Page 1

Quick Start Guide

Universal

Radio Communication Tester

R&SCMU 200

1100.0008.02/10/30/53

Printed in Germany

1100.4961.62

-04

Test and Measurement Division

Page 2

The firmware of the instrument makes use of several valuable open source software packages. The

most important of them are listed below together with their corresponding open source license. The

verbatim license texts are provided in on the user documentation CD-ROM (included in delivery).

Package Link License

STLPort http://www.stlport.org/ STLPort License

InfoZIP http://www.info-zip.org Copyright InfoZIP

UNTGZ http://www.t-st.org/untgz_f.htm GNU GPL v. 2 / R&S Copyright

MD5 http://www.rsa.com Copyright RSA Data Security

Axis2 http://ws.apache.org/axis2/ Apache License v. 2.0

Jetty Server http://www.mortbay.org/ Apache License v. 2.0

Xerces http://xerces.apache.org/xerces2-j/ Apache License v. 2.0

This product includes UNTGZ for DOS (http://www.t-st.org/untgz_f.htm), and includes as the GPL'ed

source code for this program

Rohde & Schwarz would like to thank the open source community for their valuable contribution to

embedded computing.

R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

Trade names are trademarks of the owner

Page 3

R&S CMU Documentation Map

Quick Start Guide

The present quick start guide describes everything that is needed

to put the instrument into operation and helps you to get familiar

with the radio communication tester. In particular, the quick start

guide describes the safety-related aspects to be observed when

setting up or operating the instrument. The guide contains:

• The product brochure and specifications

• Safety instructions

• Certificates

• Customer support information, Rohde & Schwarz addresses

• Chapter 1: Preparation for Use

• Chapter 2: Getting Started

• Index for chapter 1 and chapter 2

Documentation CD-ROM

The CD-ROM provides the complete user documentation for the

radio communication testers R&S CMU 200 and R&S CMU 300:

• Printable versions of the complete operating manual

(including the contents of this quick start guide) and the

service manual

• Printable versions of the manuals for R&S CMU network test

options (see order list on the following page) and accessories

• Help systems corresponding to the contents of the quick start

guide and to the complete operating manual

• The product brochure and specifications in printable form.

• Application notes and articles

• Links to different useful sites in the R&S internet.

Optional Documentation

1100.4961.62

The complete operating manual for the radio communication

testers R&S CMU 200 and R&S CMU 300 and the manuals for

the network test options provide the complete reference

information for operation and programming. The service manual

instrument contains the performance test and other servicerelated information.

Printed versions of the manuals can be ordered as options; see

ordering information on the next page.

Note: The CD-ROM delivered with the instrument contains

printable (.pdf) versions of all these manuals.

1 E-3

Page 4

R&S CMU Models

This manual describes the following models of the Universal Radio Communication Tester R&S

CMU 200:

• Universal Radio Communication Tester R&S CMU 200, stock no. 1100.0008.02, for all mobile

station and user equipment tests including Bluetooth™ device tests.

• Universal Radio Communication Tester R&S CMU 200, stock no. 1100.0008.53, only for

Bluetooth™ device tests.

• High End Service Tester R&S CMU 200v10, stock no. 1100.0008.10. For an introduction to the

features of this model refer to the enclosed product brochure.

• Non Signalling Tester R&S CMU 200v30, stock no. 1100.0008.30. For an introduction to the

features of this model refer to the enclosed R&S CMU 200 product brochure.

The Universal Radio Communication Tester R&S CMU 300, stock no. 1100.0008.03, is described in

a separate quick start guide, stock no.

1100.4978.62

.

1100.4961.62

2 E-3

Page 5

List of Printed Manuals

The following operating manuals are related to the Universal Radio Communication Tester R&S

CMU 200 and to network test options for the R&S CMU 200. Printed manuals can be ordered from

Rohde & Schwarz using the order numbers listed below.

For Options

Manual Order Number Type, R&S… Description Stock No.

Operating Manual

CMU 200/300

Service Manual Inst.

CMU 200/300

Operating Manual

CMU-K20/-K21/K22/-K23/-K24/-K26

Operating Manual

CMU-K27/-K28

1100.4984.12

CMU 200

CMU 300

CMU-B41

CMU-B95/96

CMU-B17

CMU-K48

CMU-K14

1100.4903.82

CMU 200

CMU 300

1115.6088.12 CMU-K20

CMU-K21

CMU-K22

CMU-K23

CMU-K24

CMU-K26

CMU-K42

CMU-K43

CMU-K44

CMU-K45

CMU-K47

1115.6688.12 CMU-K27

CMU-K28

Univ. Radio Communication Tester

for mobile stations / UE

for base stations

Audio Generator and Analyzer

Additional RF Generator

I/Q and IF Interface

I/Q vs. Slot Measurement

FM Stereo Transmitter

Univ. Radio Communication Tester

for mobile stations / UE

for base stations

GSM400-MS for CMU-B21

GSM900-MS for CMU-B21

GSM1800-MS for CMU-B21

GSM1900-MS for CMU-B21

GSM850-MS for CMU-B21

GSM GT800 for CMU-B21

GPRS software extension for GSM

EGPRS software extension for GSM

Dual Transfer Mode

AMR GSM for CMU200

R&S Smart Alignment @ GSM-MS

TDMA800-MS for CMU-B21

TDMA1900-MS for CMU-B21

1100.0008.02/53

1100.0008.10/30

1100.0008.03

1100.5300.02

1159.0504.02

1159.1600.02

1157.5309.02

1200.7503.02

1100.0008.02/53

1100.0008.10/30

1100.0008.03

1115.5900.02

1115.6007.02

1115.6107.02

1115.6207.02

1115.6307.02

1115.6507.02

1115.4691.02

1115.6907.02

1157.4277.02

1150.3100.02

1157.4477.02

1115.6607.02

1115.6707.02

Operating Manual

CMU-K29

Operating Manual

CMU-K53

1100.4961.62

1115.6888.12 CMU-K29 AMPS-MS for CMU-B21 1115.6807.02

1115.5081.12 CMU-K53 Bluetooth for CMU 1115.5000.02

3 E-3

Page 6

Manual Order Number Type, R&S… Description Stock No.

For Options

Operating Manual

CMU-K61…-K69

Operating Manual

CMU-K81/-K82

Operating Manual

CMU-K83/-K84/

-K85/-K86

1115.4962.12 CMU-K65

CMU-K66

CMU-K67

CMU-K68

CMU-K69

CMU-K61

CMU-K62

CMU-K63

CMU-K57

CMU-K58

CMU-K59

CMU-K16

CMU-K17

CMU-K15

CMU-K64

CMU-K60

CMU-K56

CMU-K96

CMU-K46

CMU-K47

1115.5581.12 CMU-K81

CMU-K82

1150.0382.12 CMU-K83

CMU-K84

CMU-K85

CMU-K86

CMU-K87

CMU-K47

WCDMA UE TX Test (3GPP/FDD)

WCDMA UE DL Generator

WCDMA UE Band III Signalling

WCDMA UE Band I Signalling

WCDMA UE Band II Signalling

WCDMA UE Band IV Signalling

WCDMA UE Band V Signalling

WCDMA UE Band VI Signalling

WCDMA UE Band VII Signalling

WCDMA UE Band VIII Signalling

WCDMA UE Band IX Signalling

WCDMA UE Band X Signalling

WCDMA UE Band XI Signalling

WCDMA UE Band S Signalling

HSDPA 3.6 Mbps

HSDPA 10 Mbps

HSUPA 5.76 Mbps

WCDMA Application Testing

Wideband AMR Codec

Smart Alignment @ WCDMA UE

CDMA800-MS (IS95) for CMU-B81

CDMA1900-MS (IS95) for CMU-B81

CDMA2000-MS (450 MHz band)

CDMA2000-MS (cellular band)

CDMA2000-MS (PCS band)

CDMA2000-MS (IMT-2000 band)

CDMA2000 Data Testing

Smart Alignment @ CDMA2000

1115.4891.02

1115.5100.02

1150.3000.02

1115.5300.02

1115.5400.02

1157.3670.02

1157.3770.02

1157.3870.02

1150.3000.02

1115.5300.02

1115.5400.02

1200.9158.02

1200.9106.02

1200.9258.02

1157.3970.02

1200.8200.02

1200.7803.02

1157.4177.02

1200.8800.02

1157.4477.02

1115.5500.02

1115.5600.02

1150.3500.02

1150.3600.02

1150.3700.02

1150.3800.02

1150.4007.02

1157.4477.02

Operating Manual

CMU-K88

1150.3998.12

1200.8300.02

1200.8400.02

1200.8500.02

1200.8600.02

CMU-K88

CMU-K839

CMU-K849

CMU-K859

CMU-K869

1xEV-DO for CMU-B88

1xEV-DO 450MHz

1xEV-DO cellular band

1xEV-DO PCS band

1xEV-DO IMT-2000 band

1150.3900.02

1200.8300.02

1200.8400.02

1200.8500.02

1200.8600.02

1100.4961.62

4 E-3

Page 7

CustomerInformationRegardingProductDisposal

TheGermanElectricalandElectronicEquipment(ElektroG)Actisanimplementationofthe

followingECdirectives:

· 2002/96/EConwasteelectricalandelectronicequipment(WEEE)and

· 2002/95/EContherestrictionoftheuseofcertainhazardoussubstancesin

electricalandelectronicequipment(RoHS).

