Operating Manual

Universal

Radio Communication Tester

R&S CMU 200

1100.0008.02/53

R&S CMU 300

1100.0008.03

Printed in Germany

Test and Measurement Division

1100.4984.12-01 1

®

R&S

is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

Trade names are trademarks of the owners.

R&S CMU Tabbed Divider Overview

Tabbed Divider Overview

Safety Instructions

Tabbed Divider

1 Chapter 1: Putting into Operation

2 Chapter 2: Getting Started

3 Chapter 3: Operation

4 Chapter 4: Functional Description

5 Chapter 5: Remote Control – Basics

6 Chapter 6: Remote Control – Commands

7 Chapter 7: Remote Control – Program Examples

8 Chapter 8: Maintenance and Hardware Interfaces

9 Chapter 9: Error Messages

10 Index

1100.4984.12 RE E-1

R&S® CMU What’s New

What's new in this Revision...

This operating manual desc ribes version V3.60 and higher of the CMU base software including RF and

Audio measurements and the IQ-IF interface. Compared to previous versions , this new firmware pro-

vides numerous extensions and improvements. The most important new features described in this

manual are listed below.

New Features Description Refer to...

Remote service tool Software utility for file transfer, firmware installation and remote

Freq. dependent

attenuation

Extended selftests Selftests for new hardware component s added Chapter 4,

Task priority

management

Remote debug mode Special test m ode for remote control scri pts. Chapter 5,

Screen saver Configurable screen save time. Chapter 4,

control of the R&S CMU.

Frequency-dependent input and output attenuat i on f actors can

be defined for function group RF and several network options.

Measurements and generators can be defined as being persistent or releasable.

Chapter 1,

→ Remote Service Tool

Chapter 4, RF Measurements

→ Frequency Dep. Attenuation

→ Maintenance

Chapter 5,

→ Task Priority Management

→ Setup – Remote

→ Setup – Misc.

Frequently Used Abbreviations

Att. Attenuation

Cnt Center

Ext. External

Freq. Frequency

GPIB General Purpose Interface Bus = I EEE Bus according to s t andard

IF Intermediate Frequency

Max. Maximum (Level)

Pk Peak

RBW Resolution Bandwidth

Ref. Reference

Rel. Relative

RF Radio Frequency

SSB Single Side Band

SW Software

IEC 625.1/IEEE 488. 1

1100.4984.12 0.1 E-1

Supplement to the Operating Manual

®

R&S

New Features in Firmware V3.80 (TCP/IP, Selftests, Aux TX, I/Q Recorder)

Table of Contents

TCP/IP Settings....................................................................................................................................1

Remote Control: TCPIp...............................................................................................................5

New Selftests.....................................................................................................................................11

Improved AuxTx Signal.....................................................................................................................12

Signal Configuration..................................................................................................................12

RF Connector Settings..............................................................................................................14

Remote Control: AUXTx ...........................................................................................................15

Frequency-Dependent Attenuation .................................................................................................16

I/Q Recorder.......................................................................................................................................17

Measurement Control................................................................................................................17

CMU 200/300

Test Configuration.....................................................................................................................19

Subarray Configuration.............................................................................................................22

ASCII Results – Subsystem IQRecorder:ARRay......................................................................23

Measured Subarrays – Subsystem IQRecorder:SUBarray.......................................................26

Binary Results – Subsystem IQRecorder:BINary:ARRay.........................................................29

TCP/IP Settings

In the new TCP/IP tab of the Setup menu, it is pos sible to configure the R&S CMU with the IP address

information necessary for communicating with other hosts and applications through an IP network:

• The CMU-B21 section provides the IP address information f or the Universal Signalling Unit CMU-

B21 V14, to be used for GSM and WCDMA UE data application tests. For detailed information refer

to the operating manuals for WCDMA UE Tests (R&S CMU-K61, …, K69), for the WCDMA

Message Analyzer and Recorder (R&S CMU-Z46), and for (E)GPRS Application Testing (R&S

CMU-K92).

• The CMU-B83 section provides the IP address information f or the Universal Signalling Unit CMU-

B83, to be used for CDMA2000 data application tests. For detailed information refer to the operating

manuals for CDMA200 Mobile Tests (R&S CMU-K83, …, K87) and for the Message Monitor for

CDMA2000 Signalling Unit (R&S CMU-B87).

Attention! If you choose static TCP/IP addressing, contact your network administrator to obtain a valid

IP address. Connection errors can affect the entire network.

The TCP/IP information is not changed after a reset (*RST) of the instrument. The default

values (factory settings) can be restored using the Default Settings switches.

TCP/IP settings are available for R&S CMU200 instruments only.

1100.4984.12 S.1 V3.80_E-1

TCP/IP Settings R&S CMU 200

SETUP

Fig. 1 Setup – TCP/IP menu

To avoid a m ix up of the two addr ess blocks, a popup m enu is opened when one of the addresses is

changed. The popup m enu c ontains the (s tatic ) addr ess es f or a single s ignalling unit; they are closed by

pressing the SETUP key again.

The following static address information is assigned to the CMU-B21 signalling unit:

CMU-B21 – Default Settings

Remote

Control

CMU-B21 –

Static

Remote

Control

The following address information is assigned to the CMU-B83 signalling unit:

CMU-B83 –

Default Settings

CMU-B83 –

Type of CMU IP

Addressing

Restores the default IP addresses for R&S CMU-B21 shown in the figure above.

The values are also quoted in the com mand des cription. A reset does not affec t the

IP addresses.

SYSTem:TCPip:PRIMary:DEFault ON | OFF

IP addresses for the R&S CMU, to be used for GSM and WCDMA UE data application tests.

IP Address IP address of the CMU

Subnet Mask Subnet mask address of the CMU

Default Gateway Address used to configure a default route in the CMU

SYSTem:TCPip:PRIMary:STATic:IPADdress <IP1>, <IP2>, <IP3>, <IP4>

SYSTem:TCPip:PRIMary:STATic:SMASk <SM1>, <SM2>, <SM3>, <SM4>

SYSTem:TCPip:PRIMary:STATic:DGATeway <GW1>, <GW2>, <GW3>, <GW4>

Restores the default IP addresses for R&S CMU-B83 shown in the figure above.

The values are also quoted in the com mand description in Chapter 6. A reset does

not affect the IP addresses.

Remote control

SYSTem:TCPip:SECondary:DEFault ON | OFF

Depending on the network capacities and the us er pref er enc es, the TCP/IP address

information for the R&S CMU-B83 can be configured in two different ways:

Static Manual setting of the addresses in the Static TCP/IP address

subsection. This option m ust be s elected if the network does not

1100.4984.12 S.2 V3.80_E-1

R&S CMU 200 TCP/IP Settings

support dynamic TCP/IP configuration using the Dynamic Host

Configuration Protocol (DHCP).

Dynamic Automatic assignm ent of all nec essary addresses (including the

MS PPP IP and BS PPP IP addresses dis played in the Service

Config. tab of the Connection Control m enu for the CDMA2000

function groups; see Chapter 8 of the CDMA200 operating manual) using a definite CMU hostname and DHCP (dynamic

TCP/IP configuration). See desc ription of the Dynamic subsection below.

Dynamic (Retry)? Repeat the dynamic addressing procedure. This message is

displayed after a failed attempt to use dynamic addressing. Possible error scenarios are listed in Table 1 below.

CMU-B83 –

Static

Remote

CMU-B83 –

Dynamic

Control

Remote control

SYSTem:TCPip:SECondary:MODE

STATic | DYNamic (| PENDing | UDEF)

SYSTem:TCPip:SECondary:FCODE?

Sets the IP addresses to be used if Static CMU IP addressing is selected:

IP Address IP address of the CMU

Subnet Mask Subnet Mask address of the CMU

Default Gateway Address used to configure a default route in the CMU

SYSTem:TCPip:SECondary:STATic:IPADdress <IP1>, <IP2>, <IP3>, <IP4>

SYSTem:TCPip:SECondary:STATic:SMASk <SM1>, <SM2>, <SM3>, <SM4>

SYSTem:TCPip:SECondary:STATic:DGATeway <GW1>, <GW2>, <GW3>, <GW4>

Sets the CMU hostnam e and dis plays the IP addresses obtained f r om the network if

Dynamic CMU IP addressing is selected. To establish a dynamic IP connection

proceed as follows:

Remote

Control

1. In the Dynamic subsection, enter the CMU Hostname you wish to assign to the

CMU.

2. Select dynamic Type of CMU IP Addressing.

During the IP address acquisition phase, the CMU hostname is r egistered with the

DHCP server and the CMU displays the message DHCP Procedure Pending. This

operation may take several seconds to complete depending on network traffic,

DHCP server congestion, etc. W hen the DHCP procedure completes, the acquired

addresses are be displayed in the Dynamic TCP/IP address subsection. If dynamic

TCP/IP configuration f ails , the R&S CMU dis plays one of the f ailure messages listed

in Table 1 below and the Ethernet interface is disabled.

Note: When the DHCP s erver on the network is running Windows Server, the

DNS is not properly notified of the CMU hostname. In order to identify

the CMU by its hostname, it will be necessary to add the hostname,

along with the IP address obtained from DHCP and displayed on the

CMU, to the DNS table. This must be done whenever the CMU is rebooted and thus obtains a new address via DHCP. If the CMU is not

added to the DNS table, the instrument mus t be identified only by its IP

address.

SYSTem:TCPip:SECondary:DYNamic:HNAMe

SYSTem:TCPip:SECondary:DYNamic:DNS?

