Page 1

Installation Instructions

W-Series Brushless Servo Motor

(Catalog Number W-3016-N, W-4030-M, W-4030-P, W-4050-P, and W-4075-R)

These installation instructions describe how to install the W-Series

motors. Use this document if you are responsible for installing,

®

maintaining, or troubleshooting the Allen-Bradley

products. Please read all instructions before installing the motor.

For: See Page

Receiving and Maintenance Information 2

Motor Catalog Number Identification 2

Before You Install the Motor 3

Guidelines for Installation and Maintenance 4

Prolonging Washdown Motor Life 4

Using Couplings and Pulleys 5

Building and Installing Cables 6

Preventing Electrical Noise 7

Using Shaft Seals 8

Installing Your Motor 9

Mounting Dimensions 14

Connector Data 16

Motor Load Force Ratings 17

Radial Load and Axial Load Force Ratings 17

Shaft Seals 18

Using Shaft Seals 18

Removal and Installation of Shaft Seals 18

Shaft Seal Kits 20

Interconnect Cables 20

W-Series motor

Publication 1398-IN520A-EN-P — May 2001

Page 2

2 W-Series Motor Installation Instructions

Receiving and Maintenance Information

The customer is responsible for inspecting the equipment before

accepting the shipment from the freight company. Check the item(s) you

receive against your purchase order. Notify the carrier of any shipping

damage immediately.

W-Series (washdown) motors are designed for long-term use in harsh

environments. However, you should store your motor for future use

within the following environmental conditions:

• in a clean, dry location

• within the storage temperature range, -30° to 70° C (-22° to 158° F)

