecting the AC power supply, it is important to ensure that the power

supply specifications given for the system or instruments match the nominal specifications for the local power supply network. The power supply circuit must be protected by means of fuses in order to prevent overloads and short circuits.

●

Miniature modules have neutral conductor fuses. As a result, the power supply

may still be connected even after interruption of the circuit by a fuse.

Safety Instructions

Special Hazard Information

. Never work on live compo-

2.3.1.2 Changing Fuses

●

Fuses which are accessible to the operator should only be changed after the

instruments have been disconnected from the power supply. They must always be

replaced with fuses that have the same electrical rating, tripping characteristics and

breaking capacity.

●

Motor protection switches and automatic line fuses in those parts of a transmitter

system that can be accessed by users must be tripped. If their response range is

adjustable, the ex‑factory setting must not be altered. If settings are changed inadvertently, the correct values specified in this documentation must be set.

2.3.2 Hazards from High‑Energy Electric Circuits

The instruments contain low-voltage circuits that can be fed from a voltage source with

an extremely low impedance (e.g. amplifier operating voltage). These circuits carry

dangerously high levels of energy. At Rohde & Schwarz, we treat these circuits in the

same way as circuits with hazardous contact voltages. Normally, these circuits are protected by covers to prevent unintentional contact. The cover has a warning label.

In practice it has been repeatedly shown that short circuits caused by small metallic

tools result in severe burns. For safety reasons, any high‑energy electric circuits in

areas of the equipment that can be accessed by users are concealed by protective

covers.

●

Exercise the same amount of caution for measurements on low‑impedance voltages (e.g. for repair purposes) that you would when performing measurements on

operating voltages which constitute a shock hazard.

17System Manual 2506.5060.02 ─ 03

Page 24

R&S®TLx9

2.3.3 Hazards from RF Radiation

2.3.3.1 Obligation to Instruct Personnel

Safety Instructions

Special Hazard Information

Wear suitable protective gear when necessary.

●

Before opening any equipment or removing a particular cover, turn of

supply and wait 5 minutes to ensure that capacitors have discharged sufficiently.

●

Do not discharge capacitors by short‑circuiting them.

●

The operator must train all personnel in the operation of this transmitter or instrument in line with EN60215 and/or IEC215. It is essential that these regular training

sessions emphasize the dangers related to high frequency that exist at the respective transmitter or instrument. Operating personnel are only authorized to adjust

and operate the equipment after they have completed the respective training sessions and their participation has been documented.

f the power

High‑energy RF circuits inside the transmitter or instrument are routed via conventional

removable RF connectors (e.g. type N). Depending on the output power, the output

ports of the transmitter and instrument are equipped with screw-type or plug-in RF

lines or ducts.

If RF lines or modules carry high power, the connection point or the entire module is

tagged with the general danger warning label (yellow triangle with a black exclamation

mark).

2.3.3.2 RF Shielding

Transmitters and instruments from Rohde & Schwarz are shielded so that even in the

immediate vicinity there is no danger from RF radiation when all RF lines are connected. This applies to statutory provisions in Germany, i.e. the regulation concerning electromagnetic fields:

Limits for electrical and magnetic field strengths of high‑frequency installations are

defined in the 26th ordinance of the German Federal Government's Emission Control

Act of December 16, 1996 (26. BImSchV).

2.3.3.3 Rules When Operating an Amplifier

Disconnecting RF lines that are in operation can result in arcs. These can cause burns

and eye injuries.

●

Operation of the amplifier is only permitted if a main or dummy antenna is connected

●

Never disconnect RF lines when the amplifier is in operation

●

Never open the amplifier or modules when the amplifier is in operation

●

Never operate the amplifier if RF lines are exposed

18System Manual 2506.5060.02 ─ 03

Page 25

R&S®TLx9

2.3.3.4 Rules When Working on an Open Amplifier

Safety Instructions

Special Hazard Information

Operation with RF power is not permitted if the instrument has been opened or covers

have been removed.

19System Manual 2506.5060.02 ─ 03

Page 26

R&S®TLx9

Safety Instructions

Special Hazard Information

20System Manual 2506.5060.02 ─ 03

Page 27

R&S®TLx9

Design and Function – R&S TLx9

3 Transmitter System R&S TLx9

3.1 Design and Function – R&S TLx9

The TV transmitters of the TLx9 transmitter family cover the range between 470 MHz

and 790 MHz (UHF band IV/V) and support the digital standards DVB-T, DVB-T2 and

ISDB-T

standards are not supported.

The TLx9 series follows the concept of one product for all scenarios. The TLx9-platform is able to address the applications digital TV transmitter, digital radio transmitter

for band III and GapFiller for many digital standards.

Regarding firmware and software, the TLx9 will apply the Tx9 platform which allows

having a common software and firmware framework for all transmitter systems being

part of the Tx9 generation.

. With the retransmitter option it is going to support DVB-T/T2 only. Analog TV

(B)

Transmitter System R&S TLx9

Product features:

●

Compliance with the digital modulation standards DVB-T, DVB-T2 (full R&S DVBT2 feature set), ISDB-T

●

Output power level per transmitter 5 W up to 15 W in a 19” x 1 HU housing for UHF

(before Bandpass filter)

●

Output power level per transmitter 25 W up to 200 W in a 19” x 2 HU housing for

UHF (before Bandpass filter)

●

Equipped with adaptive non-linear pre-distortion and automatic linear pre-distortion

●

Fully integrated redundancy components (ASI distribution, LAN switch board) for B

transmitter

●

For standard configurations there is no need to do customer specific adaptations in

the factory

●

State of the art GUI

●

Cooling optimized for rack mounting (front – back)

●

Highly flexible system configuration. One product for any application:

– Transmitter

– Retransmitter

– Ready for GapFiller

●

Optional fully integrated control for redundancy components (N+1, 1+1)

●

Flexible configuration of redundancy systems:

– Configuration as a N+1-system with N ≤ 8

– Operation of redundant (B-)transmitter in mixed configurations, e.g. DVB-T and

DVB-T2

– Support of a Backup TX system (1+1, no external Redundancy Control Board

necessary)

, ATSC and DTMB

(B)

21System Manual 2506.5060.02 ─ 03

Page 28

R&S®TLx9

Transmitter System R&S TLx9

Design and Function – R&S TLx9

●

Common Remote Management over Web-Interface and SNMP

. All transmitters of

one redundancy system are:

– visible over the management interfaces as one system

– able to be controlled, monitored and managed by the operator of the TLx9 as

one system

●

Optionally integrated GPS receiver (fitting variant of the Exciter / GapFiller board)

●

Optionally integrated OCXO to provide hold over mode stability in SFN networks

for 24 h in case GPS or external 1 PPS signal fails (fitting variant of the Exciter /

GapFiller board)

●

For transmitter a transport stream feeding over ASI, IP over Gigabit Ethernet or

satellite receiver is possible

●

DVB-T/T2 receiver for retransmission or monitoring application to be optionally

integrated into the TLx9 system

●

DVB-S/S2 receiver module (with on-board CAM module and BTS recovery functionality) to be optionally integrated into the TLx9 system

3.1.1 Rack Design

The TLx9 is an all-in-one solution which means a complete transmitter system is integrated in a 19” x 1 or 2 HU housing (depending on the type) and minimal depth of maximum 600 mm in the power class of 5 W to 200 W.

Figure 3-1: TLx9 front view (1 HU)

Figure 3-2: TLx9 front view without air filter (2 HU)

22System Manual 2506.5060.02 ─ 03

Page 29

R&S®TLx9

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Figure 3-3: TLx9 front view with air filter (2 HU)

It allows inserting up to two hardware option modules (Re-TX, Sat RX, 1+1 control

option etc.) to adjust the configuration for several different scenarios.

Figure 3-4: TLx9 back view, no options mounted (2 HU)

1 = Option slot A

2 = Option slot B

Figure 3-5: TLx9 back view with mounted option (2 HU)