SYSTem:TCPip:SECondary:DYNamic:IPADdress?

SYSTem:TCPip:SECondary:DYNamic:SMASk?

SYSTem:TCPip:SECondary:DYNamic:DGATeway?

1100.4984.12 S.3 V3.80_E-1

TCP/IP Settings R&S CMU 200

DHCP Failure The R&S CMU contacts the DHCP server during the following scenarios:

• At R&S CMU initialization (if Type of CMU IP Addressing is set to Dynamic).

• At run-time when the user changes the Type of CMU IP Addressing from Static

to Dynamic.

• At run-time when the lease has expired. The DHCP client is required to renew

its lease with the DHCP server when the lease duration has expired.

The DHCP procedure may fail for a number of reasons. Possible failure scenarios

and error messages in the Type of CMU IP Addressing field are listed in Table 1

below. In case of a failure the Dynamic parameter field and a yellow notice box

show DHPC Failure – External Ethernet IP connection is now disabled.

Remote Control

Whenever a DHCP f ailure condition is detected, the R&S CMU takes the following

actions:

• The CMU200 Ethernet interface is disabled.

• Bit no. 14 of the STATus:OPERation register f or the R&S CMU base system

and bit no. 1 of the extended STATus:OPERation register for the CDMA2000

function groups is set (see Chapter 5 of the CMU 200/300 manual and the

CDMA2000 operating manual).

By disabling the Ethernet interface, the CMU200 will not be able to com municate

with any remote host.

• Dynamic CMU IP Address is set to “169.254.X.X” (where X.X is derived from

the serial number of the CMU200).

• Dynamic CMU Subnet Mask is set to “255.255.0.0”.

• Dynamic CMU Default Gateway address is removed.

• Dynamic MS and BS PPP IP Addresses (see Chapter 8 of the CDMA2000 op-

erating manual) are set to the static MS and BS PPP IP Address values.

By maintaining these PPP IP Addresses, the CMU200 will still be able to establish

SO33 data calls to a CDMA2000 mobile station. O nly the internal FTP s erver can be

used to transfer data to/from the mobile since no outside communication is possible.

SYSTem:TCPip:SECondary:FCODE?

1100.4984.12 S.4 V3.80_E-1

R&S CMU 200 TCP/IP Settings

Table 1 DHCP Failure Scenarios, error messages and error codes

Message in Type of

CMU IP Addressing

Dyn. Event Failed –1 The DHCP Server failed to

No Target IP Allocated –2 The DHCP Server failed to

Interface Down –3 The CMU200 Ethernet Inter-

No Router IP Allocated –4 The DHCP Server failed to

Mobile Home IP Addr. –5 The DHCP Server failed to

Bind Failure –6 The CMU200 failed to initial-

Error code

CONF:TCP:SEC:FCOD?

Failure reason P ossi ble cause

respond or rejected the

DHCP request.

allocate the Target (CMU200)

IP Address.

face is disabled.

allocate the Router/Gateway

IP Address.

allocate the BS and MS PPP

IP Addresses.

ize the DHCP client soft ware.

• CMU200 ethernet cable not properly

connected to LAN

• DHCP server unavailable

• CMU200 ethernet cable not properly

connected to LAN

• DHCP server unavailable

CMU200 ethernet cable not properly connected to LAN

DHCP server not configured to support

TAG 3 (router). See RFC 2132 for more

details.

• DHCP server not configured to support

TAG 68 (mobile IP home agent). See

RFC 2132 for more details.

• DHCP server not configured to return 2

IP Addresses in TAG 68 (mobile IP

home agent). See RFC 2132 for more

details.

Internal CMU200 DHCP software initial i zation problem.

Remote Control: TCPIp

The comm ands in this section configure the R&S CMU with the IP address inform ation necessary for

communicating with other hosts and applications through an IP network. The c omm ands correspond to

the TCP/IP tab of the Connection Control menu.

The TCP/IP information is not changed after a reset (*RST ) of the instrument. The default v al-

ues (factory settings) can be restored using SYSTem:TCPip:PRIMary:DEFault ON or

SYSTem:TCPip:SECondary:DEFault ON.

SYSTem:TCPip:PRIMary:DEFault <Enable> Default Settings

<Enable>

ON |

OFF

Command descripti on

If used as a setting command with the parameter ON, this command sets all parameters of the TCP/IP addressing commands for the signalling unit R&S CMU-B21 V14 to their default values (the setting OFF results in an error message). If used as a query, the command returns whether all parameters are set to their default values

(ON) or not (OFF).

Description of paramet ers Def. value Def. unit FW vers.

The parameters are set to their default values (factory settings)

Some or all parameters differ from their default values

ON

– V3.80

1100.4984.12 S.5 V3.80_E-1

TCP/IP Settings R&S CMU 200

CONFigure:TCPip:PRIMary:STATic:IPADdress Static IP Address

<IP Address 1>, <IP Address 2>, <IP Address 3>, <IP Address 4>

<IP Address 1>

0 to 255, First segment of IP address 192 – V3.80

<IP Address 2>

0 to 255, Second segment of IP address 168 – V3.80

<IP Address 3>

0 to 255, Third segment of IP address 168 – V3.80

<IP Address 4>

0 to 255 Fourth segment of IP address 170 – V3.80

Command descripti on

This command sets the static IP address of the signalling unit R&S CMU-B21 V14.

CONFigure:TCPip:PRIMary:STATic:SMASk Static Subnet Mask

<Subnet Mask 1>, <Subnet Mask 2>, <Subnet Mask 3>, <Subnet Mask 4>

<Subnet Mask 1>

0 to 255, First segment of subnet mask 255 – V3.80

<Subnet Mask 2>

0 to 255, Second segment of subnet mask 255 – V3.80

<Subnet Mask 3>

0 to 255, Third segment of subnet mask 0 – V3.80

<Subnet Mask 4>

0 to 255 Fourth segment of subnet mask 0 – V3.80

Command descripti on

This command sets the static subnet mask of the signalling unit R&S CMU-B21 V14.

CONFigure:TCPip:PRIMary:STATic:DGATeway Static Default Gateway

<Gateway 1>, <Gateway 2>, <Gate way 3>, <Gateway 4>

<Gateway 1>

0 to 255, First segment of default gateway 192 – V3.80

<Gateway 2>

0 to 255, Second segment of default gateway 168 – V3.80

<Gateway 3>

0 to 255, Third segment of default gateway 0 – V3.80

<Gateway 4>

0 to 255 Fourth segment of default gateway 1 – V3.80

Command descripti on

This command sets the static default gateway of the signalling unit R&S CMU-B21 V14.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

1100.4984.12 S.6 V3.80_E-1

R&S CMU 200 TCP/IP Settings

The TCP/IP addr ess es for R&S CMU-B83 (SYST em:TCPip:SECondar y …) c annot be c hanged

while a CDMA2000 packet data connection is active (see CONFigure:SCONfig:

SCLass:SERVice PDAT in the CDMA2000 operating manual). See also description of CONFigure:TCPip:SECondary:MODE below.

SYSTem:TCPip:SECondary:DEFault <Enable> Default Settings

<Enable>

ON |

OFF

Command descripti on

If used as a setting command with the parameter ON, this command sets all parameters of the TCP/IP addressing commands for the signalling unit R&S CMU-B83 to their default values (the setting OFF results in an error

message). If used as a query, the command returns whether all parameters are set to their default values (ON) or

not (OFF).

CONFigure:TCPip:SECondary:MODE <Mode> Type of CMU IP Addressing

<Mode>, settings

STAT |

DYN

<Mode>, query

STAT | DYN |

PEND |

UDEF

Command descripti on

This command specifies whether the IP address information is assigned manually or automatically. The command can also be used to query the DHCP Procedure Pending and IP Connection Undefined states.

Description of paramet ers Def. value Def. unit FW vers.

The parameters are set to their default values (factory settings)

Some or all parameters differ from their default values

Description of paramet ers Def. value Def. unit FW vers.

Manual assignment of IP address

ON

– V3.80

STATic – V3.80

Automatic assignment u sing DHCP

Description of paramet ers Def. value Def. unit FW vers.

Manual or automatic assignment

STATic – V3.80

DHCP Procedure Pending, no change of IP addressing mode possible

DHCP Failure (IP Connection Undefined); bit 14 of

the event status register is set.

The type of IP addressing is not changed after a *RST. The following error messages may be generated:

–221,"Setting conflict" The IP addressing mode is changed while packet data is active.

–213,"Init ignored" The IP addressing mode is changed while the DCHP procedure is pending.

CONFigure:TCPip:SECondary:STATic:IPADdress Static IP Address

<IP Address 1>, <IP Address 2>, <IP Address 3>, <IP Address 4>

<IP Address 1>

Description of paramet ers Def. value Def. unit FW vers.

0 to 255, First segment of IP address 192 – V3.80

<IP Address 2>

Description of paramet ers Def. value Def. unit FW vers.

0 to 255, Second segment of IP address 168 – V3.80

<IP Address 3>

Description of paramet ers Def. value Def. unit FW vers.

0 to 255, Third segment of IP address – – V3.80

<IP Address 4>

Description of paramet ers Def. value Def. unit FW vers.

0 to 255 Fourth segment of IP address – – V3.80

Command descripti on

This command sets the static IP address of the CMU. The factory setting for the address depends on the CMU

serial number.

