Page 1

Test and Measurement

Division

Operating Manual

Handheld Spectrum Analyzer

R&SFSH

1145.5850.03

1145.5850.13

1145.5850.23

1145.5850.06

1145.5850.26

1145.5850.18

1145.5973.12-14- 1

Page 2

Dear Customer,

R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

Trade names are trademarks of the owners.

1145.5973.12-14- 2

Page 3

R&S FSH Contents

Contents

Specifications

Safety Instructions

Certificate of Quality

EC-Certificate of Conformity

Support Center Address

List of R&S Representatives

1 Putting into Operation..............................................................................................................1.1

Front view..........................................................................................................................................1.1

Putting into Operation......................................................................................................................1.2

Unpacking the Instrument ...........................................................................................................1.2

Setting up the Instrument............................................................................................................1.3

Switching on the Spectrum Analyzer ..........................................................................................1.4

Spectrum Analyzer Connectors ..................................................................................................1.5

Screen Settings...........................................................................................................................1.8

Country-Specific Settings..........................................................................................................1.10

Setting the Date and Time ........................................................................................................1.11

Setting the date ............................................................................................................1.11

Setting the time ............................................................................................................1.11

Charging the Battery......................................................................................................................1.12

Selecting the Instrument Default Setup .......................................................................................1.13

External Reference / External Trigger Switchover ......................................................................1.14

Controlling the RF Attenuator.......................................................................................................1.15

Using a Preamplifier .......................................................................................................................1.15

PIN Entry..........................................................................................................................................1.17

Connecting Printers .......................................................................................................................1.19

Setting the Baud Rate for Remote Control ..................................................................................1.21

Enabling Options............................................................................................................................1.21

Checking the Installed Options.....................................................................................................1.22

1145.5973.12 I.1 E-14

Page 4

Contents R&S FSH

2 Getting Started ............................................................................................................................2.1

Measurements on CW Signals ........................................................................................................2.1

Level measurement ....................................................................................................................2.1

Setting the Reference Level........................................................................................................2.2

Frequency Measurements ..........................................................................................................2.3

Harmonic Measurements of a Sinewave Signal.........................................................................2.4

Power Measurements Using the Power Sensor .........................................................................2.5

Power and Return Loss Measurements with the R&S FSH-Z14 or the R&S FSH-Z44..............2.7

Two-Port Transmission Measurements ......................................................................................2.9

Measurement of Return Loss ...................................................................................................2.11

Performing Distance-To-Fault Measurements..........................................................................2.14

Operation in Receiver Mode..........................................................................................................2.20

Measuring the Carrier-to-Noise Ratio...........................................................................................2.25

Reference power/reference level ..............................................................................................2.26

Measuring the noise power.......................................................................................................2.27

Saving and Recalling Settings and Test Results ........................................................................2.28

Saving Measurement Results ...................................................................................................2.28

Saving Calibration Data ............................................................................................................2.29

Recalling Measurement Results ...............................................................................................2.30

Printing Out Measurement Results ..............................................................................................2.31

1145.5973.12 I.2 E-14

Page 5

R&S FSH Contents

3 Operation .......................................................................................................................................3.1

Screen Layout ...................................................................................................................................3.1

Screen layout for spectrum-mode measurements without markers ...........................................3.1

Screen layout when the marker mode is selected ......................................................................3.2

Entering Measurement Parameters ................................................................................................3.3

Entering values and texts............................................................................................................3.3

Entering units ..............................................................................................................................3.4

Menu Overview .................................................................................................................................3.5

Frequency entry........................................................................................................................3.5

Frequency span ........................................................................................................................3.5

Level setting ..............................................................................................................................3.5

Bandwidth setting.....................................................................................................................3.5

Sweep.........................................................................................................................................3.6

Trace setting..............................................................................................................................3.6

Measurement functions ...........................................................................................................3.7

Markers .....................................................................................................................................3.10

Save and print menu ..............................................................................................................3.12

Instrument setup.....................................................................................................................3.12

Status display............................................................................................................................3.12

Menus in the Receiver Mode (Option R&S FSH-K3) ...................................................................3.13

Menu for 3GPP BTS Code Domain Power Measurement (Option R&S FSH-K4) ...................3.16

1145.5973.12 I.3 E-14

Page 6

Contents R&S FSH

4 Instrument Functions ..........................................................................................................................4.1

Instrument Default Setup.................................................................................................................4.1

Status Display ...................................................................................................................................4.1

Setting the Frequency......................................................................................................................4.2

Entering the center frequency.....................................................................................................4.2

Setting a frequency offset ...........................................................................................................4.2

Entering the center-frequency step size .....................................................................................4.3

Entering the start and stop frequency .........................................................................................4.4

Working with channel tables .......................................................................................................4.4

Setting the Span ...............................................................................................................................4.6

Setting the Amplitude Parameters..................................................................................................4.7

Setting the reference level ..........................................................................................................4.8

Entering the display range ..........................................................................................................4.9

Entering the display unit..............................................................................................................4.9

Entering the reference offset ....................................................................................................4.10

Entering the input impedance ...................................................................................................4.10

Setting the Bandwidths .................................................................................................................4.11

Resolution bandwidth................................................................................................................4.11

Video bandwidth........................................................................................................................4.13

Setting the Sweep...........................................................................................................................4.15

Sweep time ...............................................................................................................................4.15

Sweep mode .............................................................................................................................4.16

Trigger.......................................................................................................................................4.16

Trace Settings.................................................................................................................................4.19

Trace mode...............................................................................................................................4.19

Detector ....................................................................................................................................4.20

Trace memory...........................................................................................................................4.22

Trace mathematics ...................................................................................................................4.23

Using the Markers ..........................................................................................................................4.24

Automatic marker positioning ...................................................................................................4.25

Using more than one marker at a time (multimarker mode).....................................................4.27

Marker functions .......................................................................................................................4.30

Measuring the noise power density..............................................................................4.30

Measuring the frequency..............................................................................................4.31

AF demodulation.......................................................................................................................4.32

1145.5973.12 I.4 E-14

Page 7

R&S FSH Contents

Using the Display Line ...................................................................................................................4.33

Setting and Using the Measurement Functions..........................................................................4.34

Measuring the channel power of continuously modulated signals ..........................................4.34

Selecting the standard ..............................................................................................................4.35

Setting the reference level ........................................................................................................4.37

Setting the channel bandwidth..................................................................................................4.37

Changing the span....................................................................................................................4.38

Power display............................................................................................................................4.39

Power measurements on TDMA signals......................................................................................4.41

Selecting a standard .................................................................................................................4.41

Setting the measurement time ..................................................................................................4.43

Optimizing the reference level ..................................................................................................4.43

Power readout...........................................................................................................................4.44

Setting the trigger......................................................................................................................4.44

Measuring the occupied bandwidth .............................................................................................4.45

Selecting a standard .................................................................................................................4.46

Setting the reference level ........................................................................................................4.47

Setting the channel bandwidth..................................................................................................4.48

Entering the power percent to determine the occupied bandwidth ...........................................4.49

Displaying the occupied bandwidth...........................................................................................4.49

Changing the span....................................................................................................................4.50

Measuring the Carrier-to-Noise Ratio...........................................................................................4.51

Determining the reference ........................................................................................................4.52

DIGITAL Tx mode........................................................................................................4.52

ANALOG TV mode ......................................................................................................4.53

CW Tx mode................................................................................................................4.53

Manual reference mode ...............................................................................................4.54

Setting the reference channel ......................................................................................4.54

Setting the reference channel bandwidth.....................................................................4.55

Setting the analyzer reference level for the reference channel measurement.............4.56

Inserting the C/N reference ..........................................................................................4.57

Units of the C/N reference ...........................................................................................4.57

Measuring the noise channel power and calculating the carrier power/noise power ................4.57

Setting the noise channel.............................................................................................4.58

Setting the noise channel bandwidth ...........................................................................4.59

Setting the R&S FSH reference level during noise channel measurement .................4.59

Selecting the C/N result display ...................................................................................4.60

C/N measurement result display..................................................................................4.60

Changing the span.......................................................................................................4.61

1145.5973.12 I.5 E-14

Page 8

Contents R&S FSH

Using the R&S FSH in receiver mode...........................................................................................4.62

Setting the frequency ................................................................................................................4.63

Setting the reference level ........................................................................................................4.65

Setting the bandwidth................................................................................................................4.66

Setting the detector...................................................................................................................4.67

Setting the measurement time ..................................................................................................4.67

Measurement on multiple frequencies or channels (scan) .......................................................4.68

Measurements using the power sensor.......................................................................................4.70

Connecting the power sensor ...................................................................................................4.70

Zeroing the power sensor .........................................................................................................4.72

Selecting the unit for the power readout ...................................................................................4.73

Setting the averaging time ........................................................................................................4.74

Taking additional loss or gain into account ...............................................................................4.74

Measuring forward and reflected power ......................................................................................4.76

Zeroing the power sensor .........................................................................................................4.78

Setting the power measurement weighting...............................................................................4.79

Selecting the unit for the power readout ...................................................................................4.80

Taking additional attenuation into account................................................................................4.82

Two-port measurements with the tracking generator ................................................................4.83

Measuring the transmission of two-ports ..................................................................................4.85

Vector transmission measurement ..............................................................................4.88

Measuring the transmission magnitude .......................................................................4.90

Measuring the transmission phase ..............................................................................4.90

Measuring the electrical length when measuring transmission....................................4.93

Measuring the group delay when measuring transmission..........................................4.94

Transmission measurement using the connected VSWR Bridge R&S FSH-Z3..........4.96

Spectrum measurements with the VSWR Bridge R&S FSH-Z3 or R&S FSH-Z2

connected.....................................................................................................................4.97

Setting for detecting the R&S FSH-Z3 in the transmission and spectrum meas. ........4.98

Supplying DC voltage to active DUTs..........................................................................4.99

Reflection measurements ............................................................................................4.99

Scalar measurement of reflection ..............................................................................4.100

Vector measurement of reflection..............................................................................4.102

Measuring the reflection magnitude...........................................................................4.105

Measuring the reflection phase..................................................................................4.105

Measuring the electrical length when measuring reflection .......................................4.106

Displaying the reflection in the Smith chart.................................................4.107

Measuring the group delay when measuring reflection..............................................4.112

Spectrum measurements with the VSWR Bridge R&S FSH-Z3 or R&S FSH-Z2

connected...................................................................................................................4.113

Settings for detection of the R&S FSH-Z2 and R&S FSH-Z3 ....................................4.114

One-Port Measurement of Cable Loss .......................................................................................4.115

1145.5973.12 I.6 E-14

Page 9

R&S FSH Contents

Cable Measurements....................................................................................................................4.116

Cable selection .......................................................................................................................4.117

Selecting the frequency range ................................................................................................4.120

Calibrating the test setup ........................................................................................................4.121

Locating cable faults by means of the marker function ..........................................................4.124

Measuring spectrum and reflection.........................................................................................4.127

Further information .................................................................................................................4.128

Setting the span .........................................................................................................4.128

Selecting the center frequency...................................................................................4.129

Measurement .............................................................................................................4.130

Length measurement accuracy..................................................................................4.130

Using Limit Lines..........................................................................................................................4.131

Measurements with limit lines .................................................................................................4.133

Definition range of limit lines ...................................................................................................4.134

Data sets containing limit lines................................................................................................4.134

Measuring with Transducer Factors...........................................................................................4.135

Unit for measurements with transducers ................................................................................4.137

Reference level settings for measurements with transducers ................................................4.137

Frequency range of transducer...............................................................................................4.138

Data sets containing transducer factors .................................................................................4.138

Field-Strength Measurement with Isotropic Antenna...............................................................4.139

Connecting the antenna to the R&S FSH ...............................................................................4.139

Measurement of the resultant field strength in a transmission channel with large bandwidth 4.141

Code Domain Power Measurement on 3GPP FDD Signals ......................................................4.148

Saving and Loading Instrument Settings and Measurement Results.....................................4.153

Saving results .........................................................................................................................4.154

Entering a data set name........................................................................................................4.155

Loading measurement results ................................................................................................4.155

Deleting saved data sets.........................................................................................................4.156

Deleting all data sets...............................................................................................................4.157

Printing out Measurement Results .............................................................................................4.158

Measurements ..............................................................................................................................4.159

How a spectrum analyzer operates ........................................................................................4.159

1145.5973.12 I.7 E-14

Page 10

R&S FSH3, R&S FSH6, R&S FSH18 Data Sheet

Specifications

Specifications are valid under the following conditions: 15 minutes warm-up time at ambient temperature, specified environmental conditions met and

calibration cycle adhered to. Data without tolerances: typical values. Data designated as "nominal": design parameters, i.e. not tested.

