Page 1

User Manual

Original Instructions

VersaView 5000 ThinManager Thin Clients and Industrial

Computers

Bulletin Numbers 6200P, 6200T, 6200V

Page 2

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are

required to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Page 3

Table of Contents

Preface

Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1

VersaView 5400 Industrial

Computer Features

VersaView 5200 ThinManager

Thin Client Features

Install the Thin Client or

Computer

Operating Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Computer Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Hardware Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 2

Thin Client Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Hardware Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 3

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Environment and Enclosure Information. . . . . . . . . . . . . . . . . . . . 18

European Union Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Installation Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Enclosure Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Mounting Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Install the Thin Client or Computer. . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Panel Mounting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Panel Cutout Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Mount an Integrated Display Model in a Panel . . . . . . . . . . . . . . . 24

VESA Mounting for Integrated Display Models. . . . . . . . . . . . . . 26

Mount a Non-display Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connect Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Connect Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Connect DC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

AC Power Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Operate the Thin Client or

Computer

Chapter 4

Operating Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Touch Screen Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Touch Screen Driver Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Start the Thin Client or Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Restart the Thin Client or Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Shut Down the Thin Client or Computer. . . . . . . . . . . . . . . . . . . . . . . 36

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 3

Page 4

Table of Contents

Chapter 5

Configure the UEFI (BIOS)

Settings

Set-up Utility Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Access the Set-up Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

UEFI Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Help Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

H/W Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Restore the OS Image. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Upgrade to a New UEFI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

For All VersaView 5000 ThinManager® Thin Client and

Industrial Computers Except Cat. No. 6200T-BA. . . . . . . . . . . . 40

For VersaView 5200 ThinManager Thin Client Cat. No.

6200T-BA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Chapter 6

Troubleshoot the System Hardware (H/W) Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Load the System Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Ship or Transport the Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Dispose of the Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Chapter 7

Clean the Thin Client or Computer Clean the Thin Client or Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Clean the Integrated Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Clean the Air Openings and Cooling Fins . . . . . . . . . . . . . . . . . . . 50

Remove Paint and Grease from Bezel . . . . . . . . . . . . . . . . . . . . . . . 50

Appendix A

Install Accessories Available Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Disconnect Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Electrostatic Discharge Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Pre-configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Post-configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Replace a Factory-installed Bookshelf Mounting Plate. . . . . . . . . . . . 53

For Non-display VersaView ThinManager Thin Client and

Industrial Computers (cat. nos. 6200T-KB, 6200T-NA, and

6200P-NS3xx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

For VersaView 5200 ThinManager Thin Client Non-display

Computer (cat. no. 6200T-BA). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Install the VESA Mounting Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

For Non-display VersaView ThinManager Thin Client and

Industrial Computers (cat. nos. 6200T-KB, 6200T-NA, and

6200P-NS3xx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

Page 5

Table of Contents

For VersaView 5200 ThinManager Thin Client Single Display

Model (cat. no. 6200T-BA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Install the DIN Rail Mounting Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

For Non-display VersaView ThinManager Thin Client and

Industrial Computers (cat. nos. 6200T-KB, 6200T-NA, and

6200P-NS3xx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

For VersaView 5200 ThinManager Thin Client Single Display

Model (cat. no. 6200T-BA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Install the Machine Mounting Bracket Kit . . . . . . . . . . . . . . . . . . . . . . 61

For Non-display VersaView ThinManager Thin Client and

Industrial Computers (cat. nos. 6200T-KB, 6200T-NA, and

6200P-NS3xx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

For Non-display VersaView 5200 ThinManager Thin Client

Multi-4K Display Models (cat. nos. 6200T-RC and

6200T-RE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Install the Legacy Mounting Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 5

Page 6

Table of Contents

Notes:

6 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

Page 7

Preface

This manual is a user guide for VersaView® 5000 ThinManager® thin client and

industrial computers. It provides procedures to the following:

• Install the thin client or industrial computer.

• Make thin client or industrial computer connections.

• Operate the thin client or industrial computer.

• Troubleshoot the thin client or industrial computer.

