Page 1

WebPakCS Software

Ver sion 1.0

Instruction Manual

D2-3447

Page 2

The information in this manual is subject to change without notice.

Trademarks not belonging to Rockwell Automation are property

of their respective companies.

Throughout this manual, the following notes are used to alert you to safety considerations:

ATTENTION:Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss.

!

Important: Identifies information that is critical for successful application and understanding of the product.

ATTENTION:Only qualified electrical personnel familiar with the construction and operation of

this equipment and the hazards involved should install, operate, or service this equipment. Read

!

and understand this manual and other applicable manuals in their entirety before proceeding.

Failure to observe this precaution could result in severe bodily injury or loss of life.

ATTENTION:Only qualified personnel should develop or change drive configuration. Read and

understand the drive hardware and software instruction manuals in their entirety before

proceeding with the configuration edit function. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION:Parameter assignments made while the software in controlling and communicating

to the drive overwrite the parameter values in the drive. Read and understand this manual and

all other applicable manuals in their entirety before changing drive parameter values. Failure to

observe this precaution could result in severe bodily injury or loss of life.

IBM is a trademark of International Business Machine Corporation.

Microsoft, Windows, and MS-DOS are trademarks of Microsoft Corporation.

Pentium is a trademark of Intel Corporation.

WebPak, WebPakCS, and Reliance are trademarks of Rockwell Automation.

© 2000 Rockwell International Corporation

Page 3

Chapter 1 Introduction

1.1 About the WebPakCS Software ................................... ....... ...... ....... ...... .........1-1

1.2 Software Requirements................................... ....... ...... ....... ............................1-1

1.3 Hardware Requirements.................................................................................. 1-2

1.4 Cables .............................................................................................................1-2

1.5 Safety Information ...........................................................................................1-3

1.6 Purpose of This Manual................................................................................... 1-3

1.7 Intended Audience........................................................................................... 1-3

1.8 Terms Used in This Manual............................................................................. 1-4

1.9 Where to Find Additional Information..............................................................1-4

Chapter 2 Getting Started

2.1 Installing the WebPakCS Software on a Personal Computer.......................... 2-1

2.2 Setting Up Communication Between the WebPakCS Software and the Drive 2-2

2.2.1 Connecting the Personal Computer’s Serial Port to the Drive..............2-2

2.2.2 Setting Up the Drive to Communicate with the Personal Computer......2-3

2.2.3 Selecting the Correct Communication Port........................................... 2-4

2.3 Starting the Software .......................................................................................2-4

2.4 About the Menus and Toolbars ........................................... ...... ....... ...............2- 4

2.4.1 About the Menus................................................ ....... ...... ....... ...... ....... .. 2-5

2.4.2 About the Toolbar .. ....... ...... ...... ....... ...... ................................................ 2-5

2.5 Exiting the WebPakCS Software..................................................................... 2-6

CONTENTS

Chapter 3 Configuring the Drive

3.1 Selecting an Application Type.........................................................................3-1

3.2 Creating a New Configuration .........................................................................3-2

3.3 Opening a Drive Configuration File .................................................................3-3

3.4 Editing a Configuration ........... ...... ...... ....... ...... ....... ...... ....... ...... ......................3-4

3.4.1 Example Configuration Setup/Edit Window...........................................3-4

3.4.2 Application Edit Left View Operations................................................... 3-5

3.4.3 Application Edit Right View Operations.................................................3-5

3.4.4 Ending an Editing Session .................................................................... 3-5

3.5 Saving a Drive Configuration.............. ....... ...... ................................................ 3-5

3.6 Saving the Open Drive Configuration to Another File...................................... 3-6

3.7 Printing a Configuration ...................................................................................3-7

Chapter 4 Uploading and Downloading Drive Configurations

4.1 Uploading a Drive Configuration......................................................................4-1

4.2 Downloading a Configuration to the Drive.......................................................4-2

4.3 Comparing the Drive Configuration to the Opened Configuration...................4-2

Chapter 5 Monitoring and Editing Drive Parameters

5.1 About the Parameter Monitor .......................... ....... ...... ....... ...... ....... ...............5-1

5.2 Adding Parameters to the Monitor List ............................................................5-3

5.3 Removing Parameters from the Monitor List...................................................5-3

5.4 Assigning Values to Parameters in the Drive .................................................. 5-4

5.5 Saving a Monitor List .......................................................................................5-6

Contents

I

Page 4

5.6 Displaying a Monitor List..................................................................................5-7

5.7 Exiting the WebPakCS Parameter Monitor......................................................5-7

Chapter 6 Monitoring Drive Status and Alarms

6.1 Displaying and Clearing the Fault Log and Alarm Log.....................................6-1

6.2 Restoring Default Values to Drive Parameters ................................................6-3

6.3 Saving Drive Parameter Values to Non-Volatile Memory on the Drive............6-3

6.4 Restoring Drive Parameter Values from Non-Volatile Memory in the Drive.....6-3

Chapter 7 Controlling the Drive

7.1 Controlling a Drive............................................................................................7-1

7.2 Selecting the Control Source ...........................................................................7-2

7.3 Setting the Line Speed Reference...................................................................7-3

7.4 Setting the Jog Reference................................................................................7-3

7.5 Starting and Stopping the Drive.......................................................................7-4

7.6 Monitoring Drive Indicators ..............................................................................7-4

Chapter 8 Using PC Scope

8.1 About PC Scope..................... ....... ...... ...... ....... ...... ....... ................................... 8-1

8.2 Setting Up a Trace ...........................................................................................8-4

8.2.1 Specifying Signals .................................................................................8-5

8.2.2 Setting Up Data Sampling .....................................................................8-5

8.2.3 Setting Up the Trigger............................................................................8-6

8.3 Acquiring a Trace.............................................................................................8-7

8.4 Working with the Cursors........................................................... ...... ....... ...... ...8-8

8.4.1 Moving a Cursor ....................................................................................8-9

8.4.2 Specifying the Cursors To Track Each Other........................................8-9

8.5 Changing Views ...............................................................................................8-9

8.5.1 Turning Cursors On and Off ..................................................................8-9

8.5.2 Turning Grids On and Off......................................................................8-9

8.5.3 Magnifying the Trace Display ..............................................................8-10

8.6 Taking a Trace Snapshot...............................................................................8-10

8.6.1 Taking a Snapshot...............................................................................8-10

8.6.2 Choosing the Trace Snapshot Colors..................................................8-11

8.7 Saving a Trace File ........................................................................................8-11

8.8 Clearing the Trace Display and Setup ...........................................................8-12

8.9 Opening a Trace File......................................................................................8-12

8.10 Closing PC Scope..........................................................................................8-13

Chapter 9 Troubleshooting

9.1 Using Error Messages......................................................................................9-1

9.2 Getting Assistance from Reliance Electric.......................................................9-1

Index ...........................................................................................................................Index-1

II

WebPakCS Software V1.0

Page 5

List of Figures

Figure 2.1 – RS-232 Cable Connector Pinouts for Drives with a 25-Pin Connector. 2-2

Figure 2.2 – Sample Main Window for an Established Connection..........................2-4

Figure 2.3 – Graphical Tool Bar................................................................................ 2-5

Figure 3.1 – Example of Configuration Setup and Edit View....................................3-2

Figure 3.2 – Open Configuration File Dialog Box.....................................................3-3

Figure 3.3 – Example of a Configuration Setup/Edit Window...................................3-4

Figure 3.4 – Save Configuration Dialog Box............................................................. 3-6

Figure 3.5 – Sample Configuration File Printout.......................................................3-7

Figure 5.1 – Parameter Monitor Window.................................................................. 5-2

Figure 5.2 – Add Parameters to Monitor List Dialog Box..........................................5-3

Figure 5.3 – Save Monitor List Dialog Box ............................................................... 5-6

Figure 5.4 – Recall Monitor List Dialog Box.............................................................. 5-7

Figure 6.1 – Sample Fault Log List Box.................................................................... 6-1

Figure 6.2 – Sample Alarm Log List Box..................................................................6-2

Figure 7.1 – Drive Control Window...........................................................................7-2

Figure 8.1 – The PC Scope Screen..........................................................................8-2

Figure 8.2 – Trace Signal Setup Dialog Box.............................................................8-4

Figure 8.3 – Sample Trace .......................................................................................8-8

Figure 8.4 – Save a Signal Trace File Dialog Box.................................................. 8-11

Figure 8.5 – Open Signal Trace File Dialog Box ....................................................8-12

Contents

III

Page 6

IV

WebPakCS Software V1.0

Page 7

List of Tables

Table 1.1 – Cables.................................................................................................... 1-2

Table 1.2 – Terms.....................................................................................................1-4

Table 2.1 – Overview of the Menu............................................................................2-4

Table 2.2 – Toolbar Icons and Menus......................................................................2-5

Table 6.1 – Using the Fault and Alarm Logs ............................................................ 6-2

Table 8.1 – PC Scope Toolbar Buttons....................................................................8-3

Contents

V

Page 8

VI

WebPakCS Software V1.0

Page 9

This section describes the computer requirements for the WebPakCS™ software and

presents general information about the software and this manual.

1.1 About the WebPakCS Software

Use the WebPakCS software to help you develop drive configurations on your

personal computer for WebPak

communicates with the drive through the personal computer’s RS-232 port.

Using the WebPakCS software, you can:

• Create, modify and store WebPak drive configurations.

• Download and upload configurations to or from a WebPak drive.

• Display and change parameters in the drive.

• Control and monitor the drive.

™ 3000 drives. The WebPakCS software

CHAPTER 1

Introduction

• View waveforms in the drive.

• Read and reset the drive fault and error log.

• Send Memory Sav e , Memory Restore and Restore Defaults commands to a drive.

• Print a drive configuration on a printer or to a text file.

