Page 1

R&S®Tx9

For information only!

This manual, dated April 25, 2014 reflects the

technical status as of that date. There may

have been technical changes since that time.

Transmitter System

Operating Manual

(E9é:2)

2109.9110.02 ─ 07

Broadcasting

Operating Manual

Page 2

© 2014 Rohde & Schwarz GmbH & Co. KG

Mühldorfstr. 15, 81671 München, Germany

Phone: +49 89 41 29 - 0

Fax: +49 89 41 29 12 164

E-mail: info@rohde-schwarz.com

Internet: www.rohde-schwarz.com

Subject to change – Data without tolerance limits is not binding.

R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

Trade names are trademarks of the owners.

The following abbreviations are used throughout this manual: R&S®XYZ1234 is abbreviated as R&S XYZ1234.

Page 3

Quality management

Certied Quality System

ISO 9001

and environmental

management

Sehr geehrter Kunde,

Sie haben sich für den Kauf

eines Rohde & Schwarz Produktes entschieden. Sie erhalten

damit ein nach modernsten Fertigungsmethoden hergestelltes

Produkt. Es wurde nach den

Regeln unserer Qualitäts- und

Umweltmanagementsysteme

entwickelt, gefertigt und geprüft.

Rohde & Schwarz ist unter anderem nach den Managementsystemen ISO 9001 und ISO 14001

zertifiziert.

Der Umwelt verpflichtet

❙ Energie-efziente,

RoHS-konforme Produkte

❙ Kontinuierliche

Weiterentwicklung nachhaltiger

Umweltkonzepte

❙ ISO 14001-zertiziertes

Umweltmanagementsystem

Dear customer,

You have decided to buy a

Rohde & Schwarz product. This

product has been manufactured

using the most advanced methods. It was developed, manufactured and tested in compliance

with our quality management

and environmental management systems. Rohde & Schwarz

has been certified, for example, according to the ISO 9001

and ISO 14001 management

systems.

Environmental commitment

❙ Energy-efcient products

❙ Continuous improvement in

environmental sustainability

❙ ISO 14001-certied

environmental management

system

Certied Environmental System

ISO 14001

Cher client,

Vous avez choisi d’acheter un

produit Rohde & Schwarz. Vous

disposez donc d’un produit

fabriqué d’après les méthodes

les plus avancées. Le développement, la fabrication et les

tests de ce produit ont été effectués selon nos systèmes de

management de qualité et de

management environnemental.

La société Rohde & Schwarz a

été homologuée, entre autres,

conformément aux systèmes

de management ISO 9001 et

ISO 14001.

Engagement écologique

❙ Produits à efcience

énergétique

❙ Amélioration continue de la

durabilité environnementale

❙ Système de management

environnemental certié selon

ISO 14001

1171.0200.11 V 05.01

1171020011

Page 4

Customer Support

Technical support – where and when you need it

For quick, expert help with any Rohde & Schwarz equipment, contact one of our Customer Support

Centers. A team of highly qualified engineers provides telephone support and will work with you to find a

solution to your query on any aspect of the operation, programming or applications of Rohde & Schwarz

equipment.

Up-to-date information and upgrades

To keep your instrument up-to-date and to be informed about new application notes related to your

instrument, please send an e-mail to the Customer Support Center stating your instrument and your wish.

We will take care that you will get the right information.

Europe, Africa, Middle East

North America

Latin America

Asia/Pacific

China

Phone +49 89 4129 12345

customersupport@rohde-schwarz.com

Phone 1-888-TEST-RSA (1-888-837-8772)

customer.support@rsa.rohde-schwarz.com

Phone +1-410-910-7988

customersupport.la@rohde-schwarz.com

Phone +65 65 13 04 88

customersupport.asia@rohde-schwarz.com

Phone +86-800-810-8228 /

+86-400-650-5896

customersupport.china@rohde-schwarz.com

1171.0200.22-06.00

Page 5

R&S®Tx9

Contents

Contents

1 Information about this Manual..............................................................9

2 Safety Instructions...............................................................................11

2.1 Safety Instructions for Transmitter Systems and Equipment................................ 11

2.2 General Safety Instructions....................................................................................... 12

2.2.1

2.3.1 Hazards from AC Supply Voltage................................................................................. 19

2.3.1.1 AC Power Supply.......................................................................................................... 19

2.3.1.2 Changing Fuses............................................................................................................ 19

2.3.2 Hazards from High‑Energy Electric Circuits..................................................................19

2.3.3 Hazards from RF Radiation...........................................................................................20

2.3.3.1 Obligation to Instruct Personnel.................................................................................... 20

2.3.3.2 RF Shielding..................................................................................................................20

2.3.3.3 Rules When Operating an Amplifier..............................................................................20

2.3.3.4 Rules When Working on an Open Amplifier..................................................................21

2.3.4 Conditions for Assembly Work on Cooling System.......................................................21

2.3.5 Safety Data Sheets for Hazardous Substances............................................................22

Safety Instructions.........................................................................................................12

2.3 Special Hazard Information........................................................................................19

3 Introduction to Operation....................................................................23

3.1 Operation via R&S TDU900........................................................................................ 23

3.1.1 Opening Display............................................................................................................23

3.1.2 Closing Display............................................................................................................. 23

3.1.3 Using Touchscreen Function........................................................................................ 23

3.2 Operation via Browser................................................................................................24

3.2.1 Connection Setup and Login.........................................................................................26

3.3 Structure of User Interface.........................................................................................26

3.3.1 Elements of User Interface............................................................................................26

3.3.2 Views.............................................................................................................................27

3.3.3 Basic Functions on Menu Bar....................................................................................... 28

3.3.3.1 Logbook........................................................................................................................ 29

3.3.3.2 Help...............................................................................................................................29

3.3.3.3 Local/Remote................................................................................................................ 29

3Operating Manual 2109.9110.02 ─ 07

Page 6

R&S®Tx9

Contents

3.3.3.4 Login/Logout................................................................................................................. 29

3.3.3.5

3.3.3.6 Task View......................................................................................................................30

3.3.4 Navigation..................................................................................................................... 30

3.3.5 Input Fields....................................................................................................................30

3.3.6 Editors........................................................................................................................... 30

3.3.6.1 Numeric Editor.............................................................................................................. 31

3.3.6.2 Text Editor.....................................................................................................................31

3.3.7 Special Tasks................................................................................................................31

3.3.7.1 Finding an Error............................................................................................................ 31

3.3.7.2 Managing Users............................................................................................................ 32

3.3.8 Logbook........................................................................................................................ 32

3.3.8.1 Intelligent Filtering......................................................................................................... 32

3.3.8.2 Chronological View....................................................................................................... 33

3.3.8.3 Manual Filter (Filter/Options).........................................................................................35

3.3.8.4 Scroll Function.............................................................................................................. 36

Device View.................................................................................................................. 29

4 Device View Description......................................................................39

4.1 System Overview........................................................................................................ 39

4.1.1 Forward Power..............................................................................................................39

4.1.2 Reflected Power............................................................................................................40

4.1.3 Transmitter.................................................................................................................... 40

4.1.4 N+1 Redundancy.......................................................................................................... 41

4.1.4.1 Manual Switchover........................................................................................................41

4.1.4.2 Automatic Switchover....................................................................................................41

4.1.4.3 Configuring N+1 Automatic Function............................................................................ 41

4.2 Transmitter.................................................................................................................. 43

4.2.1 Automatic Switchover....................................................................................................44

4.2.1.1 Automatic Input Signal.................................................................................................. 44

4.2.1.2 Automatic Exciter Switchover........................................................................................47

4.2.2 Transmitter Status.........................................................................................................48

4.2.3 Amplifiers...................................................................................................................... 49

4.2.4 Rack.............................................................................................................................. 64

4.2.5 Output Stage................................................................................................................. 65

4Operating Manual 2109.9110.02 ─ 07

Page 7

R&S®Tx9

Contents

4.3 Exciter DVB-T2............................................................................................................ 65

4.3.1

4.3.2 Setting Transmit Frequency and Output Power............................................................ 74

4.3.3 Signal Feed................................................................................................................... 75

4.3.3.1 Configuring Physical Inputs...........................................................................................75

4.3.3.2 Input Signal Switchover.................................................................................................80

4.3.4 Controlling Time of Transmission in Single-Frequency Networks (SFN)...................... 82

4.3.4.1 Settings......................................................................................................................... 84

4.3.5 Using Frequency Control.............................................................................................. 86

4.3.6 Precorrection at ATV.....................................................................................................88

4.4.1 Coder for DVB-T........................................................................................................... 92

4.4.2 Setting Transmit Frequency and Output Power............................................................ 96

4.4.3 Signal Feed................................................................................................................... 96

4.4.3.1 Configuring Physical Inputs...........................................................................................96

4.4.3.2 Input Signal Switchover...............................................................................................101