• within the relative humidity range, 5% to 95% non-condensing

• in an non-corrosive atmosphere

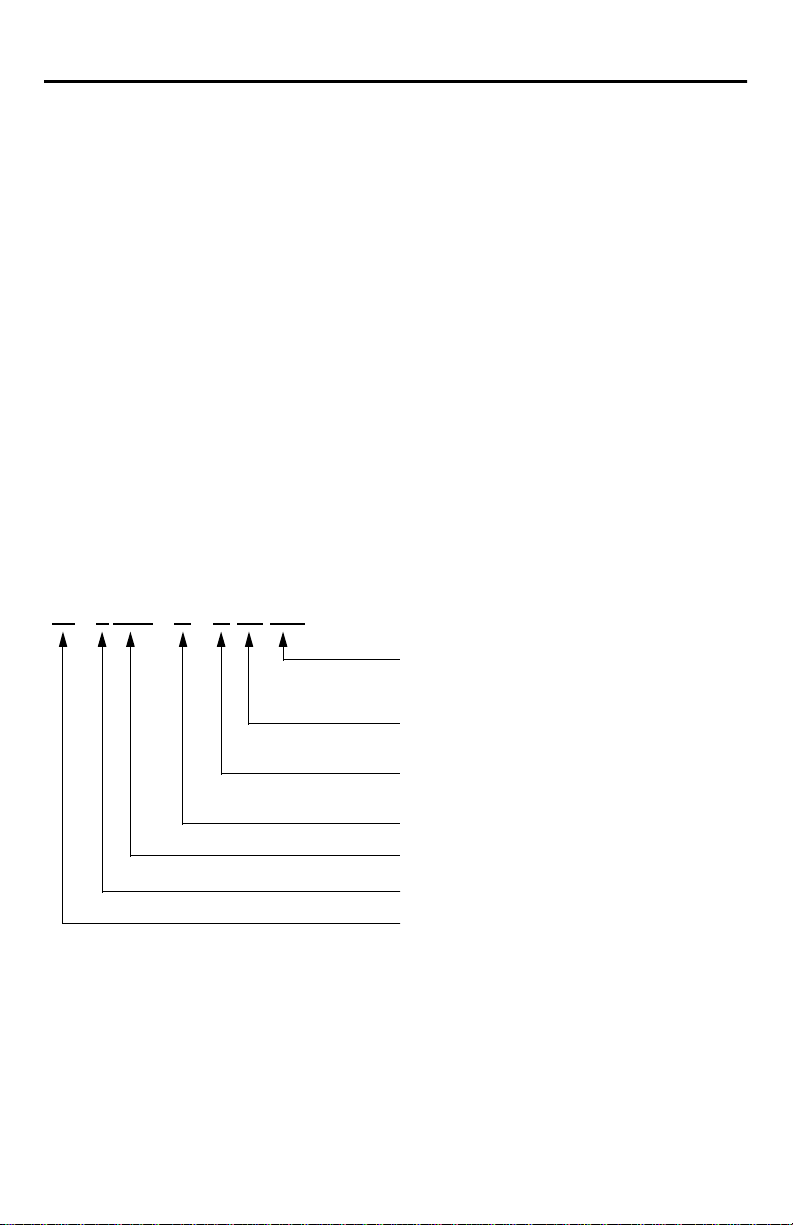

Motor Catalog Number Identification

W - 3 016 - N - H 00 AA

Publication 1398-IN520A-EN-P — May 2001

FACTORY DESIGNATED OPTIONS

AA Teflon Shaft Seal for above foodline applications

AB Viton Shaft Seal for below foodline applications

OPTIONS

00 Standard

OPTICAL ENCODER LINE COUNT

H 2000 Standard

MOTOR WINDING Ke DESIGNATOR

TORQUE RATING / MOTOR LENGTH DESIGNATOR

FRAME SIZE

SERIES DESIGNATOR

W Washdown

Page 3

W-Series Motor Installation Instructions 3

ATTENTION

!

Before You Install the Motor

Before installing or storing the motor:

1. Remove the motor carefully from its shipping container.

2. Visually inspect the motor for any damage.

3. Examine the motor frame, front output shaft, and mounting pilot for

any defects.

Do not open or attempt to open the motor while power

is applied to the motor.

Only a qualified Allen-Bradley employee can service this

type of motor. However, the user can access the power

and feedback connectors by removing the back cover.

Failure to observe these safety procedures could result

in personal injury or damage to equipment.

Publication 1398-IN520A-EN-P — May 2001

Page 4

4 W-Series Motor Installation Instructions

Guidelines for Installation and Maintenance

The following sections provide general installation and maintenance

information. The information should assist you to correctly install and to

provide maintenance that will prolong the lifetime of your W-Series servo

motor.

Prolonging Washdown Motor Life

Thoughtful design and proper maintenance can increase the life of a

washdown motor. The following are guidelines to maximize the life of a

servo motor in a washdown environment:

• Avoid spraying liquids under high pressure directly on the junction of

the motor shaft and housing. Fluids under high pressure can be forced

around worn seals, and contaminate the motor bearings. Bearing

contamination will significantly shorten the life of a servo motor.

If design requirements permit, provide shields that protect the motor

housing, shaft, seals and their junctions from product contamination

and high pressure fluids.

• Always use watertight cord grips (cable glands) to seal the encoder and

power cable openings, and provide a drip loop in each cable.

• If conduit encloses the power or encoder cables:

– Ensure that conduit lines do not have a negative pressure (vacuum)

that may draw water into the conduit line or motor enclosure.

– Install a short section of flexible conduit between the motor and the

rigid conduit to prevent machine vibration or constant pressure from

causing cable abrasion or motor misalignment.

• Replace the shaft seal at or before its expected lifetime.

– Teflon seals have an expected lifetime of 3 to 6 months.

– Viton seals have an expected lifetime of 12 months or greater.

Refer to Shaft Seals on page 18 for more information on shaft seals.

• Inspect the motor and seals for damage or wear on a regular basis. If

damage or adverse wear is suspected, replace the item.

Publication 1398-IN520A-EN-P — May 2001

Page 5

W-Series Motor Installation Instructions 5

ATTENTION

!

