Page 1

Visualization Solutions

PanelView Terminals (including ArmorView Plus 7 Terminals) and

Industrial Computers, Monitors, and Thin Clients

Selection Guide

Original Instructions

Page 2

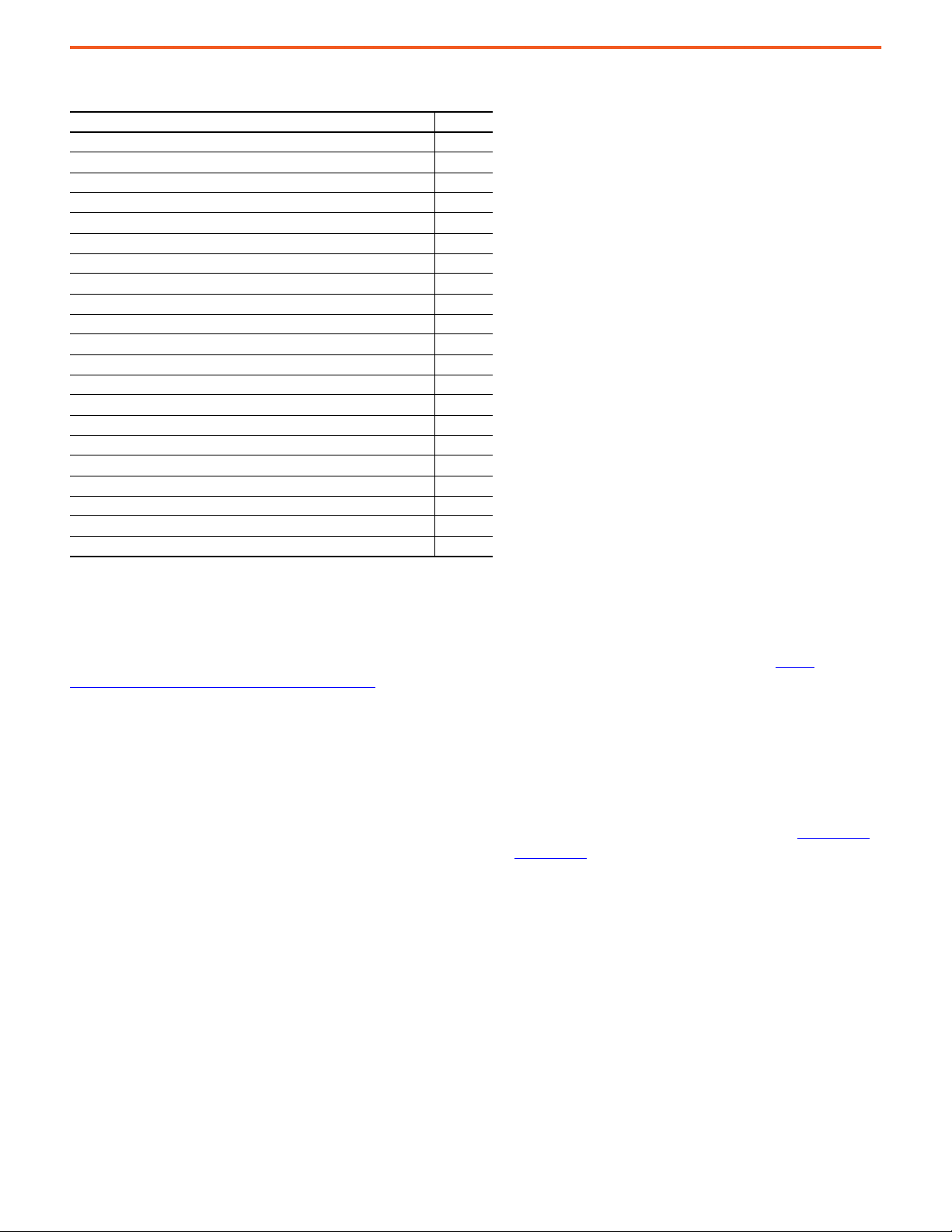

Visualization Solutions Selection Guide

What’s Inside

Top ic Pa ge

What’s New 2

Add Visualization to Your Control System 3

PanelView 5310 Terminals 17

PanelView 5510 Terminals 19

ArmorView Plus 7 Terminals 21

PanelView Plus 7 – Performance Terminals 23

PanelView Plus 7 – Standard Terminals 27

PanelView Plus 6 – 700, 1000, 1250, and 1500 Terminals 29

PanelView Plus 6 – 400 and 600 Terminals 33

PanelView Plus 6 – Compact Terminals 35

MobileView Tethered Operator Terminals 37

PanelView 800 Terminals 39

PanelView Terminal Accessories 41

VersaView 5000 Computers 59

6181P Integrated Display Computers 63

Hazardous Location Computers 69

Non-display Computers 71

VersaView 5100 Monitors 73

Industrial Monitors 75

Industrial Computer Accessories 77

HMI Software 85

This selection guide is meant to help you make initial decisions for the visualization products that are best suited for your system

requirements. For detailed technical specifications, certifications, and environmental specifications, see the documentation links on the

front cover of this selection guide.

For assistance and validation in final product selections, consider using the Configuration and Selection tools available at http://

www.rockwellautomation.com/en/e-tools/index.html.

What’s New

To help you optimize productivity, Rockwell Automation is expanding its product line by introducing the conformal coating option for all

PanelView® 5310 and 5510 terminal sizes. For more information about these terminals, including complete technical specifications,

certifications, and environmental specifications, see the PanelView 5310 Terminals Specifications Technical Data, publication 2713P-TD001

and the PanelView 5510 Terminals Specifications Technical Data, publication 2715P-TD001

.

,

2 Rockwell Automation Publication VIEW-SG001Z-EN -P - May 2020

Page 3

Add Visualization to Your Control System

As a machine builder or end user, you design control solutions with an eye toward how to improve safety, achieve higher

levels of performance and efficiency, and better integrate with the rest of the manufacturing operation. To achieve these

goals, you need a scalable, modular control system that offers safety, throughput, and information management capabilities

to match the requirements of each application.

Visualization products from Rockwell Automation comprise a suite of scalable HMI software and operator interface hardware

that provide plant floor machine operators, supervisors, engineers, and business managers a window to critical data and

production and process information. All of this information can be obtained from the plant floor and displayed on a local HMI

or remotely on a web browser.

Whether it’s a machine-level or site-level HMI, a Windows CE platform, a smaller component HMI, or an industrial computer,

Rockwell Automation has a portfolio of visualization solutions to match your system requirements. Use the following tables

to help you decide which products to use.

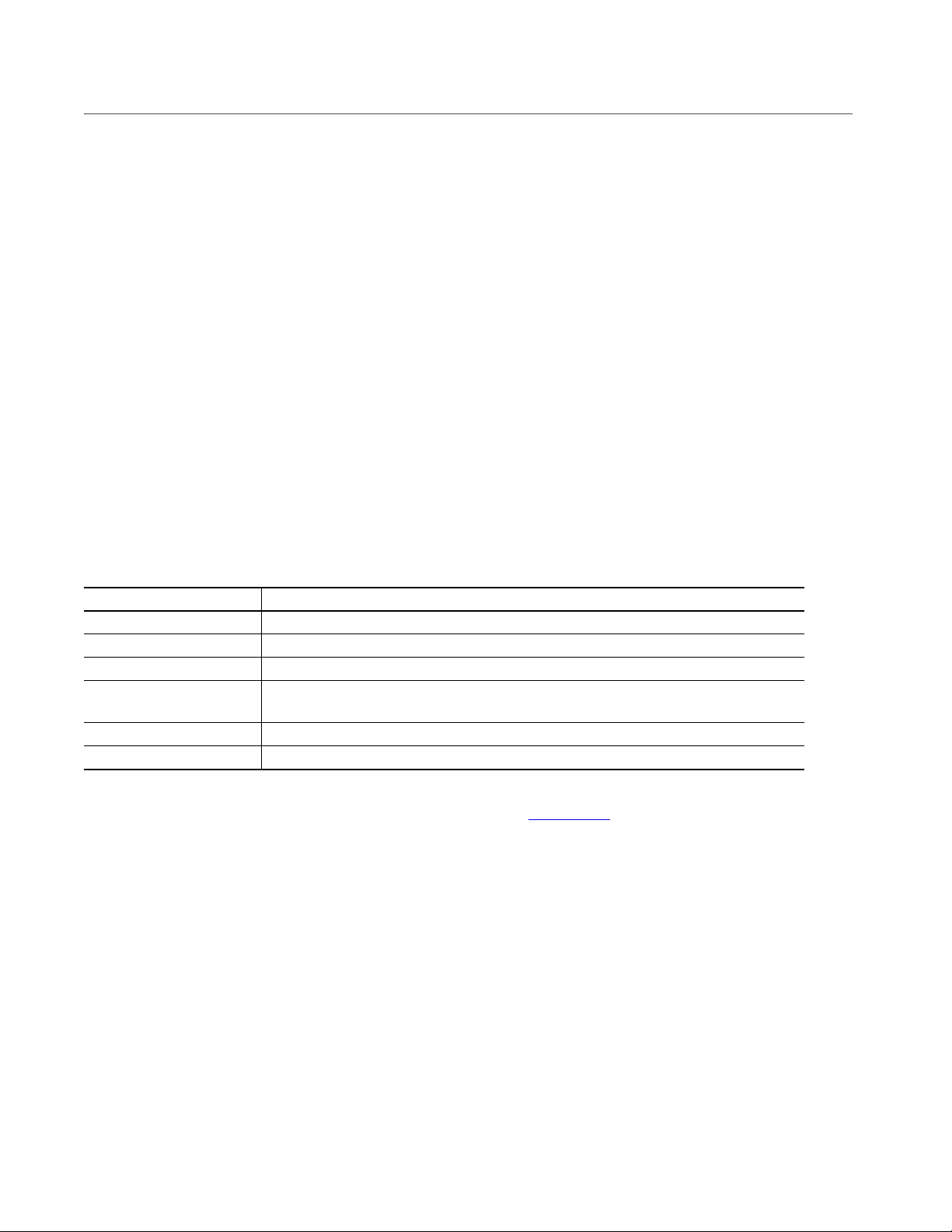

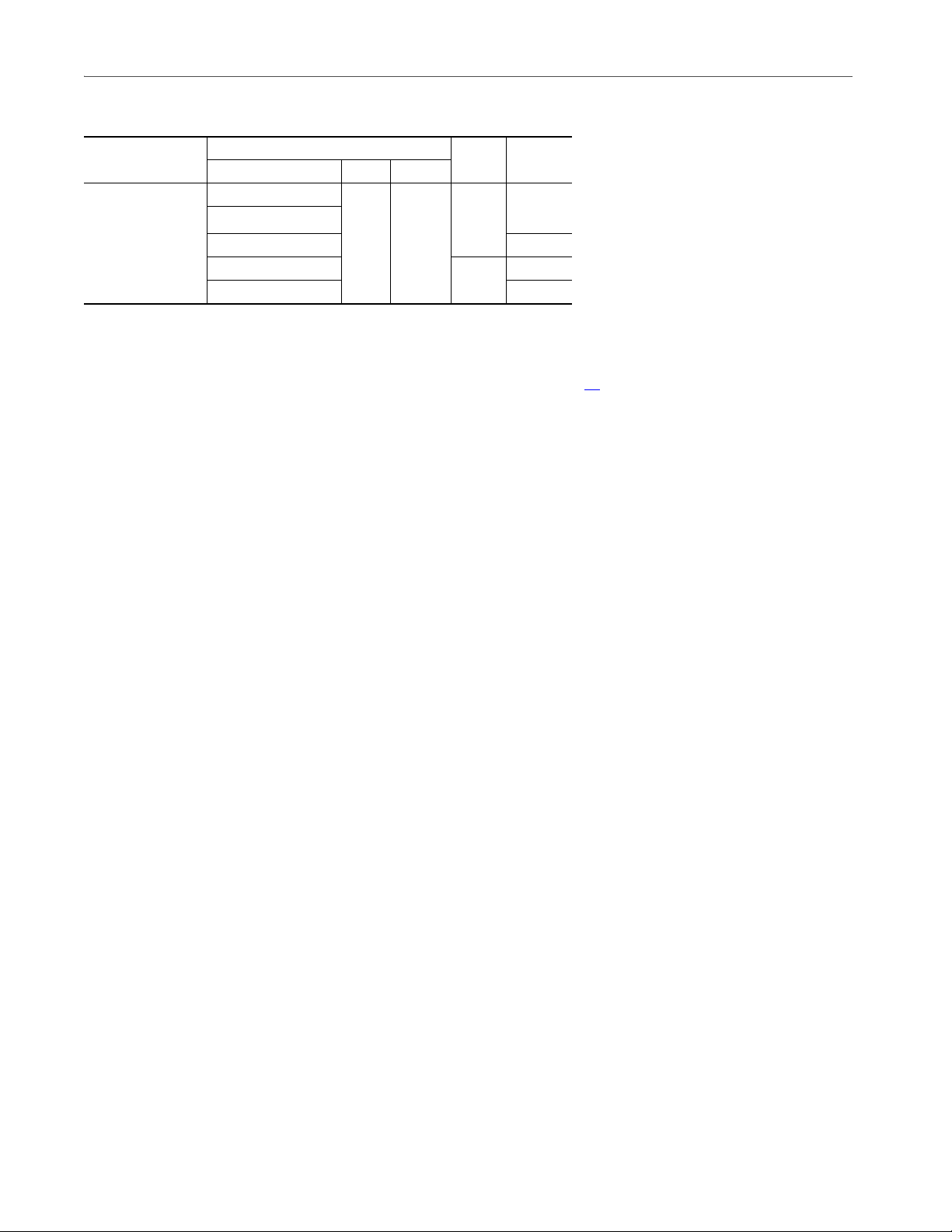

To control a machine, consider these options To control a site, consider these options

If you want to use… Consider this product line… If you want to use… Consider this product line…

Open architecture with your own software: VersaView® 5200 Thin Client Display-only Monitors VersaView 5100

6176M

6186M

Small or Medium Computers VersaView 5400 Thin Client VersaView 5200 Thin Client

Large Computers 6181P or 6177R Small or Medium Computers VersaView 5400

Hazardous Location Computers 6181X Large Computers 6181P or 6177R

Display-only Monitors VersaView 5100

6176M

6186M

Small HMI Systems PanelView® 5310

PanelView 800

PanelView Plus 7 Standard

PanelView Plus 6 Compact

Medium or Large HMI Systems PanelView Plus 6

ArmorView™ Plus 7

Panelview Plus 7 Performance

PanelView 5510

Mobile View

Hazardous Location Computers 6181X

In addition, consider the following questions, along with the PanelView Terminal Comparison table on page 4

configuration diagrams beginning on page 10

, to guide your selection:

• Which controller and communication network are you connecting to?

• Which development environment (runtime version) does the terminal need to support?

• Which terminal size and screen count do you need?

• How many controllers and alarms do you need?

• Which features are required and desired?