4.4.4 Controlling Time of Transmission in Single-Frequency Networks (SFN).................... 104

Coder for DVB-T2......................................................................................................... 65

4.4 Exciter DVB-T.............................................................................................................. 92

4.4.4.1 Settings....................................................................................................................... 106

4.4.5 Using Frequency Control............................................................................................ 108

4.4.6 Precorrection...............................................................................................................110

4.5 Exciter ISDB-T........................................................................................................... 116

4.5.1 Coder for ISDB-T........................................................................................................ 116

4.5.2 Setting Transmit Frequency and Output Power.......................................................... 121

4.5.3 Signal Feed................................................................................................................. 122

4.5.3.1 Configuring Physical Inputs.........................................................................................122

4.5.3.2 Input Signal Switchover...............................................................................................127

4.5.4 Controlling Time of Transmission in Single-Frequency Networks (SFN).................... 129

4.5.4.1 Settings....................................................................................................................... 132

4.5.5 Using Frequency Control............................................................................................ 134

4.5.6 Precorrection...............................................................................................................136

4.6 Exciter ATSC............................................................................................................. 142

4.6.1 Coder for ATSC...........................................................................................................142

4.6.2 Setting Transmit Frequency and Output Power.......................................................... 144

5Operating Manual 2109.9110.02 ─ 07

Page 8

R&S®Tx9

Contents

4.6.3 Signal Feed................................................................................................................. 145

4.6.3.1

4.6.3.2 Input Signal Switchover...............................................................................................150

4.6.4 Controlling Time of Transmission in Single-Frequency Networks (SFN).................... 152

4.6.4.1 Settings....................................................................................................................... 155

4.6.5 Using Frequency Control............................................................................................ 157

4.6.6 Precorrection...............................................................................................................160

4.7.1 Coder for DTMB.......................................................................................................... 165

4.8.1 Coder for ATV............................................................................................................. 169

4.8.2 Setting Transmit Frequency and Output Power.......................................................... 175

4.8.3 Signal Feed................................................................................................................. 176

4.8.4 Using Frequency Control............................................................................................ 179

4.8.5 Precorrection at ATV...................................................................................................181

4.9.1 Coder for DAB.............................................................................................................187

Configuring Physical Inputs.........................................................................................145

4.7 Exciter DTMB.............................................................................................................165

4.8 Exciter ATV................................................................................................................ 169

4.9 Exciter DAB............................................................................................................... 187

4.9.2 Using Frequency Control............................................................................................ 189

4.9.3 Precorrection...............................................................................................................191

4.10 Exciter FM.................................................................................................................. 197

4.10.1 Coder for FM............................................................................................................... 197

4.10.2 Setting Transmit Frequency and Output Power for FM...............................................199

4.10.3 Signal Feed................................................................................................................. 200

4.10.3.1 Configuring Physical Inputs.........................................................................................200

4.10.3.2 Input Signal Switchover...............................................................................................203

4.10.4 Using Frequency Control............................................................................................ 204

4.11 Switchless Combiner................................................................................................207

4.11.1 Settings....................................................................................................................... 208

4.12 Cooling System......................................................................................................... 210

4.12.1 Liquid Cooling (High‑Performance).............................................................................210

4.12.1.1 Configuring Switching Thresholds (Pressure) and Flow Volumes.............................. 210

4.12.1.2 Configuring Fans and Pumps......................................................................................213

4.12.1.3 Status of Cooling System............................................................................................214

6Operating Manual 2109.9110.02 ─ 07

Page 9

R&S®Tx9

Contents

4.12.2 Small Cooling – Simplified Liquid Cooling System (FM Transmitter)..........................214

4.12.2.1

4.12.2.2 Status.......................................................................................................................... 215

4.12.3 Air Cooling (Medium‑Power)....................................................................................... 217

Configuration of Cooling System.................................................................................215

5 Task View Description....................................................................... 219

5.1 Basic Settings........................................................................................................... 219

5.2 Parameters: Input Configuration............................................................................. 227

5.3 System Control..........................................................................................................229

5.3.1 Simple Network Management Protocol (SNMP)......................................................... 229

5.3.1.1 General....................................................................................................................... 229

5.3.1.2 Settings on Transmitter End........................................................................................229

5.3.1.3 Settings on Manager End............................................................................................230

5.3.1.4 Which MIBs Must Be Used?....................................................................................... 232

5.3.1.5 Which OIDs from a MIB Must Be Used?.....................................................................233

5.3.1.6 Setting Alarms.............................................................................................................234

5.3.1.7 Testing the SNMP Communications........................................................................... 235

5.3.1.8 Setting Alarms Using SNMP....................................................................................... 236

5.3.1.9 Type plates - the ENTITY MIB.................................................................................... 238

5.4 Maintain Software..................................................................................................... 240

5.4.1 Software Update......................................................................................................... 240

5.4.2 Backup/Restore...........................................................................................................242

5.5 Options.......................................................................................................................244

6 Operating the Device Manager......................................................... 247

6.1 Basic Settings........................................................................................................... 247

7 User Administration...........................................................................257

7.1 Creating New User Profiles...................................................................................... 257

7.2 Changing User Profiles (Users and Access Rights)..............................................257

7.3 Deleting User Profiles...............................................................................................258

7.4 Closing Active Sessions.......................................................................................... 258

7Operating Manual 2109.9110.02 ─ 07

Page 10

R&S®Tx9

Information about this Manual

1 Information about this Manual

This manual is part of the documentation for the R&S THU9 transmitter family from

Rohde & Schwarz. The individual manuals for the transmitter family have a modular

structure and complement each other.

Structure

The system manual, which is the central and overarching part of the overall documentation, describes all the steps involved in installing a transmitter.

Operation of the transmitter system after installation and the steps required to put the

system into operation are described in the operating manual.

The service manual describes all maintenance, troubleshooting and service tasks that

customers can carry out themselves. At certain points in the transmitter manual, the

reader is referred to the appropriate operating manual or service manual.

Contents

The manuals for the transmitter family describe all activities required for installation,

startup, operation, maintenance, troubleshooting and servicing of the transmitter and

its component parts. The appendix contains the interface descriptions and the technical documentation.

Safety

All skilled personnel working with a transmitter or its components have a duty to read

the associated manuals and to follow the safety measures described in the section

"Safety" and given at appropriate points in the manual. It must be ensured that the

transmitter and the individual components of the transmitter are used only for their

intended use. All activities connected with the transmitter or individual transmitter components must be carried out by skilled personnel. If activities require additional skills

and qualifications, this is indicated at the appropriate points in the manual.

Symbols and notation

The "warning triangle" symbol refers the reader to potential hazards. The degree of

danger is indicated by different signal words next to the warning symbol.

Instructions are given in numbered steps. All other formatting options are intended to

improve clarity and are self‑explanatory.

9Operating Manual 2109.9110.02 ─ 07

Page 11

R&S®Tx9

Introduction to Operation

Operation via R&S TDU900

3 Introduction to Operation

The R&S TDU900 is a display unit with a touchscreen function and a graphical user

interface for configuring Tx9 transmitter systems.

3.1 Operation via R&S TDU900

3.1.1 Opening Display

When in the idle state, the display is inside the R&S TDU900 operating unit.

Unlock the display by pressing firmly on the trapezoidal area.

1.

2. The display slowly slides forward out of the instrument.

3. Tilt the display until you have reached the most ergonomically comfortable angle

for operation.

3.1.2 Closing Display

1. Tilt the display to a horizontal position until you feel the display engage.

2. Push the display all the way into the R&S TDU900 housing until the display

engages in the transport lock.

3. The display illumination automatically switches off in this state.

Tip: Close the operating unit during long periods of inactivity to prolong the service

life of the backlighting.

3.1.3 Using Touchscreen Function

The display has a touchscreen function for operating all of the transmitter functions.

Using sharp‑edged objects can damage or destroy the surface. Therefore only use

your finger to operate the touchscreen.

1. A light touch on a button is enough to trigger a user action.

2.

A button lights up orange for as long as your finger remains there. The action is not

carried out until you remove your finger from the button.

23Operating Manual 2109.9110.02 ─ 07

Page 12

R&S®Tx9

Introduction to Operation

Operation via Browser

Tip: To cancel an inadvertently selected action, slide your finger to the side away

from the button highlighted orange and then lift your finger off the touchscreen.

3.2 Operation via Browser

The graphical user interface (GUI) of the Tx9 transmitter series has been implemented

in JAVA to ensure optimum user experience. Java technology provides maximum compatibility between different versions of operating systems and browsers.