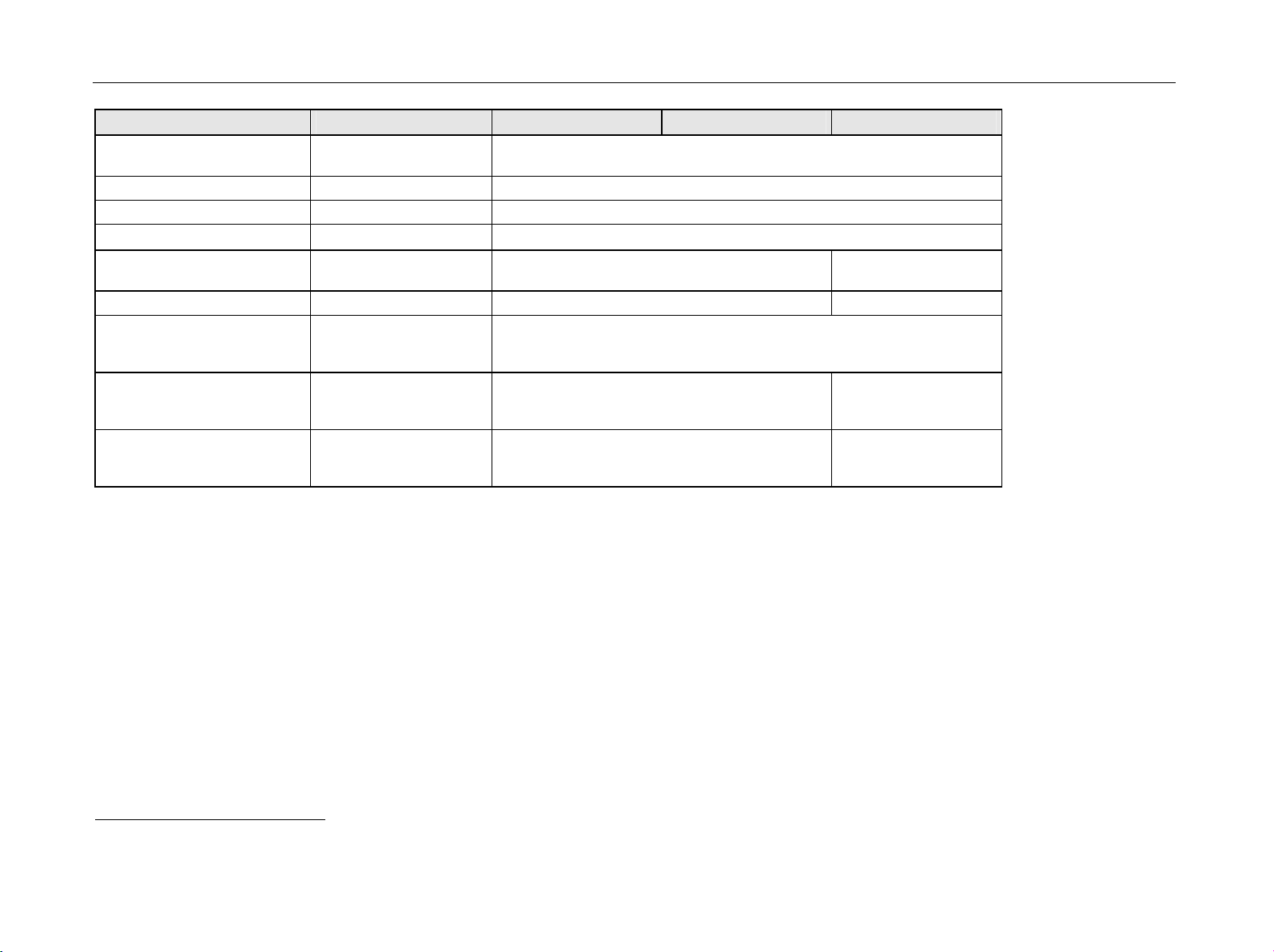

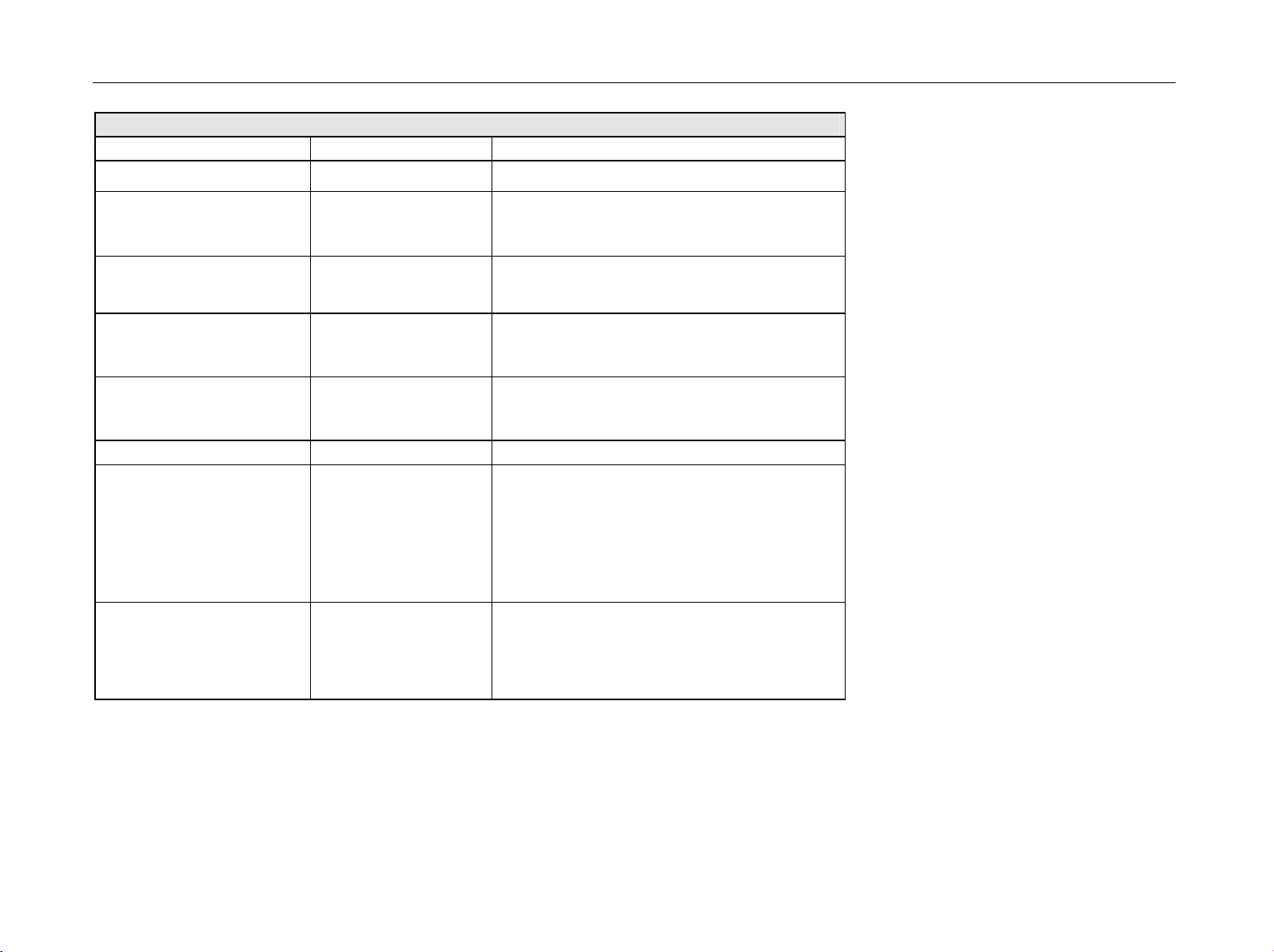

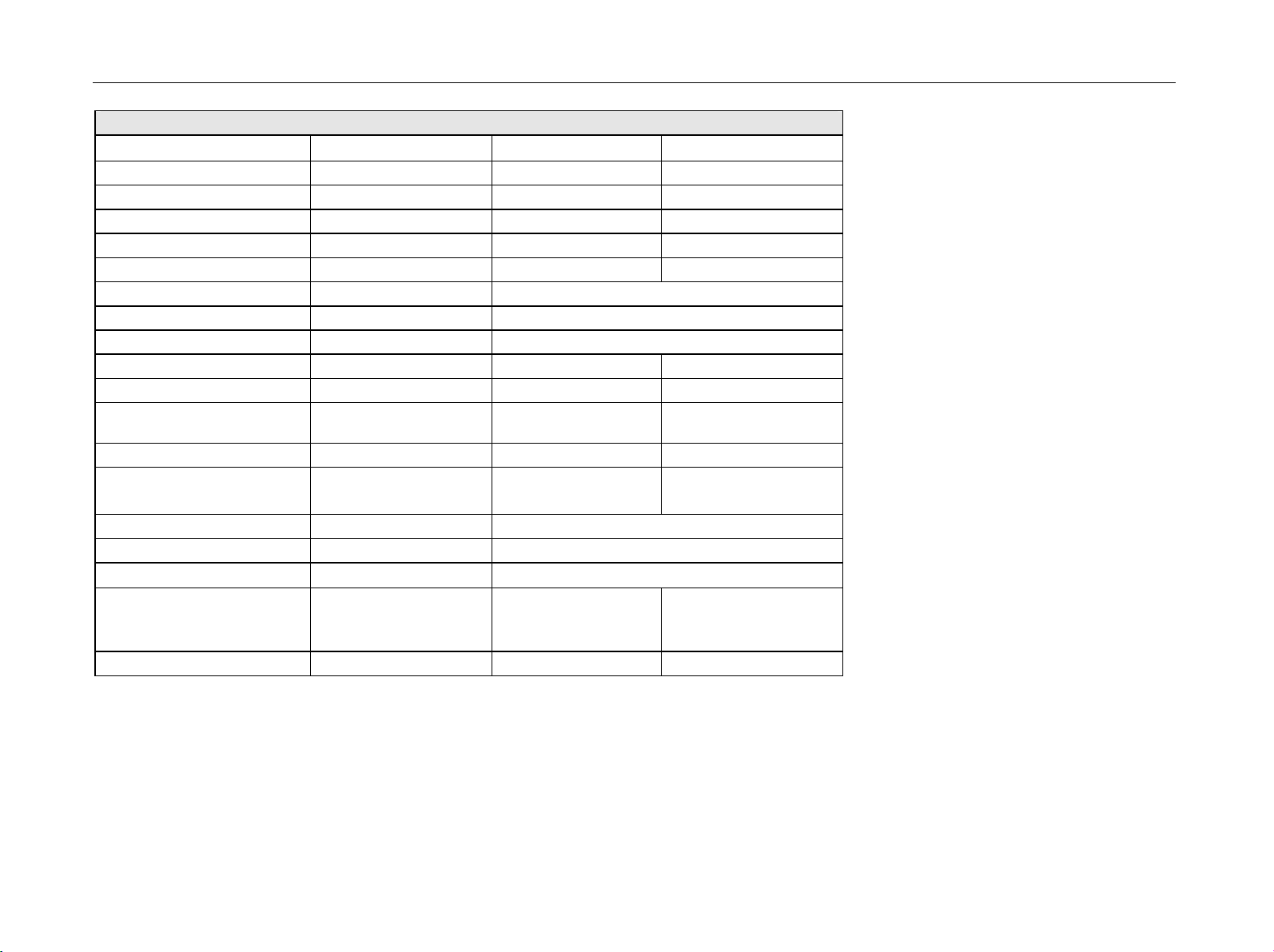

Specification Condition R&S FSH3 R&S FSH6 R&S FSH18

Frequency

Frequency range 100 kHz to 3 GHz 100 kHz to 6 GHz 10 MHz to 18 GHz

Reference frequency

Aging 1 ppm/year

Temperature drift 0 °C to 30 °C

30 °C to 50 °C

Frequency counter

Resolution 1 Hz

Frequency span 0 Hz, 100 Hz to 3 GHz 0 Hz, 100 Hz to 6 GHz 0 Hz, 100 Hz to 18 GHz

1145.5850.13 0 Hz, 1 kHz to 3 GHz - -

Spectral purity

SSB phase noise f = 500 MHz, 20 to 30 °C

30 kHz from carrier <-85 dBc/(1 Hz) <-85 dBc/(1 Hz)