ProductlabelinginaccordancewithEN50419

Oncethelifetimeofaproducthasended,thisproductmustnotbedisposedofinthe

standarddomesticrefuse.Evendisposalviathemunicipalcollectionpointsforwaste

electricalandelectronicequipment isnotpermitted.

Rohde&SchwarzGmbH&Co.KGhasdevelopedadisposalconceptforthe

environmentalfriendlydisposalorrecyclingofwastematerialandfullyassumesits

obligationasaproducertotakebackanddisposeofelectricalandelectronicwastein

accordancewiththeElektroGAct.

Pleasecontactyourlocalservicerepresentativetodisposeoftheproduct.

Page 8

Page 9

Certificate No.: 99035, page 1

This is to certify that:

EC Certificate of Conformity

Equipment type

Stock No. Designation

CMU200 1100.0008.02/.10/.30/.53 Universal Radio Communication Tester

CMU300 1100.0008.03

complies with the provisions of the Directive of the Council of the European Union on the

approximation of the laws of the Member States

- relating to electrical equipment for use within defined voltage limits

(73/23/EEC revised by 93/68/EEC)

- relating to electromagnetic compatibility

(89/336/EEC revised by 91/263/EEC, 92/31/EEC, 93/68/EEC)

Conformity is proven by compliance with the following standards:

EN61010-1 : 2001-12

EN61326-1 : 1997 + A1 : 1998

For the assessment of electromagnetic compatibility, the limits of radio interference for Class

B equipment as well as the immunity to interference for operation in industry have been used

as a basis.

Affixing the EC conformity mark as from 1999

ROHDE & SCHWARZ GmbH & Co. KG

Mühldorfstr. 15, D-81671 München

Munich, 2006-02-06 Central Quality Management FS-QZ / Radde

1100.0008.02-s1- CE E-12

Page 10

Certificate No.: 99035, page 2

This is to certify that:

EC Certificate of Conformity

Equipment type

Stock No. Designation

CMU-B11 1100.5000.02 Reference Oscillator

CMU-B12 1100.5100.02 Reference Oscillator

CMU-B15 1100.6006.02 Additional RF und IF Connections

CMU-B17 1100.6906.02 IQ and IF Interfaces

CMU-B21 1100.5200.02/.14/.54 Versatile Signalling Unit

CMU-B41 1100.5300.02 Audio Generator and Analyzer

CMU-B52 1100.5400.02/.14 Spreech Codec for Versatile Signalling Unit

CMU-B53 1100.5700.02/.14 Bluetooth Extension

CMU-B54 1150.2604.14 Sig. Module

CMU-B56 1150.1850.14 3GPP Signalling Unit

CMU-B66 1149.9509.02 Versatile Base Band Board

CMU-B68 1149.9809.02 Layer1 Board

CMU-B71 1100.6406.02 ABIS Interface Unit

CMU-B73 1150.2004.02 Analog Telephon Line Interface

CMU-B76 1150.0601.02 Layer1 Board for WCDMA

CMU-B78 1159.1800.02 Layer1 Board for WCDMA

complies with the provisions of the Directive of the Council of the European Union on the

approximation of the laws of the Member States

- relating to electrical equipment for use within defined voltage limits

(73/23/EEC revised by 93/68/EEC)

- relating to electromagnetic compatibility

(89/336/EEC revised by 91/263/EEC, 92/31/EEC, 93/68/EEC)

Conformity is proven by compliance with the following standards:

EN61010-1 : 2001-12

EN61326-1 : 1997 + A1 : 1998

For the assessment of electromagnetic compatibility, the limits of radio interference for Class

B equipment as well as the immunity to interference for operation in industry have been used

as a basis.

Affixing the EC conformity mark as from 1999

ROHDE & SCHWARZ GmbH & Co. KG

Mühldorfstr. 15, D-81671 München

Munich, 2006-02-06 Central Quality Management FS-QZ / Radde

1100.0008.02-s2- CE E-18

Page 11

Certificate No.: 99035, page 3

EC Certificate of Conformity

This is to certify that:

Equipment type

Stock No. Designation

CMU-B81 1100.6506.02 CDMA(IS95) Signalling Unit

CMU-B82 1150.0201.02/.04 ACCESS Board für CDMA Signalling Unit

CMU-B83 1150.0301.02/.04/.12/.14 CDMA2000 Signalling Unit

CMU-B85 1100.7002.02/.04/.12 Speech Codec for CDMA2000

CMU-B87 1150.2404.02/.04 Message Monitor for CDMA2000

CMU-B88 1158.9908.02 1xEV-DO Extension

CMU-B95 1159.0504.02 Additional RF Generator

CMU-B96 1159.1600.02 Additional RF Generator

CMU-B99 1150.1250.02 RF1 Level Range identical to RF2

CMU-U61 1100.5500.02 Floppy Disk Drive

CMU-Z1 1100.7490.02 Memory Card

complies with the provisions of the Directive of the Council of the European Union on the

approximation of the laws of the Member States

- relating to electrical equipment for use within defined voltage limits

(73/23/EEC revised by 93/68/EEC)

- relating to electromagnetic compatibility

(89/336/EEC revised by 91/263/EEC, 92/31/EEC, 93/68/EEC)

Conformity is proven by compliance with the following standards:

EN61010-1 : 2001-12

EN61326-1 : 1997 + A1 : 1998

For the assessment of electromagnetic compatibility, the limits of radio interference for Class

B equipment as well as the immunity to interference for operation in industry have been used

as a basis.

Affixing the EC conformity mark as from 1999

ROHDE & SCHWARZ GmbH & Co. KG

Mühldorfstr. 15, D-81671 München

Munich, 2006-02-06 Central Quality Management FS-QZ / Radde

1100.0008.02-s3- CE E-5

Page 12

Page 13

R&S CMU 200 Contents of Chapter 1

Contents

1 Preparing the R&S CMU for Use ........................................................................ 1.1

Front and Rear View.........................................................................................................................1.1

Rear View ..........................................................................................................................................1.7

Putting the Instrument into Operation .........................................................................................1.10

Unpacking the Instrument ......................................................................................................1.10

Setting up the Instrument .......................................................................................................1.10

Bench Top Operation...................................................................................................1.10

Mounting in a Rack.................................................................................................................1.11

Connecting the Instrument to the AC Supply .........................................................................1.12

Switching on the Instrument / Startup Test ............................................................................1.12

Switching off the Instrument ...................................................................................................1.13

How to Ensure EMC...............................................................................................................1.14

Input Level..............................................................................................................................1.14

Connecting the CMU to the Test Setup........................................................................................1.15

Connecting a Controller..........................................................................................................1.15

Connecting an External Keyboard..........................................................................................1.17

Connecting a Monitor .............................................................................................................1.17

Connecting a Printer...............................................................................................................1.18

Synchronization with External Devices; Connection of Further Components ........................1.18

Software Update and Version Management ................................................................................1.19

R&S Remote Service Tool .....................................................................................................1.19

Remote Control of the R&S CMU ................................................................................1.26

File Versions.new.........................................................................................................1.27

CMU VersionManager............................................................................................................1.29

1100.4961.62 I-1.1 E-3

Page 14

Page 15

R&S CMU 200 Front and Rear View

1 Preparing the R&S CMU for Use

This chapter describes the controls and connectors of the Universal Radio Communication Tester CMU

and gives all information that is necessary to put the instrument into operation and connect external

devices. Notes on reinstallation of the CMU software and a description of the VersionManager appear at

the end of this chapter.

Caution!