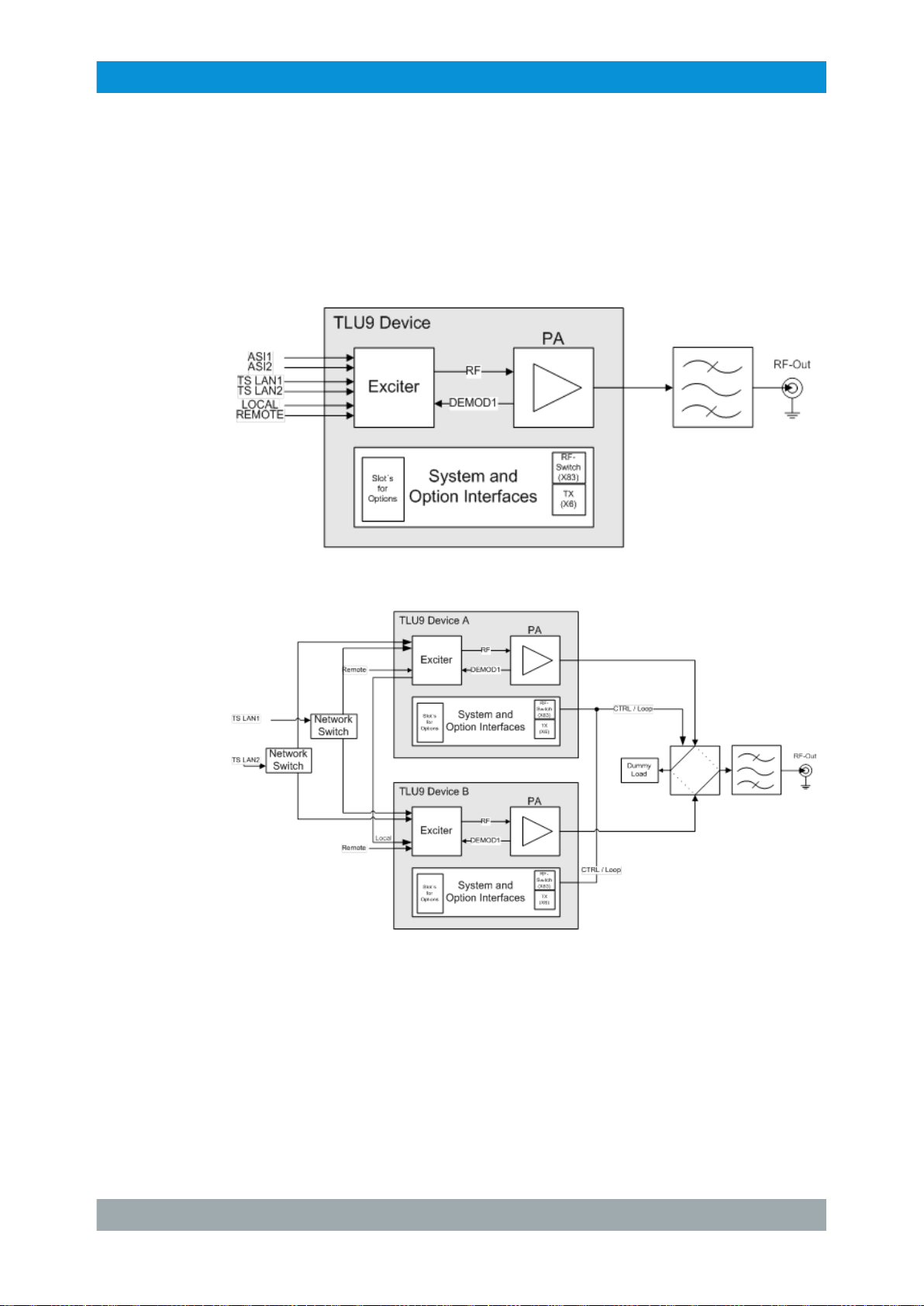

3.1.2 TLx9 system applications

The logical units are arranged according to the following rules:

23System Manual 2506.5060.02 ─ 03

Page 30

R&S®TLx9

Transmitter System R&S TLx9

Design and Function – R&S TLx9

24System Manual 2506.5060.02 ─ 03

Page 31

R&S®TLx9

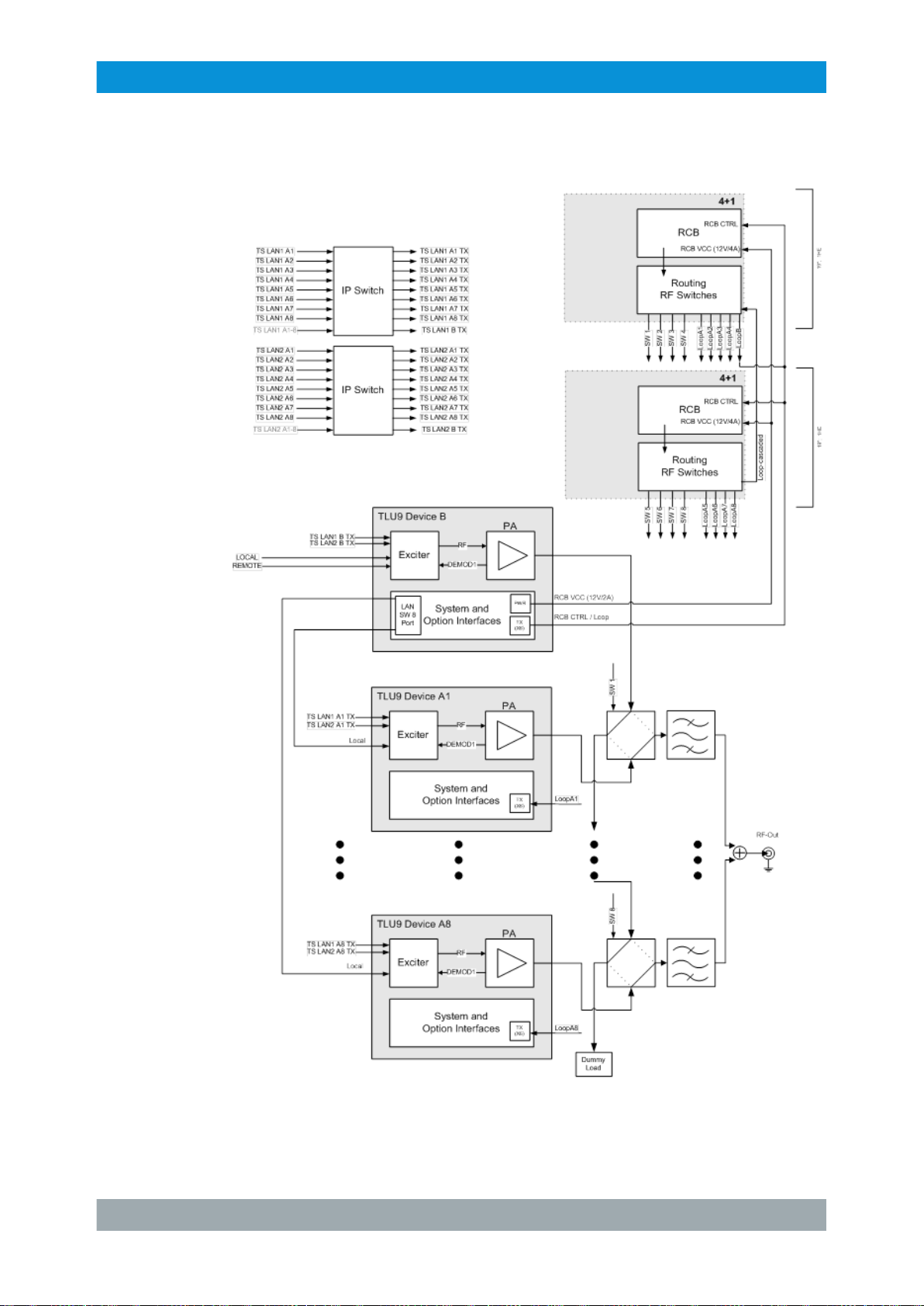

3.1.3 TLx9 redundancy systems

Transmitter System R&S TLx9

Design and Function – R&S TLx9

The TLx9 will support a maximum of up to 8 active transmitters in an N+1 system

(8+1). For system configurations (e.g. N+1) no additional external control devices are

necessary. The complete system control is placed inside the reserve B-T

Single TX configuration:

ransmitter.

Backup TX with LAN feeding:

25System Manual 2506.5060.02 ─ 03

Page 32

R&S®TLx9

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Backup TX wit ASI feeding:

26System Manual 2506.5060.02 ─ 03

Page 33

R&S®TLx9

Transmitter System R&S TLx9

Design and Function – R&S TLx9

N+1 with ASI feeding (max. 8+1):

27System Manual 2506.5060.02 ─ 03

Page 34

R&S®TLx9

Transmitter System R&S TLx9

Design and Function – R&S TLx9

N+1 with LAN feeding (max. 8+1):

28System Manual 2506.5060.02 ─ 03

Page 35

R&S®TLx9

3.1.4 Modules and devices

3.1.4.1 Overview

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Figure 3-6: Block diagram

29System Manual 2506.5060.02 ─ 03

Page 36

R&S®TLx9

3.1.4.2 Inside View (1HU)

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Figure 3-7: Inside View (1HU)