1.2 Software Requirements

The WebPakCS software requires Microsoft Windows 9x or later versions (including

Windows NT) and Internet Explorer version 5.0 or later. Make sure these programs

are installed and configured on your personal computer before attempting to install the

WebPakCS software.

Introduction

1-1

Page 10

1.3 Hardware Requirements

Before installing and using the WebP akCS software, make sure you have the following

hardware:

• An IBM or IBM-compatible 486 or Pentium personal computer running

Windows 9x or Windows NT

• 16 Mbytes of RAM (minimum)

• A hard drive with at least 1 Mbytes free space available for the WebPakCS

software

• A CD-ROM drive

• A monochrome or color monitor: VGA or better

• An RS-232 serial COM port for communicating with the drive

• An RS-232 serial cable with:

• A 25-pin or 9-pin D-shell connector for your personal computer

• A 25-pin male D-shell connector for the drive

The WebPak 3000 drive is equipped with a terminal strip as well as a 9-pin D-shell

connector. Either one can be used to connect to the personal computer. Refer to

section 2.2.1 for additional information.

1.4 Cables

This table lists the cables you can use to connect a personal computer to the drive.

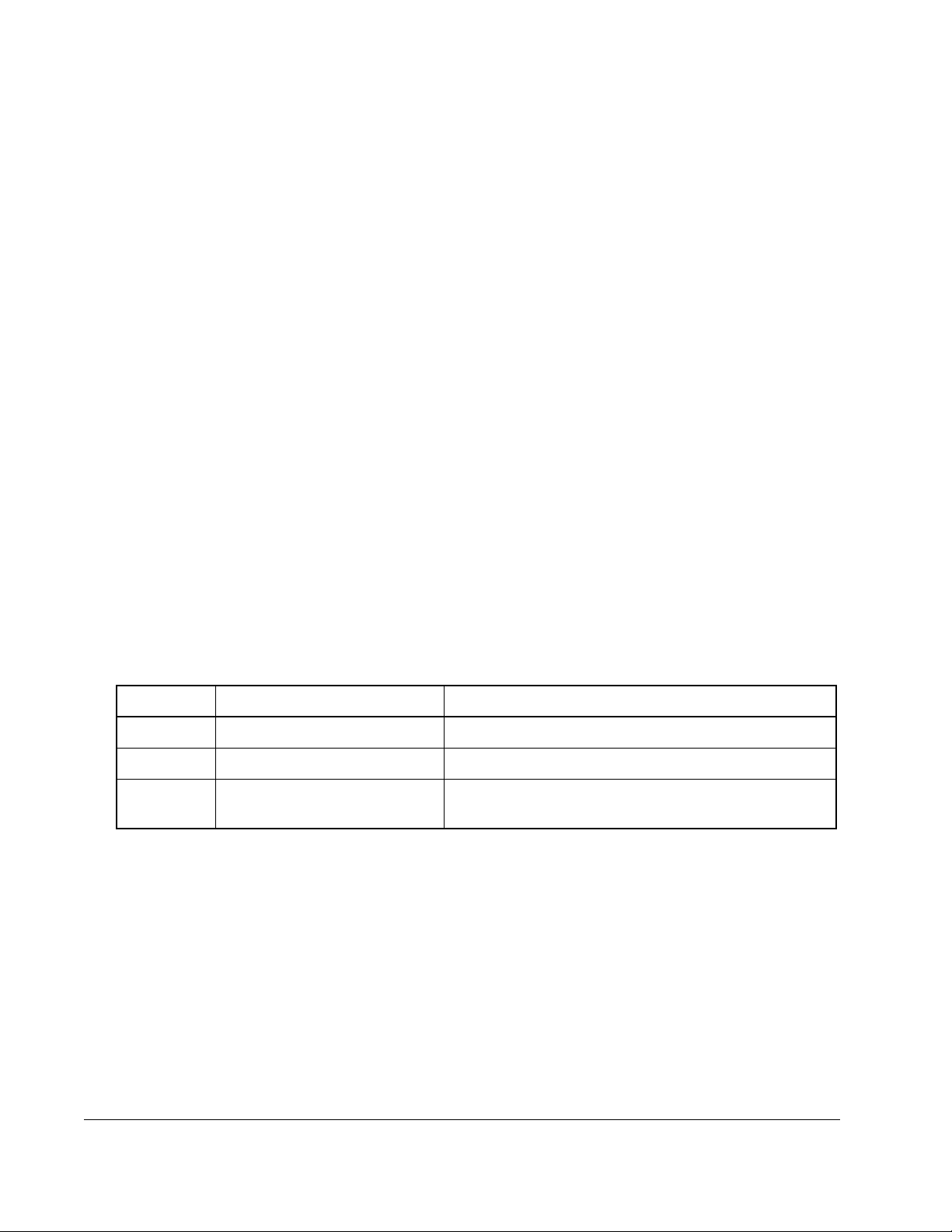

Table 1.1 – Cables

Cable M/N Type Purpose

61C127 Interface cable, 9-pin to 25-pin directly connects the personal computer to the drive

2CA3000 Interface cable, 9-pin to 9-pin use with adapter cable 2CA3001

2CA3001 Adapter cable,9-pin to 25-pin connects a 9-pin COM port on the personal computer

to the drive via the M/N 2CA3000 Interface cable

1-2

WebPakCS Software V1.0

Page 11

1.5 Safety Information

ATTENTION:Do not run other Windows or DOS software applications

while you are using the WebPakCS software for drive control.

!

The WebPakCS software operates as a Windows 95 application. It cannot preempt

other applications or functions in Windows and, therefore, cannot guarantee a

response time to user input actions. Using other applications while controlling a drive

with the WebPakCS software can tie up PC resources and cause drive commands to

be delayed.

To prevent drive commands (run, stop, and jog) from unexpectedly executing, the

WebPakCS software specifies a time-out period (approximately 2 seconds) when it

establishes a link with the drive. While the link is established, the WebPakCS software

sends messages to the drive to validate the link. If a message fails to reach the drive

within the time-out period because program execution has been delayed, the drive

invalidates the link. If the link becomes invalid, the drive does not accept drive

commands. If the drive was running, it stops, and a serial fault is generated.

Before a drive control command is sent to the drive, the drive’s status is checked to

validate the link. If communication between the WebPakCS software and the drive

have been interrupted and you have selected a drive command, the command is not

sent and a message is displayed.

Unexpected machine motion could result. Failure to observe this

precaution could result in severe bodily injury or loss of life.

The time-out period is also used by the Parameter Monitor and Download functions,

both of which could be running while the Drive Control Window is open. If the link

becomes invalid while these functions are running, a message will be displayed in the

Drive Control window before the link is re-established. When you select the Download

command while the Drive Control window is open, you cannot execute drive command

controls until the download is complete.

1.6 Purpose of This Manual

This manual describes how to use the WebPakCS software to configure WebPak

3000 drives. Refer to the WebPak 3000 Software Reference instruction manual for

information about parameters.

1.7 Intended Au dience

This manual is written for those who must install the WebPakCS software and use the

software to configure and run WebPak 3000 drives. This manual assumes you are

familiar with Windows and makes references to it throughout.

You will need to know the basic Windows functions before using the WebPakCS

software.

Introduction

1-3

Page 12

1.8 Terms Used in This Manual

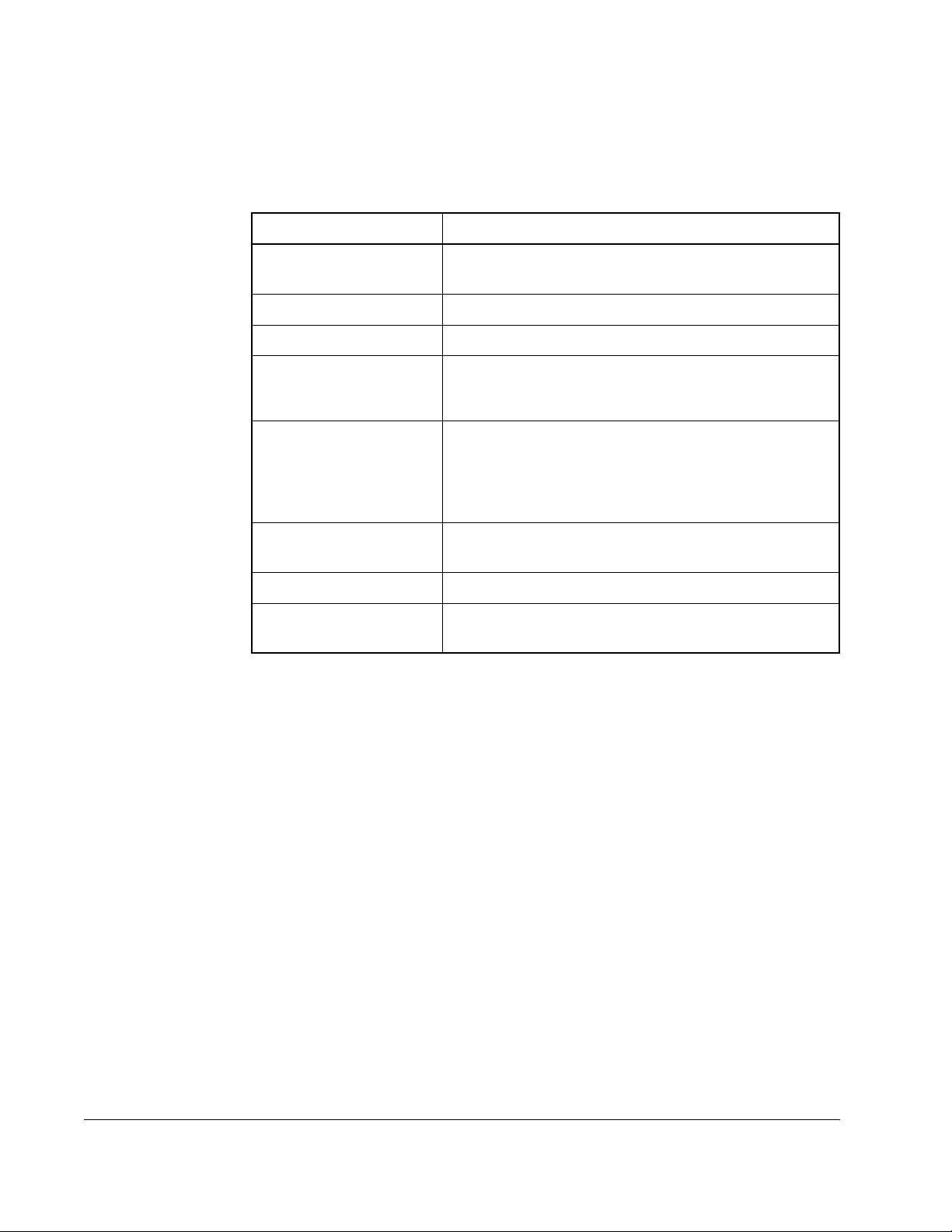

The following terms are used throughout this manual:

Table 1.2 – Terms

Term Definition

WebPakCS software The software used to configure, monitor, and operate

the WebPak 3000 drive.