Please observe the instructions of the following sections so that you cannot cause

damage to the instrument or endanger people. This is of particular importance when

you use the instrument for the first time. Also observe the general safety instructions

at the beginning of this manual.

A more detailed description of the hardware connectors and interfaces can be found in chapter 8 of the

complete operating manual. Chapter 2 of the operating manual provides an introduction to the operation

of the CMU by means of typical examples of configuration and measurement; for a description of the

operating concept refer to Chapter 3.

For remote control of the CMU refer to the general description of the SCPI commands, the instrument

model, the status reporting system, and measurement control in Chapter 5 of the operating manual.

Front and Rear View

The front panel of the CMU consists of the VGA display with the softkey area (left side) and the hardkey

area (right side, see Fig. 1-1). Brief explanations on the controls and connectors of the hardkey area and

the rear panel are to be found on the next pages. Operation by means of softkeys is described in Chapter 3 of the operating manual, Manual Operation.

9 softkeys with

alternating function

ON/Standby key (p.4)

LC display with

menu example

UNIVERSAL RADIO COMMUNICATION TESTER CMU 200

9 softkeys with

alternating function

Escape key (p.4)

.

ESCAPE

FUNCTION SYSTEM

MENU

DATA

DATA

89

ghi

def

56

pqr

yz

vwx

E

#

*

.

-

symb

mark

ENTER

CONT/HALT

DEL

AUTO

RESET

CTRL

G/n

mV

M/7

7V

W

k/m

dB7V

F

*

dBm

dB

UNIT...

AUX 1 AUX 2

AF IN AF OUT

SELECT

7

abc

4

jkl mno

123

stu

0

_ 7

ON / OFF

EXP/CMP

CONTROL

CLR

INS

VOL

INFO

Keys and connectors

PRINT

HEL P SETUP

VARIATION

A

B

C

D1

RF4 IN

13 dBm

1100.0008.02

DATA 1

DATA 2

AUX 3

SPEECH

RF 2 RF 1

RF 3 OUT

2W

13 dBm

MAX

MAX

50 W

MAX

MAX

Bar with 8 hotkeys

Fig. 1-1 CMU front view

1100.4961.62 1.1 E-3

Page 16

Front and Rear View R&S CMU 200

Data input

Selection of the most important

CMU functions via menus

Loudspeaker, for

future extensions

PCMCIA interface

as an alternative:

Floppy disk drive

(option CMU-U61)

Fig. 1-2 CMU front view – hardkeys

FUNCTION Operating manual

Preselection of the menus:

MENU SELECT Menu selection

DATA File manager

CTRL For GSMxxx-MS Signalling tests:

Measurement Wizard

Chap. 3

Chap. 4

DATA Operating manual

Data input:

0 ... 9 Numerical input (letters for string editors)

* . E Special characters, dec. point, hex value "E"

# - F Spec. characters, sign change, hex value "F"

G/n mV A Factor 109/10-9, unit, hex value "A"

M/

µ µ

V W Factor 106/10-6, unit, hex value "B"

k/m dB µV Factor 103/10-3, unit, hex value "C"

*1 dBm dB Factor 100, unit, hex value "D"

ON / OFF Switching on/off editors/measurements

EXP/COMP

ENTER Confirmation of entry in editors

CONT/HALT Calling/quitting editors,

measurement control

UNIT

For future extensions

Chap. 3

1100.4961.62 1.2 E-3

Page 17

R&S CMU 200 Front and Rear View

System control Variation of numeric values and

group selection in popup menus

Fig. 1-3 CMU front view – hardkeys

SYSTEM Operating manual

System control:

HELP Displays online help

SETUP Instrument settings

PRINT Initialize printing of a screenshot

Chap. 3

VARIATION Operating manual

Value variation and group selection:

Rotary knob Value variation in input fields and

parameters, line selection in tables, field

selection in popup menus. Press to

expand/compress tables and pull-down

lists and to confirm entries and

selections.

Cursor key Group selection in popup menus

vertical (vertical)

Cursor key Group selection in popup menus

horizontal (horizontal),

Cursor positioning in editors and

tables

Chap. 3

1100.4961.62 1.3 E-3

Page 18

Front and Rear View R&S CMU 200

Extended editor

and instrument

control functions

Fig. 1-4 CMU front view – hardkeys

CONTROL Operating manual

Extended control functions:

CLR Clears the complete editor string

(back space)

INS Changes between insertion and overwriting

in the editor

DEL Deletes the character marked by the

cursor

VOL For future extensions

AUTO For future extensions

INFO System info and hardware diagnosis

RESET Resets to default values

Deletes the character to the left of the cursor

Chap. 3

Further Keys Operating manual

ESCAPE

ESCAPE Quits popup menus, closes an editor

discarding the entries made

ON/STANDBY Switches between operation (green LED)

and standby (orange LED)

Chap. 3

1100.4961.62 1.4 E-3

Page 19

R&S CMU 200 Front and Rear View

For future extensions

Auxiliary input/output

AUX3

Signals from/to

speech codec

(option CMU-B52)

AF inputs and outputs

Fig. 1-5 CMU front view connectors

DATA1, DATA2 Operating manual

For future extensions

Chapter 8, "Hard-

ware connectors"

AUX 3 and SPEECH Operating manual

AUX 3

SPEECH

Input and output for status, control, and trigger signals:

CMU 300: External trigger signal for

wired synchronization

Signals from/to speech codec (option CMU-B52)

Chapter 8, "Hard-

ware connectors "

Chapter 8, "Hard-

ware connectors"

AF connectors Operating manual

Connectors for audio signals:

AUX1/2 Additional input/output for audio signals

that may be used in remote control (secondary audio analyzer)

AF IN/OUT Standard input/output for the (primary)

audio analyzer

Caution: Note the maximum permissible input levels for all

AF connectors according to the data sheet in order to prevent damage to the instrument!

Chapter 4, "Audio

Generator and

Analyzer";

Chapter 8, "Hard-

ware connectors"

1100.4961.62 1.5 E-3

Page 20

Front and Rear View R&S CMU 200

Bidirectional RF connectors

RF 1 und RF 2

Sensitive RF input, high-level RF output

Fig. 1-6 CMU front view– connectors

RF connectors Operating manual

Bidirectional RF connectors for various power ranges according to the data sheet.

The two LEDs above the connectors are illuminated as long

as the CMU sends signals

Connector with high output level and connector for sensitive

RF measurements (antennas). Power ranges according to the

data sheet. Maximum permissible input and output level according to the label on the front panel.

The two LEDs above the connectors are illuminated as long

as the CMU sends signals

Caution:

Note the maximum permissible input levels for all RF connectors according to the label on the front panel or the data sheet

in order to prevent damage to the instrument!

RF connectors may warm up very much when high RF power

is fed in!

or is ready for reception .

or is ready for reception .

Chapter 8,

"Hardware

connectors "

Chapter 8,

"Hardware

connectors"

1100.4961.62 1.6 E-3

Page 21

R&S CMU 200 Rear View

Rear View

Synchronization inputs and outputs, IF interface (with option CMU-B17)

Interfaces for remote control

Signal inputs and outputs

and peripheral equipment

Fig. 1-7 CMU rear view

Mains switch Operating manual

Mains connector with switch

Mains power switch

Mains connector

Chapter 1, "Switching on the Instrument,

Startup test"

Chapter 1, "Connecting the instrument to the

AC supply”

Interfaces Operating manual

GPIB-bus connector

(IEEE 488 / IEC 625),

Parallel interface: 25-contact

printer connector, Centronicscompatible

Connector for serial interface 1: 9contact Sub-D connector

Connector for serial interface 2: 9contact Sub-D connector

Connector for an external VGA

monitor: 15-contact Sub-D

connector

USB connector for external

keyboard only (not for other

pointing or storage devices)

Chapter 1, "Connecting an External Keyboard"

Chapter 8, "Hardware Interfaces "

Chapt. 1, "Connecting an Output Device"

Chapter 8, "Hardware Interfaces”

Chapter 8, "Hardware Interfaces”

Chapter 8, "Hardware Interfaces”

Chapter 1, "Connecting a Monitor"

Chapter 8, "Hardware Interfaces”

Chapter. 8, "Hardware Interfaces”

1100.4961.62 1.7 E-3

Page 22

Rear View R&S CMU 200

Inputs and outputs for reference frequency and network-specific clock frequency

Intermediate

frequency

from CMU receiver,

IF interface

Auxiliary and

service connectors,

I/Q interface

Fig. 1-8 CMU rear view – signal inputs and outputs

Intermediate frequency Operating manual

IF3 RX CH1 (BNC connector) from CMU receiver

Chapter 8,

"Hardware

Connectors"

Reference frequency Operating manual

REF IN Input for external reference frequency

REF OUT 1 Output of reference frequency of CMU:

10 MHz or the signal of input REF IN

REF OUT 2 Output for network-specific clock

frequency

Caution!