Supported operating systems

Windows XP, Windows Vista (32 bit version)

●

Windows 7 (32 bit and 64 bit version)

●

Windows 8 (32 bit and 64 bit version)

●

Supported browsers

Google Chrome

●

Mozilla Firefox

●

Internet Explorer 7

●

Internet Explorer 8

●

Internet Explorer 9 (32 bit version)

●

Internet Explorer 10 (32 bit and 64 bit desktop version)

●

Supported JAVA virtual machines

Oracle (previously: Sun) JRE 7 in 32 bit version

●

Troubleshooting

You can ensure trouble‑free operation of the GUI in a browser by installing the browser

and the Java VM with their default settings on a computer configured with its factory

settings.

The following solutions are available if the computer settings differ from the standard

installation and there are problems:

The 64 bit version of Internet Explorer 9 is not supported

●

The 32 bit version, which is also installed, must be used

–

– Use another browser, such as Google Chrome or Mozilla Firefox.

Internet Explorer 10 is to be used on a 64 bit operating system (Windows 7/8):

●

"Enhanced Protection Mode" must be disabled in the browser under "Tools >

Options > Advanced" (this is the default setting).

Windows 8 Modern UI (previously: Metro) does not support Java.

●

– Start the desktop version of Internet Explorer 10 from the desktop.

– Start Google Chrome or Firefox from a link in Modern UI.

The error message "Application blocked by security settings" appears on the login

●

page.

24Operating Manual 2109.9110.02 ─ 07

Page 13

R&S®Tx9

Introduction to Operation

Operation via Browser

Set the security level to "High" in the Java Control Panel and restart the browser.

Only a 64 bit Java runtime environment (JRE) is installed.

●

Remove the 64 bit JRE and install the 32 bit version.

A 64 bit JRE is installed and required by another application (unlikely)

●

Install a 32 bit JRE to run in parallel with the 64 bit version.

You can determine the Java version (32 or 64 bit) as follows:

Open an input prompt window (Start > Run > Open, insert "cmd" and press <OK>)

●

Enter: java -d32 -version

●

The version number is shown if a 32 bit JRE is installed, otherwise an error mes-

●

sage appears.

Java security

In order to ensure the optimum protection against malicious software (malware), the

user interface for the Tx9 transmitter series has been implemented in Java. Java technology eliminates the need to run potentially unsafe ActiveX or Flash plug‑ins in your

browser. Java offers numerous security functions:

Java security settings

●

The security level in the Java Control Panel should be set to "High". A corresponding security warning appears then appears when opening a website with Java contents; you have to acknowledge this message. This prevents Java programs from

untrusted websites from being started unintentionally.

Detecting a secure browser

●

The Java version installed on the computer should be displayed at the bottom left

corner of the login page only after the security notice for running Java code has

been confirmed. If the Java version is displayed without confirming the security

notice, then you are using an unsecured browser or an outdated version of Java on

your computer.

Detecting the right web server

●

The security notice for running the Java code shows the IP address of the transmitter that loaded the Java code to the browser.

Transmitters in the Tx9 series are protected against malware by various security measures. Nevertheless, it is important to follow this general information on security to protect other computers in the same network against malware:

Always keep your browser updated to the latest version!

●

Always update your Java runtime environment to the most recent version immedi-

●

ately after starting your browser.

Avoid using unsecured browsers, such as MS Internet Explorer 7.

●

Always use a firewall to display Internet pages from servers outside your LAN.

●

The transmitter should be accessible within its protected intranet at all times. If this

●

is not technically feasible, take additional measures to secure communications

between the transmitter and browser (e.g. via a VPN).

25Operating Manual 2109.9110.02 ─ 07

Page 14

R&S®Tx9

Introduction to Operation

Structure of User Interface

3.2.1 Connection Setup and Login

1. Create a physical network connection to the transmitter. The following options are

available:

a) Remote access via WAN (Wide Area Network)

b) Local access directly to a transmitter using a LAN cable

2. Start the browser and enter the following information in the address bar:

a) IP address of the transmitter

The website for operating the transmitter is called (login page).

3. Enter your user name and password.

Note: The following login information is preconfigured at the factory

● User name: Query

Password: 1234

● User name: Operation

Password: 1234

● User name: Maintenance

Password: 1234

● User name: Configuration

Password: 1234

Change the user names and passwords after logging in for the first time chap-

ter 3.3.7.2, "Managing Users", on page 32.

After successfully logging in, the actual user interface is displayed.

3.3 Structure of User Interface

3.3.1 Elements of User Interface

The user interface is composed of the following elements:

Menu bar:

●

The menu bar provides access to the most important functions.

System status:

●

This display provides a constantly visible, general overview of the entire system

status.

Path bar:

●

The path bar shows the current position within the menu structure and provides the

ability to quickly return to higher menu levels.

Working area:

●

The various tasks and configuration steps are carried out in the working area.

26Operating Manual 2109.9110.02 ─ 07

Page 15

R&S®Tx9

Introduction to Operation

Structure of User Interface

1 = Menu bar

2 = System status

3 = Path bar

4 = Working area

3.3.2 Views

The user interface provides two different views of the transmitter system:

Device View

●

Task View

●

Device View

In this view, all of the transmitter's functions are structured in the form of block diagrams. All parameters relevant to operation are accessible.

27Operating Manual 2109.9110.02 ─ 07

Page 16

R&S®Tx9

Introduction to Operation

Structure of User Interface

Fig. 3-1: Hierarchical structure of a transmitter system

1 = View at transmitter system level

2 = View at single transmitter level

3 = View at exciter level

Task View

This view combines certain, frequently recurring tasks. A task includes exactly those

cross‑instrument parameters which are required for working on this task. All of the

parameters relevant to startup and maintenance are accessible.

Certain parameters are only accessible in the Task View.

3.3.3 Basic Functions on Menu Bar

All of the functions of a R&S TDU900 required for basic operation of a transmitter are

combined on the menu bar.

The following functions are available:

Logbook

●

Help

●

Local/Remote

●

Login/Logout

●

28Operating Manual 2109.9110.02 ─ 07

Page 17

R&S®Tx9

Device View

●

Task View.

●

Introduction to Operation

Structure of User Interface

3.3.3.1 Logbook

The logbook is used for logging all system events and for troubleshooting and error

analysis.

3.3.3.2 Help

This button is used to activate the help function. The following steps must be performed:

Press the Help button.

1.

All of the elements for which help information is available are identified by a blue

frame.

2. Select the desired element.

The corresponding help information is shown in a separate window.

3.3.3.3 Local/Remote

The transmitter can be operated via both local access and via remote access.

The Local/Remote button allows you to toggle between the two types of access.

The transmitter can be switched from remote operation to local operation from at any

time.

For safety reasons, remote operation is not possible if the system is currently being

operated locally.

The current status (L = Local, R = Remote) is shown directly on the Local/Remote button. The corresponding status of each transmitter is shown individually for multi‑transmitter systems.

3.3.3.4 Login/Logout

The login dialog allows a user to log in or log out of the system.

3.3.3.5 Device View

This button is used to switch to the Device View.

29Operating Manual 2109.9110.02 ─ 07

Page 18

R&S®Tx9

Introduction to Operation

Structure of User Interface

3.3.3.6 Task View

This button is used to switch to the Task View.

3.3.4 Navigation

The Device View is used to navigate through the transmitter menus. Pressing one of

the visibly raised block diagram elements allows you to navigate further into the transmitter structure. Parameters that may be spread out over multiple tabs are located on

the lowest menu level. A path bar is shown at the bottom of the screen. :

This has two functions:

Displaying the current menu level

●

Returning to higher menu levels

●

3.3.5 Input Fields

Additional information regarding the editability of respective parameters is visualized

using icons on the display and input fields. The various display forms have the following meaning:

●

This value can be edited without restriction.

●

This value can be edited, but has no effect in the current configuration.

●

This value has been changed and has not yet been stored in a preset.

●

This value cannot be edited with the user rights currently in effect.

3.3.6 Editors

All of the functions of a R&S TDU900 required for basic operation of a transmitter are

combined on the menu bar.

The following functions are available:

30Operating Manual 2109.9110.02 ─ 07

Page 19

R&S®Tx9

Introduction to Operation

Structure of User Interface

3.3.6.1 Numeric Editor

The numeric editor features the following functions.

1 = By pressing one of these buttons, the value is changed directly in the display without the use of the enter

button.

2 = The value entered using the numeric keypad is accepted by the system by pressing this button.

3 = Pressing this button discards all of the changes made in this window and restores the original value.

Violating the allowed value ranges causes an error message to appear and disables

the input elements (Increase/Decrease/Enter).

3.3.6.2 Text Editor

The text editor allows letters, digits and special characters to be entered.

3.3.7 Special Tasks

3.3.7.1 Finding an Error

There are two ways of locating an error:

Block diagrams

●

You can use the traffic light signaling of the elements in the block diagrams to find

the cause of an error in just a few steps, as long as the error is currently active.