100 kHz from carrier < -100 dBc/(1 Hz) < -90 dBc/(1 Hz)

1 MHz from carrier < -120 dBc/1 Hz) < -100 dBc/(1 Hz)

Sweep time span = 0 Hz 1 ms to 100 s

span > 0 Hz 20 ms to 1000 s, min. 20 ms/600 MHz

Bandwidths

Resolution bandwidths

(-3 dB)

Tolerance

1145.5850.13 1, 3, 10, 30,100, 200, 300 kHz, 1 MHz

1145.5850.03, .23,

1145.5850.06, .26, .18

300 kHz ± 5 %, nominal

1 MHz

in addition 2 ppm/10°C

In addition 100, 300 Hz

2 ppm

± 10 %, nominal

1145.5973.12 TI.1 E-14

Page 11

Data Sheet R&S FSH3, R&S FSH6, R&S FSH18

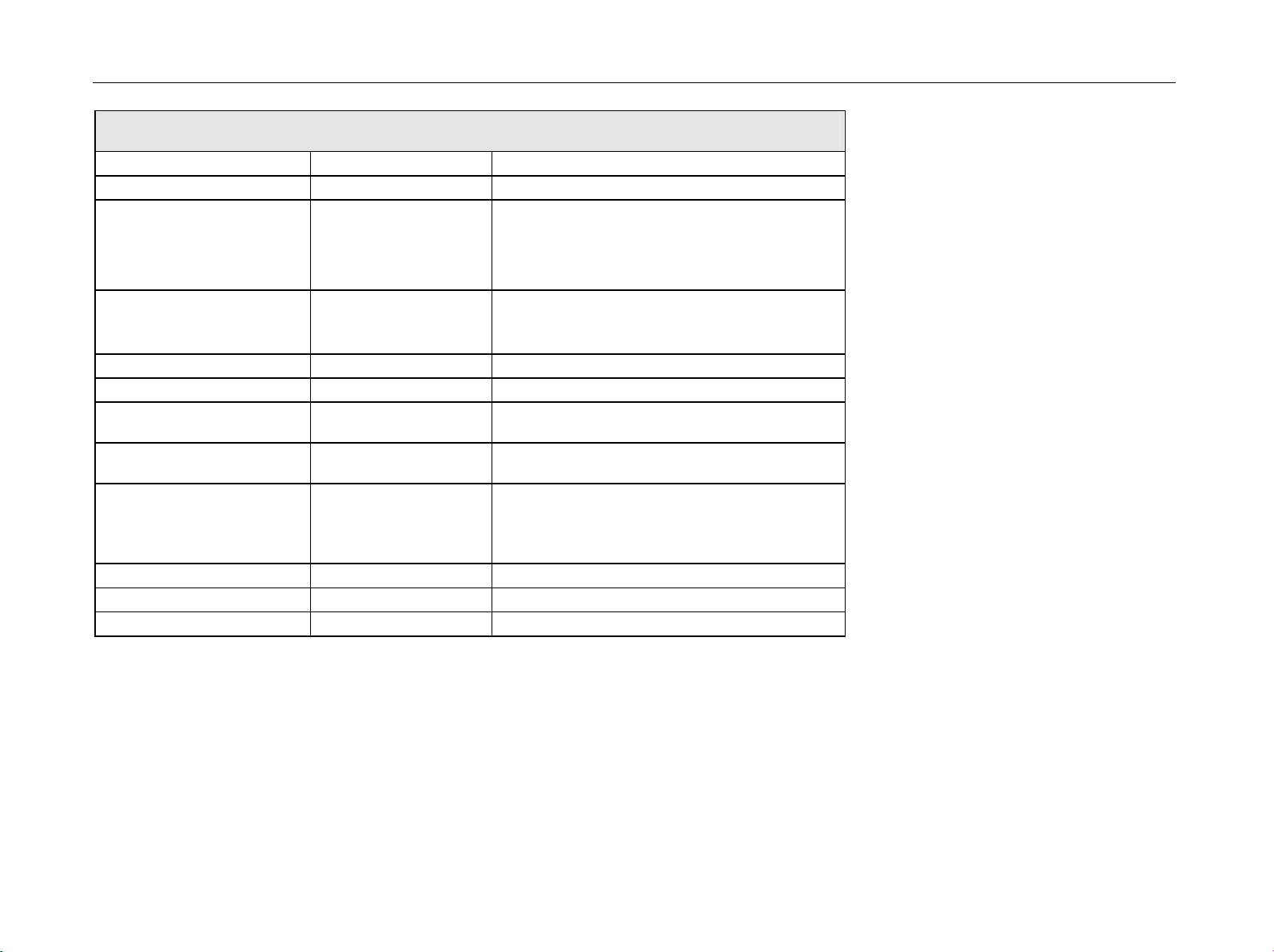

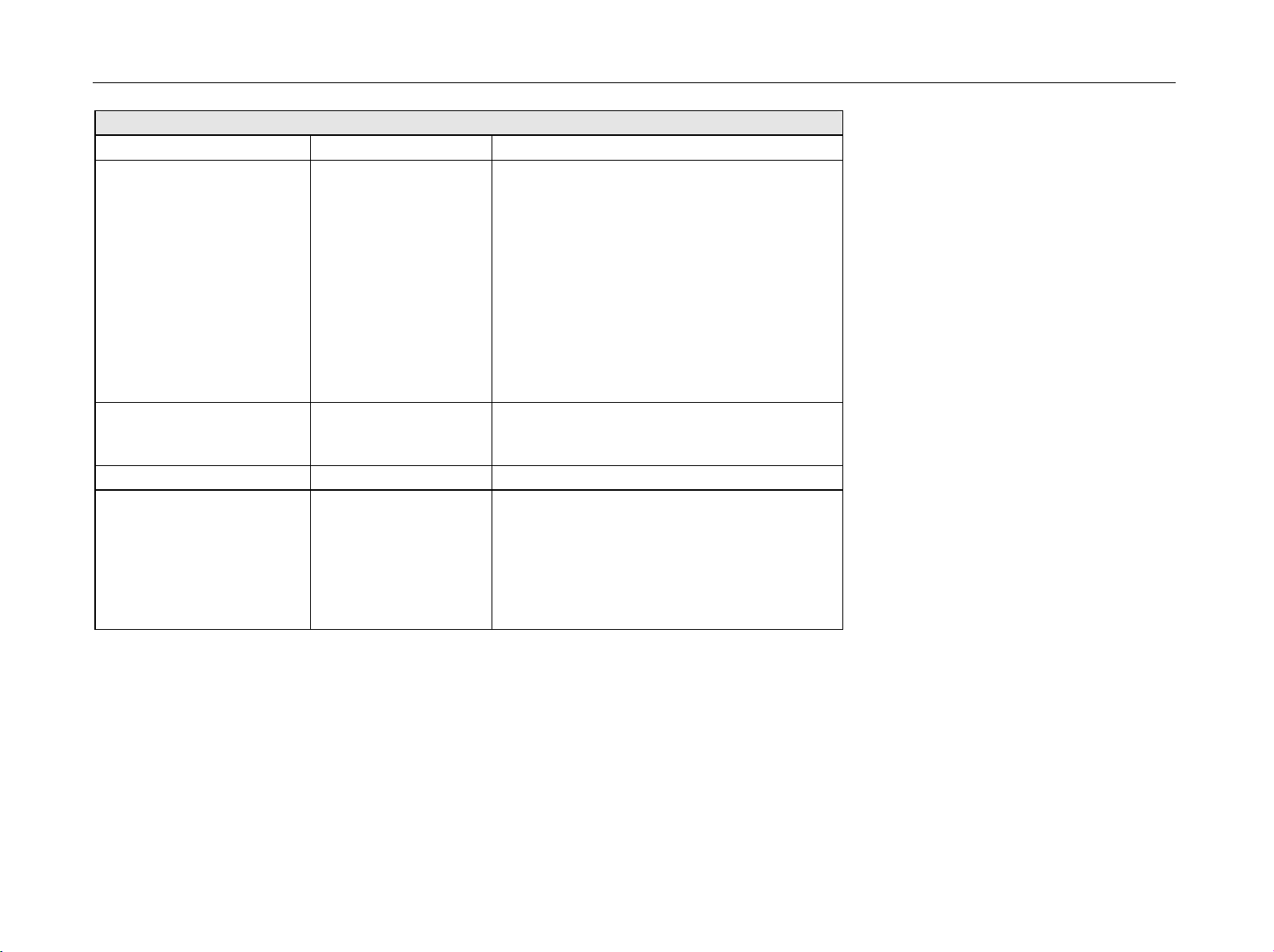

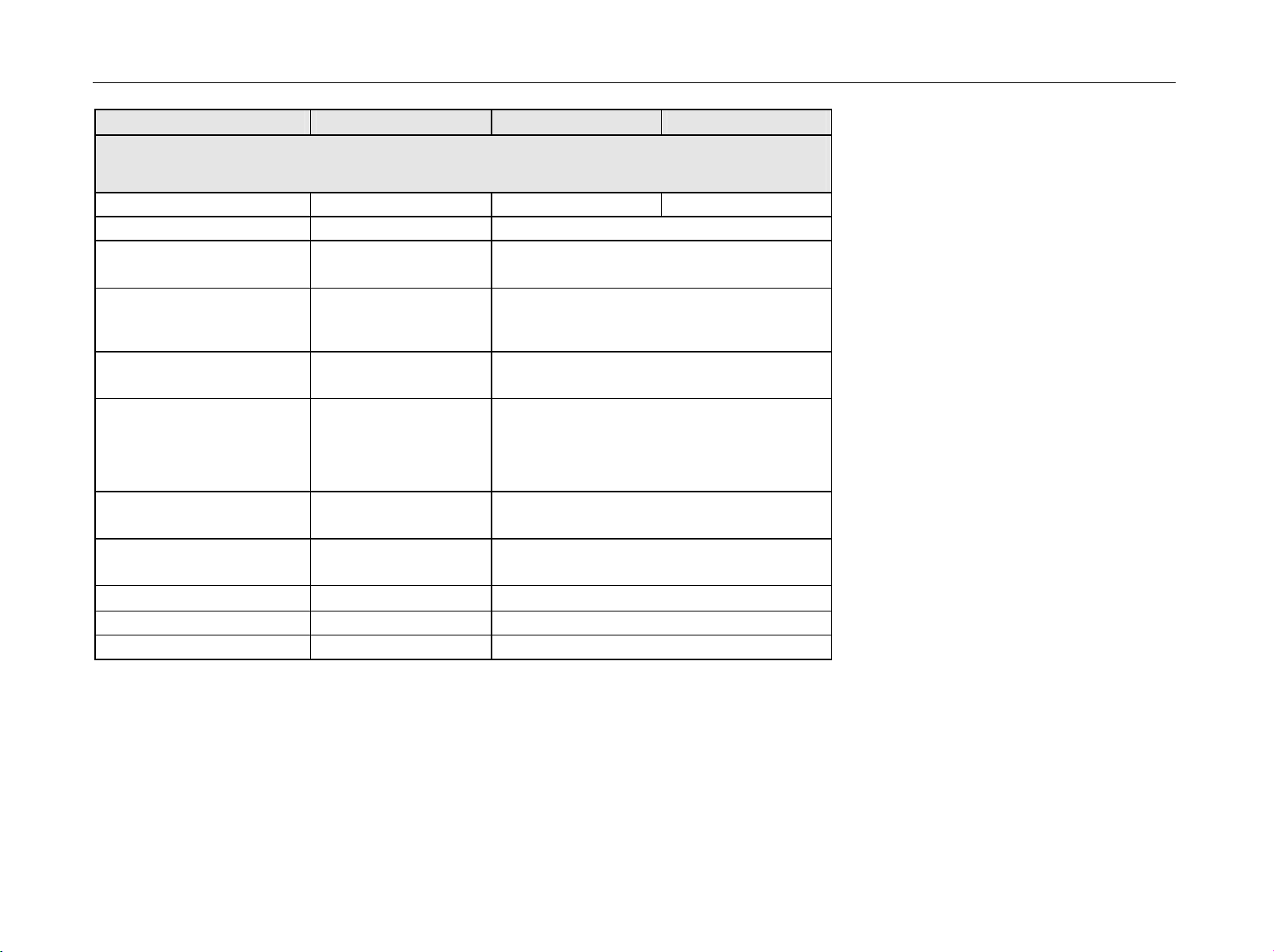

Specification Condition R&S FSH3 R&S FSH6 R&S FSH18

Resolution bandwidths

(-6 dB)

Video bandwidths 10 Hz to 1 MHz in 1, 3 steps

Amplitude

Display range

Maximum permissible DC

voltage at RF input

Maximum power 20 dBm, 30 dBm (1 W) for max. 3 minutes 20 dBm

Intermodulation-free dynamic

range

Carrier offset 2 MHz

Carrier offset > 2 MHz 66 dB (+13 dBm third-order intercept) 50 dB (nominal)

with option R&S FSH-K3

installed

third-order IM products,

2 x -20 dBm, reference

level = -10 dBm

in addition 200 Hz, 9 kHz, 120 kHz, 1 MHz

average noise level displayed to +20 dBm

50 V / 80 V1)

50 V

60 dB (+10 dBm third-order intercept) 50 dB (nominal)

(+5 dBm third-order

intercept)

(+5 dBm third-order

intercept)

1

80 V valid as of serial number 100900 (model 1145.5850.03) or 101600 (model 1145.5850.13); models 1145.5850.23, 1145.5850.06 and .26 all serial numbers.