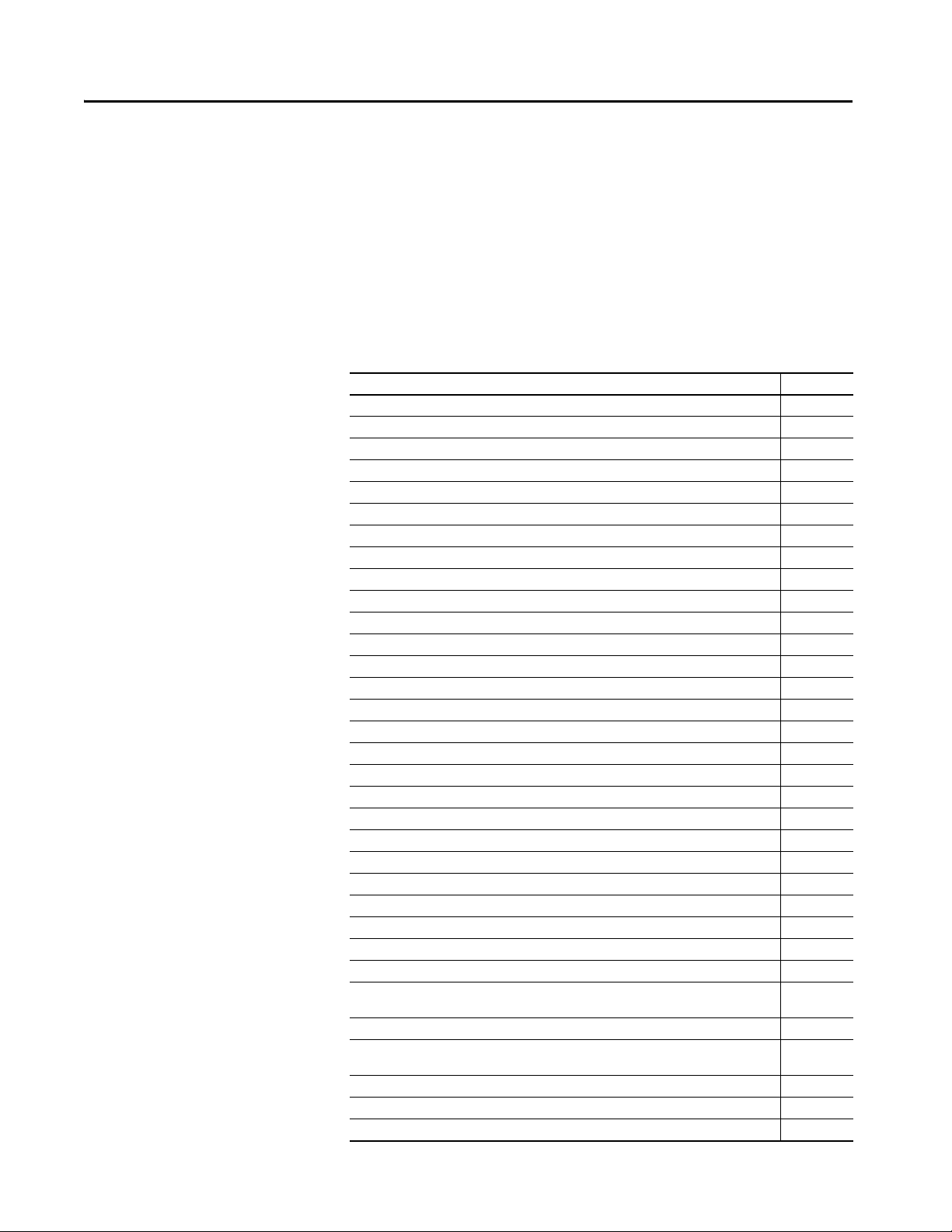

Summary of Changes

This manual contains new and updated information as indicated in the

following table.

Top ic Pag e

Revised Chapter 1 so it details only VersaView 5400 industrial computer features. 9

Replaced photo in Figure 1 to include factory-supplied mounting plate. 11

Added item 11, ground stud, to Figure 1 table. 11

Added Figure 2 table footnote. 11

Created a new Chapter 2 that details only VersaView 5200 ThinManager thin client features. 13

Added cat. nos. 6200T-KB, 6200T-RC, 6200T-RE, and footnote to Table 2. 13

Replaced photo in Figure 3 to include factory-supplied mounting plate. 14

Added item 8, ground stud, to Figure 3 table. 14

Replaced photo in Figure 4 to include factory-supplied mounting plate. 14

Added item 11, ground stud, to Figure 4 table. 14

Added Figure 5 photo and table. 15

Added Figure 6 photo and table. 15

Added Figure 7 table footnote. 16

Added ‘four rubber mount pads’ and footnote 4 to Parts List table. 17

Revised cable length information in Attention table in European Union Directive subsection. 18

