User Manual P1

Carbon

User Manual

Service and Maintenance

Table of Contents

Safety Information

03

Specication

06

Connection

07

Control System

21

Accessories

Installation

09

10

22

23

Package

User Manual P2

WARNING !

Safety hazard.

Risk of severe

injury or death.

Refer to manual before

installing, powering

or servicing.

Hazardous voltage.

Risk of lethal or

severe electric shock.

Hot surface.

Do not touch.

Fire hazard. Emission hazardous

to eyesight.

This product is for professional use only. It is not for household use.

This product presents risks of severe injury or death due to re hazards, electric shock and falls.

Read this manual before installing, powering or servicing this product, follow the safety precautions

listed below and observe all warnings in this manual and printed on the product.

If you have questions about how to operate the tile safely, please contact your ROE supplier.

PROTECTION FROM ELECTRIC SHOCK

Connect the product to AC mains power within the range 100-240V nominal at 50 or 60 Hz only.

Disconnect the product from power when not in use.

Always ground (earth) the product electrically.

Before using the product, check that all power distribution equipment and cables are in perfect

condition and rated for the current requirements of all connected devices.

Do not use the product if the power cable or a power plug is in any way damaged, defective or

showing signs of overheating.

Do not attempt to open any cover.

Refer any service operation not described in this manual to a qualied technician.

01

Safety Information:

Read the safety precautions in this section before

installing, powering, operating or servicing this product.

The following sysmbols are used to identify important safety information on the product and in this manual:

WARNING! WARNING! WARNING! WARNING! WARNING! WARNING!

User Manual P3

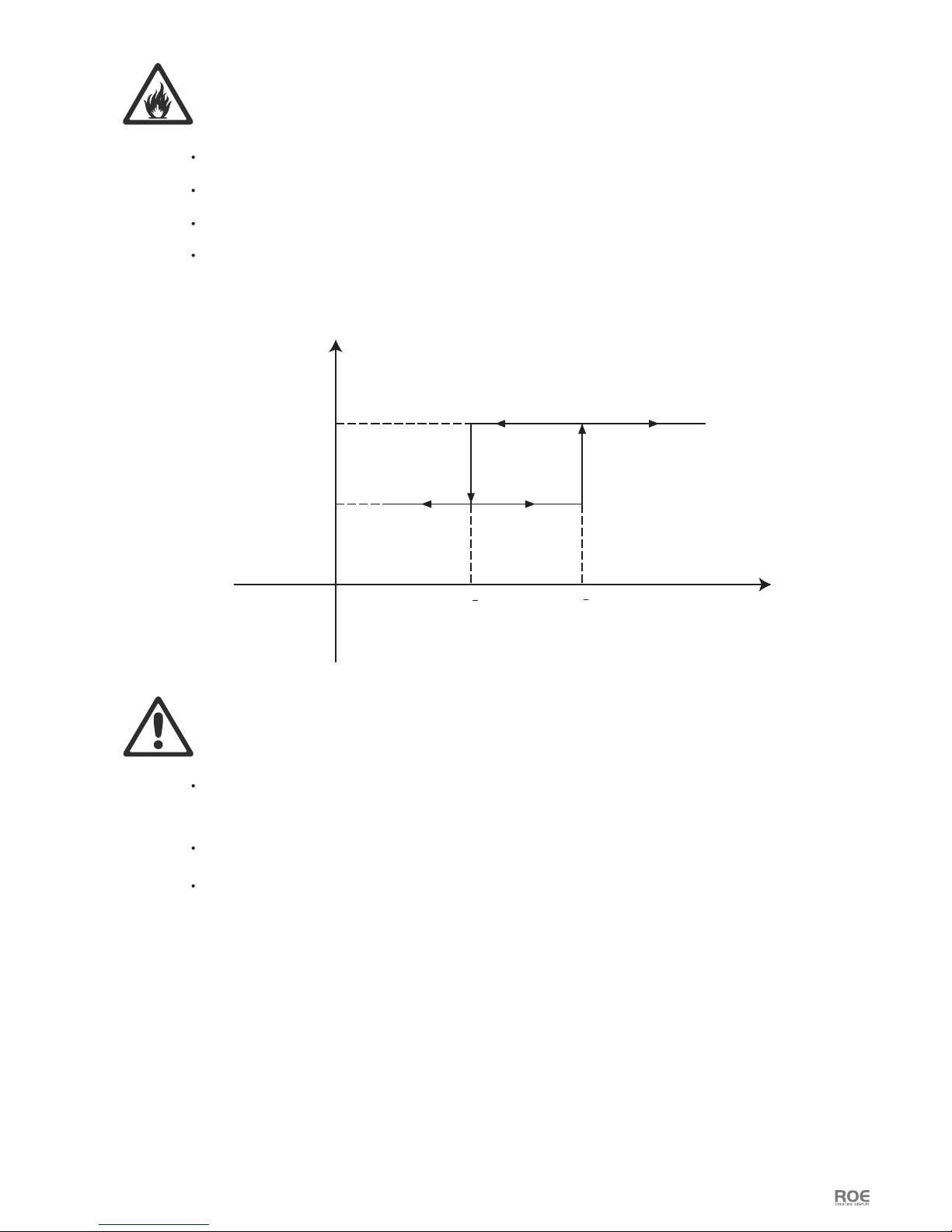

165+5

PROTECTION FROM FIRE

Do not stick lters, masks or other materials directly onto LED modules.

Do not modify the product in any way not described in this manual.

Install only genuine ROE parts in or on the product unless an alternative is described in this manual.

Create an installation by installing tiles at the top and working downwards. Disassemble an installation

by removing tiles at the bottom and working upwards.

Check that all external covers and rigging hardware are securely fastened.

Block access below the work area and work from a stable platform whenever installing, servicing or

moving the product.

Do not operate the product full load if the ambient temperature of power units (Ta) exceeds 45°C

(113° F) or less than -20°C(-4° F).

170+5

1480

2000

Pout/W

Vin/Vac

PROTECTION FROM INJURY

Important warnings

Maximum and minimum ambient temperature:

The maximum ambient temperature for the LED wall is 45 °C; the minimum temperature is (-20°C.)

User Manual P4

High leakage current:

The combination of power boxes in an installation results in increased levels of Leakage current.

In order to avoid risk of electric shock due to high leakage current, proper grounding of the installation

is required.

Data cables:

The data cables provided with this system have special properties for safety. They are not user serviceable.

If the data cables are damaged, replace them only with new ones. Never try to repair a data cable. Per

requirements of the National Electrical Code in the USA, the length of a data cable must not exceed 100 m

(332 feet). Avoid exposure of data cables to accidental contact with lightning or power conductors.

®

Carbon LED tiles cannot be hot swapped:

Always disconnect the power cord from the control box before connecting or disconnecting the cable string

or one of Carbon tiles.

Power system

Mains cords:

The power cords delivered with this system have special properties for safety. They are not user Serviceable.

If the power cords are damaged, replace them only with new ones. Never try to repair a power cord.