CD-ROM drive The personal computer’s CD-ROM drive.

COM port Communication port.

configuration file Drive configurations stored on the personal computer

that can only be read and written to by the WebPakCS

software.

drive The Power Module and regulator combination that

controls a motor.

Drives can be configured using the WebPakCS

software.

drive configuration The set of drive parameters and assignment values

that specify how the drive runs.

hard drive The personal computer’s hard disk drive.

opened configuration The configuration that is active in the WebPakCS

software.

1.9 Where to Find Additional Information

See the following instruction manuals for more information about the drives that can

be configured using the WebPakCS software:

• D2-3443 WebPak 3000 DC Drive Hardware Reference, Installation, and

Troubleshooting

• D2-3444 WebPak 3000 DC Drive Software Reference Manual

• D2-3345 WebPak 3000 Operator Interface Module (OIM) User Guide

• D2-3446 WebPak 3000 DC Drive Application Workbook

1-4

WebPakCS Software V1.0

Page 13

CHAPTER 2

Getting Started

This section describes how to install the WebPakCS software and use the menus and

toolbars.

2.1 Installing the WebPakCS Software on a Personal

Computer

All files needed to install the WebPakCS software are on the WebPakCS CD-ROM

disk. Use the following steps to install the WebPakCS software.

Important: To exit installation, select Cancel from any screen or press .

Step 1. Start Microsoft Windows.

Step 2. Insert the WebPakCS software disk into the CD-ROM drive.

Step 3. From the Start Menu, select Run.

Step 4. In the Open field, type in the drive letter followed by SETUP. For example, if

your CD-ROM drive is D:, you would type D:SETUP

Follow the screen prompts.

Step 5. At the Choose Destination Location window, specify the location where you

want to install the software. The location defaults to

C:\Program Files\Rockwell Automation\WebPakCS

Select OK when the drive and directory are correct. The installation software

automatically creates the new path.

Step 6. At the prompt “Enter desired default location for WebPakCS work files,”

specify the location where you want to store the drive configuration files. The

default location is C:\WebPakCS_Work. Select OK when the drive and

directory are correct.

The program begins its installation sequence.

After creating the program group and icon, the WebPakCS software installation is

complete. The installation program automatically exits, and you return to Windows.

You should see a new entry in your Windows Start | Programs menu titled

“WebPakCS.”

Step 7. Remove the WebPakCS disk from the CD-ROM drive.

The WebPakCS software is now installed and ready to use.

Getting Started

2-1

Page 14

2.2 Setting Up Communication Betwee n the WebPakCS

Software and the Drive

The following sections describe the setup required for communication between the

WebPakCS software and the drive. To enable communication between the

WebPakCS software and the drive:

• Physically connect the personal computer to the drive through a serial port

connection (see section 2.2.1)

• Set up the drive for communication through a serial port (see section 2.2.2)

• Select the correct communication port on the personal computer (see section

2.2.3)

2.2.1 Connecting the Personal Computer’s Serial Port to the Drive

For the WebPakCS software to communicate with the drive, connect the personal

computer to the drive using an appropriate cable by following these instructions:

Step 1. The drive’s RS-232 port uses a 25-pin male D-shell connector. Connect the

communication cable’s 25-pin male connector to the drive. Refer to the drive

instruction manual for the location of the RS-232 port on the drive.

Step 2. Connect the other end of the communication cable to the personal

computer’s COM1 port. If the COM1 port is not available, refer to section

2.2.3 for information about selecting the correct communication port. The

personal computer COM port might have either a 25-pin or a 9-pin connector .

Refer to figure 2.1 for cable connector and pinout signals for 9-pin and 25-pin

.

configurations.

2-2

Personal Computer

25-pin Female

Data OUT

Data IN

Ground

Person al Com pute r

9-pin Female

Data OUT

Data IN

Ground

Figure 2.1 – RS-232 Cable Connector Pinouts for Drives with a 25-Pin Connector

- 3

- 2

- 7

- 3

- 2

- 5

Drive

25-pin Male

3 -

Data IN

2 -

Data OUT

7 -

Ground

Drive

25-pin Male

3 -

Data IN

2 -

Data OUT

7 -

Ground

WebPakCS Software V1.0

Page 15

2.2.2 Setting Up the Drive to Communicate with the Personal Computer

For the WebPakCS software to communicate with the drive, the drive’s operation

control source parameter must be set up properly. Set parameter P.000 to specify

serial communication. Refer to the WebPak 3000 Software Reference manual for

more information.

2.2.3 Selecting the Correct Communication Port

The WebPakCS software communicates with the drive through the personal

computer’s serial port. The software defaults to the COM1 port. If COM1 is already

being used, you must select another COM port. To change the COM port:

Step 1. Start the WebPakCS software.

Step 2. From the Options menu, select COM.

Step 3. Select the appropriate COM port from the options displayed in the dialog box.

Step 4. Select OK when the correct COM port is selected. This returns you to the

WebPakCS main window.

2.3 Starting the Software

Follow this procedure to start the WebPakCS software.

Step 1. From the Start menu, choose Programs | WebPakCS.

Step 2. Select an application type by one of the following methods:

• From the File menu, select Application T ype, or from the toolbar, click .

Then select the application type from the list box. (To build a configuration

using all of the parameters, select Generic as the application type.)

• From the File menu, select Open, or from the toolbar, click . Then

select a configuration file using the Open dialog box.

• From the Config menu, select Upload. The current drive configuration will

be uploaded.

2.4 About the Menus and Toolbars

Use the menus and toolbar to navigate through the software as described in the

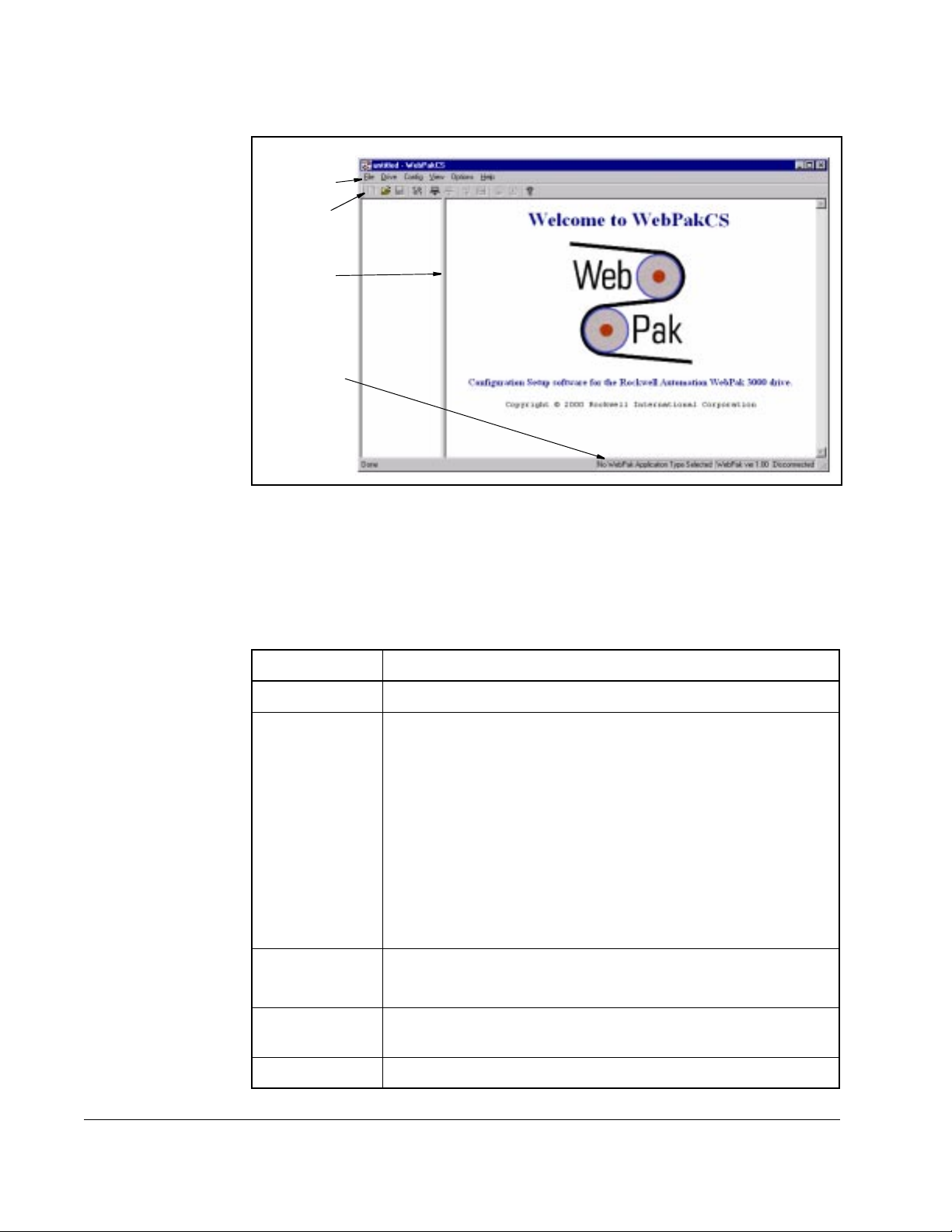

following sections. Figure 2.2 shows the WebPakCS Main Window. The main window

contains the main menu, toolbar, status bar, and two views separated by a splitter bar.