1 = Exciter / GapFiller board

2 = Backplane

3 = Capacitor backup battery

4 = System power supply

5 = Power Amplifier module

6 = Power Amplifier power supply

7 = Fan E1

8 = Fan E2

9 = Fan E3

3.1.4.3 Replaceable Modules (1HU)

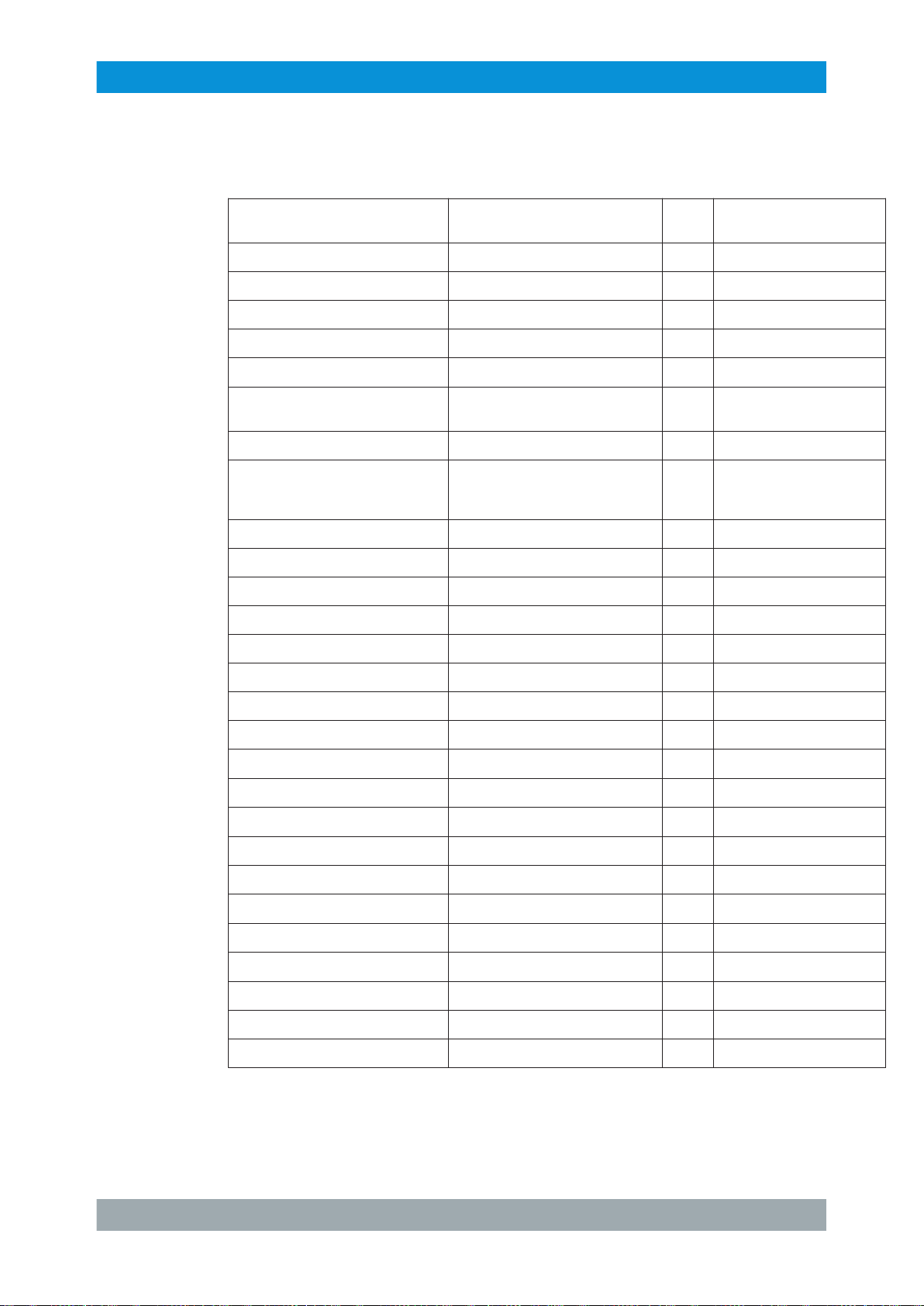

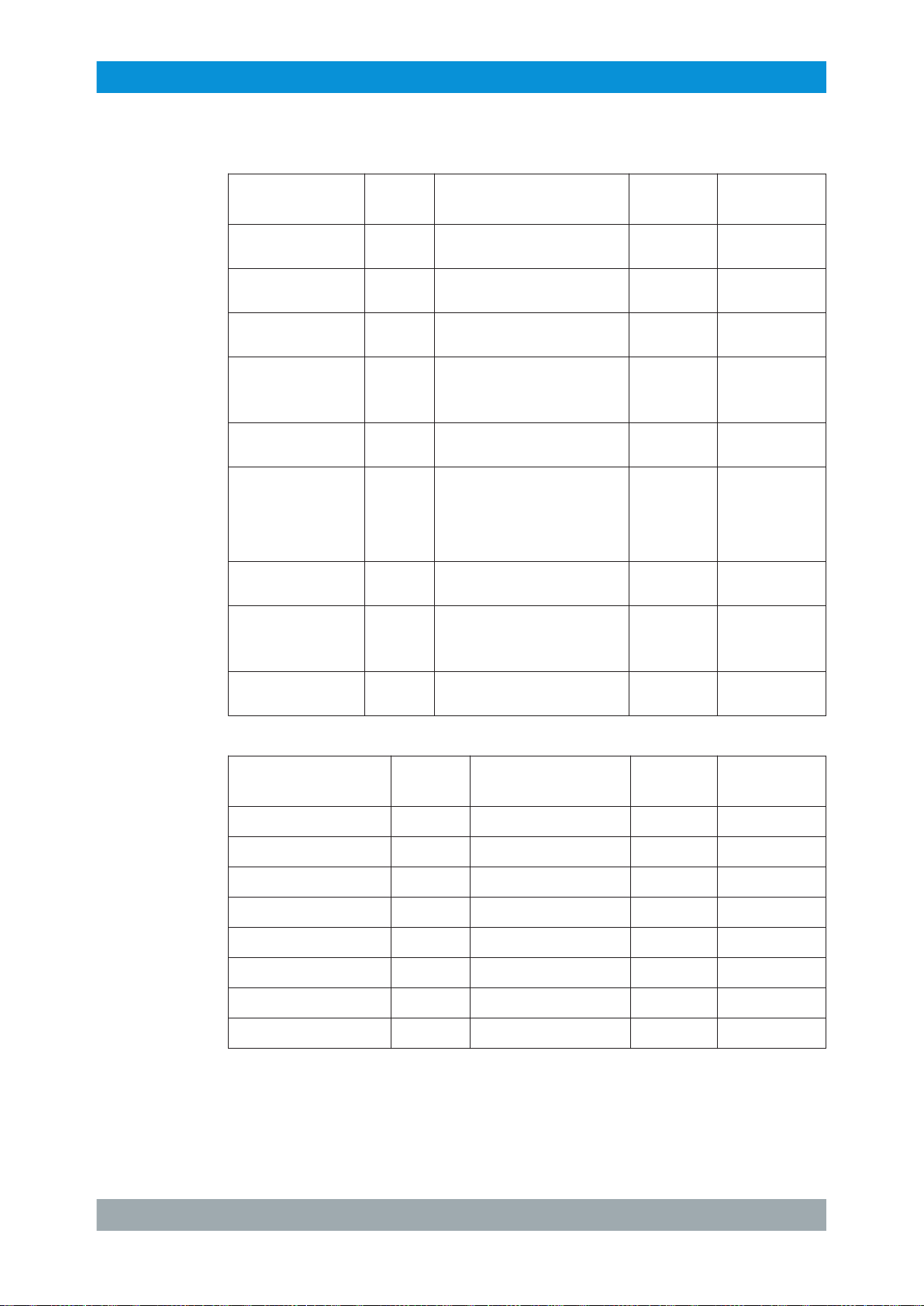

Module Comment

EMI Filter D-SUB 9/15 Pole Filter Circuit Boards

TDK Lambda HWS150A-12 12 V system power supply A4 2506.7604.00

TDK Lambda HWS100A-24/A PSU 108 W power supply A9 3592.0364.00

Capacitor Backup Battery TLx9-B69 A10 2506.8698.02

4GByte Micro SD card for initial installation of TLx9 Exciter /

GapFiller software a device test system (2509.4812.10) is needed

Ref.

des.

Part number

2507.2264.02

2507.3054.00

Chip Card via chip card service kit

1+1 ASI Distribution Board TLx9-B60 (Option slot A/B)

DVB-T / T2 Receiver TLx9-B61 (Option slot A/B)

DVB-S / S2 Receiver TCE900-M10 (Option slot A/B)

1201.5610.23

2506.8600.02

2506.8617.02

2109.3193.02

30System Manual 2506.5060.02 ─ 03

Page 37

R&S®TLx9

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Module Comment

Mini LAN Switch Board TLx9-M6 (Option slot B)

LAN Switch Board TCE900-M6 (Option slot B)

1+1 RF Switch Board TLx9-B59 (Option slot A/B)

PA / System Fan Fan 1 / 2 / 3

12 V 40X40X28 LC

Lithium battery CR 2032

Fuse 10 A F1, F2 0606.3136.00

Mains filter 5/15 W X1 1201.8184.00

Air Filter Mat 1 HU

DX 12 V Ext. Cable Terminal Supply W17 2506.7056.00

X60 RF Cable RF OUT RF output W60 2506.7410.00

X61 RF Cable RF MON RF monitor output W13 2506.7391.00

X66 GPS ANT Cable GPS antenna input W66 2506.7491.00

Insulation Film Insulation film for cover power sup-

ply

Ref.

des.

E1

E2

E3

Part number

2109.2380.03

2109.2897.02

2506.8598.02

3622.9805.00

0858.2049.00

2506.4205.00

2509.4293.00

Cover Power Supply complet Cover with insulation film

2509.4529.00

31System Manual 2506.5060.02 ─ 03

Page 38

R&S®TLx9

3.1.4.4 Inside View (2HU)

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Figure 3-8: Inside View, example 200 W (2HU)