1145.5973.12 TI.2 E-14

Page 12

R&S FSH3, R&S FSH6, R&S FSH18 Data Sheet

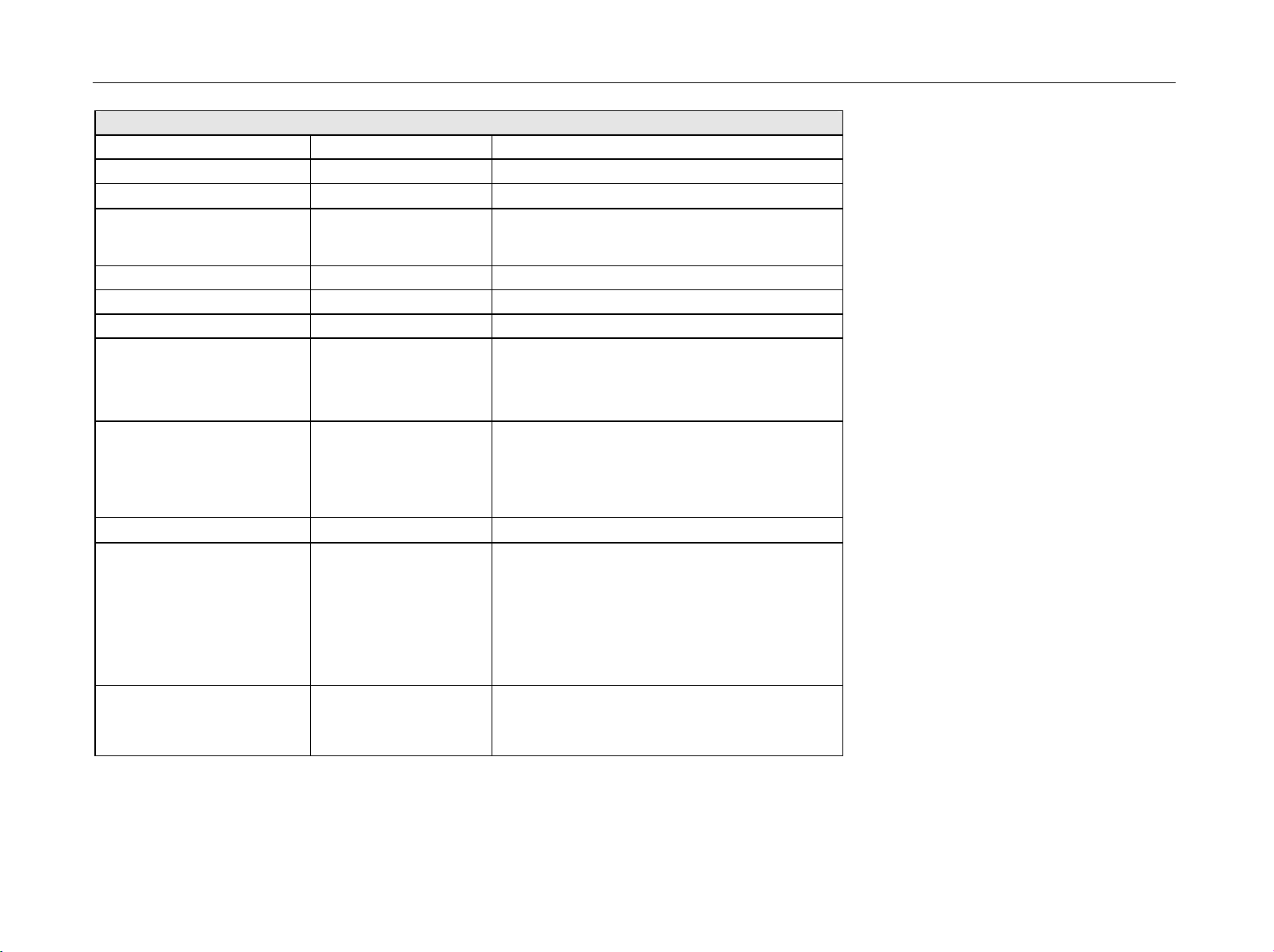

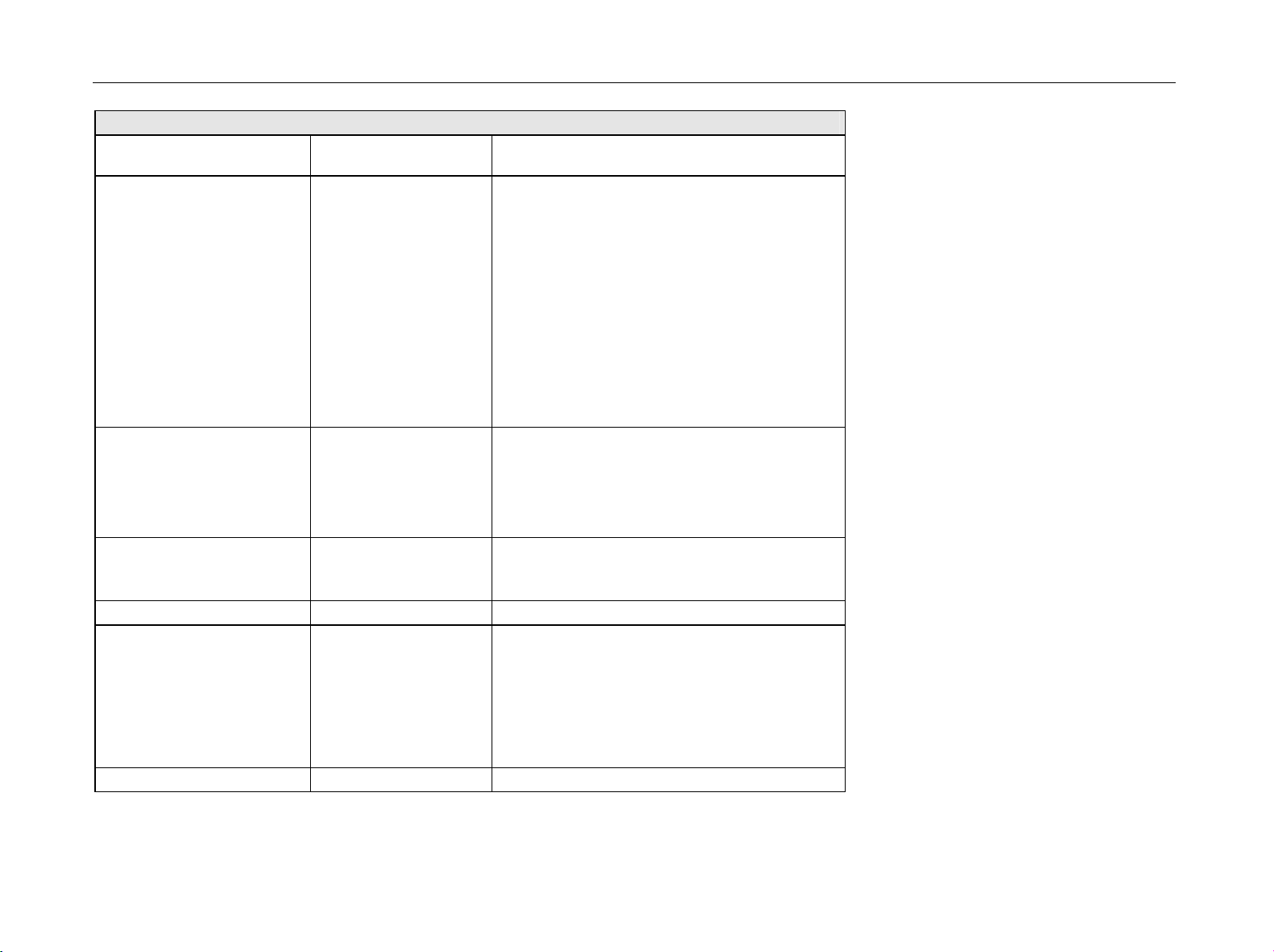

Specification Condition R&S FSH3 R&S FSH6 R&S FSH18

Displayed average noise level average value,

resolution bandwidth

1 kHz,

video bandwidth 10 Hz,

reference level -30 dBm

10 MHz to 50 MHz <-105 dBm,

typ. -114 dBm

50 MHz to 3 GHz <-105 dBm,

typ. -114 dBm

3 GHz to 5 GHz - <-103 dBm,

5 GHz to 6 GHz - <-96 dBm,

6 GHz to 8 GHz - - <-108 dBm,

8 GHz to 12 GHz - - <-105 dBm,

12 GHz to 16 GHz - - <-100 dBm,

16 GHz to 18 GHz - - <-90 dBm,

With preamplifier

10 MHz to 2.5 GHz

only models

1145.5850.03

1145.5850.23,

2

),

<-120 dBm,

typ. -125 dBm

1145.5850.06 and

1145.5850.26

2.5 GHz to 3 GHz <-115 dBm,

typ. -120 dBm

3 GHz to 5 GHz - <-115 dBm,

5 GHz to 6 GHz - <-105 dBm,

<-105 dBm,

typ. -112 dBm

<-105 dBm,

typ. -112 dBm

typ. -108 dBm

typ. -102 dBm

<-120 dBm,

typ. -125 dBm

<-115 dBm,

typ. -120 dBm

typ. -120 dBm

typ. -110 dBm

<-90 dBm,

typ. -98 dBm

<-110 dBm,

typ. -118 dBm

<-110 dBm,

typ. -118 dBm

<-110 dBm,

typ. -118 dBm

typ. -113 dBm

typ. -113 dBm

typ. -108 dBm

typ. -102 dBm

-

-

-

-

2

As of serial number 100900 and firmware version 6.0 or higher.