1100.4984.12 S.7 V3.80_E-1

TCP/IP Settings R&S CMU 200

CONFigure:TCPip:SECondary:STATic:SMASk Static Subnet Mask

<Subnet Mask 1>, <Subnet Mask 2>, <Subnet Mask 3>, <Subnet Mask 4>

<Subnet Mask 1>

0 to 255, First segment of subnet mask 255 – V3.80

<Subnet Mask 2>

0 to 255, Second segment of subnet mask 255 – V3.80

<Subnet Mask 3>

0 to 255, Third segment of subnet mask 0 – V3.80

<Subnet Mask 4>

0 to 255 Fourth segment of subnet mask 0 – V3.80

Command descripti on

This command sets the static subnet mask of the CMU.

CONFigure:TCPip:SECondary:STATic:DGATeway Static Default Gateway

<Gateway 1>, <Gateway 2>, <Gate way 3>, <Gateway 4>

<Gateway 1>

0 to 255, First segment of default gateway 192 – V3.80

<Gateway 2>

0 to 255, Second segment of default gateway 168 – V3.80

<Gateway 3>

0 to 255, Third segment of default gateway 0 – V3.80

<Gateway 4>

0 to 255 Fourth segment of default gateway 1 – V3.80

Command descripti on

This command sets the static default gateway of the CMU.

CONFigure:TCPip:SECondary:DYNamic:HNAMe <Name> Dynamic Addressing: Host name

<Name>

‘<max. 32 characters>’ Hostname assigned to the CMU, string variable ‘CMU200’ – V3.80

Command descripti on

This command sets the hostname that is assigned to the CMU and transferred to the DHCP server if dynamic IP

addressing is selected (CONFigure:TCPip:SECondary:DYNamic:IPADdress:MODE DYNamic).

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

1100.4984.12 S.8 V3.80_E-1

R&S CMU 200 TCP/IP Settings

[SENSe:]IPADdress:FCODe? Dynamic Addressing: Failure Code

Response

0 |

–1 |

–2 |

–3 |

–4 |

–5 |

–6 |

Command descripti on

This command is always a query and returns the possible cause for an error during dynamic allocation of the

CMU’s IP address. The response is 0 unless dynamic IP address allocation failed (in which case the query CON-

Figure:TCPip:SECondary:DYNamic:IPADdress:MODE? returns UDEF).

CONFigure:TCPip:SECondary:DYNamic:DNS? Dynamic Domain Name Server

<DNS 1>, <DNS 2>, <DNS 3>, <DNS 4>

<IP Address 1>

0 to 255, First segment of DNS INV – V3.80

<IP Address 2>

0 to 255, Second segment of DNS INV – V3.80

<IP Address 3>

0 to 255, Third segment of DNS INV – V3.80

<IP Address 4>

0 to 255 Fourth segment of DNS INV – V3.80

Command descripti on

This command is always a query and returns the dynamically acquired CMU Domain Name Server.

CONFigure:TCPip:SECondary:DYNamic:IPADdress? Dynamic IP Address

<IP Address 1>, <IP Address 2>, <IP Address 3>, <IP Address 4>

<IP Address 1>

0 to 255, First segment of IP address INV – V3.80

<IP Address 2>

0 to 255, Second segment of IP address INV – V3.80

<IP Address 3>

0 to 255, Third segment of IP address INV – V3.80

<IP Address 4>

0 to 255 Fourth segment of IP address INV – V3.80

Command descripti on

This command is always a query and returns the dynamically acquired IP address of the CMU.

Description of paramet ers Def. value Def. unit FW vers.

No error

0 – V3.80

Dyn. Event Failed

No Target IP Allocated

Interface Down

No Router IP Allocated

Mobile Home IP Addr.

Bind Failure

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

1100.4984.12 S.9 V3.80_E-1

TCP/IP Settings R&S CMU 200

CONFigure:TCPip:SECondary:DYNamic:SMASk? Dynamic Subnet Mask

<Subnet Mask 1>, <Subnet Mask 2>, <Subnet Mask 3>, <Subnet Mask 4>

<Subnet Mask 1>

0 to 255, First segment of subnet mask INV – V3.80

<Subnet Mask 2>

0 to 255, Second segment of subnet mask INV – V3.80

<Subnet Mask 3>

0 to 255, Third segment of subnet mask INV – V3.80

<Subnet Mask 4>

0 to 255 Fourth segment of subnet mask INV – V3.80

Command descripti on

This command is always a query and returns the dynamically acquired subnet mask of the CMU.

CONFigure:TCPip:SECondary:DYNamic:DGATeway? Dynamic Default Gateway

<Gateway 1>, <Gateway 2>, <Gate way 3>, <Gateway 4>

<Gateway 1>

0 to 255, First segment of default gateway INV – V3.80

<Gateway 2>

0 to 255, Second segment of default gateway INV – V3.80

<Gateway 3>

0 to 255, Third segment of default gateway INV – V3.80

<Gateway 4>

0 to 255 Fourth segment of default gateway INV – V3.80

Command descripti on

This command is always a query and returns the dynamically acquired default gateway of the CMU.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

Description of paramet ers Def. value Def. unit FW vers.

1100.4984.12 S.10 V3.80_E-1

R&S CMU 200 New Selftests

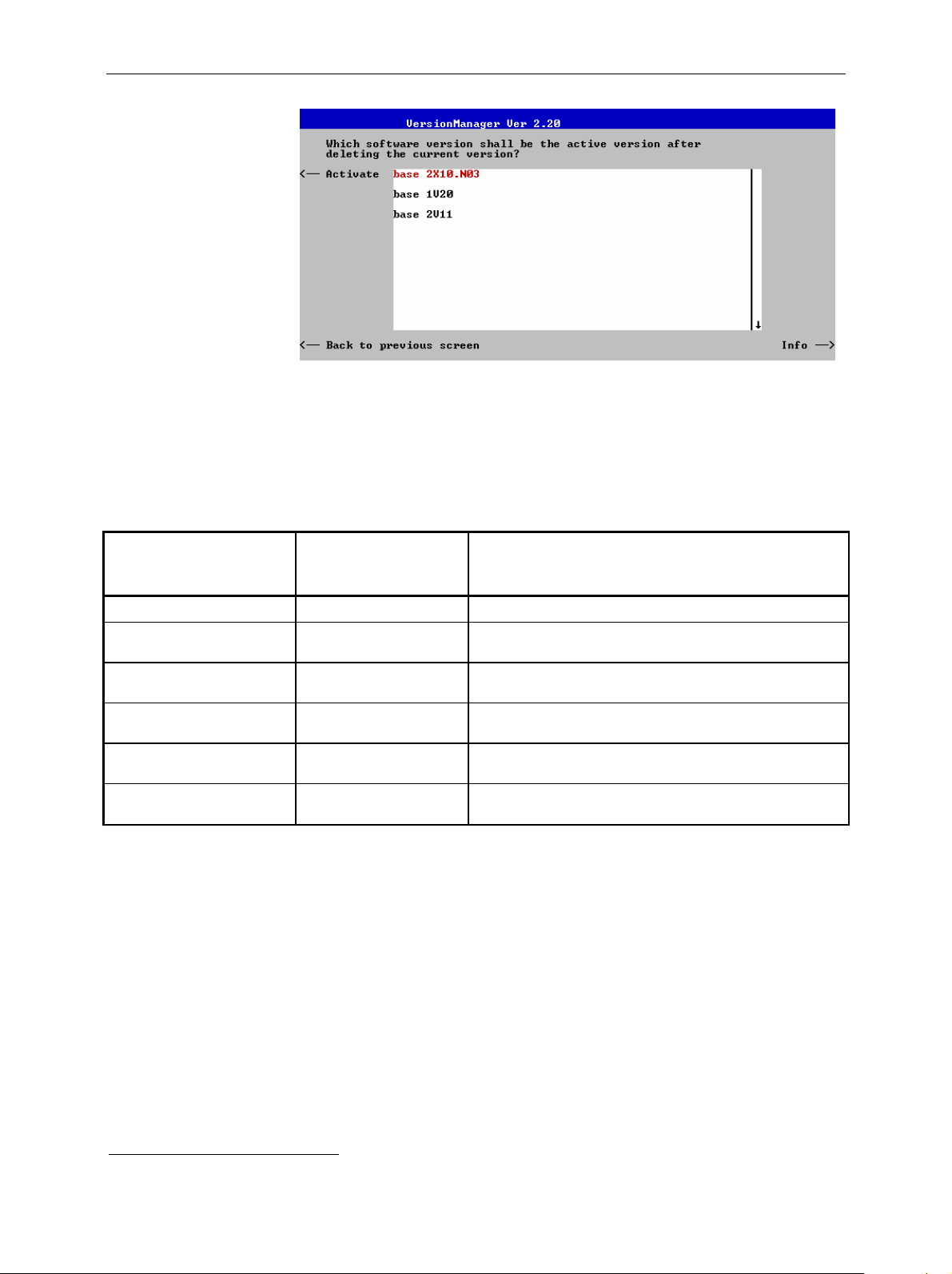

New Selftests

In the Maintenance menu, a number of new selftests have been added.