Using Couplings and Pulleys

Mechanical connections to the motor shaft, such as couplings and pulleys,

require a torsionally rigid coupling or a reinforced timing belt. The high

dynamic performance of servo motors can cause couplings, pulleys or

belts to loosen or slip over time. A loose or slipping connection will cause

system instability and may damage the motor shaft. All connections

between the system and the servo motor shaft must be rigid to achieve

acceptable response from the system. Periodically inspect connections to

verify their rigidity.

When mounting couplings or pulleys to the motor shaft, ensure that the

connections are properly aligned and that axial and radial loads are within

the specifications of the motor. Refer to Motor Load Force Ratings on

page 17 for guidelines on how to achieve 20,000 hours of motor bearing

life.

Damage may occur to the motor bearings and the

feedback device if sharp impact to the shaft is applied

during installation of couplings and pulleys. Damage to

the feedback device may result by applying leverage

from the motor mounting face to remove devices

mounted on the motor shaft.

Do not strike the shaft, couplings, or pulleys with tools

during installation or removal. Use a wheel puller

applying pressure from the user end of the shaft to

remove any friction fit or stuck device from the motor

shaft.

Failure to observe these safety procedures could result

in damage to the motor and its components.

Publication 1398-IN520A-EN-P — May 2001

Page 6

6 W-Series Motor Installation Instructions

ATTENTION

!

Building and Installing Cables

Knowledgeable cable routing and careful cable construction improves

system ElectroMagnetic Compatibility (EMC). Refer to Installing Your

Motor on page 9 for suggested feedback and power cable trim lengths,

and for cable shield grounding at the motor frame.

To build and install cables, perform the following steps:

1. Keep wire lengths as short as physically possible.

2. Route signal cables (encoder, serial, analog) away from motor and

power wiring.

3. Separate cables by 0.3 m (1 ft) minimum for every 9 m (30 ft) of parallel

run.

4. Ground both ends of the cable shield and twist the signal wire pairs to

prevent electromagnetic interference (EMI) from other equipment.

High voltage can be present on the shield of a power

cable, if the shield is not grounded.

Ensure there is a connection to ground for any

power cable shield.

Failure to observe these safety procedures could

result in personal injury or damage to equipment.

Publication 1398-IN520A-EN-P — May 2001

Page 7

W-Series Motor Installation Instructions 7

Preventing Electrical Noise

ElectroMagnetic Interference (EMI), commonly called noise, may

adversely impact motor performance by inducing stray signals. Effective

techniques to counter EMI include filtering the AC power, shielding and

separating signal carrying lines, and practicing good grounding

techniques.

Effective AC power filtering can be achieved by using isolated AC power

transformers or properly installed AC line filters.

To help avoid EMI:

• Physically separate signal lines from motor cabling and power wiring.

Do not route signal wires with motor and power wires, or over the vent

openings of servo drives.

• Ground all equipment using a single-point parallel ground system that

employs ground bus bars or large straps. If necessary, use additional

electrical noise reduction techniques to reduce EMI in noisy

environments.

Publication 1398-IN520A-EN-P — May 2001

Page 8

8 W-Series Motor Installation Instructions

Using Shaft Seals

A seal is required on the motor shaft near the motor front bearing to

reduce exposure to fluids or fine dust that could contaminate the motor

bearing and reduce its lifetime. Refer to Motor Catalog Number

Identification on page 2 to identify the Frame Size and Shaft Seal type for

a particular motor. Refer to Shaft Seals on page 18 for usage information.

Publication 1398-IN520A-EN-P — May 2001

Page 9

W-Series Motor Installation Instructions 9

ATTENTION

!

Installing Your Motor

W-Series motors include a mounting pilot for aligning the motor on a

machine. Preferred fasteners are stainless steel. The installation must

comply with all local regulations and use of equipment and installation

practices that promote electromagnetic compatibility (EMC) and safety.

Unmounted motors, disconnected mechanical couplings,

and/or disconnected cables are dangerous if power is

applied.

Disassembled equipment should be appropriately

identified (tagged-out) and access to electrical power

restricted (locked-out).

Failure to observe these safety procedures could result in

personal injury.