This equipment MUST be earthed:

In order to protect against risk of electric shock, the installation should be properly grounded. Defeating

the purpose of the grounding type plug will expose you to the risk of electric shock.

User Manual P5

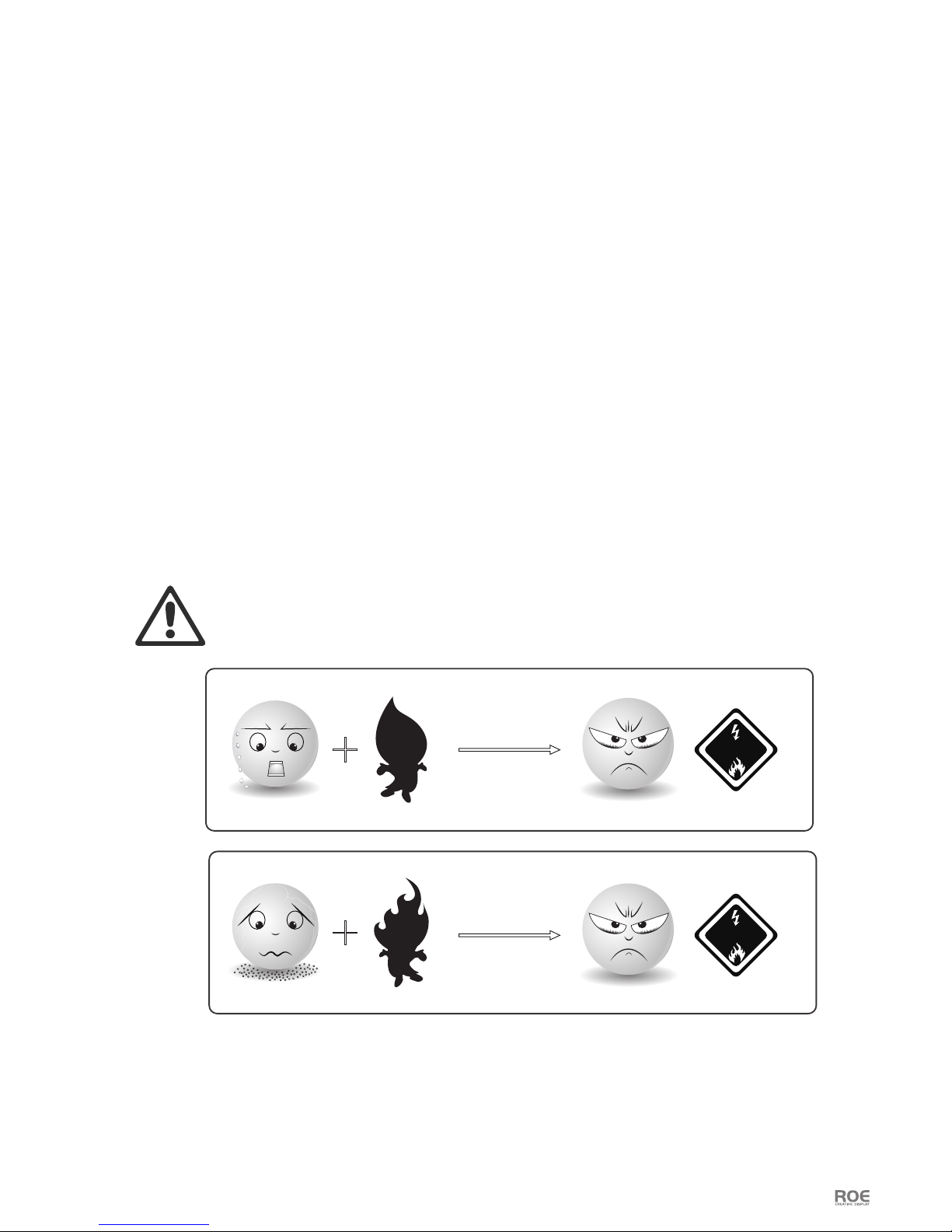

FRAME PROTECTION

Water>150°C

FirePowder

Danger

Danger

Note: At normal temperature environment, Magnesium alloy is abosolutely stable and safe.

It’s dangerous only in:

1. Temperature higher than 150°C with water;

2. Powder with re.

Mg

Mg

Mg

Mg

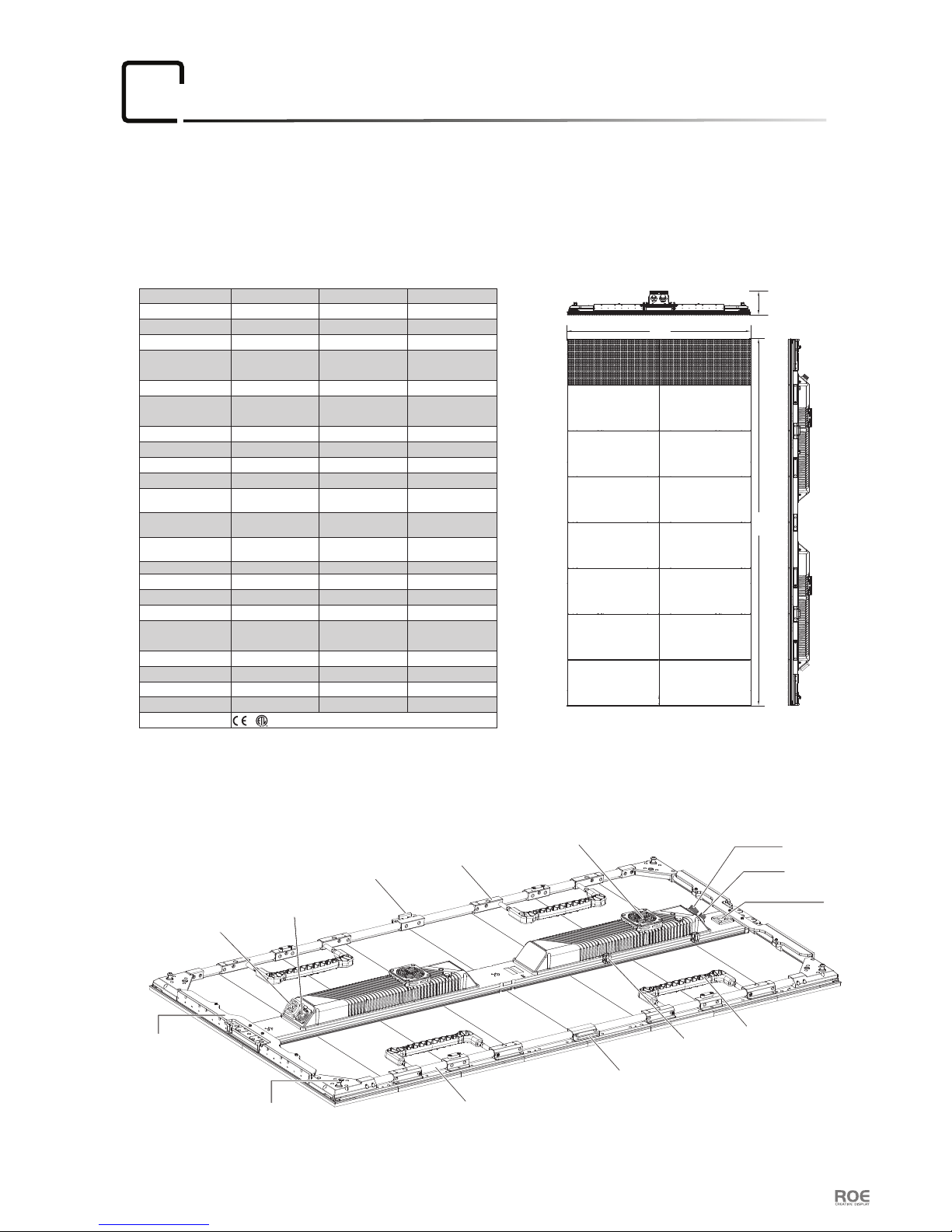

600.0mm

1200.0mm

77.0mm

Carbon-5 Dimensions:

Carbon Specication:

Diagram:

Specification:

02

User Manual P6

Carbon panels are our rst line incorporating lightweight carbon ber technology. More and more uses are being

found for versatile, ultra-lightweight panels from the stage to the corporate event, and Carbon panels strike the

perfect balance of stability and weight. All this whilst preserving the easy setup and maintenance of all ROE

product to save on time and labor costs.

Power Out

Data Out

Carry Handle

Carbon Fibre Tube

Fixed Block

Clip

Side Lock

Fixed Block

Cooling Fan

Dowel Pin

Magnet

Data In

Power In

Testing Button

Pixel Pitch

LED Conguration

Viewing Angle(Hor/Vert)

Max. Brightness

Transparency

Pixel Density

Pixel / Tile

Refresh Rate

Gray Scale

Scan

Frame Material

Tile Weight/Tile

Tile Dimension(W×H×D)

Carbon

Carbon Fiber + Magnesium

Alloy

5.77mm

HB Black SMD 3-in-1

White SMD 3-in-1

140°/110°

4,500nits(Multicolor 2727)

6,000nits(NationStar 1921)

Solid

30,044/sqm

104×208

3,840Hz

16bit

13.9kg

1/4

600mm×1,200mm×77mm

23.6”×47.2”×3.0”

CB5CB3

Curve(optional)

Concave Max. 15°

Convex Max. 10°

600mm×1,200mm×72mm

23.6”×47.2”×2.8”

Carbon Fiber + Magnesium

Alloy

8.33mm

White SMD 3-in-1

140°/110°

5,000nits(NationStar 2727)

Solid

14,400/sqm

72×144

2,880Hz

16bit

12.7kg

Concave Max. 15°

Convex Max. 10°

1/6

CB8

Carbon Fiber + Magnesium

Alloy

3.75mm

Black SMD 3-in-1

140°/140°

1,500nits(NationStar 2121)

Solid

71,111/sqm

160×320

1,920Hz

16bit

13.2kg

1/16

600mm×1,200mm×77mm

23.6”×47.2”×3.0”

Concave Max. 15°

Convex Max. 10°

IP Rating(Front/Rear)

Max Power/Tile

Lifetime

Operating Temp/Humidity

Processor Brompton Brompton Brompton

Storage Temp/Humidity

Max. Hanging*

IP65

650W

500W

≥50,000h

-20°C to 45°C, 10~90%RH

-40°C to 60°C, 10~90%RH

12 tiles

Max. Stacking 4 tiles

IP65

320W

≥50,000h

-20°C to 45°C, 10~90%RH

-40°C to 60°C, 10~90%RH

12 tiles

4 tiles

IP43

540W

≥50,000h

-20°C to 45°C, 10~90%RH

-40°C to 60°C, 10~90%RH

12 tiles

4 tiles

Certications

*Notes: The single hanging bar is able to support up to 12 tiles when the safety factor is 5.