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 3

, and the

Page 4

Add Visualization to Your Control System

PanelView Plus 6

PanelView Plus 6

PanelView Plus 7

Compact

(End of Life)

(End of Life)

Mobil eView™ PanelVi ew 800

Standard

25/1/200

Yes Yes

(5)

and CPU)

No limit (based on memory

50/1/400

and CPU)

No limit (based on memory

(4)

100/1/500

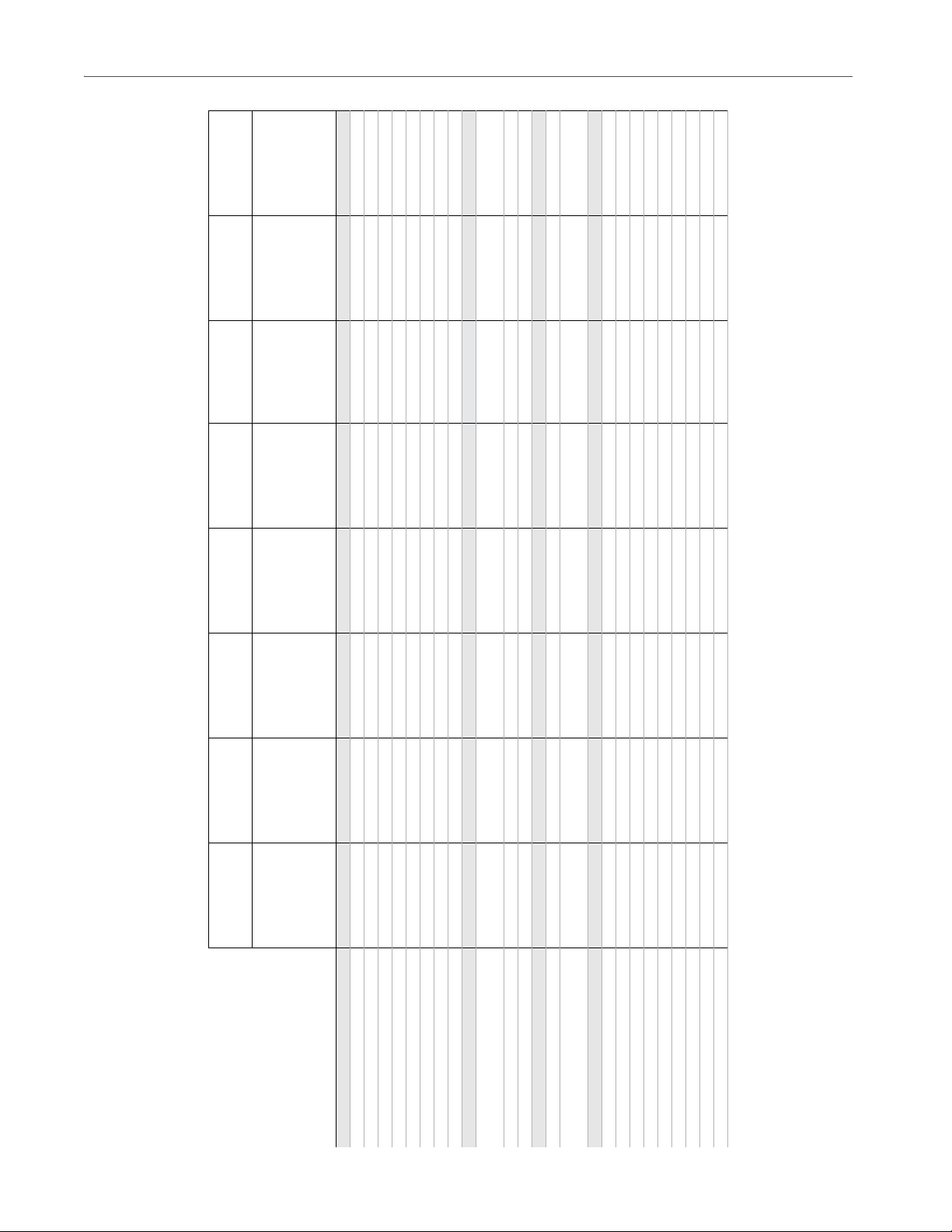

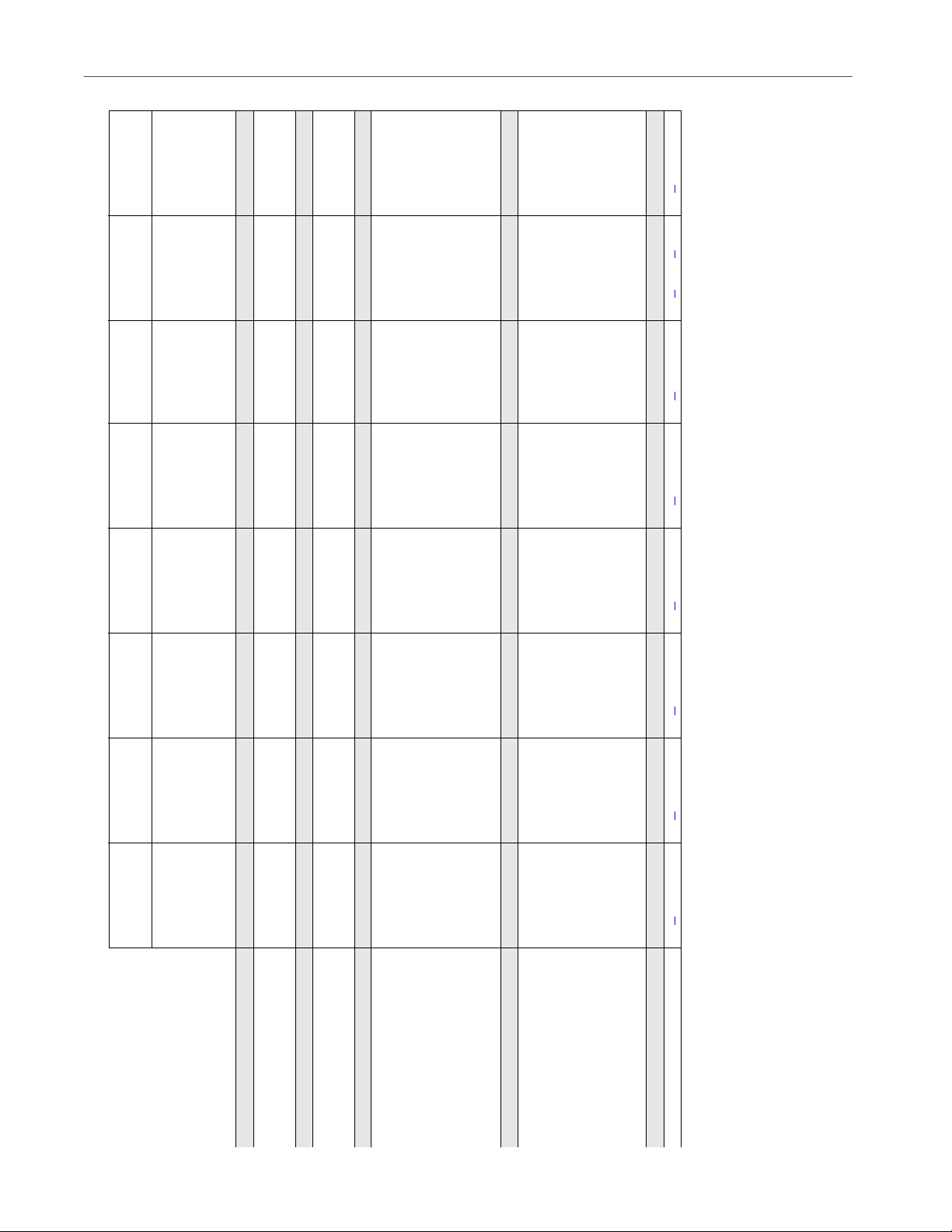

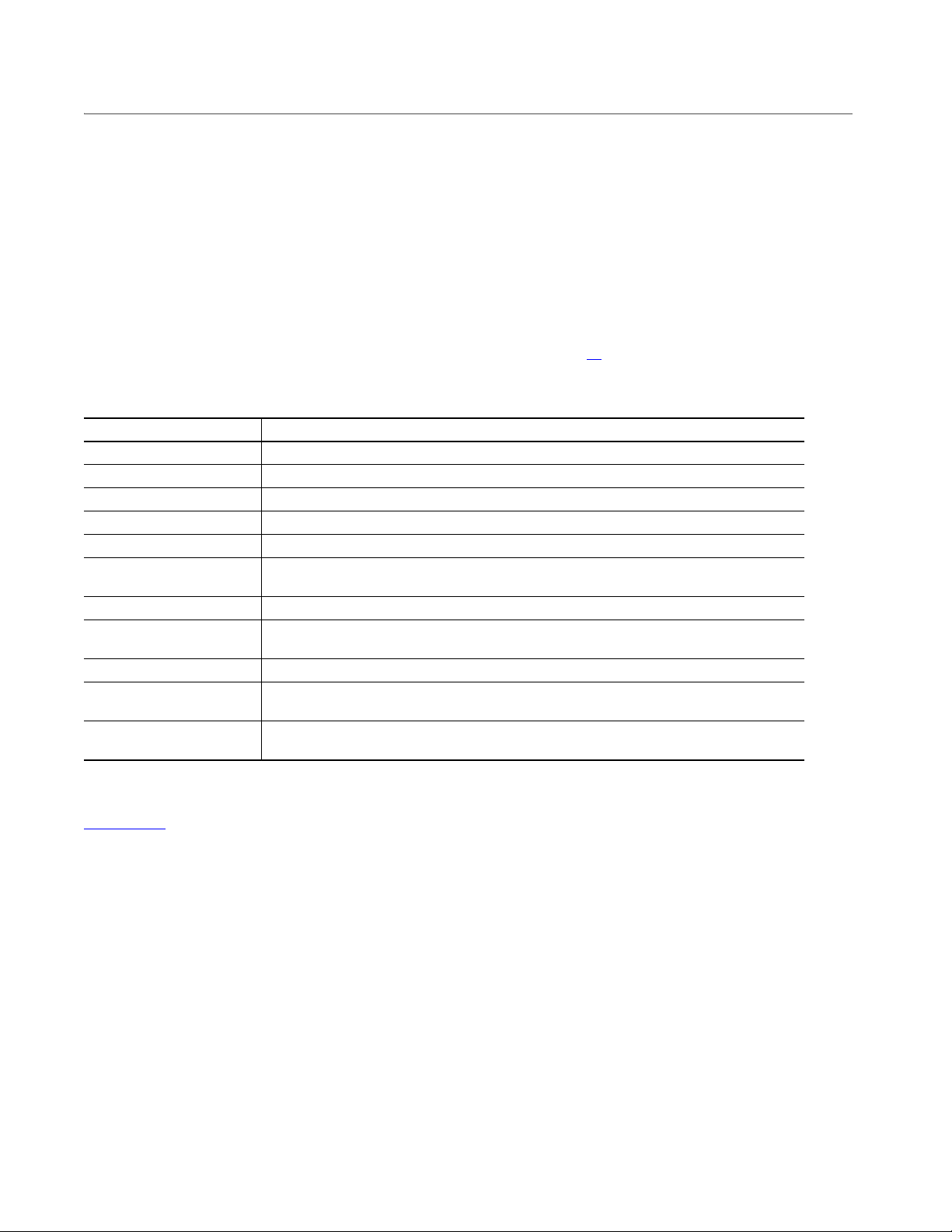

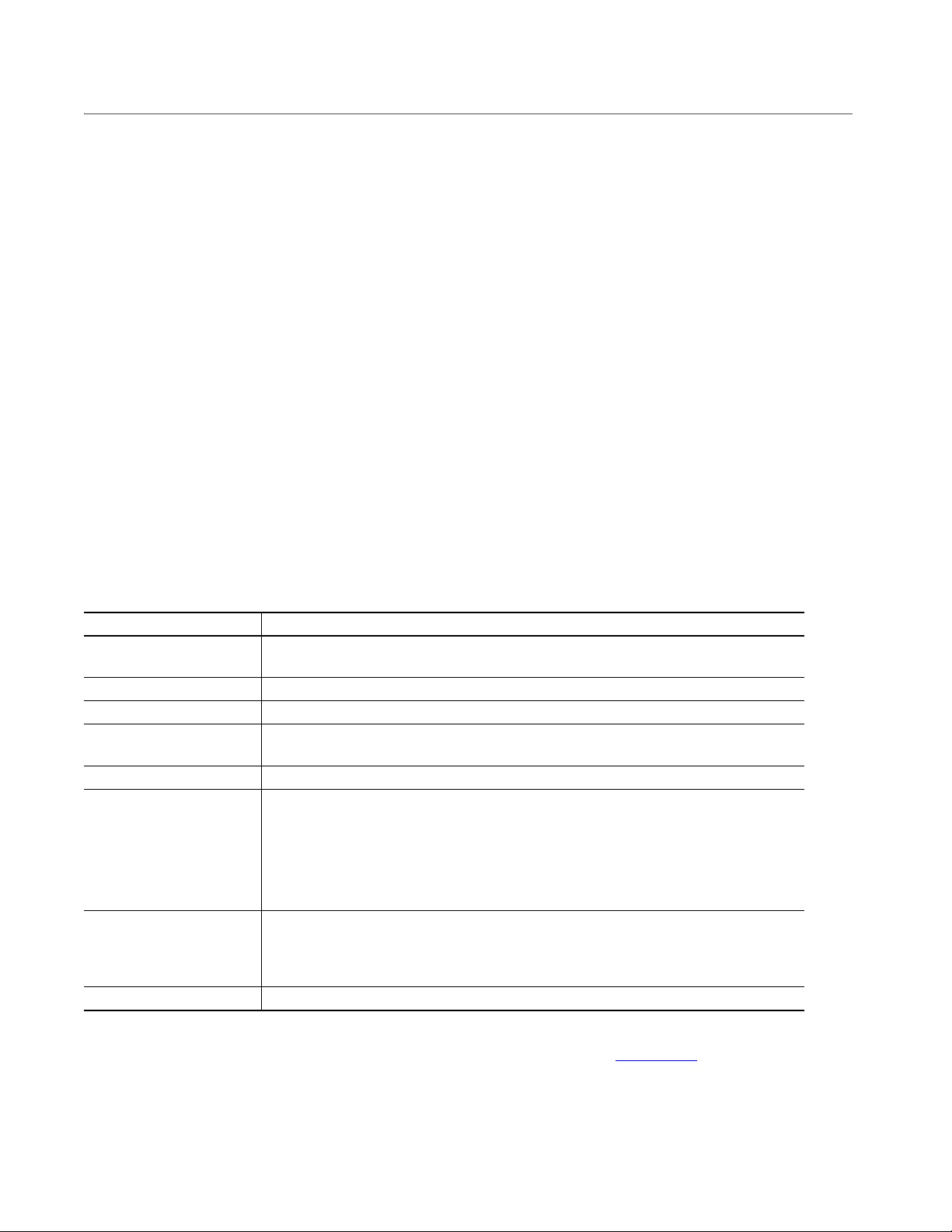

PanelView HMI Terminals

This table provides a quick glance at comparisons between the different PanelView HMI terminal platforms. Information about the PanelView Plus 7 Performance

terminals also applies to the ArmorView Plus 7 product, which contains a PanelView Plus 7 Performance terminal.