Getting Started

2-3

Page 16

.

Main Menu

Toolbar

Splitter Bar

Status Bar

Figure 2.2 – Sample Main Window for an Established Connection

2.4.1 About the Menus

Table 2.1 explains the WebPakCS software functions you can access through the

menus.

Table 2.1 – Overview of the Menu

Use this menu: To:

File Access application types and edit configuration files

Drive • Connect to and disconnect from the drive

• Control the drive

• View drive status and alarms

• Use the PC Scope

• Set parameters in the drive to the default values

• Save drive parameter values to the drive’s non-volatile

memory

• Restore values from the drive’s non-volatile memory to its

run-time memory

Config • Upload or download a configuration file

• Compare a configuration file

Option Choose the COM port on the personal computer which is being

used to connect to the drive.

2-4

Help Access the online help.

WebPakCS Software V1.0

Page 17

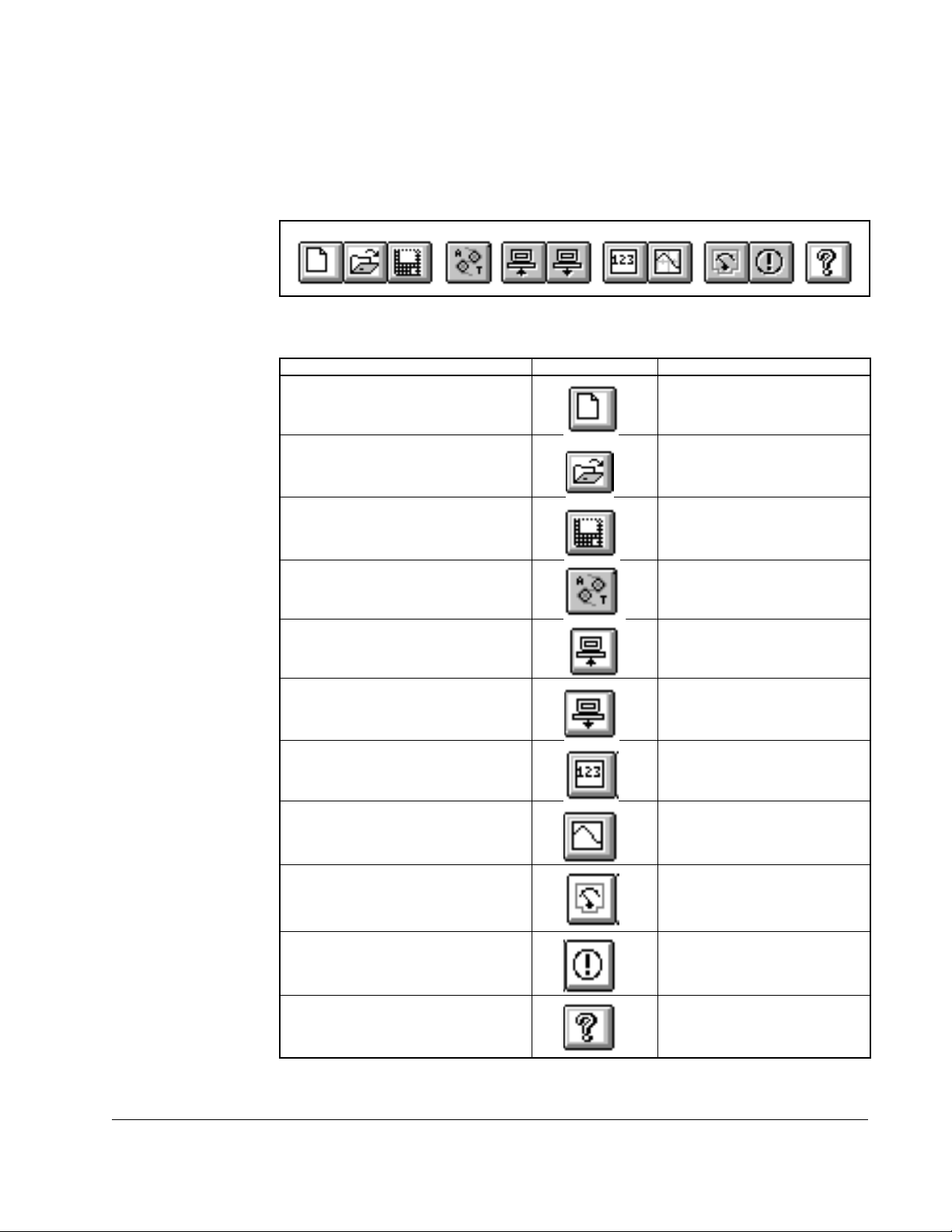

2.4.2 About the Toolbar

A graphical tool bar, displayed below the main menu in the main window, provides a

shortcut method for ex ecuting commonly-used main menu functions. Figure 2.3 shows

the toolbar, and table 2.2 lists the functions represented by each icon.

To: Use this icon: Or this menu command:

Create a new configuration file. File | New

Open a configuration file. File | Open

Save a configuration file. File | Save

Figure 2.3 – Graphical Tool Bar

Table 2.2 – Toolbar Icons and Menus

Select an application type File | Application type

Upload a configuration file from a

Config | Upload

drive.

Download a configuration file to a

Config | Download

drive.

Monitor drive parameters. Drive | Parameter Monitor

Access the PC Scope. Drive | PC Scope

Control the drive. Drive | Control

Display the drive’s fault and alarm

Drive | Fault/alarm

logs.

Access the on-line help. Help | Contents

Getting Started

2-5

Page 18

2.5 Exiting the WebPakCS Software

To exit the software, choose Exit from the File menu. Exit closes the WebPakCS

software. If you modified the open configuration, you are prompted to save the

changes to a configuration file.

2-6

WebPakCS Software V1.0

Page 19

Configuring the Drive

This chapter describes how to configure a WebPak 3000 drive.

3.1 Selecting an Application Type

The WebPak 3000 drive can be configured for nine different application types: eight

named applications and Generic. The application types are as follows:

• Constant Diameter Speed Regulator

• Variable Diameter Speed Regulator

• Constant Diameter Current Regulator

• Variable Diameter Current Regulator

• Constant Diameter Position Regulator

• Variable Diameter Position Regulator

• Constant Diameter Tension Regulator

• Variable Diameter Tension Regulator

• Generic

CHAPTER 3

To select an application type:

Step 1. From the File menu, select Application Type, or from the toolbar, click .

Step 2. A list box will be displayed. When you select an application type, the

application edit view is reset to the first screen in the application edit

sequence.

The application type you select determines which screens are displayed in the

Configuration Setup and Edit view (see figure 3.1). The named application types will

show only the parameters that are pertinent to that application type. If a specific

application type cannot be determined during file open or drive connect, then the

application type defaults to Generic.

The Generic application type is used to display screens which are not tailored toward

any particular application. The generic application screens make all input parameters

available for editing.