03

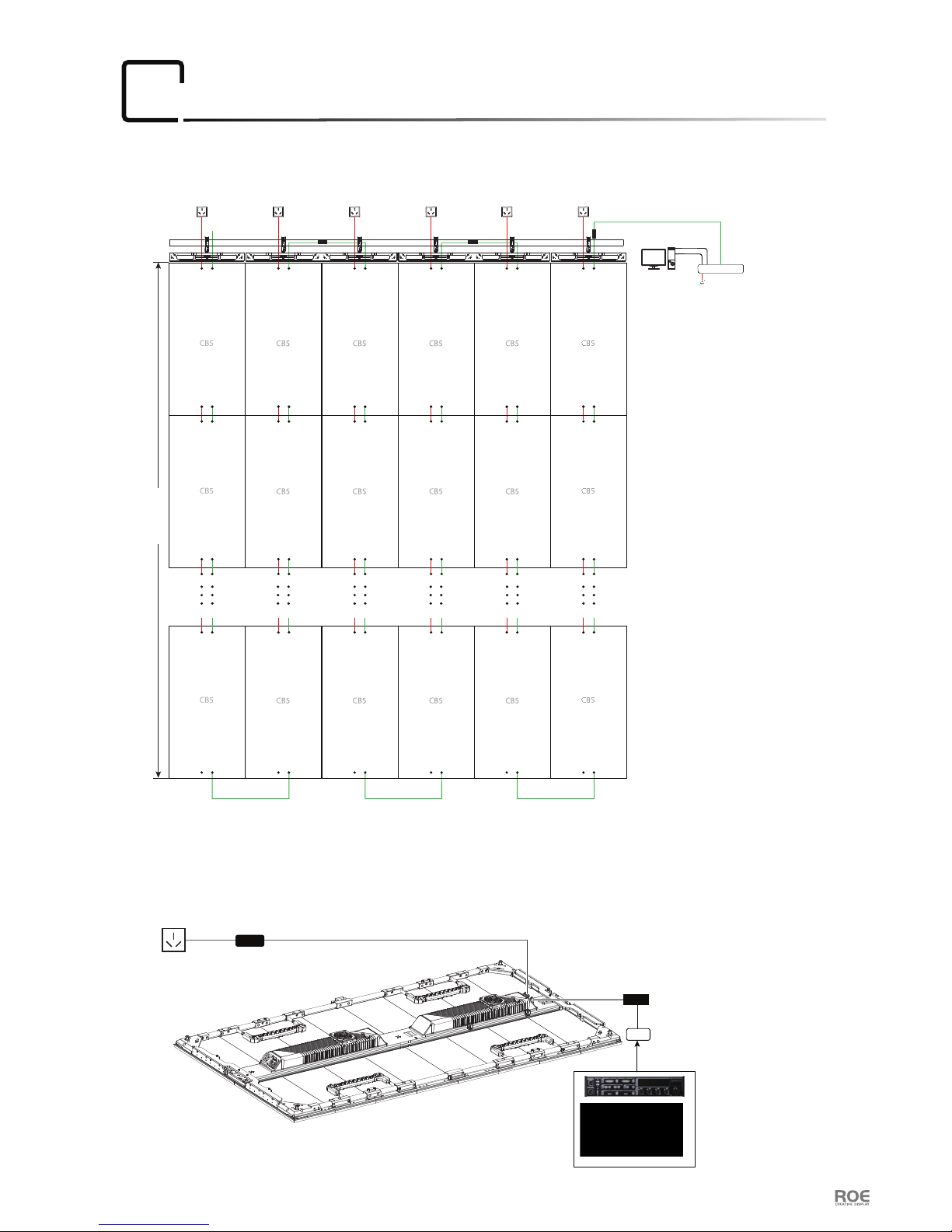

Connection

User Manual P7

Processor

AC 220V

CAT-5

DVI

①

②

Carbon 5 Built in Power Supply

Input Voltage AC 220V

Hanging System

1. Neither Hanging Bar nor Vertical Connector can load more than 20 tiles of Carbon 5.

2. When the Input Voltage is 220V, one Power Cable can load 4 tiles of Carbon 5; and the Input Voltage is 110V,

one Power Cable can load 2 tiles of Carbon 5.

Notes:

AC 220V AC 220V AC 220V AC 220V AC 220V AC 220V

③

④

⑤ ⑤

⑤

⑥

4 tiles high

CB5

CB5

CB5

CB5

CB5

CB5

Power and Data connections of Carbon tiles

Data

WeiPu

Brompton

Power

Data Adaptpr

User Manual P8

Processor

AC 220V

CAT-5

DVI

①

②

Carbon 8 Built in Power Supply

Input Voltage AC 220V

Hanging System

1. Neither Hanging Bar nor Vertical Connector can load more than 20 tiles of Carbon 8.

2. When the Input Voltage is 220V, one Power Cable can load 8 tiles of Carbon 8; and the Input Voltage is 110V,

one Power Cable can load 4 tiles of Carbon 8.

Notes:

AC 220V AC 220V AC 220V AC 220V AC 220V AC 220V

③

④

⑤ ⑤

⑤

⑥

8 tiles high

CB8

CB8

CB8

CB8

CB8

CB8

Power and Data connections of Carbon tiles

Data

WeiPu

Brompton

Power

Data Adaptpr

Accessories

04

User Manual P9

Name

SAP No.

Dimension

Weight

Brompton

311003-00010

W508×H432×D89mm

12.0kg

:

:

:

:

Name

SAP No.

Dimension

Weight

Data Cable

208004S0242

30m

1.4kg

:

:

:

:

Name

SAP No.

Dimension

Weight

Max Capacity

Power Cable

208001S0754/0611

10/30m

1.8kg/4.6kg

16A

:

:

:

:

:

Name

SAP No.

Dimension

Weight

Data Cable

208002S0262

0.93m

0.2kg

:

:

:

:

Name

SAP No.

Dimension

Weight

Data Adaptor

203000S0015

W56×H32×D26mm

0.1kg

:

:

:

:

① ② ③ ④

⑤

Name

SAP No.

Dimension

Weight

Max.Capacity

Flightcase

30900300330

W1300×H840×D800mm

80kg

7 tiles of CB

:

:

:

:

Name

SAP No.

Dimension

Weight

Max.Capacity

Dolly

206002C0277

W1310×H1605×D790mm

102kg

12 tiles of CB

:

:

:

:

:

Name

SAP No.

Dimension

Weight

Hanging Bar

207002S0096

W589×H188×D157mm

3kg

:

:

:

:

Name

SAP No.

Dimension

Weight

Hanging Bar

207002S0097

W1189×H188×D157mm

6.1kg

:

:

:

:

⑥

⑥

⑥

Name

SAP No.

Dimension

Weight

Material

Hanging Connection Plate

206002S0384

W142×H82×D25mm

232g

ADC12/SUS304

:

:

:

:

:

Name

SAP No.

Dimension

Weight

Material

Connection Plate

304012001080

W142×H45×D25mm

125g

SUS304

:

:

:

:

:

Name

SAP No.

Dimension

Weight

Material

Hanging Connection Plate

206002S0638

W110×H38×D25mm

232g

ADC12/SUS304

:

:

:

:

:

Name

SAP No.

Dimension

Weight

Material

Connection Plate

30401201079

W142×H90×D25mm

240g

SUS304

:

:

:

:

:

Name

SAP No.

Dimension

Weight

Material

Hanging Curve

Connection Plate

206002S0468

W142×H118×D85mm

390g

ADC12/SUS304

:

:

:

:

:

Name

SAP No.

Dimension

Weight

Material

Curve Connection Plate

30401201044

W152×H72×D85mm

288g

SUS304

:

:

:

:

:

Name

SAP No.

Dimension

Weight

Material

Curve Connection Plate

30401201043

W142×H109×D85mm

376g

SUS304

:

:

:

:

:

User Manual P10

Installation:

05

Hanging System

Hanging Bar Diagram:

0.6m Hanging Bar Dimensions:

1.2m Hanging Bar

Optional

Eyebolt

Adjusting Screw

Adjusting Knob

Hanging Clamps

Fixed Seat

Dowel Pin

Magnet Component

589mm

1189mm

188mm

157mm

User Manual P11

Flat Installation

Just turn the Adjusting Screw, to make the Clamps close, the Hanging Bar will be xed on the

Truss safely.

1. Fix the Hanging Bar on the Truss

Tiles will be attached to the Hanging Bar by Magnets automatically.

Notes: (For Safety) Please do this by two persons.

2. Connect Carbon tiles with the Hanging Bar

connection plate diagram:

Control Button

Handle

Connection Plate

Bolt Hole for celling

(

Round screw M10×10mm)

3. Fix Carbon tiles on Hanging Bar by Connection Plate

Locating Hole Position Pin

User Manual P12

Two kinds of Connection plate.

two handles: four handles:

Press the red button to loosen the handle, align the locating hole and dowel pin, push handle back for locking.

1

2

3. Use Connection Plate with eyebolt for hanging also.

Case 1

Locating

Hole

Case 2

User Manual P13

5. Flat Installation Components

Major components of at installation assembly are:

0.6m Hanging Bar × 2 1.2m Hanging Bar × 2 Connection Plate × 19 CB tiles × 12

4. Interconnect Side Lock

For the Magnet components,

in vertical connection at the

edge of CB tiles, must use

Connection Plate .

