Service Manual Instrument

Universal

Radio Communication Tester

R&SCMU 200

1100.0008.02/53

R&SCMU 300

1100.0008.03

Printed in Germany

1100.4903.82-05

Test and Measurement Division

Trade names are trademarks of the owners

.

R&S®is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

R&S CMU Tabbed Divider Overview

Tabbed Divider Overview

Spare Parts Express Service

List of R&S Representatives

Safety Instructions

Contents

Contents of Manuals for Universal Radio Communication Tester R&S CMU

Tabbed Divider

1 Chapter 1: Performance Test

2 Chapter 2: Adjustment

3 Chapter 3: Repair

4 Chapter 4: Software Update / Installation of Options

5 Chapter 5: Documents

Index

1100.4903.82 RE E-5

Safety Instructions

WARNING

Danger of injuries

When removing the rear feet, the unit can slip out of the cabinet.

Put the unit onto the front handles, before removing the rear feet and taking off the

cabinet. Thus the risk of personal injuries and damages to the unit is avoided.

When mounting the cabinet take care not to pen in the fingers. Also pay attention not

to damage or pull off cables. Screw the rear feet back on immediately after mounting

the cabinet. Do not move the unit with the rear feet missing.

ATTENTION

To avoid damage of electronic components, the operational site must be protected against

electrostatic discharge (ESD).

Wrist strap with cord

Building ground

Floor mat

Heel strap

Ground connection

of operational site

The following two methods of ESD protection may be used together or separately:

• Wrist strap with cord to ground connection

• Conductive floor mat and heel strap combination

1171.0300.62 E-1

CMU Contents

Contents

1 Performance Test

General ..............................................................................................................................................1.1

A) Calibration by an R&S Representative with an ACS Calibration System.........1.1

B) Sending the Instrument to the Factory (Memmingen, Germany)......................1.1

Necessary Documents .............................................................................................................1.1

Measuring Instruments and Auxiliary Equipment.........................................................................1.2

Test Setups ..............................................................................................................................1.3

Reference Frequencies..................................................................................................1.3

TX Level Measurements ................................................................................................1.3

General TX measurements............................................................................................1.4

RX Level measurements................................................................................................1.5

General RX Measurements ...........................................................................................1.5

RX Demodulation Measurements ..................................................................................1.5

Tolerance Analysis ...........................................................................................................................1.6

Manual Test Procedure....................................................................................................................1.7

Selftest .....................................................................................................................................1.7

Interface Test ...........................................................................................................................1.8

IEC-bus Interface ...........................................................................................................1.8

RS–232 Interface ...........................................................................................................1.8

Reference Frequencies ............................................................................................................1.9

REF IN ...........................................................................................................................1.9

REF OUT 1 ..................................................................................................................1.10

REF OUT 2 ..................................................................................................................1.10

TX Frequency Accuracy .........................................................................................................1.11

.......................................................................................................................1.1

TX Frequency Settling Time...................................................................................................1.11

TX Level Error ........................................................................................................................1.11

VSWR ....................................................................................................................................1.11

TX Level Settling Time ...........................................................................................................1.12

TX Harmonics ........................................................................................................................1.12

TX Non Harmonics .................................................................................................................1.12

TX In-Band Spurious Signals .................................................................................................1.12

TX Fixed Spurious Signals .....................................................................................................1.13

TX SSB Phase Noise .............................................................................................................1.13

TX Residual FM......................................................................................................................1.13

TX Residual AM .....................................................................................................................1.13

1100.4903.82 3 E-5

Contents CMU

TX Carrier/Sideband Suppression, Max. Distortion ...............................................................1.14

RX Power Meter (Frequency-Selective).................................................................................1.14

RX Power Meter (Wideband) .................................................................................................1.14

RX Harmonics ........................................................................................................................1.15

RX Spurious Response / Image Rejection .............................................................................1.15

RX SSB Phase Noise.............................................................................................................1.15

RX Residual FM/AM...............................................................................................................1.16

RX Dynamic/ Average Noise Level ........................................................................................1.16

Options for R&S CMU200 ......................................................................................................1.17

GSM-MS ......................................................................................................................1.17

TX GSM Modulation.....................................................................................................1.17

RX GSM Dem odulation........................................................................................1.17

CDMA2000.............................................................................................................................1.18

TX CDMA2000 Modulation ..........................................................................................1.18

RX CDMA2000 Dem odulation.................................................................................1.19

WCDMA .......................................................................................................................1.20

TX WCDMA Modulation...............................................................................................1.20

RX WCDMA Dem odulation .....................................................................................1.20

Function Test with Mobile Stations (R&S CMU200)...............................................................1.21

GSM mobile test ..........................................................................................................1.21

CDMA mobile test ........................................................................................................1.21

CDMA2000 mobile test ................................................................................................1.21

IS136-mobile test .........................................................................................................1.21

AMPS-mobile test ........................................................................................................1.22

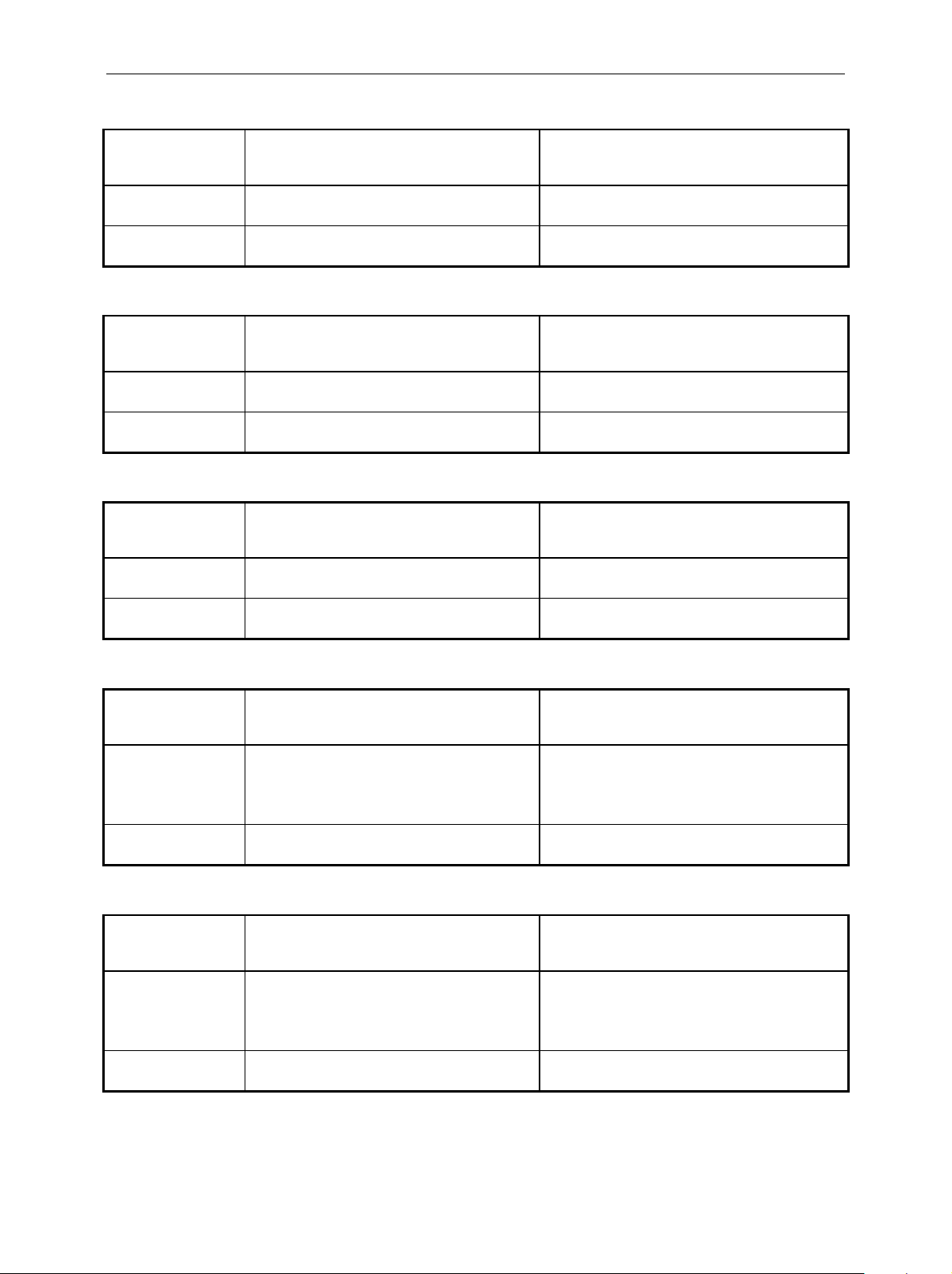

Test Report......................................................................................................................................1.23

2 Adjustment....................................................................................................................................2.1

Manual Adjustment ..........................................................................................................................2.1

Measuring Instruments and Auxiliary Equipment .....................................................................2.1

Preparing the Instrument..........................................................................................................2.2

Adjusting the + 5 VDC Reference Voltage ...............................................................................2.2

Adjusting the 10 MHz Reference Frequency............................................................................2.3

TCXO .............................................................................................................................2.3

OCXO REFERENCE OSC. R&S CMU -B11 .................................................................2.3

OCXO REFERENCE OSC. R&S CMU -B12 .................................................................2.3

Automatic Adjustment of Module Data ..........................................................................................2.4

Preparing the adjustment .........................................................................................................2.4

Performing the adjustment .......................................................................................................2.4

1100.4903.82 4 E-5

CMU Contents

3 Repair ..............................................................................................................................................3.1

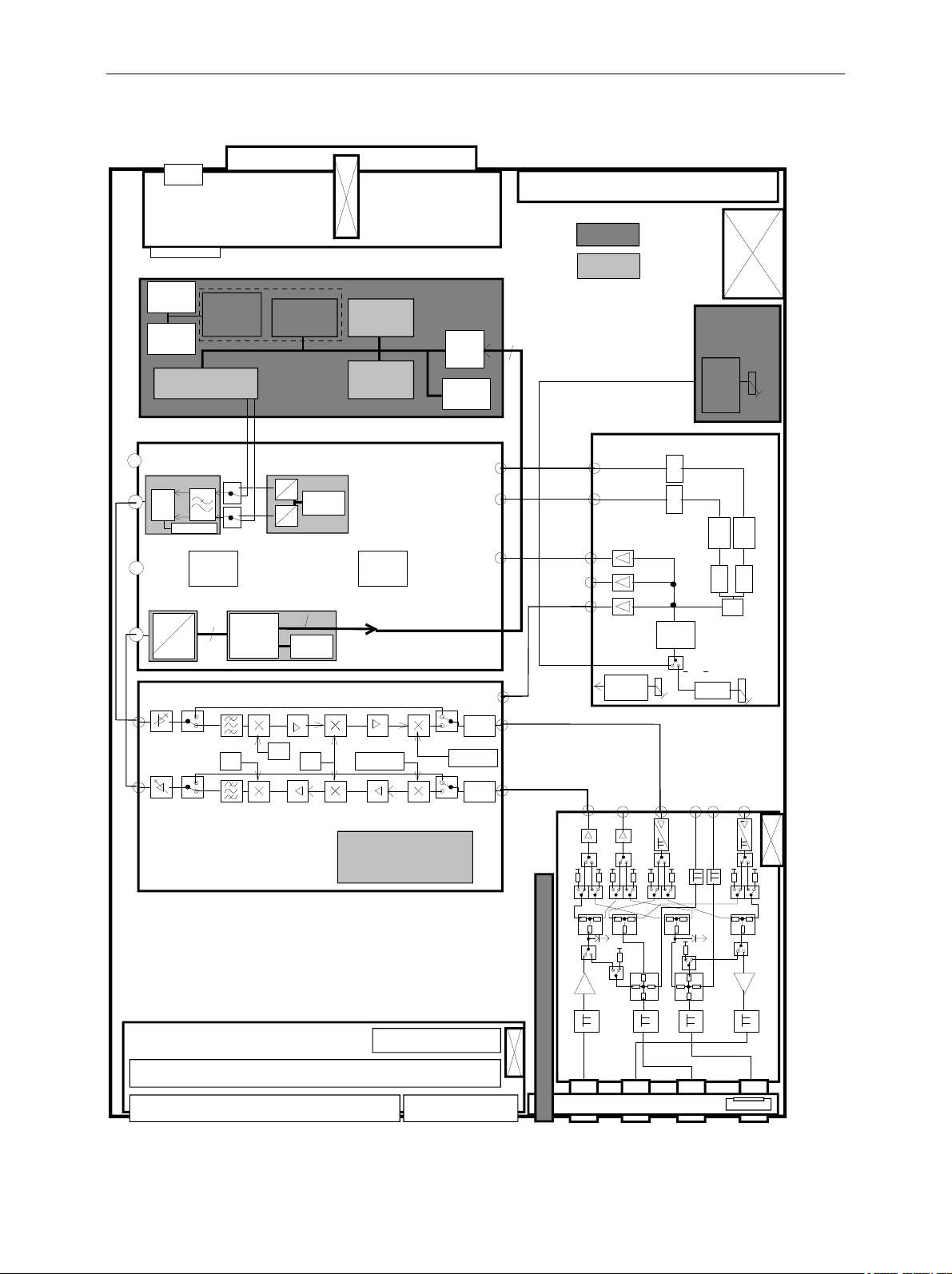

Instrument Design and Function Description ...............................................................................3.1