Configuring the Drive

3-1

Page 20

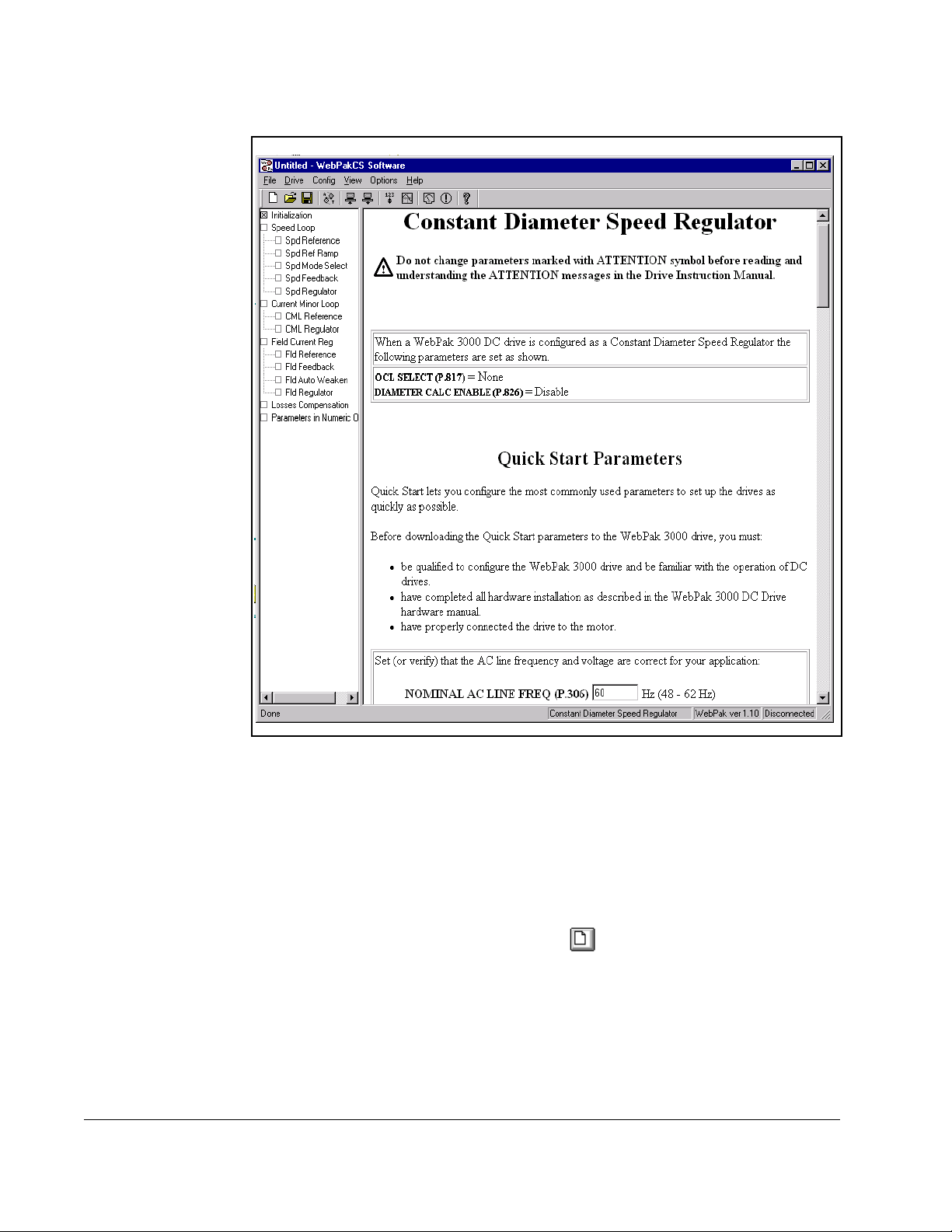

Figure 3.1 – Example of Configuration Setup and Edit View

3.2 Creating a New Configuration

You can create a new drive configuration, which sets the parameter values to their

defaults for the selected application. You assign a name to the configuration file when

you save it. See sections 3.5 and 3.6 for information about saving configurations.

To create a new configuration:

• From the File menu, choose New, or click .

If a configuration file is already open and has been changed, a dialog box is displayed

that asks if you want to save the current configuration file. If you select Yes, the Save

As dialog box is displayed before the new configuration file is opened.

When you select an application type, parameters that depend on the control type are

changed to their defaults. The control type determines which parameters are

displayed.

3-2

WebPakCS Software V1.0

Page 21

3.3 Opening a Drive Configuration File

Opening a drive configuration file loads the file from the personal computer to the

WebPakCS software. Once the configuration file is opened, you can download it to the

drive.

To open a configuration file:

Step 1. From the File menu, choose Open, or click .

Step 2. If you already have a configuration file open and have made edits to it that

have not been saved, you are prompted to save the changes. Make the

appropriate selection. See section 3.6 for more information about saving

configuration files.

The Open dialog box is displayed. An example is shown in figure 3.2.

Configuring the Drive

Figure 3.2 – Open Configuration File Dialog Box

Step 3. The Open dialog box defaults to the work directory of the WebPakCS

software, which was specified during installation. If this is not the correct

directory, select the directory where the file is stored.

Step 4. Select the name of the file you want to open. The name of the file should be

copied in the File Name box. If not, click on it again.

If the configuration file you want does not have the .wpc extension, it does not

show up automatically in the box under File Name. In this case, select *.* in

the List Files of Type box to display all of the available files in the File Name

list.

Step 5. Open the file by selecting OK. The name of the file you selected now appears

in the Opened Configuration field of the main window.

To close the dialog box without selecting a file, select Cancel.

3-3

Page 22

3.4 Editing a Configuration

Use the Configuration Setup and Edit function to create and edit drive configurations.

It provides drive application-specific entry and edit features. The Configuration Setup/

Edit window contains a combination of help information and user entry fields.

The setup and edit function provides the capability for you to move either sequentially

through all screens or to move directly to a portion of a previously completed setup for

the purpose of changing it.

You can move sequentially through the edit screens or move directly to a specific

screen by selecting it in the tree control list which is displayed in the left view. When

you select a section of the configuration, the appropriate setup window is displayed in

the right view. The tree control list contains only entries that are pertinent to the

particul ar dri ve applicat ion .

3.4.1 Example Configuration Setup/Edit Window

When the Setup/Edit window is opened, the application type you select determines

which Setup/Edit windows are displayed. If you open an existing configuration file, the

software will determine the application type based on the values of a set of "footprint"

parameters in the configuration file. If the configuration satisfies more than one

application footprint, then the application type will default to Generic.

Figure 3.3 shows an example of a Configuration Setup/Edit window.

3-4

Figure 3.3 – Example of a Configuration Setup/Edit Window

WebPakCS Software V1.0

Page 23

3.4.2 Application Edit Left View Operations

The left view contains a tree list of available right-view screens. The tree list in the left

view may or may not have collapsible nodes depending on the number of right-view

screens needed for applications. If there are collapsible nodes, then the operations in

the left view are as follows:

• Double-click on a collapsed node in the tree list to expand the node.

• Double-click on an expanded node in the tree list to collapse the node.

• Click on a node or leaf in the tree list to display the Setup/Edit window for the

selected area of the configuration.

3.4.3 Application Edit Right View Operations

Parameter entry fields consist of edit controls and combo boxes.

3.4.4 Ending an Editing Session

When you have finished editing parameters:

• Use the Save command from the File menu to save the edited configuration file to

disk.

or

• Use the Download command to write the edited configuration file to the drive.

If you select Cancel from the Configuration Editor, a message is displayed prompting

you to ignore the changes or accept them. If you ignore the changes, any new

parameter values entered during the editing session are ignored, and the session

ends.

3.5 Saving a Drive Configuration

Saving a file writes the open drive configuration to the configuration file that is shown

in the main window. This writes over the configuration file shown in the main window.

To save a file:

• From the File menu, choose Save, or click .

If the configuration file is “Untitled” or “Untitiled Upload,” the Save Configuration File

dialog box is displayed. Refer to section 3.6 for more information.

Configuring the Drive

3-5

Page 24

3.6 Saving the Open Drive Configuration to Another File

You can write the open drive configuration to a configuration file other than the one

shown in the main window. To do this:

Step 1. From the File menu, choose Save As. The Save Configuration File dialog box

is displayed, as shown in figure 3.4.

Figure 3.4 – Save Configuration Dialog Box

Step 2. Select the disk drive and directory where you want to store the configuration.

Selecting Network lets you access any mapped network drive.

Step 3. Specify the file name in the File Name field. Configuration file names must be

eight alphanumeric characters or fewer. The file name should have the

extension .wpc.

Step 4. Select OK to save the file. Select Cancel to close the dialog box without

saving.

3-6

WebPakCS Software V1.0

Page 25

3.7 Printing a Configuration

You can send a copy of the open configuration to a printer or to a text file. The printout

lists the configuration parameters and their assigned values.

To print a configuration:

Step 1. From the left view, select WebPak Parameters - Numerical Order.

Step 2. Click anywhere on the right view.

Step 3. From the File menu, choose Print, or click .

The standard Windows Print dialog box is displayed.

Figure 3.5 shows part of an sample printout.

Configuring the Drive

Figure 3.5 – Sample Configuration File Printout

3-7

Page 26

3-8

WebPakCS Software V1.0

Page 27

Uploading and Downloading Drive

This chapter describes how to upload, download, and compare drive configurations.

4.1 Uploading a Drive Configuration

You can upload the drive configuration from the connected drive to the personal

computer.

To upload a configuration:

Step 1. Make sure the personal computer is connected to the drive. Refer to sections

2.2 and 3.1 if you need instructions for connecting the personal computer to a

drive.

Step 2. From the Config menu, choose Upload or click .

CHAPTER 4

Configurations

Step 3. If a drive configuration is already opened, you are prompted to save that

configuration to a file. The open configuration (if any) is replaced by the

uploaded drive configuration.

After uploading the drive configuration, the open configuration is displayed as

“UNTITLED UPLOAD.”

Uploading and Downloading Drive Configurations

4-1

Page 28

4.2 Downloading a Configuration to the Drive

You can copy the opened configuration currently in the WebPakCS software to the

connected drive.

ATTENTION:The download command replaces the parameter values in

the drive with the parameter values from the open configuration. Only

!

Important: If WebPak 3000 parameter changes are disabled by the drive’s Program

To download an opened configuration to the connected drive, follow these steps:

Step 1. Make sure the personal computer is connected to the drive. Refer to sections

Step 2. Make sure the drive is stopped before downloading a configuration to the

Step 3. From the Config menu, choose Download, or click .

qualified personnel should develop and download drive configurations.

Read and understand the drive instruction manuals in their entirety

before downloading a configuration. Failure to observe this precaution

could result in severe bodily injury or loss of life.

Protection jumper (J16), you cannot write parameters to the drive.

2.2 and 3.1 if you need instructions for connecting the personal computer to a

drive.

drive.

Step 4. If the downloaded configuration contains parameter values that are out of

range for the drive, the software on the drive modifies these parameter

values to bring them within allowed ranges. If this occurs, a message box

asking if you want to do a Config Compare is displayed. This dialog box

displays the differences between the downloaded configuration and the

configuration currently in the drive.

4.3 Comparing the Drive Configuration to the Opened

Configuration

You can compare all of the parameter values in the opened configuration with the

parameter values in the drive. To compare the parameters in an open configuration

with those on the drive, follow these steps:

Step 1. Make sure the personal computer is connected to the drive. Refer to sections

2.2 and 3.1 if you need instructions for connecting the personal computer to a

drive.

Step 2. From the Config menu, choose Compare Drive.

4-2

WebPakCS Software V1.0

Page 29

Monitoring and Editing Drive

This chapter describes how to monitor and edit parameters using the Parameter

Monitor.

5.1 About the Parameter Monitor

Use the Parameter Monitor to view and edit parameter values in the connected drive.

You can also set up monitor lists to store your choices for future use. The Parameter

Monitor is not affected by and does not affect the opened configuration.

Important: If WebPak 3000 parameter changes are disabled by the drive’s Program

Protection jumper (J16), you cannot write parameters to the drive.