User Manual P14

Curve Installation

Hanging bar and Connection Plate indicate

The connecting angle of curve connection plates can be adjustable with any size (Max.concave 15°,

Max.convex 10°).

concave 15°

(four handles)

convex 10°

(four handles)

1

1

2

2

at

(two handles)

at

(two handles)

3

4

4

4

4

concave 15°

(two handles)

convex 10°

(two handles)

5

6

5

6

User Manual P15

Hanging Connection Plate

145

concave 15°

Sliding Plate

Eyebolt

Degree Handle

Handle

Control

Button

7

7

at

8

convex 10°

9

9

Connection Plate

or

2 6

or

or

Nothing

User Manual P16

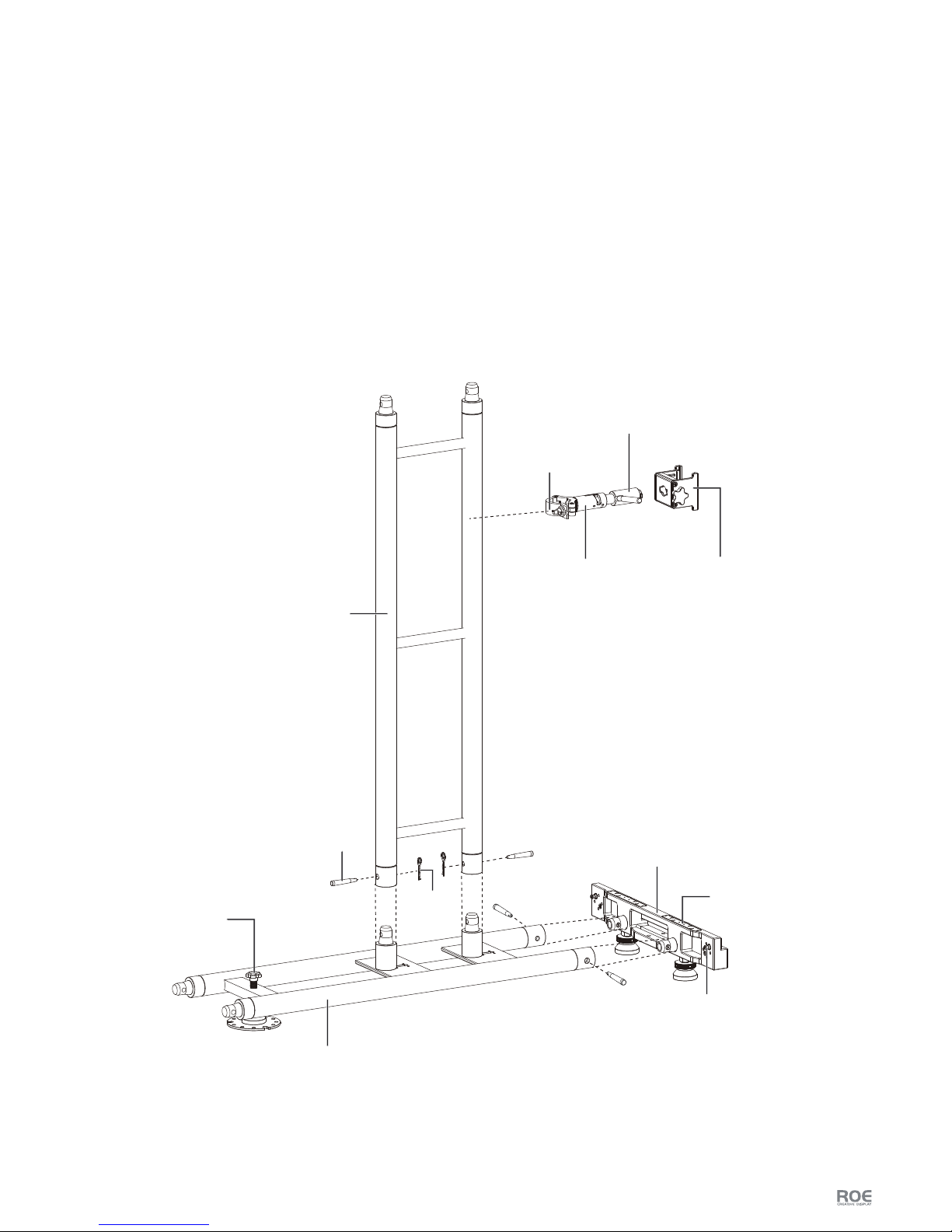

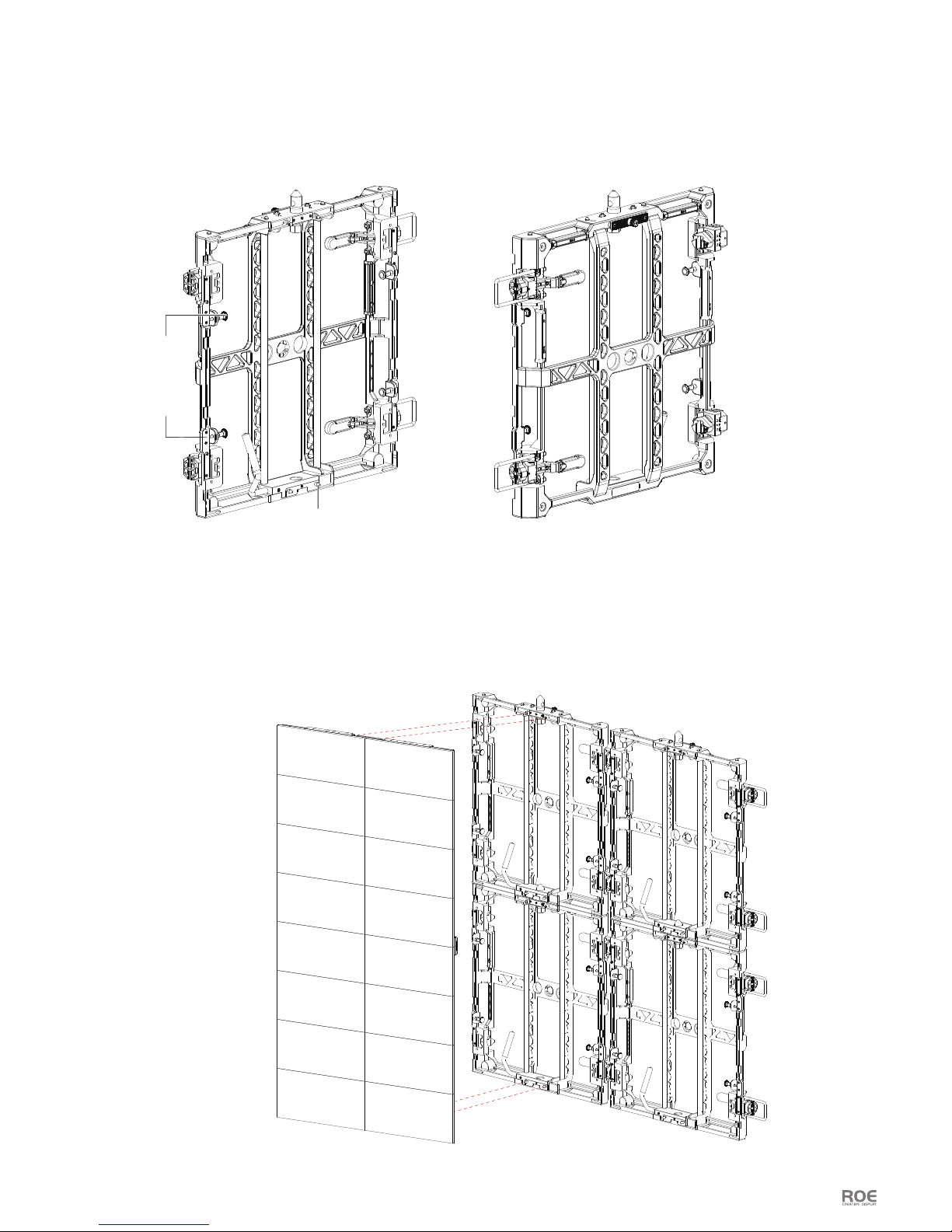

Stacking System

Stacking system assembly exploded diagram.