Allow sufficient clearances in the area of the motor for it to stay within its

specified operating temperature range, 0° to 40° C (32° to 104° F). Do not

enclose the motor unless forced air is blown across the motor for cooling.

A fan blowing air across the motor will improve its performance. Keep

other heat producing devices away from the motor.

Refer to Mounting Dimensions on page 14 to determine the mounting

dimensions of your motor.

Publication 1398-IN520A-EN-P — May 2001

Page 10

10 W-Series Motor Installation Instructions

IMPORTANT

To install your motor:

1. Remove the endplate (back cover) of the motor by loosening the

screws securing it to the motor housing.

Use care when removing or installing the endplate to

avoid damaging the seal.

2. External feedback and power cables must be stripped to a specified

length to provide effective electrical contact with the connector without

exposing excessive bare wire. Refer to the table on page 12 for

recommended wire strip lengths for Feedback and Power cables.

• trim length for the cable jacket

• shield and strip lengths for wire exposure

• location and length of shield to expose for ground clamp contact

Note that power cable strip lengths differ for the W-3000 or W-4000

servo motors. Refer to Interconnect Cables on page 20 for factory

available feedback and power cables.

3. Route the external power and feedback cables through the plastic cord

grips (cable glands) in the motor endplate. The opening of the strain

relief extension may be increased by turning it counterclockwise.

4. Connect the power and feedback cables to the motor as shown in

Figure 1 or Figure 2 on page 13 and described below:

a. Connect the ground clamps to the power and feedback cables

where the shield wire is exposed. Refer to the figures on page 12.

b. Connect the ground clamps to the motor.

c. Route and connect the individual feedback and power wires to their

respective terminals. Connector Data on page 16 lists the signal

terminals, screw torque values, and acceptable wire sizes.

Note: The top terminal bar on the feedback connector is removable.

Removing it improves access to the power cable terminals in addition to

providing clear access to the feedback cable terminals and screws.

Publication 1398-IN520A-EN-P — May 2001

Page 11

W-Series Motor Installation Instructions 11

ATTENTION

!

5. Seal the motor housing by performing the following sequential steps:

a. Position the endplate on the motor while ensuring the cable lengths

and routing internal to the motor remain proper.

b. Torque the screws securing the endplate to 3.4 Nm (30 in-lb) to seal

the motor.

c. Turn clockwise the strain relief extension on the plastic cord grips

(cable glands) to seal the encoder and power cable openings.

6. Properly mount and align the motor. Refer to Mounting Dimensions on

page 14 as necessary.

7. After the motor is mounted, ensure that all power and encoder cables

have a drip loop in the cable to keep liquids flowing away from the

motor.

Outer surfaces of motor can reach high temperatures,

100° C (212° F) during motor operation.

Take precautions to prevent accidental contact with hot

surfaces. Consider motor surface temperature when

selecting motor mating connections and cables.

Failure to observe these safety procedures could result in

personal injury or damage to equipment.

Publication 1398-IN520A-EN-P — May 2001

Page 12

12 W-Series Motor Installation Instructions

Feedback Cable Power Cable

Terminal

No. or Wire

1 101.60 (4.0) A

2 101.60 (4.0) A-

3 101.60 (4.0) B

W-3000 and W-4000 Terminal

mm (in.) Signal mm (in) mm (in.)

or Wire

1

R

1

S

1

T

W-3000 W-4000

55.75 (2.25) 69.85 (2.75)

53.98 (2.125) 63.50 (2.5)

50.8 (2.0) 57.15 (2.25)

4 101.60 (4.0) B- G 44.45 (1.75) 50.8 (2.0)

5 101.60 (4.0) I Shield 9.53 (0.38) 9.53 (0.38)

6 101.60 (4.0) I- Cable

7 101.60 (4.0) Ground

Jacket

8 101.60 (4.0) ABS Wire

9 114.30 (4.5) +5VDC

10 114.30 (4.5) COM

11 114.30 (4.5) Hall B

12 114.30 (4.5) Hall C

Strip

Length

1

Cables and drives may label the R, S and T

power phases as U, V and W respectively.