You cannot change parameter values in the opened configuration using the Parameter

Monitor. To copy changes made in Monitor into the opened configuration, you must

upload the drive configuration from the drive (refer to chapter 4).

CHAPTER 5

Parameters

To access the Parameter Monitor, choose Parameter Monitor from the Drive menu, or

click .

The first time you access the Par ameter Monitor, the window is blank. Use the Add,

Remove, Assign, and Save buttons at the top of the window to create a parameter list

that can be saved for future use. See the following sections for information about using

these functions.

When parameters are displayed in the Parameter Monitor window, the parameter

values are updated periodically from the drive.

Monitoring and Editing Drive Parameters

5-1

Page 30

You can select a parameter shown in the Monitor window by clicking the parameter

name, or by using PgUp, PgDn, and the arrow keys. The Remove and Assign

functions work on the selected parameter. Figure 5.1 shows an example of the

Parameter Monitor window.

Figure 5.1 – Parameter Monitor Window

The sections that follow describe the functions available when using the WebPakCS

Parameter Monitor function.

5-2

WebPakCS Software V1.0

Page 31

5.2 Adding Parameters to the Monitor List

You can add up to 20 parameters to the Monitor List. When you select Add, the Add

Parameters to Monitor List dialog box is displayed. The Sort By options let you display

the parameters by parameter number or by description (alphabetically). Figure 5.2

shows a sample Add Parameters to Monitor List dialog box.

Figure 5.2 – Add Parameters to Monitor List Dialog Box

To add parameters, follow these steps:

Step 1. Use the scroll bar or the arrow keys to move up and down the list of

parameters.

Step 2. Use the mouse or the spacebar to select the parameters you want to monitor.

You can select multiple parameters before choosing Add. You can select a

total of 20 parameters.

Step 3. Do one of the following:

• To add the parameters to the monitor list and continue to display the

dialog box, select Add.

• To add the parameters and return to the monitor window, select OK.

5.3 Removing Parame te rs from the Monitor List

To delete parameters from the Monitor List, follow these steps:

Step 1. Select the parameter you want to remove from the list.

Step 2. Click on the Remove button.

Important: You can clear all the parameters from a Monitor List by selecting Clear.

Monitoring and Editing Drive Parameters

5-3

Page 32

5.4 Assigning Values to Parameters in the Drive

The Assign button assigns a value to the selected parameter. The assigned value is

displayed on the Parameter List screen and can be sent to the drive.

Important: The Assign function is available only when you are connected to a drive.

You cannot assign parameter values unless you are connected to a drive.

If you are not connected to a drive, the parameter list displays “???” for all

parameter values.

When the drive is running, new values can be assigned only to tunable parameters.

For configurable parameters, the drive must be stopped before new values can be

assigned. Refer to the appropriate drive instruction manual to determine which

parameters are tunable.

When you select Assign or double-click on the parameters, a Parameter Assignment

dialog box is displayed. The options in this dialog box depend on the options for the

parameter.

5-4

WebPakCS Software V1.0

Page 33

If the parameter: The dialog box looks like this: Do the following:

can be set to any

value within a range

Enter the value in the box or

change the value by using the

scroll bar.

has limited options Click the arrow and select from

the options.

can be set through

the options or by

selecting a value

within a range

Click the arrow and select from

the options, or enter the value in

the box.

To send the new parameter value to the drive, choose the Send button. Send does not

exit the parameter Assignment dialog box, so you can continue to make adjustments

to the value of the selected parameter and monitor the effect on the drive.

When you have finished making adjustments to the value of a parameter, select OK to

send the parameter value to the drive and exit the Parameter Assign dialog box.

If you select Cancel, the parameter value that appears in the Parameter Assign dialog

box is ignored and the Parameter Assign dialog box is closed.

Monitoring and Editing Drive Parameters

5-5

Page 34

5.5 Saving a Monitor List

The Save command creates a file containing the list of parameter numbers you have

displayed in the parameter monitor. When you select Save, the Save Monitor List

dialog box is displayed as shown in figure 5.3.

To save a monitor list file, follow these steps:

Step 1. Select the drive and directory for the monitor list file.

Step 2. Enter a file name. The file name should include the extension .MON.

Step 3. Save the monitor list by selecting OK, or select Cancel to exit the dialog box

without saving.

5-6

Figure 5.3 – Save Monitor List Dialog Box

WebPakCS Software V1.0

Page 35

5.6 Displaying a Monitor List

To display a previously saved monitor list in the WebPakCS Parameter Monitor

screen, use the Recall button. The monitor list file must have been created and saved.

Any parameters currently being displayed in the Parameter Monitor are replaced by

the list of parameters read in from the monitor list file. Figure 5.4 shows the Recall

Monitor List dialog box.

Figure 5.4 – Recall Monitor List Dialog Box

Use the following steps to read and display a Monitor List file:

Step 1. Select the drive and directory path that contains the monitor list files.

Step 2. If the monitor list files were saved using a file extension other than .MON,

select *.* in the List Files of Type box to display all of the files.

Step 3. Enter a file name, or select the file name from the displayed list.

Step 4. To recall the file and display it in the Parameter Monitor window, select OK.

To close the dialog box without recalling the monitor list file, select Cancel.

5.7 Exiting the WebPakCS Parameter Monitor

To exit the monitor list and return to the WebPakCS main window, choose the Close

command from the WebPakCS Parameter Monitor window. If a parameter list is

displayed in Parameter Monitor and it has not been saved to a file, you are prompted

to save the list. See section 5.5 for inf ormation about saving monitor list files.

Monitoring and Editing Drive Parameters

5-7

Page 36

5-8

WebPakCS Software V1.0

Page 37

CHAPTER 6

Monitoring Drive Status and Alarms

This section describes how to monitor drive status indicators and alarms.

6.1 Displaying and Clearing the Fault Log and Alarm Log

You can display fault or alarm logs to help you troubleshoot problems.

To upload the fault log or alarm log from the drive, follow these steps:

Step 1. Make sure the personal computer is connected to the drive. Refer to chapters

2 and 3 for instructions about connecting the personal computer to a drive.

Step 2. From the Drive menu, choose Fault/alarm, or click .

The fault or alarm number, description, and time stamp is displayed in the list box. The

displayed log is updated about once a second with any new alarm or fault information.

Figure 6.1 shows a sample fault log while figure 6.2 shows a sample alarm log.

Monitoring Drive Status and Alarms

Figure 6.1 – Sample Fault Log List Box

6-1

Page 38

Figure 6.2 – Sample Alarm Log List Box

To switch between the fault and alarm list boxes, select the appropriate option for Log

Select.

The time stamp displays the time when the fault or alarm occurred. This time is from

the drive memory. See the WebPak 3000 OIM User Guide (D2-3445) for information

about the time stamp.

Table 6.1 describes how you can use the logs.

Table 6.1 – Using the Fault and Alarm Logs

To: Do the following:

Clear the fault or alarm log Select Clear.

The logged faults or alarms are deleted

from the log. This command clears only

the log that is currently displayed. Clear

does not reset drive faults or eliminate the

cause of the alarms; it simply clears the

log.

Reset the drive after a fault Select Stop/Reset in the Drive Control

window.

A reset command will be sent to the drive.

This command will not be available if the

WebPakCS software is not the control

source.

6-2

Exit the log window Select Close.

WebPakCS Software V1.0

Page 39

6.2 Restoring Default Values to Dri ve Parameters

You can restore the default values to all of the drive parameters that have defaults. To

do this:

• From the Drive menu, choose Restore defaults.

6.3 Saving Drive Parameter Values to Non-Volatile

Memory on the Drive

You can save the values of the drive parameters in the drive’s runtime memory to nonvolatile memory on the drive. To do this:

• From the Drive menu, choose Memory save.

6.4 Restoring Drive Parameter Values from Non-Volatile

Memory in the Drive

You can write the values stored by the Memory save command from non-volatile

memory on the drive into the drive’s runtime memory. To do this:

• From the Drive menu, choose Memory restore.

Monitoring Drive Status and Alarms

6-3

Page 40

6-4

WebPakCS Software V1.0

Page 41

CHAPTER 7

Controlling the Drive

This section describes how to control the drive using the WebPakCS software.

7.1 Controlling a Drive

ATTENTION:Only qualified electrical personnel familiar with the

construction and operation of the equipment and the hazards involved

!

Using the Drive Control dialog box, you can control the WebPak 3000 drive by:

• selecting the control source, reference mode, and motor rotation dir ecti on

• setting the drive reference

• starting and stopping the drive

• monitoring the drive indicators

To access the Drive Control dialog box, follow these steps:

Step 1. Make sure the personal computer is connected to the drive. Refer to section

should adjust or operate this equipment. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION:Do not run other Windows or DOS software applications

while you are using the WebPakCS software for drive control.

Unexpected machine motion could result. Failure to observe this

precaution could result in severe bodily injury or loss of life.

7.1 for information about establishing communication with the drive.

Controlling the Drive

Step 2. From the Drive menu, choose Control or click .

An Attention message is displayed.

Step 3. Make sure you understand this message, then select OK to display the Drive

Control window. Figure 7.1 shows an example of a Drive Control window.

7-1

Page 42

Figure 7.1 – Drive Control Window

You can also access other WebPakCS software functions while the Drive Control

window is on the screen. The Drive Control window remains open until you close the

window (by selecting the Close button) or exit the WebPakCS software.

The following sections describe how to use the Drive Control window to control a

drive’s functions.

Important: If a running drive that is being controlled by the WebP akCS software loses

communication with the software, a serial fault occurs and the drive stops.

If the running drive is being controlled by its front-panel and

communication with the software is lost, the message “Disconnected”

appears in the main window status bar.

7.2 Selecting the Contr ol Sou rce

You can select one of the following as the control source for the drive:

• Local

• Terminal Strip

•Serial

•Network

7-2

WebPakCS Software V1.0

Page 43

You must select Serial to control the drive using the Drive Control window. If an y other

control source is selected, you can only monitor the drive functions displayed in the

Drive Metering window or reset faults and alarms. All of the other drive commands on

the Drive Control screen are disabled.