31Operating Manual 2109.9110.02 ─ 07

Page 20

R&S®Tx9

Introduction to Operation

Structure of User Interface

Valuable information about an error's cause and tips for correcting the error can be

retrieved using the help function of the respective error message.

Logbook

●

Complex error situations including behavior over time can be analyzed using the

logbook. The help function again provides a multitude of valuable information.

3.3.7.2 Managing Users

User management is only available if the R&S TDU900 is operated using a browser.

The following login must be selected for this purpose:

User name: Superuser

Password: 1234

For more details, see chapter 7, "User Administration", on page 257

3.3.8 Logbook

All system events are recorded in the logbook. The following functions are available for

simplifying troubleshooting and error analysis:

Intelligent filtering

●

Events are intelligently prefiltered based on the context of the menu currently open.

Chronological view

●

Events are shown in their chronological order. Associated events are marked

accordingly.

Manual filter (Filter and Options)

●

Events or event groups can be chosen selectively with the help of specific criteria.

Scroll function

●

Enables fast navigation in long event lists

.

3.3.8.1 Intelligent Filtering

Depending on which menu is used to open the logbook, only events relevant in the

context of the respective menu are displayed. These filters significantly increase clarity

in the logbook.

System overview

●

Opening in the system overview: With MultiTX and N+1 systems, shows all of the

events affecting the core components (e.g. cooling, N+1 automatic switchover) as

well as the most important messages from individual transmitters within the system. With SingleTX systems, all of the detailed messages from the transmitter are

also shown.

Transmitter level:

●

Opening in a transmitter-specific menu: Shows in detail all of the events that affect

the respective transmitter (incl. exciters).

32Operating Manual 2109.9110.02 ─ 07

Page 21

R&S®Tx9

Introduction to Operation

Structure of User Interface

Depending on which menu is used to open the logbook, only events relevant in the

context of the respective menu are displayed. These filters significantly increase

clarity in the logbook.

Exciter level

●

Shows in detail all of the events that affect the respective exciter.

A total of up to 500 events is logged in the logbook.

3.3.8.2 Chronological View

All of the event messages are listed here in strictly chronological order. The most

recent messages are always shown at the top of the list.

Fig. 3-2: Logbook – chronological view

A thread consists of a group of messages that refer to the same event. The color of the

thread is determined by the most critical message within the thread. Clicking a thread

marker opens a window containing the associated messages.

33Operating Manual 2109.9110.02 ─ 07

Page 22

R&S®Tx9

Introduction to Operation

Structure of User Interface

Fig. 3-3: Logbook – thread

1 = Thread marker

2 = Click to open detail view

For most messages there is an entry indicating when the message occurred and when

it disappeared.

Each entry consists of the following information:

Alarm level

●

–

Error

–

Error no longer present/remedied

–

Warning

–

Warning no longer present

–

Info

Error message text

●

System component (control, amplifier, exciter, etc.)

●

Time

●

Clicking an entry within the thread view displays a detailed description with the following contents.

34Operating Manual 2109.9110.02 ─ 07

Page 23

R&S®Tx9

Introduction to Operation

Structure of User Interface

From: / To:

●

Displays the time when an event starts or ends.

State:

●

Indicates whether an event is still active or already remedied.

Duration:

●

Indicates how long an event was active.

Component:

●

Indicates the system components affected by an event.

Description:

●

Displays a detailed description of an event.

3.3.8.3 Manual Filter (Filter/Options)

Fig. 3-4: Logbook – filter/options

The filter function allows filtering of the messages according to the following criteria:

Level filter:

●

35Operating Manual 2109.9110.02 ─ 07

Page 24

R&S®Tx9

Introduction to Operation

Structure of User Interface

The messages can be filtered selectively according to individual or multiple levels

(Info | Warning | Fault) at the same time by selecting/deselecting the checkboxes

"Show Infos"

, "Show Warnings" and "Show Faults".

Selecting the "Show open issues only" checkbox will cause only messages that are

still active to be displayed, in other words, messages that still have not been remedied,

Component filter:

●

The messages can be filtered selectively according to individual or multiple system

components (System | Exciter A/B | Output Stage) at the same time by selecting/

deselecting the checkboxes.

Options:

●

The following options are available:

– Clear logbook

"Clear Logbook" is used to completely delete the contents of the logbook.

– Restore logbook

"Restore Logbook" is used to restore the logbook after it has been inadvertently

deleted.

– Messages

The "Messages" display shows the number of entries in the logbook.

– Close

"Close" is used to close the entire filter function.

3.3.8.4 Scroll Function

The scroll function enables navigation within a long event list and the selection and

detailed view of specific events.

36Operating Manual 2109.9110.02 ─ 07

Page 25

R&S®Tx9

Introduction to Operation

Structure of User Interface

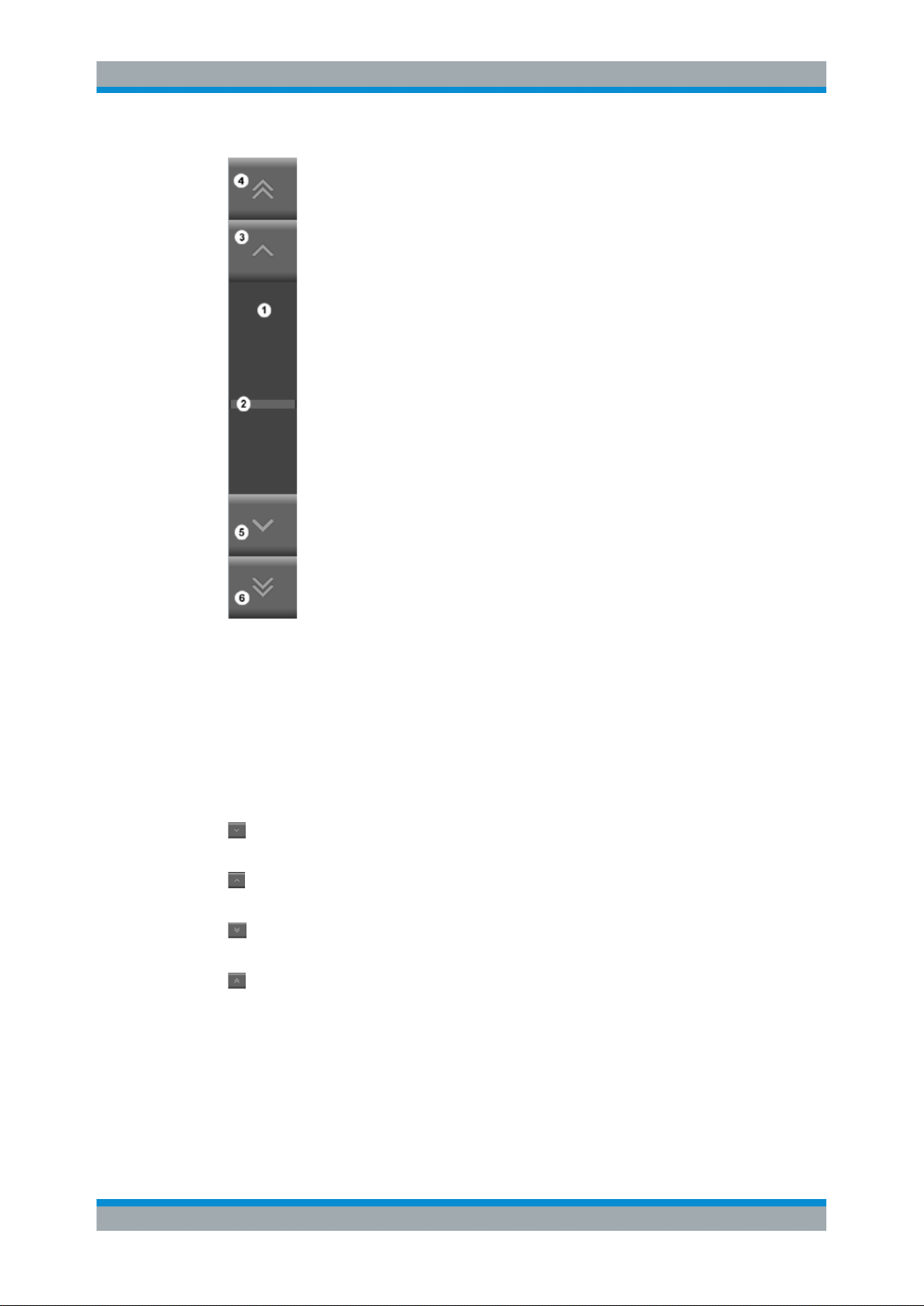

Fig. 3-5: Scroll functions

1 = Scroll box

2 = Scroll thumb

3 = Entry up

4 = Page up

5 = Entry down

6 = Page down

Clicking inside the scroll box moves the "scroll thumb" directly to the corresponding

position.

Entry down: This button is used to scroll down by one entry in the direction of the

oldest date.