Stacking System Support Components

Major components of the Stacking System support assembly are:

1. Base Bar

2. Base Truss

3. Rear Support Truss

4. Rear Bridge(Half Coupler, Brace Arm, Stacking Connector, Clamp Adaptor)

Base Bar

Base Truss

Adjusting Knob

Rear Support Truss

Stacking Connector

Half Coupler

Pin

Safely Clip

Position Pin

Magnet Component

Brace Arm Clamp Adaptor

User Manual P17

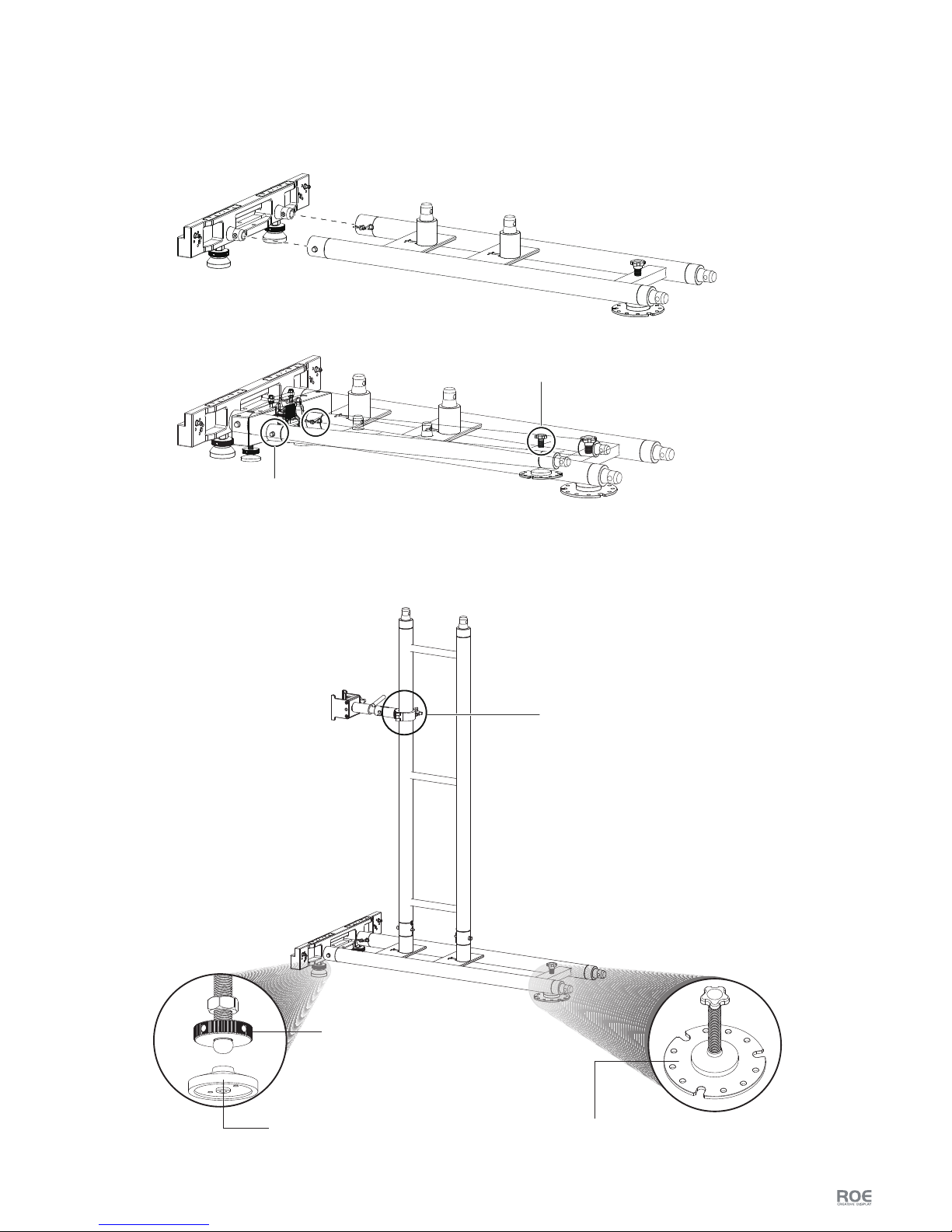

Stacking Installation

1. Base Bar connection with Base Truss

Connect the Base Bar and Base Truss by Pin and Safely Clip.

2. Rear Support Truss and Rear Bridge installation

Lock of Base Truss

Adjust the Knob and make sure the Base Truss

and Base Bar in same horizontal

Half Coupler and Screw

Knob

(Adjusting height)

Universal Adjusting Footpad

(Keep the Base Bar always horizontal )

Plate

(Fix the Base Truss on the ground )