1145.5973.12 TI.3 E-14

Page 13

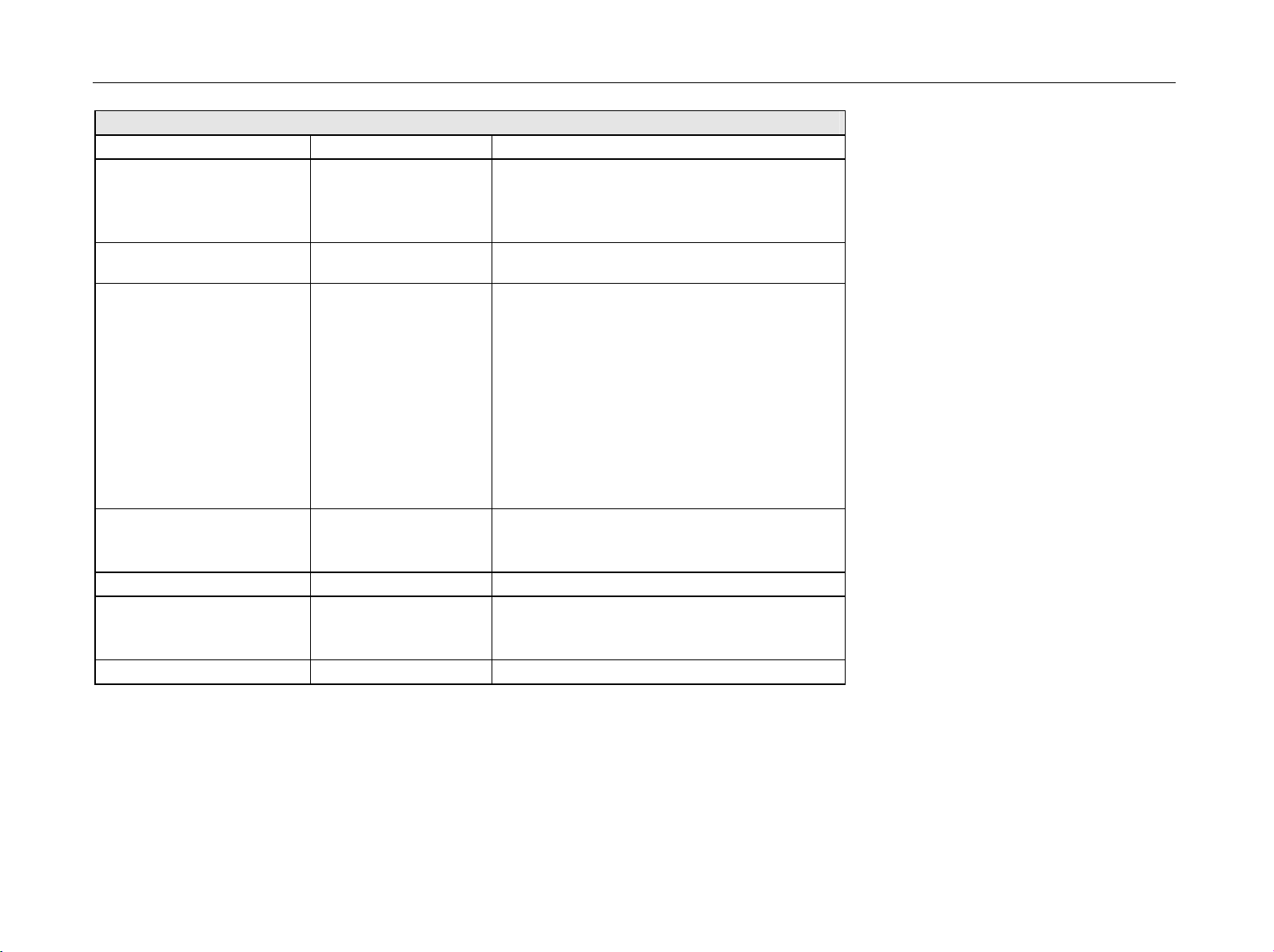

Data Sheet R&S FSH3, R&S FSH6, R&S FSH18

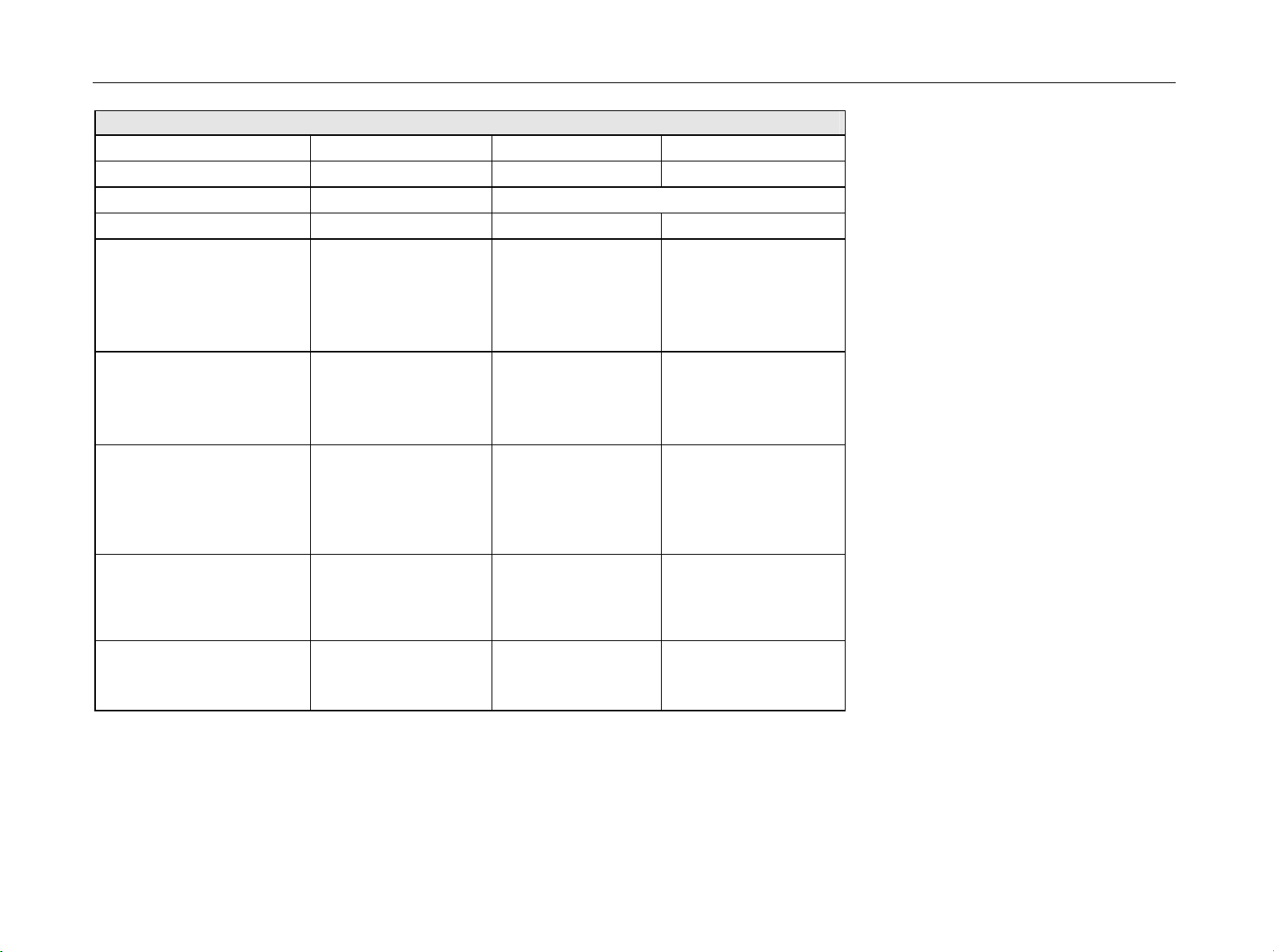

Specification Condition R&S FSH3 R&S FSH6 R&S FSH18

Inherent spurious

Input related spurious

R&S FSH3 / FSH6

Receive frequency

Up to 3 GHz

3 GHz to 6 GHz

reference level -20 dBm,

f > 30 MHz,

RBW 100 kHz,S/N>10dB

mixer level -40 dBm

carrier offset >1 MHz

<-80 dBm <-80 dBm <-80 dBm

-70 dBc (nominal)

-70 dBc (nominal)

-64 dBc (nominal)

Receive frequency =

signal frequency – 2.0156 GHz

Input related spurious

R&S FSH18

Receive frequency:

10 MHz to 14 GHz

14 GHz to 18 GHz

Receive frequency =

signal frequency – 3.9 GHz

signal frequency + 0.6 GHz to +

1 GHz

signal frequency – 0.6 GHz to

– 1 GHz

2nd harmonic

Receive frequency

Up to 6 GHz

6 GHz to 9 GHz

Level display

Reference level -80 to +20 dBm in steps of 1 dB

Display range 100 dB, 50 dB, 20 dB, 10 dB, linear

signal frequency

2 GHz to 3.2 GHz

mixer level

carrier offset >1MHz

signal frequency:

10 MHz to 7.6 GHz

7.6 GHz to 18 GHz

10 MHz to 2.8 GHz

2.8 GHz to 7.6 GHz

7.6 GHz to 18 GHz

signal frequency:

3.9 GHz to 18 GHz

7.4 GHz to 7.7 GHz

7.8 GHz to 8.5 GHz

mixer level -40 dBm

-20 dBm

55 dBc (nominal)

-60 dBc (nominal) -60 dBc (nominal)

55 dBc (nominal)

-60 dBc (nominal)

-50 dBc (nominal)

-50 dBc (nominal)

-30 dBc (nominal)

-50 dBc (nominal)

-40 dBc (nominal)

-45 dBc(nominal)

-45 dBc(nominal)

-60 dBc (nominal)

-50 dBc (nominal)

1145.5973.12 TI.4 E-14

Page 14

R&S FSH3, R&S FSH6, R&S FSH18 Data Sheet

Specification Condition R&S FSH3 R&S FSH6 R&S FSH18

Display units

Logarithmic

Linear

Traces 1 trace and 1 memory trace

Trace mathematics A-B and B-A (trace – memory trace and memory trace – trace)

Detectors auto peak, maximum peak, minimum peak, sample, RMS

with option R&S FSH-K3

installed

Level measurement error

at reference level down to

-50 dB, 20 °C to 30 °C

1 MHz to 10 MHz

10 MHz to 20 MHz

20 MHz to 6 GHz

6 GHz to 14 GHz

14 GHz to 18 GHz

Markers

Number of markers or delta

markers

Marker functions peak, next peak, minimum, center = marker frequency,

Marker displays normal (level), noise marker, frequency counter (count)

Trigger

Audio demodulation

with transducer also dBIV/m and dBIA/m

with transducer also V/m, mV/m , IV/m and W/m

in addition average and quasi-peak

< 1.5 dB, typ. 0.5 dB

< 1.5 dB, typ. 0.5 dB

< 1.5 dB, typ. 0.5 dB

reference level = marker level, all markers to peak

AM (video voltage without AGC) and FM

dBm, dBIV, dBmV

IV, mV, V, nW, µW, mW, W

-

-

max. 6

free-running, video, external

2

-

< 2 dB

< 1.5 dB

< 2.5 dB

< 3.0 dB

1145.5973.12 TI.5 E-14

Page 15

Data Sheet R&S FSH3, R&S FSH6, R&S FSH18

Specification Condition R&S FSH3 R&S FSH6 R&S FSH18

Inputs

RF input N female

Input impedance

VSWR 10 MHz to 3 GHz

3 GHz to 6 GHz

6 GHz to 15 GHz

15 GHz to 18 GHz

Trigger/external reference input BNC female, selectable

Trigger voltage TTL

Reference frequency 10 MHz

Required level

Outputs

AF output 3.5 mm mini jack

Output impedance

Open-circuit voltage

Tracking generator only models 145.5850.13,

Frequency range 5 MHz to 3 GHz 5 MHz to 6 GHz -

Output level model 1145.5850.13

Output impedance

from 50

1145.5850.23 und

1145.5850.26

model 1145.5850.23

model 1145.5850.26

f < 3 GHz

f > 3 GHz

<1.5 nominal <1.5 nominal

adjustable up to 1.5 V

-20 dBm (nominal)

0 dBm / -20 dBm,

selectable

Interfaces

RS-232-C optical interface

Baud rate 1200, 2400, 9600, 19200, 38400, 57600, 115200 baud

Power sensor 7-contact female connector (type Binder 712)

50

<1.5 nominal

10 dBm

100

- 10 dBm (nominal)

- 20 dBm (nominal)

50 , nominal

<1.5 nominal

<1.5 nominal

<2 nominal

<3 nominal

-

1145.5973.12 TI.6 E-14

Page 16

R&S FSH3, R&S FSH6, R&S FSH18 Data Sheet

Accessories

Power Sensors R&S FSH-Z1 and R&S FSH-Z18

Frequency range R&S FSH-Z1 10 MHz to 8 GHz

R&S FSH-Z18 10 MHz to 18 GHz

VSWR

10 MHz to 30 MHz

30 MHz to 2.4 GHz

2.4 GHz to 8 GHz

8 GHz to 18 GHz

Maximum input power average power

peak power

(<10 Is, 1% duty cycle)

Measurement range 200 pW to 200 mW (-67 dBm to +23 dBm)

Signal weighting average power

Effect of harmonics

Effect of modulation

Absolute measurement

uncertainty

10 MHz to 8 GHz

8 GHz to 18 GHz

Zero offset after zeroing < 110 pW

Dimensions 48 mm x 31 mm x 170 mm, connecting cable 1.5 m

Weight < 0.3 kg

sine signals,

no zero offset

15 °C to 35 °C

0 °C to 50 °C

15 °C to 35 °C

0 °C to 50 °C

<0.5 % (0.02 dB) at harmonic ratio of 20 dB

<1.5 % (0.07 dB) for continuous digital modulation

< 1.15

< 1.13

< 1.20

<1.25

400 mW (+26 dBm)

1 W (+30 dBm)

<2.3 % (0.10 dB)

<4.2 % (0.18 dB)