Block diagram ..........................................................................................................................3.2

Instrument Frame .....................................................................................................................3.3

ear of Instrument Frame ........................................................................................................3.3

R

Front of Instrument Frame .......................................................................................................3.3

Cooling the Instrument .............................................................................................................3.4

FRONT MODULE ....................................................................................................................3.5

POWER SUPPLY ....................................................................................................................3.6

MOTHERBOARD .....................................................................................................................3.7

REFERENCE BOARD .............................................................................................................3.9

Option OCXO REFERENCE OSC. R&S CMU-B11 or B12 ...................................................3.10

RF FRONTEND .....................................................................................................................3.10

RXTX BOARD1 ......................................................................................................................3.11

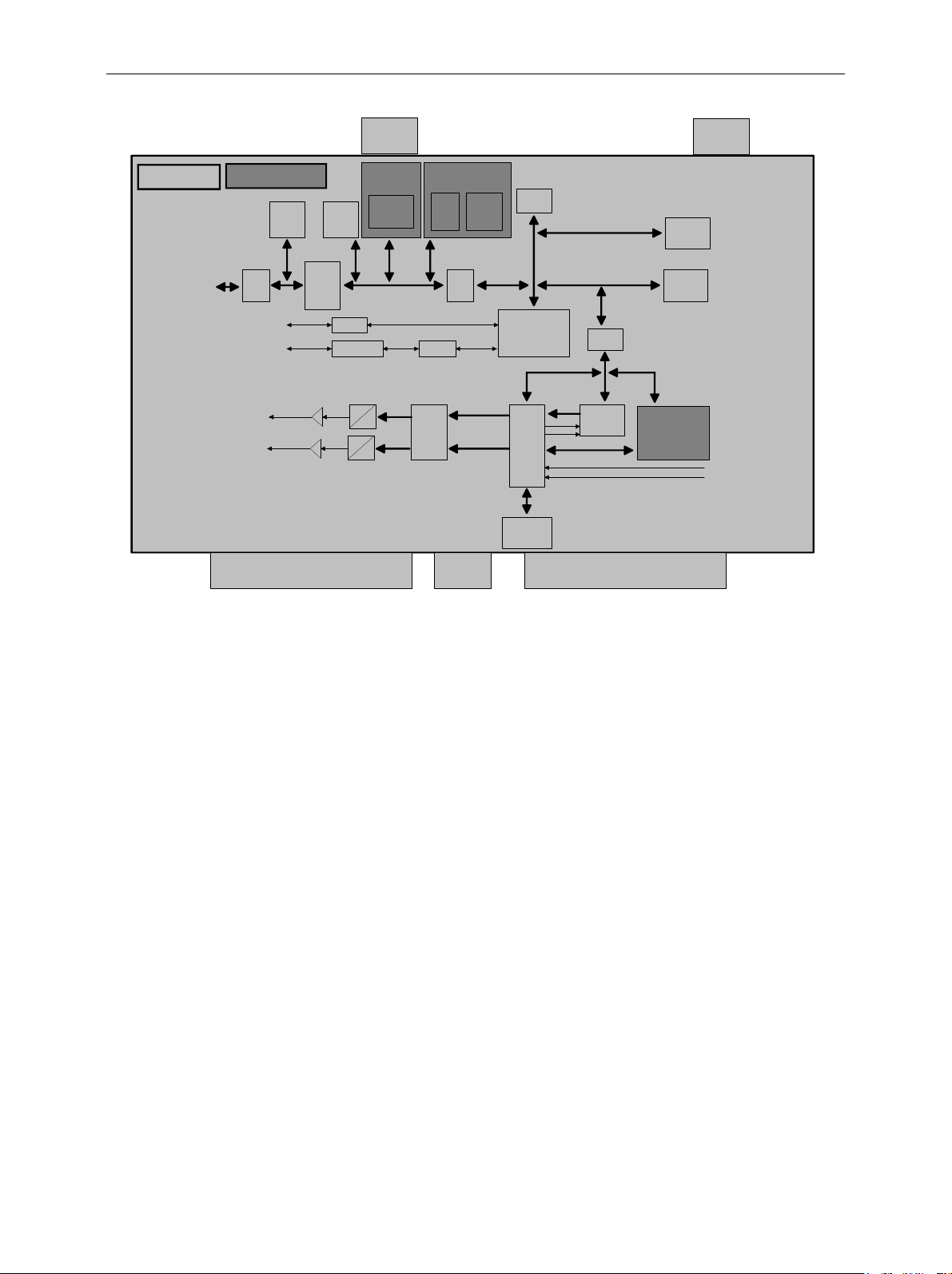

DIGITAL BOARD....................................................................................................................3.13

Option UNIVERSAL SIGNALLING UNIT R&S CMU-B21 Var02 ...........................................3.14

Option UNIVERSAL SIGNALING UNIT R&S CMU-B21 Var 14/54 .......................................3.16

Option AUDIO-GEN. + ANA. R&S CMU-B41.........................................................................3.18

Option WCDMA L1COPRO R&S CMU-B66/68/76/78 ..........................................................3.19

Option CDMA (IS95) Signaling Unit R&S CMU-B81 ..............................................................3.21

Option CDMA2000 Signaling Unit R&S-B83 Var12 ...............................................................3.22

Option CDMA2000 Signaling Unit R&S CMU-B83 Var22 ......................................................3.23

MODULE Replacement...................................................................................................................3.25

Replacing the FRONT MODULE ...........................................................................................3.25

Opening the instrument and removing the FRONT MODULE ........................3.25

Installing the new FRONT MODULE and completing the instrument .............3.26

Putting into operation ......................................................................................3.26

Replacing the FRONT MODULE CONTROLLER in the FRONT MODULE ..........................3.27

Opening the instrument and removing the FRONT MODULE ........................3.27

Removing the FRONT MODULE CONTROLLER ..........................................3.28

Installing the new FRONT MODULE CONTROLLER .....................................3.28

Installing the option again and completing the instruments ............................3.28

Putting into operation ......................................................................................3.29

Replacing the Lithium Battery in the FRONT MODULE.........................................................3.30

Opening the instrument and removing the FRONT MODULE ........................3.30

Removing the lithium battery and installing the new battery ...........................3.31

Completing the instrument ..............................................................................3.32

Putting into operation ......................................................................................3.32

Replacing the Hard Disk in the FRONT MODULE .................................................................3.33

Opening the instrument and removing the FRONT MODULE ........................3.33

Removing the hard disk from the FRONT MODULE ......................................3.33

Installing the new hard disk.............................................................................3.33

Putting into operation ......................................................................................3.33

1100.4903.82 5 E-5

Contents CMU

Replacing the Memory Modules in the FRONT MODULE .....................................................3.34

Opening the instrument and removing the FRONT MODULE ........................3.34

Making the memory modules accessible ........................................................3.35

Removing the memory module .......................................................................3.35

Installing the new memory module and completing the instrument ................3.35

Putting into operation ......................................................................................3.36

Replacing the LCD and/or DC/AC Converter in the FRONT MODULE .................................3.37

Opening the instrument and removing the FRONT MODULE ........................3.37

Making the LCD accessible.............................................................................3.38

Removing the LCD and/or DC/AC Converter..................................................3.38

Installing the new LCD and/or DC/AC converter and compl. the instrument ..3.38

Putting into operation ......................................................................................3.38

Replacing the Keyboard Membrane and/or Mat on the FRONT MODULE............................3.39

Opening the instrument and removing the FRONT MODULE ........................3.39

Removing the membrane................................................................................3.40

Installing the new membrane and completing the instrument.........................3.40

Putting into operation ......................................................................................3.40

Replacing the Labeling Panel on the FRONT MODULE........................................................3.41

Removing the old labeling panel .....................................................................3.41

Installing the new labeling panel and completing the instrument ....................3.41

Putting into operation ......................................................................................3.41

Replacing the Options FLOPPY DISK DRIVE R&S CMU-B61 or PCMCIA INTERFACE......3.42

Opening the instrument and removing the FRONT MODULE ........................3.42

Replacing the option........................................................................................3.43

Completing the instrument and putting into operation.....................................3.43

Replacing the RF FRONTEND ..............................................................................................3.44

Opening the instrument and removing the RF FRONTEND ...........................3.44

Installing the new RF FRONTEND MODULE and compl. the instrument.......3.44

Automatic module data adjustment.................................................................3.44

Replacing the REFERENCE BOARD ....................................................................................3.45

Opening the instrument and removing the REFERENCE BOARD .................3.45

Installing the new REFERENCE BOARD and completing the instrument ......3.45

Automatic module data adjustment.................................................................3.45

Replacing the RXTX BOARD1 ...............................................................................................3.46

Opening the instrument and removing the RXTX BOARD1 ...........................3.46

Installing the new RXTX BOARD1 and completing the instrument.................3.46

Automatic module data adjustment.................................................................3.46

Replacing the TR-CORRECTION MODULE in the RXTX BOARD1 .....................................3.47

Opening the instrument and removing the TR-CORRECTION MODULE ......3.47

Installing the new TR-CORRECTION BOARD and compl. the instrument.....3.47

Automatic module data adjustment.................................................................3.47

Replacing the DIGITAL BOARD.............................................................................................3.48

Opening the instrument and removing the DIGITAL BOARD .........................3.48

Installing the new DIGITAL BOARD and completing the instrument ..............3.48

Automatic module data adjustment.................................................................3.48

Replacing the MODULES: ADC MODULE1, DDC MODULE1, TXDSP MODULE1, AUC

MODULE1 in the DIGITAL BOARD .......................................................................................3.49

Opening the instrument and removing the modules .......................................3.49

Installing the new sandwich module and completing the instrument ..............3.49

Automatic module data adjustment.................................................................3.50

1100.4903.82 6 E-5

CMU Contents

Replacing the Option OCXO REFERENCE OSC. R&S CMU-B11 or R&S CMU-B12 ..........3.51

Opening the instrument and rem. the OPTION OCXO REFERENCE OSC...3.51

Installing the new OPTION OCXO REFERENCE OSC. and

completing the instrument ...............................................................................3.51

Manual OCXO adjustment ..............................................................................3.51

Replacing the Option UNIVERSAL SIGNALLING UNIT R&S CMU-B21 Var02 ...................3.52

Opening the instrument and removing the OPTION UNIV. SIGN. UNIT ........3.52

Installing the new OPTION UNIV. SIGN. UNIT and compl. the instrument ....3.52

Automatic module data adjustment.................................................................3.52