Menu SelectMenu Select

Fig. 2 Selftest – Maintenance menu

Select

The Select softkey selects the type of selftest or correction procedure to be performed. The following new selftests are available with firmware version V3.80:

B83 Selftest Reloads the firmware for CMU-B83 including CMU-B88 (if

Internal Aux Tx

Loop Path 1/2 Same as Internal RF Loop Test, but for the (low-level) Aux Tx

Internal Aux TxW

Loop Path 1/2 Same as Internal RF Loop Test, but for the Overrange Aux T x

Hardware Data

Verification Performs a plausibility check for the EEPROM data of all

Settling Time Cal. Determines the settling times for RX and TX signals that the

available) and reboots the system.

signal (option R&S CMU-B95 for path 1, option R&S CMU-B96

for path 1 or path 2). The overrange signals of option CMUB96 are tested separately using the Internal Aux TxW Loop

Path 1/2 tests.

signal associated with path 1 or path 2 (option CMU-B96). T he

low-level Aux Tx signals of option CMU-B96 are tested

separately using the Internal Aux Tx Loop Path 1/2 tests. The

Aux TxW tests can not be performed if option CMU-B95 is

fitted instead of option CMU-B96.

installed hardware modules.

instrument requires af ter a change to a frequency band above

1.2 GHz. The obtained value is stored and applied in order to

avoid measurement inac curacies. A settling time calibration is

relevant for RXTX board versions with TAZ ≤ 10.00 only.

1100.4984.12 S.11 V3.80_E-1

Improved AuxTx Signal R&S CMU 200

Improved AuxTx Signal

for RF Measurements (Option R&S CMU-B96)

With option CMU-B96, Additional RF Generator, the CMU provides three additional AuxTx signals:

• Two low-level signals Path 1 and Path 2 can be configured with different f requencies and levels.

When it is switched on the AuxTx generator activates one of the preconfigured low-level signals.

• An additional Overrange signal at the frequency of the active low-level AuxT x signal but with possi-

bly higher level can be generated together with the low-level signal. If it not needed, this signal can

be switched off.

It is possible to superimpos e AuxTx and T x signals and to assign independent external attenuation factors.

AuxTx is generated with the modulation settings of the primary Tx signal (in remote control:

...RFGenerator:MODulation...) but with no frequency hopping or ramping. Options R&S CMUB95/B96 extend the functionality of the GSM-MS and WCDMA UE measurements, see operating

manuals for options R&S CMU-K20/…/K24 and for options R&S CMU-K61/…/-K69.

The Aux Tx signals are not compatible with FM modulation. The Aux Tx generator is

switched off when the modulation mode is set to FM. It remains in the O ff state even when

FM modulation is deactivated.

Options R&S CMU-B95 and R&S CMU-B96 are available for R&S CMU200 instruments

only.

Signal Configuration

The AuxTx signals are configured in the Generator tab of the Connection Control menu.

Fig. 3 Connection Control – RF generator settings (table)

1100.4984.12 S.12 V3.80_E-1

R&S CMU 200 Improved AuxTx Signal

Generator

Control

Path Selection

Remote control

RF Level

AuxTx Levels Option R&S CMU-B95 provides a single AuxTx signal at a definite f requency and

Remote control

Frequency

Generator Control controls the AuxTx RF generator and indicates its operating state

(ON | OFF).

Remote Control

INITiate:RFGenerator:AUXTx

ABORt:RFGenerator:AUXTx

FETCh:RFGenerator:AUXTx:STATus?

Selects one of the (low-level) signals c onfigured in the Path 1 or Path 2 sections. In

addition the Overrange signal can be generated at the frequency of the selected

low-level signal.

SOURCe:RFGenerator[:TX]:PATH P1 | P2

RF Level defines the total level of the generated RF signals in dBm. The value

range depends on the selected RF output (RF 1, RF 2 or RF 3 OUT).

level. Option R&S CMU-B96 provides two configurable low-level signals plus an

additonal overrange signal.

Note: Superimposing the Overrange signal with the Tx signal at the same

output connector can impair the Tx level accuracy. Refer to the data

sheet for option R&S CMU-B96 for details.

SOURce:RFGenerator:AUXTx:LEVel <Level>

Frequency defines the frequency of the generated RF signals.

Note: The frequency of the Aux Tx signals is restriced to several distinct

ranges. The two signal paths of option R&S CMU-B96 have different

frequency ranges; see remote control description. The Overrange

signal is always at the frequency of the active low-level signal.

Remote control

SOURCe:RFGenerator:AUXTx:FREQuency <Frequency>

1100.4984.12 S.13 V3.80_E-1

Improved AuxTx Signal R&S CMU 200

RF Connector Settings

The output connectors for the AuxTx signals and the external attenuations are selected in the RF tab

of the Connection Control menu.

Fig. 4 Connection Control – RF generator settings (table)

Tx

Aux Tx

RF AuxTx

Output

Tx / Aux Tx toggles between the primary RF signal Tx and the additional signals

Aux Tx, to be routed to one of the RF output connectors of the instrument.

The RF signals are independent f rom each other. It is pos sible to route the signals

to different RF output connectors or superimpose them at the same connector. If

Aux Tx is selected, RF Tx Output changes to RF Aux Tx Output, the RF Input softkey is replaced by Ovr. Lev. AuxTx, and Ext. Att. Input by Ext. Att. Output.

Remote control

The keywords [:TX] and :AUXTX in the OUTPut:…[:STATe] commands distinguish between the Tx and the Aux Tx signal.

The RF Aux Tx Output softkey selects the output connector for Aux Tx. Aux Tx

must be output at RF1 or RF2.

Remote control

OUTPut:AUXTx[:STATe] RF1 | RF2

1100.4984.12 S.14 V3.80_E-1

R&S CMU 200 Improved AuxTx Signal

Ovr. Lev.

AuxTx

The Ovr. Lev. AuxTx sof tkey selects the output connector f or the Overrange signal

(with option R&S CMU-B96). The selected RF output is indicated by a

symbol.

Note: The output connectors for the Overrange signal and the (low-level)

AuxTx signal are independent from each other. The following

restriction holds for a combination of the Tx and the O verrange signal:

While the Overrange signal is at RF 1 the Tx signal cannot be fed to

RF 3 OUT and vice versa.

Superimposing the Overrange signal with the Tx signal at the same

output connector can impair the Tx level acc uracy. Refer to the data

sheet for option R&S CMU-B96 for details.

An attenuation factor for the Overrange signal can be defined with the Ext. Att.

Output softkey below Ovr. Lev. AuxTx.

Remote control

OUTPut:AUXTx:OLEVel[:STATe] RF1 | RF2 | RF3

[SENSe:]CORRection:LOSS:OUTPut<nr>AUXTx:OLEVel[:MAGNitude] <Loss>

SOURce:CORRection:LOSS:OUTPut<nr>AUXTx:OLEVel[:MAGNitude] <Loss>

Remote Control: AUXTx

The following commands complement the AUXTx comm and described in Chapter 6 of the operating

manual.

SOURce:RFGenerator:AUXTx:PATH Path Selection

Returned value

P1 | P2 Path 1 P1 – V3.80

Command descripti on

This command selects one of the low-level AuxTx signals configured via SOURce:RFGenerator:AUXTx:…:P1

or SOURce:RFGenerator:AUXTx:…:P2.

SOURce:RFGenerator:AUXTx:LEVel:P<nr> <Level> RF Level (R&S CMU-B96)

<Level>

–122 dBm to –72 dBm

–110 dBm to –60 dBm

Command descripti on

This command defines the levels of the Aux Tx path 1 and path 2 (<nr> = 1, 2) signals. The level ranges and

default values are identical for both paths. In contrast, the resolution for path 1 is 1 dB (all values entered are

rounded to integer dBm values) whereas the resolution for path 2 is 0.1 dB.

Parameter descripti on Def. value Def. unit FW vers.

Parameter descripti on Def. value Def. unit FW vers.

Aux Tx output level at RF 1

Aux Tx output level at RF 2

–72.0

–72.0

dBm

dBm

V3.80

The level range depends on the used RF output of the CMU and the external attenuation. Moreover, in the SSB

mode (see command SOURce:RFGenerator:MODulation SSB), the level ranges for all three connectors are

shifted by –2 dB. The level ranges are also modified if the Tx and Aux Tx signals are both active and superimposed at the same connector or if option R&S CMU-U99 (RF 1 with RF 2 Level Range) is fitted.

1100.4984.12 S.15 V3.80_E-1

Frequency-Dependent Attenuation R&S CMU 200

SOURce:RFGenerator:AUXTx:OLEVel <Level> RF Level Overrange (R&S CMU-B96)

<Level>

–100 dBm to –27 dBm | OFF

–100 dBm to –10 dBm | OFF

–100 dBm to +13 dBm | OFF

Command descripti on

This command defines the level of the Overrange signal. The resolution is 1 dB (all values entered are rounded

to integer dBm values). OFF switches the overrange signal off entirely.

The level range depends on the used RF output of the CMU and the external attenuation. Moreover, in the SSB

mode (see command SOURce:RFGenerator:MODulation SSB), the level ranges for all three connectors are

shifted by –2 dB. The level ranges are also modified if the Tx and Aux Tx signals are both active and superimposed at the same connector or if option R&S CMU-U99 (RF 1 with RF 2 Level Range) is fitted.

SOURce:RFGenerator:AUXTx:FREQuency:P<nr> <Frequency> Frequency (R&S CMU-B96)

<Frequency>

350 MHz to 550 MHz |

700 MHz to 1100 MHz |

1400 MHz to 2200 MHz

Command descripti on

This command defines the frequency of the Aux Tx path 1 and path 2 (<nr> = 1, 2) signals. The resolution is

2.5 kHz; all values entered are rounded to 2.5 kHz steps. If a value between the three distinct frequency bands

is entered, the instrument generates an error message. The lowest band is available for the path 1 signal only.

OUTPut:AUXTx:OLEVel[:STATe] <State> RF Output (Overrange)

<State>

RF1 |

RF2 |

RF3

Command descripti on

This command determines the output connector to be used for the Overrange signal. Note that while the

Overrange signal is at RF 1 the Tx signal (OUTPut[:TX][:STATe]) cannot be fed to RF 3 OUT and vice versa.