Entry up: This button is used to scroll up by one entry in the direction of the most

recent date.

Page down: This button is used to scroll by one page at a time in the direction of the

oldest date.

Page up: This button is used to scroll by one page at a time in the direction of the

most recent date.

37Operating Manual 2109.9110.02 ─ 07

Page 26

R&S®Tx9

Device View Description

System Overview

4 Device View Description

4.1 System Overview

The screenshot below shows the Device View Home menu view. It represents the

transmitter system level. The function of the individual buttons and the meaning of specific parameters are explained in the following chapters.

Fig. 4-1: Device View Home menu view

4.1.1 Forward Power

Path:Device View Home > TX An

●

The "Forward Power" field shows the forward power of the transmitter system in kW.

This field lights up green provided that the forward power is above the user‑selectable

warning threshold. If the forward power drops to the warning level, the field lights up

yellow. If the forward power drops below the user‑selectable fault threshold, the field

lights up red.

Pressing the green area opens the "Power and Limits" view. The following user‑selectable values are displayed in the Forward Power field:

Power (in percent)

●

Forward power: can be set between 0 % and 130 %. The nominal transmitter

power corresponds to 100 %.

Warning Limit (in dB)

●

Warning threshold: can be set between 0 dB and ‒20 dB.

39Operating Manual 2109.9110.02 ─ 07

Page 27

R&S®Tx9

Device View Description

System Overview

Fault Limit (in dB)

●

Fault threshold: can be set between 0 dB and ‒20 dB.

RF Fail Timeout (in s).

●

Delay time: can be set between 0 s and 10 s. This is the time between undershooting of the "Fail Limit" fault threshold and indication of the fault in the transmitter status display.

4.1.2 Reflected Power

Path:Device View Home > TX An

●

The "Reflected Power" field indicates the reflected power of the transmitter system in

W. This field lights up green provided that the reflected power is below the user‑selectable warning threshold. If the reflected power exceeds this threshold, the field lights up

yellow. If the reflected power exceeds the user‑selectable fault threshold, the field

lights up red.

Pressing the green area opens the "Power and Limits" view. The following user‑selectable values are displayed in the Forward Power field:

Warning Limit (in dB)

●

Warning threshold: can be set between ‒28 dB and ‒17 dB.

Fault Limit (in dB)

●

Fault threshold: can be set between ‒17 dB and ‒14 dB.

4.1.3 Transmitter

The icons and buttons for the TX A1 to TX An and TX B transmitters (depending on the

system configuration) are shown in the "Device View Home" menu overview.

The function of the buttons is explained in the next chapter, see chapter 4.2, "Transmit-