Replacing the MODULES: DSP MODULE0/1, IQOUT MODULE, BLUETOOTH MODULE,

SPEECH CODEC R&S CMU-B52 (INCLUDES DSP MODULE3) in the UNIV. SIGN. UNIT

Var02......................................................................................................................................3.53

Opening the instrument and removing the modules .......................................3.53

Installing the new sandwich module and completing the instrument ..............3.53

Automatic module data adjustment.................................................................3.54

Replacing the Option UNIVERSAL SIGNALLING UNIT CMU-B21 Var14/54........................3.55

Opening the instrument and removing the OPTION UNIV. SIGN. UNIT ........3.55

Installing the new OPTION UNIV. SIGN. UNIT and compl. the instrument ....3.55

Automatic module data adjustment.................................................................3.55

Replacing the MODULES: SPEECH CODEC, BLUETOOTH MODULE, MC 68K, DSP

MODULE, POWER PC MODULE, OPTION SPEECH CODEC CMU-B52VAR 14

in the UNIV. SIGN. UNIT Var14/54 ........................................................................................3.56

Opening the instrument and removing the modules .......................................3.56

Installing the new sandwich module and completing the instrument ..............3.56

Automatic module data adjustment.................................................................3.57

Replacing the Option WCDMA L1COPRO CMU-B66/68/76/78.............................................3.57

Opening the instrument and removing the OPTION WCDMA L1COPRO......3.57

Installing the new OPTION UNIV. SIGN. UNIT and compl. the instrument ....3.57

Automatic module data adjustment.................................................................3.57

Replacing the MODULES: WCDMATX MODULE, TX-FEC MODULE, WDDC MODULE,

RX-FEC MODULE , in the WCDMA L1COPRO CMU-B66/68/76/78 ....................................3.58

Opening the instrument and removing the modules .......................................3.58

Installing the new sandwich module and completing the instrument ..............3.59

Automatic module data adjustment.................................................................3.59

Replacing the Option CDMA2000 Signaling Unit CMU-B83 Var12........................................3.59

Opening the instrument and removing the OPTION

CDMA2000 SIGNALING UNIT........................................................................3.59

Installing the new OPTION CDMA2000 SIGNALING UNIT and

completing the instrument ...............................................................................3.60

Automatic module data adjustment.................................................................3.60

Replacing the MODULES: ACCESS MODULE CMU-B82, SPEECH CODEC MODULE

CMU-B85, HDR MODULE CMU-B88 in the CDMA2000 Signaling Unit CMU-B83 Var12.....3.60

Opening the instrument and removing the modules .......................................3.60

Installing the new sandwich module and completing the instrument ..............3.60

Automatic module data adjustment.................................................................3.61

Replacing the Option CDMA2000 Signaling Unit CMU-B83 Var22........................................3.61

Opening the instrument and removing the OPTION

CDMA2000 SIGNALING UNIT........................................................................3.61

Installing the new OPTION CDMA2000 SIGNALING UNIT and

completing the instrument ...............................................................................3.62

Automatic module data adjustment.................................................................3.62

1100.4903.82 7 E-5

Contents CMU

Replacing the MODULES: 1xEV-DO MODULE CMU-B89, SPEECH CODEC MODULE

CMU-B85 VAR22, POWER QUICC3 MODULE in the CDMA2000 Signaling Unit

MU-B83 Var22 .....................................................................................................................3.62

C

Opening the instrument and removing the modules .......................................3.62

Installing the new sandwich module and completing the instrument ..............3.63

Automatic module data adjustment.................................................................3.63

Replacing the Option AUDIO-GEN. + ANA. CMU-B41 ..........................................................3.64

Opening the instrument and removing the Option AUDIO-GEN. + ANA. .......3.64

Installing the new Option AUDIO-GEN. + ANA. and compl. the instrument ...3.64

Automatic module data adjustment.................................................................3.64

Replacing the POWER SUPPLY ...........................................................................................3.65

Removing the POWER SUPPLY ....................................................................3.65

Installing the new POWER SUPPLY...............................................................3.65

Replacing the Instrument Fan ................................................................................................3.66

Opening the instrument and removing the fan ................................................3.66

Installing the new fan and completing the instrument .....................................3.66

Replacing the MOTHERBOARD (1100.0908.02) ..................................................................3.67

MOTHERBOARD1 (big MOTHERBOARD) .................................................................3.67

Opening the instrument and removing MOTHERBOARD1 ............................3.67

Installing the new MOTHERBOARD1 and completing the instrument............3.67

MOTHERBOARD2 (small MOTHERBOARD) .............................................................3.68

Opening the instrument and removing MOTHERBOARD2 ............................3.68

Installing the new MOTHERBOARD2 and completing the instrument............3.68

FRONTPANEL BOARD (at the front of the instrument frame) ....................................3.68

Opening the instrument and removing the FRONTPANEL BOARD...............3.68

Installing the new FRONTPANEL BOARD and completing the instrument ....3.68

REARPANEL BOARD1 (Interface board for Standard Connectors at the Rear

of the Instrument Frame) .............................................................................................3.69

Opening the instrument and removing the REARPANEL BOARD1 ...............3.69

Installing the new REARPANEL BOARD1 and completing the instrument.....3.69

REARPANEL BOARD2 (Interface Board for Further Connectors at the Rear of the

Instrument Frame) .......................................................................................................3.69

Opening the Instrument and removing the REARPANEL BOARD2 ...............3.69

Installing the new REARPANEL BOARD2 and completing the instrument.....3.69

Replacing the MOTHERBOARD (1100.2352.02)...........................................................................3.70

MOTHERBOARD1 (big MOTHERBOARD) .................................................................3.70

Opening the instrument and removing MOTHERBOARD1 ............................3.70

Installing the new MOTHERBOARD1 and completing the instrument............3.70

MOTHERBOARD2 (small MOTHERBOARD) .............................................................3.71

Opening the instrument and removing MOTHERBOARD2 ............................3.71

Installing the new MOTHERBOARD2 and completing the instrument............3.71

FRONTPANEL BOARD (at the front of the instrument frame) ....................................3.71

Opening the instrument and removing the FRONTPANEL BOARD...............3.71

Installing the new FRONTPANEL BOARD and completing the instrument ....3.71

REARPANEL BOARD2 (Interface Board for Further Connectors at the Rear

of the Instrument Frame) Opening the Instrument and removing

the REARPANEL BOARD2..........................................................................................3.72

Installing the new REARPANEL BOARD2 and completing the instrument.....3.72

1100.4903.82 8 E-5

CMU Tables

Troubleshooting .............................................................................................................................3.73

Troubleshooting using the LEDs (H1 to H8) on the MOTHERBOARD ..................................3.74

Troubleshooting using the SELFTEST Menu for Modules .....................................................3.76

More troubleshooting..............................................................................................................3.79

General errors on the transmitter side of the R&S CMU........................................................3.79

General errors on the receiver side of the R&S CMU ............................................................3.80

4 Software Update/Installing Options ...................................................................................4.1

New Installation of the CMU Software............................................................................................4.1

Software Update via PCMCIA INTERFACE.............................................................................4.1

Software Update via FLOPPY DISK DRIVE ............................................................................4.1

Performing a Software Update .................................................................................................4.2

Reinstalling the Old Software .........................................................................................................4.3

Loading Software as long as there is no VersionManager in the R&S CMU ..............................4.3

Installing the Options.......................................................................................................................4.4

SW Packages for various network tests R&S CMU-Kxx ......................................................4.4

5 Documents ....................................................................................................................................5.1

Module and Cable Exchange...........................................................................................................5.1