7.3 Setting the Line Spee d Reference

The Line Speed Reference box lets you set the drive reference.

Set the line speed reference by:

• moving the scroll bar to change the reference value and automatically send the

value to the drive, or

• entering a new value in the edit box and selecting the Set button to send the

reference value to the drive

7.4 Setting the Jog Referenc e

The Jog Reference box lets you set the jog reference. The valid values are the same

as for the line speed reference. To do this:

Step 1. Click in the Jog reference box and type a new value.

Step 2. Press the Jog Set button.

Controlling the Drive

7-3

Page 44

7.5 Starting and Stopping the Drive

Use the Run, Jog, and Stop/Reset buttons as follows:

To send this command to the drive: Press: Description:

Tension the web Tension On Engages the tension loop. The motor will turn

until slack is out of the web, then wait for

Section Run command.

This control is disabled if the WebPakCS

software is not the control source or if

OCL SELECT (P.817) is set to NONE.

Start Section Run Starts the drive. The motor will ramp up to the

selected line speed reference.

This control is disabled if the WebPakCS

software is not the control source.

Jog forward

Jog reverse

Stop STOP - Section off This control is always enabled, regardless of

Jog Fwd

Jog Rev

The drive will jog while the button is pressed.

Releasing the button sends a stop command

to the drive.

These cont rols ar e di sab led if th e WebPak CS

software is not the control source.

the control source.

7.6 Monitoring Drive Indicators

The Drive Metering box displays five drive indicators for WebPak 3000 drives:

• Selected reference

• Motor speed

• Armature volts

• Motor current

• Percent load

Each drive metering value is displayed as a visual thermometer-type indicator and as

a numeric value. If the numeric value exceeds the range of the indicator, the indicator

moves slightly beyond the far right line in the indic ator gr id .

7-4

WebPakCS Software V1.0

Page 45

This section describes how to use the PC Scope.

8.1 About PC Scope

Use PC Scope to plot drive signals. PC Scope displays the plotted values as a trace.

The type of signals you can acquire depends upon the drive you have connected.

With PC Scope, you can:

• acquire traces of up to two signals at a time

• capture a trace and save it as a snapshot, which you can then compare to a newly

acquired trace

• define a trigger for the traces and specify how much data is gathered and

displayed before the trigger condition

• define a data sampling rate and the number of samples to capture for a given

trace

CHAPTER 8

Using PC Scope

• define a color for each to help you discern traces and trace snapshots

Figure 8.1 shows the PC Scope screen. The screen has its own toolbar and status

window. Table 8.1 explains the PC Scope toolbar buttons.

Using PC Scope

8-1

Page 46

Trace Display Window

Trace aquisition

radio buttons

Tool Bar

T1, T2 position

Aquisition status

Figure 8.1 – The PC Scope Screen

File name

8-2

WebPakCS Software V1.0

Page 47

Table 8.1 – PC Scope Toolbar Buttons

To: Use this button: Or this menu command:

Clear the trace setup, display ,

File | New

and data.

Open a saved trace file. File | Open

Save the currently displayed

File | Save

trace data, set up, and the

snapshots as a trace or ASCII

file.

Open the Trace Signal Setup

Trace | Setup

dialog box.

Zoom the trace display to the

View | Zoom In

area bounded by the cursors.

Redisplay the trace in the

View | Zoom X1

normal view.

Using PC Scope

Turn cursors on or off. View | Cursors

Turn cursor tracking on or off. Cursor | Track

Access the online help. Help

8-3

Page 48

To begin using PC Scope, follow these steps:

Step 1. Set up the trace by clicking and defining the trace information. (See

section 8.2 for more information.)

Step 2. Choose how to acquire the trace data. (See section 8.3 for more information.)

8.2 Setting Up a Trace

Before you can acquire any trace data, you must set up the trace by:

• specifying the signals for the trace(s) (See section 8.2.1.)

• setting up data sampling (See section 8.2.2.)

• setting up the trigger (See section 8.2.3.)

Set up a trace by using the Trace Signal Setup dialog box. To access this dialog box:

• From the Trace menu, choose Setup or click .

Figure 8.2 shows the Trace Signal Setup dialog box.

8-4

Figure 8.2 – Trace Signal Setup Dialog Box

WebPakCS Software V1.0

Page 49

8.2.1 Specifying Signals

Use the Traces group box in the Trace Signal Setup dialog box to specify the signal for

each trace.

To specify a signal, follow these steps:

Step 1. Select the drive signal whose values you want to plot as a trace. The

available signals are determined by the type of drive that is connected.

• Choose the signal or None to be used for Trace A by using the Channel A

list box.

• Choose the signal or None to be used for Trace B by using the Channel B

list box.

Step 2. Choose the type of scale you want to use for each trace.

.

To: Do the following:

Use rounded units per division

values based on the data in the

trace waveform

Specify actual trace vertical axis

minimum and maximum values

Use the scale for Trace A as the

scale for Trace B

8.2.2 S et ting Up Data Sampling

Use the Data sampling group box in the Trace Setup dialog box to define how the

signal data is to be sampled. The settings apply to both traces. To set up data

sampling, follow these steps:

Select the Auto Scale option for the trace you

are defining.

The difference between the minimum and

maximum values in the trace data is

determined from the waveform data, and the

values are rounded up to the next whole

value. For example, a value of 1.763 is

rounded to 2.

The minimum and maximum values are also

set to values beyond the actual values in the

trace waveform data.

Enter the vertical axis minimum and maximum

values in the Min and Max boxes for the trace

you are defining.

Select the option: Use chan A scale.

Using PC Scope

Step 1. Choose how often you want to acquire signal data by choosing a sampling

rate. Choose from 0.5 ms to 10 s.

Step 2. Choose the number of data samples in the trace. Choose a value from 1000

to 100.

Once you select the sample rate and number of samples, the amount of time

for the acquisition is displayed.

8-5

Page 50

8.2.3 S et ting Up the Trigger

Use the Trigger and Trigger delay/position group boxes in the Trace Signal Setup

dialog box to define a trigger that will begin a data acquisition. You do not need to set

up a trigger if you plan to use Auto or Manual to acquire traces. See section 8.3 for

more information.

To set up trigger, follow these steps:

Step 1. Choose a drive signal you want to use as a trigger from the Signal list box.

Step 2. Choose the trigger operation (if desired) that causes the trigger condition by

using the Operation list box. The available trigger operations are determined

by the drive type. Some examples of trigger operations are: less than, greater

than, and equal to.

Step 3. Choose a trigger level that is to be used by the trigger operation. The units

and normalization depend upon the trigger signal.

Step 4. Choose a trigger position or delay by selecting the appropriate option and

entering a value.

To: Choose:

specify how many samples are displayed in the trace before

and after the trigger.

For a trigger position of zero percent, the trigger is at the

beginning of the trace (all samples displayed were acquired

after the trigger). For a trigger position of 100%, the trigger is

at the end of the trace, a position of 50% is in the center, etc.

specify the amount of time between the trigger and the

beginning of data acquisition.

The delay is measured in seconds.

Position

Delay

8-6

WebPakCS Software V1.0

Page 51

8.3 Acquiring a Trace

Once you set up a trace, you must define how the trace is to be acquired. A trace can

be acquired:

• continuously, regardless of a trigger condition

• continuously or once, as specified by a defined trigger

Use the Trace menu or the radio buttons in the toolbar to define how a trace is to be

acquired.

To:

From the Trace menu, choose this

option, or click on this radio button:

Continuously acquire trace data by

sending a manual trigger.

The trigger setup has no effect on the

trace acquisition.

Acquire trace data by sending a

manual trigger to the drive.

The trigger setup has no effect on the

trace acquisition.

Continuously acquire trace data

based on the trigger setup.

After the trace is uploaded and

displayed, the trace acquisition is reenabled, and the cycle starts over.

Trace data is acquired until you

change the trace acquisition

selection.

Acquire a trace based on the trigger

setup.

The trace data is acquired when the

trigger condition has been reached.

Stop a trace acquisition in progress.

If an acquisi tion is no t in pro gre ss, t he

trace display is frozen as it is.

Auto

Manual

Normal

Single

Hold

Using PC Scope

Figure 8.3 illustrates an acquired trace.

8-7

Page 52

T race ma x.

value

Values at

the cursor

Actual data

points

Trace min..

value

V alues at the T cursor location

Figure 8.3 – Sample Trace

8.4 Working with the Cursors

Cursors help you read the value at a specific point on a trace waveform to help you

tune and troubleshoot the drive. PC Scope has two cursor types:

• Y cursors are positioned on a vertical value on the display

• T cursors are positioned on a horizontal or time value

You can read actual data points where the waveform crosses the T cursors. These

values are labeled as@T1 and @T2. Because these are actual data points, you can

use them for calculations. The Y cursor values are based on the scale of the trace

display, so the value is determined by the display resolution and are not as accurate

as the actual data points displayed as the @T1 and @T2 values.

8-8

WebPakCS Software V1.0

Page 53

8.4.1 Moving a Cursor

You can select a cursor by:

• clicking on the cursor label with the mouse

• using the Cursor menu

• using the [Tab] key

Move the cursors by:

• using the up, down, right, and left arrow keys or Shift + arrow key

• clicking on the label with the mouse and dragging the cursor

8.4.2 Specifying the Cursors To Track Each Other

You set the cursors to track together when you move them. This way the cursors can

move left and right and up and down while maintaining the same distance between T1

and T2 or Y1 and Y2.

To set the T and Y cursors so they track together:

• From the Cursor menu, choose Track or click .

Turning track off lets you move the T cursors independently from each other and the Y

cursors independently from each other. Cursor tracking can be turned on and off by

toggling the menu selection or toolbar button.