Do not use open or unshielded cables in order to comply with EMC directives!

Chapter 8,

"Hardware

Connectors

Chapter 3, "RF

Connection

Control"

AUX, SERVICE, AUX4, extensions Operating manual

Two 9-contact and one 15-contact SUB-D connectors:

AUX Auxiliary connector providing a DC

voltage to supply external equipment

such as CMU-Z6

SERVICE Service connector for RXTX board

(only for internal test purposes)

AUX4 Bidirectional input/output for digital

status, control, and trigger signal

Chapter 8,

"Hardware

Connectors

The remaining 15-contact SUB-D connectors are

reserved for future extensions.

1100.4961.62 1.8 E-3

Chapter 8,

"Hardware

Connectors

Page 23

R&S CMU 200 Rear View

IF interface

Option CMU-B82

Access Board for

CDMA Sign. Units

I/Q interface

Fig. 1-9 CMU rear view – I/Q-IF inputs and outputs

Option CMU-B87

Message Monitor for

CDMA2000

I/Q-IF Interface (with option CMU-B17) Operating manual

Four 50 BNC connectors for option CMU-B17, I/Q and

IF Interface:

IF3 RX CH1 IN RX path, IF IN

IF3 RX CH1 OUT RX path, IF OUT

IF3 TX CH1 IN TX path, IF IN

IF3 TX CH1 OUT

15-contact SUB-D connector for input and output of I/Q

signals (option CMU-B17, I/Q and IF Interface)

The SUB-D connector below IQ CH 1 is not used.

TX path, IF OUT

Chapter 4,

"Hardware

Connectors"

Chapter 8,

"Hardware

Connectors"

Chapter 8,

"Hardware

Connectors"

Optional interfaces for data applications

Digital I/Q connector for option R&S

CMU-B82, Access Board for CDMA

Signalling Units

Ethernet connector e.g. for option R&S CMU-B87,

Message Monitor for CDMA2000

An additional Ethernet connector can be fitted below,

e.g. for option R&S CMU-Z46, WCDMA Message

Analyzer and Recorder.

1100.4961.62 1.9 E-3

Installation

instructions for

options

Installation

instructions for

options

Page 24

Putting the Instrument into Operation R&S CMU 200

Putting the Instrument into Operation

This section describes the basic steps to be taken when setting up the CMU for the first time.

Caution!

Please make sure to observe the instructions of the following sections so that you

cannot cause damage to the instrument or endanger people. This is of particular

importance when you use the instrument for the first time.

Unpacking the Instrument

When receiving your instrument, first perform the following steps.

1. Remove the instrument from its packaging and check the equipment for completeness using the

delivery note and the accessory lists for the various items.

2. First, pull off the polyethylene protection pads from the instrument's rear feet and then carefully

remove the pads from the instrument handles at the front.

3. Pull off the corrugated cardboard cover that protects the rear of the instrument.

4. Carefully unthread the corrugated cardboard cover at the front that protects the instrument

handles and remove it.

5. Check the instrument for any damage. If there is damage, immediately contact the carrier who

delivered the instrument. In this case, make sure not to discard the box and packing material.

It is advisable to keep the original packing material in order to prevent control elements and connectors

from being damaged in case the instrument is to be transported or shipped at a later date.

Setting up the Instrument

The R&S CMU is designed for use under laboratory conditions, either on a bench top or in a rack. The

general ambient conditions required at the operating site are as follows:

• The ambient temperature must be in the ranges specified for operation and for compliance with

specifications (see data sheet).

• All fan openings including the rear panel perforations must be unobstructed. The distance to the wall

should be at least 10 cm.

Notes: For safe and convenient operation of the instrument note the following:

Avoid moisture condensation. If it occurs, the instrument must be wiped dry before

switching on.

Note the warm-up time of the temperature-controlled OCXO reference oscillator (Option

CMU-B11/B12), see data sheet.

Bench Top Operation

Permissible operating positions of the CMU:

• Horizontal position, standing on the feet.

1100.4961.62 1.10 E-3

Page 25

R&S CMU 200 Putting the Instrument into Operation

• For applications in the laboratory or on a work bench, it is recommended that the support feet on the

bottom of the instrument be extended. For the LCD display, this provides the optimum viewing angle

which typically ranges from perpendicular to the display front to approximately 30° below.

Warning! Danger of injury

The feet may fold in if they are not folded out completely or if the instrument is shifted.

The feet may break if they are overloaded. Fold the feet completely in or completely out

to ensure stability of the instrument and personal safety. To avoid injuries, never shift the

instrument when its feet are folded out.

The overall load (the instrument's own weight plus that of the instruments stacked on top

of it) on the folded-out feet must not exceed 500 N.

Place the instrument on a stable surface. Secure the instruments stacked on top of it

against slipping (e.g. by locking their feet on the top front frame).

When the instrument is standing on its folded-out feet, do not work under the instrument

and do not put anything under it, otherwise injuries or material damage could occur.

The instrument can be used in each of the positions shown here.

Mounting in a Rack

Using the adapter ZZA-411 (order number 1096.3283.00) the instrument can be mounted in 19" racks

according to the mounting instructions supplied with the rack adapter.

Note: For convenient operation of the instrument note the following:

Allow for sufficient air supply in the rack.

Make sure that there is sufficient space between the ventilation holes and the rack

casing.

1100.4961.62 1.11 E-3

Page 26

Putting the Instrument into Operation R&S CMU 200

Connecting the Instrument to the AC Supply

Caution!

After moisture condensation, allow the instrument to dry before switching on.

Note the permissible ambient temperature according to the data sheet.

Do not cover the lateral and rear ventilation holes.

The CMU may be connected to one-phase AC supplies with nominal voltages ranging from 100 V to

240 V and nominal frequencies ranging from 50 Hz to 400 Hz (see inscription on the rear panel and data

sheet). Depending on the options installed, the power consumption ranges from 120 W to 230 W.

Note: The CMU is automatically adapted to the AC supply voltage applied. External

switchover or adaptation of the fuses are not necessary.

For the mains connection use the supplied mains connector.

o

I

Mains

connector

As the instrument is designed according to the regulations for safety class

EN61010, it must be connected to a grounded power outlet.

Switching on the Instrument / Startup Test

The CMU can be switched on using the mains switch at the rear of the

instrument and the ON/STANDBY key at the bottom left of the instrument

front.

o

I

STANDBY

ON

ON/

STANDBY

key

Start procedure

Mains

switch

The mains switch can be set to two positions:

0 The 0 position implies an all-pole disconnection of the instrument

from the mains.

I In the I position, the instrument is in standby mode or in operation,

depending on the position of the ON/STANDBY key at the front of

the instrument.

The ON/STANDBY key activates two different operating modes indicated

by colored LEDs:

Standby Only the OCXO reference frequency oscillator (Option CMU-

B11/B12), if installed, is supplied with operating voltage. The

orange LED (STANDBY) on the right is illuminated.

Operation In this operating mode, all modules of the instrument are

supplied with operating voltage. The green LED (ON) on the

left is illuminated.

To switch on the CMU set the mains switch to the position I.

The CMU enters standby mode.

• Set the CMU to operating mode by pressing the ON/STANDBY key

once.

Caution! When switching on the CMU, no disk should be inserted in the

drive; otherwise, one of the actions stored on the flash disk will

be performed.

1100.4961.62 1.12 E-3

Page 27

R&S CMU 200 Putting the Instrument into Operation

Startup menu

Displays in startup

menu

After activation of the operating mode, the startup menu appears for a few

seconds. While it is displayed the CMU performs a startup test.

The display windows of the startup menu provide information on

• The startup procedure (Process)

• Instrument model, serial number and version of the CMU base software

(Info).

• Installed hardware and software options and equipment (Options).

Available software options are listed with their version numbers.

• Progress of the startup procedure (Startup bar graph).

After terminating the startup procedure, the instrument changes to the last

main menu or graphical measurement menu of the previous session.

Switching off the Instrument

In order not to lose any settings that have been made, proceed in the

following order to switch off the CMU:

Remove any storage medium from the PCMCIA interface or floppy disk

drive.