PanelView Terminal Comparison

Perf orman ce

PanelView Plus 7

v30+(View Designer v4+) - - - - - -

v4+)

PanelView 5510 PanelView 5310

Connectivity

CompactLogix® 5370 and ControlLogix® 5570 (L7) Controllers Yes (Studio 5000, v27+) Yes (Studio 5000, v27+) Yes Yes Yes L1, L2, L3

CompactLogix 5380 (L3) & ControlLogix 5580 (L8) Controllers Yes (Studio 5000, v29+) Yes (Studio 5000, v29+) Yes Yes Yes - Yes Yes

CompactLogix 5480 Yes (Studio 5000, v31+) Yes (Studio 5000, v31+)

PLC-5/SLC Controllers - Ethernet - - Yes Yes Yes Yes Yes Yes

PLC-5/SLC/MicroLogix™ Controllers - Serial (DF1) - - - - - Yes Yes Yes

PLC-5/SLC Controllers - DH+ / ControlNet - - - - - - Yes -

v30+(View Designer

Development Environment

Studio 5000® Environment

FactoryTalk® ME Software - - 3.2, 4, 5.x, 6.x, 7, 8.x, 9.x 5.1, 6.x, 7.x, 8.x, 9.x 3.2, 4, 5.x, 6.x, 7, 8.x, 9.x - 3.2, 4, 5.x, 6.x, 7, 8.x, 9.x 5.1, 7, 8.x, 9.x

Th ird Pa rt y C ont ro ll er s - - Yes Yes Yes - Ye s Yes

Micro800® Controllers - - Yes Yes Yes Yes Yes Yes

Connected Components Workbench™ Software - - - - - 7, 8.x, 9.x,10.x, 11.x, 12.x - -

and CPU)

No limit (based on memory

100/1/4000

(1)

Scale

Screen Size (Rounded Inches) 7, 7W, 9W, 10, 12W, 15, 19 6, 7W, 9W, 10, 12W 7, 9W, 10, 12W, 15, 19 4W, 6, 7, 9W, 10, 12W, 15 10W 4, 7, 10 4, 6, 7, 10, 12, 15 4, 6, 10

High Performance Features

High Speed on Screen Buttons Yes Yes - - - - - -

Scalable Vector Graphics Yes Yes - - - - - -

Automatic Rescaling Yes Yes - - - - - -

Alignment Guides Yes Yes - - - - - -

Navigation Button with on Screen Pop-up Menu Yes (Hard) Yes (Soft) - - - - - -

Predefined controller/network/terminal status screens Yes Yes - - - - - -

Screen Count / Controllers / Alarms 100/4/4000

Property Binding Yes Yes - - - - - -

Smart Runtime Error Notifications Yes Yes - - - - - -

Events and Commands Yes (View Designer v6+) Yes (View Designer v6+) - - - - - -

4 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 5

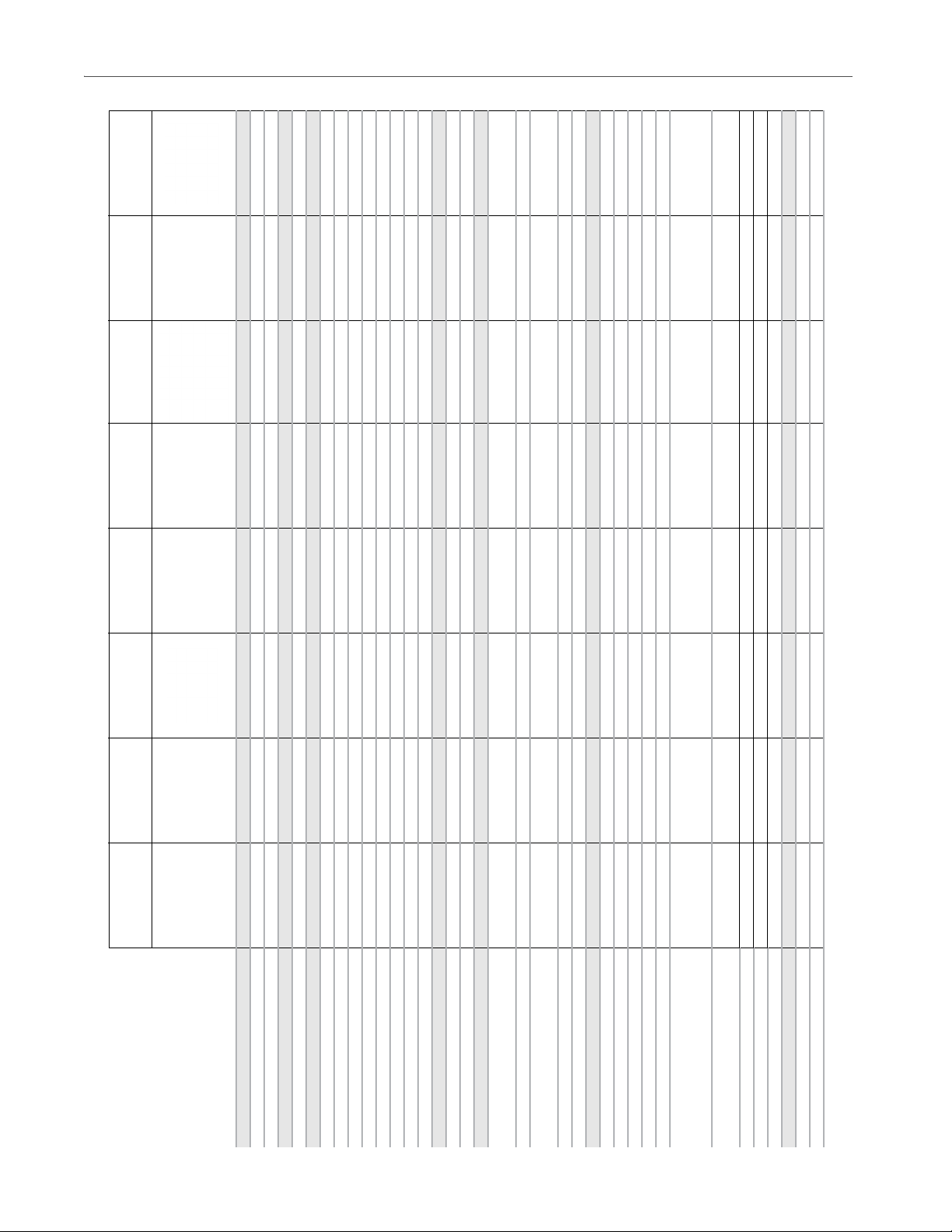

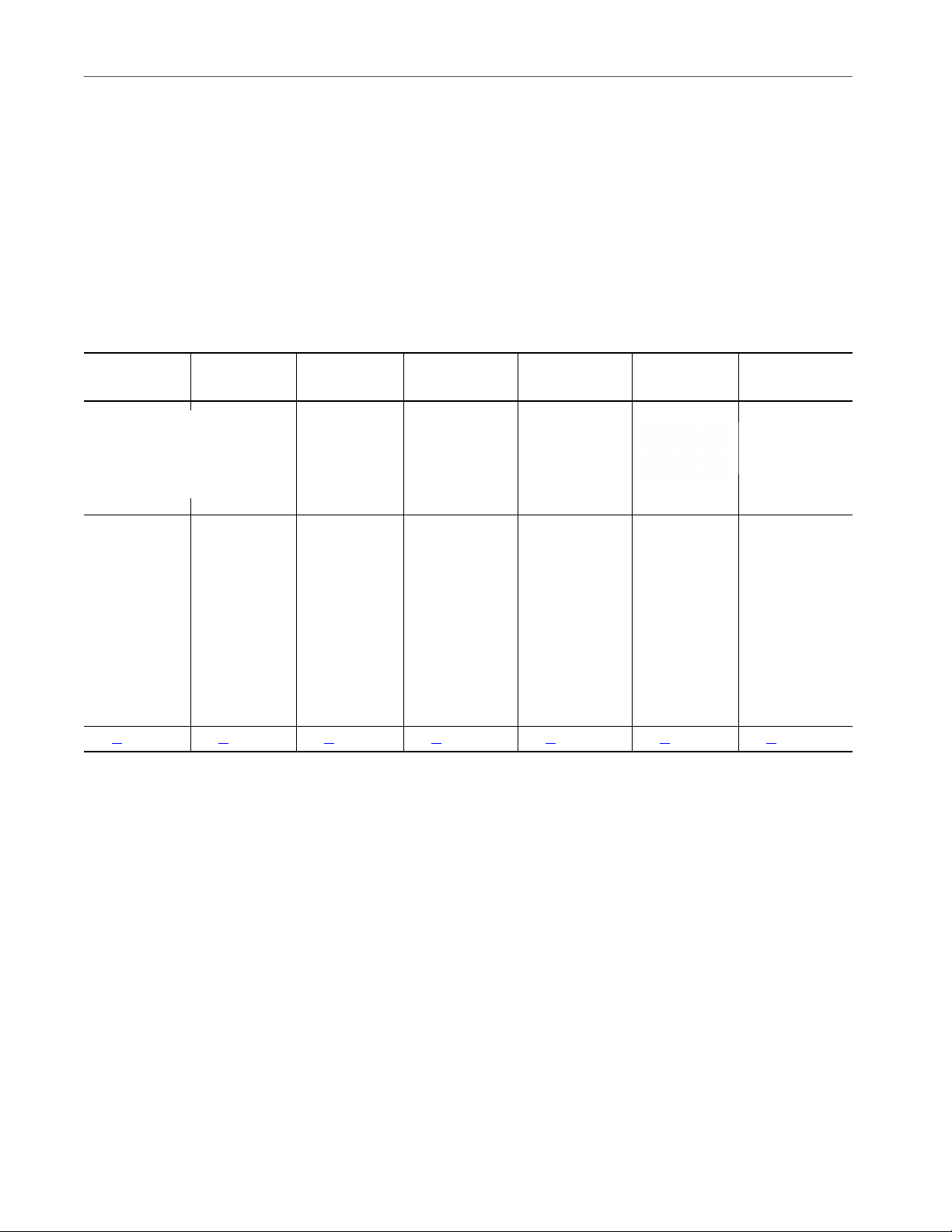

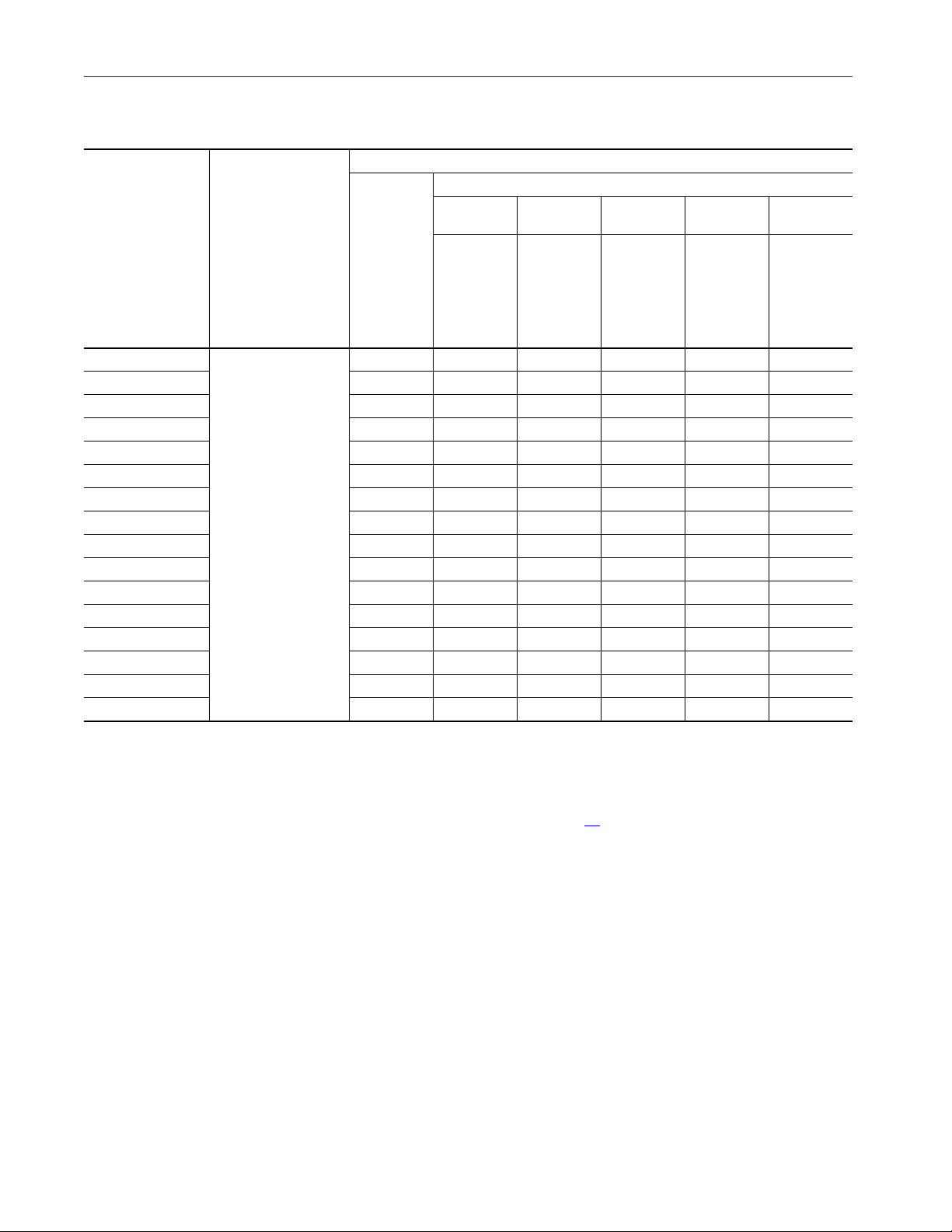

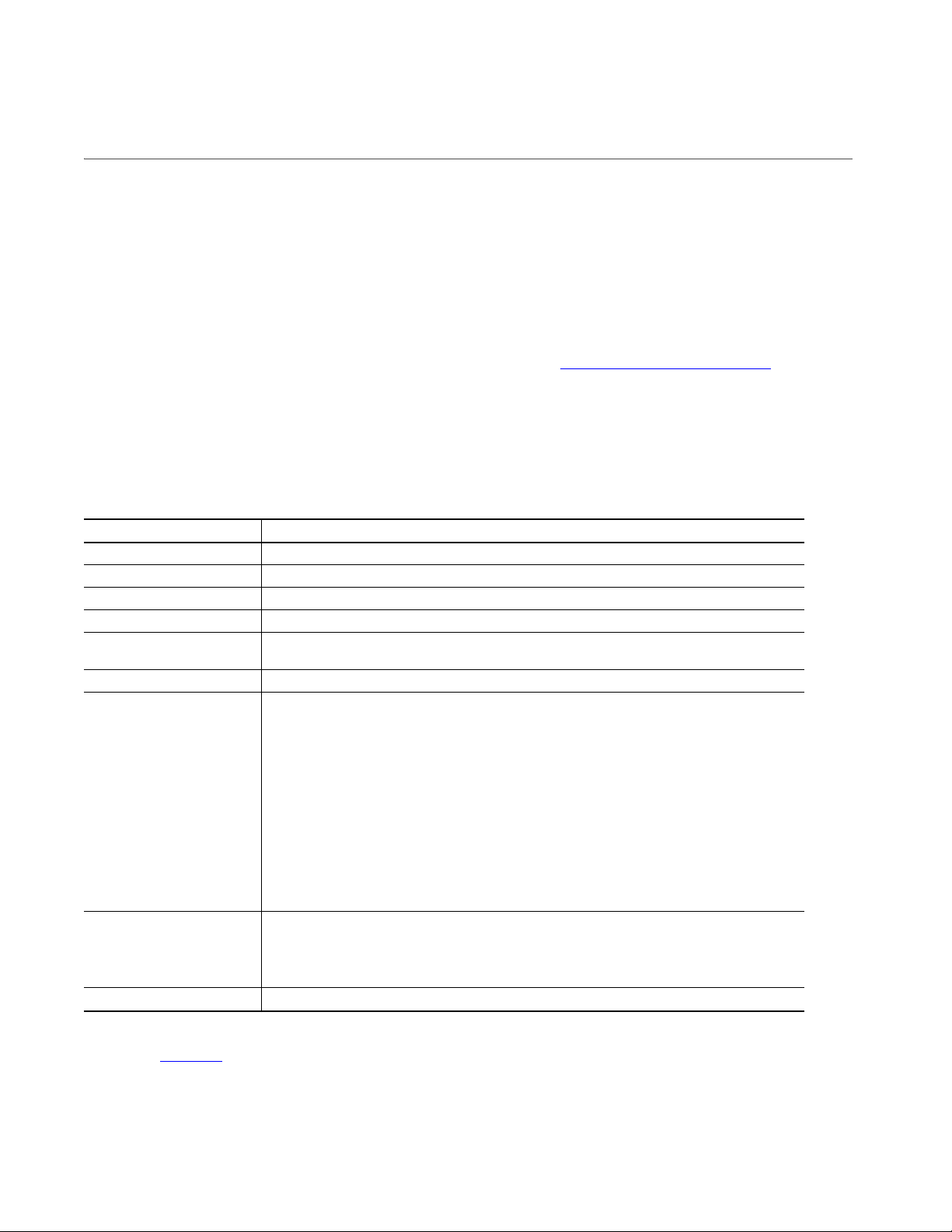

PanelView Plus 6

Compact

(End of Life)