ter", on page

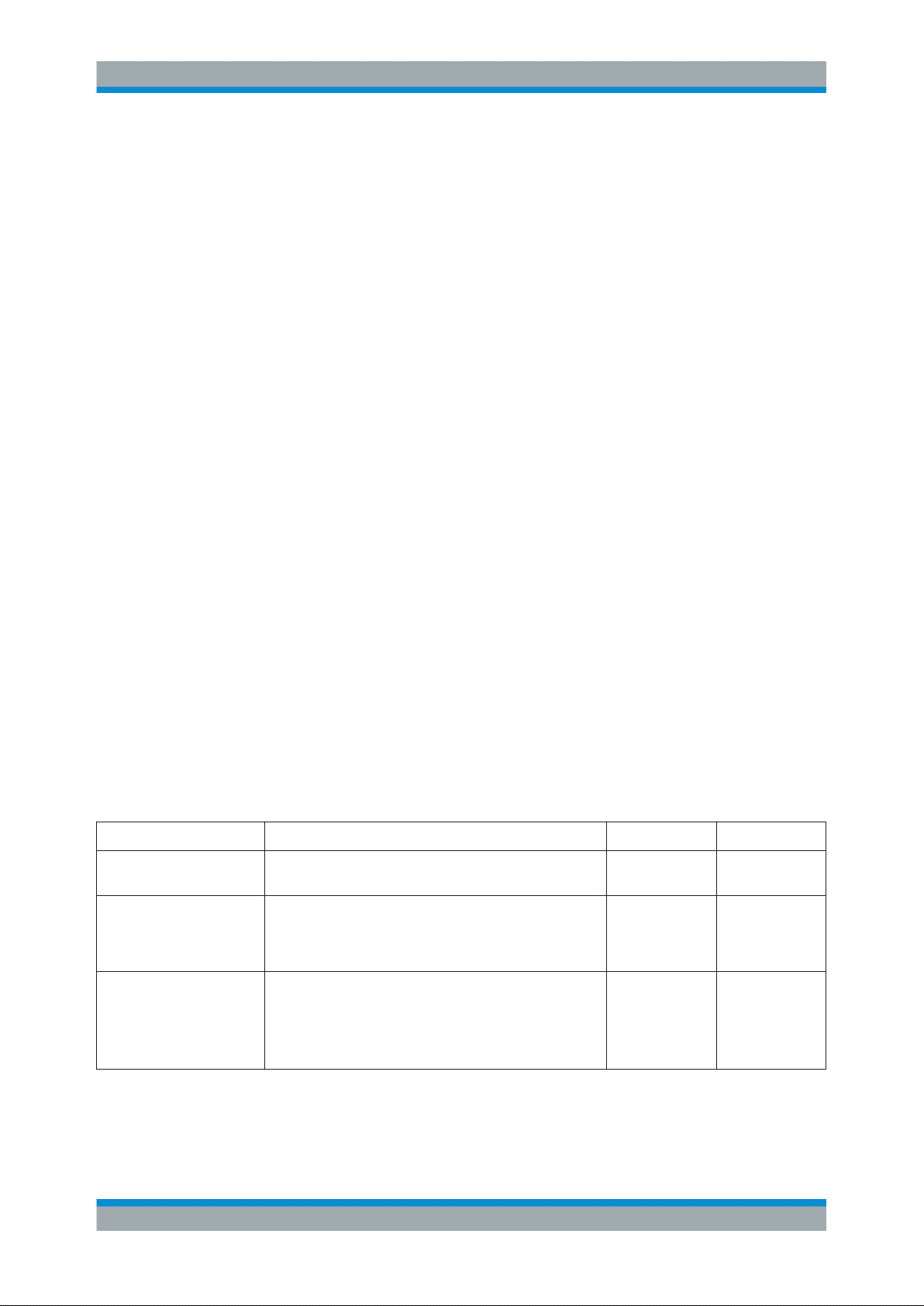

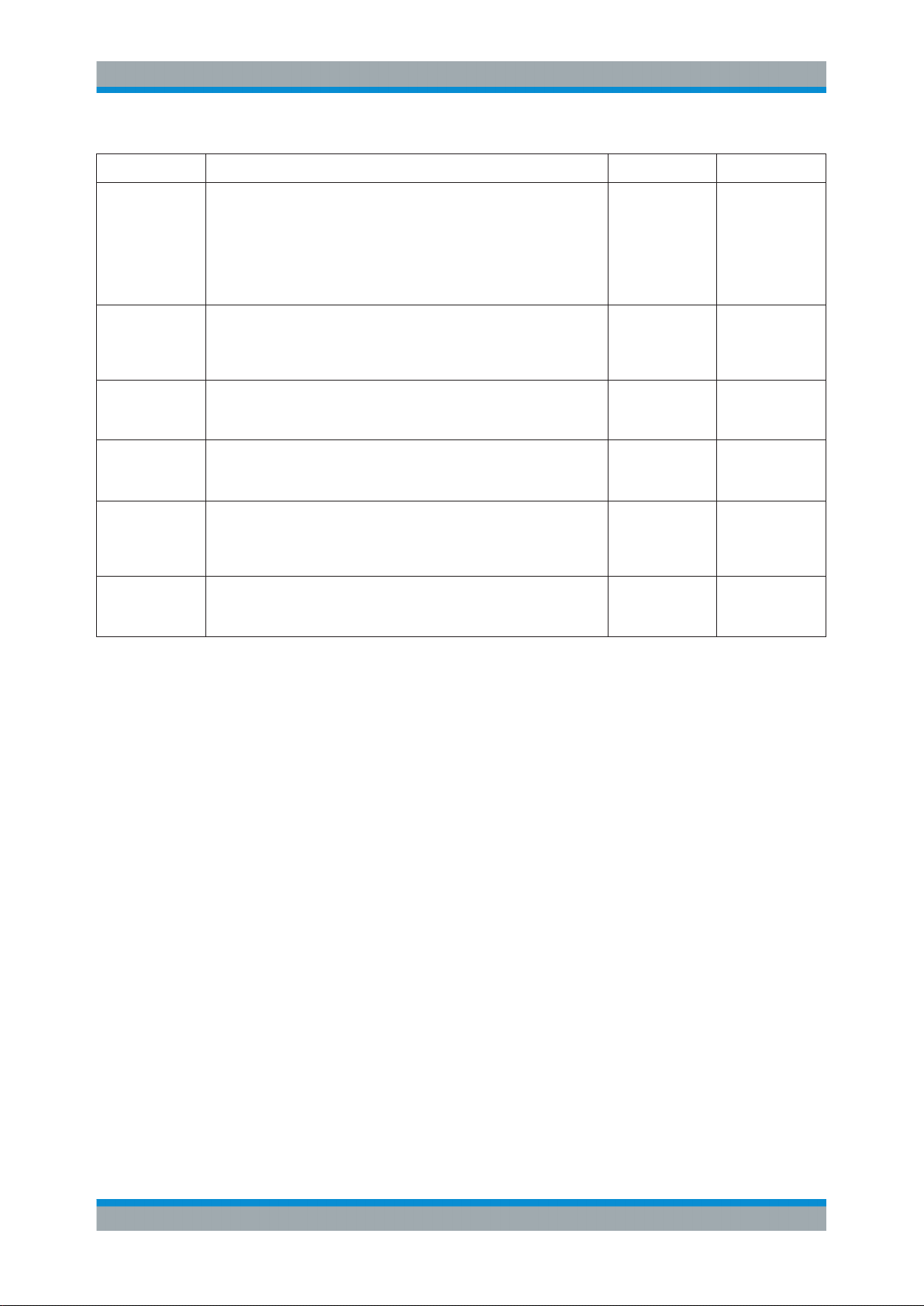

Name Description Value range Access right

Program On Switch used to switch the components in the program path

of the transmitter on and off.

Reserve On Switch used to switch all components in the standby path of

the transmitter on and off (standby exciter with "dual drive"

redundancy concept and standby output stage with "active

PA Reserve" redundancy concept).

Reset Faults Switch used to reset all faults stored in the transmitter.

Stored faults are: Reflection Fail.

Resetting stored faults can cause automatic redundancy

functions, which are currently in the switched-over state, to

switch back to their original preselected state.

43.

Off; On Operation

Off; On Operation

Operation

40Operating Manual 2109.9110.02 ─ 07

Page 28

R&S®Tx9

Device View Description

System Overview

Program

The currently active program 1 can be switched off using the "Program 1 – ON/OFF"

button.

4.1.4 N+1 Redundancy

The task of the N+1 automatic function is to provide a B standby transmitter for up to

eight A transmitters. This B transmitter takes over the program of an A transmitter if an

A transmitter signals a fault. The output of the B transmitter is normally connected to a

dummy antenna. The B transmitter is connected to an antenna by the N+1 automatic

function as soon as the B transmitter takes over the program of the A transmitter.

4.1.4.1 Manual Switchover

Manual switchover of a program from an A transmitter to the B transmitter is performed

by connecting the A transmitter concerned to the dummy antenna (button: To Load on

the corresponding A transmitter). As a result of this switchover, a) the A transmitter

becomes the standby transmitter for the B transmitter and b) the B transmitter is now

no longer available as the standby transmitter for other A transmitters (exception: priority control).

4.1.4.2 Automatic Switchover

If the N+1 automatic function is active and ready for operation and the A transmitter is

available for the N+1 automatic function, a fault in the A transmitter causes the program to switch over to the B transmitter. The N+1 automatic function signals the

switchover by changing its status to "changed". The user can now either acknowledge

the switchover by pressing the "Accept changeover" key and adopt it as the new operating state, or attempt by pressing the "Reset Faults" key to reset the N+1 automatic

function to the original state and to delete the fault which caused the switchover.

4.1.4.3 Configuring N+1 Automatic Function

The switching behavior of the N+1 automatic function with regard to checkout times

and automatic switchback can be configured according to individual requirements. Furthermore, for the B transmitter it is possible to define the A transmitter from which the

program settings are to be adopted when the B transmitter operates as a standby

transmitter.

Configuring Program‑Specific Settings

The B transmitter must store all program‑specific settings of all A transmitters internally

so that they can be activated immediately in the event of a fault. Program‑specific settings are all settings which directly affect the signal path through the transmitter, i.e.

settings for the coder, the exciter inputs and outputs, the transmit frequency and the

output power. The program‑specific settings are made at the A transmitters and stored

using the menu item "Save Preset" in the Task View of the A transmitter. The settings

41Operating Manual 2109.9110.02 ─ 07

Page 29

R&S®Tx9

Device View Description

System Overview

stored for the A transmitters are synchronized with the B transmitter automatically even

if the B transmitter was switched off when the settings were stored. If the program‑specific settings are changed at A transmitters without these settings being stored as presets, the changes will not be available on the B transmitter in the event of a switchover.

Presets can only be stored on the A transmitters.

Configuring Power‑Specific Settings

All settings which have been stored on an A transmitter as presets and synchronized

with the B transmitter can be overwritten individually in the B transmitter. This can be

used to calibrate the power test points of the B transmitter to the frequency and output

power of the respective A transmitter. To do so, the "Program Settings" of the A transmitter concerned must be activated in the B transmitter ("Load Program Settings") and

then the corresponding settings must be made in the menus of the B transmitter.

Finally, the changed settings must be stored in the B transmitter ("Save Tx B Set-

tings"). This must be repeated for all programs that the B transmitter can take over.

Settings that have been changed directly at the B transmitter are no longer synchronized with the B transmitter using the "Save Preset" function on the A transmitters. It is

therefore recommended to overwrite the preset settings of the A transmitters at the

B transmitter only for purposes of calibrating the power test points, and never to make

program‑specific settings directly at the B transmitter.

If a setting has been inadvertently changed on the B transmitter and stored for an

A transmitter, automatic synchronization can be reactivated for this setting value in the

following way:

On the B transmitter, set the setting value to the same value as on the A transmit-

●

ter.

Press "Save Tx B Settings" in the menu of the N+1 automatic function

●

This setting value is now synchronized again together with all program‑specific setting

values of the A transmitter.

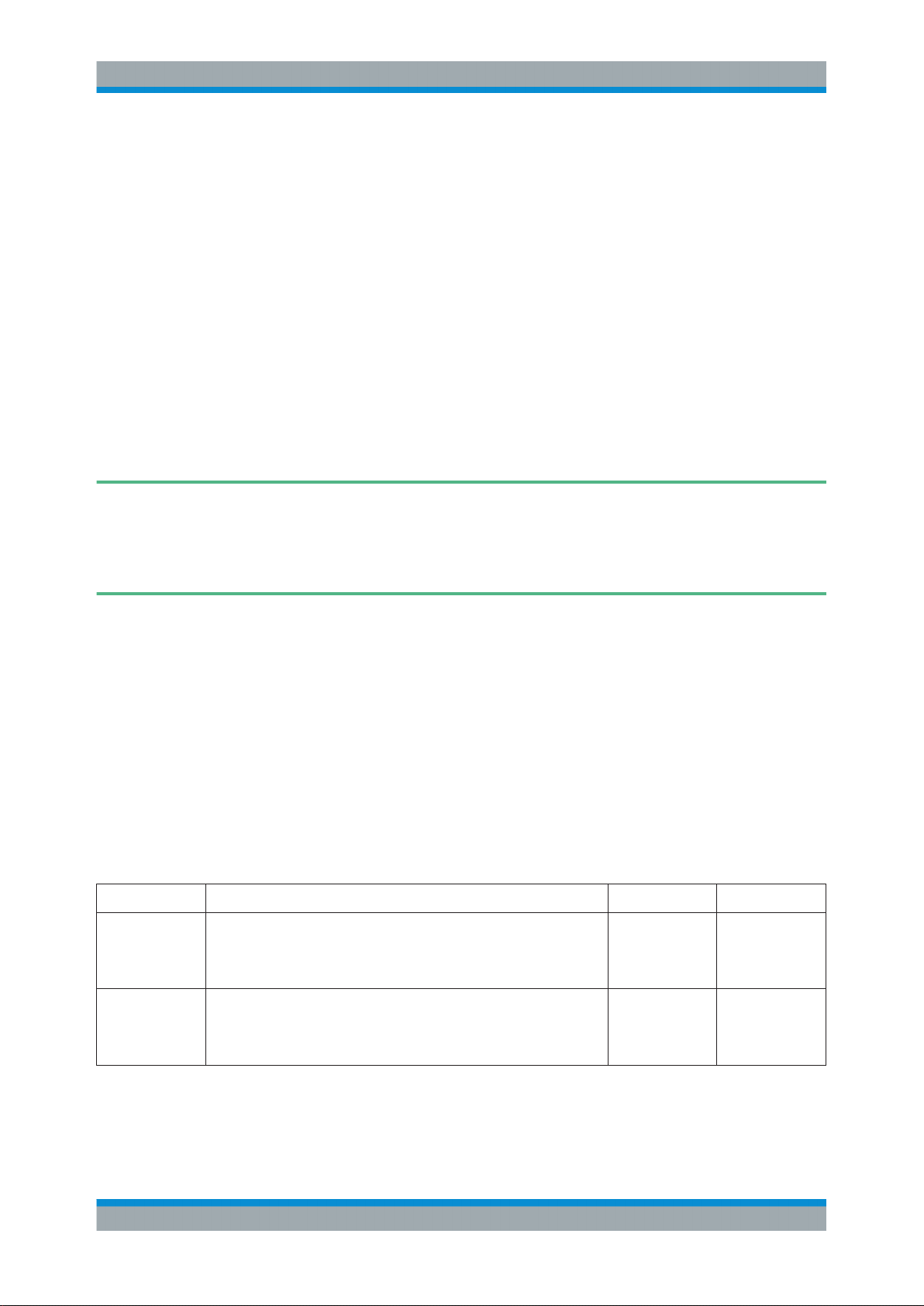

"N+1 Automatic" parameters

Path: "Device View (Home)"

●

Name Description Value range Access right

Automatic (Auto

Switch)

Guard Time (Auto

Switch)

Used to activate the n+1 automatic function. If the n+1 automatic function is active, a fault within an A transmitter causes a switchover and

the program of the A transmitter is taken over by the standby B transmitter.