1 = Fan E2

2 = Fan E1

3 = Fan E3

4 = Capacitor backup battery

5 = System power supply

6 = Power Amplifier power supply

7 = Backplane

8 = Power Amplifier module

9 = Exciter / GapFiller board

32System Manual 2506.5060.02 ─ 03

Page 39

R&S®TLx9

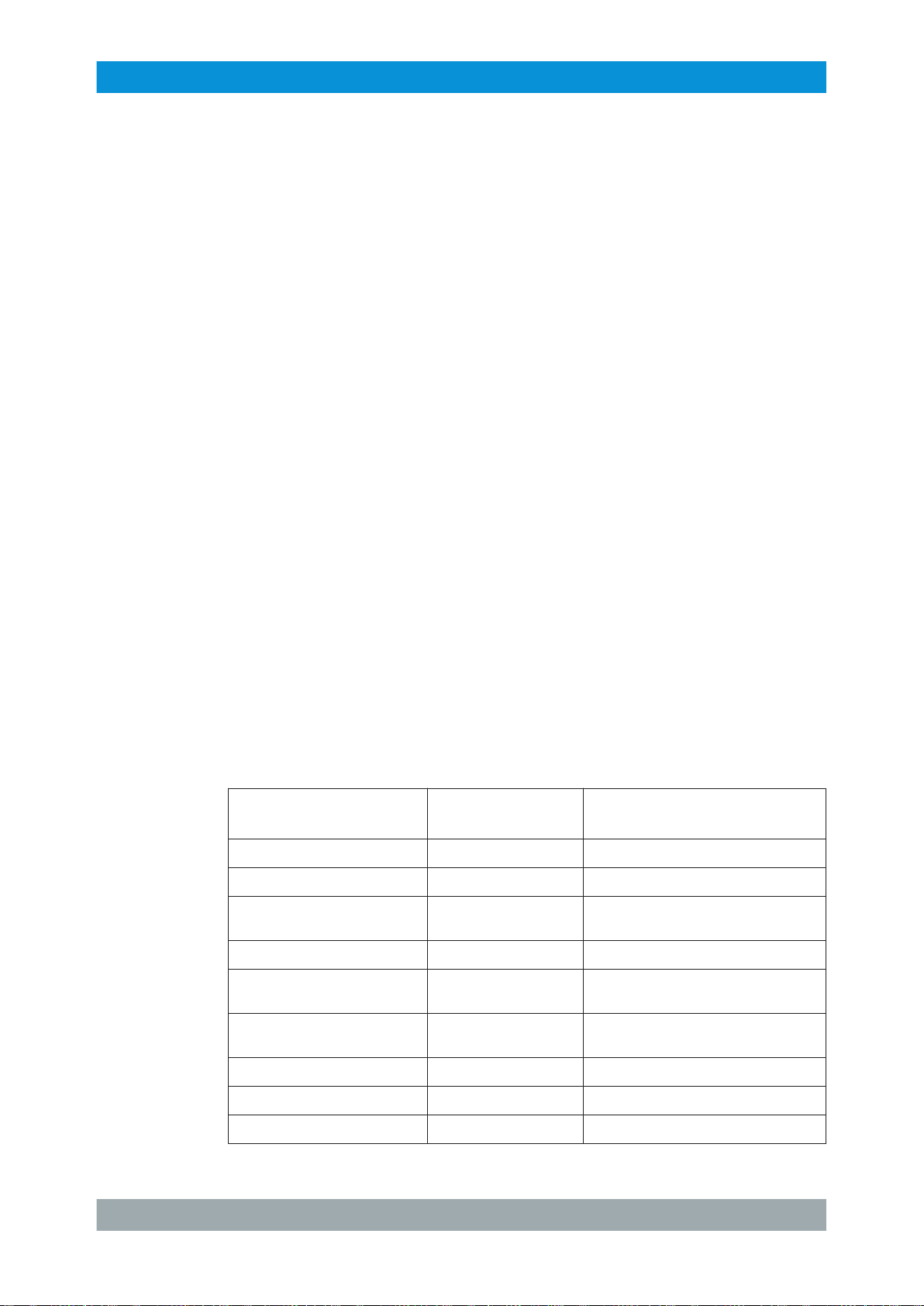

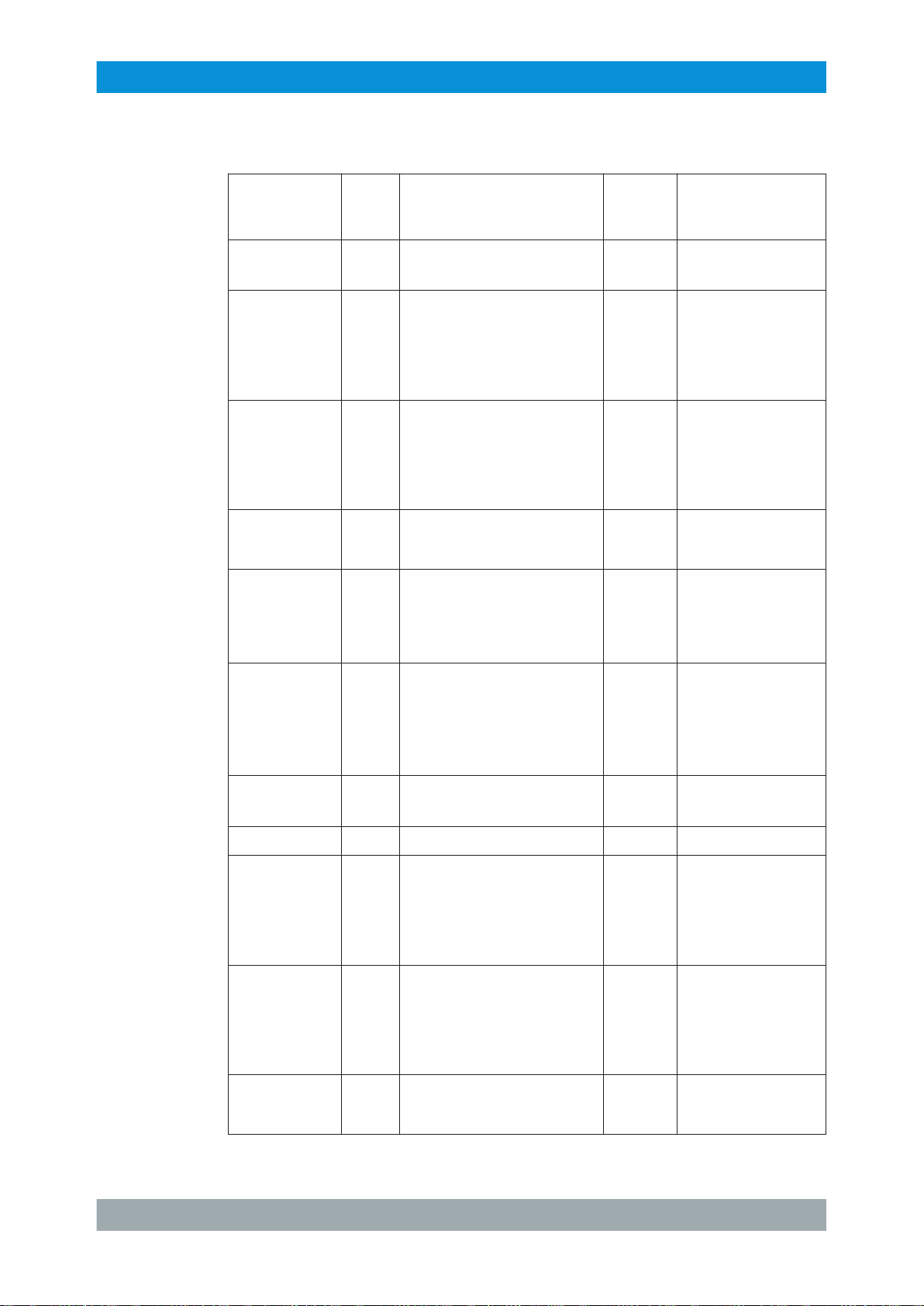

3.1.4.5 Replaceable Modules (2HU)

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Module Comment

EMI Filter D-SUB 9/15 Pole Filter Circuit Boards

TDK Lambda HWS150A-12 12 V system power supply A4 2506.7604.00

TSP901 Transmitter Status Panel A5 2507.2935.02

TDK Lambda HFE1600-48 200 W PA related power supply A6 3589.9506.00

TDK Lambda GWS500-36 100

Emerson/Artesyn LCM300Q-T 24 V /

300 W

Capacitor Backup Battery TLx9-B69 A10 2506.8698.02

4GByte Micro SD card for initial installation of TLx9 Exciter /

Chip Card via chip card service kit

1+1 ASI Distribution Board TLx9-B60 (Option slot A/B)

DVB-T / T2 Receiver TLx9-B61 (Option slot A/B)

DVB-S / S2 Receiver TCE900-M10 (Option slot A/B)

Mini LAN Switch Board TLx9-M6 (Option slot A)

W P

A related power supply A8 2506.7804.00

W and 50 W PA related power

25

supply

GappFiller software a device test

system (2509.4812.10) is needed

Ref.

des.

A9

Part number

2507.2264.02

2506.7704.00

2507.3054.00

1201.5610.23

2506.8600.02

2506.8617.02

2109.3193.02

2109.2380.03

LAN Switch Board TCE900-M6 (Option slot A)

1+1 RF Switch Board TLx9-B59 (Option slot A/B)

LAN Local Backup TX TLx9-B58 (Option slot A)