Add Visualization to Your Control System

(2)

Yes

Windows CE 6.0

(2)

(End of Life)

PanelView Plus 6

MobileView PanelView 800

Standard

PanelView Plus 7

Perf orman ce

PanelView Plus 7

Yes Yes

Yes (not applicable to

Compac tLogix c ontrolle r)

FactoryTalk Viewpoint FactoryTalk Viewpoint - - FactoryTalk Viewpoint FactoryTalk Viewpoint

Yes

Windows CE 6.0

None

Yes Ye s

Microsoft Windows Embedded

(2)

Windows CE 6.0

(2)

Yes Yes Yes Yes Yes Yes

DC AC or DC DC

None Secured Desktop Access Secured Desktop Access

DC

None

Standard 7 SP1

DC

(3)

AC or D C

PanelView Terminal Comparison (Continued)

support

Future - Remote client

support

PanelView 5510 PanelView 5310

Alarming

HM I- ba se d A lar ms Fu tu re Fu tu re Yes Yes Yes Yes Yes Yes

Datalogging

HMI-based Datalog Yes (View Designer v4+) Yes (View Designer v4+) With CSV Export With CSV Export With CSV Export With CSV Export With CSV Export With CSV Export

Graphics

High Resolution and Wide Screens Yes Yes Yes Yes Yes Yes - -

Custom Graphic Reuse Yes Yes Yes Yes Yes Yes Yes Yes

Vector Graphics Yes Yes - - - - - -

Automatic display of Logix-based Alarms Yes Yes - - - - - -

Di sp la y I mpo r t / Exp or t Fu tu re Fu tu re Yes Yes Yes - Yes Yes

Fa cep la te s Yes ( Vie w D es ign er v4 +) Yes (Vi ew De si gn er v4+ ) Yes Ye s Yes Ye s Ye s Ye s

Multi-language Support

Di sp la y R eu se w it h P ara me te rs Ye s Ye s Ye s Yes Yes - Ye s Ye s

Animation Yes Yes Yes Yes Yes - Yes Yes

Portrait / Landscape Display Mode Future Future Yes - - Yes - -

Future - Remote client

Locali zed Keyboa rd Futu re Futu re Yes Yes Yes - Yes Yes

Language Switching Yes Yes Yes Yes Yes Yes Yes Yes

VNC Server Yes (View Designer v4+) Yes (View Designer v4+) Yes Yes Yes - can be installed Yes Yes Yes

FTP Server - - Yes Yes Yes - can be installed

Re mo te De sk top Cl ie nt - - Ye s Ye s Yes - Ye s Yes

Remote Access

Web HMI Server (Remote Viewing / Control)

VN C C li ent - - Ye s Ye s Yes - c an b e i ns ta ll ed - Ye s Yes

Other

De vi ce Lev el Ri ng Yes - Yes O pti on al - - - -

Ac ti ve X Co nt rol s - - Yes Yes Yes - Ye s Ye s

Enhanced Write Filter - - - - Yes - - -

Em ul at or Ye s ( Vie w D es ig ne r v4 +) Yes (V iew De si gn er v4 +) Yes Ye s Ye s - Ye s Ye s

v6+)

Load project and firmware

from media (View Designer

v6+)

Load project and firmware

from media (View Designer

Operating system None None Windows CE 6.0

Desktop N one Non e Sec ured Desktop Ac cess Secured Des ktop Access

SD Ca rd Ye s Yes Yes Yes Yes ( in te rna l o nl y) Yes Yes Yes

Recipes

Recipe Manager Logix based Logix based Yes Yes Yes Yes Yes Yes

Ma c r os - - Ye s Yes Yes - Ye s Ye s

Power DC DC

Backup / Restore / Cloning

USB Input Yes Yes Yes Yes

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 5

Page 6

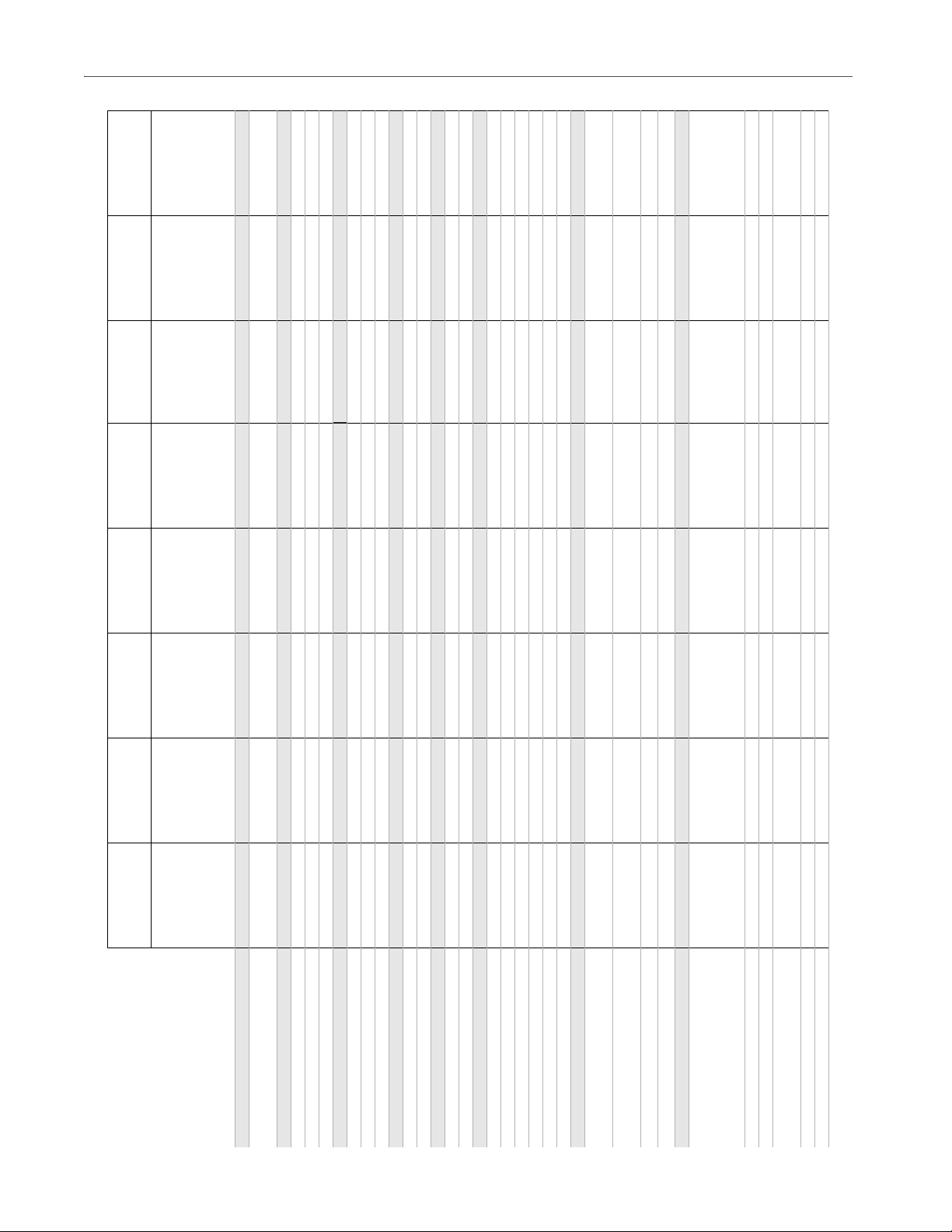

Add Visualization to Your Control System

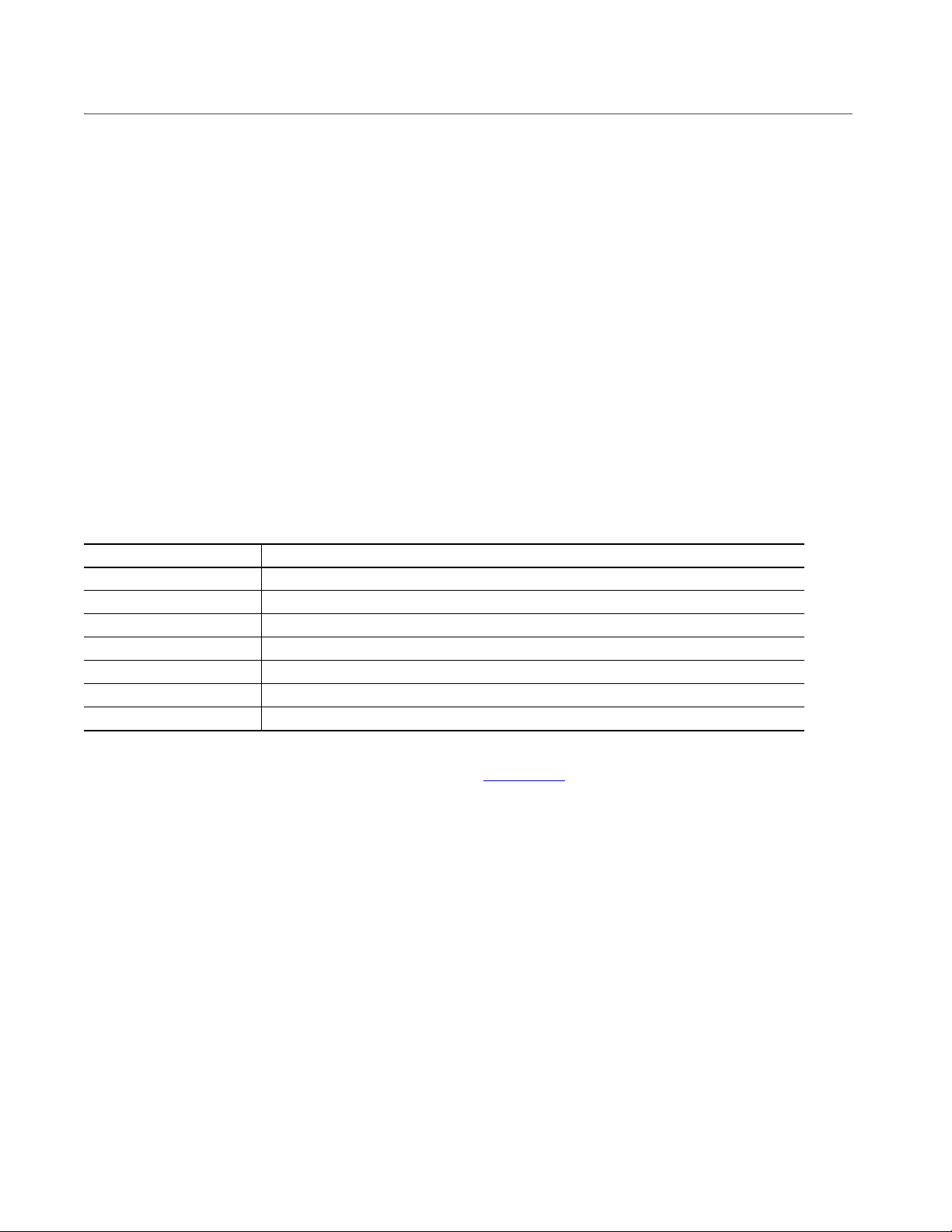

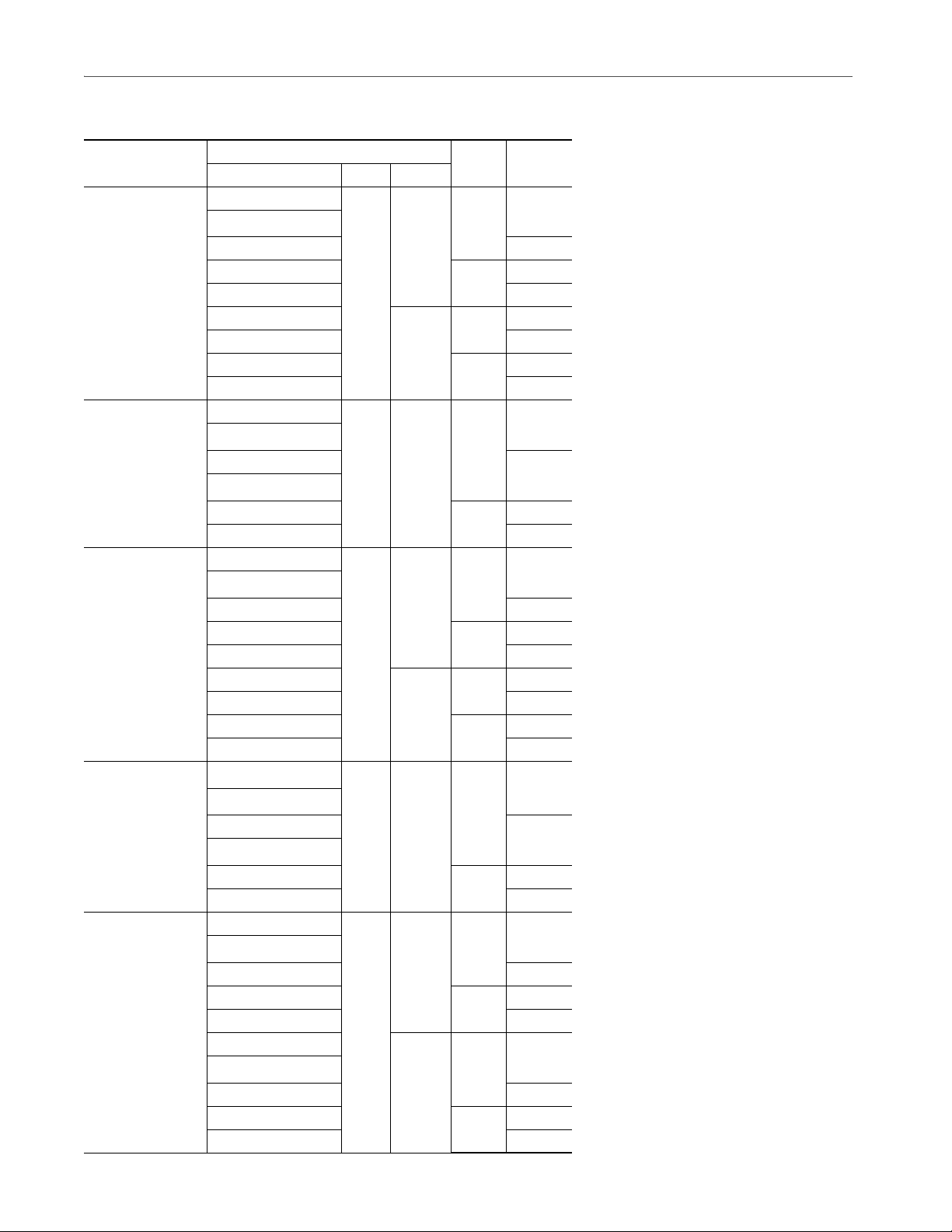

Compact

(End of Life)

PanelView Plus 6

Yes Yes

(End of Life)

PanelView Plus 6

Yes (not applicable to

Compac tLogix c ontrolle r)

MobileView PanelView 800

- - Class I Div 2 Class I Div 2

cULus; CE; RCM; RoHS cULus; CE; KCC; RCM; RoHS cULus; CE; KCC; RCM; RoHS cULus; CE; KCC; RCM; RoHS

Standard

PanelView Plus 7

Perf orman ce

PanelView Plus 7

PanelView 5510 PanelView 5310

EAC

ATEX Zone 2, 22

IECEx, CCC Ex, Class 1 Div 2;

cULus; CE; KCC; RCM; RoHS;

cULus; CE; KCC; RCM; RoHS

EAC

cULus; CE; KCC; RCM; RoHS;

EAC

cULus; CE; KCC; RCM; RoHS;

- - - 7 in., 12 in. -

15 in.