Added cable types to table, and separated shielded and unshielded cable types. 19

Revised footnote for cable types table to refer to the Connection Peripherals table. 19

Added Table 3 to Installation Guidelines section. 19

Added table to bullet point about maximum humidity levels. 20

Revised figure title, and added catalog numbers to illustrations and table in Figure 8. 21

Revised figure title, and added catalog numbers to illustrations and table in Figure 9. 22

Added catalog numbers to each mounting example in Figure 11. 27

Added Category and For Cat. No. columns, and six new peripherals in Connect Peripherals table. 28

Added bullet point for the AC to 40 W, 24V DC power adapter in AC Power Options subsection. 31

Added footnote 2 to AC Power Options subsection. 31

Added example headings and second screen shot and in UEFI Overview section. 38

Added second screen shot of boot menu in step 10 of Upgrade to a New UEFI section. 41

Added cat. no. 6200T-BA to For Non-display VersaView ThinManager thin client and Industrial

Computers subtitles.

Added Tip table to step 8 in the Install the VESA Mounting Plate section. 56

Added the introductory sentence and two bullet points to the Install the Machine Mounting

Bracket Kit section.

Added the subtitle before the cat. no. 6200V-BXMACH installation instructions. 61

Added machine mounting bracket dimensions to step 7. 63

Added the cat. no. 6200V-BXMACH2 installation instructions section. 64

53, 55, 58

61

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 7

Page 8

Preface

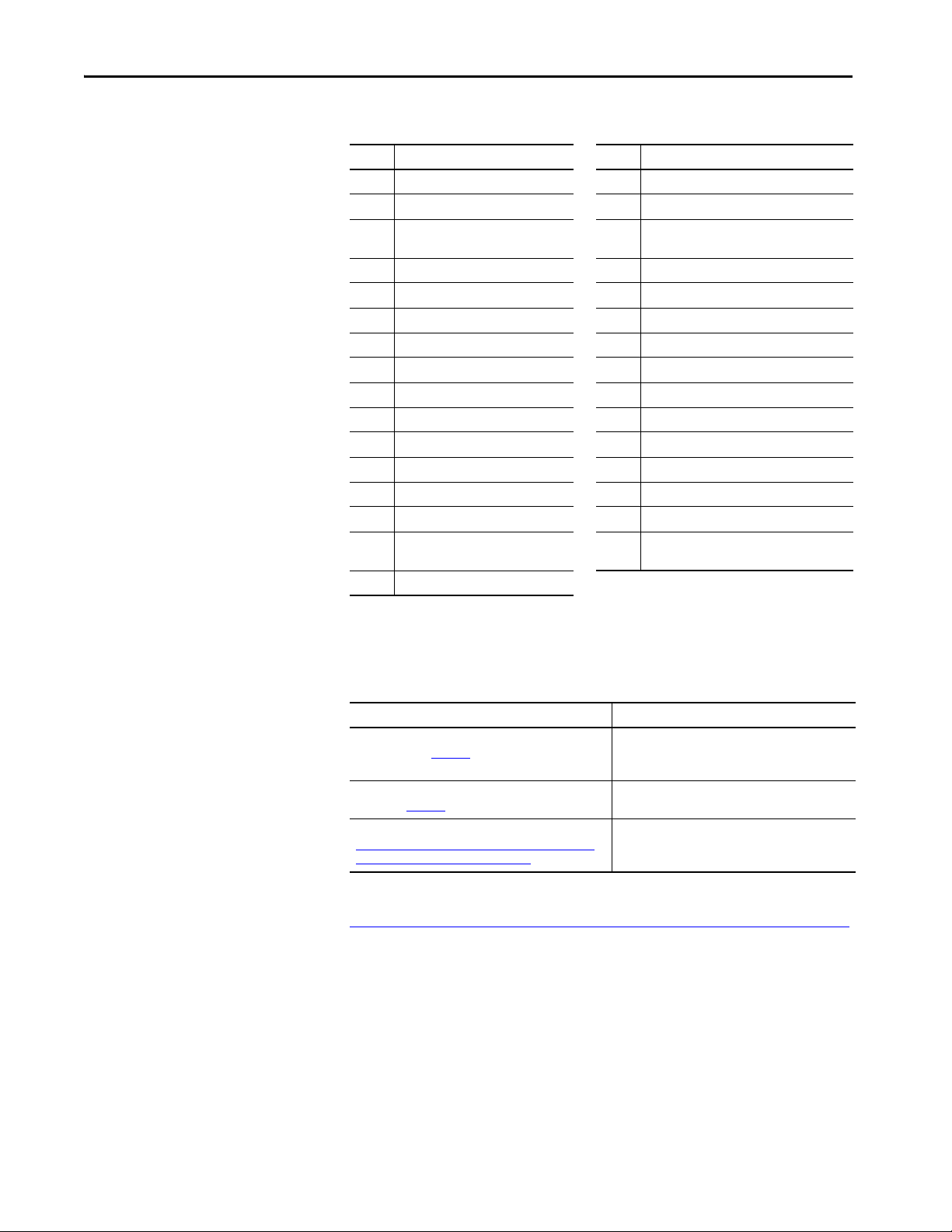

Abbreviations

This publication can use the following abbreviations.

Abbr Meaning Abbr Meaning

BIOS Basic input/output system PCB Printed circuit board

CF CompactFlash PCDC Product Compatibility and Download Center

CMOS Complementary metal oxide

semiconductor

COM Communication (serial port interface) PCIe Peripheral component interconnect express

DDR Double data rate (RAM) PELV Protective extra-low voltage

DIMM Dual in-line memory module POST Power on self-test

DP DisplayPort (digital display interface) RAM Random access memory

DVI Digital video interface RTC Real-time clock

EEA European Environment Agency SELV Safety extra low voltage

EMC Electromagnetic compatibility SSD Solid-state drive

ESD Electrostatic discharge TFT Thin film transistor

IEC International Engineering Consortium UEFI Universal extensible firmware interface

LAN Local area network USB Universal serial bus

NDM

Non-display model

NEMA

National Electrical Manufacturers

Association

PCAP

Protective capacitive (touch screen)

PCI Peripheral component interconnect

UPS Uninterruptible power source

VGA Video graphics array

Additional Resources

These documents contain additional information about related products from