PA Fan Fan 1 (25 W and 50 W) E1 3593.0951.00

PA Fan Fan 1 (100/200 W) E1 3593.0945.00

PA Fan Fan 2 (200 W) E2 3593.0945.00

System Fan Fan 3 (25/50/100/200 W) E3 3593.0945.00

Lithium battery CR 2032

Fuse 10 A F1, F2 0606.3136.00

Mains Filter 25/50/100 W X1 1201.8184.00

Mains Filter 200 W X1 3622.7631.00

Air Filter Mat 2 HU

Fan Sealing Pad

X66 GPS ANT Cable GPS antenna input W66 2506.7210.00

2109.2897.02

2506.8598.02

2506.8581.02

0858.2049.00

2506.6143.00

2506.6243.00

33System Manual 2506.5060.02 ─ 03

Page 40

R&S®TLx9

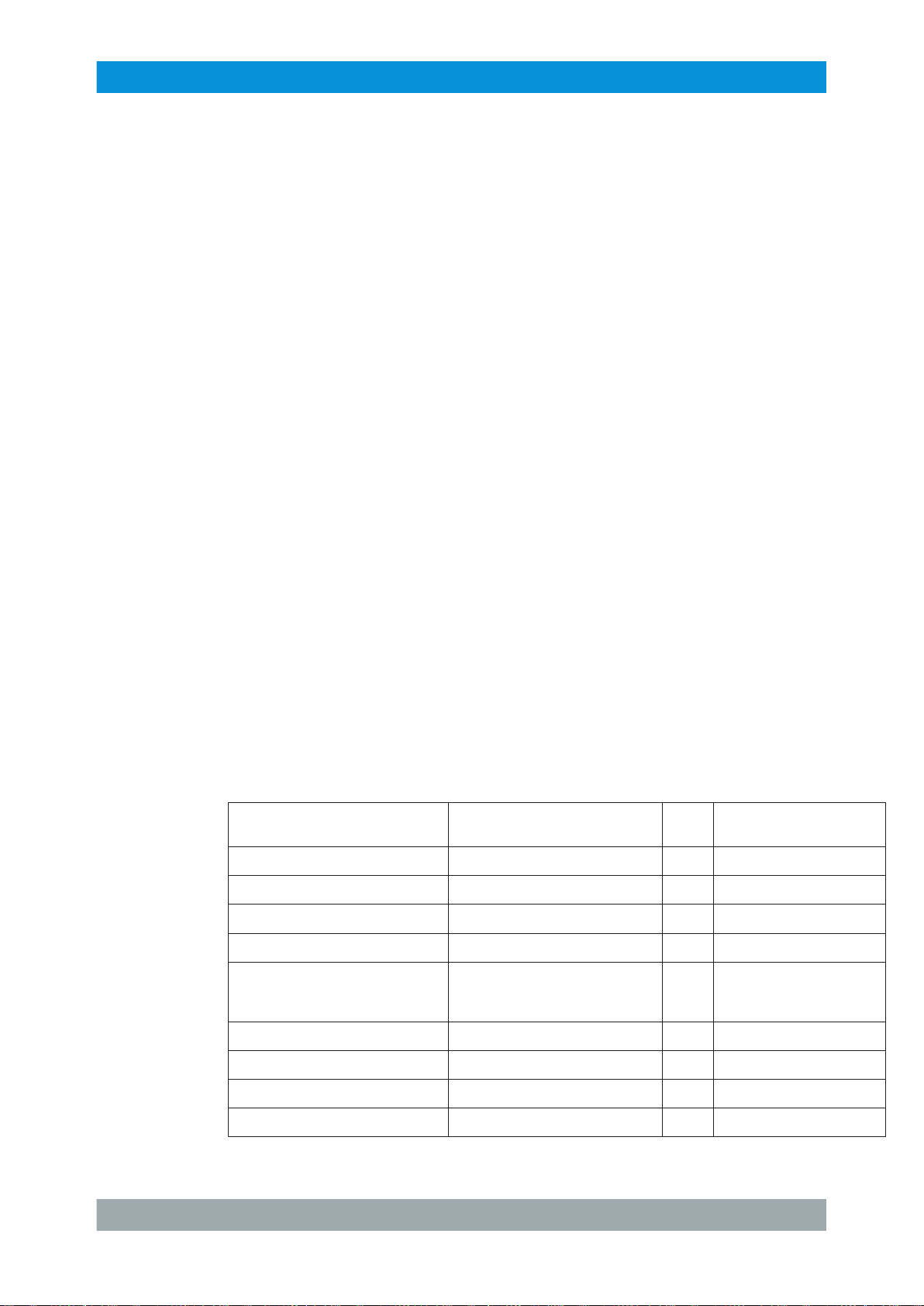

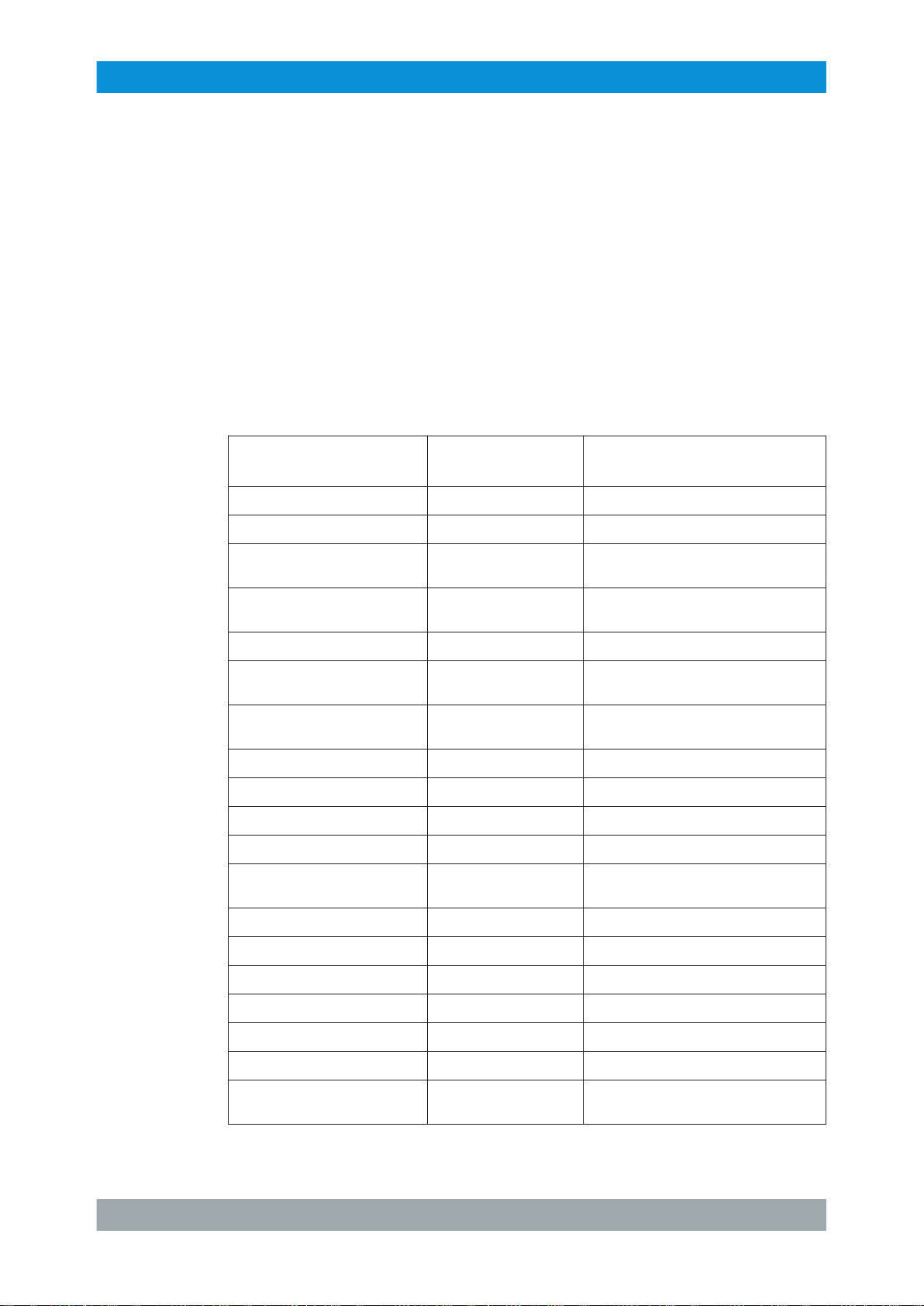

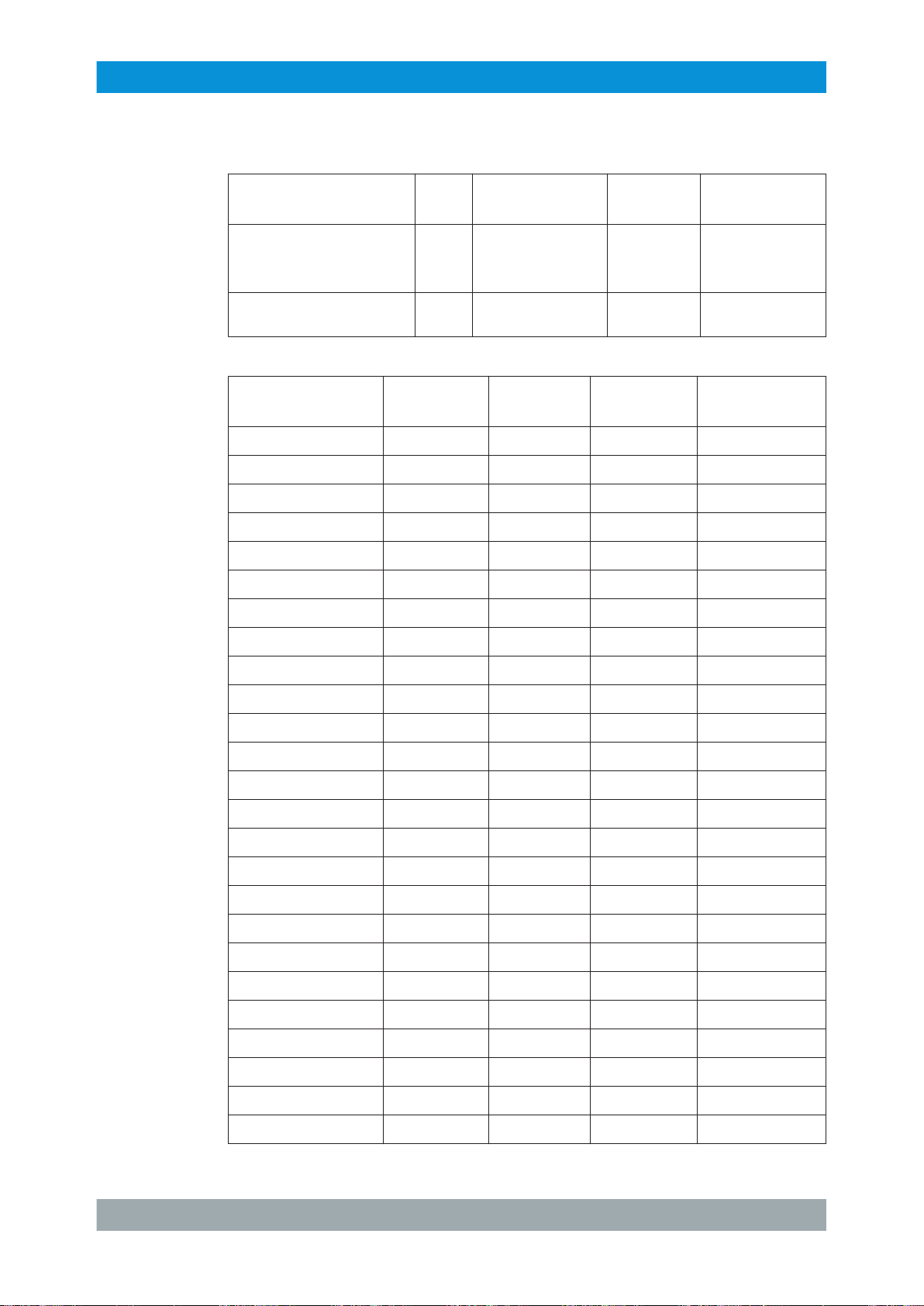

3.1.4.6 Option Keys

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Option Part number Comment

Service-K0

TLX9-FACTORY

TIME-CONTROL

K00

TLX9-K02 2506.9020.02 Option key SNMP

TLX9-K06 2506.9065.02 Option key DTMB (Transmitter only)