Checkout time which must pass before an A transmitter is replaced by

the standby B transmitter. A long Guard Time suppresses switchover

operations caused by brief faults, but also reduces the availability of

the program.

> "Automatic" > "n+1 Automatic"

On, Off Read / Write

(Operation)

0 s to 60 s Read / Write

(Maintenance)

42Operating Manual 2109.9110.02 ─ 07

Page 30

R&S®Tx9

Device View Description

Transmitter

Name Description Value range Access right

Switch Mode

(Auto Switch)

Load Program

Settings (Auto

Switch)

Save Tx B Settings (Auto

Switch)

Automatic (Status)

Tx B is Reserve

for (Status)

RF Switch (Status)

Used to define the switching behavior of the N+1 automatic function.

Single switch: Switchover of an A transmitter to the B transmitter can

occur once only. Multiple switch: Following a switchover operation, the

system can switch back to the A transmitter automatically when the

A transmitter no longer signals a fault but the B transmitter indicates a

fault. If priority control is active, this switch should be set to Multiple

Switch.

Used to load the program‑specific settings of an A transmitter to the

B transmitter.

Used to save settings, which have been changed relative to the loaded

A transmitter, in the B transmitter.

Indicates the status of the N+1 automatic function by means of three

elements. If the N+1 automatic function is on, it can be "ready"/"not

ready" and at the same time "changed"/"not changed".

If a switchover operation has taken place, this indicates which program

of an A transmitter the B transmitter has taken over.

Indicates a fault if in the event of a switchover one of the RF switches

could not be turned correctly or if one of the jumpers has not been

positioned correctly on the patch panel (if used).

Single, Multiple Read / Write

(Maintenance)

Tx A1, Tx A2, Tx

A3, Tx A4, Tx A5,

Tx A6, Tx A7, Tx

A8

On, Off, Ready,

Not Ready,

Changed

Tx A1, Tx A2, Tx

A3, Tx A4, Tx A5,

Tx A6, Tx A7, Tx

A8

Ready / Not

Ready

Read / Write

Read Only

Read Only

Read Only

4.2 Transmitter

The screenshot below shows the Transmitter menu view. It represents the single transmitter level. The function of the individual buttons and the meaning of specific parameters are explained in the following chapters.

43Operating Manual 2109.9110.02 ─ 07

Page 31

R&S®Tx9

Device View Description

Transmitter

4.2.1 Automatic Switchover

4.2.1.1 Automatic Input Signal

The R&S®TCE900 in the R&S®TCE900 exciter configuration has an automatic switchover function which, in the event of a signal failure at one logical input, switches over to

the other logical input (provided that a valid input signal is available at the other logical

input). Before a failure occurs, the preselected input is active. The way in which this

automatic switchover function operates is determined by the following factors:

Automatic input switchover ON/OFF

If automatic switchover is OFF, the preselected input remains active even if the input

signal fails. If automatic switchover is ON and there is a failure at the (preselected)

input, switchover to the standby input takes place.

Input priority (Preferred Input = Logical Input 1/2)

Following switchover of the priority logical input to the standby input, the automatic system switches back to this priority input as soon as a signal returns. All switchover operations are delayed for the set delay times. If the signal fails at both the operating input

and the standby input, the priority input always remains active.

Inputs with equal priority (Preferred Input = none)

Following switchover of the active logical input, the second input with the same priority

remains active until the input signal fails on this input also. The automatic system

switches back to the preselected input, but only if a signal is present on it once again

(and if

"Switch to" is set to "reserve & back"). All switchover operations are delayed for

the set delay times.

44Operating Manual 2109.9110.02 ─ 07

Page 32

R&S®Tx9

Device View Description

Transmitter

Selecting this operating mode minimizes the number of switchover operations and, in

certain cases, the number of breaks in transmission.

Direction of switchover (Switch to)

The "to reserve and back"

and from the standby input, depending on which of the two logical inputs is currently

faulty.

The "reserve" switch position ensures that switchover takes place once only. Following

switchover, the automatic system switches to "switched" and the "Active" indicator disappears.

Switchback to the preselected input takes place when the active input is switched over

by pressing the input selector switch (Selector) and then selecting the preselected

input.

If the switch is set to "reserve", the switchback to the preselected input is suppressed.

Manual switchover between inputs

The input can be switched over in the

pressing the input selector switch ("Selector") and then selecting the desired input.

Depending on the configuration and switching state (ON/OFF) of the automatic input

signal switchover function, this menu contains either the switch used to change the

preferred input or the switch used to switch over the active input.

The automatic input signal switchover function is configured in the following way:

switch position enables switchover in both directions, i.e. to

"Home" > "Transmitter" > "Exciter" menu by

1. Navigate to the following destination using the menu bar:

"Devices" > "Tx<n>" > "Exciter A|B" > "Input Auto"

2. The following parameters must be defined on the Automatic tab:

a) for Configuration:

● Automatic:

● Preferred Input:

● Guard Time to Reserve:

● Guard Time Back:

● Switch to:

b) for Reserve Control:

● If Reserve Input Fails.

c) for Seamless Switching:

● Seamless Switching:

● Delay between Inputs

● Pre-Delay:

45Operating Manual 2109.9110.02 ─ 07

Page 33

R&S®Tx9

Device View Description

Transmitter

d) for Input Control:

● Force Exciter Changeover:

● Mute on Input Fail

● If Reserve Input fails

"Automatic input signal switchover" parameters

Name Description Value range Access right

Automatic (State) Indicates the state of the automatic input signal switchover function.

Not Ready:

●

The automatic switchover function is not ready. An input signal is

not present at the standby input or a switchover has already taken

place and the automatic switchover function is configured such

that automatic switchback is not permitted.

Ready:

●

The automatic switchover function is ready to switch the currently

active input over to the input currently not in use as soon as the

input signal of the currently active input fails.

Changed:

●

The automatic switchover function has switched over from the

preferred input to the standby input.

Seamless Switching

Automatic Activates automatic switchover of the input signal to the standby input

Preferred Input Used to select the preferred input which the automatic input signal

Active Input Used to select the active input to be used when the automatic input

Indicates whether seamless switching of the input signal is possible.

"Not Possible" always appears if only one input signal is supplied or in

cases where two different data streams are present at the two inputs. If

seamless switching is possible, it always takes place immediately

when required, regardless of whether a "Guard Time to Reserve" or

"Guard Time Back" has been set.

if the preferred input fails.

switchover function should use whenever possible.

signal switchover function is off. If the automatic switchover function is

on, the input can only be switched over using this switch if Preferred

Input is set to "No Preference" or a switchover to the standby input has

taken place.

undefined, Not

Ready, Ready,

Changed+Ready,

Changed+Not

Ready

undefined, not

Possible, Possible

Off, On Operation

Input 1, Input 2,

No Preference

Input 1, Input 2 Operation

Read only

Read only

Operation

Switch to Used to set the operational response of the automatic switchover func-

tion.

"To Reserve Only":

●

The automatic switchover function switches over once from the

preferred input to the standby input and then assumes the "not

ready" state". Switching the active input over manually to the preferred input reactivates the automatic switchover function.

"To Reserve and Back":

●

Following successful switchover to the standby input, the automatic switchover function can also switch back automatically if the

signal at the standby input fails.

Guard Time to

Reserve

Used to set a guard time which must elapse before the automatic

switchover function switches over to the standby input if the input signal at the preferred input fails. The set guard time has no effect if

seamless switching is possible. In this case, the switchover always

takes place immediately without interruption (i.e. seamlessly).