Shortly press ON/STANDBY to initiate the shutdown process and save

the current data to the internal hard disk.

Wait until the shutdown process has been terminated before setting the

o

I

mains switch at the rear to the 0 position.

Note: Instruments equipped with a Front Module controller FMR 6

display the message Shutdown in Progress after the

ON/STANDBY key has been pressed. Keeping ON/STANDBY

pressed for about 4 s on those instruments initiates a

hardware shutdown where data may be lost.

1100.4961.62 1.13 E-3

Page 28

Putting the Instrument into Operation R&S CMU 200

How to Ensure EMC

In order to avoid electromagnetic interference, the instrument may only be operated when it is closed

and with all shielding covers fitted.

REF OUT 1 and REF OUT 2: Use doubleshielded cables and match signal with 50 in order to

comply with EMC directives!

Input Level

Caution!

In order to prevent damage to the instrument note the maximum permissible input

levels at the AF inputs AF IN and AUX 1 as well as for the RF inputs RF 1, RF 2 and

RF 4 IN at the front of the instrument.

1100.4961.62 1.14 E-3

Page 29

R&S CMU 200 Connecting the CMU to the Test Setup

Connecting the CMU to the Test Setup

Warning:

Connect external devices and peripherals only when the instrument is

switched off or in STANDBY mode. Otherwise, future errors cannot be

excluded.

Connecting a Controller

The CMU can be connected to an external controller via the GPIB bus (IEEE bus according to standard

IEEE 488; throughout this documentation we will primarily use the term GPIB bus which is also used in

the operating menus and in the SCPI command syntax) or via serial interface:

Connection via GPIB

bus

IEEE 488

625

GPIB Bus

Configuration

The CMU is connected to the GPIB interface of the controller via the GPIB

bus connector (IEEE 488 / IEC 625) at the rear of the instrument and a

shielded cable. The technical specifications of the GPIB interface are listed in

section Hardware Interfaces in Chapter 8 of the operating manual.

In the default configuration the CMU accepts commands from either the GPIB

or COM 1 interface. The parameters for GPIB bus control of the CMU are set

in the Remote tab of the Setup popup menu (in the following abbreviated by

Setup – Remote, see also Chapter 4 of the operating manual, Settings for

Remote Control).

To open the Setup - Remote menu, press the SETUP key at the front of

the instrument and activate the Remote hotkey at the lower edge of the

screen.

Use the rotary knob to move the focus onto the SCPI Connection section

of the Setup table. If necessary, press the rotary knob or the ON/OFF key

to expand the parameters in the table (see Chapter 3 of the operating

manual).

1100.4961.62 1.15 E-3

Page 30

Connecting the CMU to the Test Setup R&S CMU 200

In the Port table row select either GPIB + Com 1 or GPIB bus interface

for transmission.

The bus address is factory-set to 20. It can be changed in the Primary

Address input field.

Connection via serial

interface

COM 1

The CMU can be connected to the serial interface of a controller via one of

the serial interfaces COM 1 or COM 2 and a so-called null-modem cable. The

pin assignment and wiring of a null-modem cable are described in section

Handshake of Chapter 8 of the operating manual. The technical

specifications of the serial (RS-232-C) interface are also discussed in

Chapter 8 (refer to section Hardware Interfaces).

Either a 25-pin or a 9-pin connector can be used on the controller side. It may

be necessary to use an appropriate adapter (see Chapter 8, Hardware

Interfaces).

Selection

Configuration

In the default configuration the CMU accepts commands from either the GPIB

or COM 1 interface. The COM 2 interface must be selected explicitly.

Proceed as described above to activate the Remote tab of the Setup

menu.

In the Port table row, select GPIB + Com 1 or COM 1 or COM 2 to

activate one of the RS-232 interfaces for data transfer.

After selection of a serial interface, the transmission parameters must be set

to comply with the parameters of the addressed device. This is done in the

Comm. (communications) tab of the Setup menu:

To open the Setup – Comm. tab press the SETUP key at the front of the

instrument and activate the Comm. hotkey at the lower edge of the

screen.

In the table section corresponding to the selected COM port check the

settings for the Baudrate, Data Bits, Parity, and Protocol.

1100.4961.62 1.16 E-3

Page 31

R&S CMU 200 Connecting the CMU to the Test Setup

Connecting an External Keyboard

USB

An external PC keyboard to the CMU can be connected to the USB

connector at the rear of the instrument. An external keyboard facilitates the

input of numbers and texts.

For the interface description see section Hardware Interfaces in Chapter 8 of

the operating manual.

The key assignment can be changed in the Misc. tab of the Setup menu:

Language assignment To open the Setup – Misc. tab press the SETUP key at the front of the

instrument and activate the Misc. hotkey at the lower edge of the screen.

Use the rotary knob to select Keyboard and set the desired language (US

or German).

Connecting a Monitor

MONITOR

An external VGA monitor can be connected to the 15-contact Sub-D

connector at the rear of the instrument.

For the interface description see section Hardware Interfaces in Chapter 8 of

the operating manual.

1100.4961.62 1.17 E-3

Page 32

Connecting the CMU to the Test Setup R&S CMU 200

Connecting a Printer

LPT

A printer can be connected via the 25-contact parallel interface LPT at the

rear of the instrument (recommended) or one of the serial interfaces COM 1

or COM 2. For the interface description see section Hardware Interfaces in

Chapter 8 of the operating manual.

The printer type and port must be set in the Print tab of the Setup menu:

To open the Setup – Print tab press the SETUP key at the front of the

instrument and activate the Print hotkey at the lower edge of the screen.

In the Printer section set the printer type and port (COM 1 or COM 2 for

the serial (RS-232) ports; LPT 1 for the parallel printer port).

It is recommended to connect the output device to the parallel interface LPT,

if possible: With this selection, configuration of the interface is not necessary;

besides, the serial connectors may be used for GPIB bus etc.

Synchronization with External Devices; Connection of Further

Components

REF IN REF OUT 1 REF OUT 2

The three BNC female connectors REF IN, REF OUT 1, REF OUT 2 are

provided for synchronization of the CMU with external devices.

1100.4961.62 1.18 E-3

Page 33

R&S CMU 200 Software Update and Version Management

Software Update and Version Management

Your CMU was delivered with the latest software and firmware version available. New firmware can be

easily installed via the floppy disk drive (option CMU-U61) or the PCMCIA interface on the front of the

instrument.

Note: When copying an installation version to a PCMCIA card or floppy, ensure that all folders

containing a base system version or network option (the lowest-level folders in Fig. 1-9

below) are in the root directory. Otherwise the R&S CMU will not be able to detect the

firmware and start the installation. If a Versions.new text file (see section File Versions.new

on p. 1.27 ff.) is used, it must also be in the root directory of the external storage medium.

New software options must be enabled by means of a key code entered in the Setup –

Options menu (see Chapter 4 of the operating manual). This is necessary only once; all

options remain enabled after a software update.

Installation of new firmware versions and the use of different applications and versions on the same

instrument is made easier by the following tools:

• The R&S Remote Service Tool (see p. 1.19 ff.) transfers software versions to the instrument.

• The VersionManager (see p. 1.29 ff.) is designed to manage different software versions stored on

the instrument.

Installation instructions are also given in Chapter 1 of the operating manuals for the individual software

options.

R&S Remote Service Tool

The R&S Remote Service Tool organizes the exchange of data between the R&S CMU and an external

PC or laptop, in particular to:

• Copy software versions and install them on the R&S CMU.

• Copy or move data files (e.g. screenshots created with the Print menu of model R&S CMU).

• Send remote control commands to the instrument.

The tool is available for download on the CMU Customer Web (https://gloris.rohde-

schwarz.com/gloris/1cmp/cmucustomer/index.html). It consists of a single *.exe file which can be copied

to any directory. When the executable file is started (double-clicked), the R&S Remote Service Tool

opens the following main application window.

1100.4961.62 1.19 E-3

Page 34

Software Update and Version Management R&S CMU 200

Fig. 1-9 Remote Service Tool main screen (example)

Connecting the

R&S CMU

The R&S Remote Service Tool can communicate with the R&S CMU via the

GPIB (IEEE 488) or a RS-232 interface. To ensure fast transmission, it is

recommended to use the GPIB interface, connecting the GPIB cable to the

IEEE 488 / IEC 625 connector on the rear panel of the instrument.