TLX9-K08 2506.9088.02 Option key ISDB-T(B) (Transmitter only)

TLX9-K12 2506.9120.02 Option key DVB-T (Transmitter only)

TLX9-K25 2506.9259.02 Option key DVB-T2 RF MONITORING

TLX9-K31 2506.9313.02 Option key TS OVER IP (Transmitter only)

TLX9-K35 2506.9359.02 Option key MPLP (Transmitter only)

TLX9-K37 2506.9371.02 Option key GPS (Transmitter only)

TLX9-K41 2506.9213.02 Option key ATSC (Transmitter only)

TLX9-K43 2506.9436.02 Option key SIGNAL ANALYSIS (Transmitter only)

TLX9-K44 2506.9442.02 Option key DVB-T2 (Transmitter only)

TLX9-K47 2506.9471.02 Option key DVB-T2 MISO (Transmitter only)

Service Key

TLx9-Factory

Reset time monitoring data

TLx9K0 Demo key

TLX9-K49 2506.9494.02 Option key DVB-T2 LITE (Transmitter only)

TLX9-K50 2506.9507.02 Option key DVB-T2 TONE RESERVATION (Trans-

mitter only)

TLX9-K55 2506.9559.02 Option key DVB-S/S2 RX IP OUTPUT (Transmitter

only)

TLX9-K56 2506.9565.02 Option key DVB-S/S2 RX DECRYPTION (Transmit-

ter only)

TLX9-K59 2506.9594.02 Option key NIT RESTAMPING (Transmitter only)

TLX9-K60 2506.9607.02 Option key BTS DECOMPRESSION (Transmitter

only)

TLX9-K62 2506.9620.02 Option key WINDOW SIZE 14US (GapFiller only)

TLX9-K63 2506.9636.02 Option key WINDOW SIZE 17US (GapFiller only)

TLX9-K64 2506.9642.02 Option key R&S SMART EC (GapFiller only)

TLX9-K65 2506.9659.02 Option key HTML5 GUI

TLX9-K71 2506.9713.02 Option key REDUNDANT FEEDING (Transmitter

only)

TLX9-K73 2506.9736.02 Option key GLONASS (Transmitter only)

TLX9-K74 2506.9742.02 Option key DVB-S/S2 Multistream (Transmitter only)

34System Manual 2506.5060.02 ─ 03

Page 41

R&S®TLx9

3.1.4.7 Material Number Assignment

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Option Part number Comment

TLX9-K80 2506.9807.02 Option key SYSTEM CONTROL

TLX9-K83 2506.9836.02 Option key 10 W

TLX9-K84 2506.9842.02 Option key 15 W

TLX9-K85 2506.9859.02 Option key 50 W

Material No.

of article

2506.5001K02 TLX9 TLx9 System KMAT (Transmitter) 2506.5001.02

2506.5001K03 TLX9-GF TLx9 System KMAT (GapFiller) 2506.5001.02

2506.8023.02 TLX9-B02 Advanced Transmitter Exciter Board 2506.8023.02

2506.8023.02 TLX9-B02 Advanced Transmitter Exciter Board 2507.2229.05

2506.8030.06 TLX9-B03 GapFiller Board 6 MHz 2507.2006.03

2506.8030.08 TLX9-B03 GapFiller Board 8 MHz 2507.2006.02

2506.5001.10 In TLX9 1HE 5/10/15 W Amplifier 2507.2629.02

2506.5001.30 In TLX9-GF

2506.8223.02 TLX9-B22 Air Filter 2 HU *

2506.8423.02 TLX9-B42 25 W Amplifier 2507.2729.02

2506.8430.02 TLX9-B43 50 W Amplifier 2507.2729.02

2506.8446.02 TLX9-B44 100 W Amplifier 2507.2829.02

2506.8452.02 TLX9-B45 200 W Amplifier 2507.2829.02

Name Comment

Keycard 2506.9907.02

5/10/15 W Amplifier 2507.2629.02

1HE

Corresponding Board

Material No. in SW

2109.2380.03 TLX9-M6 Mini LAN Switch, Variant for TLx9 with

mechanical components

2109.2897.02 TCE900-M6 LAN Switch (big version) 2109.2900.02

2506.8581.02 TLX9-B58 Local LAN2 Board Backup TX (only 2HU

devices)

2506.8598.02 TLX9-B59 1+1 RF Switch Board 2507.2135.02

2109.3193.02 TCE900-M10 DVB-S/S2 Receiver (Transmitter only) 5303.7500.02

2506.8600.02 TLX9-B60 1+1 ASI Distribution card 2507.2429.02

2506.8617.02 TLX9-B61 DVB-T/T2 Receiver 2113.9986.02

2506.8698.02 TLX9-B69 Exciter Backup Battery

2506.5101.04

TLX9 CD-ROM Doku

2509.4735.02

No EEPROM

35System Manual 2506.5060.02 ─ 03

Page 42

R&S®TLx9

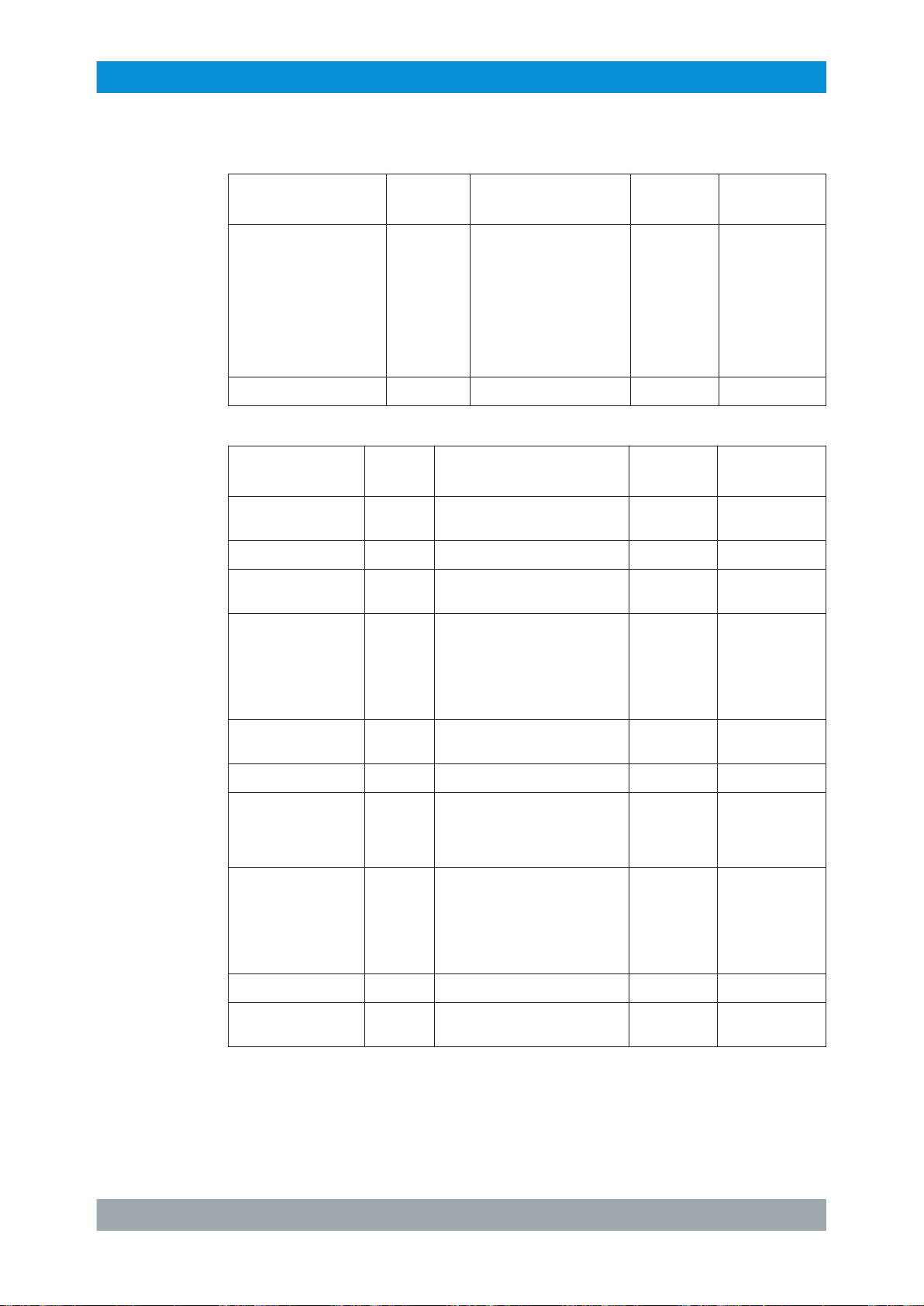

3.1.4.8 Option Boards

Transmitter System R&S TLx9

Design and Function – R&S TLx9

* The air filter for 1 HU TLU9 is directly installed at the device frame.