12.7 (0.50) 12.7 (0.50)

4.76 (0.19) 4.76 (0.19)

13 114.30 (4.5) Thermostat

14 114.30 (4.5) Thermostat

15 114.30 (4.5) Hall A

Shield 9.53 (0.38) Shield

Cable

12.7 (0.50) —

Note: Shield

Exposed for

Ground Clamp

R

S

T

G

Jacket

Wire

Strip

Length

7.0 (0.28) —

Shield

Cable

Jacket

Wire

Strip

Length

Note: Shield

Exposed for

Ground Clamp

Shield

Publication 1398-IN520A-EN-P — May 2001

See Chart

Cable

Jacket

Wire

Strip

Length

Page 13

W-Series Motor Installation Instructions 13

Figure 1

W-3000 Cable Connector and Ground Clamp Locations

Power Cable Ground Clamp

installed between Mounting Dimples

Feedback Cable Ground Clamp

installed between Mounting Dimples

Figure 2

W-4000 Cable Connector and Ground Clamp Locations

Feedback Cable

Ground Clamp

Power Cable

Ground Clamp

Publication 1398-IN520A-EN-P — May 2001

Page 14

14 W-Series Motor Installation Instructions

Mounting Dimensions

The dimension symbols and actual dimensions of the different models in

the W-Series are referenced in the table on the next page.

Figure 3

Reference Drawing for Mounting Dimensions

L

P

N

W

FULL

DEPTH

U

ES

AK

S

Power and Feedback Cable Access

through Self-Sealing Plastic Cord

Grips in Removable Endplate.

Threads are 1/2 inch NPT.

BF = DIA. HOLES

AJ = DIA. BOLT CIRCLE

BD = DIA. MOUNTING PLATE

Publication 1398-IN520A-EN-P — May 2001

Page 15

W-Series Motor Installation Instructions 15

Dimension

(Refer to drawing)

Motor Measurement

W-3016 W-4030 W-4050 W-4075

1

AJ mm 125.7 145.0 145.0 145.0

(in.) (4.95) (5.71) (5.71) (5.71)

AK mm 80.0 110.0 110.0 110.0

(in.) (3.15) (4.33) (4.33) (4.33)

BD mm 142.0 162.8 162.8 162.8

(in.) (5.59) (6.41) (6.41) (6.41)

BF mm 7.1 10.0 10.0 10.0

(in.) (0.28) (0.39) (0.39) (0.39)

ES mm 20.0 40.0 40.0 40.0

(in.) (0.79) (1.57) (1.57) (1.57)

L mm 305.0 317.0 368.0 419.0

(in.) (12.01) (12.48) (14.49) (16.50)

N mm 30 50 50 50

(in.) (1.18) (1.97) (1.97) (1.97)

P mm 102 126 126 126

(in.) (4.02) (4.96) (4.96) (4.96)

S mm5666

(in.) (0.20) (0.24) (0.24) (0.24)

U mm 14 19 19 19

(in.) (0.59) (0.79) (0.79) (0.79)

W mm3333

(in.) (0.12) (0.12) (0.12) (0.12)

Key (supplied) mm 5 x 5 x 20 6 x 6 x 40 6 x 6 x 40 5 x 5 x 20

Shaft End Hole Thread mm M4 x 0.7 M6 x 1 M6 x 1 M6 x 1

Shaft End Hole

Thread Depth

mm 10 15 15 15

(in.) (3.94) (5.90) (5.90) (5.90)

Tolerances AK mm -0.030 -0.35 -0.35 -0.35

(in.) (-0.001) (-0.001) (-0.001) (-0.001)

L mm ±0.5 ±0.5 ±0.5 ±0.5

(in.) (±0.002) (±0.002) (±0.002) (±0.002)

N mm ±0.5 ±0.5 ±0.5 ±0.5

(in.) (±0.002) (±0.002) (±0.002) (±0.002)

S mm -0.030 -0.030 -0.030 -0.030

(in.) (-0.001) (-0.001) (-0.001) (-0.001)

U mm -0.011 -0.013 -0.013 -0.013

(in.) (-0.0005) (-0.0005) (-0.0005) (-0.0005)

W mm ±0.2 ±0.2 ±0.2 ±0.2

(in.) (±0.008) (±0.008) (±0.008) (±0.008)

1

W-Series motors are designed to metric dimensions. Inch measurements are mathematical conversions.