Installing software

versions

Note: The GPIB settings of the Remote Service Tool and of the R&S

CMU must be the same. Refer to section Connecting a Controller

on p. 1.15 to learn how to configure the R&S CMU’s GPIB

settings.

1. Connect the GPIB cable to the IEEE 488 / IEC 625 connector on the rear

panel of the instrument.

2. Start the Remote Service Tool.

3. Click the Options menu and make sure that Use GPIB is selected.

4. Click Options – GPIB Options and check that the Board Index and Primary

Address settings are equal to the R&S CMU configuration (CMU default

settings: board index GPIB0, primary address 20).

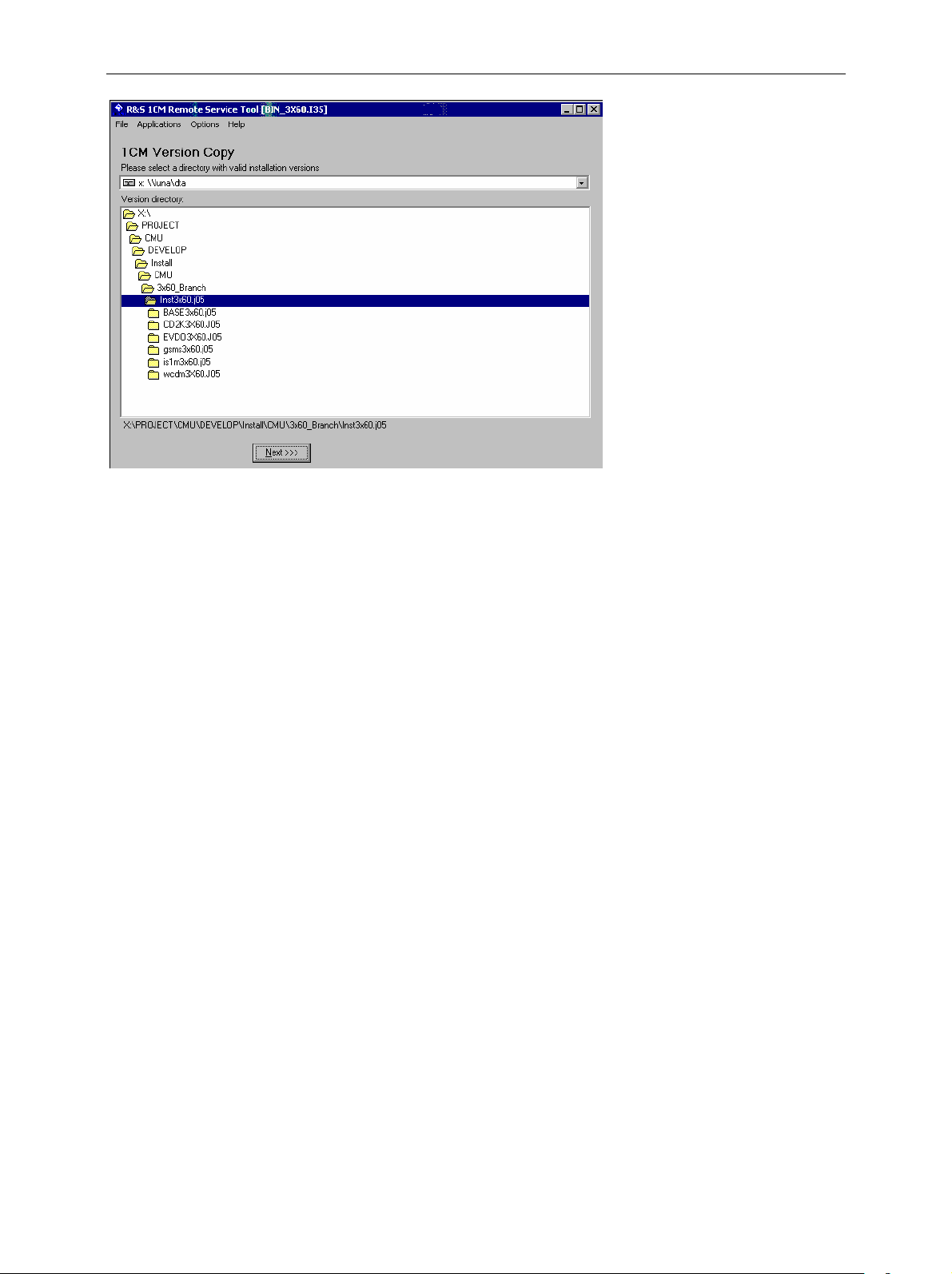

To copy a new software version to the CMU…

1. Switch on and start up your R&S CMU.

2. Select Applications – Version Copy from the menu bar of the Remote

Service Tool.

3. In the Version directory of the main application window, select the folder

from where you want to copy your software version and click Next >>>.

1100.4961.62 1.20 E-3

Page 35

R&S CMU 200 Software Update and Version Management

4. Select the software version you wish to install and click Start >>>.

The software version is copied to the internal drive C:\INTERNAL\INSTALL of

your R&S CMU. In addition, a text file named Versions.new (see section File

Versions.new on p. 1.27 ff.) is generated and copied to the same directory.

With default installation options (see figure above), the following happens after

the file transfer is completed:

• The CMU is rebooted and the new software version is installed and

activated (a key code must be entered once when a new software package

is installed; see section Hardware and Software Options in chapter 4 of the

operating manual).

• The Remote Service Tool is closed automatically.

Old software versions are not affected. You can delete or activate an old

software version using the VersionManager (see p. 1.29 ff.).

Note: You can also copy a software version to the internal hard disk and

use the VersionManager for the installation.

1100.4961.62 1.21 E-3

Page 36

Software Update and Version Management R&S CMU 200

Listing and

modifying software

versions

The Remote Service Tool can not only install firmware versions but also display

and modify the installed firmware configurations.

To list the firmware configurations installed on your CMU…

Click Application – List Software.

The list of installed versions has a tree structure. Each expandable node

contains a software configuration consisting of one base system version and

one or more network options. The active configuration is marked as (active)

and also displayed in the title bar of the Remote Service Tool. You can use the

controls on the left side to do the following:

• Select a configuration in the list and click Activate to label the configuration

active.

• Select a configuration in the list which is not the active configuration and

click Delete to label the configuration deleted. Repeat this for all

configurations you wish to delete.

Labeled configurations are not deleted immediately. You can simply Restore

any configuration that you labeled inadvertently.

Click Perform Actions to activate and/or delete the labeled configurations.

The labeled configurations are written to the Versions.new text file (see section

File Versions.new on p. 1.27 ff.) which is copied to the internal drive

C:\INTERNAL\INSTALL of your R&S CMU. In the default configuration where

Force device reboot is enabled, the R&S CMU is rebooted immediately so that

the VersionManager can activate and delete the labeled configurations.

Tip: Disable Force device reboot in case you wish to postpone the

actions until next time you switch on your instrument.

Copying files To transfer a file from the CMU to the PC or vice versa…

1. Switch on and start up your R&S CMU.

2. Select Applications – File Transfer from the menu bar of the Remote

Service Tool.

The main application window shows the directories and files on your PC and on

the INTERNAL directory of the CMU’s hard disk.

1100.4961.62 1.22 E-3

Page 37

R&S CMU 200 Software Update and Version Management

3. Select a directory, a file or several files and use the commands in the

FileCtrl menu to initiate the file transfer. You can also right-click the file list

to open the equivalent context menu.

Extracting

screenshots

A screenshot transferred by means of the Remote Service Tool can be viewed

and copied to the clipboard so that you can use it in another application.

To generate, transfer and further process a screenshot…

1. Press the PRINT button on the front panel of the CMU to open the Print

dialog, select Internal WMF as a destination and specify a file name

<file>.wmf for the generated image file (without adding a path).

2. Press OK to write the file to the INTERNAL\USERDATA\PRINT directory of

the CMU.

3. Proceed as described above to transfer the file <file>.wmf from the CMU to

your PC.

4. Double-click the transferred file (alternative: select the file and press

Enter).

The Remote Service Tool acts as a viewer for the file:

5. Right-click to open a context menu and either copy or close the file.

1100.4961.62 1.23 E-3

Page 38

Software Update and Version Management R&S CMU 200

Remote control of

the R&S CMU

You can use the Remote Service Tool to transfer remote control commands or

command scripts to be executed on the R&S CMU.

To transfer a single command or command sequence…

1. Click Applications – Command to activate the remote control screen.

2. Select the appropriate function group in the Secondary address mapping

panel.