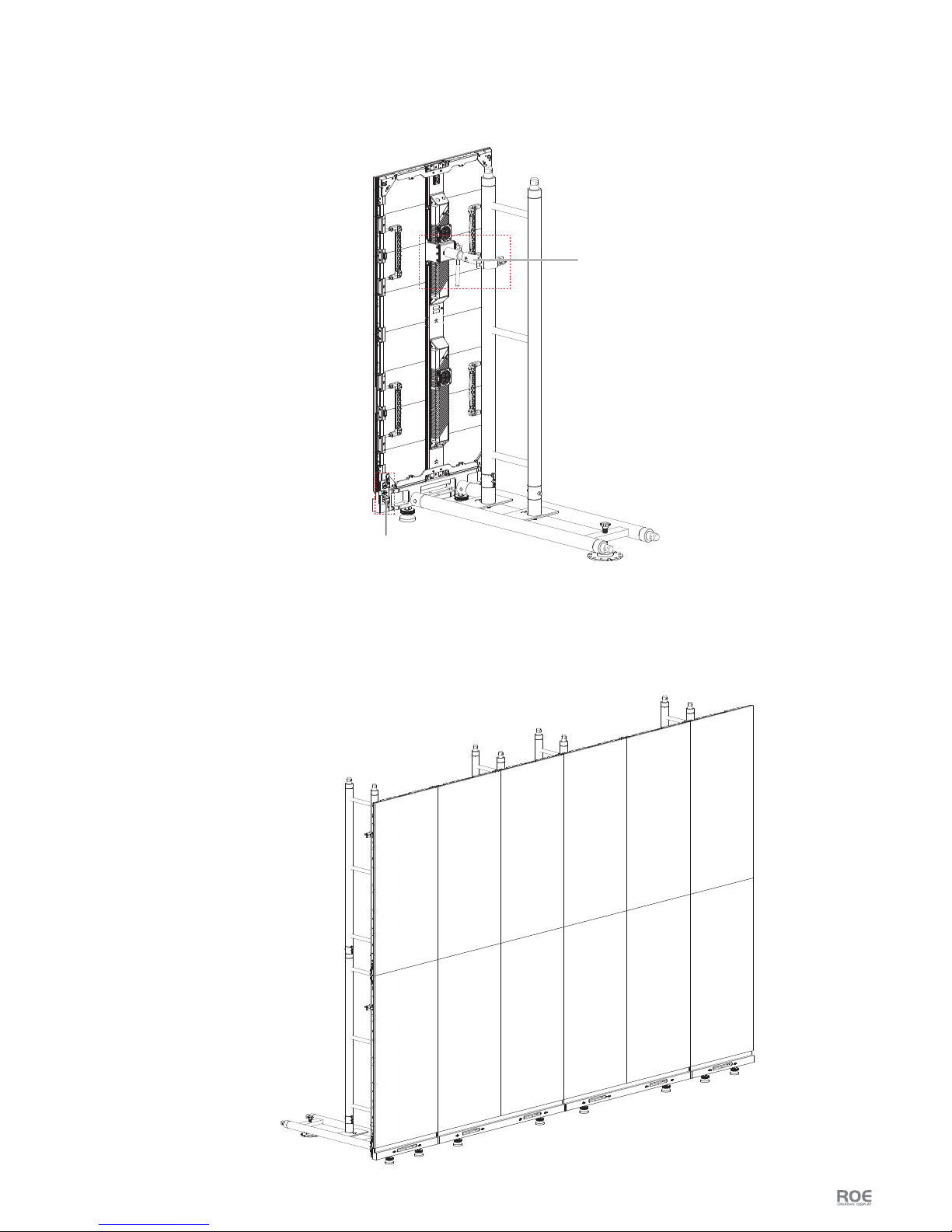

User Manual P18

3. Tiles Installation

Connect the tiles and Base Bar by Vertical Connector, and Rear Support Truss by Rear bridge.

4. Stacking Installation

Tile(2×6)Accessories Count:

Base Bar: 2×0.6m, 1×1.2m

Base Truss: 4

Rear Support Truss: 8

Rear Bridge: 8

Connection Plate: 19

Vertical Connector

Rear Bridge

User Manual P19

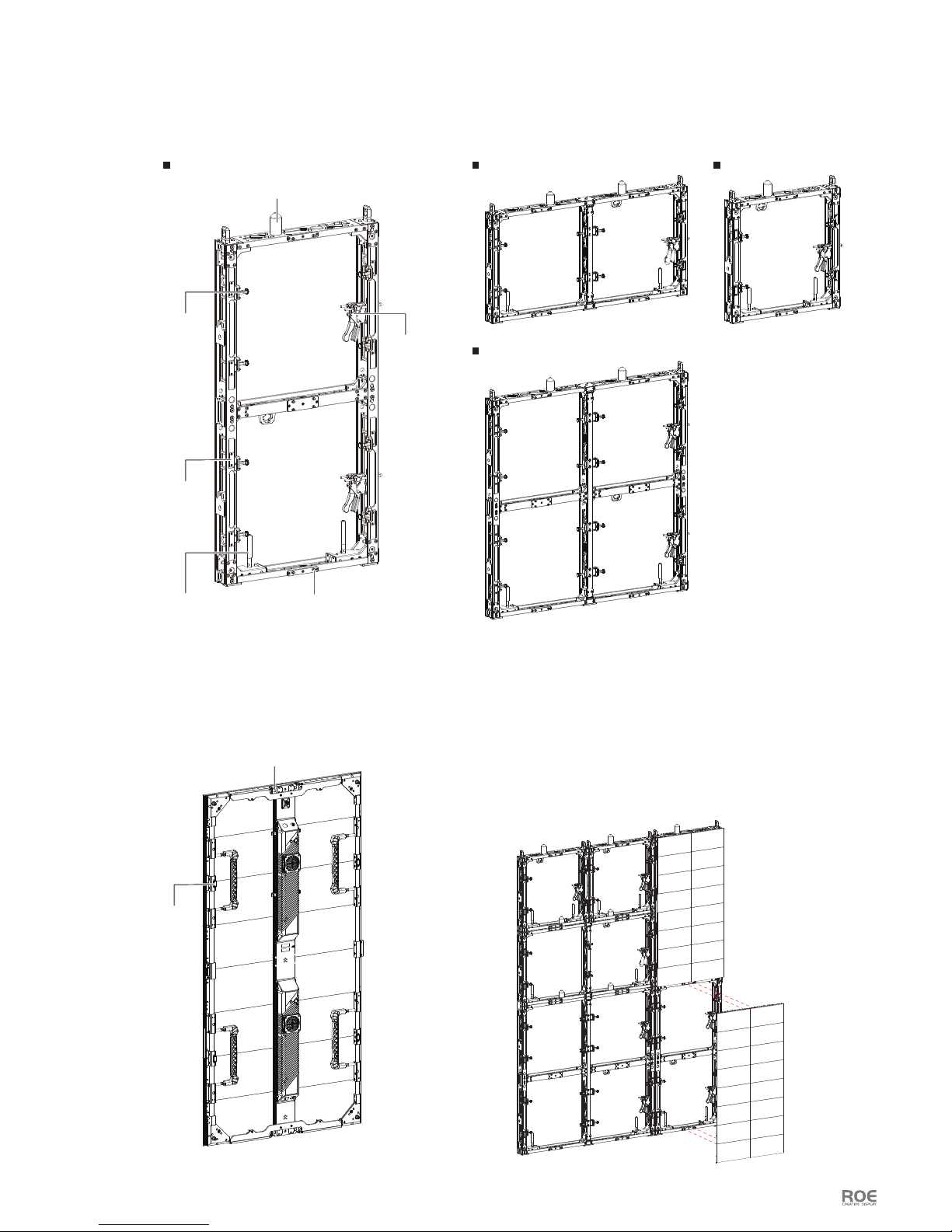

Mounting System

Diagram: Touring Frame - T4

T4V T4H T4M

T4S

Diagram: CB tiles Connect CB tiles with T4 Touring Frame

Keep the lock pin of T4 Open.

Alignment the position pin of T4 and locating hole of

CB, it will be attached to T4 by Magnets automatically.

Then loosen the lock pin for locking.

Lock Pin

Magnet

Position Pin

Locating Hole

Iron Plate

②

①

③

Vertical Interconnect Latch Lever

Horizontal

Interconnect Lock

Vertical King Pin

User Manual P20

Diagram: Touring Frame - T2

Magnet

Position Pin

Connect CB tiles with T2 Touring Frame

Keep the lock pin of T2 Open.