Parameter descripti on Def. value Default unit FW vers.

Connector RF1 used as output

Connector RF2 used as output

Connector RF3 OUT used as output

Ext. Att. Output (Overrange)

[SENSe:]CORRection:LOSS:OUTPut<nr>:AUXTx:OLEVel[:MAGNitude] <Absorption>

SOURce:CORRection:LOSS:OUTPut<nr>:AUXTx:OLEVel[:MAGNitude] <Absorption>

<Absorption>

–50 dB to +90 dB Value for external attenuation at output <nr>,

Command descripti on

This command assigns an external attenuation value to the outputs of the instrument. An external attenuation of

x dB increases the Aux Tx signal level (SOURce:RFGenerator:AUXTx:OLEVel) by x dB.

Parameter descripti on Def. value Default unit FW vers.

where <nr> = 1, 2, 3

Parameter descripti on Def. value Def. unit FW vers.

Overrange output level at RF 1

Overrange output level at RF 2

Overrange output level at RF 3 OUT

OFF

OFF

OFF

dBm

dBm

V3.80

Parameter descripti on Def. value Def. unit FW vers.

Aux Tx frequency band 1 (path 1 only)

Aux Tx frequency band 2 (path 1 and 2)

Aux Tx frequency band 3 (path 1 and 2)

350 MHz (p.1)

Hz

700 MHz (p.2)

RF2 – V3.80

0.0

dB

V3.80

V3.80

Frequency-Dependent Attenuation

The Frequency Dependent Attenuation menu provides 50 (instead of 25) frequency values.

1100.4984.12 S.16 V3.80_E-1

R&S CMU 200 I/Q Recorder

I/Q Recorder

The I/Q Recorder (IQRecorder) provides the I/Q data that the R&S CMU200/300 acquires with different IF filter settings. After the m easurement is started, the instr ument records a predefined number of

samples (CONFigure:IQRecorder:CONTrol:CLENgth). The meas urement can be s tarted explicitly

(INITiate:IQRecorder, with Free Run trigger) or by an appropriate trigger source (power trigger,

external trigger). The trigger settings are described on p. 6.32 ff. of the R&S CMU200/300 operating

manual. A measurement-specific trigger delay can be added; see CONFig-

ure:IQRecorder:CONTrol:TDELay.

Measurement results are retrieved by means of the READ:IQRecorder…, FETCh:IQRecorder…,

SAMPle:IQRecorder... commands. The application provides different (complex or polar) output

formats; see CONFigure:IQRecorder:RMODe. Moreover it is possible to obtain the results as

comma-s eparated ASCII arrays or in binary format (keywords ARRay or BINary). Binary data transfer

offers several advantages:

• The transfer is f as ter and more efficient (the size of the output str ings is typically reduced by a factor

of 3 to 4).

• Binary data can be directly post-processed by many external applications without previous conversion

On the other hand, the transfer of ASCII arrays can be refined by means of subarray commands.

The I/Q Recorder (IQRecorder) is a remote control application which is located in the RF function

group. There is no equivalent measurement menu in manual control.

The performance of the application is improved with option R&S CMU-U65, Measurement DSP for

WCDMA; see overview below.

Table 1 I/Q Recorder performance with option R&S CMU-U65

No option R&S CMU-U65V02 R&S CMU-U65V04

IF Bandwidth

(see Table 2 on p. 19)

Sampling Rate

(see Table 2 on p. 19)

Max. Capture Length

Max. Trigger Delay

50 kHz to 1 MHz 50 kHz to 1 MHz 50 kHz to 5 MHz

200 kHz to 4000 kHz 200 kHz to 4000 kHz 200 kHz to 10000 kHz

32768 samples 65536 samples 65536 samples

±32000 samples ±64000 samples ±64000 s amples

Measurement Control

The following commands control the measurement.

INITiate:IQRecorder Start new measurement

ABORt:IQRecorder Abort running measurement and switch off

STOP:IQRecorder Stop measurement after current stat. cycle

Description of com mand FW vers.

These commands have no query form. They start and stop the measurement, setting it to the status

indicated in the top right column.

⇒

RUN

⇒

OFF

⇒

STOP

V3.80

1100.4984.12 S.17 V3.80_E-1

I/Q Recorder R&S CMU 200

CONFigure:IQRecorder:EREPorting <Mode> Event Reporting

<Mode>

SRQ |

SOPC |

SRSQ |

OFF

Description of com mand

This command defines the events generated when the measurement is terminated or stopped (event reporting,

see Chapter 5 of the operating manual).

FETCh:IQRecorder:STATus? Measurement Status

Ret. values

OFF |

RUN |

STOP |

ERR |

RDY,

NONE

Description of com mand

This command is always a query. It returns the status of the measurement (see Chapters 3 and 5 of the operating manual).

FETCh:IQRecorder:FSBW? Filter Characteristics

Ret. values

NYQ | GAUS,

400000 Hz to 10000000 Hz,

50000 Hz to 5000000 Hz

Description of com mand

This commands are always queries. They return the status of the measurement (see Chapters 3 and 5 of the

operating manual).

Description of paramet ers Def. value Def. unit FW vers.

Service request

OFF – V3.80

Single operation complete

SRQ and SOPC

No reporting

Description of paramet ers Def. value Def. unit FW vers.

Measurement in the OFF state (*RST or ABORt)

Running (after INITiate or READ)

Stopped (STOP)

OFF (could not be started)

Stopped according to repetition mode and stop condition

No statistical mode set

Description of paramet ers Def. value Def. unit FW vers.

Filter type

Sampling rate

Filter bandwidth

OFF

NONE

NYQ

2000000

1000000

–

–

–

Hz

Hz

V3.80

V3.80

1100.4984.12 S.18 V3.80_E-1

R&S CMU 200 I/Q Recorder

Table 2 I/Q recorder filter types, bandwidths, and filter types

Filter Type Bandwidth / kHz Sampling Rate / kHz Required Option

Gauss

Nyquist

(roll off = 0.5)

50 400 No option, CMU-U65V02, CMU-U65V04

100 800 No option, CMU-U65V02, CMU-U65V04

200 2000 No option, CMU-U65V02, CMU-U65V04

300 4000 No option, CMU-U65V02, CMU-U65V04

500 4000 No option, CMU-U65V02, CMU-U65V04

1000 4000 No option, CMU-U65V02, CMU-U65V04

50 200 No option, CMU-U65V02, CMU-U65V04

100 400 No option, CMU-U65V02, CMU-U65V04

200 1000 No option, CMU-U65V02, CMU-U65V04

285.714 (setting: 300) 2000 No option, CMU-U65V02, CMU-U65V04

500 2000 No option, CMU-U65V02, CMU-U65V04

1000 2000 No option, CMU-U65V02, CMU-U65V04

2000 4000 No option, CMU-U65V02, CMU-U65V04

3000 10000 CMU-U65V04

5000 10000 CMU-U65V04

Test Configuration

The following commands configure the I/Q Recorder measurement.

CONFigure:IQRecorder:CONTrol:FILTer <Type> Filter

<Tpye>

GAUS |

NYQ

Description of com mand

This command specifies the IF filter type.

CONFigure:IQRecorder:CONTrol:GFILTer <Bandwidth> Filter

<Bandwidth>

F50k | F100K | F200K |

F300K | F500K | F1M

Description of com mand

This command specifies the filter bandwidth for IF filters of Gaussian type (CONFigure:IQRecorder: CON-

Trol:FILTer GAUS).

Desciption of paramet ers Def. value Def. unit FW vers.

Gauss filter

NYQ – V3.80

Nyquist filter

Desciption of paramet ers Def. value Def. unit FW vers.

50 kHz, 100 kHz, 200 kHz,

F1M – V3.80

300 kHz, 500 kHz, 1 MHz,

1100.4984.12 S.19 V3.80_E-1

I/Q Recorder R&S CMU 200

CONFigure:IQRecorder:CONTrol:NFILTer <Bandwidth> Filter

<Bandwidth>

F50k | F100K | F200K |

F300K | F500K | F1M | F2M |

F3M | F4M

Description of com mand

This command specifies the filter bandwidth for IF filters of Nyquist type (CONFigure:IQRecorder: CON-

Trol:FILTer NYQ). The 3-MHz and 5-MHz bandwidths correspond to highest sampling rates and require option CMU-U65V04; see Table 2 on p. 19. The F300K setting actually corresponds to a bandwidth of

285.714 kHz.

CONFigure:IQRecorder:CONTrol:TDELay <Delay> Trigger Delay

<Delay>

–32000 samples to +32000 samples

–64000 samples to +64000 samples

Description of com mand

This command specifies a number of sample periods between the trigger event and the start of the measurement. The resulting trigger delay time depends on the filter settings; see Table 2 on p. 19. The samples are continuously acquired and stored so that negative trigger delays are allowed.

CONFigure:IQRecorder:CONTrol:CTIMeout <Timeout> Capture Timeout

<Timeout>

1 s/10 to 600 s/10

OFF

Description of com mand

This command specifies a maximum time between the start of the measurement and the trigger time in tenths of

a second (numeric entry: 1 to 600). The setting is valid for power and external trigger events. If no trigger occurs,

the READ…:ARRay:… commands return NTR.

CONFigure:IQRecorder:CONTrol:CLENgth <Samples> Capture Length

<Samples>

1 sample to +32768 samples

1 sample to +65536 samples

Description of com mand

This command specifies the number of samples acquired in every single measurement.