<3.5 % (0.15 dB)

<5.0 % (0.21 dB)

1145.5973.12 TI.7 E-14

Page 17

Data Sheet R&S FSH3, R&S FSH6, R&S FSH18

Directional Power Sensor R&S FSH-Z14

Frequency range 25 MHz to 1 GHz

Power measurement range 30 mW to 300 W

VSWR referenced to 50

Power-handling capacity depending on temperature

and matching

(see diagram below)

Insertion loss < 0.06 dB

Directivity > 30 dB

Average power

Power measurement range

CW, FM, PM, FSK, GMSK

Modulated signals

Measurement uncertainty

25 MHz to 40 MHz

40 MHz to 1 GHz

Zero offset after zeroing

Range of typical meas. error

with modulation

FM, PM, FSK, GMSK

AM (80 %)

2 CW carriers with identical

power

EDGE, TETRA

CF: ratio of peak envelope

power to average power

sine signal,

18 °C to 28 °C, no zero

offset

*) if standard is selected

on the R&S FSH

30 mW to 300 W / CF

4.0 % of measured value (0.17 dB)

3.2 % of measured value (0.14 dB)

0 % of measured value (0 dB)

± 3 % of measured value (± 0.13 dB)

± 2 % of measured value (± 0.09 dB)

± 0.5 % of measured value (± 0.02 dB) *)

< 1.06

100 W to 1000 W

30 mW to 300 W

± 4 mW

Temperature coefficient

25 MHz to 40 MHz

40 MHz to 1 GHz

0.40 %/K (0.017 dB/K)

0.25 %/K (0.011 dB/K)

1145.5973.12 TI.8 E-14

Page 18

R&S FSH3, R&S FSH6, R&S FSH18 Data Sheet

Directional Power Sensor R&S FSH-Z14

Max. peak envelope power

Power measurement range

Video bandwidth 4 kHz

200 kHz

600 kHz

Measurement uncertainty 18°C to 28°C same as for average power plus effect of peak hold

Error limits of peak hold

circuit for burst signals

Duty cycle 0.1 and

repetition rate 100 / s

20/s repetition rate <100/s

0.001 duty cycle < 0.1

Temperature coefficient

25 MHz to 40 MHz

40 MHz to 1 GHz

Load matching

Matching measurement range

Return loss

VSWR

Minimum forward power specs met from 0.4 W 0.06 W

video bandwidth 4 kHz

200 kHz

600 kHz

± (3 % of measured value + 0.05 W) starting from a

± (3 % of measured value + 0.20 W) starting from a

± (7 % of measured value + 0.40 W) starting from a

plus ± (1.6 % of measured value + 0.15 W)

0.4 W to 300 W

1 W to 300 W

2 W to 300 W

circuit

burst width of 200 Is

burst width of 4 Is

burst width of 2 Is

plus ± 0.10 W

0.50 %/K (0.022 dB/K)

0.35 %/K (0.015 dB/K)

0 dB to 23 dB

> 1.15

1145.5973.12 TI.9 E-14

Page 19

Data Sheet R&S FSH3, R&S FSH6, R&S FSH18

Directional Power Sensor R&S FSH-Z14

Error limits for matching

measurements

Power-handling capacity

Dimensions 120 mm x 95 mm x 39 mm, connecting cable 1.5 m

Weight 0.65 kg

1145.5973.12 TI.10 E-14

Page 20

R&S FSH3, R&S FSH6, R&S FSH18 Data Sheet

Directional Power Sensor R&S FSH-Z44

Frequency range 200 MHz to 4 GHz

Power measurement range

VSWR referenced to 50

200 MHz to 3 GHz

3 GHz to 4 GHz

Power-handling capacity depending on temperature

and matching

(see diagram below)

Insertion loss

200 MHz to 1.5 GHz

1.5 GHz to 4 GHz

Directivity

200 MHz to 3 GHz

3 GHz to 4 GHz

Average power

Power measurement range

CW, FM, PM, FSK, GMSK

3GPP W-CDMA,

cdmaOne, cdma2000,

DAB, DVB-T

Other modulated signals

Measurement uncertainty

200 MHz to 300 MHz

300 MHz to 4 GHz

CF: ratio of peak envelope

power to average power

sine signal,

18 °C to 28 °C, no zero

offset

4.0 % of measured value (0.17 dB)

3.2 % of measured value (0.14 dB)

30 mW to 300 W

< 1.07

< 1.12

120 W to 1000 W

< 0.06 dB

< 0.09 dB

> 30 dB

> 26 dB

30 mW to 300 W

30 mW to 120 W

30 mW to 300 W / CF

1145.5973.12 TI.11 E-14

Page 21

Data Sheet R&S FSH3, R&S FSH6, R&S FSH18

Directional Power Sensor R&S FSH-Z44

Zero offset after zeroing

Range of typical measurement error with modulation

FM, PM, FSK, GMSK

AM (80 %)

2 CW carriers with identical

power

/4-DQPSK

EDGE

cdmaOne, DAB

3GPP W-CDMA, cdma2000

DVB-T

Temperature coefficient

200 MHz to 300 MHz

300 MHz to 4 GHz

Max. peak envelope power

Power measurement range

DAB, DVB-T, cdmaOne,

cdma2000, 3GPP W-CDMA

Other signals at

video bandwidth 4 kHz

200 kHz

4 MHz

*) if standard is selected

on the R&S FSH

0 % of measured value (0 dB)

± 3 % of measured value (± 0.13 dB)

± 2 % of measured value (± 0.09 dB)

± 2 % of measured value (± 0.09 dB)

± 0.5 % of measured value (± 0.02 dB) *)

± 1 % of measured value (± 0.04 dB) *)

± 2 % of measured value (± 0.09 dB) *)

± 2 % of measured value (± 0.09 dB) *)

± 4 mW

0.40 %/K (0.017 dB/K)

0.25 %/K (0.011 dB/K)

4 W to 300 W

0.4 W to 300 W

1 W to 300 W

2 W to 300 W

1145.5973.12 TI.12 E-14

Page 22

R&S FSH3, R&S FSH6, R&S FSH18 Data Sheet

Directional Power Sensor R&S FSH-Z44

Measurement uncertainty 18°C to 28°C same as for average power plus effect of peak hold

circuit

Error limits of peak hold

circuit for burst signals

Duty cycle 0.1 und

repetition rate 100 / s

20/s repetition rate <100/s

0.001 duty cycle < 0.1

Burst width 0.5Is

Burst width 0.2Is

Range of typical measurement error of peak hold

circuit for

cdmaOne, DAB

DVB-T, cdma2000,

3GPP W-CDMA

Temperature coefficient

200 MHz to 300 MHz

300 MHz to 4 GHz

Load matching

Matching measurement range

Return loss

200 MHz to 3 GHz

3 GHz to 4 GHz

VSWR

200 MHz to 3 GHz

3 GHz to 4 GHz

Minimum forward power specs met from 0.2 W 0.03 W

video bandwidth 4 kHz

200 kHz

4 MHz

video bandwidth 4 MHz

and standard selected on

the R&S FSH

± (3 % of measured value + 0.05 W) starting from a

burst width of 100 Is

± (3 % of measured value + 0.20 W) starting from a

burst width of 4 Is

± (7 % of measured value + 0.40 W) starting from a

burst width of 1 Is

plus ± (1.6 % of measured value + 0.15 W)

plus ± 0.10 W

plus ± 5 % of measured value

plus ± 10 % of measured value

± (5% of measured value + 0.4 W)

± (15% of measured value + 0.4 W)

0.50 %/K (0.022 dB/K)

0.35 %/K (0.015 dB/K)

0 dB to 23 dB

0 dB to 20 dB

> 1.15

> 1.22

1145.5973.12 TI.13 E-14

Page 23

Data Sheet R&S FSH3, R&S FSH6, R&S FSH18

Directional Power Sensor R&S FSH-Z44

Error limits for matching

measurements

Power-handling capacity

6

dB

4

2

0

Measurement error

-2

-4

0 5 10

1000

800

600

AVG -10 °C to 35 °C

SWR < 3

400

Forwar d power

AVG 35 °C to 50 °C

200

SWR < 3

0.2 GHz to 3 GHz

3 GHz to 4 GHz

20

15

dB

Return loss

PEAK (max 10 ms), SWR < 3

AVG -10 °C to 35 °C

SWR < 1.5

25

100

0,2

0,4

1

0,7

2 3

Frequency

4 GHz

Dimensions 120 mm x 95 mm x 39 mm, connecting cable 1.5 m

Weight 0.65 kg

1145.5973.12 TI.14 E-14

Page 24

R&S FSH3, R&S FSH6, R&S FSH18 Data Sheet

VSWR Bridge R&S FSH-Z2 / R&S FSH-Z3

R&S FSH-Z2 R&S FSH-Z3

Frequency range 10 MHz to 3 GHz 10 MHz to 3 GHz

Impedance

VSWR bridge

Directivity

10 MHz to 30 MHz

30 MHz to 1 GHz

1 GHz to 3 GHz

3 GHz to 6 GHz

Directivity, corrected

2 MHz to 10 MHz

10 MHz to 3 GHz

3 GHz to 6 GHz

Return loss at test port

10 MHz to 50 MHz

50 MHz to 3 GHz

3 GHz to 6 GHz

Return loss at test port,

corrected

2 MHz to 3 GHz

3 GHz to 6 GHz

Insertion loss

Test port

Bypass

typ. 30 dB

typ. 30 dB

typ. 25 dB

-

option R&S FSH-K2

typ. 40 dB

typ. 43 dB

-

20 dB, typ.

20 dB, typ.

-

option R&S FSH-K2

typ. 35 dB

-

typ. 9 dB

-

50

typ. 16 dB

> 20 dB, typ. 28 dB

> 20 dB, typ. 28 dB

> 16 dB, typ. 25 dB

typ. 40 dB

typ. 40 dB

typ. 37 dB

> 12 dB, typ. 18 dB

> 16 dB, typ. 22 dB

> 16 dB, typ. 22 dB

typ. 40 dB

typ. 37 dB

typ. 9 dB

typ. 4 dB

1145.5973.12 TI.15 E-14

Page 25

Data Sheet R&S FSH3, R&S FSH6, R&S FSH18

VSWR Bridge R&S FSH-Z2 / R&S FSH-Z3

R&S FSH-Z2 R&S FSH-Z3

DC bias

Max. input voltage - 50 V

Max. input current - 300 mA /600 mA *

Type of connector - BNC female

Connectors

Generator input/RF output N male

Test port N female

Control interface 7-contact connector (type Binder)

General data

Power consumption - 3 mW (nominal)

Dimensions (W x H x D) 169 mm x 116 mm x

Weight 485 g 620 g

Calibration standards

R&S FSH-Z30/-Z31

Short/open N male

50 load

Impedance

Return loss

DC to 3 GHz

3 GHz to 6 GHz

Power-handling capacity 1 W 1 W

-

30 mm

R&S FSH-Z29

> 43 dB

-

)

149 mm x 144 mm x

45 mm

R&S FSH-Z28

N male

50

> 40 dB, typ. 46 dB

> 37 dB, typ. 43 dB

*)

as of serial number 100500

1145.5973.12 TI.16 E-14

Page 26

R&S FSH3, R&S FSH6, R&S FSH18 Data Sheet

Distance-to-Fault Measurement R&S FSH-B1

(only with R&S FSH3 models 1145.5850.13, 1145.5850.23 and R&S FSH6 model 1145.5850.26)

Display 301 pixels

Maximum resolution, distance

to fault

Display range

Return loss

VSWR

Reflection coefficient

mRho

Cable length depending on cable loss 0 m to max. 1000 m

Maximum permissible spurious

signal

Specification Condition R&S FSH3 R&S FSH6

Transmission measurements (only with R&S FSH3 models 1145.5850.13, 1145.5850.23 and R&S FSH6

model 1145.5850.26)