Publication 1398-IN520A-EN-P — May 2001

Page 16

16 W-Series Motor Installation Instructions

Connector Data

The tables below list the signal descriptions for the feedback and power

connector terminals.

Feedback Connector 1 Power Connector 4

Te rm in al

2

Signal

Terminal

5

1 A 1

2 A- 2

3 B 3

4 B- 4 Ground

5I

6 I-

7

Ground 3

8 ABS

9 +5VDC

10 Common

11 Hall B

12 Hall C

13 Thermostat

14 Thermostat

15 Hall A

Removable Top Terminal Half

Terminal Screws for

Feedback Signal Wires

located on the front of

Top Terminal Half

NOTES:

1

Feedback connector accepts wire diameter

0.08–1.5 mm

2

Screw torque values for the feedback signal

wires are 0.23–0.25 Nm (2.0–2.2 lb-in).

3

Terminal 7, Ground is provided for termination

of a cable drain wire when braided shield is not

available. Use of the ground clamp for

termination of braided shield is preferred over

the use of terminal 7.

4

Power connector accepts wire diameter:

W-3000 = 4 mm

W-4000 = 6 mm

5

Screw torque values for the power leads are

0.45–0.68 Nm (4.0–6.0 lb-in).

6

Cables and drives may label the R, S and T

power phases as U, V and W respectively.

2

(AWG 28–16).

Lead

Phase R

Phase S

Phase T

2

(AWG 12) maximum

2

(AWG 10) maximum

6

6

6

Publication 1398-IN520A-EN-P — May 2001

Page 17

W-Series Motor Installation Instructions 17

Motor Load Force Ratings

Motors are capable of operating with sustained maximum radial or

maximum axial shaft loads. The measurement points for maximum radial

and axial load forces are shown in the figure below.

Figure 4

Load Forces on Shaft

Radial load force (FR)

Axial load force (F)

Radial load force (FR) applied to center of shaft extension

The following table represents load factors that provide a 20,000 hour L10

bearing fatigue life for W-Series motors. These load factors do not account

for possible application-specific life reduction factors that may occur, such

as bearing contamination from external sources.

Radial Load and Axial Load Force Ratings

Motor 500 rpm 1000 rpm 2000 rpm 3000 rpm

kg (lbs) kg (lbs) kg (lbs) kg (lbs)

W-3016

W-4030

W-4050

W-4075

When motor shaft has no radial load, axial load rating = 100% of radial load rating listed above.

When motor shaft has both a radial load and an axial load, axial load rating = 44% of radial load rating

listed above.

57.2 (126) 45.8 (101) 35.8 (79) 31.3 (69)

76.7 (169) 69 (152) 54.4 (120) 47.6 (105)

93 (205) 74.4 (164) 58.5 (129) 51.3 (113)

97.5 (215) 78.5 (173) 62.1 (137) 53.5 (118)

Publication 1398-IN520A-EN-P — May 2001

Page 18

18 W-Series Motor Installation Instructions

IMPORTANT

Shaft Seals

Shaft seals that provide environmental sealing of W-Series motors are

available from Allen-Bradley. They provide an additional barrier to

moisture and particle intrusion to the motor bearings. W-Series motors are

shipped with either a Teflon or a Viton shaft seal installed.

Using Shaft Seals

Teflon shaft seals are primarily for applications above a foodline. As such,

Teflon shaft seals are not lubricated and are typically replaced at 3 to 6

month intervals.

Viton shaft seals may be lubricated and should only be used in

applications below a foodline. Viton shaft seals are typically replaced at

12 month or greater intervals when lubricated. Lubricant is supplied with

Viton shaft seal kits.