Desciption of paramet ers Def. value Def. unit FW vers.

50 kHz, 100 kHz, 200 kHz,

F1M – V3.80

300 kHz, 500 kHz, 1 MHz,

3 MHz, 5 MHz (with option CMU-U65V04)

Desciption of paramet ers Def. value Def. unit FW vers.

Trigger delay without option

0 (samples) V3.80

Trigger delay with option R&S

CMU-U65V02 or CMU-U65V04

Desciption of paramet ers Def. value Def. unit FW vers.

Capture timeout (in multiples of 0.1 s)

10 1/10 s V3.80

No timeout checked

Desciption of paramet ers Def. value Def. unit FW vers.

Capture length without option

1024 (samples) V3.80

Capture length with option R&S CMUU65V02 or CMU-U65V04

1100.4984.12 S.20 V3.80_E-1

R&S CMU 200 I/Q Recorder

CONFigure:IQRecorder:CONTrol:RMODe <Format> Format

<Format>

IQ |

PLW |

PLUW

Description of com mand

This command specifies the output format for the I/Q data. Rectangular values can be retrieved by means of the

commands READ…:ARRay:IQRecorder:I?, READ…:ARRay:IQRecorder:Q? etc. Polar values can be retrieved by means of READ…:ARRay:IQRecorder:PHASe?, READ…:ARRay:IQRecorder:LEVel?,

READ…:ARRay:IQRecorder:PL? etc. Polar and rectangular representation of the results are equivalent:

<Magnitude> = sqrt (<I>

<I> = <Magnitude> * cos (<Phase>) <Q> = <Magnitude> * sin (<Phase>)

Wrapped phase means that the phase is limited to values between –180° and +180°.

CONFigure:IQRecorder:CONTrol:LFORmat <Unit> Unit

<Unit>

VOLT | DBM Linear or logarithmic magnitude DBM – V3.80

Description of com mand

This command specifies the unit for the magnitude if one of the polar formats is active (CONFig-

ure:IQRecorder:CONTrol:RMODe PLW | PLUW). Volts and dBm values are converted assuming a reference impedance of 50 Ω.

Desciption of paramet ers Def. value Def. unit FW vers.

Rectangular values (I and Q amplitudes)

PLW – V3.80

Polar values (magnitude and wrapped phase)

Polar values (magnitude and unwrapped phase)

2

+ <Q>2); <Phase> = arctan (<Q>/<I>)

Desciption of paramet ers Def. value Def. unit FW vers.

For the rectangular (I/Q) format, the unit is always V, and negative values are allowed.

DEFault:IQRecorder:CONTrol <Enable> Default Settings

<Enable>

ON |

OFF

Description of com mand

Description of paramet ers Def. value Def. unit FW vers.

The parameters are set to default values

Some or all parameters differ from the default values

ON

– V3.80

If used as a setting command with the parameter ON this command sets all parameters of the subsystem to

default values (the setting OFF results in an error message). If used as a query the command returns whether

all parameters are set to default values (ON) or not (OFF).

1100.4984.12 S.21 V3.80_E-1

I/Q Recorder R&S CMU 200

Subarray Configuration

The subsystem SUBarrays:POWer:SLOT defines the measurement range and the type of output values.

CONFigure:SUBarrays:IQRecorder <Mode>,<Start>,<Samples>{,<Start>,<Samples>}

Definition of Subarrays

<Mode>

ALL |

ARIThmetical |

MINimum |

MAXimum |

IVAL,

<Start>

1 to N, First sample in current range 1 –

<Samples>

1 to N Number of samples in current range N – V3.80

Description of com mand

This command configures the READ:SUBarrays:IQRecorder..., FETCh:SUBarrays:IQRecorder...,

and SAMPle:SUBarrays:IQRecorder... commands. It restricts the measurement to up to 32 subranges

where either all measurement results (the number of which is given by the second numerical parameter) or a

single statistical value is returned. The subranges are defined by the current number of the first sample and the

number of samples within a subrange.

Description of paramet ers Def. value Def. unit

Return all measurement values

Return arithm. mean value in every range

Return minimum value in every range

Return maximum value in every range

Return single value at <Start>

Description of paramet ers Def. value Def. unit

Description of paramet ers Def. value Def. unit FW vers.

ALL –

The subranges may overlap but must be within the range of the I/Q Recorder measurement which is defined by

the capture length N (CONFigure:IQRecorder:CONTrol:CLENgth). Results outside this range are not

available (result NAN) and do not enter into the ARIThmetical, MINimum and MAXimum values.

By default, only one range corresponding to the total measurement range is used and all measurement values

are returned.

Subarrays are only available for data transfer in ASCII format.

1100.4984.12 S.22 V3.80_E-1

R&S CMU 200 I/Q Recorder

ASCII Results – Subsystem IQRecorder:ARRay

The subsystem IQRecorder:ARRay...? measures and returns the I/Q Recorder results as a commaseparated array of ASCII values.

Phase values

READ:ARRay:IQRecorder:PHASe? Start single shot measurement and return results

FETCh:ARRay:IQRecorder:PHASe? Read out meas. results (unsynchronized)

SAMPle:ARRay:IQRecorder:PHASe? Read out measurement results (synchronized)

Returned values

OK | NTR | OFLW | INV,

1 | N,

–180 deg to +180 deg,

…,

–180 deg to +180 deg

Description of com mand

These commands are always queries. They start a IQRecorder measurement (READ...)and/or return the

phases. A polar format (CONFigure:IQRecorder:CONTrol:RMODe PLW | PLUW) must be active to obtain

valid results. In the unwrapped phase format (PLUW), the phase is not restricted to the range between –180 deg

and +180 deg.

N denotes the total number of samples acquired (capture length, CONFigure:IQRecorder:CONTrol

:CLENgth). The status indicators have the following meaning:

Description of paramet ers Def. value Def. unit FW vers.

Measurement status indicators

Number of values

st

value for phase (status = OK only)

1

…

th

value for phase (status = OK only)

N

INV

NAN

NAN

NAN

NAN

–

–

deg

deg

deg

V3.80

OK Valid measurement data. The output array contains N phase values (OK, N, phase

, …, phaseN).

1

NTR No trigger event received during the capture timeout (CONFigure:IQRecorder:CONTrol

:CTIMeout). The output array reads (NTR, 1 NAN).

OFLW Overflow, input path overdriven. The output array reads (OFLW, 1 NAN).

INV Invalid measurement data (e.g. because the wrong format was selected). The output array reads

(INV, 1 NAN).

Magnitude values

READ:ARRay:IQRecorder:LEVel? Start single shot measurement and return results

FETCh:ARRay:IQRecorder:LEVel? Read out meas. results (unsynchronized)

SAMPle:ARRay:IQRecorder:LEVel? Read out measurement results (synchronized)

Returned values

OK | NTR | OFLW | INV,

1 | N,

–100 dBm to +60 dBm,

…,

–100 dBm to +60 dBm

Description of com mand

Description of paramet ers Def. value Def. unit FW vers.

Measurement status indicators

Number of values

st

value for magnitude (status = OK only)

1

…

th

value for magnitude (status = OK only)

N

INV

NAN

NAN

NAN

NAN

–

–

dBm

dBm

dBm

V3.80

These commands are always queries. They start a IQRecorder measurement (READ...)and/or return the

magnitudes. A polar format (CONFigure:IQRecorder:CONTrol:RMODe PLW | PLUW) must be active to

obtain valid results. If the magnitude is expressed as an equivalent voltage, the output values are approx. in the

range 2.2*10

–6

V to 220 V.

N denotes the total number of samples acquired (capture length, CONFigure:IQRecorder:CONTrol

:CLENgth). The status indicators are described on p. 23.

1100.4984.12 S.23 V3.80_E-1

I/Q Recorder R&S CMU 200

Phase and magnitude values

READ:ARRay:IQRecorder:PL? Start single shot measurement and return results

FETCh:ARRay:IQRecorder:PL? Read out meas. results (unsynchronized)

SAMPle:ARRay:IQRecorder:PL? Read out measurement results (synchronized)

Returned values

OK | NTR | OFLW | INV,

1 | N,

–180 deg to +180 deg,

–100 dBm to +60 dBm,

…,

–180 deg to +180 deg,

–100 dBm to +60 dBm

Description of com mand

These commands are always queries. They start a IQRecorder measurement (READ...)and/or return the

phases and magnitudes. A polar format (CONFigure:IQRecorder:CONTrol:RMODe PLW | PLUW) must be

active to obtain valid results. In the unwrapped phase format (PLUW), the phase is not restricted to the range

between –180 deg and +180 deg. If the magnitude is expressed as an equivalent voltage, the output values are

approx. in the range 2.2*10

N denotes the total number of samples acquired (capture length, CONFigure:IQRecorder:CONTrol

:CLENgth). The status indicators are described on p. 23.

I amplitudes

READ:ARRay:IQRecorder:I? Start single shot measurement and return results

FETCh:ARRay:IQRecorder:I? Read out meas. results (unsynchronized)

SAMPle:ARRay:IQRecorder:I? Read out measurement results (synchronized)

Returned values

OK | NTR | OFLW | INV,

1 | N,

–220 V to +220 V,

…,

–220 V to +220 V

Description of com mand

These commands are always queries. They start a IQRecorder measurement (READ...)and/or return the I

amplitudes. The rectangular format (CONFigure:IQRecorder:CONTrol:RMODe IQ) must be active to obtain

valid results.