Reserve Only,

Reserve & Back

Maintenance

Maintenance

46Operating Manual 2109.9110.02 ─ 07

Page 34

R&S®Tx9

Device View Description

Transmitter

Name Description Value range Access right

Guard Time Back Used to set a guard time which must elapse before the automatic

switchover function switches back to the preferred input if the input signal at the standby input fails. If seamless switching is possible, switchover always takes place immediately without interruption regardless of

the set guard time. If "to Reserve Only" was selected as the "Direction", the set guard time has no effect.

If Reserve Fails Used to determine whether the signal at the standby input is to be

monitored.

If the transmitter is operated with only one input signal or the

●

standby input is connected only temporarily, "Do Not Show Warning" must be selected.

If two redundant input signals are normally supplied to the trans-

●

mitter, "Show Warning" must be selected.

4.2.1.2 Automatic Exciter Switchover

The automatic exciter switchover function enables a faulty exciter to be automatically

switched over to a functional standby exciter.

In the "Exciter Automatic" menu it is possible to switch automatic switchover between

two exciters on and off and to select the basic operating behavior of the function. The

"Switch Mode" switch is used to select whether automatic switchover to a standby

exciter is to take place once only (Single Switch) or whether a switchback is also to be

performed if the standby exciter signals a fault, but the preselected exciter is no longer

faulty (Multiple Switch).

Do Not Show

Warning, Show

Warning

Maintenance

Maintenance

It is also possible to set a guard time which must always expire before a switchover

can take place. This prevents unwanted switchover operations resulting from brief fault

events.

Operation

One of the two exciters can be preselected for operation by pressing the exciter selector switch (or via the ExciterAuto -> Exciter Switch tab). This exciter is switched on

together with the output stage by pressing the

"Program Path On" switch (in the

"Transmitter" menu). If necessary, the RF of the standby exciter can be switched on for

measuring and monitoring purposes by pressing the "Reserve Path (on)" switch (in the

"Transmitter" menu). A switchover operation causes the standby exciter to become the

main exciter and vice versa. The ON/OFF switches then act on the other exciter in

each case.

"Single Switch" Mode

If a fault occurs in the preselected exciter, the automatic switchover function will swap

the main and standby exciter and display an "Automatic changed" message.

Either the new state can now be accepted by changing the "preselected exciter"

("Automatic changed" disappears) or the automatic switchover function can be reset to

its original state by pressing "Reset Faults" (in the "Transmitter" menu).

47Operating Manual 2109.9110.02 ─ 07

Page 35

R&S®Tx9

Device View Description

Transmitter

"Multiple Switch" Mode

This mode is identical to "Single Switch", except that following a double switchover

operation the "preselected" exciter becomes the active exciter again. The

"Automatic

Changed" message is still displayed in this case. To delete this message, either the

new state of the automatic switchover can be adopted by pressing the "Recommand

Selection" button (in the "Transmitter" > "Exciter Auto" menu, "Exciter Switch" tab) or

the original state can be assumed again by pressing "Reset Faults" (in the Transmitter

menu).

4.2.2 Transmitter Status

Name Description Value range Access right

Program On Indicates whether all components in the program path of the

Reserve On Indicates whether all components in the reserve path of the

Overall LED Gray: Off

RF LED Gray: Off

Reflection LED Gray: Off

Off; On Read Only

transmitter have been switched on or off (reserve exciter

with "Dual Drive" redundancy concept and reserve output

stage with "active PA reserve" redundancy concept).

Off; On Read Only

transmitter have been switched on or off (reserve exciter

with "Dual Drive" redundancy concept and reserve output

stage with "active PA reserve" redundancy concept).

Read Only

Green: OK

Yellow: Warning

Red: Fault

Read Only

Green: OK

Yellow: Warning

Red: Fault

Read Only

Yellow: Warning

Red: Fault

Automatic (Backup Drive /

Dual Drive)

Ready (Backup Drive / Dual

Drive)

changed Over (Backup

Drive / Dual Drive)

switch Failed (Backup

Drive / Dual Drive)

Indicates whether the automatic exciter switchover function

has been activated. If the automatic switchover function is

active, the system will switch over to the standby exciter if

the active exciter fails.

Indicates whether the automatic exciter switchover function

is ready. If "not ready" is indicated, either the automatic

exciter switchover function has already switched over to the

standby exciter or a fault has occurred in the exciter switch.

Indicates whether the automatic exciter switchover function

has switched over to a reserve exciter.

Indicates that switchover to the reserve exciter has failed.

Off; On Read Only

Yes; No Read Only

Read Only

Read Only

48Operating Manual 2109.9110.02 ─ 07

Page 36

R&S®Tx9

Device View Description

Transmitter

4.2.3 Amplifiers

Fig. 4-2: "Amplifiers" menu view (Multi

‑

Tx)

R&S PHU901/R&S PHU902/R&S PHV902: "Status" parameters

Path: "Device View (Home)" > "Tx <n>" > "Output Stage" > "Amplifiers" > "Ampli-

●

fier <n>" > Tab "Status"

Name Description Value range Access right

Amplifier Indicates whether the amplifier has been switched on or off by the R&S

TCE900 Tx control.

Link Indicates the status of the communication link between the amplifier

and the R&S TCE900 Tx control.

The status is indicated as follows:

Ok

●

A link exists between the amplifier and the R&S TCE900 Tx control.

Warning

●

No link exists between the amplifier and the R&S TCE900 Tx control. Check the power supply of the amplifier.

RF In Fail Indicates that the amplifier is receiving an input signal, the level of

which is too low.

If this message occurs at all amplifiers at the same time, the fault is

●

located at the exciter switch, splitter or exciter.

If this fault occurs at only some of the amplifiers, the output level of

●

the exciters and splitter must be checked.

If the fault occurs at only one amplifier, the self‑engaging connec-

●

tor of the RF signal on the rear panel of the amplifier must be

checked for mechanical damage.

Off, On Read only

Ok, Warning Read only

No, Yes (warning)

Read only

49Operating Manual 2109.9110.02 ─ 07

Page 37

R&S®Tx9

Device View Description

Transmitter

Name Description Value range Access right

Mute Indicates that the amplifier is suppressing its output signal.

This indicator appears in the following cases:

No input signal is present

●

During bias adjustment

●

An external absorber signals via connector X11 that it is overheat-

●

ing.

Init Fail Indicates a fault if the amplifier detects an internal fault at power ON. If

other faults are indicated at the same time, the cause of these faults

must be rectified first. If the "Init Fail" fault still exists after other faults

have been rectified, the amplifier must be replaced.

Reflection Indicates whether the reflection at the RF output is becoming too great.

In this case, the antenna as well as the link between the amplifiers and

the antenna via the coupling switches and output stage switches (if

present) must be checked.

The occurrence of reflection is stored in a nonvolatile memory. After the

reason for the reflection has been rectified, this message must be reset

manually by pressing the "Reset Faults Transmitter" button or "Reset

Faults System" button.

RF Power Fail Indicates that the output power of the amplifier is more than 3 dB below

the nominal value.

Temp. Fail Indicates that the amplifier has overheated internally.

The shut‑off taps for the coolant must be checked. They must be open.

The occurrence of this message is stored in a nonvolatile memory. After

the reason for the overheating has been rectified, this message must be

reset manually by pressing the "Reset Faults Transmitter" button or

"Reset Faults System" button.

No, Yes (warning)

No, Yes (fault) Read only

No, Yes (warning)

No, Yes (fault) Read only

No, Yes (fault) Read only

Read only

Read only

Transistor Fail Indicates that one or more driver or power transistors are defective.

NOTE: Only personnel with the relevant special service training are

permitted to change the transistors.

BIAS Fail Indicates a fault if the quiescent current of one or more transistors can-

not be adjusted.

"No Error": Automatic quiescent current adjustment has been per-

●

formed properly.

Abort Adjust: Adjustment has been aborted because a constant

●

temperature has not settled in the amplifier. In this case, adjustment should be started again immediately after the fault has occurred.

"Error on PA On" or "Adjust Error": There is a technical fault in the

●

amplifier; the amplifier should be replaced.

Doherty Active Indicates whether the Doherty mode of the amplifier is active or not (not

valid for R&S TCE900).

No, Yes (fault) Read only

No Error, Abort

Adjust, Error on

PA On, Adjust

Error

Off, On Read only

Read only

50Operating Manual 2109.9110.02 ─ 07

Page 38

R&S®Tx9

Device View Description

Transmitter

Name Description Value range Access right

Freq. ID With R&S PHU902 only:

Indicates the frequency ranges in which the amplifier can be operated

in Doherty mode.

B2: 575 MHz to 660 MHz

B4: 470 MHz to 500 MHz; 660 MHz to 715 MHz

B5: 500 MHz to 530 MHz; 715 MHz to 750 MHz

B6: 530 MHz to 575 MHz; 750 MHz to 790 MHz