Touc h Mo del s

Touch/Keypad Model

7 in., 9 in. (wide), 10 in.,

12 in. (wide), 15 in., 19 in.

10 in., 12 in. (wide)

6 in., 7 in. (wide), 9 in. (wide),

15 in., 19 in.

10 in., 12 in. (wide),

7 in., 7 in. (wide), 9 in. (wide),

-----

9 in. (wide) Brandless

12 in. (wide) Brandless

PanelView Terminal Comparison (Continued)

HM I Tag s - - Yes Yes Yes Yes Yes Yes

FactoryTalk Software Users - - Yes Yes Yes - Yes Yes

Microsoft Active Directory Users - - Yes Yes Yes - Yes Yes

Hi st or ica l Tre nd in g Yes (V ie w D esi gn er v4 +) Ye s ( Vi ew D es ig ne r v 4+ ) Ye s Yes Yes - Ye s Ye s

PDF Yes (View Designer v4+) YES (View Designer V5+) Yes Yes Yes - Yes Yes

Device Diagnostic Screens (PLC and HMI) Yes Yes Faceplates + ActiveX control Faceplates + ActiveX control Faceplates + ActiveX control - Faceplates + ActiveX control Faceplates + ActiveX control

Excel - - Yes - - - Optional -

PowerPoint - - Yes - - - O ptional -

Certifications

Word - - Yes - - - O pt ion al -

Web Browser Future - Yes - Yes - Option al -

Major Certifications

Media Player Future - Yes - - - Optional -

Reporting

Email Yes (View Designer v6+) Yes (View Designer v6+) Yes Yes Yes

Security

Local Users Yes Yes Yes Yes Yes Yes Yes Yes

Tags

Logix Tag Extended Properties Yes Yes - - - - - -

Direct Reference Tags Yes Yes Yes Yes Yes Micro800 only Yes Yes

Tren din g

Real-time Trending Yes Yes Yes Yes Yes Yes Yes Yes

Troubleshooting

Smart Runtime Error Notifications Yes Yes - - - - - -

Viewers

6 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

On-Machine Future - 12 in. (wide) ArmorView - - - - -

High Bright Display Future - - - - - 12 in. -

INMETRO ---Yes----

Marine Certification Yes - - - - Yes Yes -

Hazardous Locations Class I Div 2 - Class I Div 2

Modified Terminals

Confo rmal Coat ing

Stainless Steel Future -

Illuminated E-stop - - - - Gen 2 Only - - -

Configurable Junction Box ID - - - - Gen 2 O nly - - -

Page 7

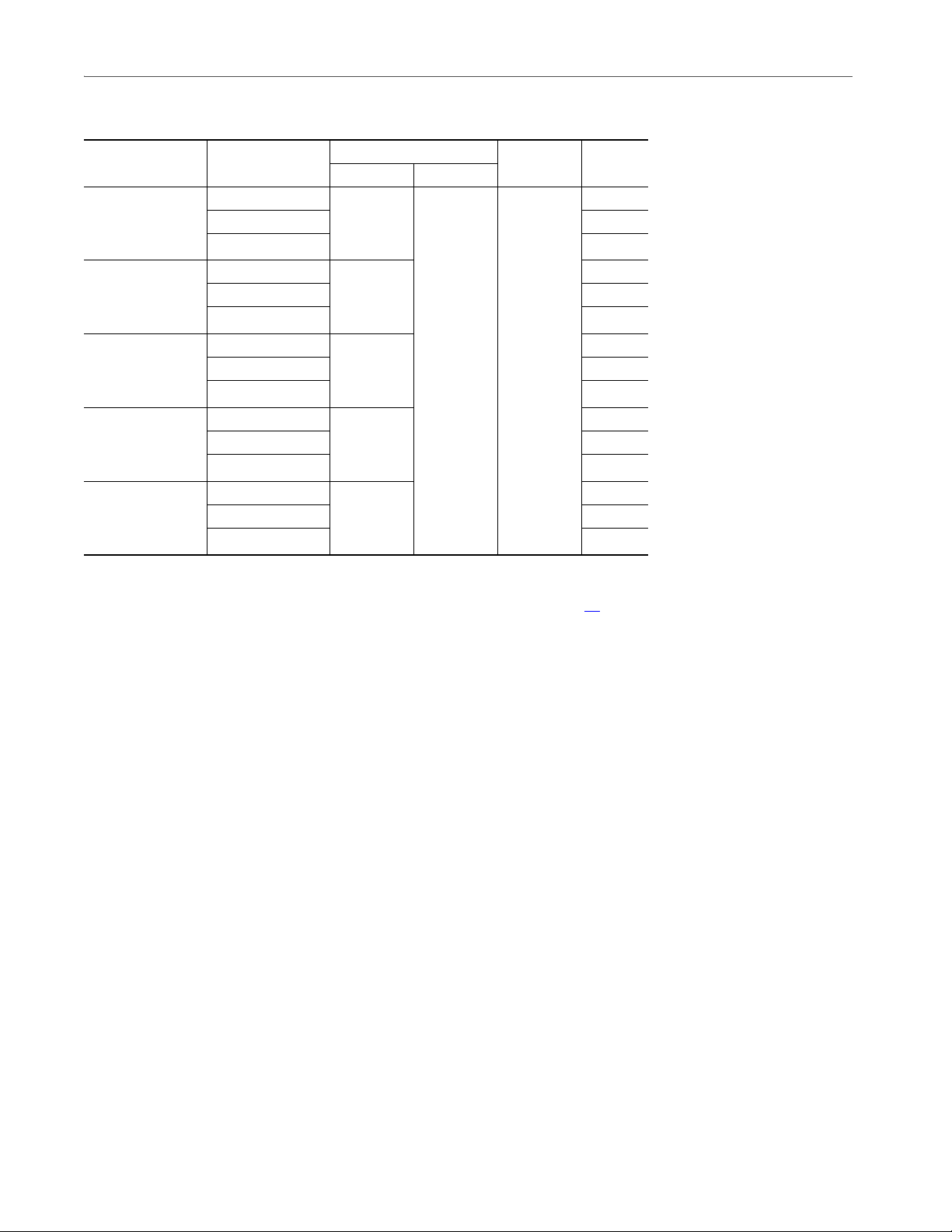

PanelView Plus 6

PanelView Plus 6

Compact

(End of Life)

(End of Life)

MobileView PanelView 800

Add Visualization to Your Control System

LED backlit LCD,

262K colors,

grayscale options

keypad

touch scre en

keypad /touch scre en

EtherNet/IP, DF1 (RS-232),

and DH-485 (RS-232).

Kepware Server available to

support third-party Ethernet

and RS-232 protocols

(Modbus TCP/RTU).

LED backlit LCD,

262K colors,

grayscale options

keypad

touch scre en

keypad/touch screen

EtherNet/IP, DF1 (RS-232),

and DH-485 (RS-232).

Optional communication

modules for 7-inch and larger

sizes to support DH+, DH-485

(RS-485), and ControlNet.

Kepware Server available to

support third-party Ethernet

and RS-232 protocols

Third-party communications:

Modbus ASCII, Modbus RTU

(Master and Slave/Unsolicited),

LED backlit LCD,

65K colors,

widescreen options

touch screen

touch screen + 4 keys

LED backlit LCD,

262K colors

Function keys/touch

Tou c h

and Modbus TCP.

EtherNet/IP EtherNet/IP, DF1, and DH-485

400 and 600 only–

256 MB RAM/512 MB

nonvolatile memory

(approx. 73 MB free user

memory)

1000 only–

512 MB RAM/512 MB

nonvolatile memory

(approx. 79 MB free user

memory)

(Modbus TCP/RTU).

400 and 600 only–

256 MB RAM/512 MB

nonvolatile memory

(approx. 73 MB free user

memory)

700 to 1500–

512 MB RAM/512 MB

nonvolatile memory

(approx. 79 MB free user

memory)

storage

4 GB DRAM/32 GB Flash 256 MB RAM and 256 MB

Standard

PanelView Plus 7

Perf orman ce

PanelView Plus 7

LED backlit LCD,

262K colors,

widescreen options

touch screen

LED backlit LCD,

262K colors,

widescreen options

LED backlit LCD, 24-bit 16.7M

colors,

widescreen options

touch screen touch screen

EtherNet/I P with optional DLR

support

Kepware Server available to

support third-party Ethernet

protocols.

keypad/touch screen

Kepware Server available to

support third-party Ethernet

protocols.

512 MB RAM and 512 MB

storage

512 MB RAM and 512 MB

storage

1 GB RAM and 1 GB user

storage

Approx. 80 MB nonvolatile

storage for applications

Approx. 80 MB nonvolatile

storage for applications

PanelView 5510 PanelView 5310

LED backlit LCD, 24-bit 16.7M

colors,

widescreen options

touch screen

keypad/ touchscreen

EtherNet/IP with DLR support EtherNet/IP EtherNet/IP with DLR support

1 GB RAM and 1 GB user

storage

page 19 page 17 page 23 page 27 page 37 page 39 page 29 and page 33 page 35

PanelView Terminal Comparison (Continued)

Display

Input type

Communication

User storage

More Information

(1) The PanelView 5510 can support up to 4000 Logix tag-based alarms or up to 1000 Logix instruction-based alarm per controller. Use Logix Designer v32 or later for Logix tag-based alarms..

(2) Windows CE 6.0 operating system supports these features: FTP Server, VNC client/server, PDF reader, Active X controls, third-party device support.

(3) The ArmorView Plus 7 product is available only with the DC version of the PanelView Plus 7 Performance terminal.

(4) FactoryTalk View Machine Edition v11 or newer.

(5) Only applies to CompactLogix 5370, excluding L37 and L38.

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 7

Page 8

Add Visualization to Your Control System

Industrial Computers and Thin Clients

Rockwell Automation® industrial computers and monitors are built with high-grade components that are critical to the safety

and success of applications in demanding industrial environments:

• Seamless integration with the full suite of Rockwell Software® solutions, including the Integrated Architecture®

platform and FactoryTalk® View software

• Utilities for system backup and restore, hardware analysis, and troubleshooting

• Unit-level immediate exchange program to reduce downtime

If you need the processing power of an industrial computer with open-desktop and modern operating-system support,

choose from the following options:

VersaView 5000

Computers

Complete line of open

architecture industrial

PCs, and monitors. The

open architecture

supports modern

operating systems and

various software

applications. Available

in both compact nondisplay and integrateddisplay versions. Ideal

for standard HMI

applications.

page 61

VersaView 5200

ThinManager® Th in

Clients

Integrated display and

non-display

ThinManager thin

clients that are

designed to deliver

content in harsh

industrial

environments.

page 59 page 63 page 69 page 71 page 73 page 75

6181P IntegratedDisplay Industrial

Computers

Select models with and

without displays for

high performance

applications. Ideal for

complex and large HMI

applications with

integrated displays.

Hazardous Location

Computers

Extreme environment

computers that combine

safety with extended

operating temperature

ratings. These computers

are designed to endure

the harsh extremes of

heat and cold.

Non-Display Computers VersaView® 5100

Machine or rack-mount

computers for

applications where you

do not need a display. The

focus of these computers

is on expandability. Ideal

for complex and large

HMI applications with

external displays.

Monitors

All widescreen

industrial monitors that

provide modern

connectivity with full

HD options. These

monitors feature native

DisplayPort, DVI, and

VGA connectivity to a

variety o f computing

devices.

Industrial Monitors

Standard a nd

Performance options for

when you need a Class 1

Div 2 rated industrial

monitor to enhance your

system.

8 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 9

Add Visualization to Your Control System

PanelView HMI Terminals

PanelView™ 5310 terminals, PanelView 5510 terminals, PanelView Plus 7 Performance terminals, PanelView Plus 7 Standard

terminals, PanelView

Designer®, FactoryTalk®

ways:

• Reduced programming time with Logix native addressing and the ability to browse directly to Logix tags without

creating a separate database.

• Simplified interaction of all networks with support for all Core Integrated Architecture® CIP™ networks including

EtherNet/IP™, ControlNet, and numerous other drivers.

• Simplified development time with pre-engineered, pre-tested faceplates for specific motion, drives, and process

applications.

PanelView HMI terminals are available with the following levels of control:

• Component Class

• Small Control Class

• Integrated Architecture Class

Plus 6 terminals, MobileView™ tethered operator terminals, PanelView 800 terminals, Studio 5000 View

View Machine Edition, and FactoryTalk View Site Edition provide premier integration in a number of

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 9

Page 10

Add Visualization to Your Control System

Network

Component Class

This class combines a simple, powerful control core, a full suite of associated components, and a dedicated set of classleading application development tools. These features provide enough control to meet machine control and end-customer

requirements in the shortest possible time.

Typical Configurations

Micro800® with PanelView 800

10 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 11

Add Visualization to Your Control System

Small Control Class

This scalable control system helps machine builders and their customers cost-effectively match their application needs and

standardize on one control platform while receiving real-time information for smaller applications.

Typical Configurations

The following configurations are typically used in the midrange class:

• Star configuration

• Linear configuration

• Device Level Ring configuration

Star Configuration

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 11

Page 12

Add Visualization to Your Control System

Linear Configuration

12 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 13

Add Visualization to Your Control System

CompactLogix 5380

ArmorView Plus 7

or

Device Level Ring Configuration

The PanelView Plus 7 standard terminal and the CompactLogix™ 5370 controller provide an integrated, Device Level Ring

(DLR) capable solution for mid-size applications. Typically, these applications are machine-level control applications that

require smaller I/O quantities and benefit from EtherNet/IP communication capabilities. PanelView Plus 7 Performance

terminals come with DLR and PanelView Plus 7 Standard terminals have DLR only as an option.

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 13

Page 14

Add Visualization to Your Control System

5500

ControlLogix 5580

PanelView 5000

Integrated Architecture Class

The Integrated Architecture™ system is unique in that it offers scalable, integrated safety, motion control, and visualization

capabilities that are ideal for machine builders and end users who want one control and development environment,

regardless of the application size or complexity. Large control systems integrate all control disciplines - process batch,

discrete, drives, safety, and motion - into one connected and segmented, plant-wide infrastructure that uses a common

design environment for all automation disciplines.

Typical Configurations

The following configurations are typically used in the integrated architecture class:

• Star configuration

• Linear configuration

• Device Level Ring configuration

Star Configuration

14 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 15

Linear Configuration

ArmorView Plus 7

or

ControlLogix 5580

[

Add Visualization to Your Control System

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 15

Page 16

Add Visualization to Your Control System

FLEX™ I/O

Device Level Ring Configuration

16 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 17

PanelView 5310 Terminals

PanelView™ 5310 terminals are operator interface terminals for

small- to medium-sized applications. They monitor and control

devices that are attached to ControlLogix® 5570, 5580 controllers,

and CompactLogix™ 5370, 5380 and 5480 controllers over an

EtherNet/IP™ network. Animated graphic and text displays provide

operators a view into the operating state of a machine or process.

Operators interact with the control system by using the touch

screen.

Features include the following:

•Tightly-integrated control and design environment for

information sharing between the terminal and the Logix platforms

• Studio 5000® environment provides one point of access for both Studio 5000 View Designer® and Studio 5000 Logix

Designer® applications

• Connection to one ControlLogix 5570, 5580 or one CompactLogix 5370, 5380 or 5480 controller running V27 firmware

or later over an EtherNet/IP network

• Supports up to 100 displays in the application

• Supports up to 4000 Logix-based alarms

• Conformal coating available for all terminal sizes.