1100.4903.82 9 E-5

Tables CMU

Tables

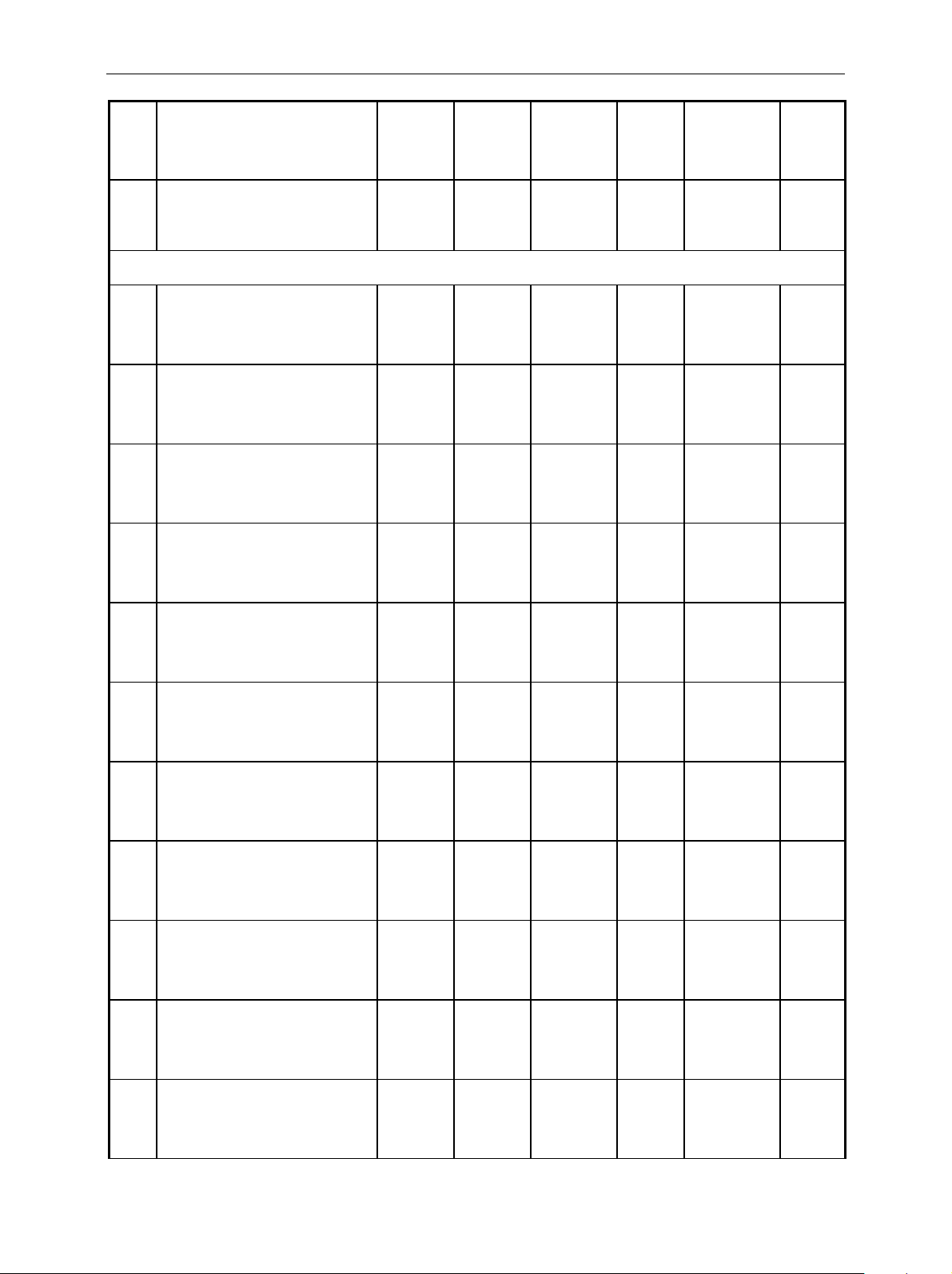

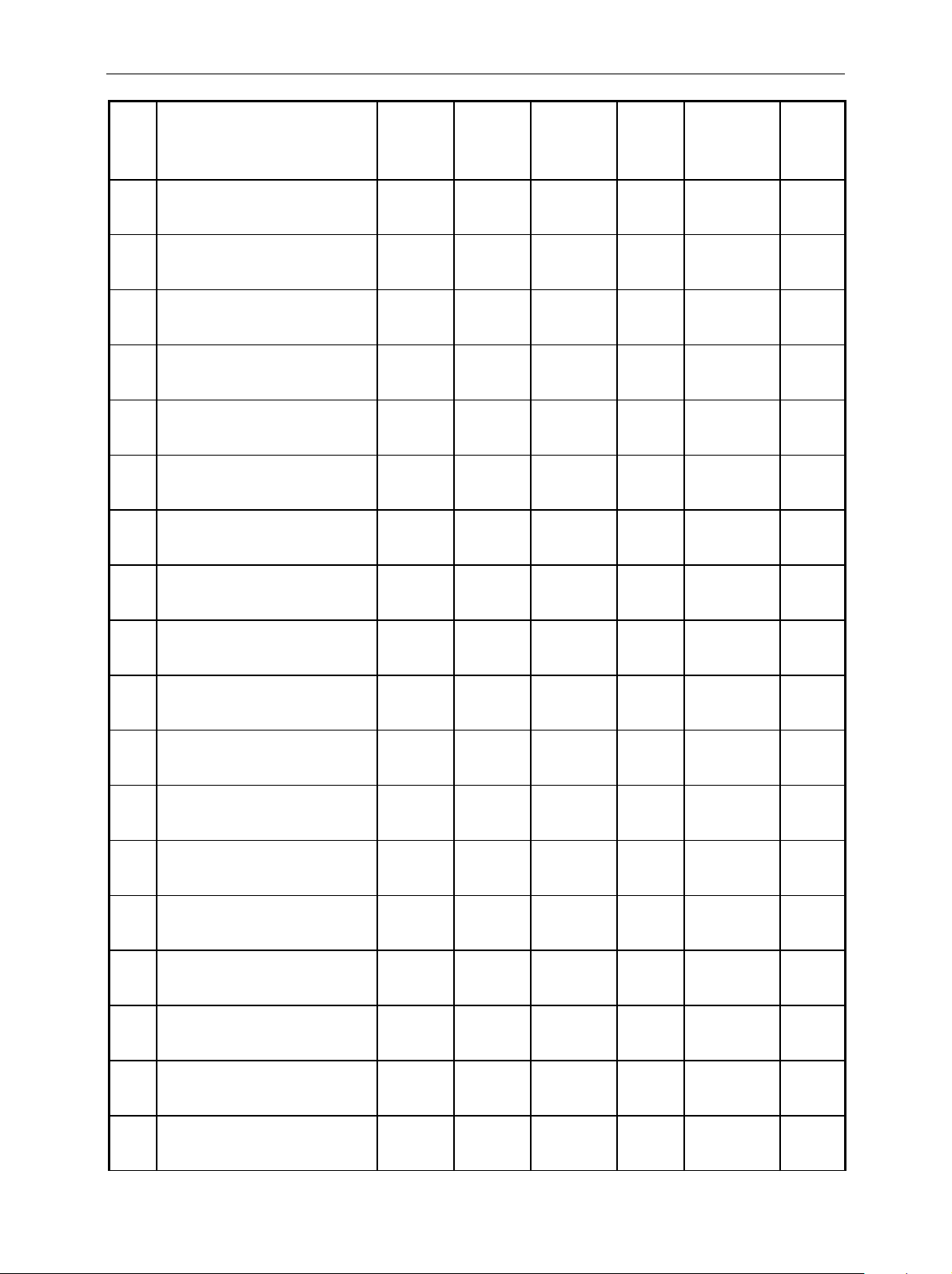

Table 1-1 Measuring instruments and auxiliary equipment for manual performance test......................1.2

Table 1-2 Test report ............................................................................................................................1.18

Table 2-1 Measuring instruments and auxiliary equipment for manual adjustment of the R&S CMU ...2.1

Table 5-1 List of power cables available ................................................................................................5.2

1100.4903.82 10 E-5

R&S CMU Index

Index

DSP Module0/1.................. 3.53, 3.55, 3.58, 3.60, 3.62

A

ADC Module1 (DIGITAL Board) ................................... 3.13

Adjustment

+ 5 VDC Reference Voltage..................................... 2.2

10 MHz Reference-Frequency .................................2.3

Automatic of Module Data........................................ 2.4

AUC Module1 (DIGITAL Board) ................................... 3.14

AUDIO-GEN. + ANA., R&S CMU-B41.......................... 3.18

Auxiliary means.............................................................. 1.2

B

Block diagram ................................................................ 3.2

C

CDMA (IS95) Signalling Unit ...................... 3.21, 3.22, 3.23

Circuit documents (basic unit) ........................................ 5.3

Cooling the instrument ...................................................3.4

D

DDC Module1 (DIGITAL Board)................................... 3.13

DIGITAL Board............................................................. 3.13

Documents..................................................................... 5.1

Drawing of all CMU spare parts.......................... See annex

DSP Module (UNIV. SIGN. Unit) ......................... 3.15, 3.16

F

Fan See cooling the instrument

FLOPPY DISK DRIVE (Software Update) ...................... 4.1

FRONT Module.............................................................. 3.5

FRONTPANEL Board.............................................. 3.7, 3.8

Function test with Mobile Stations................................ 1.21

FLOPPY Disk Drive R&S CMU-B61 .......................3.42

Front Module..........................................................3.25

FRONT Module Controller......................................3.27

FRONTPANEL Board....................................3.68, 3.71

Hard Disk ...............................................................3.33

Instrument fan ........................................................3.66

IQOUT Module................... 3.53, 3.55, 3.58, 3.60, 3.62

Keyboard Membrane ..............................................3.39

Labeling Panel........................................................3.41

LCD........................................................................3.37

Lithium Battery .......................................................3.30

Mat .........................................................................3.39

Memory Modules....................................................3.34

Motherboard .................................................. 3.67, 3.70

Motherboard1 ................................................ 3.67, 3.70

Motherboard2 ................................................ 3.68, 3.71

Option AUDIO-GEN. + ANA. CMU-B41..................3.63

Option OCXO REFERENCE OSC..........................3.51

Option SPEECH CODEC ... 3.53, 3.55, 3.58, 3.60, 3.62

PCMCIA Interface R&S CMU-B62..........................3.42

POWER SUPPLY...................................................3.65

REARPANEL Board1 .............................................3.69

REARPANEL Board2 ....................................3.69, 3.72

REFERENCE Board...............................................3.45

RF Frontend...........................................................3.44

RXTX Board1.........................................................3.46

TR-CORRECTION Module.....................................3.47

TXDSP Module1.....................................................3.49

UNIVERSAL SIGNALLING Uni

t.......................................... 3.52, 3.55, 3.57, 3.59, 3.61

Motherboard ...................................................................3.7

Motherboard1 ..........................................................3.7, 3.8

Motherboard2 ..........................................................3.7, 3.8

N

Netclock generation........................................................3.9

H

Hard disk (FRONT Module)............................................ 3.5

I

Instrument design........................................................... 3.1

Instrument frame ............................................................ 3.3

Interface test

IEC bus.................................................................... 1.8

RS-232.....................................................................1.8

IQOUT Module (UNIV. SIGN. Unit) ..................... 3.15, 3.19

L

LCD (FRONT Module).................................................... 3.5

Loudspeaker .................................................................. 3.3

M

Manual Test Procedure .................................................. 1.7

Maximum distortion ...................................................... 1.14

Measuring instruments ................................................... 1.2

Module replacement

ADC Module1......................................................... 3.49

AUC Module1......................................................... 3.49

DDC Module1 ........................................................ 3.49

DIGITAL Board ...................................................... 3.48

O

OCXO

Adjustment ...............................................................2.3

REFERENCE OSC. R&S CMU-B11 or B12 (Option)

...............................................................................3.10

Options

Installing...................................................................4.4

List ...........................................................................4.4

Overtemperature protection (POWER SUPPLY) ............3.6

P

PCMCIA INTERFACE (Software Update).......................4.1

Performance Test ...........................................................1.1

Power cables..................................................................5.2

Power Factor Correction (PFC, POWER SUPPLY) ........3.6

POWER SUPPLY...........................................................3.6

POWERGOOD signal (POWER SUPPLY) .....................3.6

R

R&S CMU-B21 ...........................................3.14, 3.16, 3.19

R&S CMU-B41 .............................................................3.18

R&S CMU-B81 ...........................................3.21, 3.22, 3.23

R&S CMU-K21 (Option)..................................................4.4

REARPANEL Board1 .....................................................3.7

1100.4903.82 I.1 E-5

R&S CMU Index

REARPANEL Board2 ..................................................... 3.8

REFERENCE Board....................................................... 3.9

Reference frequencies ...................................................1.9

Repair ............................................................................3.1

RF Frontend................................................................. 3.10

RX Dynamic / average noise level................................ 1.16

RX GSM Demodulation .............................. 1.17, 1.19, 1.20

RX Harmonics .............................................................. 1.15

RX Power meter (Frequency selective) ........................1.14

RX Power meter (Wideband)........................................ 1.14

RX Residual FM/AM.....................................................1.16

RX Spurious response / image rejection....................... 1.15

RX SSB Phase Noise...................................................1.15

RXTX Board1............................................................... 3.11

S

Selftest........................................................................... 1.7

Software Update

New installation........................................................4.1

Performing ............................................................... 4.2

Reinstalling the Old Software................................... 4.3

Spare parts (order)......................................................... 5.1

SPEECH CODEC (UNIV. SIGN. UNIT)3.15, 3.17, 3.19,

3.22, 3.24

Spinwheel (FRONT Module) .......................................... 3.5

STANDBY circuit (POWER SUPPLY) ............................ 3.6

STANDBY/ON signal (POWER SUPPLY)...................... 3.6

T

TCXO

Adjustment ...............................................................2.3

Function ...................................................................3.9

Test report....................................................................1.23

Tolerance analysis..........................................................1.6

Troubleshooting

General errors ........................................................3.79

using the error messages .......................................3.78

using the LEDs.......................................................3.74

using the SELFTEST Menu for Modules ................ 3.76

TX carrier/sideband suppression ..................................1.14

TX Frequency Accuracy ...............................................1.11

TX Frequency settling time ...........................................1.11

TX GSM Modulation ................................... 1.17, 1.18, 1.20

TX Harmonics...............................................................1.12

TX Level Error ..............................................................1.11

TX Level Settling time...................................................1.12

TX Nonharmonics .........................................................1.12

TX Residual AM............................................................1.13

TX Residual FM............................................................1.13

TX SSB Phase Noise ...................................................1.13

TXDSP Module1 (DIGITAL Board) ...............................3.14

U

Universal Signalling Unit............................. 3.14, 3.16, 3.19

Update (software) ...........................................................4.2

V

VersionManager (loading)...............................................4.3

VSWR ..........................................................................1.11

1100.4903.82 I.2 E-5

R&S CMU Documentation

Contents of Manuals for Universal Radio Communication Tester R&S CMU200/ R&S CMU300

Service Manual Instrument

This service manual for Universal Radio Communication Tester R&S CMU provides information on

checking the instrument for compliance with rated specifications, as well as on adjustment, repair

and troubleshooting. It further contains all the information necessary for repairing the instrument by

the replacement of modules.

The service manual comprises five chapters and an annex (chapter 5) containing the R&S CMU circuit

documentation:

Chapter 1 Provides all the information necessary to check R&S CMU for compliance with

rated specifications. The required test equipment is included, too.

Chapter 2 Describes the adjustment of the +5 VDC reference source and of the 10-MHz

reference frequency source as well as the software-controlled adjustment of individual module data following module replacement.

Chapter 3 Describes the design of R&S CMU as well as simple measures for repair and

fault

diagnosis, in particular the replacement of modules and access to hardware settings by means of service commands.

Chapter 4 Contains information on the extension and modification of R&S CMU by installing

instrument software and retrofitting options.

Chapter 5 Contains spare parts lists and exploded views of R&S CMU.

Operating Manual

In the operating manual for R&S CMU basic unit you will find information about the technical specifications of R&S CMU, the controls and connectors on the front and rear panel, necessary steps for

putting the instrument into operation, the basic operating concept, manual and remote control.