Removal and Installation of Shaft Seals

Damage to the motor surface where shaft seals make

contact can cause excessive wear and early failure of the

shaft seal.

Use care to prevent scratching or damaging the surface

of the motor.

Failure to observe these safety procedures could result in

damage to equipment.

Teflon seals may be removed by carefully lifting with a small, flat-bladed

screwdriver around the outside edge of the seal.

Viton seals are mounted on a steel carrier. They may be removed by

carefully forcing a small, flat-bladed screwdriver between the seal and the

end cap periphery. This deforms the metal inward until there is sufficient

room to grasp the deformed steel with a needle-nose pliers and remove

the seal.

Publication 1398-IN520A-EN-P — May 2001

Page 19

W-Series Motor Installation Instructions 19

To install a new shaft seal:

1. Remove shaft key, if provided.

2. Check the motor shaft and faceplate. Remove nicks and burrs.

3. Protect the seal lip from the sharp edges of the keyway. If necessary,

place masking tape over the keyway.

4. Position the seal on the shaft with the sealing lips positioned and

slanting outward as shown in Figure 5. If using a Viton shaft seal,

lubricant may be applied prior to seating the shaft seal. Do not use

lubricant with a Teflon shaft seal.

5. Use proper tooling to seat the shaft seal. Do not hammer directly on

shaft seal. Apply force evenly around the outer edge with a soft face

tool, arbor press, or a work piece made from soft wood.

6. Push shaft seal into motor just far enough so outer diameter of the seal

is flush with the front surface of the motor. This leaves a slight

clearance between the shaft seal and the motor bearing.

Figure 5

Teflon and Viton Shaft Seal Installation

Teflon shaft seal lips face outward (away from housing)

Clearance

maintained

Exploded Views of

Correct Shaft Seal

Position

between shaft seal

and motor bearing.

Viton shaft seal lips and opening face outward

(toward shaft)

tool

tool

Publication 1398-IN520A-EN-P — May 2001

Wood

Soft

face

hammer

Metal

hammer

Page 20

20 W-Series Motor Installation Instructions

Shaft Seal Kits

Shaft seal kits available from the factory include:

Catalog

Number

Description Applicable

Motor

0041-5072 Teflon shaft seal kit for use above foodlines W-3000

0041-5073

Viton shaft seal for use below foodlines

1

0041-5074 Teflon shaft seal kit for use above foodlines W-4000

0041-5075

1

Lubricant is provided with Viton shaft seal kits.

Viton shaft seal for use below foodlines

1

Interconnect Cables

Factory manufactured cables are available in standard cable lengths. They

can provide environmental sealing and shield termination. The following

cables are for connecting the W-Series motors.

Catalog Number Description Applicable Motor

1

2090-UXNPAHF-16-Sxx

2090-UXNPAHF-14-Sxx

2090-UXNFBHF-Sxx

1

Cable length (xx) is specified in meters: 01, 03, 09, 15 or 30 (3.3, 9.8, 29.5, 49.2 or 98.5 ft)

2

H-Series Power and Feedback Cables have an MS connector on the motor end of the cable.

H-3000 Power Cable

1

H-4000 Power Cable

1

H-Series Feedback Cable

Remove the MS connector to use the cable with W-Series motors.

2

2

2

W-3000

W-4000

W-3000 and W-4000

Publication 1398-IN520A-EN-P — May 2001

Page 21

Notes

W-Series Motor Installation Instructions 21

Publication 1398-IN520A-EN-P — May 2001

Page 22

22 W-Series Motor Installation Instructions

Publication 1398-IN520A-EN-P — May 2001

Page 23

W-Series Motor Installation Instructions 23

Publication 1398-IN520A-EN-P — May 2001

Page 24

For more information refer to our web s ite: www.ab.com/motion

Allen-Bradley is a registered trad emark of Rockwell Automation.

Publication 1398-IN520A-EN-P — May 2001 PN 0013-1063-001 Rev B

Supercedes 1398-5.8 April 1999 © 2001 Rockwell International Corporation. Printed in the U.S.A.

Loading...

Loading...