Description of paramet ers Def. value Def. unit FW vers.

Measurement status indicators

Number of values

st

value for phase (status = OK only)

1

st

value for magnitude (status = OK only)

1

…

th

value for phase (status = OK only)

N

th

value for magnitude (status = OK only)

N

–6

V to 220 V.

Description of paramet ers Def. value Def. unit FW vers.

Measurement status indicators

Number of values

st

value for I amplitude (status = OK only)

1

…

th

value for I amplitude (status = OK only)

N

INV

NAN

NAN

NAN

NAN

NAN

NAN

INV

NAN

NAN

NAN

NAN

–

–

deg

dBm

deg

dBm

–

–

V

V

V

V3.80

V3.80

N denotes the total number of samples acquired (capture length, CONFigure:IQRecorder:CONTrol

:CLENgth). The status indicators are described on p. 23.

1100.4984.12 S.24 V3.80_E-1

R&S CMU 200 I/Q Recorder

Q amplitudes

READ:ARRay:IQRecorder:Q? Start single shot measurement and return results

FETCh:ARRay:IQRecorder:Q? Read out meas. results (unsynchronized)

SAMPle:ARRay:IQRecorder:Q? Read out measurement results (synchronized)

Returned values

OK | NTR | OFLW | INV,

1 | N,

–220 V to +220 V,

…,

–220 V to +220 V

Description of com mand

These commands are always queries. They start a IQRecorder measurement (READ...)and/or return the Q

amplitudes. The rectangular format (CONFigure:IQRecorder:CONTrol:RMODe IQ) must be active to obtain

valid results.

N denotes the total number of samples acquired (capture length, CONFigure:IQRecorder:CONTrol

:CLENgth). The status indicators are described on p. 23.

I and Q amplitudes

READ:ARRay:IQRecorder:IQ? Start single shot measurement and return results

FETCh:ARRay:IQRecorder:IQ? Read out meas. results (unsynchronized)

SAMPle:ARRay:IQRecorder:IQ? Read out measurement results (synchronized)

Returned values

OK | NTR | OFLW | INV,

1 | N,

–220 V to +220 V,

–220 V to +220 V,

…,

–220 V to +220 V

–220 V to +220 V

Description of com mand

These commands are always queries. They start a IQRecorder measurement (READ...)and/or return the I

and Q amplitudes. The rectangular format (CONFigure:IQRecorder:CONTrol:RMODe IQ) must be active to

obtain valid results.

Description of paramet ers Def. value Def. unit FW vers.

Measurement status indicators

Number of values

st

value for Q amplitude (status = OK only)

1

…

th

value for Q amplitude (status = OK only)

N

Description of paramet ers Def. value Def. unit FW vers.

Measurement status indicators

Number of values

st

value for I amplitude (status = OK only)

1

st

value for Q amplitude (status = OK only)

1

…

th

value for I amplitude (status = OK only)

N

th

value for Q amplitude (status = OK only)

N

INV

NAN

NAN

NAN

NAN

INV

NAN

NAN

NAN

NAN

NAN

NAN

–

–

V

V

V

–

–

V

V

V

V

V

V3.80

V3.80

N denotes the total number of samples acquired (capture length, CONFigure:IQRecorder:CONTrol

:CLENgth). The status indicators are described on p. 23.

1100.4984.12 S.25 V3.80_E-1

I/Q Recorder R&S CMU 200

Measured Subarrays – Subsystem IQRecorder:SUBarray

The subsystem IQRecorder:SUBarray...? measures and returns the I/Q Recorder subarray results.

Phase values

READ:SUBarrays:IQRecorder:PHASe? Start single shot measurement and return results

FETCh:SUBarrays:IQRecorder:PHASe? Read out meas. results (unsynchronized)

SAMPle:SUBarrays:IQRecorder:PHASe? Read out measurement results (synchronized)

Returned values

OK | NTR | OFLW | INV,

1 | N,

–180 deg to +180 deg,

…,

–180 deg to +180 deg

Description of com mand

These commands are always queries. They start a IQRecorder measurement (READ...)and/or return the

phases in the subranges defined by means of the CONFigure:SUBarrays:IQRecorder command (see p.

22). A polar format (CONFigure:IQRecorder:CONTrol:RMODe PLW | PLUW) must be active to obtain valid

results. In the unwrapped phase format (PLUW), the phase is not restricted to the range between –180 deg and

+180 deg.

The CONFigure:SUBarrays:IQRecorder command defines a maximum of 32 subranges. If one of the statistical modes (ARIThmetical, MINimum, MAXimum, IVAL) is set, only one value is returned per

subrange.

Description of paramet ers Def. value Def. unit FW vers.

Measurement status indicators

Number of values

st

value for phase (status = OK only)

1

…

th

value for phase (status = OK only)

N

INV

NAN

NAN

NAN

NAN

–

–

deg

deg

deg

V3.80

N denotes the total number of returned values. The status indicators are described on p. 23.

Magnitude values

READ:SUBarrays:IQRecorder:LEVel? Start single shot measurement and return results

FETCh:SUBarrays:IQRecorder:LEVel? Read out meas. results (unsynchronized)

SAMPle:SUBarrays:IQRecorder:LEVel? Read out measurement results (synchronized)

Returned values

OK | NTR | OFLW | INV,

1 | N,

–100 dBm to +60 dBm,

…,

–100 dBm to +60 dBm

Description of com mand

Description of paramet ers Def. value Def. unit FW vers.

Measurement status indicators

Number of values

st

value for magnitude (status = OK only)

1

…

th

value for magnitude (status = OK only)

N

INV

NAN

NAN

NAN

NAN

–

–

dBm

dBm

dBm

V3.80

These commands are always queries. They start a IQRecorder measurement (READ...)and/or return the

magnitudes in the subranges defined by means of the CONFigure:SUBarrays:IQRecorder command (see

p. 22). A polar format (CONFigure:IQRecorder:CONTrol:RMODe PLW | PLUW) must be active to obtain

valid results. If the magnitude is expressed as an equivalent voltage, the output values are approx. in the range

–6

2.2*10

V to 220 V.

The CONFigure:SUBarrays:IQRecorder command defines a maximum of 32 subranges. If one of the statistical modes (ARIThmetical, MINimum, MAXimum, IVAL) is set, only one value is returned per

subrange.

N denotes the total number of returned values. The status indicators are described on p. 23.

1100.4984.12 S.26 V3.80_E-1

R&S CMU 200 I/Q Recorder

Phase and magnitude values

READ:SUBarrays:IQRecorder:PL? Start single shot measurement and return results

FETCh:SUBarrays:IQRecorder:PL? Read out meas. results (unsynchronized)

SAMPle:SUBarrays:IQRecorder:PL? Read out measurement results (synchronized)

Returned values

OK | NTR | OFLW | INV,

1 | N,

–180 deg to +180 deg,

–100 dBm to +60 dBm,

…,

–180 deg to +180 deg,

–100 dBm to +60 dBm

Description of com mand

These commands are always queries. They start a IQRecorder measurement (READ...)and/or return the

phases and magnitudes in the subranges defined by means of the CONFigure:SUBarrays:IQRecorder

command (see p. 22). A polar format (CONFigure:IQRecorder:CONTrol:RMODe PLW | PLUW) must be

active to obtain valid results. In the unwrapped phase format (PLUW), the phase is not restricted to the range

between –180 deg and +180 deg. If the magnitude is expressed as an equivalent voltage, the output values are

approx. in the range 2.2*10

The CONFigure:SUBarrays:IQRecorder command defines a maximum of 32 subranges. If one of the statistical modes (ARIThmetical, MINimum, MAXimum, IVAL) is set, only one value is returned per

subrange.

Description of paramet ers Def. value Def. unit FW vers.

Measurement status indicators

Number of values

st

value for phase (status = OK only)

1

st

value for magnitude (status = OK only)

1

…

th

value for phase (status = OK only)

N

th

value for magnitude (status = OK only)

N

–6

V to 220 V.

INV

NAN

NAN

NAN

NAN

NAN

NAN

–

–

deg

dBm

deg

dBm

V3.80

N denotes the total number of returned values. The status indicators are described on p. 23.

I amplitudes

READ:SUBarrays:IQRecorder:I? Start single shot measurement and return results

FETCh:SUBarrays:IQRecorder:I? Read out meas. results (unsynchronized)

SAMPle:SUBarrays:IQRecorder:I? Read out measurement results (synchronized)

Returned values

OK | NTR | OFLW | INV,

1 | N,

–220 V to +220 V,

…,

–220 V to +220 V

Description of com mand

Description of paramet ers Def. value Def. unit FW vers.

Measurement status indicators

Number of values

st

value for I amplitude (status = OK only)

1

…

th

value for I amplitude (status = OK only)

N

INV

NAN

NAN

NAN

NAN

–

–

V

V

V

V3.80

These commands are always queries. They start a IQRecorder measurement (READ...)and/or return the I

amplitudes in the subranges defined by means of the CONFigure:SUBarrays:IQRecorder command (see p.

22). The rectangular format (CONFigure:IQRecorder:CONTrol:RMODe IQ) must be active to obtain valid

results.

The CONFigure:SUBarrays:IQRecorder command defines a maximum of 32 subranges. If one of the sta-

tistical modes (ARIThmetical, MINimum, MAXimum, IVAL) is set, only one value is returned per

subrange.

N denotes the total number of returned values. The status indicators are described on p. 23.