For introduction typical measurement tasks are explained in detail using the functions of the user interface and program examples.

The operating manual contains all information on the characteristics, operation and remote control of

the R&S CMU including RF and Audio measurements. It further provides hints on preventive maintenance and fault diagnosis by means of warnings and error messages output by the unit.

Service Manual Modules

The service manual modules is not delivered with the instrument but may be obtained from your R&S

service department using the order number 1100.4903.92.

Service manual modules contains information about the individual modules of R&S CMU. This comprises the test and adjustment of the modules, fault detection within the modules and the interface

description.

1100.4903.82 0.1 E-5

R&S CMU General

1 Performance Test

his chapter provides the necessary information for checking the technical data of the R&S CMU.

T

Please read the general notes on the test procedure on page 1.7 first. Then follows a list of the

measuring equipment required for the performance test; a form for the test report is to be found at the

end of this chapter.

The adjustment of the instrument for restoring the data integrity and the measuring equipment required

for this purpose will be described in chapter 2 of this service manual.

General

The technical data of a R&S CMU can be checked in the following ways:

A) Calibration by an R&S Representative with an ACS Calibration System

Advantages

• Automatic procedure

• Small measurement uncertainties

• Calibration and readjustment

• In most cases, the instrument does not have to leave the country

B) Sending the Instrument to the Factory (Memmingen, Germany)

Advantages

• Automatic procedure at the final test setup

• Minimum measurement uncertainties

• Calibration and readjustment

Necessary Documents

• Operating manual R&S CMU200/R&S CMU300

• Data sheet R&S CMU200

Note: It is recommended to read the following journal on the subjects "measurement uncertainty"

and "tolerance analysis": ETSI Technical Report ETR 028, June 1997

1100.4903.82 1.1 E-5

Measuring Instruments and Auxiliary Equipment R&S CMU

Measuring Instruments and Auxiliary Equipment

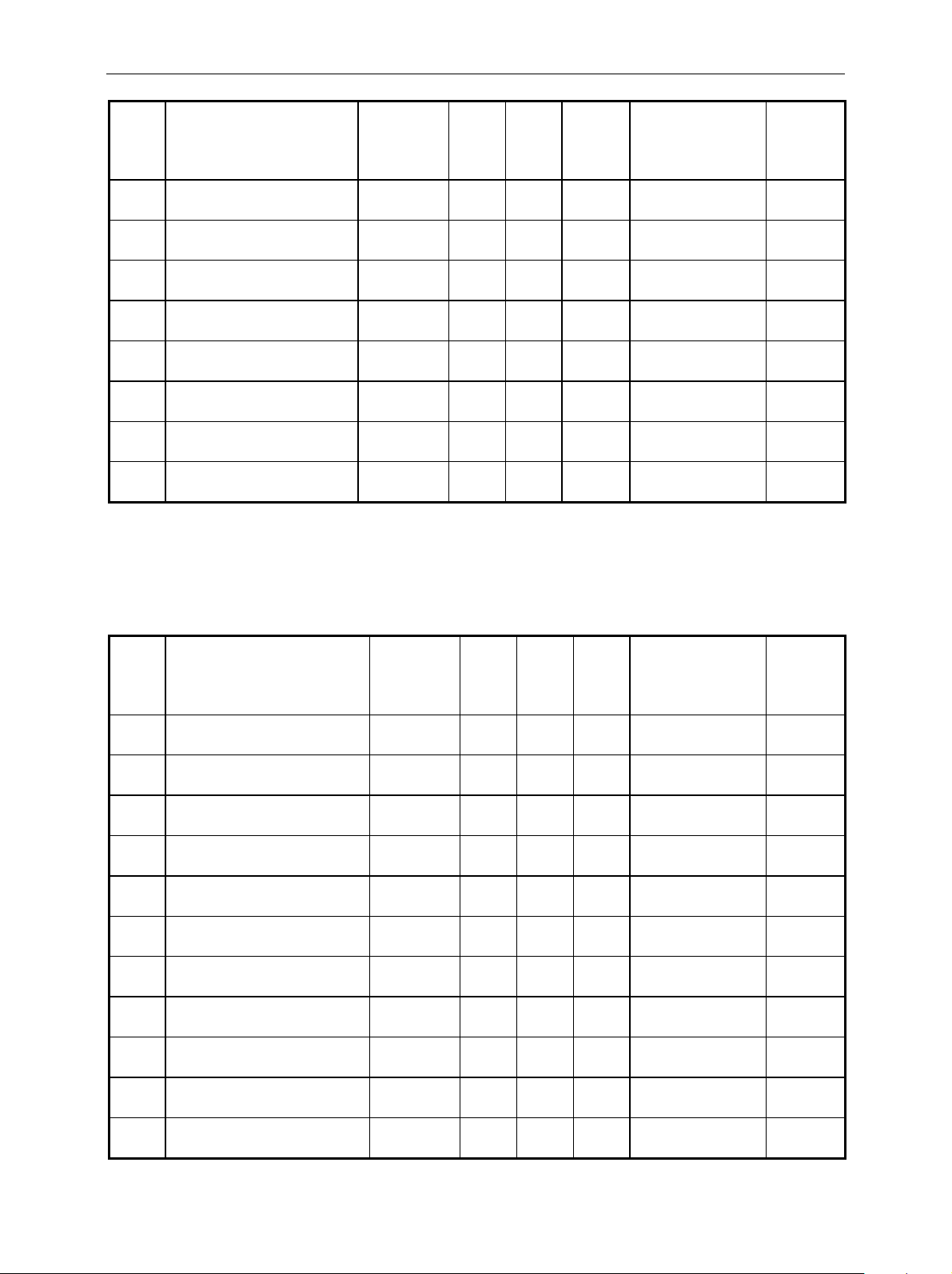

Table 1-1 Measuring instruments and auxiliary equipment for manual performance test

Item Type of instrument Required characteristics Appropriate device R & S

1 Signal generator 100 kHz to 2.7 GHz,

2 Spectrum analyzer 100 kHz to 7 GHz,

3 Power meter R&S NRVD with sensors

4 Power amplifier 100 kHz to 2.7 GHz,

5 Harmonics filter attenuate the harmonics of the

6 Directional coupler 50 MHz to 2.7 GHz,

7 Network analyzer

or VSWR Bridge

Generation of a

GSM/CDMA2000/WCDMA

signal (dummy burst)

Demodulation of

GSM/CDMA2000/WCDMA

signals

Pout = 100 W

power amplifiers to min 30 dBc

up to 100 W

100 kHz to 2.7 GHz R&S ZVR

R&S SME03

R&S SMIQ03 with

options B42/B60

R&S FSE with

R&S FSE-B7

R&S FSIQ-7 with options

B4/B5/B7/B11/B12/B70/

K71

R&S FSP–3

R&S NRV-Z4

R&S NRV-Z51

RX measurements

RX measurements

RX measurements

R&S ZRC

order number

1038.6002.03

1125.5555.03

1066.3010.20/30

1119.5005.17

1164.4391.03

RX measurements,

1043.0009.61 Reflection coefficient/

Use

RX measurements

TX measurements

TX measurements

VSWR

RF connectors

1100.4903.82 1.2 E-5

R&S CMU Measuring Instruments and Auxiliary Equipment

REF1

REF2

TX1

Test Setups

The quality of the test setup has an effect on the measurement procedures.

Note: Make sure to use only high-quality coax cables and coax connectors as well as calibrated

measuring equipment.

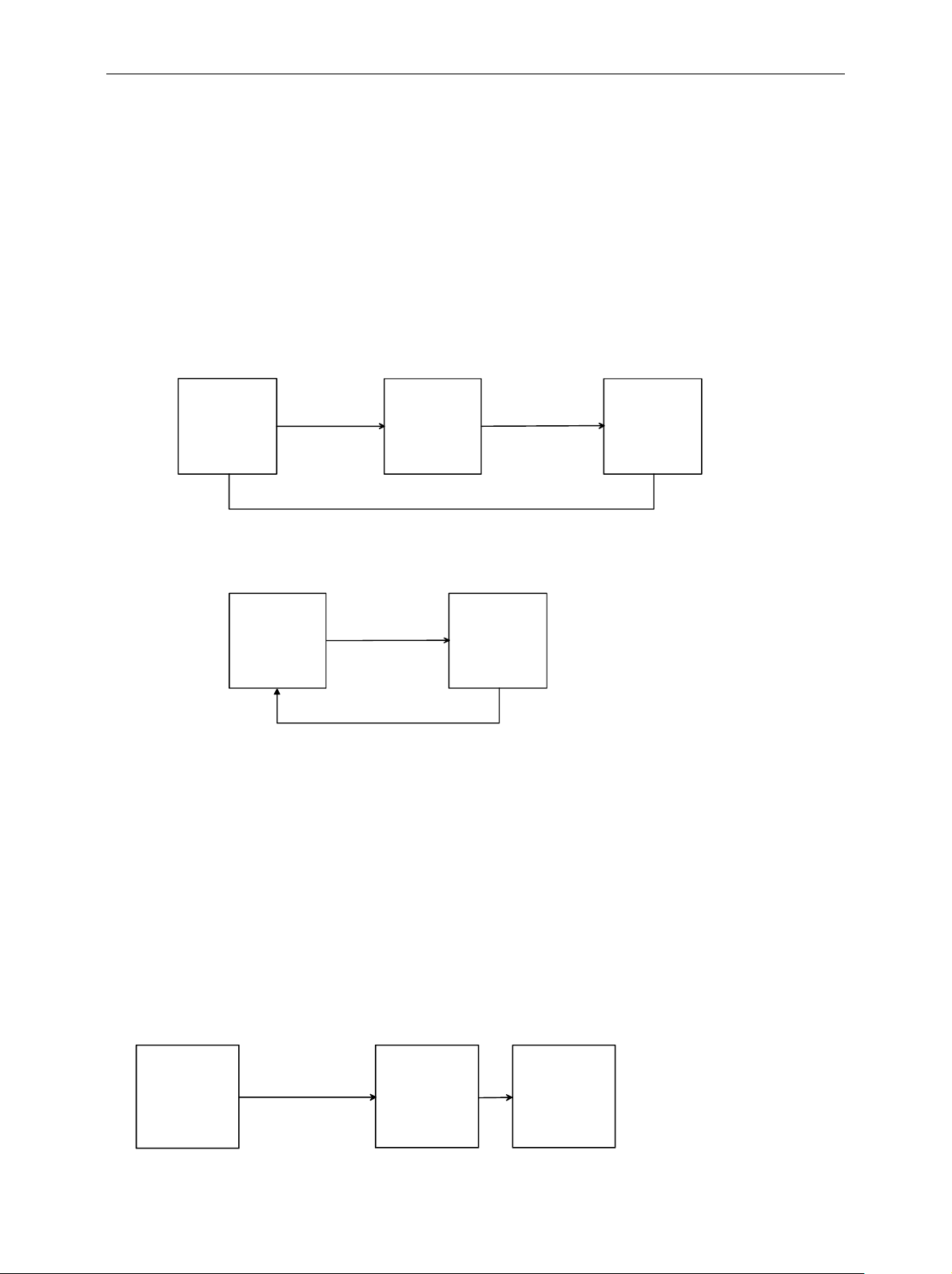

Reference Frequencies

Test setup REF1:

Spectrum

Analyzer

(FSE

or

FSIQ)

GEN

REFIN

DUT

(CMU)

R

F3 OUT

10 MHz Reference Freq.

Test setup REF2:

Spectrum

Analyzer

(FSE or

FSIQ)

DUT

(CMU)

REF IN

REF OUT 2

10 MHz Reference Freq.

TX Level Measurements

Test setup TX1, TX2, TX3, TX4 (depending on level range):

Normalize spectrum analyzer (FSIQ) to wideband power meter (NRVD) at Max. Level setting of the

R&S CMU (test setups TX1, TX2, TX3).