Termin a l Fe a t u res

Features Description

High memory capacity 1 GB RAM and 1 GB user storage

Power i nput DC

Communication ports One 10/100Base-T, Auto MDI/MDI-X, Ethernet/IP port for controller communication

USB ports One USB high-speed 2.0 host por t (type A) support removable flash drive for external storage

Secu re Digital (SD) card slot One S D card slot

Software Studio 5000 environment provides single portal to View Designer and Logix Designer applications

Preferred controller

For complete technical specifications, certifications, and environmental specifications on the PanelView 5310 terminals, refer

to the PanelView 5310 Specifications Technical Data, publication 2713P-TD001

ControlLogix 5570, 5580 controllers, and CompactLogix 5370, 5380 and 5480 controllers

.

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 17

Page 18

PanelView 5310 Terminals

Termin a l S elec t ion

Model Cat. No.

2713P – T6CD1

6 in.

2713P – T6CD1-B x

2713P – T6CD1-K

2713P – T7WD1

7 in. (wide)

2713P – T7WD1-B x

2713P – T7WD1-K

2713P – T9WD1

9 in. (wide)

2713P – T9WD1-B x

2713P – T9WD1-K

2713P – T10CD1

10 in.

2713P – T10CD1-B x

2713P– T10CD1-K

2713P – T12WD1

12 in. (wide)

2713P – T12WD1-B x

2713P – T12WD1-K

(1) This model includes conformal coating.

Color Display

Size Input

Input

Power

Brandless

6 in.

(1)

7 in. (wide)

(1)

9 in. (wide)

(1)

Tou c h DC

10 in.

(1)

12 in. (wide)

(1)

For information about accessories that are available for these terminals, see page 41.

18 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 19

PanelView 5510 Terminals

The PanelView™ 5510 terminals are operator interface devices that

monitor and control devices attached to ControlLogix® 5570, 5580

controllers, and CompactLogix™ 5370, 5380 and 5480 controllers

over an EtherNet/IP™ network. Animated graphic and text displays

provide a view to operators into the operating state of a machine

or process. Operators interact with the control system by using the

touch screen or keypad of the terminal.

Features include the following:

•Tightly integrated control and design environment allows

information to be shared between the PanelView 5510 terminal

and the Logix platforms.

• The Studio 5000® environment provides one point of access for the Studio 5000 View Designer® and Studio 5000 Logix

Designer® applications.

• Connection up to four ControlLogix 5570, 5580 and CompactLogix 5370, 5380 or 5480 controllers running V27

firmware or later over an EtherNet/IP network

• Supports a maximum of 100 user-defined screens.

• Supports a maximum of 4,000 Logix tag-based alarms or 1000 Logix instruction-based alarms per controller.

• Ethernet communication that supports Device Level Ring (DLR), linear, or star network topologies.

• High-speed human machine interface (HMI) button control and easily configured navigation menu.

• Conformal coating available for all terminal sizes.

Termin a l Fe a t u res

(1)

(1)

Features Description

High memory capacity 1 GB RAM and 1 GB nonvolatile storage for projects

Power i nput DC

Communication ports Two 10/100Base-T, Auto MDI/MDI-X Ethernet ports that support (Device Level Ring) DLR, linear, or star network topologies.

USB ports Two USB 2.0 high-speed (type A) host ports to support removable USB drives for external storage.

One USB 2.0 high-speed (type B) device port to connect to a host computer that is software-feature dependent.

Software Studio 5000 environment provides single portal to View Designer and Logix Designer applications

Preferred controller

ControlLogix 5570, 5580 controllers, and CompactLogix 5370, 5380 and 5480 controllers

For complete technical specifications, certifications, and environmental specifications on the PanelView 5510 terminals, see

the PanelView 5510 Terminals Specifications Technical Data, publication 2715P-TD001

.

(1) The PanelView 5510 terminal can support up to 4000 Logix tag-based alarms or up to 1000 Logix instruction-based alarms per controller. Use Logix Designer v. 32 or later for Logix tag-based alarms. Use View Designer

v. 6 and later for 4000 alarms per controller. Earlier versions only supported up to 4000 alarms total.

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 19

Page 20

PanelView 5510 Terminals

Termin a l S elec t ions

Model Cat. No.

2715P-T7CD

2715P-T7CD-B x

6.5-in.

2715P-T7CD-K

2715P-B7CD

2715P-B7CD-B x

2715P-B7CD-K

2715P-T7WD

7-in.

2715P-T7WD-B x

2715P-T7WD-K

2715P-T9WD

9-in.

2715P-T9WD-B x

2715P-T9WD-K

2715P-T10CD

2715P-T10CD-B x

10.4-in.

2715P-T10CD-K

2715P-B10CD

2715P-B10CD-B x

2715P-B10CD-K

2715P-T12WD

12.1-in.

2715P-T12WD-B x

2715P-T12WD-K

2715P-T15CD

2715P-T15CD-B x

15-in.

2715P-T15CD-K

2715P-B15CD

2715P-B15CD-B x

2715P-B15CD-K

2715P-T19CD

19-in.

2715P-T19CD-B x

2715P-T19CD-K

Color Display

Size Input

Input

Power

Brandless

Tou c h

(1)

6.5-in.

Touch with

(1)

keypad

7-in. Touch

(1)

9-in. Touch

(1)

Tou c h

(1)

10.4-in.

DC

Touch with

(1)

keypad

12.1-in. Touch

(1)

Tou c h

(1)

15-in.

Touch with

(1)

keypad

19-in. Touch

(1)

(1) This model includes conformal coating.

For information about accessories that are available for these terminals, see page 41.

20 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 21

ArmorView Plus 7 Terminals

The ArmorView™ Plus 7 terminal, which ships with an

arm mount adapter, can be mounted on an arm

mount system, a wall, or a pedestal. An optional VESA

kit is available for operators who prefer to mount the

terminal on a VESA-compatible bracket (purchased

separately). If operators choose the VESA mount, they

must install an I/O plate (included with the VESA kit) in

place of the arm mount adapter.

The ArmorView Plus 7 terminal is based on the

PanelView™ Plus 7 Performance terminal. In addition to

the features of the PanelView Plus 7 Performance terminal that are listed on page 23

includes the features that are listed in the following table.

Termin a l Fe a t u res

Features Description

Enclosure Custom cast-aluminum enclosure. Provides NEMA4/IP66 Ingress protection (when properly mounted).

PanelView terminal Full-function PanelView Plus 7 Performance 12-inch wide-screen terminal with touch interface.

Button plate Positionable below (standard), above, or to either side of the display.

Display Landscape (standard) or portrait orientation. (Button plate on either side requires portrait display orientation).

E-stop button (pre-configured options) Lighted, twist-to release E-stop with N.O., N.C., and self-monitoring contact blocks.

Buttons (pre-configured options) Mix of momentary pushbuttons, two- and three-position selector switches, and three-position key selector switch with N.O. contact

blocks connected to an integrated ArmorBlock Ethernet I/O module.

Buttons (customer configured) Seven allowable locations for any 22 mm (0.87 in.) buttons, lamps, or connection ports.

Stack light (accessory, customer

configured)

Handle (accessory) Three locations for stainless steel handle mounting.

Arm mount Arm mount adapter mates to leading industry arm mount systems or electrical enclosures. Orientations include hanging mount,

VESA mount (accessory) VESA mounting to industry standard (100x100) arms and brackets. (Accessory includes I/O plate with bulkhead power, Ethernet, and

Two locations for stack light mounting.

pedestal (bottom) mount, or side mount.

E-stop connectors).

, the ArmorView Plus 7 terminal also

For complete technical specifications, certifications, and environmental specifications on the PanelView Plus 7 Performance

terminals and the ArmorView Plus 7 terminal, refer to the PanelView Plus 7 Performance Terminals Technical Data, publication

2711P-TD009

.

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 21

Page 22

ArmorView Plus 7 Terminals

Terminal Selections

Additional Components Included with Individual Catalog Numbers

Button Plate Components

Cat. No.

2711P-T12W22D9P-BM001

Components Included with

All Catalog Numbers

(1)

Ethernet I/O

(3)

Module

(1732E-8CFGM8R)

E-stop Button

• Twist-to-release

E-stop Button

(800FM-LMT44)

• Latch (800F-ALP)

• Self-monitoring

Contact Block

(800F-X01S)

• Red LED Module

(800F-N3R)

• Dual-circuit Contact

Block (800F-X11D)

# Push

Buttons

• Push Button

(800FM-F9)

• Latch (800F-ALP)

• Contact Block, 1 N.O.

(800F-X10)

(5)

Two- positi on

Selector

• Two-position

Selector Switch

(800FM-SM22

• Latch (800F-ALP)

• Contact Block, 1 N.O.

(800F-X10)

• Three-position

• Latch (800F-ALP)

• Contact Block, 1 N.O.

2711P-T12W22D9P-BM002 x

2711P-T12W22D9P-BM003 x

2711P-T12W22D9P-BM004 x x

2711P-T12W22D9P-BM005 x x 2

2711P-T12W22D9P-BM006 x x 2 x

2711P-T12W22D9P-BM007 x x 2 x

2711P-T12W22D9P-BM008 x x 2 x

2711P-T12W22D9P-BM009 x x 3

2711P-T12W22D9P-BM010 x x 3 x

• ArmorView Plus 7 terminal

• PanelView Plus 7 Performance

module

• Arm mount adapter

• Button plate

• Standard access cover

• Product Information

document

2711P-T12W22D9P-BM011 x x 3 x

2711P-T12W22D9P-BM012 x x 3 x

2711P-T12W22D9P-BM013 x x 6

2711P-T12W22D9P-BM014 x x 5 x

2711P-T12W22D9P-BM015 x x 5 x

2711P-T12W22D9P-BM016 x x 5 x

(1) This catalog number represents the most basic configuration of the ArmorView Plus 7 product. It is shipped with an arm mount adapter, a blank button plate, and a standard access cover. It does not include any extra features.

(2) All catalog numbers come with nine M4 screws (6 for the access cover and 3 for grounding the subassembly chassis) and eight wire routing clips.

(3) The Ethernet I/O module is used to interface to the buttons on the button plate. It in cludes eight ports that can be configured as inputs o r outputs.

(4) All button plate components (push buttons, selector switche s, and key selector switches) are 22 mm (0.87 in.) in diameter.

(5) Catalog numbers 2711P-T12W22D9P-BM005…2711P-T12W22D9P-BM016 include nine push button key caps (assorted colors) that can be used to customize the button color and location.

(2)

(4)

Three-position

Selector

Selector Switch

(800FM-SM32)

(800F-X10)

Three-position

Key Selector

• Three-position Key-

Selector Switch

(800FM-KM33

• Latch (800F-ALP)

• Contact Block, 1 N.O.

(800F-X10)

For information about accessories that are available for these terminals, see page 43.

22 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 23

PanelView Plus 7 – Performance Terminals

PanelView™ Plus 7 performance terminals are operator interface terminals.

They monitor and control devices attached to ControlLogix® and

CompactLogix™ controllers on an EtherNet/IP network. Animated graphic

and text displays provide operators a view into the operating state of a

machine or process. Operators interact with the control system by using

touch screen or keypad input.

Features include the following:

• FactoryTalk® View Machine Edition software provides a familiar environment for creating HMI applications.

• Windows CE operating system with desktop access for configuration and third-party applications.

• Connection to ControlLogix or CompactLogix controllers.

• Ethernet communication that can support Device Level Ring (DLR), linear, or star network topologies.

• Web browser, Microsoft file viewers, text editor, PDF viewer, remote desktop connection, and media player on the

terminal desktop.

• Conformal-coating available for all DC power, touch-only terminals, and the 15-inch DC power, touch/keypad terminal.

• Stainless steel, hygienic, brandless, DC-power, and conformal-coating are available for the 9-in. wide-screen, touch-

only units and the 12-in. wide-screen, touch- only units.

• On-machine mounting available for the 12-inch wide-screen, DC-powered, touch-screen PanelView™ Plus 7

performance terminal. For more information, see ArmorView Plus 7 Terminals on page 21

Termin a l Fe a t u res

.

Features Description

High memory capacity 512 MB RAM and 512 MB storage

Approx. 80 MB nonvolatile storage for applications

Power i nput DC or AC

Communication ports Two 10/100Base-T, Auto MDI/MDI-X, built-in DLR Ethernet port for controller communication

USB ports Two USB 2.0 high-speed host port (type A) support removable flash drives for storage

One high-speed 1.0 device port (type B) suppor ts future connection to host computer

Secu re Digital (SD) card slot One S D card slot

Operating system All terminals run the Windows CE 6.0 operating system (OS) which provides OS functionality that meets the needs of most users:

• FTP server

• VNC client/server

• PDF reader

• Active X controls

• Third-party device support

• FactoryTalk® ViewPoint

Software FactoryTalk® View Machine Edition Station (runtime) software, version 8.0 or later, is preloaded and activated on each terminal

Single license support for FactoryTalk ViewPoint software, version 1.2 or later, gives remote users access to terminal displays via a

standard web browser

HMI applications are developed with FactoryTalk View Studio for Machine Edition software, which is purchased separately

Preferred controller

Contr olLogi x

For complete technical specifications, certifications, and environmental specifications on the PanelView Plus 7 Performance

terminals, refer to the PanelView Plus 7 Performance Terminals Technical Data, publication 2711P-TD009

.

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 23

Page 24

PanelView Plus 7 – Performance Terminals

Termin a l S elec t ion

Model

700

900W

1000

1200W

1500

TFT Color Display

Cat No. Size Input

Input

Power

Brandless

2711P-T7C22D9P

2711P-T7C22D9PK

2711P-T7C22D9P-B x

(1)

Tou c h

2711P-T7C22A9P

2711P-T7C22A9P-B x

7-in.

2711P-B7C22D9P

2711P-B7C22D9P-B x

2711P-B7C22A9P

Touch with

keypad

2711P-B7C22A9P-B x

2711P-T9W22D9P

2711P-T9W22D9PK

2711P-T9W22D9P-B x

2711P-T9W22D9P-BSHK

(1)

9-in.

(Wide)

(2)

Tou c h

DC

AC

DC

AC

DC

2711P-T9W22A9P AC

2711P-T9W22A9P-B x

2711P-T10C22D9P

2711P-T10C22D9PK

2711P-T10C22D9P-B x

(1)

Tou c h

DC

2711P-T10C22A9P AC

2711P-T10C22A9P-B x

2711P-B10C22D9P

2711P-B10C22D9P-B x

2711P-B10C22A9P AC

10-in.

DC

Touch with

keypad

2711P-B10C22A9P-B x

2711P-T12W22D9P

2711P-T12W22D9PK

2711P-T12W22D9P-B x

2711P-T12W22D9P-BSHK

(3)

(1)

12-in.

(Wide)

(2)

Tou c h

DC

2711P-T12W22A9P AC

2711P-T12W22A9P-B x

2711P-T15C22D9P

2711P-T15C22D9PK

2711P-T15C22D9P-B x

(1)

Tou c h

DC

2711P-T15C22A9P AC

2711P-T15C22A9P-B x

2711P-B15C22D9P

2711P-B15C22D9PK

(1)

2711P-B15C22D9P-B x

15-in.

DC

Touch with

keypad

2711P-B15C22A9P AC

2711P-B15C22A9P-B x

24 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 25

Termin a l S elec t ion (Contin u e d)

PanelView Plus 7 – Performance Terminals

Model

1900

TFT Color Display

Cat No. Size Input

2711P-T19C22D9P

2711P-T19C22D9PK

2711P-T19C22D9P-B x

(1)

19-in. Touch

Input

Power

DC

Brandless

2711P-T19C22A9P AC

2711P-T19C22A9P-B x

(1) This model includes conformal coating.