3. Enter a command in the Enter remote command… input field and press

Enter.

4. Repeat steps 2 and 3 for all commands you wish to execute.

To execute a command script…

5. Generate an ASCII text file of remote control commands, either manually

or by saving a previously transferred command sequence (Save… button

in the remote control screen.

6. In the remote control screen, click Load… and open the file.

The script is transferred and executed automatically. The remote control

screen provides further control elements to make the command transfer more

convenient; see section Remote Control of the R&S CMU on p. 1.26 ff.

1100.4961.62 1.24 E-3

Page 39

R&S CMU 200 Software Update and Version Management

Table 1 Overview of R&S

Menu Command Function

File

Application

Options

Help

Close Close the Remote Service Tool.

Version Copy Copy a software version to the R&S CMU. See the application

List Software Display of all software configurations installed on the R&S CMU

Command Transfer of remote control commands or command scripts to be

File Transfer Transfer of data between a PC and the R&S CMU. This

Error Reports For future extensions

Use GPIB Use the GPIB bus for communication with the R&S CMU.

USE RS232 Use the RS232 bus for communication with the R&S CMU.

GPIB Options Change GPIB connection parameters. The default settings for the

RS232 Options Change RS232 transmission parameters. The following settings

Device Clear Clear the screen.

Go to Local Exit remote control mode and return to manual operation.

Device Reboot Reboot the R&S CMU.

About Shows an information box with the current version of the Remote

Remote Service Tool functions

example Installing software versions above.

and activate and/or delete configurations. See the application

example Listing and modifying software versions above.

executed on the R&S CMU. This command activates an additional Cmd Ctrl menu to generate log files and customize the screen. See application example Transferring remote control commands above and section Remote Control of the R&S CMU on p. 1.26 ff.

command activates an additional FileCtrl menu to create

directories, copy or delete files. See application examples

Copying files and Extracting screenshots above.

Note: This communication mode is recommended.

Note: Use the RS 232 Options quoted below if you choose this

communication mode.

R&S CMU are:

Board Index: 0

Primary Address: 20

Note: The GPIB settings of the Remote Service Tool and of the

R&S CMU must be the same. Refer to section Connecting a

Controller on p. 1.15 to learn how to configure the R&S CMU’s

GPIB settings.

ensure a reliable connection:

Baud Rate: 115200

Data Bits: 8

Stop Bits: 1

Parity: None

Protocol: CtsRts (do not change! )

Note: The RS232 settings of the Remote Service Tool and of the

R&S CMU must be the same. Refer to section Connecting a

Controller on p. 1.15 to learn how to configure the R&S CMU’s

RS232 settings. Should you experience any problems with the

data transfer, first check and possibly exchange the connecting

cable.

Service Tool.

1100.4961.62 1.25 E-3

Page 40

Software Update and Version Management R&S CMU 200

Remote Control of the R&S CMU

The remote control screen transfers remote control commands or command scripts to be executed on

the R&S CMU; see application example Remote control of the R&S CMU on p. 1.24. It is opened by

clicking Application – Command.

Fig. 1-10 Remote control screen

The commands to be executed are entered in the Enter remote command… input field; the responses of

the R&S CMU and possible error messages are displayed below. Besides the remote control screen

provides the following control elements:

Execute all

commands

Report Display /

Report File

Load / Save

Clear

Refresh sec.

address mapping

While the remote control screen is active, an additional Cmd Ctrl menu is available:

Execute all commands entered since the Remote Service Tool was started or

since the list was cleared. The complete command list appears in a pull-down

list associated with the Enter remote command… input field.

Display the remote report on the R&S CMU’s remote screen and create a

report file. These functions are identical with the Report Display and Report

File hotkeys in the CMU’s remote screen.

Load an ASCII text file (default extension: *.lst, can be changed at will), with a

command script to be executed or save the current command list to a text file

file.

Clear the current command list.

Refresh the list of assigned secondary addresses and function groups, e.g.

after the mapping was changed on the R&S CMU. Commands are sent to the

secondary address selected in the list.

1100.4961.62 1.26 E-3

Page 41

R&S CMU 200 Software Update and Version Management

Table 2 Overview of Cmd Ctrl menu in the Remote Service Tool

Command Function

Filename…

Logging Toggle function: Enable or disable logging.

Append File Toggle function: If enabled, new information is appended at the end of the log file. Otherwise the log

Button Setup Open a dialog to create command buttons, to be used as shortcuts for manual entry of frequently

Call up an Open File dialog to define the name and location of a log file containing all executed

commands and device responses. The responses can be up to 2 MByte in size, so the log file

information is often more complete than the remote report displayed on the instrument’s remote

screen.

file is overwritten at the beginning of each Remote Service Tool session.

used commands. The command buttons idn, opc, and Reset in Fig. 1-10 on p. 1.26 are created as

follows:

File Versions.new

The Versions.new file stores the software configurations that the R&S CMU VersionManager has to

install, delete, or activate. The following Versions.new file initiates the installation of a software

configuration containing a base system, a GSM network option package, and a IS136 package:

BASE3x60.i35

GSMS3x60.i35

IS1M3x60.i35

Automatic Install

Creating a

Versions.new file

Restrictions

The file is most conveniently created using the Remote Service Tool; see

application examples Installing software versions on p. 1.20 and Listing and

modifying software versions on p. 1.22. The Remote Service Tool also copies

the file to its location on the CMU’s internal hard disk (C:\INTERNAL\INSTALL)

so that it will be executed when the VersionManager is started.

Alternatively, the file can be created manually and copied to the

C:\INTERNAL\INSTALL directory or to the root directory of a PCMCIA

card/floppy disk.

The information in the Versions.new file must be unambiguous: Only one

software configuration with 1 base system software can be installed at once.

Alternatively, the file may list several network options to be combined with an

already installed, compatible base system version.

1100.4961.62 1.27 E-3

Page 42

Software Update and Version Management R&S CMU 200

Only one software configuration can be active, however, several configurations

can be deleted together. To avoid errors, it is recommended to use different

files for installation and deletion/activation.

Typical application Copy a Versions.new file to the root directory of a PCMCIA card containing

several installation versions and insert the card into the R&S CMU’s

PCMCIA slot.

After the instrument is booted, the VersionManager is started automatically and

installs the software packages listed in the file.

1100.4961.62 1.28 E-3

Page 43

R&S CMU 200 Software Update and Version Management

CMU VersionManager

The VersionManager is a tool designed to activate, delete, install, combine, or list different software

versions in a convenient way. Moreover, it provides information on the hardware and software

configuration of the instrument (Edit service tables, Scan disk), resets the startup settings stored in the

non volatile ram, copies information to an external storage medium (Write log files to disk, List all

versions to disk), and loads and activates user correction tables (see section Chapter 1 of the complete

operating manual).

The VersionManager is part of each CMU firmware version. It is opened automatically after the boot-up

process if the CMU detects a storage medium in its floppy disk drive/PCMCIA slot that contains an

installation version of the CMU firmware. Alternatively, it can be called up by pressing the Menu Select

key after the boot-up sequence is terminated (from the moment when the CMU display turns black until

the end of the 3-beep acoustic signal).

with floppy / PCMCIA

card or

MENU

SELECT

Fig. 1-9 VersionManager main screen (example)

The different functions of the VersionManager are activated by pressing the corresponding softkeys.

Some of them (labeled optional below) are available in a particular configuration of the hard disk only.

The upper two softkeys in both softkey bars are not assigned.

Activate other version

(optional)

Activate other version opens a list of all firmware configurations stored on the

CMU hard disk except the current configuration. Therefore, this function is

not available if the hard disk contains only a single configuration (to retrieve

information, List software can be used instead).

1100.4961.62 1.29 E-3

Page 44

Software Update and Version Management R&S CMU 200

Each entry in the list corresponds to a firmware configuration consisting of

Delete software

(optional)

exactly one CMU base software version (top level on the left side) plus a set

of associated options

activated is displayed in red color on top of the list. To select another version,

the list can be scrolled using the rotary knob or the cursor keys.

Activate Activate the current firmware configuration.

Back to previous screen Close the current screen and go back to the main

Info Open the Info screen associated with the current

Delete software opens a list of all firmware configurations stored on the CMU

hard disk. The dialog can be operated as explained above; see Activate

software. The last firmware configuration can not be deleted, so this function

is not available if the hard disk contains only a single configuration.