The attenuator of the spectrum analyzer must be held at this position over 60 dB.

Normalize spectrum analyzer with preamplifier to spectrum analyzer at last level (test setups TX3,

TX4).

The attenuator of the spectrum analyzer must be held at this position over 60 dB.

DUT

(CMU)

+5 dBm

RF3OUT

NRV-Z51

NRVD

1100.4903.82 1.3 E-5

Measuring Instruments and Auxiliary Equipment R&S CMU

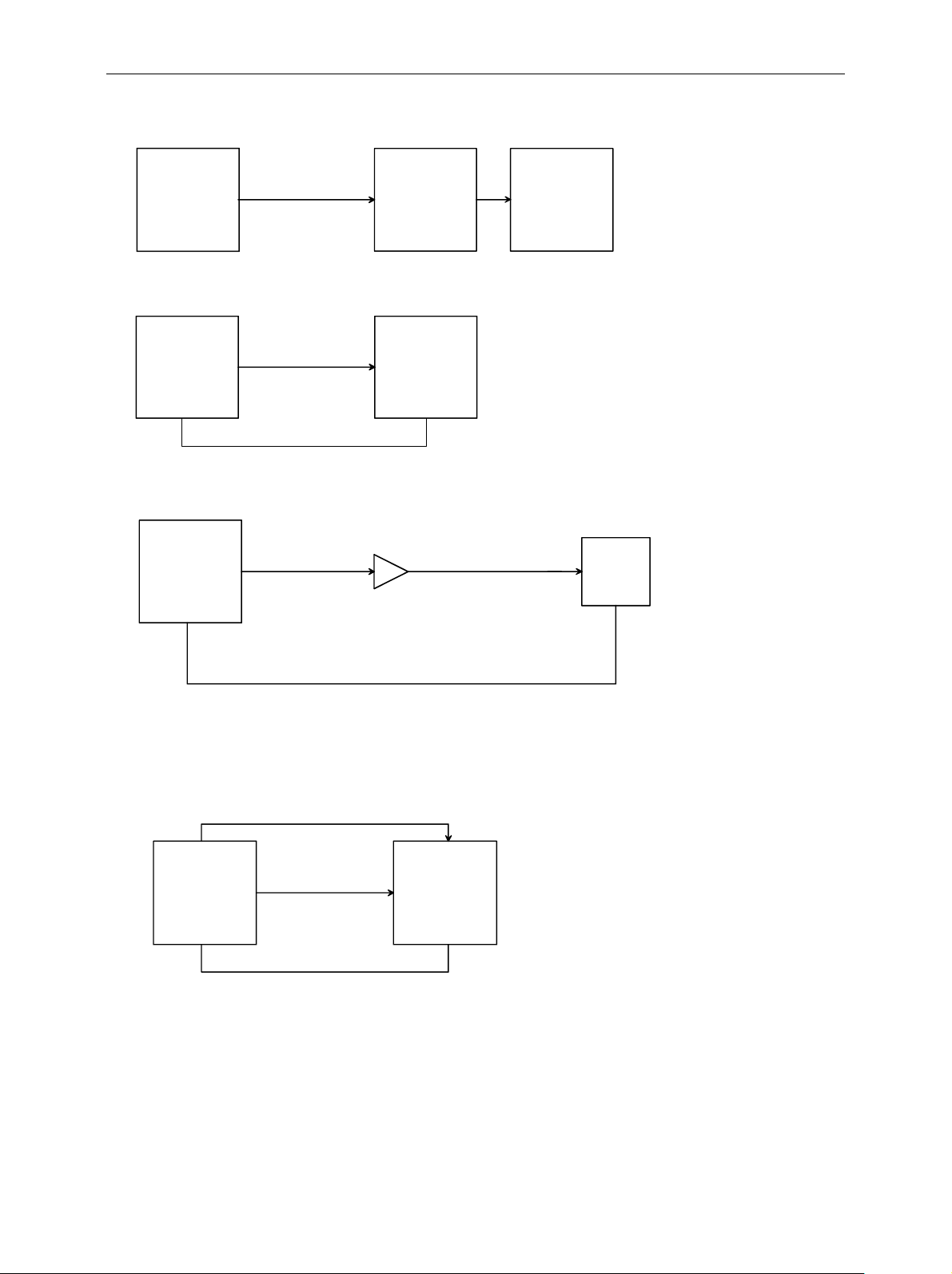

TX2

TX3

TX4

ext. Trigger input

TX5

-33 dBm/

DUT

(CMU)

DUT

(CMU)

-16 dBm

R

F1 /

R

F2

-93 dBm to -33 dBm/

-76 dBm to -16 dBm/

-55 dBm to +5 dBm

RF1 /

RF2 /

R

F3 OUT

10 MHz Reference Freq.

NRV-Z4

FSIQ or FSE

NRVD

-130 dBm to -93 dBm/

-117 dBm to -76 dBm/

DUT

(CMU)

-90 dBm to -55 dBm

RF1/

RF2/

RF3 OUT

10 MHz Reference Freq.

General TX measurements

Test setup TX5:

AUX3, pin2

DUT

(CMU)

RF1, RF2, RF3 OUT

10 MHz Reference Freq.

RF-PreAmp

36 dB

FSE

or FSIQ

Spectrum

analyzer

(FSE or

FSIQ)

1100.4903.82 1.4 E-5

R&S CMU Measuring Instruments and Auxiliary Equipment

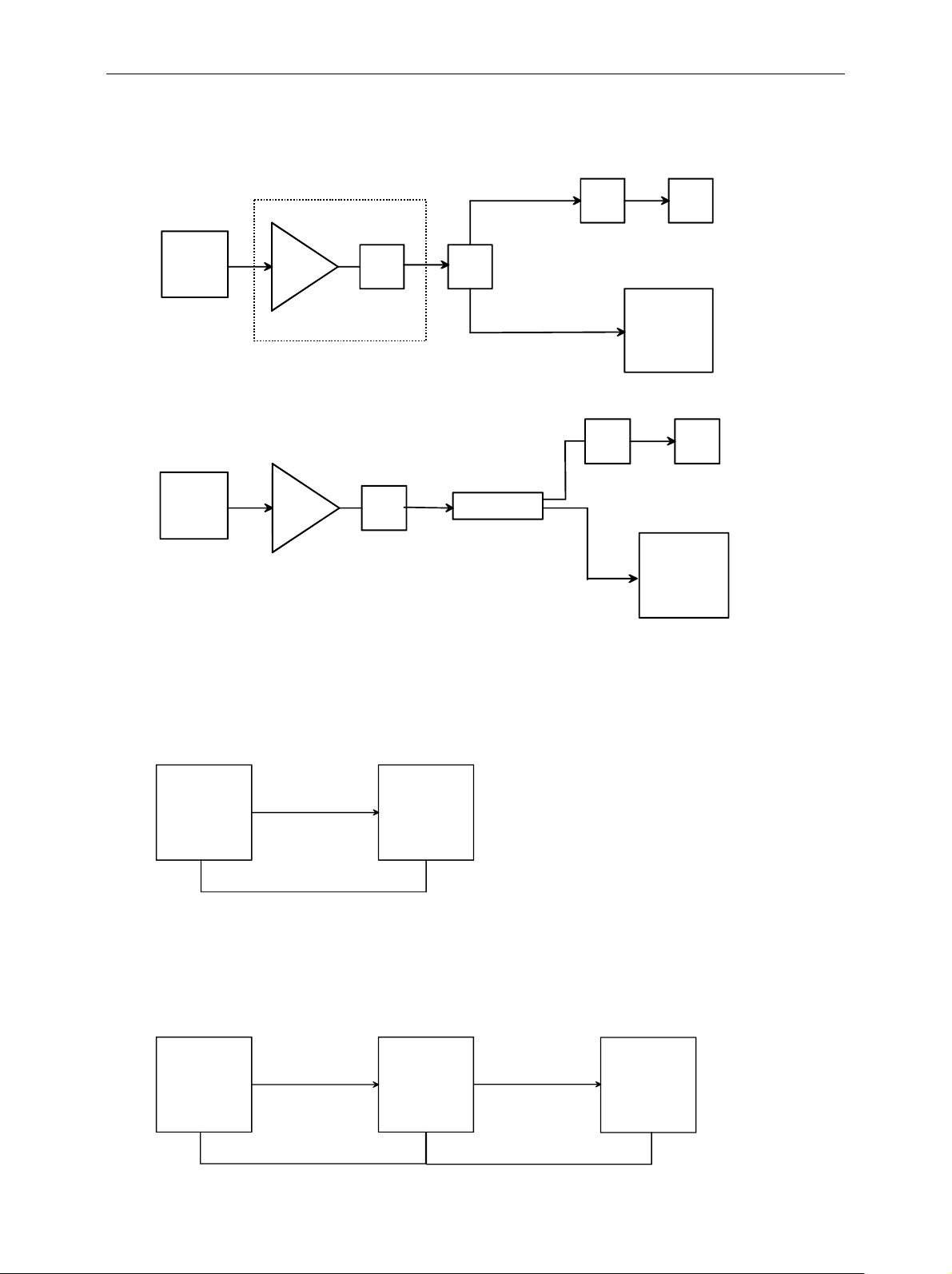

RX3

RX4

RX Level measurements

Test setup RX1, RX2 (depending on level range):

RX1

NRVZ4

NRVD

GEN

Power

Ampl.

depending on max.

level of power splitter

RX2

GEN

Power

Ampl.

General RX Measurements

Test setup RX3:

LPF

LPF

Power

Splitter

direct. coupl

-30 dB

NRV-

Z4

DUT

(CMU)

NRVD

DUT

(CMU)

GEN

RF, RF2, RF4IN

10 MHz Reference Freq.

DUT

(CMU)

RX Demodulation Measurements

Test setup RX4:

Demodulator

GEN

RF4IN

10 MHz Reference Freq.

DUT

(CMU)

IF3RX CH1

10 MHz Reference Freq.

1100.4903.82 1.5 E-5

(FSE with

FSE-B7 or

FSIQ)

Tolerance Analysis R&S CMU

Tolerance Analysis

Due to the small measurement uncertainty of the R&S CMU, the measuring equipment must meet

stringent requirements. Since the measurement uncertainty of the measuring equipment to be achieved

depends on the test setup used, it is recommended to perform a tolerance analysis.

To be able to trace back errors in the measurement, the measurement uncertainty should also be

indicated in the test report.

The tolerances given in the test report refer to the values specified in the data sheet, ie the

measurement uncertainties of the test setup used are to be taken into account as well.

Unless otherwise specified, the specified tolerances are always to be observed.

Note: Please take into account the ETSI Technical Report ETR 028.

The given tolerances refer to R&S CMU data sheet 04/99.

1100.4903.82 1.6 E-5

R&S CMU Manual Test Procedure

Manual Test Procedure

Some additional measurements can only be performed using a mobile phone via the normal operating

menus of the R&S CMU. These measurements are described in the section 'Function Test with Mobile

Stations'.

The suggested frequencies and levels at which the measurements should be performed have been

selected according to the instrument concept. The user can of course also select other frequencies and

levels within the scope of values guaranteed in the data sheet.

Note: Before testing the rated specifications, allow the instrument to warm up for at least 15 min.

The ambient temperature should be 23 °C to 26 °C.

Selftest

The R&S CMU offers various selftest options for checking the functioning and for troubleshooting.

Before carrying out the performance test, the Maintanance menu in the BASE function group should be

called up and the following selftests should be performed:

• Continuous Selftest

• 1

Preparation:

Test: Select the individual test in the BASE (MAINTENANCE) menu and check the results

Note: The Continuous Selftest combines the System Selftest and Internal RF Loop Selftest. In

1

To obtain more detailed information start the following tests:

4/32 RF Loop Test

Start user SW of the R&S CMU (switch on instrument).

(Continuous Selftest, 1

this test, only a passed/failed message with error output is indicated. In case of errors, an

error file ‘cst.err’ is created in addition.