(2) No brand identity, stainless steel, hygienic, conformal coat.

(3) This model is included with the ArmorView Plus 7 product.

For information about accessories that are available for these terminals, see page 44.

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 25

Page 26

PanelView Plus 7 – Performance Terminals

Notes:

26 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 27

PanelView Plus 7 – Standard Terminals

PanelView™ Plus 7 Standard terminals are operator interface

devices. They monitor and control devices that are attached to

ControlLogix® and CompactLogix™ controllers on an

EtherNet/IP network. Animated graphic and text displays

provide operators a view into the operating state of a machine

or process. Operators interact with the control system by using

touch screen input.

PanelView Plus 7 Standard terminals include these features:

• Terminal functionality permits connection to 1 controller, 100 screens, and 500 alarms. This functionality was added

with the FactoryTalk® View Machine Edition 11.0 release.

• FactoryTalk View Machine Edition software provides a familiar environment for creating HMI applications.

• Windows CE operating system with desktop access for configuration and third-party applications.

• Ethernet communication that supports linear, star, and ring network topologies.

• PDF viewer to access PDF files that are stored on the terminal.

• More screen options including 4-in., 6-in., 7-in., 9-in.,10-in., 12-in., and 15-in. terminals.

• Widescreen displays in three sizes: 4-in., 9-in., and 12-in. terminals.

• Greater screen resolution.

• Terminals are available with an Allen-Bradley® label, or with no label.

• Certifications including Class 1, Div 2, ATEX zones 2 and 22, IECEx, CCC Ex, and InMetro.

Termin a l Fe a t u res

Features Description

High memory capacity 512 MB RAM and 512 MB storage

Approx. 80 MB nonvolatile storage for applications

Power i nput DC

Communication ports Single 10/100Base-T, Auto MDI/MDI-X, Ethernet port for controller communication, or DLR

USB ports One USB 2.0 high-speed host por t (type A) support removal flash drives for storage

One high-speed 1.0 device port (type B) suppor ts connection to host computer

Secu re Digital (SD) card slot One S D card slot.

Operating system All terminals run the Windows CE 6.0 operating system (OS) which provides OS functionality that meets the needs of most users:

Software FactoryTalk® View Machine Edition Station (runtime) software, version 7.0 or later, is preloaded and activated on each terminal

Preferred controller

• FTP server

• VNC client/server

• PDF reader

• Active X controls

• Third-party device support

• FactoryTalk® ViewPoint

Single license support for FactoryTalk ViewPoint software, version 1.2 or later, gives remote users access to terminal displays via a

standard web browser

HMI applications are developed with FactoryTalk View Studio for Machine Edition software, which is purchased separately

Comp actLog ix

For complete technical specifications, certifications, and environmental specifications on the PanelView Plus 7 Standard

terminals, refer to the PanelView Plus 7 Standard Terminals Technical Data, publication 2711P-TD008

.

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 27

Page 28

PanelView Plus 7 – Standard Terminals

Termin a l S elec t ion

Model

400W

600

700

900W

1000

1200W

1500

Color Touch Display

Cat. No. Size

2711P-T4W21D8S

2711P-T4W21D8S-B x

2711P-T4W22D8S x

2711P-T4W22D8S-B x x

2711P-T6C21D8S

2711P-T6C21D8S-B x

2711P-T6C22D8S x

2711P-T6C22D8S-B x x

2711P-T7C21D8S

2711P-T7C21D8S-B x

2711P-T7C22D8S x

2711P-T7C22D8S-B x x

2711P-T9W21D8S

2711P-T9W21D8S-B x

2711P-T9W22D8S x

2711P-T9W22D8S-B x x

2711P-T10C21D8S

2711P-T10C21D8S-B x

2711P-T10C22D8S x

2711P-T10C22D8S-B x x

2711P-T12W21D8S

2711P-T12W21D8S-B x

2711P-T12W22D8S x

2711P-T12W22D8S-B x x

2711P-T15C21D8S

2711P-T15C21D8S-B x

2711P-T15C22D8S x

2711P-T15C22D8S-B x x

4 in.

(Wide)

6 in.

7 in.

9 in.

(Wide)

10 in.

12 in.

(Wide)

15 in.

DLR

Support

Brandless

For information about accessories that are available for these terminals, see page 46.

28 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 29

PanelView Plus 6 – 700, 1000, 1250, and 1500

Terminals

This platform uses modular components with value-added options for flexible

system configuration. These components are usable across the entire PanelView™

Plus 6 platform and install with minimal effort:

• Color display modules that range from 6.5 inches to 15 inches in size with

either key, touch screen, or combination key/touch-screen input

• Windows CE logic modules providing desktop access

• Optional communication modules for network communication

Configured terminals with a display module and logic module can be ordered as

one catalog number or as separate components for field installation. Refer to Modular Components on page 31

A high-bright display for outdoor use, plus conformal-coated and marine-certified components, extend the ability of this

platform to operate in environments with even more stringent and varying requirements.

The core component of this platform is the high-performance logic module that runs a closed or open Windows CE desktop

environment with optional, extended features and file viewers. System integrators and OEMs can configure and deploy

systems that allow or restrict desktop access.

Termin a l Fe a t u res

Features Description

High memory capacity 512 MB RAM and 512 MB nonvolatile memory (approx. 79 MB free user memory)

Power input AC or D C

Network interface Optional DH+™, DH-485, or ControlNet communication module

Communication ports Ethernet, RS-232 serial

USB ports 2 USB host ports for connecting a USB mouse, keyboard, printer, and USB drives that are hot swappable

1 USB device port for connecting a host personal computer

Secure Digital (SD) card slot Hot-swappable card slot supports 1784-SDx and SDHCx SD cards for transferring files, upgrading firmware, or logging data

Operating system All terminals run the Windows CE 6.0 operating system (OS) which provides OS functionality that meets the needs of most users:

• FTP server

• VNC client/server

• PDF reader

• Active X controls

• Third-party device support

• FactoryTalk ViewPoint

.

Additional functionality is available by ordering terminals with optional, ex tended features:

• Internet Explorer™ web browser

• Remote desk top connection

• Media player

• Microsoft file viewers for PowerPoint, Excel, and Word

• Word Pad t ext edit or

Software

Preferred controller

FactoryTalk® View Machine Edition Station (runtime) software, version 6.0 or later, is preloaded and activated on each terminal

Single license support for FactoryTalk ViewPoint software, version 1.2 or later, gives remote users access to terminal displays via a

standard web browser

HMI applications are developed with FactoryTalk View Studio for Machine Edition software, which is purchased separately

ControlLogix or CompactLogix

For complete technical specifications, certifications, and environmental specifications on the PanelView Plus 6 terminals, refer to the PanelView Plus 6 Specifications Technical

Data, publication 2711P-TD005.

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 29

Page 30

PanelView Plus 6 – 700, 1000, 1250, and 1500 Terminals

Termin a l S elec t ion

Model

700

1000

1250

1500

(1)

Keypad Touch Keypad/Touch

Input Type

Color Display Size

2711P-K7C4D8 2711P-T7C4D8 2711P-B7C4D8

–

2711P-T7C4D8K

2711P-K7C4A8 2711P-T7C4A8 2711P-B7C4A8 AC

(2)

–

7-in.

2711P-K7C4D9 2711P-T7C4D9 2711P-B7C4D9 DC

2711P-K7C4A9 2711P-T7C4A9 2711P-B7C4A9 AC

2711P-K10C4D8 2711P-T10C4D8 2711P-B10C4D8

2711P-K10C4A8 2711P-T10C4A8 2711P-B10C4A8 AC

2711P-K10C4D9 2711P-T10C4D9 2711P-B10C4D9 DC

10-in

2711P-K10C4A9 2711P-T10C4A9 2711P-B10C4A9 AC

2711P-K12C4D8 2711P-T12C4D8 2711P-B12C4D8

–

2711P-T12C4D8K

2711P-K12C4A8 2711P-T12C4A8 2711P-B12C4A8 AC

(2)

–

12-in

2711P-K12C4D9 2711P-T12C4D9 2711P-B12C4D9 DC

2711P-K12C4A9 2711P-T12C4A9 2711P-B12C4A9 AC

2711P-K15C4D8 2711P-T15C4D8 2711P-B15C4D8

2711P-K15C4A8 2711P-T15C4A8 2711P-B15C4A8 AC

2711P-K15C4D9 2711P-T15C4D9 2711P-B15C4D9 DC

15-in.

2711P-K15C4A9 2711P-T15C4A9 2711P-B15C4A9 AC

Input

Power

DC

DC

DC

DC

Operating System

Windows CE 6.0

Windows CE 6.0 with extended features

Windows CE 6.0

Windows CE 6.0 with extended features

Windows CE 6.0

Windows CE 6.0 with extended features

Windows CE 6.0

Windows CE 6.0 with extended features

(1) These PanelView Plus 6 terminals include Ethernet and RS-232 Communication ports, and two USB ports.

(2) This model includes conformal coating.

30 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 31

PanelView Plus 6 – 700, 1000, 1250, and 1500 Terminals

Modular Components

Display modules, logic modules, and communication modules can be ordered as separate components for field installation.

Display Modules

Model Cat. No. Input Type Display

700

1000

1250

1500

2711P-RDK7C

2711P-RDK7CK x

2711P-RDT7C

2711P-RDT7CM x

2711P-RDB7C

2711P-RDB7CM x

2711P-RDK10C Keypad

2711P-RDT10C

2711P-RDT10CM x

2711P-RDB10C

2711P-RDB10CM x

2711P-RDK12C

2711P-RDK12CK x

2711P-RDT12C

2711P-RDT12CK x

2711P-RDT12AG x

2711P-RDT12H

2711P-RDB12C

2711P-RDB12CK x

2711P-RDK15C Keypad

2711P-RDT15C

2711P-RDT15AG x

2711P-RDB15C Keypad/Touch

(1)

Keypa d

Tou c h2711P-RDT7CK x

Keypad/Touch2711P-RDB7CK x

Tou c h

Keypad/Touch

Keypa d

Tou c h

Keypad/Touch

Tou c h

7-in. color

10-in. color

12-in. color

15-in. color

Marine

Certified

Conformal

Coated

Built-in

Antiglare Overlay

(1) This catalog number is a high-bright display module, indicated by the H at end of cat. no., which is designed for outdoor applications. The high-bright display module can be used only with

DC-powered logic modules.

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 31

Page 32

PanelView Plus 6 – 700, 1000, 1250, and 1500 Terminals

Logic Modules

Extended

Feature s

Cat. No. Power

2711P-RP8A AC

2711P-RP8D

No

2711P-RP8DK x x

2711P-RP9A AC

2711P-RP9D

Yes

2711P-RP9DK x x

Input

DC

DC

Memory

RAM/Nonvolatile

512 MB/512 MB

(approximately 79 MB

free user memory)

512 MB/512 MB

(approximately 79 MB

free user memory)

Communication Marine

• Ethernet

• RS-232

• Network interface for

communication module

• Ethernet

• RS-232

• Network interface

communication module

Certifi ed

x • Windows CE 6.0 operating system without

x

x • Windows CE 6.0 operating system with extended

x

Communication Modules

Cat. No.

Ethernet DH+ DH-485 ControlNet

2711P-RN6 x x

2711P-RN6K x x x

2711P-RN15S x x

2711P-RN15SK x x

Communication

2711P-RN20

(1)

x

Conformal

(2)

Coated

Marine

Certif ied

Conformal

Coated

Included Software

extended features/file viewers

• FactoryTalk View Machine Edition Station

(runtime), version 6.0 or later

• FactoryTalk ViewPoint software, version 1.2 or

later

features/file viewers

• FactoryTalk View Machine Edition Station

(runtime), version 6.0 or later

• FactoryTalk ViewPoint software, version 1.2 or

later

(1) All terminals have an Ethernet port. The cat. no. 2711P-RN20 module provides an additional Ethernet port.

(2) Scheduled and unscheduled communication.

For information about accessories that are available for these terminals, see page 47.

32 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 33

PanelView Plus 6 – 400 and 600 Terminals

The smaller PanelView™ Plus 6 - 400 and 600 terminals combine the display, logic,

memory, and power into one base unit:

• The 400 model has a 3.5-in. color graphic display with keypad or

combination key and touch input, or a grayscale display with keypad input.

• The 600 model has a 5.7-in. color or grayscale graphic display with keypad,

touch screen, or combination keypad/touch-screen input.

This new generation of terminals runs the Windows CE 6.0 operating system similar

to the PanelView Plus 6 - 700...1500 terminals. The terminals run HMI applications

but also allow access to the desktop. For users with more complex application requirements, the 600 color terminals can be

ordered with optional, extended features and file viewers.

Termin a l Fe a t u res

Features Description

High memory capacity 256 MB RAM and 512 MB nonvolatile memory (approximately 73 MB free user memory)

Power inpu t AC or DC

Communication ports Units are available with one of these communication options:

• RS-232

• Ethernet and RS-232

Separate communication modules are not supported.

USB ports • 1 USB host ports for connecting a USB mouse, keyboard, printer, and USB drives that are hot swappable

• 1 USB device port for connecting a host personal computer

Secure Digital (SD) card slot Hot-swappable card slot supports 1784-SDx SD cards for transferring files, upgrading firmware, or logging data

Operating system All terminals run the Windows CE 6.0 operating system (OS) which provides OS functionality that meets the needs of most users:

• FTP server

• VNC client/server

• PDF reader

• FactoryTalk Viewpoint

• Active X controls

• Third-party device support

Additional functionality is available for the 600 terminals by ordering terminals with these optional, extended features:

• Internet Explorer™ web browser

• Media player

• Microsoft file viewers for PowerPoint, Excel, and Word

• Word Pad tex t ed itor

Software • FactoryTalk® View Machine Edition Station (runtime) software, version 6.10 or later, is preloaded and activated on each

termina l

• HMI applications are developed with FactoryTalk View Studio for Machine Edition software, which is purchased separately

Reset and default switches Provide easy access to diagnostic and repair operations

Preferred controller

CompactLogix™ or ControlLogix®

For complete technical specifications, certifications, and environmental specifications on the PanelView Plus 6 terminals, refer to the PanelView Plus 6 Specifications Technical

Data, publication 2711P-TD005.

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 33

Page 34

PanelView Plus 6 – 400 and 600 Terminals

Termin a l S elec t ion

Model

400

600

(1)

Keypad Touch Keypa d/Touch RS-232 Ethe rnet

Input Type

Display Size

2711P-K4M5A8 — —

Communication

xAC

2711P-K4M5D8 — — x DC

2711P-K4M20A8 — — x x AC

4-in. Grayscale

2711P-K4M20D8 — — x x DC

2711P-K4C5A8 — 2711P-B4C5A8

xAC

2711P-K4C5D8 — 2711P-B4C5D8 x DC

2711P-K4C20A8 — 2711P-B4C20A8 x x AC

4-in. Color

2711P-K4C20D8 — 2711P-B4C20D8 x x DC

2711P-K6M5A8 2711P-T6M5A8 2711P-B6M5A8

2711P-K6M5D8 2711P-T6M5D8 2711P-B6M5D8 x DC

6-in. Grayscale

xAC

2711P-K6M20A8 2711P-T6M20A8 2711P-B6M20A8 x x AC

2711P-K6M20D8 2711P-T6M20D8 2711P-B6M20D8 x x DC

2711P-K6C5A8 2711P-T6C5A8 2711P-B6C5A8

xAC

2711P-K6C5D8 2711P-T6C5D8 2711P-B6C5D8 x DC

2711P-K6C20A8 2711P-T6C20A8 2711P-B6C20A8 x x AC

2711P-K6C20D8 2711P-T6C20D8 2711P-B6C20D8 x x DC

6-in. Color TFT

2711P-K6C5A9 2711P-T6C5A9 2711P-B6C5A9 x AC

2711P-K6C5D9 2711P-T6C5D9 2711P-B6C5D9 x DC

2711P-K6C20A9 2711P-T6C20A9 2711P-B6C20A9 x x AC

2711P-K6C20D9 2711P-T6C20D9 2711P-B6C20D9 x x DC

Input

Power

Operating System

Windows CE 6.0

Windows CE 6.0 with

extended features and file

viewers

(1) These PanelView™ Plus 6 terminals include one USB port.