Rockwell Automation.

Resource Description

Industrial Computer and Monitor Specifications Technical

Data, publication IC-TD001

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website,

https://www.rockwellautomation.com/global/support/

technical-documentation/overview.page

Provides technical specifications for Rockwell

Automation indu strial computers and monitors, which

includes VersaView computers.

Provides general guidelines to install a Rockwell

Automation industrial system.

Provides declarations of conformity, certificates, and

other certification details.

You can view or download publications at

http://www.rockwellautomation.com/global/literature-library/overview.page

To order paper copies of technical documentation, contact your local

Allen-Bradley distributor or Rockwell Automation sales representative.

.

8 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

Page 9

Chapter 1

VersaView 5400 Industrial Computer Features

Top ic Pa ge

Operating Systems 9

Computer Options 10

Hardware Features 11

The Allen-Bradley® VersaView® 5400 portfolio is a line of industrial computers

that can be used for standalone machine-level and distributed HMI

applications. The open architecture supports modern operating systems and

various software applications, including FactoryTalk® View SE software for

distributed applications. The line is fanless with little maintenance needed,

which reduces costly machine downtime.

Operating Systems

The VersaView 5400 integrated display computers have an edge-to-edge, all

glass, ten-point multi-touch screen that can also be operated with gloves. The

touch screens are precalibrated so that recalibration is not necessary.

All VersaView non-display computers perform the same as the integrated

display computers, in a compact design that supports multiple mounting

options.

The following Microsoft-licensed operating systems are available:

• Windows 7 Professional (64 bit), SP 1

• Windows Embedded Standard 7 (64 bit)

• Windows 10 IoT Enterprise (64 bit)

No operating system updates have been applied to the factory image beyond

the above listed service packs.

To obtain a copy of a factory system image, contact your local technical support

center or access the Rockwell Automation® PCDC site:

https://compatibility.rockwellautomation.com/Pages/home.aspx

.

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 9

Page 10

Chapter 1 VersaView 5400 Industrial Computer Features

Computer Options

Ta b l e 1 describes what options ship currently with VersaView 5400 industrial

computers. To identify your model’s configuration, compare the sticker on your

model to Ta b l e 1

A comparative summary of features is in publication IC-TD001

.

, Industrial

Computer and Monitors Specifications Technical Data.