Frequency range 5 MHz bis 3 GHz 5 MHz bis 6 GHz

Dynamic range

10 MHz to 2.2 GHz

2.2 to 3 GHz

3 to 5 GHz

5 to 6 GHz

maximum zoom cable length/1023 pixels

10, 5, 2, 1 dB/div, linear

1 to 2 ,1 to 6, 1 to 10 und 1 to 20 with option

R&S FSH-K2 in addition

1 to 1.2 and 1 to 1.5

0 to 1, 0 to 0.1, 0 to 0.01, 0 to 0.001

0 to 100, 0 to 100, 0 to 10, 0 to 1

1st mixer 1 dB compression point typ. +10 dBm

IF overload at reference level typ. +8 dB

scalar mode

vector mode, option

R&S FSH-K2

scalar mode

vector mode, option

R&S FSH-K2

scalar mode

vector mode, option

R&S FSH-K2

scalar mode

vector mode, option

R&S FSH-K2

typ. 60 dB

typ. 80 dB

typ. 50 dB

typ. 65 dB

-

-

-

-

typ. 80 dB

typ. 90 dB

typ. 70 dB

typ. 85 dB

typ. 40 dB

typ. 55 dB

typ. 35 dB

typ. 50 dB

1145.5973.12 TI.17 E-14

Page 27

Data Sheet R&S FSH3, R&S FSH6, R&S FSH18

Specification Condition R&S FSH3 R&S FSH6

Reflection measurements

(only with R&S FSH3 model 1145.5850.13 or 1145.5850.23, R&S FSH6 model 1145.5850.26 and

R&S FSH-Z2/-Z3)

Frequency range 10 MHz to 3 GHz 10 MHz to 3 GHz

Display range of return loss 10, 20, 50, 100 dB, selectable

VSWR display range 1 to 2 , 1 to 6, 1 to 10 und 1 to 20, selectable,

with option R&S FSH-K2 also 1 to 1.2 and 1 to 1.5

Display range

Reflection coefficient

mRho

Smith chart only with option

R&S FSH-K2

Marker formats:

Reflection dB mag and phase

Impedance R+jX

Admittance G+jB

Reference impedance Z

0

Zoom function expansion factor 2, 4, 8

Measurement uncertainty see diagrams

0 to 1, 0 to 0.1, 0 to 0.01, 0 to 0.001

0 to 100, 0 to 100, 0 to 10, 0 to 1

lin mag and phase

real and imag

(R+jX)/Z

(G+jB)/Z

0

0

10 m to 10 k

1145.5973.12 TI.18 E-14

Page 28

R&S FSH3, R&S FSH6, R&S FSH18 Data Sheet

3

2

Measurement

Uncertainty / dB

1

0

-1

-2

-3

0 2 4 6 8 10 12 14 16 18

Measurement uncertainty with scalar

measurements

Return Loss DUT / dB

20

3

2

Measurement

Uncertainty / dB

1

0

-1

-2

-3

0 5 10

15

20

Measurement uncertainty with vector

measurements (option R&S FSH-K2)

25 30

Return Loss DUT / dB

Specification Condition R&S FSH3 R&S FSH6

Phase measurements (transmission, reflection)

(only with R&S FSH3 models 1145.5850.13 or 1145.5850.23, R&S FSH6 1145.5850.26 and R&S FSH-K2)

Frequency range

Reflection

Transmission

Display range

with R&S FSH-Z2/-Z3 10 MHz to 3 GHz

5 MHz to 3 GHz

± 180° (wrap)

0° to 54360° (unwrap)

10 MHz to 6 GHz

5 MHz to 6 GHz

Group delay measurements

(only with R&S FSH3 models 1145.5850.13 or 1145.5850.23, R&S FSH6 1145.5850.26 and R&S FSH-K2)

Frequency range

Reflection

Transmission

with R&S FSH-Z2/-Z3 10 MHz to 3 GHz

5 MHz to 3 GHz

10 MHz to 6 GHz

5 MHz to 6 GHz

Aperture increments 1 to 300

Display range

10 ns, 20 ns, 50 ns, 100 ns, 200 ns, 500 ns,

1000 ns,

selectable

1145.5973.12 TI.19 E-14

Page 29

Data Sheet R&S FSH3, R&S FSH6, R&S FSH18

Specification Condition R&S FSH3

(only for model 1145.5850.23 as of serial

number 103500)

3GPP FDD code domain power BTS/Node B measurement

(only with R&S FSH-K4 1300.7633.02)

Frequency range

Carrier frequency error

Measurement range

Measurement uncertainty

Total power

Measurement range

Measurement uncertainty

CPICH power

Measurement range

Measurement uncertainty

P-CCPCH power

Measurement range

Measurement uncertainty

PSCH/SSCH power

Measurement range

Measurement uncertainty

Symbol EVM

Measurement range

Measurement uncertainty

Residual EVM

symbol

S/N > 30 dB

S/N > 30 dB

frequency > 1 MHz

20 °C to 30 °C

-40 dBm < P

P

REF_LEV

P

REF_LEV

total

-30dB < P

+3dB

< 20 dBm

S/N > 30 dB

-40 dBm < P

- P

-20 dBm < P

total

< 20 dBm P

total

S/N > 30 dB

-40 dBm < P

P

-20 dBm < P

total

< 20 dBm P

total

S/N > 30 dB

-40 dBm < P

P

-20 dBm < P

total

3% < EVM

10% < EVM

< 20 dBm P

total

symbol

symbol

total

CPICH

PCCPCH

PSCH

< 10%

< 20%

<

< P

< P

< P

total

10 MHz to 3 GHz

(test case 6.3 in accordance with 3GPP 25.141)

±1 kHz

< 50 Hz + Sf

1)

ref

(T = 20 Hz)

(test case 6.2.1 in accordance with 3GPP 25.141)

-60 dBm < P

< 20 dBm

total

± 1.5 dB, typ. 0.5 dB

(test case 6.2.2 in accordance with 3GPP 25.141)

total

total

-20 dB < P

total

± 1.5 dB, typ. 0.5 dB

-40 dB < P

total

± 1.5 dB, typ. 0.5 dB

-30 dB < P

total

CPICH

PCCPCH

SCH

< P

< P

< P

± 2.5 dB, typ. 1.5 dB

3% < EVM

symbol

< 25%

± 2.5% typ.

± 3.0% typ.

3% typ.

total

total

total

1145.5973.12 TI.20 E-14

Page 30

R&S FSH3, R&S FSH6, R&S FSH18 Data Sheet

Specification Condition R&S FSH3

3GPP FDD scrambling code detection

Frequency range

± 1 kHz

10 MHz to 3 GHz

Single scrambling code

detection

Calculation time

CPICH EC/ I

0

24 s

> -18 dB

Multiple scrambling code

detection

Max. number of

scrambling codes

Calculation time 57 s

CPICH EC/ I

CPICH power

0

-40 dBm < P

total

< 20 dBm

> -21 dB

± 4.2 dB

Measurement uncertainty

1)

2)

f

= uncertainty of reference frequency source.

ref

Probability of detection >50% with test model 1.16 in accordance with 3GPP TS 25.141 test specifications.

2)

8

2)

1145.5973.12 TI.21 E-14

Page 31

Data Sheet R&S FSH3, R&S FSH6, R&S FSH18

General data

Display

Resolution 320 x 240 pixels

Memory

Settings and traces

Environmental conditions

Temperature

Operating temperature range

R&S FSH powered from internal battery

R&S FSH powered from AC power supply

Storage temperature range -20°C to +60 °C

Battery charging mode 0 °C to 40 °C

Climatic conditions

Relative humidity 95 % at 40 °C (IEC60068)

IP class of protection

Mechanical resistance

Vibration, sinusoidal complies with EN 60068-2-1, EN61010-1

Vibration, random complies with EN60068-2-64

Shock complies with EN 60068-2-27

RFI suppression

Immunity to radiated interference

Level display at 10 V/m (reference level -10 dBm)

Input frequency

IF

Other frequencies

14 cm (5.7") LC color display

CMOS RAM

100

0°C to 50 °C

0°C to 40 °C

51

5 Hz to 55 Hz: max. 2 g, 55 Hz to 150 Hz: 0.5 g constant,

12 minutes per axis

10 Hz to 500 Hz, 1.9 g, 30 minutes per axis

40 g shock spectrum

complies with EMC directive of EU (89/336/EEC)

and German EMC legislation

10 V/m

< -75 dBm (nominal)

< -85 dBm (nominal)

< displayed noise level

1145.5973.12 TI.22 E-14

Page 32

R&S FSH3, R&S FSH6, R&S FSH18 Data Sheet

Power supply

AC supply plug-in AC power supply (R&S FSH-Z33)

100 V AC to 240 V AC, 50 Hz to 60 Hz, 400 mA

External DC voltage 15 V to 20 V

Internal battery NiMH battery (type Fluke BP190, R&S FSH-Z32)

Battery voltage 6 V to 9 V

Operating time with fully charged battery typ. 4 h with tracking generator off, typ. 3 h with

tracking generator on, typ. 3 h for R&S FSH18

Battery charging time 4 h with instrument off

Lifetime 300 to 500 charging cycles

Power consumption typ. 7 W

Safety

Test mark VDE, GS, CSA, CSA-NRTL

Dimensions (W x H x D)

Weight

Order No.

Handheld Spectrum Analyzer R&S FSH3

100 kHz to 3 GHz, with preamplifier

Handheld Spectrum Analyzer R&S FSH3

100 kHz to 3 GHz, with tracking generator

Handheld Spectrum Analyzer R&S FSH3

100 kHz to 3 GHz, with tracking generator and

preamplifier

Handheld Spectrum Analyzer R&S FSH6

100 kHz to 6 GHz, with preamplifier

Handheld Spectrum Analyzer R&S FSH6

100 kHz to 6 GHz, with tracking generator and

preamplifier

Handheld Spectrum Analyzer R&S FSH18

10 MHz to 18 GHz

complies with EN 61010-1, UL 3111-1,

CSA C22.2 No. 1010-1

170 mm x 120 mm x 270 mm

2.5 kg

1145.5850.03

1145.5850.13

1145.5850.23

1145.5850.06

1145.5850.26

1145.5850.18

1145.5973.12 TI.23 E-14

Page 33

Data Sheet R&S FSH3, R&S FSH6, R&S FSH18

Power supply

Accessories supplied

Options

Distance-to-Fault Measurement for the R&S FSH

(includes 1 m cable, R&S FSH-Z2 required)

Remote Control via RS-232-C for the R&S FSH R&S FSH-K1 1157.3458.02

Vector Transmission and Reflection Measurements

for the R&S FSH

Receiver Mode for the R&S FSH R&S FSH-K3 1157.3429.02

3GPP FDD Code Domain Power BTS/Node B

Measurement for the R&S FSH3 model 23 as of

serial number 103500

Optional accessories

Power Sensor for the R&S FSH, 10 MHz to 8 GHz R&S FSH-Z1 1155.4505.02

VSWR Bridge and Power Divider for the R&S FSH,

10 MHz to 3 GHz (incl. calibration standards open,

short, 50 U load)

VSWR Bridge with DC Bias and Bypass Connector

for the R&S FSH, 10 MHz to 6 GHz (incl. calibration

standards open, short, 50 U load)

external power supply, battery pack (built-in),

RS-232-C optical cable, headphones, Quick Start manual,

CD-ROM with Control Software R&S FSH View and

documentation

Designation Order No.

R&S FSH-B1 1145.5750.02

R&S FSH-K2 1157.3387.02

R&S FSH-K4 1300.7633.02

Designation Order No.

R&S FSH-Z2 1145.5767.02

R&S FSH-Z3 1300.7756.02

1145.5973.12 TI.24 E-14

Page 34

R&S FSH3, R&S FSH6, R&S FSH18 Data Sheet

Power supply

Optional accessories

Designation Order No.

Directional Power Sensor for the R&S FSH,

25 MHz to 1 GHz

Power Sensor for the R&S FSH, 10 MHz to 18 GHz

Directional Power Sensor for the R&S FSH,

200 MHz to 4 GHz

Matching Pad, 50/75 U, 0 Hz to 2700 MHz RAZ 0358.5714.02

Spare RF Cable (1 m),

connectors N male/N female for R&S FSH-B1

12 V Car Adapter for the R&S FSH R&S FSH-Z21 1145.5873.02

Serial/Parallel Converter for the R&S FSH R&S FSH-Z22 1145.5880.02

Carrying Bag for the R&S FSH R&S FSH-Z25 1145.5896.02

Transit Case for the R&S FSH R&S FSH-Z26 1300.7627.00

Spare Combined Short/Open and 50 Load for

VSWR and DTF calibration, DC to 6 GHz

Combined Short/Open and 50 Load for VSWR

and DTF calibration, DC to 3 GHz

Spare Short/Open Calibration Standard for

R&S FSH-Z2 for VSWR calibration, DC to 3 GHz

Spare 50 Load Standard for R&S FSH-Z2 for

VSWR and DTF calibration, DC to 3 GHz

Spare Battery Pack for the R&S FSH R&S FSH-Z32 1145.5796.02

Spare AC Power Supply for the R&S FSH R&S FSH-Z33 1145.5809.02

R&S FSH-Z14 1120.6001.02

R&S FSH-Z18 1165.1909.02

R&S FSH-Z44 1165.2305.02

R&S FSH-Z20 1145.5867.02

R&S FSH-Z28 1300.7804.02

R&S FSH-Z29 1300.7504.02

R&S FSH-Z30 1145.5773.02

R&S FSH-Z31 1145.5780.02

1145.5973.12 TI.25 E-14

Page 35

Data Sheet R&S FSH3, R&S FSH6, R&S FSH18

Power supply

Optional accessories

Designation Order No.