The following table shows all possible combinations for the plug‑in of option boards:

Device Option A Option B

DVB-T/T2 RX Yes Yes

DVB-S/S2 RX Yes Yes

ASI Distribution 1+1 Yes Yes

Antenna Switch Yes Yes

LAN Switch (1HU)

LAN Switch (2HU)

*

Wide (200 x 150 mm) and small (200 x 90 mm) options can be mounted.

*

*

No Yes

Yes No

Figure 3-9: Option board positions in 1 HU device

Figure 3-10: Option board positions in 2 HU device

3.1.4.9 Backplane

This module is the base for the inter-board communication.

36System Manual 2506.5060.02 ─ 03

Page 43

R&S®TLx9

3.1.4.10 Exciter Board

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Figure 3-11: Backplane, example 2HU

This board provides the TLx9 Exciter functions, depending on the HW fitting variant:

●

External (customer) interfaces

●

Video input signal handling

●

Channel coding

●

Generation of modulated OFDM signal

●

RF signal generation.

●

Reference and sync input signal handling

●

Regulation of P

●

Digital linear precorrection and non-linear PA precorrection

●

Control of power supplies

●

Control of redundancy switching

●

Different HW fitting variants:

A output power

– Advanced (2 x ASI input, 2 x TSoIP input, GPS and OCXO reference oscillator)

– GapFiller (1 x RF input and OCXO reference oscillator)

●

TCE901 (GPS and OCXO, dual inputs, TS monitoring, local LAN2, measurement

couplers, RF mon, PCIe SW, COFDM out, +13 dBm amp)

37System Manual 2506.5060.02 ─ 03

Page 44

R&S®TLx9

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Figure 3-12: Exciter Board, example type Advanced

3.1.4.11 GapFiller Board

The GapFiller board replaces the Exciter board for GapFiller functions.

The GapFiller is integrated in the x9 transmitter family and supports all commercially

available broadcast standards; such as DVB-T, DVB-T2 (full R&S DVB-T2 feature set),

ISDB-T

, A

TSC and DTMB.

(B)

38System Manual 2506.5060.02 ─ 03

Page 45

R&S®TLx9

Transmitter System R&S TLx9

Design and Function – R&S TLx9

GapFiller Receiver:

●

High performance echo cancellation algorithm: at least -25 dB echo cancellation

gain

●

The echo cancellation settings are automatically adapted to the specific echo situation at the installation site

●

The signal quality at the output is better compared to the R&S XLX8000

Figure 3-13: GapFiller Board

3.1.4.12 TSP901 (Transmitter Status Panel) of 1HU device

The functionality is identical with the TSP901 of the 2HU device (see Chapter 3.1.4.13,

"TSP901 (T

ransmitter Status Panel) of 2HU device", on page 40) but the LEDs and

buttons are arranged in a different way.

39System Manual 2506.5060.02 ─ 03

Page 46

R&S®TLx9

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Figure 3-14: Local operation for 1HU device

3.1.4.13 TSP901 (T

The TSP901 allows local operation of a transmitter and shows basic informations.

Figure 3-15: TSP901 (Transmitter Status Panel)

For N+1 and MultiTX transmitters, each individual transmitter has a separate TSP901,

which allows local operation of the single transmitters.

Meaning of LEDs

LED Message

OK (green) Transmitter, everything OK

Warning (orange)

ransmitter Status Panel) of 2HU device

[1]

Warning for transmitter

Fault (red) Fault for transmitter

Input OK Sum input status of the Exciter / GapFiller is OK

W Sum input status of the Exciter / GapFiller has a Warning

F Sum input status of the Exciter / GapFiller has a

Reference OK Sum reference of the Exciter / GapFiller is OK

W Sum reference of the Exciter / GapFiller has a Warning

F Sum reference of the Exciter / GapFiller has a Fail

Fail

40System Manual 2506.5060.02 ─ 03

Page 47

R&S®TLx9

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Off Reference signal (10 MHz/ PPS/GPS…) is not present and is not

required, since frequency regulation source is set to "Manual"

RF OK Transmitter RF OK

W Transmitter RF W

F

Off Transmitter program off

Local Transmitter Local/Remote

On Transmitter On

[1]

During an update of the FPGA firmware (e.g. after installing a new software version)

T

ransmitter RF Fail

LED shows the Local status (yellow)

(ON/OFF command accepted by the transmitter)

the Warning LED is flashing.

[2]

Special case: Saved RF Fail for (switched over and) switched off transmitter

3.1.4.14 TDU901 (Transmitter Display Unit)

The R&S TDU901 is a display unit with a touchscreen function and a graphical user

interface for configuring Tx9 transmitter systems.

arning

[2]

.

Figure 3-16: TDU901 (Transmitter display unit)

The display has a touchscreen function for operating all of the transmitter functions.

Using sharp‑edged objects can damage or destroy the surface. Therefore only use

your finger to operate the touchscreen.

1. A light touch on a button is enough to trigger a user action.

2. A button lights up orange for as long as your finger remains there. The action is not

carried out until you remove your finger from the button.

41System Manual 2506.5060.02 ─ 03

Page 48

R&S®TLx9

3.1.4.15 Power Amplifier Module

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Tip: To cancel an inadvertently selected action, slide your finger to the side away

from the button highlighted orange and then lift your finger of

f the touchscreen.

The TDU901 Touch-Screen is existing in two variants. The Var. 02 is the standard configuration with mechanical holder and coated front plate. The Var. 03 is extended with a

front LOCAL LAN connection for more convenient LAN cabling (local operation with

Laptop).

If the USB Display Var. 03 is ordered together with a 2HU TLx9 Backup TX System it is

mandatory to order also the option LOCAL LAN2 for the system control device, otherwise the local LAN control at the front is not possible.

The amplifier-pallet operates from 470 MHz to 790 MHz. The whole amplifier stage is

designed as a fixed gain amplifier without any compensation of gain and temperature

and frequency response. There is no internal power or gain control. The entire FPGAbased power control is done on the Exciter / GapFiller board by a variable gain amplifier (VGA) and a voltage variable attenuator (VVA). The detection of the output power

is done on the TLx9 PA module.

Fitting variants:

●

PA Pallet and 200 W heat sink and 2 fans

●

PA Pallet and 100 W heat sink and 1 fan

●

PA Pallet and 50 W heat sink and 1 fan

Figure 3-17: Power Amplifier Module (example)

42System Manual 2506.5060.02 ─ 03

Page 49

R&S®TLx9

3.1.4.16 Power Supplies

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Fitting variants:

●

200 W PA: 12 V PS and 48 V PS and adapter card and EC1

●

100 W PA: 12 V PS and 36 V PS and Euro AC connector

●

50 W PA: 12 V PS and 24 V PS and Euro AC connector

Used Power Supplys:

Voltage Power Material Number Type

12 V 150 W 2506.7604.00 TDK Lambda HWS150A-12

24 V 300 W 2506.7704.00 Emerson LCM300Q-T 24V/300W

36 V 500 W 2506.7804.00 TDK Lambda GWS500-36

48 V 1800 W 3589.9506.00 TDK Lambda HFE1600 - 48

3.1.4.17 Capacitor Backup Battery

Delivers 12 V backup power to the Exciter / GapFiller Board to avoid reboots during

power glitches.

1 AC connector

Figure 3-18: Capacitor Backup Battery

3.1.4.18 IPM2/4 Processor Board

For inter-board and interface controlling.

43System Manual 2506.5060.02 ─ 03

Page 50

R&S®TLx9

3.1.4.19 ASI Distribution Board

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Figure 3-19: IPM2/4 Processor Board

For distribution of ASI inputs between active and reserve TLx9 transmitter

one of the TLx9 option slots for 1+1 or N+1 configuration.

. Installed in

Figure 3-20: ASI Distribution Board

44System Manual 2506.5060.02 ─ 03

Page 51

R&S®TLx9

3.1.4.20 DVB-T/T2 Receiver

Transmitter System R&S TLx9

Design and Function – R&S TLx9

This module is a complete receiver for DVB-T and DVB-T2. Output of the module is a

MPEG transport stream (ASI) and a set of measurement values (RF power, MER,

BER, packet error

,…). The control is done by USB. The receiver can handle the complete VHF and UHF frequency range. To operate the board a reference frequency is

mandatory.

Figure 3-21: DVB-T/T2 Receiver

3.1.4.21 DVB-S/S2 Receiver

This board is using two single tuners and dual demodulator chips. In addition there is

one dual LNB supply and control chip which can control two independent LNBs. There

are two slots available to incorporate CI modules. With this modules the demodulated

transport streams can be encrypted if necessary. The processed transport streams are

connected via the backplane with the Exciter / GapFiller board (for further processing).

It is possible to emit the demodulated and encrypted transport streams via the Ethernet

connector X35 and the ASI out connector X25.

Features:

●

DVB-S; DVB-S2

●

Input frequency range 950 MHz to 2150 MHz

●

Supports 1 to 45 Msymbol/s

●

Continuously variable gain: 0 to 65 dB

●

Programmable 5- to 36-MHz cut-of

●

RF input power for a single carrier: - 80 dBm up to - 10 dBm

f frequency

45System Manual 2506.5060.02 ─ 03

Page 52

R&S®TLx9

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Figure 3-22: DVB-S/S2 Receiver

3.1.4.22 Mini LAN Switch Board

This board is of

●

Connectivity / activity (green LED)

●

Valid Gigabit Ethernet connection (yellow LED)

fering 4 GBit Ethernet ports. T

wo LEDs per interface are for signaling

Figure 3-23: Mini LAN Switch Board

46System Manual 2506.5060.02 ─ 03

Page 53

R&S®TLx9

3.1.4.23 LAN Switch Board

Transmitter System R&S TLx9

Design and Function – R&S TLx9

This board is offering 8 GBit Ethernet ports. T

●

Connectivity / activity (green LED)

●

Valid Gigabit Ethernet connection (yellow LED)

wo LEDs per interface are for signaling

Figure 3-24: LAN Switch Board

3.1.4.24 Local LAN2 Board

The Local LAN2 Board is a passive board to route the Local LAN network connection

from the Exciter / GapFiller Board via the Backplante to the Option Slot A (2 HU housing). This board is only used in 2HU device.