8.5 Changing Views

You can turn the cursors on and off and magnify the trace display as described in the

following sections.

8.5.1 Turning Cursors On and Off

You can choose to show or not the show the cursors on the trace display.

To turn cursors on or off:

• From the View menu, choose T Cursors or click .

• From the View menu, choose Y Cursors or click .

You cannot use the Zoom feature if the cursors are off.

8.5.2 Turning Grids On and Off

You can choose to show or not the show the grids on the trace display.

To turn grids on or off:

From the View menu, choose Grids.

Using PC Scope

8-9

Page 54

8.5.3 Magnifying the Trace Display

You can magnify the area of the trace display that is bounded by the cursors.

To magnify the display:

• From the View menu, choose Zoom In or click .

To return the display back to the normal view:

• From the View menu, choose Zoom X1 or click .

If you selected the Auto Scale option in the Trace Setup dialog box the PC Scope

scales ten vertical axis to even values. This may result in no change when you zoom

into the trace.

8.6 Taking a Trace Snapshot

You can compare one trace with another by saving trace data and displaying it as a

background for the next trace. This saved trace data is called a snapshot. You can

take a snapshot of either trace A or B or both. Also, you can choose a color to use for

displaying trace snapshots (see section 8.6.2).

8.6.1 Taking a Snapshot

To save a trace and have it displayed as the background for subsequent traces, do the

following:

:

From the Snapshot

To:

Save the current Trace A as a

snapshot.

Save the current Trace B as a

snapshot.

Save both Trace A and Trace

B as snapshots.

Clear the snapshots. Clear The snapshot traces are

menu, choose: Result:

Trace A This trace appears as

the background for the

next Trace A.

Trace B This trace appears as

the background for the

next Trace B.

Trace A & B The traces appear in the

background for the next

traces.

removed from the

background.

8-10

WebPakCS Software V1.0

Page 55

8.6.2 Choosing the Trace Snapshot Colors

You can choose the color that is used to display the snapshots of Trace A or Trace B.

Keep in mind that the trace display window is displayed using the Windows menu

background color, so be careful not to display trace snapshots in the same color, or

the trace will not show up.

To choose a color for a trace snapshot, follow these steps:

Step 1. From the Options menu, choose SnapA Color or SnapB Color.

The color selection dialog box is displayed.

Step 2. Select a standard color or create a custom color and click OK.

Traces can be displayed only in solid colors. If you choose a mixed color, the nearest

solid color is used.

8.7 Saving a Trace File

You can save a trace as either a trace file (.TRC) or an ASCII file (.TRA). Saving a

trace as an ASCII file lets you import the data into another program such as a

spreadsheet program.

Use the Save As command to save the file with a new name. To save a trace file,

follow these steps:

Step 1. From the File menu, choose Save or Save As.

The Save Signal Trace File dialog box is displayed. An example is shown in

.

figure 8.4.

Using PC Scope

Figure 8.4 – Save a Signal Trace File Dialog Box

8-11

Page 56

Step 2. In the File name field, type the name for the file.

Step 3. From the Save as type list box, choose whether you want to save the file as a

Trace file (.TRC) or as an ASCII file (.TRA).

Step 4. From the Save in list box, specify the location where you want to sav e the file.

Step 5. Click OK to save the file.

8.8 Clearing the Trace Display and Setup

You can clear the trace display and setup. To do this:

• From the File menu, choose New or click .

Creating a new trace file deletes any acquired trace data and clears the trace

display.

8.9 Opening a Trace File

You can open a previously saved trace file. To do this, follow these steps:

Step 1. From the File menu, select Open or click .

If you already have a configuration file open and made edits to it that have

not been saved, the software prompts you to save the changes. Make the

appropriate selection. See section 3.5 for more information about saving

configuration files.

The Open Signal Trace File dialog box is displayed. An example is shown in

figure 8.5.

8-12

Figure 8.5 – Open Signal Trace File Dialog Box

WebPakCS Software V1.0

Page 57

Step 2. The Open Signal Trace File dialog box defaults to the working directory of the

WebPakCS software, which was specified during installation. If this is not the

correct directory, select the directory where the file is stored. Select the name

of the file you want to open by double-clicking it with the mouse. The name of

the file should be copied in the File Name box. If not, click it again.

Step 3. Select OK to open the file. To close the dialog box without selecting a file,

select Cancel.

8.10 Closing PC Scope

Close PC Scope by choosing Close from the File menu.

Using PC Scope

8-13

Page 58

8-14

WebPakCS Software V1.0

Page 59

CHAPTER 9

Troubleshooting

This section describes basic troubleshooting information.

9.1 Using Error Messages

An error message might be displayed on the screen while you are using the

WebPakCS software. In most cases, you should be able to correct the error condition

by f ol lo win g t he c ours e of ac tio n de sc ribed by the error mes sage . Ho w e ver, if t he err or

message is preceded by an error number, in the format:

<description>

this case, write down the error and the error number, and contact Reliance Electric.

, this indicates an error that might require assistance to correct. In

9.2 Getting Assistance from Reliance Electric

If you have any questions or problems with the products described in this instruction

manual, contact your local Reliance Electric sales office.

For technical assistance, call 1-800-726-8112.

Error <number>

Troubleshooting

9-1

Page 60

9-2

WebPakCS Software V1.0

Page 61

INDEX

A

About the WebPakCS Software, 1-1

cables, 1-2

exiting the software, 2-6

hardware requirements, 1-2

intended audience, 1-3

menus, 2-4 to 2-5

overview, 1-1

purpose of this manual, 1-3

safety information, 1-3

software requirements, 1-1

starting the software, 2-4

terms used in this manual, 1-4

toolbars, 2-4 to 2-6

where to find additional information, 1-4

Additional information, 1-4

Audience, 1-3

Auto Scale, 8-5

ASCII, 8-11

C

Cables, 1-2

Communication, set up

connecting the serial port, 2-2 to 2-3

selecting the communication port, 2-4

Configuring the Drive

comparing the drive configuration to the

opened configuration, 4-2

creating a new configuration, 3-2

downloading a drive configuration, 4-2

editing a configuration, 3-7 to 3-5

assigning parameter values, 3-4 to 3-5

ending an editing session, 3-5

entering and editing a configuration de-

scription, 3-5 to 3-6

icons, 2-5 to 2-6

opening a drive configuration file, 3-3

printing a configuration, 3-7

saving a drive configuration, 3-5

saving the open drive configuration to another

file, 3-6

selecting an application type, 3-1

uploading a drive configuration, 4-1

Controlling the Drive

controlling a drive, 7-1 to 7-2

icons, 2-5 to 2-6

monitoring drive indicators, 7-4

selecting the control source, 7-2 to 7-3

setting the,

jog reference, 7-3

line speed reference, 7-3

starting and stopping the drive, 7-4

Cursors, 8-8

D

Description

configuration, 3-7

Drive Parameters

adding to monitor list, 5-3

assigning values, 5-4 to 5-5

displaying a monitor list, 5-7

exiting the monitor, 5-7

overview, 5-1 to 5-2

removing from monitor list, 5-3

saving a monitor list, 5-6

E

Editing

a configuration, 3-4 to 3-5

assigning parameter values, 3-4 to 3-5

ending an editing session, 3-5

drive parameters, 5-4 to 5-5

assigning values, 5-5 to 5-6

removing, 5-3

trace file,

acquiring, 8-7

clearing the trace display and setup, 8-12

changing views, 8-9 to 8-10

opening a trace file, 8-12

saving a trace file, 8-11

Error messages, 9-1

G

Getting assistance from Reliance Electric, 9-1

Index

Index-1

Page 62

I

Installation

setting up communication, 2-2 to 2-4

Windows 95/NT, 2-1

moving a cursor, 8-9

specifying the cursors to track each other,

8-9

Printing

drive configuration, 3-7

J

Jog

forward, 7-4

reference, 7-3

reverse, 7-4

M

Monitoring Drive Parameters, 5-1 to 5-7

Monitoring Drive Status and Alarms

displaying and clearing the fault log and alarm

log, 6-1 to 6-3

Menus, 2-4 to 2-5

N

Non-volatile memory, 6-4

P

Parameter Values

adding, 5-3

comparing, 4-3

PC Scope

acquiring a trace, 8-7 to 8-8

clearing the trace display and setup, 8-12

closing the PC Scope, 8-13

changing views, 8-9 to 8-10

icon, 2-6

magnifying the trace display, 8-10

opening a trace file, 8-13

overview, 8-1 to 8-4

saving a trace file, 8-11

setting up a trace, 8-4 to 8-6

specifying signals, 8-5

setting up data sampling, 8-5

setting up the trigger, 8-6

taking a trace snapshot, 8-10

taking a snapshot, 8-10

choosing the trace snapshot colors, 8-11

turning cursors on and off, 8-9

working with cursors, 8-8 to 8-9

R

Restoring,

default values to drive parameters, 6-4

drive parameter values from non-volatile

memory on the drive, 6-4

Requirements

hardware, 1-2

software, 1-1

RS-232, 1-2, 2-2 to 2-3

S

Safety, 1-3

Saving

drive configuration, 3-5, 3-6

drive parameters, 5-5

icon, 2-6

monitor list, 5-6

to another file, 3-6

trace file, 8-11

Section off command, 7-4

Section on command, 7-4

Setup

communication, 2-2 to 2-4

jog reference, 7-3

line speed reference, 7-3

trace, 8-4

windows, 2-1

Snapshot, 8-10

Start command, 7-4

Stop command, 7-4

T

Tension on command, 7-4

Terms used in this manual, 1-4

Toolbars, 2-5 to 2-6, 8-3

Trace files

acquiring, 8-7

clearing the display and setup, 8-12

magnifying, 8-10

opening, 8-12

saving, 8-11

Index-2

WebPakCS Software V1.0

Page 63