Spare RS-232-C Optical Cable R&S FSH-Z34 1145.5815.02

Spare CD-ROM with Control Software R&S FSH

View and documentation

Spare Headphones R&S FSH-Z36 1145.5838.02

Spare USB Optical Cable R&S FSH-Z37 1300.7733.02

Active Directional Antenna R&S HE-200 4050.3509.02

Portable EMF Measurement System, 30 MHz to

3 GHz, for the Handheld Spectrum Analyzer

R&S FSH

Near-Field Probe Set R&S HZ-15 1147.2736.02

Preamplifier for the R&S HZ-15 R&S HZ-16 1147.2720.02

R&S FSH-Z35 1145.5821.02

R&S TS-EMF 1158.9295.13

1145.5973.12 TI.26 E-14

Page 36

Before putting the product into operation for

the first time, make sure to read the following

Safety Instructions

All plants and locations of the Rohde & Schwarz group of companies make every effort to keep the

safety standard of our products up to date and to offer our customers the highest possible degree of

safety. Our products and the auxiliary equipment required for them are designed and tested in

accordance with the relevant safety standards. Compliance with these standards is continuously

monitored by our quality assurance system. The product described here has been designed and tested

in accordance with the EC Certificate of Conformity and has left the manufacturer’s plant in a condition

fully complying with safety standards. To maintain this condition and to ensure safe operation, observe

all instructions and warnings provided in this manual. If you have any questions regarding these safety

instructions, the Rohde & Schwarz group of companies will be happy to answer them.

Furthermore, it is your responsibility to use the product in an appropriate manner. This product is

designed for use solely in industrial and laboratory environments or in the field and must not be used in

any way that may cause personal injury or property damage. You are responsible if the product is used

for an intention other than its designated purpose or in disregard of the manufacturer's instructions. The

manufacturer shall assume no responsibility for such use of the product.

The product is used for its designated purpose if it is used in accordance with its product documentation

and within its performance limits (see data sheet, documentation, the following safety instructions).

Using the product requires technical skills and a basic knowledge of English. It is therefore essential

that the product be used exclusively by skilled and specialized staff or thoroughly trained personnel with

the required skills. If personal safety gear is required for using Rohde & Schwarz products, this will be

indicated at the appropriate place in the product documentation.

Observe

product

documentation

Supply

voltage

ON/OFF

Weight

indication for

units >18 kg

Standby

indication

Symbols and safety labels

Danger of

electric

shock

Warning!

Hot

surface

PE terminal Ground

Direct

current

(DC)

Alternating

current (AC)

Direct/alternating

current (DC/AC)

Ground

terminal

Attention!

Electrostatic

sensitive

devices

Device fully

protected by

double/reinforced

insulation

1171.0000.42-03.00 Sheet 1

Page 37

Safety Instructions

Observing the safety instructions will help prevent personal injury or damage of any kind caused by

dangerous situations. Therefore, carefully read through and adhere to the following safety instructions

before putting the product into operation. It is also absolutely essential to observe the additional safety

instructions on personal safety that appear in relevant parts of the product documentation. In these

safety instructions, the word "product" refers to all merchandise sold and distributed by the Rohde &

Schwarz group of companies, including instruments, systems and all accessories.

Tags and their meaning

DANGER

WARNING

CAUTION This tag indicates a hazard carrying a low risk of minor or moderate

ATTENTION

NOTE

These tags are in accordance with the standard definition for civil applications in the European

Economic Area. Definitions that deviate from the standard definition may also exist in other economic

areas or military applications. It is therefore essential to make sure that the tags described here are

always used only in connection with the related product documentation and the related product. The

use of tags in connection with unrelated products or documentation can result in misinterpretation and

thus contribute to personal injury or material damage.

This tag indicates a definite hazard carrying a high risk of death or

serious injury if not avoided.

This tag indicates a possible hazard carrying a medium risk of death or

(serious) injury if not avoided

injury if not avoided.

This tag indicates the possibility of incorrect use that can cause damage

to the product.

This tag indicates a situation where the user should pay special attention

to operating the product but which does not lead to damage.

.

Basic safety instructions

1. The product may be operated only under

the operating conditions and in the

positions specified by the manufacturer. Its

ventilation must not be obstructed during

operation. Unless otherwise specified, the

following requirements apply to

Rohde & Schwarz products:

prescribed operating position is always with

the housing floor facing down, IP protection

2X, pollution severity 2, overvoltage

category 2, use only in enclosed spaces,

max. operation altitude 2000 m above sea

level, max. transport altitude 4500 m above

sea level.

Unless specified otherwise in the data

sheet, a tolerance of ±10% shall apply to

the nominal voltage and of ±5% to the

nominal frequency.

2. Applicable local or national safety

regulations and rules for the prevention of

accidents must be observed in all work

performed. The product may be opened

only by authorized, specially trained

personnel. Prior to performing any work on

the product or opening the product, the

product must be disconnected from the

supply network. Any adjustments,

replacements of parts, maintenance or

repair must be carried out only by technical

personnel authorized by Rohde & Schwarz.

Only original parts may be used for

replacing parts relevant to safety (e.g.

power switches, power transformers,

fuses). A safety test must always be

performed after parts relevant to safety

have been replaced (visual inspection, PE

conductor test, insulation resistance

measurement, leakage current

measurement, functional test).

3. As with all industrially manufactured goods,

the use of substances that induce an

allergic reaction (allergens, e.g. nickel)

such as aluminum cannot be generally

excluded. If you develop an allergic

reaction (such as a skin rash, frequent

sneezing, red eyes or respiratory

difficulties), consult a physician immediately

to determine the cause.

1171.0000.42-03.00 Sheet 2

Page 38

Safety Instructions

4. If products/components are mechanically

and/or thermically processed in a manner

that goes beyond their intended use,

hazardous substances (heavy-metal dust

such as lead, beryllium, nickel) may be

released. For this reason, the product may

only be disassembled, e.g. for disposal

purposes, by specially trained personnel.

Improper disassembly may be hazardous to

your health. National waste disposal

regulations must be observed.

5. If handling the product yields hazardous

substances or fuels that must be disposed

of in a special way, e.g. coolants or engine

oils that must be replenished regularly, the

safety instructions of the manufacturer of

the hazardous substances or fuels and the

applicable regional waste disposal

regulations must be observed. Also

observe the relevant safety instructions in

the product documentation.

6. Depending on the function, certain products

such as RF radio equipment can produce

an elevated level of electromagnetic

radiation. Considering that unborn life

requires increased protection, pregnant

women should be protected by appropriate

measures. Persons with pacemakers may

also be endangered by electromagnetic

radiation. The employer/operator is

required to assess workplaces where there

is a special risk of exposure to radiation

and, if necessary, take measures to avert

the danger.

7. Operating the products requires special

training and intense concentration. Make

certain that persons who use the products

are physically, mentally and emotionally fit

enough to handle operating the products;

otherwise injuries or material damage may

occur. It is the responsibility of the

employer to select suitable personnel for

operating the products.

8. Prior to switching on the product, it must be

ensured that the nominal voltage setting on

the product matches the nominal voltage of

the AC supply network. If a different voltage

is to be set, the power fuse of the product

may have to be changed accordingly.

9. In the case of products of safety class I with

movable power cord and connector,

operation is permitted only on sockets with

earthing contact and protective earth

connection.

10. Intentionally breaking the protective earth

connection either in the feed line or in the

product itself is not permitted. Doing so can

result in the danger of an electric shock

from the product. If extension cords or

connector strips are implemented, they

must be checked on a regular basis to

ensure that they are safe to use.

11. If the product has no power switch for

disconnection from the AC supply, the plug

of the connecting cable is regarded as the

disconnecting device. In such cases, it

must be ensured that the power plug is

easily reachable and accessible at all times

(corresponding to the length of connecting

cable, approx. 2 m). Functional or

electronic switches are not suitable for

providing disconnection from the AC

supply. If products without power switches

are integrated in racks or systems, a

disconnecting device must be provided at

the system level.

12. Never use the product if the power cable is

damaged. Check the power cable on a

regular basis to ensure that it is in proper

operating condition. By taking appropriate

safety measures and carefully laying the

power cable, ensure that the cable cannot

be damaged and that no one can be hurt by

e.g. tripping over the cable or suffering an

electric shock.

13. The product may be operated only from

TN/TT supply networks fused with max.

16 A (higher fuse only after consulting with

the Rohde & Schwarz group of companies).

14. Do not insert the plug into sockets that are

dusty or dirty. Insert the plug firmly and all

the way into the socket. Otherwise, this can

result in sparks, fire and/or injuries.

15. Do not overload any sockets, extension

cords or connector strips; doing so can

cause fire or electric shocks.

16. For measurements in circuits with voltages

V

> 30 V, suitable measures (e.g.

rms

appropriate measuring equipment, fusing,

current limiting, electrical separation,

insulation) should be taken to avoid any

hazards.

17. Ensure that the connections with

information technology equipment comply

with IEC 950/EN 60950.

18. Unless expressly permitted, never remove

the cover or any part of the housing while

the product is in operation. Doing so will

expose circuits and components and can

lead to injuries, fire or damage to the

product.

1171.0000.42-03.00 Sheet 3

Page 39

Safety Instructions

19. If a product is to be permanently installed,

the connection between the PE terminal on

site and the product's PE conductor must

be made first before any other connection

is made. The product may be installed and

connected only by a license electrician.

20. For permanently installed equipment

without built-in fuses, circuit breakers or

similar protective devices, the supply circuit

must be fused in such a way that suitable

protection is provided for users and

products.

21. Do not insert any objects into the openings

in the housing that are not designed for this

purpose. Never pour any liquids onto or into

the housing. This can cause short circuits

inside the product and/or electric shocks,

fire or injuries.

22. Use suitable overvoltage protection to

ensure that no overvoltage (such as that

caused by a thunderstorm) can reach the

product. Otherwise the operating personnel

will be endangered by electric shocks.

23. Rohde & Schwarz products are not

protected against penetration of water,

unless otherwise specified (see also safety

instruction 1.). If this is not taken into

account, there exists the danger of electric

shock for the user or damage to the

product, which can also lead to personal

injury.

24. Never use the product under conditions in

which condensation has formed or can form

in or on the product, e.g. if the product was

moved from a cold to a warm environment.

25. Do not close any slots or openings on the

product, since they are necessary for

ventilation and prevent the product from

overheating. Do not place the product on

soft surfaces such as sofas or rugs or

inside a closed housing, unless this is well

ventilated.

26. Do not place the product on heatgenerating devices such as radiators or fan

heaters. The temperature of the

environment must not exceed the maximum

temperature specified in the data sheet.

27. Batteries and storage batteries must not be

exposed to high temperatures or fire. Keep

batteries and storage batteries away from

children. Do not short-circuit batteries and

storage batteries.

If batteries or storage batteries are

improperly replaced, this can cause an

explosion (warning: lithium cells). Replace

the battery or storage battery only with the

matching Rohde & Schwarz type (see

spare parts list). Batteries and storage

batteries must be recycled and kept

separate from residual waste. Batteries and

storage batteries that contain lead, mercury

or cadmium are hazardous waste. Observe

the national regulations regarding waste

disposal and recycling.

28. Please be aware that in the event of a fire,

toxic substances (gases, liquids etc.) that

may be hazardous to your health may

escape from the product.

29. The product can be very heavy. Be careful

when moving it to avoid back or other

physical injuries.

30. Do not place the product on surfaces,

vehicles, cabinets or tables that for reasons

of weight or stability are unsuitable for this

purpose. Always follow the manufacturer's

installation instructions when installing the

product and fastening it to objects or

structures (e.g. walls and shelves).

31. Handles on the products are designed

exclusively for personnel to hold or carry

the product. It is therefore not permissible

to use handles for fastening the product to