In 1HU devices a second local LAN is accessible at the front of the device. The 2HU

device is missing the second local LAN connection. The board is only used in Backup

TX systems.

47System Manual 2506.5060.02 ─ 03

Page 54

R&S®TLx9

3.1.4.25 RF Switch Board

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Figure 3-25: Local LAN2 Board

This board as a TLx9 option card is to be mounted in the redundancy device (i.e. TX B)

and has no fitting variant in this module.

GapFiller Redundancy 1+1 Antenna Redundancy

The main feature in this configuration is that it supports cross switching between

antenna A to device A or B and antenna B to device A or B

Figure 3-26: GapFiller Redundancy 1+1 Antenna Redundancy

GapFiller Redundancy in 1+1 Systems with Single Antenna

The main feature in this configuration is that switching between device A and B is possible. In normal operation mode, the device B will have no input and hence, no valid

output signal (i.e. passive standby).

48System Manual 2506.5060.02 ─ 03

Page 55

R&S®TLx9

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Figure 3-27: GapFiller Redundancy in 1+1 Systems with Single Antenna

1+1 RF Switch for 15W Backup TX Systems

In this configuration, the optional ASI board is required and has to be mounted in the

redundancy device (i.e. TX B). With the prerequisite fulfilled, the RF Switch board can

be used as a high power (15W OFDM max.) RF switch. In this configuration, the TX B,

in the condition with no TX A connected, must be able to open up the RF loop to avoid

“hot switching”.

Figure 3-28: 1+1 RF Switch for 15W Backup TX Systems

49System Manual 2506.5060.02 ─ 03

Page 56

R&S®TLx9

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Figure 3-29: RF Switch Board

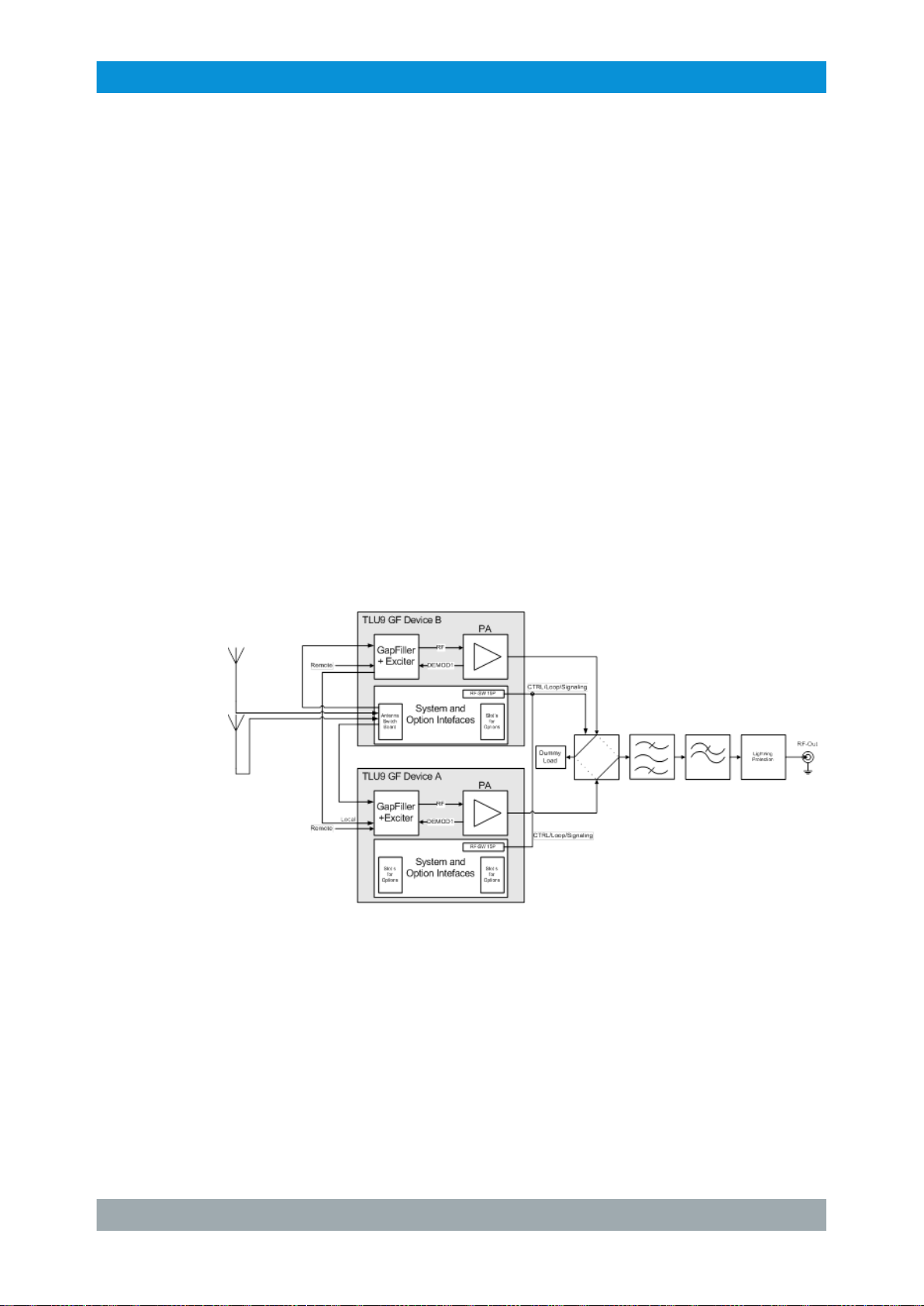

3.1.4.26 GapFiller 1+1 15W Redundancy System with RF Switching

In this configuration, 2 RF switch boards are required and has to be mounted in the

redundancy device (i.e. TX B). With the prerequisite fulfilled, the RF Switch board at

the input can be used to switch an input antenna or to support antenna redundancy

with the second switch board as a high power (15W OFDM max) RF switch. In this

configuration, the TX B, in the condition with no TX A connected, must be able to open

up the RF loop to avoid “hot switching”.

50System Manual 2506.5060.02 ─ 03

Page 57

R&S®TLx9

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Figure 3-30: GapFiller 1+1 15W Redundancy System with RF Switching

3.1.5 Specifications

3.1.5.1 General Data

Frequency range UHF band IV/V (step size 1 Hz): 470 MHz to 790 MHz

Channel bandwidth 6, 7, or 8 MHz 5, 6, 7, 8 or 10

Standards ETSI EN 300 744 ETSI EN 302 755 ARIB STD-B31 (ISDB-T)

SFN / DTx Funktion ETSI TS 101 191 ARIB STD-B31 (ISDB-T)

EMC ETSI EN 302 296/ 302 297 Rec.

DTV average Power 5 to 200 W (before bandpass filter)

RF output power stability

DVB-T DVB-T2 ISDB-T

6, 7 or 8 MHz

MHz

ABNT NBR 15601 (ISDB-T)

ABNT NBR 15601 (ISDB-TB)

ETSI EN 302 296/ 302 297 Rec. 1999/519/EC

1999/519/EC

ETSI EN 301 489-1 / -14

± 0.253 dB ( ± 6 %)

ETSI EN 301 489-1 / -14

(B)

Directivity for VSWR

measurement

MER with predistortion ≥ 34 dB

Shoulder distance with

predistortion

typical 25 to 30 dB

≥ 37 dB

51System Manual 2506.5060.02 ─ 03

Page 58

R&S®TLx9

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Harmonic distance 470 to 530 MHz: ≤ 33 dBc

Flatness with predistortion

VSWR at RF Output ≤ 1.65

Spurious emissions Non harmonics, > 10 kHz of

Frequency Carrier Offset

10 Hz -65 dBc/Hz (OCXO), -50 dBc/Hz typical (TCXO)

100 Hz -85 dBc/Hz

1 kHz -100 dBc/Hz

20 kHz -105 dBc/Hz

DVB-T DVB-T2 ISDB-T

530 to 790 MHz: ≤ 50 dBc

≤ 0.5 dB

(for VSWR ≥ 1.65 the TLx9 will reduce output power)

(for VSWR ≥ 2 the TLx9 will be muted)

fset from carrier with max. gain, sin signal:

≥

50 dBc

Phase noise

(B)

100 kHz -113 dBc/Hz

1 MHz -130 dBc/Hz

OCXO variant (average value after 10 days of operation)

Aging (after 24 hours

operation)

Aging (after 30 days

operation)

Long term aging

Heat up time 10 minutes

TCXO variant ±1 ppm/year

Aging

-9

< 1·10

-8

< 2·10

< 1·10-7/year (0.1 ppm/year)

Redundancy

Backup TX (1+1) and N+1 redundancy

Operation conditions For indoor use only

Environmental conditions

52System Manual 2506.5060.02 ─ 03

Page 59

R&S®TLx9

Transmitter System R&S TLx9

Design and Function – R&S TLx9

Cooling system Air-cooled

Max. installation altitude

Operating temperature +1 °C to +45 °C (Technical data guaranteed)

Permissible temperature

Maximum relative

humidity

Dust conditions Pollution degree 2 (IEC 60664-1)

Air Filter Compliant with DIN EN 779 G2

Environmental class ETSI EN 300-019-1-3

Immunity to radiated