4/32 RF Loop Test: Selftest RF Path RF1RF4 IN and RF3 OUTRF2 via external

N-coax cable by power measurements via internal generator and analyzer. In this test, all

measured values are indicated.

System selftest:

Internal RF Loop Selftest:

FE Selftest:

REF Selftest:

4/32 RF Loop Test).

Selftest of the instrument for diagnostic voltages; only a

passed/failed message with error output is indicated.

Selftest of the RF path by means of power measurements

via internal generator and analyzer. All measured values

are indicated.

Selftest of the RF FRONTEND module via diagnostic

voltages. All measured values are indicated.

Selftest of the REFERENCE BOARD module via diagnostic

voltages. All measured values are indicated.

DIG Selftest:

RXTX1 Selftest:

To obtain more detailed information start the following tests(depending on options and

R&S CMU SW versions):

1100.4903.82 1.7 E-5

Selftest of the DIGITAL BOARD module via diagnostic

voltages. All measured values are indicated

Selftest of the RXTX1 BOARD module via diagnostic

voltages. All measured values are indicated.

Manual Test Procedure R&S CMU

QIF Selftest:

I

AUXTX Selftest:

Linkhandler Selftest:

IF3 Selftest:

B83 Selftest:

RXTX2 Selftest:

Selftest of the R&S CMU-B17 IQIF BOARD module via

iagnostic voltages. All measured values are indicated.

d

Selftest of the R&S CMU-B95 AUXTX or R&S CMU-B96

AUXTX W BOARD module via diagnostic voltages. All

measured values are indicated.

Selftest of the R&S CMU-B21 Var02 ULH and/or R&S

CMU-B21 Var14 USU and/or R&S CMU-B66/B68/B76/B78

L1COPRO BOARD module. All measured values are

indicated.

IF3 Level Selftest of the RXTX BOARD module (greater

than Board version 11) via diagnostic voltages. All

measured values are indicated.

Selftest of the R&S CMU-B83 CDMA LH BOARD module.

All measured values are indicated.

Selftest of the RXTX2 BOARD (if available) module via

diagnostic voltages. All measured values are indicated.

Interface Test

IEC-bus Interface

Preparation:

Test: Send the string ‘*IDN?<CR><NL>’ from the controller to the R&S CMU and

Connect the IEC-bus interfaces of the R&S CMU and the controller via IEC-

bus cables.

read the reply STRING of the R&S CMU.

The reply STRING must contain the following message:

‘ROHDE & SCHWARZ,R&S CMU<Var>,<Ser_Nr>,<Firmware_Vers._Nr>’

RS–232 Interface

Preparation:

Test: Send the string ‘*IDN?<CR><NL>’ from the controller to the R&S CMU and

Connect the RS–232 interfaces of the R&S CMU and the controller via null-

modem cables

Set the RS–232 interface of the controller to 8 data bits, 1 start bit, 1 stop bit, no

parity bit, XON/XOFF handshake and 19200 baud.

read the reply string of the R&S CMU.

The reply string must contain the following message:

‘ROHDE & SCHWARZ,R&S CMU<Var>,<Ser_Nr>,<Firmware_Vers._No>’

1100.4903.82 1.8 E-5

R&S CMU Manual Test Procedure

Reference Frequencies

For different range of adjustment of the internal reference oscillator, the synchronization with an external

reference frequency is checked.

Note: The resolution of the frequency counter/analyzer should be max. 1/10 of the maximum

permissible deviation.

REF IN

The frequency and level ranges and the pull-in range are checked. The signal generator and the

frequency counter must be synchronized (test setup REF1).

Preparation:

Control: Set R&S CMU to external reference 52 MHz, RF 1 GHz (menu RF ANALYZER/

Test: Use frequency counter to measure frequency deviation from 1 GHz.

Feed in at REF IN: 52 MHz sinewave, 0.5 V(rms)

Connect frequency counter to RF3 OUT.

GENERATOR.)

Preparation:

Control: Set R&S CMU to external reference 1 MHz, RF 1 GHz.

Test: Use frequency counter to measure frequency deviation from 1 GHz.

Preparation:

Control: Set R&S CMU to external reference 10 MHz, RF 1 GHz.

Test: Use frequency counter to measure frequency deviation from 1.000 005 000 GHz.

Preparation:

Control: Set R&S CMU to external reference 10 MHz, RF 1 GHz.

Test: Use frequency counter to measure frequency deviation from 0.999 995 GHz.

Feed in at REF IN: 1 MHz sinewave, 0.5 V(rms).

Connect frequency counter to RF3 OUT.

Feed in at REF IN: 10.000 050 MHz sinewave, 1.4 V(rms).

Connect frequency counter to RF3 OUT.

Feed in at REF IN: 9.999 950 MHz sinewave, 1.4 V(rms).

Connect frequency counter to RF3 OUT.

1100.4903.82 1.9 E-5

Manual Test Procedure R&S CMU

REF OUT 1

The level and frequency are checked.

nt. 10 MHz:

I

REF IN

signal:

Set R&S CMU to internal reference.

Measure at REF OUT 1: 10 MHz, level > 1.4 V(pp).

Set R&S CMU to external reference.

Feed in at REF IN: 52 MHz TTL, (as an alternative +16 dBm from signal)

Measure at REF OUT 1: 52 MHz, level > 1.4 V(pp).

Measure at REF OUT 1: frequency 52 MHz ± 1 Hz

Feed in at REF IN: 1 MHz TTL, (as an alternative +16 dBm from signal

generator).

Measure at REF OUT 1: 1 MHz, level > 0.5 V(rms) (1.4 V(pp)).

Measure at REF OUT 1: frequency 1 MHz ± 1 Hz.

REF OUT 2

The level and frequency are checked. The R&S CMU and the frequency counter must be synchronized

(test setup REF2).

REF OUT 2

signal

13 MHz or 10 MHz:

Set R&S CMU to external reference.

Feed in at REF IN: 10 MHz sinewave, 0.5 V(rms).

Set R&S CMU to REF OUT 2 13 MHz or 10 MHz (depending on SW; menu

Connection Control – Sync.).

Measure at REF OUT 2: 13 MHz or 10 MHz, level > 1.0 V(pp).

Measure at REF OUT 2: frequency 13 MHz or 10 MHz ± 1 Hz.

1100.4903.82 1.10 E-5

R&S CMU Manual Test Procedure

TX Frequency Accuracy

Preparation: Test setup TX5, but R&S CMU not synchronized with frequency counter/analyzer

and no external trigger.

R&S CMU connector RF3 OUT.

Control: Set R&S CMU to desired frequency, level 0 dBm.

Test: Determine frequency deviation from nominal frequency.

TX Frequency Settling Time

Preparation: Test setup TX5, in addition trigger cable from R&S CMU (D-sub connector AUX3,

pin2) to analyzer.

R&S CMU connector RF3 OUT.

R&S CMU: Ramping off, hopping on, F1 = start freq., F2 = stop freq.

Analyzer: Sweep time 1 ms, Center = stop frequency, FM demodulation,

real time off, BW 50 kHz, 1 kHz/Div, external trigger, Slope

negative

Control: Set R&S CMU to desired frequencies and hopping, level 0 dBm.

Test: Time from trigger point when the specified offset (< 1 kHz) from the stop

frequency is reached.

TX Level Error

Preparation: Test setup TX1 to TX4 (depending on level range).

Control: Set R&S CMU to desired connector, frequency and level (RF Analyzer must

be OFF).

Test: Measure the TX level of the R&S CMU.

Note: The given frequencies and levels are suggested values. Of course, it is also possible to use

other values for the measurement.

VSWR

Preparation:

Control:

Test: Measure VSWR at 10 MHz, 900 MHz, 1800 MHz, 2700 MHz.

Connect (scalar) network analyzer to RF1, RF2, RF3 OUT, RF4 IN one after

the other.

Cable losses must be corrected.

R&S CMU: Switch generator on and set level to minimum (–130 dBm or

–90 dBm), switch RF wideband analyzer on (RF1/RF2/RF4 IN).

1100.4903.82 1.11 E-5

Manual Test Procedure R&S CMU

point to the point in time when the nominal

TX Level Settling Time

Preparation:

Control: Set R&S CMU to frequency = 1 GHz, specified level and ramping mode.

Test: The time period from the trigger

Test setup TX5, in addition trigger cable from R&S CMU (D-sub connector AUX3,

pin2) to analyzer.

R&S CMU: Connector RF3 OUT 1GHz, Ramping On, Hopping Off.

Analyzer: Sweep time = 40 µs, Center = 1 GHz , Span = 0, RBW = 10

MHz, external trigger.

level < 0.5 dB has been reached is measured.

TX Harmonics

Preparation: Test setup TX5, no external trigger

Analyzer: Center = 2 x f

Control: Set R&S CMU to connector RF1, specified frequency, level = –27 dBm.

Test: The suppression of the signal at twice or three times the nominal frequency is

measured relative to the nominal signal.

Control: Set R&S CMU to connector RF2, specified frequency, level = –10 dBm.

Test: The suppression of the signal at twice or three times the nominal frequency is

measured relative to the nominal signal.

Control: Set R&S CMU to connector RF3 OUT, specified frequency, level = +10 dBm.

Test: The suppression of the signal at twice and three times the nominal frequency is

measured relative to the nominal signal.

or Center = 3 x f

nom

, Span = 1 MHz.

nom

TX Non Harmonics

TX In-Band Spurious Signals

Spurious signals within the specified frequency bands are checked.

Preparation Test setup TX5, no external trigger

Analyzer Start/Stop = specified frequency range, RBW = 100 kHz

Control: Set R&S CMU to connector RF3 OUT, specified setting frequency, level = 0

dBm.

Test: The suppression of the signal is measured at the test frequency relative to the set

signal.

1100.4903.82 1.12 E-5

R&S CMU Manual Test Procedure

TX Fixed Spurious Signals

Fixed spurious signals are checked.

Preparation: Test setup TX5, no external trigger.

Analyzer: Center = specified test frequency, RBW = 100 kHz, Span = 1 MHz.

Control: Set R&S CMU to connector RF3 OUT, specified setting frequency, specified

level.

Test: The suppression of the signal is measured at the test frequency relative to the set

signal.

TX SSB Phase Noise

Preparation Test setup TX5, no external trigger

Control: Set R&S CMU generator to specified RF frequency.

Test Measure the phase noise at the specified spacing from the carrier.

Connect spectrum analyzer or modulation analyzer to RF3 OUT.

Output level at RF3 OUT 0 dBm,

Analyzer to specified center frequency,

Span = 50 kHz to 5 MHz, RBW = Span/500,

Noise measurement function.

TX Residual FM

Preparation: Test setup TX5, no external trigger.

Control: Set R&S CMU generator to the specified RF frequency.

Test: The residual FM with the specified weighting is measured.

Connect spectrum analyzer or modulation analyzer to RF1.

Output level at RF1 –27 dBm, analyzer to specified center frequency, FM

demodulator.

TX Residual AM

Preparation: Test setup TX5, no external trigger.

Control: Set R&S CMU generator to specified RF frequency.

Test: The residual AM with the specified weighting is measured.

1100.4903.82 1.13 E-5

Connect spectrum analyzer or modulation analyzer to RF1.

Output level at RF1 –27 dBm, analyzer to specified center frequency, AM

demodulator.

Manual Test Procedure R&S CMU

TX Carrier/Sideband Suppression, Max. Distortion

The modulation quality of the analog IQ modulator of the R&S CMU is measured.

Preparation Test setup TX5, no external trigger.

Connect spectrum analyzer to RF3 OUT.

Control: Set R&S CMU generator to specified RF frequency.

Output level at RF3 OUT, 0 dBm,

Switch on RF generator with offset modulation, 300- kHz baseband filter,

Set analyzer to center frequency f

= 1000 MHz, Span = 300 kHz / 3 MHz

c

Test: The suppression of the carrier at f

+ f

signal at f

.

od

c

m

is measured relative to the useful sideband

c

RX Power Meter (Frequency-Selective)

Preparation: Test setup RX1, RX2 (depending on level range).