1

(network tests, second level). The version to be

screen. This option is identical in all

VersionManager submenus.

screen; see Info on p. 1.37. This option is

identical in all VersionManager submenus.

Delete Delete the current firmware configuration.

1

Several related options may be displayed in a single line. These combinations of options can be installed together and will be simply referred to as "options" through the

remainder of this section.

1100.4961.62 1.30 E-3

Page 45

R&S CMU 200 Software Update and Version Management

If the active firmware configuration is deleted, the CMU asks which of the

remaining versions shall be activated:

Activate Activate the current firmware configuration.

Install software

Install software opens a list of all firmware installation versions available on

an internal or external storage medium that is accessible from the R&S CMU

(floppy disk/PCMCIA card). As explained in Table 1-3, this function depends

on the type and number of storage media and on the number of installation

versions available.

Table 1-3 Software installation with the VersionManager

Storage medium with FW

installation version

Floppy 1

PCMCIA card

in slot 0 or 1 (right or left side)

PCMCIA card

in slot 0 and in slot 1

Internal drive 1

2

PC-card

selection dialog:

Number of FW

installation versions

several

1

several

1 (per PC-card)

several

several

VersionManager function

Install software version <version> from floppy

Install software from floppy

–> Open software version selection dialog (see below).

Install software version <version> from PC-card slot <slot_no>

Install software from PC-card slot <slot_no>

–> Open software version selection dialog (see below).

Install software version <version> from PC-card

–> Open PC-card selection dialog (see below).

Install software from PC-card

–> Open PC-card selection dialog (see below).

Install software version <version> from internal drive

–> Open PC-card selection dialog (see below).

Install software from internal drive

–> Open PC-card selection dialog (see below).

The PC-card selection dialog selects either PCMCIA card slot 0 (right side)

or slot 1 (left side) for installation.

2

Media without FW installation versions are ignored.

1100.4961.62 1.31 E-3

Page 46

Software Update and Version Management R&S CMU 200

Install software... Select the card in slot 0 or slot 1 as an installation

medium. If the medium contains several installation

versions, the software version selection dialog is called up,

see below.

Rescan Drives… Rescans the external and internal drives in order to detect

new software installation versions and update the screen

accordingly.

Software version

selection dialog:

The software version selection dialog lists all installation versions on the

current medium (floppy, PCMCIA card). The dialog can be operated as

explained above; see Activate software.

Install Install the current firmware version.

Upgrade options:

1100.4961.62 1.32 E-3

In contrast to the Activate software dialog, the software selection dialog

handles base software versions and network options separately. As a

consequence, different versions of the base software can be combined with

different options to create new firmware configurations. For example, it is

possible to update the base software without affecting the associated

network options or vice versa. Moreover, the same base software version

can be installed several times and combined with different network options

(and vice versa), so it may enter into several firmware configurations. The

Page 47

R&S CMU 200 Software Update and Version Management

following simple rules apply:

• With a new version of a network option, it is only possible to update one

of the existing configurations. The following selection dialog is

automatically skipped.

• With a new base software version, it is possible to either update an

existing configuration or create a new one. A dialog selecting between the

two alternatives is opened:

Note: This dialog is skipped if the new base software

version is not compatible with any of the existing

configurations. An incompatible new base software

must be installed as a new base software.

Install as new base Create a new configuration based on the base

software to be installed. The upgrade selection dialog

described below is skipped. Network options can be

assigned to this base software in a second stage of

the installation.

Upgrade existing v. Select an existing configuration and replace the base

software of this version. To this end, the upgrade

selection dialog described below is opened.

Force Verm update If the option is checked the current VersionManager is

overwritten every time that a new base system is

installed, even if this means a downgrade of the

VersionManager version. This feature is primarily for

service purposes.

After selection of an upgrade software version compatible with one of the

configurations stored on the hard disk, the upgrade selection dialog is called

up:

1100.4961.62 1.33 E-3

Page 48

Software Update and Version Management R&S CMU 200

Upgrade Replace the base software version or network option selected

in the software version selection dialog.

Alternatively, if none of the configurations stored on the hard disk is

compatible with the software version selected, an error message is

displayed. E.g., for an incompatible Bluetooth version:

Back to... Close the current screen and go back to the software version

selection dialog to select a compatible software version.

Terminating the

software update:

1100.4961.62 1.34 E-3

After successful installation of each software version the CMU displays the

following screen:

Page 49

R&S CMU 200 Software Update and Version Management

Install next software... Go back to the software version selection dialog to

select additional software modules to be installed in

the same VersionManager session. This function

depends on the storage media and the number of

software installation versions available; see Table 1-3

on page 1.31.

Rescan Drives… Rescans the external and internal drives in order to

detect new software installation versions and update

the screen accordingly.

Finish installation Close the VersionManager and reboot the CMU

(remove the external disk from the disk drive). The

installed firmware configurations are then operational.

The last configuration installed is taken as the active

configuration in the subsequent measurement

session.

Lack of disk space:

Note: Notice messages after firmware updates

In most cases firmware updates do not affect the accuracy of the

measurements. There are some exceptions where a correction procedure

must be executed in the Maintenance menu after the firmware update. The

R&S CMU displays a notice message whenever this happens. The box

contains the name of the required correction procedure and appears during

startup until the correction has been performed.

Before installing the next software version, the CMU checks whether there is

enough disk space on the hard disk. If not, the following dialog is displayed:

1100.4961.62 1.35 E-3

Page 50

Software Update and Version Management R&S CMU 200

Delete Delete the current version and return back to the

previous screen.

List software

List software opens a list of all available firmware configurations. It is

possible to activate and delete configurations from the list; see description of

Activate software and Delete software functions above.

Firmware update after

board change(…)

1100.4961.62 1.36 E-3

This function depends on whether a user correction file named

USERCOR1.DAT is stored in the directory INTERNAL\USERCOR\ of the

internal hard disk.

• If no user correction file is available, Firmware update after board change

performs an update of the current firmware including a complete CMU

hardware detection. No external installation disk is required. The update

takes some time and should be attempted in case of problems or after a

modification of the CMU hardware configuration only (also after a

combined hardware/software exchange).

• If a user correction file is found, Firmware update after board change…

opens a submenu to activate or deactivate the RF user correction; see

section Chapter 1 of the complete operating manual.

Page 51

R&S CMU 200 Software Update and Version Management

Edit service tables

Exit

Write log files to disk

Delete non volatile

ram

Edit service tables calls up the Service Table Editor menu showing all

hardware modules that are possibly fitted in your instrument. For service

purposes, further information can be obtained by typing a particular board

name and board index in the two lines below the table.

Exit closes the VersionManager and resumes the CMU start-up procedure.

Write log files to disk copies all *.log files stored on the CMU hard disk to an

external storage medium (floppy or PCMCIA card). The *.log source files on

the hard disk are not deleted.

The Write log files to disk function opens a blue message box indicating the

storage capacity of the external disk needed. The *.log files can be

distributed over several disks. If no disk is available, the VersionManager

displays a warning and does not start copying.

Delete non volatile ram deletes all entries stored in the non volatile ram of the

CMU. This memory contains particular settings of the last CMU session that

can be reused in the next session (e.g. the last active function group and

measurement menu, special configuration etc.).

Deleting the non volatile ram can be useful after an abnormal termination of

a CMU measurement session.

Note: The settings stored in the non volatile ram can also be written to

a configuration file and reused in later sessions; see Chapter 3

of the operating manual, section Saving Configurations.

Scan disk

List all versions to

disk

Copy non volatile ram

to disk

Defragment disk

Info

Scan disk closes the VersionManager, executes the MS Scan Disk program

and finally returns you to the VersionManager. Refer to your Scan Disk

documentation for further information.

Note: This function is not available while a base software version

<V3.00 is active.

List all versions to disk writes the software configurations indicated via List

software to an ASCII text file that is stored on the external disk.

Copy non volatile ram to disk copies the contents of the non volatile ram to

the external disk (floppy, PCMCIA).

In this way, the settings stored in the non volatile ram can be used on

another CMU.

Defragment disk closes the VersionManager, executes the MS Defrag.exe

program and finally returns you to the VersionManager. Defragmenting the

hard disk is suitable to improve performance after installing and deleting

many different software versions. Refer to your Defrag.exe documentation

for further information.

Note: This function is not available while a base software version

<V3.00 is active.

Info opens an output window displaying information on the current screen.

Separate Info windows are provided for the different VersionManager

dialogs.

1100.4961.62 1.37 E-3

Page 52

Software Update and Version Management R&S CMU 200