For information about accessories available for these terminals, see page 47.

34 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 35

PanelView Plus 6 – Compact Terminals

The next generation PanelView™ Plus 6 Compact 400, 600, and 1000 terminals offer just the

right hardware and software functionality to meet the needs of mid-size applications. Any

application that is created for a compact terminal is also co

Plus 6 terminals. Key features include the following:

• 25 displays and 200 alarm messages supported in the FactoryTalk® View Compact

Machine Edition application

• Fixed hardware configurations without the addition or replacement of modular

components

Termi nal Feat ures

Features Description

High memory capacity 256 MB RAM and 512 MB nonvolatile memory (approximately 73 MB free user memory)

Power input DC

Communication ports RS-232 serial and Ethernet

USB ports 1 USB device port for connecting a host personal computer

Secure Digital (SD) card slot Hot-swappable card slot supports 1784-SDx SD cards for transferring files, upgrading firmware, or logging data

Operating system All terminals run the Windows CE 6.0 operating system (OS) providing OS functionality needed for most users needs:

• FTP server

• VNC client/server

• PDF reader

• FactoryTalk Viewpoint

• Active X controls

• Third-party device support

mpatible with other PanelView

(1)

Software • FactoryTalk® View Machine Edition Station (runtime) software, version 6.10 or later, is preloaded and activated on each terminal

Preferred controller

(1) The 10.4 in. terminal comes with 512 MB RAM and 512 MB nonvolatile memory (approximately 79 MB free user memory).

• Single license support for FactoryTalk ViewPoint software, version 1.2 or later, gives remote users access to a terminal display via standard

web browser

• HMI applications are developed with FactoryTalk View Studio for Machine Edition software, which is purchased separately

• Connection to single controller by using either RSLinx® Enterprise software, version 5.51 or later, or KEPServer software

CompactLogix™

For complete technical specifications, certifications, and environmental specifications on the PanelView Plus 6 terminals, refer to the PanelView Plus 6 Specifications Technical

Data, publication 2711P-TD005.

Termin a l S elec t ion

Model

400

600

1000 — 2711PC-T10C4D8 — 10-in.

Keypad Touch Keypad/Touch Size Type

2711PC-K4M20D8 — —

— — 2711PC-B4C20D8 Color

— — 2711PC-B4C20D8-LR Low Reflective

— 2711PC-T6M20D8 —

— 2711PC-T6C20D8 —

Input Type Disp lay

Grayscale

4-in.

Grayscale

6-in.

Colo r

For information about accessories that are available for these terminals, see page 50.

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 35

Page 36

PanelView Plus 6 – Compact Terminals

Notes:

36 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 37

MobileView Tethered Operator Terminals

The MobileView™ 2711T family of human machine interface (HMI) devices have a

rugged design with Microsoft® Windows® 7 Embedded Standard. The MobileView

2711T terminal features include a 3-position enable switch, touch and function keys,

and stop push buttons. These features allow operator access to the safety system of

the machine and the general interface to its control system.

The MobileView 2711T terminal is ideal for various applications, including:

• Operator panel for machines and plants

• Teach and programming panel for robots

• Test, maintenance, and startup

The MobileView 2711T terminal easily adapts to specific applications by using configurable operating and control elements.

A cable and junction box are required for the operation of a MobileView terminal.

Termi nal Feat ures

Features Description

Display size 10 in.

Enabling Switch Yes

High memory capacity 4 GB RAM/32 GB SSD

Power i nput DC

Communication ports 10/100 Ethernet

USB ports One USB host port

Secure Digital (SD) card slot Internal SD card

Operating system All terminals run the Windows® 7 Embedded Standard operating system (OS).

Software FactoryTalk® View Studio for Machine Edition

Preferred controller

Contr olLogi x®

For complete technical specifications, certifications, and environmental specifications on the MobileView tethered operator

terminals, refer to the MobileView Tethered Operator Terminals and Junction Boxes Technical Data, publication 2711T-TD001

Terminal Selection – First Generation MobileView Terminals

2-circuit Push Button

3-position

Cat. No. Display Size (in.) Touch Screen Function Keys

2711T-B10R1K1

2711T-B10R1M1

2711T-F10G1N1

2711T-T10G1N1

2711T-T10R1N1 Yes N o

10.1 Yes

Yes

No

Enabling Switch

Yes

3-position

Key Switch

Yes N o

No

Momentary

Button

Yes

No

E-stop

(red/yellow) Stop (gray)

Yes N o

No Yes

Terminal Selection – Second Generation MobileView Terminals

2-circuit Push Button

Cat. No. Display Size (in.) Touch Screen Function Keys

2711T-B10I1N1

2711T-T10I1N1-TC No

10.1 Yes

Yes

3-position

Enabling Switch

Yes N o N o Yes N o

For information about accessories that are available for these terminals, see page 52

3-position

Key Switch

Momentary

Button

.

Illuminated E-stop

(red/yellow) Stop (gray)

.

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 37

Page 38

MobileView Tethered Operator Terminals

Notes:

38 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 39

PanelView 800 Terminals

When you need an essential component but with a reduced cost, look to the

PanelView™ 800 family of operator interface devices. The PanelView 800

platform features a full line of 4-inch, 7-inch, and 10-inch displays (PanelView

Component terminals maintain their 2-inch and 3-inch displays). Preferred

integration with Allen-Bradley® MicroLogix™, Micro800®, CompactLogix™

5370, and SLC™ 500 families of logic controllers offers a control and

visualization solution for various applications. The PanelView 800 platform

includes the Connected Components Workbench™ software as the

common programming software.

Other key features include the ability to do the following:

• Secure information on screens with user name and password protection.

• Remote monitoring with Virtual Network Computing (VNC) server.

• Display information in languages including Chinese, Portuguese, French, Italian, German, Spanish, and Korean.

• Alert operators with alarm messages that include embedded variables and an alarm status/history.

• Upload and download groups of data or parameter settings within the recipe feature.

• Use Connected Components Workbench software, the integrated design and configuration software that offers HMI

programming and controller programming within the same common platform.

Termi nal Feat ures

Features Description

High memory capacity 256 MB RAM and 256 MB storage

Power input 24V DC

(1)

Communication ports Serial

USB ports One USB high-speed 2.0 host por t

Software Connected Components Workbench with DesignStation

Preferred controller

and Ethernet

MicroLogix, Micro800, and CompactLogix 5370 controllers

(2)

(1) Serial refers to RS-232 (DF1), RS-232 (DH-485), RS-485 communication.

(2) CompactLogix 5370, excluding L37 and L38.

For complete technical specifications, certifications, and environmental specifications on the PanelView 800 terminals, refer

to the PanelView 800 Terminals Technical Data, publication 2711R-TD001

.

For complete technical specifications, certifications, and environmental specifications on the PanelView Component

terminals, refer to the PanelView Component Specifications Technical Data, publication 2711C-TD001.

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 39

Page 40

PanelView 800 Terminals

Termin a l S elec t ion

Model Cat. No.

2711R-T4T 4 in.

PanelView 800

PanelView

Component C200

PanelView

Component C300

2711R-T7T 7 in.

2711R-T10T 10 in.

2711C-F2M

2711C-K2M Ten function keys and numeric keypad

2711C-T3M

2711C-K3M Ten function keys and numeric keypad

Size Type

2-in.

3-in.

Display

Color transmissive TFT

Monochrome transflective STN

Analog touch and function keys

Analog touch

Four f unctio n keys

Touch screen

For information about accessories that are available for these terminals, see page 53.

Input Type

40 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 41

PanelView Terminal Accessories

The tables in this chapter list accessories and communication cables available for PanelView™ terminals.

PanelView 5000 Accessories

The following tables list accessories for PanelView 5000 terminals. For information about keyboards and pointing devices that

are compatible with the PanelView 5000 terminals, see page 83

Protective Overlays

.

Cat. No. PanelView 5000

2711P-RGT7SP

2711P-RGB7P Touch with key-

2711P-RGT7W Touch

2711P-RGT9SP

2711P-RGT10SP

2711P-RGB10P Touch with key-

2711P-RGT12SP

2711P-RGT15SP

2711P-RGB15P Touch with key-

2711P-RGT19P 19 in. Touch

(1) Although this protective overlay was designed for the PanelView 5510 terminal, it can also be used for the corresponding size

(1)

(1)

(1)

(1)

PanelView 5310 terminal. Cat. No. 2711P-RGT6S can be used for the 6-in. PanelView 5310 terminal. When these overlays are used

on a PanelView 5310 terminal, there is an increased air gap between the overlay and the terminal screen.

Ter minal Model

7 in.

9 in.

10 in. —

12 in.

15 in.

Input Display Quantity

Tou c h

—

pad

Wide

Tou c h

3

pad

Tou c h

pad

Wide

—

Power Supplies and Power Terminal Blocks

Cat. No. Description Quantity

1606-XLP95E DIN-rail power supply, 24…28V DC output voltage, 95 W

2711P-RSACDIN DIN-rail power supply, AC-to-DC, 85…265V AC, 47…63 Hz

2711P-RTBDSP 3-pin DC power terminal block 10

11606-XLP100E DIN-rail power supply, 24…28V DC output voltage, 100 W

USB Programming Cable

Cat. No. Description Length

6189V-USBCBL2 Programming cable that connects the device port of the terminal to a USB

host port of a computer

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 41

1.8 m

(5.9 ft)

Page 42

PanelView Terminal Accessories

Mounting Hardware

Cat. No. Description Quantity

2711P-RMCP Mounting levers 16

Battery Replacement

Cat. No. Description Quantity

2711P-RY2032 Lithium coin cell battery, CR2032 equivalent 1

Secure Digital (SD) Cards

Cat. No. Description

1784-SD1 1 GB SD card

1784-SD2 2 GB SD card

1784-SDHC8 8 GB SDHC card

1784-SDHC32 32 GB SDHC card

2711C-RCSD USB to SD adapter for SD card

(1) To help reduce the chance of corruption when you use SD Cards or USB drives

with the terminal, Rockwell Automation recommends that you use only the

above SD card catalog numbers.

(1)

The SD™ and SDHC™ accessory cards in the above table have been designed to meet industrial robustness and

environmental requirements. Rockwell Automation recommends that you use these accessory cards with the terminal to

help reduce the chances of corruption. Studio 5000 View Designer software requires the following for SD cards that are

inserted into the HMI device:

• 4 GB of free space

• A supported SDHC card type, preferably one listed in the Secure Digital (SD) Cards

table

• An environmental rating for the PanelView 5000 environment

• A supported format of either FAT32 or ext3

42 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 43

ArmorView Plus 7 Accessories

The following tables list accessories for ArmorView Plus 7 terminals.

Mounting Hardware

Cat. No. Description Quantity

2711P-RVESA01 VESA kit (VESA access cover and I/O plate) 1

Handle

Cat. No. Description Quantity

(1)

2711P-RHNDL01

(1) Operators can install one, two, or three handles to the ArmorView Plus 7 terminal. Indentations for installing the handle are located opposite the

arm mount adapter (or the I/O plate), and on both sides. To install more than one handle, order multiple handle kits.

Stack Light

Cat. No. Description Quantity

854J-BVMC (vertical

(1)

mount)

Handle (83.1 x 345 x 50.7 (3.27 x 13.58 x 2.0)) 1

40 mm (1.57 in.) control tower stack light, black base, vertical mount, cap included 1

PanelView Terminal Accessories

(1) The stack light can be installed on the right, left, or both sides of the ArmorView Plus 7 terminal. If it is attached on the left side, it faces upward,

and if it is attached on the right side, it faces downward. To install more than one stack light, order multiple stack lights.

Cables

Cat. No. Description Quantity

2711P-RIOIN3M Input point cable for customer-installed switch (3-pin male Pico™ style connector

for Ethernet I/O module)

2711P-RIOUT3M Output point cable for customer-installed indicator light (3-pin male Pico style

connector for Ethernet I/O module)

1

1

Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020 43

Page 44

PanelView Terminal Accessories

PanelView Plus 7 Accessories – Performance

Term ina ls

The following tables list accessories for PanelView Plus 7 Performance terminals. For information about keyboards and

pointing devices that are compatible with the PanelView Plus 7 Performance terminals, see page 83

Protective Overlays

.

Cat. No.

2711P-RGT7SP

2711P-RGB7P Touch with keypad

2711P-RGT9SP 9 in. (wide)

2711P-RGT10SP

2711P-RGB10P Touch with keypad

2711P-RGT12SP 12 in. (wide)

2711P-RGT15SP

2711P-RGB15P Touch with keypad

2711P-RGT19P 19 in. Touch

PanelView Plus 7

Ter minal Model

7 in.

10 in.

15 in.

Input Quantity

Tou c h

Tou c h

3

Tou c h

Mounting Hardware

Cat. No. Description Quantity

2711P-RMCP

2711P-RTMC

(1) These levers are also used with the PanelView 5510 terminals.

(2) Catalog number 2711P-RTMC mounting clips are used for stainless steel terminals, catalog numbers 2711P-T9W22D9P-BSHK, or 2711P-

(1)

(2)

T12W22D9P-BSHK. Catalog number 2711P-T12W22D9P-BSHK requires 10 mounting clips. If you need more than eight clips, order two

2711P-RTMC mounting clip kits.

Mounting levers 16

Mounting clips 8

Battery Replacement

Cat. No. Description Quantity

2711P-RY2032 Lithium coin cell battery, CR2032 equivalent 1

Battery Cover

Cat. No. Description Quantity

2711P-RYKS Replacement cover for the battery compartment. 3

Cables

Cat. No. Description Quantity

9300-USBCBL-CP3 USB-A, 9 pin D-sub connector, serial, 2 m (6.56 ft) 1

9300-USBCBL-PM02 USB-A, 8-pin MicroLogix, serial, 2 m (6.56 ft) 1

44 Rockwell Automation Publication VIEW-SG001Z-EN-P - May 2020

Page 45

PanelView Terminal Accessories

Secure Digital (SD) Cards

Cat. No. Description Quantity

1784-SD1 1 GB SD card

1784-SD2 2 GB SD card

1784-SDHC8 8 GB SDHC card

1784-SDHC32 32 GB SDHC card

2711C-RCSD USB to SD adapter for SD card

(1) To help reduce the chance of corruption when you use SD Cards or USB drives with the terminal, Rockwell Automation recommends that you use

only the above SD card catalog numbers.

(1)

1

Power Supplies

Cat. No. Description Quantity

1606-XLP95E DIN-rail power supply, 24…28V DC output voltage, 95 W

11606-XLP100E DIN-rail power supply, 24…28V DC output voltage, 100 W

2711P-RSACDIN DIN-rail power supply, AC-to-DC, 85…265V AC, 47…63 Hz

Terminal Blocks

Cat. No. Description Quantity

2711P-RTBAP 3-pin AC power terminal block

2711P-RTBDSP 3-pin DC power terminal block

10

IMPORTANT Before you select the appropriate replacement gasket, you must identify the series of the PanelView Plus 7 Performance

Stainless Steel terminal. The terminal’s series information is located on the terminal’s product nameplate label. In the