Control: Set R&S CMU to desired RX frequency and level and Input in menu RF

ANALYZER/ GENERATOR.

Measuring Bandwidth = 1 kHz.

Test: Measure RX level measurement accuracy of R&S CMU.

Note: The given frequencies and levels are suggested values; of course, it is also possible to use

other values for the measurement.

RX Power Meter (Wideband)

Preparation Test setup RX1, RX2 (depending on level range).

Control: Set R&S CMU to desired RX connector, frequency and level and Input in

menu RF Analyzer/ Generator.

Measuring Bandwidth = Wide

Test: Measure RX level measurement accuracy of R&S CMU.

Note: The given frequencies and levels are suggested values; of course, it is also possible to use

other values for the measurement.

1100.4903.82 1.14 E-5

R&S CMU Manual Test Procedure

RX Harmonics

Preparation: Test setup RX3,

Generator = f

; level = 0 dBm.

in

Control: Set R&S CMU to connector RF2, Max Level = 2 dBm.

Test: The suppression of the signal at twice and three times the input frequency is

measured relative to the input signal.

Preparation:

Test setup RX3

Generator = f

n

i

; level = –2 dBm

Control: Set R&S CMU to connector RF4 IN, Max Level = 0 dBm.

Test: The suppression of the signal at twice and three times of input frequency is

measured relative to the input signal.

RX Spurious Response / Image Rejection

Preparation: Test setup RX3,

Control: Set R&S CMU to connector RF2, Max Level = 2 dBm, Mode = Low Distortion

Generator = f

; level = 0 dBm.

in

Test: The suppression of the spurious or image signal is measured relative to the

input signal.

Preparation:

Test setup RX3,

Generator = f

; level = –2 dBm.

in

Control: Set R&S CMU to connector RF4 IN, Max level = 0 dBm, Mode = Low

Distortion

Test: The suppression of the spurious or image signal is measured relative to the input

signal.

RX SSB Phase Noise

Preparation: Test setup RX3,

Control: Set R&S CMU to connector RF2, Max Level = 10 dBm and to desired

Test: The measurement is taken with a small test bandwidth at different carrier offsets.

Generator = f

+ df ; level = 10 dBm.

iCMU

frequency.

Switch on frequency-selective power meter.

Note: The input level is +10 dBm, RBW = 100 Hz

Phase noise = measured value –10 dB –21 dB.

1100.4903.82 1.15 E-5

Manual Test Procedure R&S CMU

RX Residual FM/AM

Preparation: Test setup RX4,

Control: Set R&S CMU to connector RF4 IN, Max Level = –20 dBm and to desired

Test: The measurement is taken with an external FM/AM demodulation instrument (FSE

Generator = f

frequency.

Switch on frequency-selective power meter.

with FSE-B7) via the IF3RXCH1 BNC connector at the rear panel of the R&S CMU.

Set the FSE to desired frequency, ref. level, AF filters.

; level = –20 dBm.

iCMU

RX Dynamic/ Average Noise Level

Preparation: No signal is fed in, R&S CMU generator is OFF.

Control: Set R&S CMU to given receive frequency, Max. Level, Bandwidth, Mode = Low

Noise.

Test: Use frequency-selective power meter, measurement bandwidth = 1 kHz / 500 kHz,

measured value in dB below reference level (Max. Level).

1100.4903.82 1.16 E-5

R&S CMU Manual Test Procedure

Options for R&S CMU200

GSM-MS

The following tests can be carried out only if the GSM-MS (R&S CMU-K2x) software options are

installed and enabled by entering a key code.

TX GSM Modulation

Only with options R&S CMU-K21, R&S CMU-K22, R&S CMU-K23 or R&S CMU-K24:

The GSM phase/frequency error of a TX path is measured.

Preparation: Test setup TX5:

Control: Set R&S CMU generator to specified RF frequency.

Test: Phase (rms and peak) and frequency errors are measured according to GSM

Connect spectrum analyzer FSIQ to RF3 OUT.

Output level at RF3 OUT 10 dBm

Training Sequence -> GSM0;

Bit Mod. -> PRBS

Transmission -> BURST

Settings at spectrum analyzer FSIQ:

Mode -> Digital Standards -> GSM

Mode -> Meas Result -> Result_Length -> 146 (the useful part normally comprises

147 bits, however, the FSIQ can be set to an integer number of bits only and

therefore cuts off 0.5 bits at the beginning and at the end of the measurement

range)

Trigger -> Find Sync -> ON

Trigger -> Sync Pattern -> gsm_bts0 (training sequence GSM0)

Trigger -> Sync Offset -> 60 symbols

recommendation.

RX GSM Dem odulation

Only with option R&S CMU-K21, R&S CMU-K22, R&S CMU-K23 or R&S CMU-K24:

The GSM phase/frequency error of a RX path is measured.

Preparation: Connect GSM signal generator to RF2 (test setup RX3).

Control: Signal generator SMIQ: GSM signal at given frequency, level according to table,

Test:

1100.4903.82 1.17 E-5

The signal generator must be synchronized with the R&S CMU via the 10 MHz

reference frequency.

bursted with the following settings:

Digital Std -> GSM/EDGE -> State -> ON;

Digital Std -> GSM/EDGE -> Select Slot -> Burst type -> NORM

Digital Std -> GSM/EDGE -> Select Slot -> Slot Level -> FULL

Digital Std -> GSM/EDGE -> Select Slot -> Data -> PN9

Digital Std -> GSM/EDGE -> Select Slot -> TSC -> TSC0

R&S CMU: GSM Non Signalling, training sequence = GSM 0, trigger source = IF

Power, Trigger Level = Medium

Measure GSM phase error (rms and peak) as well as frequency error.

Manual Test Procedure R&S CMU

CDMA2000

The following tests can be carried out only if the CDMA2000 (R&S CMU-K8x) software options are

installed and enabled by entering a key code.

TX CDMA2000 Modulation

Only with options R&S CMU-K83, R&S CMU-K84, R&S CMU-K85 or R&S CMU-K86:

The CDMA2000 modulation parameter of a TX path is measured.

Preparation: Test setup TX5:

Control: Set R&S CMU generator to specified RF frequency.

Connect spectrum analyzer FSIQ to RF3 OUT.

Settings at R&S CMU:

CDMA2000 450 MHz (CDMA2000 Cellular, CDMA2000 PCS, CDMA2000 IMT-

2000) Signaling Connection Control

CDMA Power = -7 dBm

Traffic level = OFF, Paging level = OFF, Sync. level = OFF, Pilot level = - 7 dB,

OCNS level = OFF

RF3OUT

RF Channel = 1, 2016 CDMA2000 450 MHz

= 1, 777 CDMA2000 Cellular

= 1, 1199 CDMA2000 PCS

= 0, 1199 CDMA2000 IMT-2000

Switch on Generator

Remote (in CDMA2000 NSig):

OUTP:STAT RF3

SOURce:RFGenerator:LEVel:OCNS:ENABle OFF

SOURce:RFGenerator:FREQuency 870.03MHZ

SOURce:RFGenerator:POWer:CDMA -7

SOURce:RFGenerator:LEVel:FPICh -7

SOURce:RFGenerator:LEVel:FSYNc OFF

SOURce:RFGenerator:LEVel:FPCH OFF

SOURce:RFGenerator:LEVel:FFCH OFF

INIT:RFGenerator

Settings at FSIQ 7:

Set Frequency 460.000 MHz, 493.48 MHz CDMA2000 450 MHz

870.03 MHz, 893.31 MHz CDMA2000 Cellular

1930.05 MHz, 1989.95 MHz CDMA2000 PCS

2110.000 MHz, 2169.95 MHz CDMA2000 IMT-2000

Set Reference Level

Rho Factor Measurement , Carrier Suppression

Annotation:

FSIQ can perform this measurement only on one active channel

The R&S CMU CDMA2000 Output level will only be equal to displayed CDMA

power with OCNS=AUTO.

Test: Rho factor and carrier suppression are measured according to CDMA2000

recommendation.

1100.4903.82 1.18 E-5

R&S CMU Manual Test Procedure

RX CDMA2000 Dem odulation

Only with option R&S CMU-K83, R&S CMU-K84, R&S CMU-K85 or R&S CMU-K86:

The CDMA2000 modulation parameter of a RX path is measured.

Preparation: Connect CDMA2000 signal generator to RF2 (test setup RX3).

Control: Signal Generator SMIQ:

CDMA RX Measurement for RC1,2(O-QPSK)

The signal generator must be synchronized with the R&S CMU via the 10 MHz

reference frequency.

Reset

Set Frequency 450.000 MHz, 483.480 MHz CDMA2000 450 MHz

825.03 MHz, 848.31 MHz CDMA2000 Cellular

1850.05 MHz, 1909.95 MHz CDMA2000 PCS

1920.000 MHz, 1979.950 MHz CDMA2000 IMT-2000

Set Level -10 dBm

Select DIGITAL STD IS95

STATE ON

MODE REV_LINK

TRIGGER MODE AUTO

R&S CMU:

CDMA 800 (CDMA 1900) NSig Analyzer/Generator

RF Channel = 1, 2016 CDMA2000 450 MHz

= 1, 777 CDMA2000 Cellular

= 1, 1199 CDMA2000 PCS

= 0, 1199 CDMA2000 IMT-2000

Analyzer Mode MAN

Expected power -10 dBm (Max Level = input level +6dB, to prevent overload in

R&S CMU SW)

RF2

Trigger: FREERUN

Remote:

INP:STAT RF2;

TRIGger[:SEQuence]:SOURce[:OQPSk]FRUN

SENSE:LEVEL:MODE MAN

LEV:MAX -10

[SENSe]:RFANalyzer:FREQuency [MHz]

READ[:SCALar]:MODulation:MQUality:OQPSk?

READ[:SCALar]:MODulation:MQUality:OQPSk?

<MSPower> {Value} dBm

<Waveform Quality> {Value}

<CarrierFrequencyError> {Value} Hz

<TransmitTimeError> {Value} s

<CarrierFeedtrough> {Value} dB

RESERVED NAN

<SidebandSuppresLower> {Value} dB

<SidebandSuppresUpper> {Value} dB

<Bursts Out Of Tolerance> {Value} %

Test:

Measure waveform quality as well as frequency measurement error.

1100.4903.82 1.19 E-5

Manual Test Procedure R&S CMU

WCDMA

he following tests can be carried out only if the WCDMA (R&S CMU-K66) software options are

T

installed and enabled by entering a key code.

TX WCDMA Modulation

Only with option R&S CMU-K66:

The WCDMA modulation parameter of a TX path is measured.

Preparation: Test setup TX5:

Control: Set R&S CMU generator to specified RF frequency.

Connect spectrum analyzer FSIQ to RF2 and RF3 OUT.

Settings at R&S CMU:

R&S CMU-WCDMA-generator:

Total level = CPICH-level

relative level : SCHs = –35dB, P-CCPCH = –35 dB, DPDCH = 0dB,

DPCCH/DPDCH = 0dB, PICH level = –35dB

DPCH Codechannel = 4 (R&S CMU SW Base >= V3.07 necessary)

Generator-Mode: 3GPP Reference Measurement Channel 12.2kbit/s and 384

kbit/s (entspricht Symbolrate 480ksps)

Settings at FSIQ 7:

WCDMA BTS Analyser, Code Domain Power,

Display-Result: Result summary

Select Channel Number:

16 für 12.2 kbit/s, 256 für 384 kbit/s

Test: Global EVM are measured.

Code Channel Conf: 480ksps für 384 kbit/s

RX WCDMA Dem odulation

Only with option R&S CMU-K65:

The WCDMA demodulation quality of a RX path is measured.

Preparation: Connect WCDMA signal generator to RF2 and RF4 IN (test setup RX3).

Control: Set R&S CMU analyzer and SMIQ to specified RF frequency.