Alignment the position pin of T2 and locating hole of CB, it will be attached to T2 by Magnets automatically.

Then loosen the lock pin for locking.

②

①

③

Lock Pin

SMART / REALTIME / SOPHISTICATED COLOUR MANAGEMENT / REMOTE

Brompton(311003-00010)

Control System:

07

Software

Please read software manual firstly, (download link as below): Http://www.roevisual.com/how-to-make-led-display.

Electrical

Input ports

Output ports

Max. capacity

Canvas size

Remote control

Dimensions

Weight

Certification

2 × SD/HD/3G-SDI, DVI-I, Bi-/Tri-level Reference Sync

4 × Tessera Protocol (Neutrik Ethercon)

2 Million Pixels (60Hz 24bit)

Internal processing

quality

12bits per colour

1920 × 1080 pixels

9.0kg/20.0lbs

CE, ETL/cETL

Support for control via eDMX (ArtNet) and DMX512

(on XLR 5-pin)

508mm × 89mm × 432mm

20” × 3.5” × 19”

100 - 240V AC, 47Hz - 60Hz, 1- 0.5A

Autoranging power supply.

User Manual P21

Specications

Rear Panel Connections

All specifications are believed to be correct at time of writing.

Specifications are not guaranteed to be free from errors, and are subject to change at any time.

DisplayPort Input

Remote Control DVI Input

Local UI

IEC Mains InputGigabit Ethernet Outputs

3G-SDI Input

DMX 512-A Input

On/Off Switch

Loop Thru Ports

Reference Inputs

Service and Maintenance:

08

User Manual P22

2. Notice the data cable and power cable connected to the HUB board in the spine when

replacing the spin. Don’t be forced to remove the spine in case of dragging out

the cables and broken the connectors.

Maintenance:

Picture 1 Picture 2 Picture 3 Picture 4

Picture 5 Picture 6 Picture 7 Picture 8

1. Loosen the screw(a total of six screws) on the front of the module.

2. The loosened screws can be remained on the tile.

3. Insert the tool into the gap on the top of the module that you want to take out.

4. Make sure that the iron piece at the front of the tool is fully inserted in the gap.

5. You can check it at the back.

6. Pull the handle.

7. The module comes out, be caution that the module falls o.

8. Take the module out from the tile.

1. Maintenance on overall installation, just replace the bad module.

(twist force: 1.8kg f-cm)

.

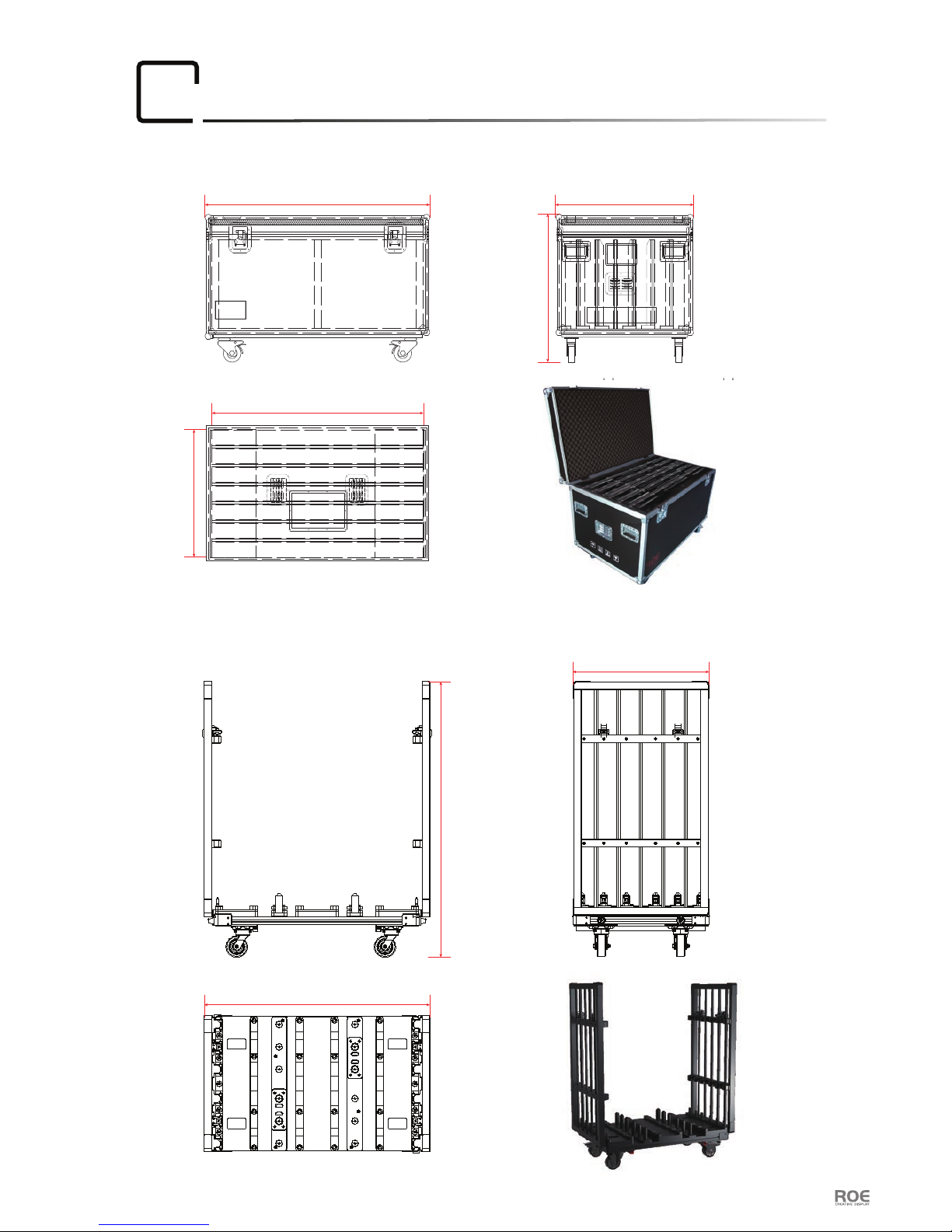

Package

09

7 pcs LED tiles per Flightcase

12 pcs LED tiles per Dolly

User Manual P23

1300mm

1210mm

800mm

840mm

774mm

1310mm

1605mm

790mm

User Manual P24

ROE Visual Co., LtdROE Visual Europe B.V ROE Visual US, Inc

www.roevisual.com www.roevisual.comwww.roevisual.com

Bldg 7, Zhong Yuntai Industrial Park,

Shiyan Town, Shenzhen, China.

E: roe@roevisual.com

T: +86-755-8392 4892

F: +86-755-8392 4891

Zernikelaan 2a,

9351VA Leek, The Netherlands.

E: europe@roevisual.com

T: +31 (0) 50 211 0990

2514 N Naomi Street,

Burbank, CA, 91504.

E: usa@roevisual.com

T: +1 747 229 9190

Loading...

Loading...