1100.4984.12 S.27 V3.80_E-1

I/Q Recorder R&S CMU 200

Q amplitudes

READ:SUBarrays:IQRecorder:Q? Start single shot measurement and return results

FETCh:SUBarrays:IQRecorder:Q? Read out meas. results (unsynchronized)

SAMPle:SUBarrays:IQRecorder:Q? Read out measurement results (synchronized)

Returned values

OK | NTR | OFLW | INV,

1 | N,

–220 V to +220 V,

…,

–220 V to +220 V

Description of com mand

These commands are always queries. They start a IQRecorder measurement (READ...)and/or return the Q

amplitudes in the subranges defined by means of the CONFigure:SUBarrays:IQRecorder command (see p.

22). The rectangular format (CONFigure:IQRecorder:CONTrol:RMODe IQ) must be active to obtain valid

results.

The CONFigure:SUBarrays:IQRecorder command defines a maximum of 32 subranges. If one of the sta-

tistical modes (ARIThmetical, MINimum, MAXimum, IVAL) is set, only one value is returned per

subrange.

N denotes the total number of returned values. The status indicators are described on p. 23.

I and Q amplitudes

READ:SUBarrays:IQRecorder:IQ? Start single shot measurement and return results

FETCh:SUBarrays:IQRecorder:IQ? Read out meas. results (unsynchronized)

SAMPle:SUBarrays:IQRecorder:IQ? Read out measurement results (synchronized)

Returned values

OK | NTR | OFLW | INV,

1 | N,

–220 V to +220 V,

–220 V to +220 V,

…,

–220 V to +220 V

–220 V to +220 V

Description of com mand

These commands are always queries. They start a IQRecorder measurement (READ...)and/or return the I

and Q amplitudes in the subranges defined by means of the CONFigure:SUBarrays:IQRecorder command

(see p. 22). The rectangular format (CONFigure:IQRecorder:CONTrol:RMODe IQ) must be active to obtain

valid results.

Description of paramet ers Def. value Def. unit FW vers.

Measurement status indicators

Number of values

st

value for Q amplitude (status = OK only)

1

…

th

value for Q amplitude (status = OK only)

N

Description of paramet ers Def. value Def. unit FW vers.

Measurement status indicators

Number of values

st

value for I amplitude (status = OK only)

1

st

value for Q amplitude (status = OK only)

1

…

th

value for I amplitude (status = OK only)

N

th

value for Q amplitude (status = OK only)

N

INV

NAN

NAN

NAN

NAN

INV

NAN

NAN

NAN

NAN

NAN

NAN

–

–

V

V

V

–

–

V

V

V

V

V

V3.80

V3.80

The CONFigure:SUBarrays:IQRecorder command defines a maximum of 32 subranges. If one of the statistical modes (ARIThmetical, MINimum, MAXimum, IVAL) is set, only one value is returned per

subrange.

N denotes the total number of returned values. The status indicators are described on p. 23.

1100.4984.12 S.28 V3.80_E-1

R&S CMU 200 I/Q Recorder

Binary Results – Subsystem IQRecorder:BINary:ARRay

The subsystem IQRecorder:BINary:ARRay...? m easures and returns the I/Q Recorder r esults in binary

format. Each value is c oded as a 32-bit (4-byte) IEEE 754 floating point num ber. The general for mat of

an output string is described in Table 3 below.

Table 3 Binary output format

Parameter Format Values, Range Description

Status ASCII [OK, NTR, OFLW, INV] Validity of the captured dat a

#L ASCII [1, …, 6] Num ber of digits of the following count er N

N ASCII [4, …, 262144] with option

Value

i

with i=1 to N/4

EOS ASCII Hex: 0x0D0A End of st ri ng character,

Example of valid measurement output data with capture l engt h 16 (and therefore N = 64):

{OK,#264 byte

Note that a comm a separates the status indicator from the data part. In the combined phase/magnitude and I/Q commands

(READ…PL?, READ:…:IQ? etc.) the number of bytes is doubled and N is replaced by 2*N.

Output in case of errors:

{INV} Invali d measurement data (e.g. because the wrong format was select ed)

{NTR} No trigger event received during the capture timeout

(CONFigure:IQRecorder:CONTrol:CTIMeout)

{OFLW} Overflow, input path overdriven

BINARY byte

byte

1,2

byte

1,1

R&S CMU-U65 V02 or R&S CMU-U65 V04

[4, …, 131072] without option

byte

byte

with i=1 to N/4

byte

1,3

i,1

1,4

byte

i,2

2,1

byte

i,3

byte

2,2

i,4

byte

byte

2,3

Total number of the following data byt es

N = 4 * capture length (CONFigure

:IQRecorder:CONTrol:CLENgth).

32-bit (4-byte) IEEE 754 float i ng poi nt number

[0x0D = carriage return] & [0x0A = line feed]

2,4

… byte

16,1

byte

16,2

byte

16,3

byte

16,4

EOS}

Phase values

READ:BINary:ARRay:IQRecorder:PHASe? Start single shot measurement and return results

FETCh:BINary:ARRay:IQRecorder:PHASe? Read out meas. results (unsynchronized)

SAMPle:BINary:ARRay:IQRecorder:PHASe? Read out measurement results (synchronized)

Returned values

OK | NTR | OFLW | INV,

L

N

<–180 deg to +180 deg>

…

<–180 deg to +180 deg>

EOS

Description of com mand

These commands are always queries. They start a IQRecorder measurement (READ...)and/or return the

phases in the binary format described in Table 3 on p. 19. Each phase value is coded as a 32-bit (4-byte) IEEE

754 floating point number. A polar format (CONFigure:IQRecorder:CONTrol :RMODe PLW | PLUW) must

be active to obtain valid results. In the unwrapped phase format (PLUW), the phase is not restricted to the range

between –180 deg and +180 deg.

Description of paramet ers Def. value Def. unit FW vers.

Measurement status indicators

Number of digits of N (status = OK only)

Number of data bytes (status = OK only)

st

value for phase (status = OK only)

1

th

value for phase (status = OK only)

N/4

End of string (status = OK only)

INV

–

–

–

–

–

–

–

–

–

deg

deg

deg

–

V3.80

N denotes four times the total number of samples acquired (capture length, CONFigure:IQRecorder

:CONTrol:CLENgth).

1100.4984.12 S.29 V3.80_E-1

I/Q Recorder R&S CMU 200

Magnitude values

READ:BINary:ARRay:IQRecorder:LEVel? Start single shot measurement and return results

FETCh:BINary:ARRay:IQRecorder:LEVel? Read out meas. results (unsynchronized)

SAMPle:BINary:ARRay:IQRecorder:LEVel? Read out measurement results (synchronized)

Returned values

OK | NTR | OFLW | INV,

L

N

<–100 dBm to +60 dBm>

…

<–100 dBm to +60 dBm>

EOS

Description of com mand

These commands are always queries. They start a IQRecorder measurement (READ...)and/or return the

magnitudes in the binary format described in Table 3 on p. 19. Each magnitude value is coded as a 32-bit (4byte) IEEE 754 floating point number. A polar format (CONFigure:IQRecorder:CONTrol:RMODe PLW |

PLUW) must be active to obtain valid results. If the magnitude is expressed as an equivalent voltage, the output

values are approx. in the range 2.2*10

N denotes four times the total number of samples acquired (capture length, CONFigure:IQRecorder

:CONTrol:CLENgth).

Description of paramet ers Def. value Def. unit FW vers.

Measurement status indicators

Number of digits of N (status = OK only)

Number of data bytes (status = OK only)

st

value for magnitude (status = OK only)

1

th

value for magnitude (status = OK only)

N/4

End of string (status = OK only)

–6

V to 220 V.

INV

–

–

–

–

–

–

–

–

–

dBm

dBm

dBm

–

V3.80

1100.4984.12 S.30 V3.80_E-1

R&S CMU 200 I/Q Recorder

Phase and magnitude values

READ:BINary:ARRay:IQRecorder:PL? [<Order>] Start single shot measurement and return results

FETCh:BINary:ARRay:IQRecorder:PL? [<Order>] Read out meas. results (unsynchronized)

SAMPle:BINary:ARRay:IQRecorder:PL? [<Order>] Read out measurement results (synchronized)

<Order>

NORMal

ALTernate

Returned values, normal order

OK | NTR | OFLW | INV,

L

2*N

<–180 deg to +180 deg>

…

<–180 deg to +180 deg>

<–100 dBm to +60 dBm>

…

<–100 dBm to +60 dBm>

EOS

Returned values, altern. order

OK | NTR | OFLW | INV,

L

2*N

<–180 deg to +180 deg>

<–100 dBm to +60 dBm>

…

<–180 deg to +180 deg>

<–100 dBm to +60 dBm>

EOS

Description of com mand

These commands are always queries. They start a IQRecorder measurement (READ...)and/or return the

phases and magnitudes in the binary format described in Table 3 on p. 19. Each phase and each magnitude

value is coded as a 32-bit (4-byte) IEEE 754 floating point number. A polar format (CONFigure:IQRecorder

:CONTrol:RMODe PLW | PLUW) must be active to obtain valid results. In the unwrapped phase format (PLUW),

the phase is not restricted to the range between –180 deg and +180 deg. If the magnitude is expressed as an

equivalent voltage, the output values are approx. in the range 2.2*10

Description of paramet ers Def. value Def. unit FW vers.

All phases first, then all magnitudes

NORMal – V3.80

Alternating phases and magnitudes

(see below)

Description of paramet ers Def. value Def. unit FW vers.

Measurement status indicators

Number of digits of 2*N (status = OK only)

Number of data bytes (status = OK only)

st

value for phase (status = OK only)

1

th