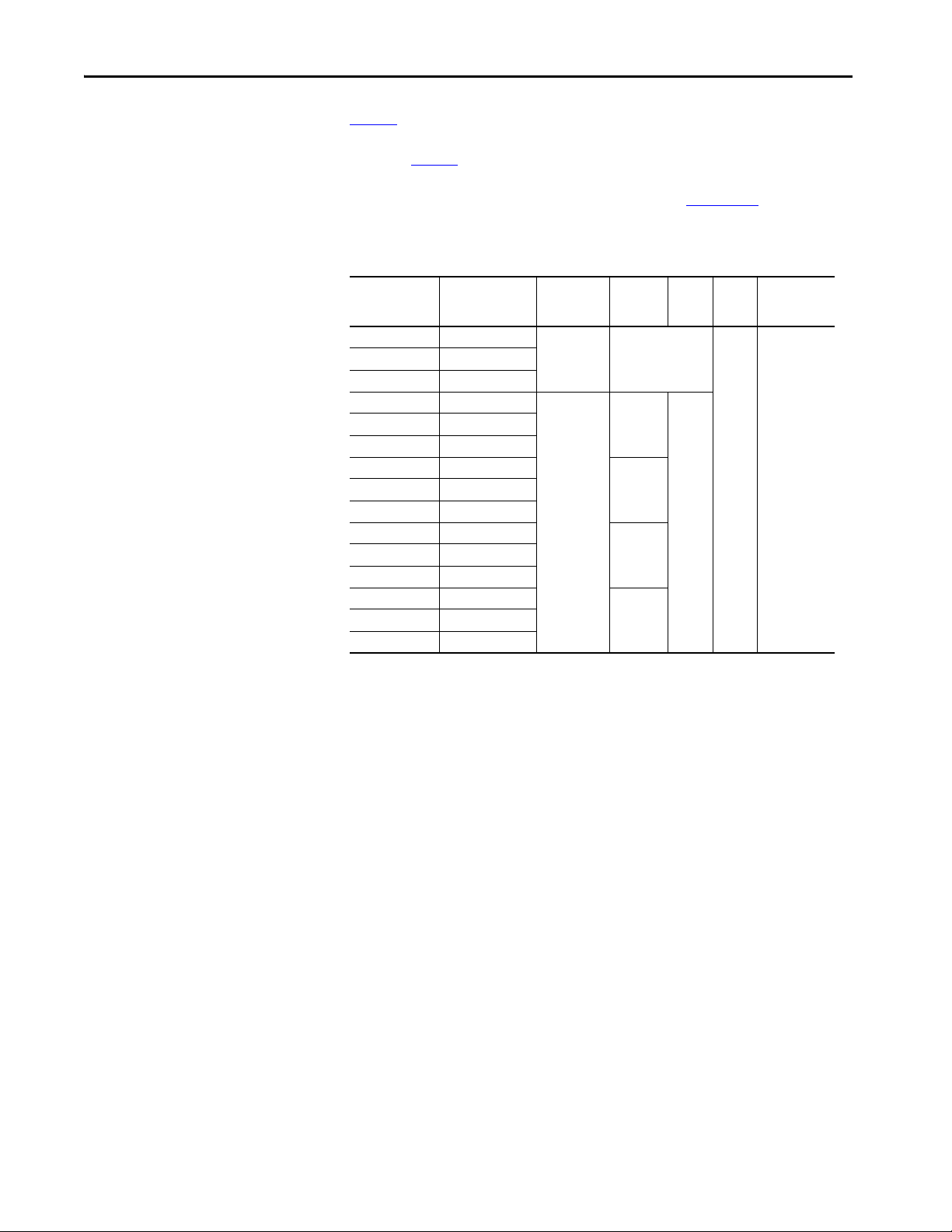

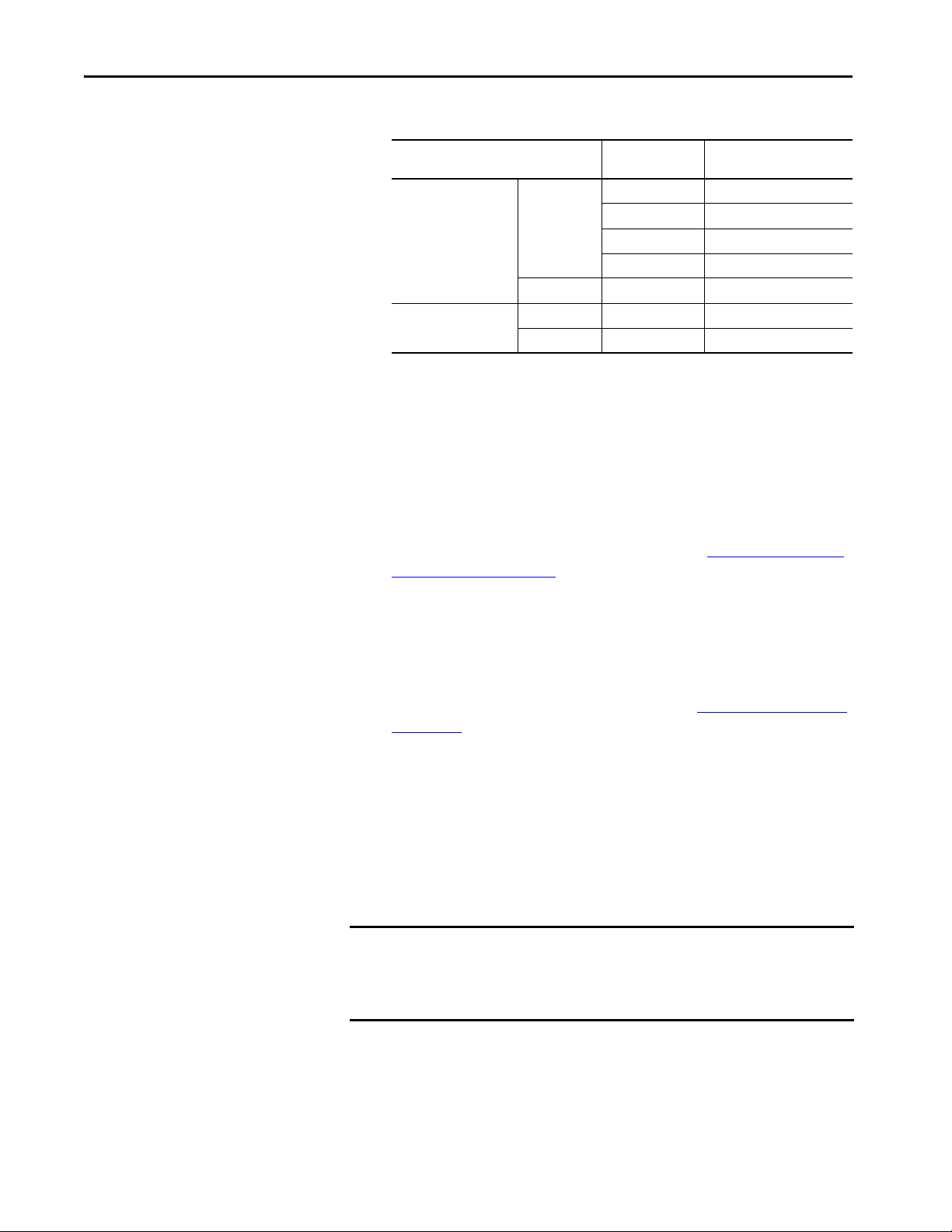

Table 1 - VersaView 5400 Non-display and Integrated Display Computer Catalog Numbers

Industrial

Cat. No. Windows OS

6200P-NS3A1 7 Pro, SP1 Non-display — Quad 128

6200P-NS3B1 WES 7

6200P-NS3C1 10 IoT Enterprise

6200P-12WS3A1 7 Pro, SP1 Display 12.1 PCAP

6200P-12WS3B1 WES 7

6200P-12WS3C1 10 IoT Enterprise

6200P-15WS3A1 7 Pro, SP1 15.6

6200P-15WS3B1 WES 7

6200P-15WS3C1 10 IoT Enterprise

6200P-19WS3A1 7 Pro, SP1 18.5

6200P-19WS3B1 WES 7

6200P-19WS3C1 10 IoT Enterprise

6200P-22WS3A1 7 Pro, SP1 21.5

6200P-22WS3B1 WES 7

6200P-22WS3C1 10 IoT Enterprise

Computer

Model

Display

Size (in.)

Tou ch

Screen

CPU

Core

MLC SSD

Storage Size

(GB)

10 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

Page 11

VersaView 5400 Industrial Computer Features Chapter 1

1

2

3

4

5

6

10

9

7

8

11

1

2 3 4 5

6

7

8

9

10

11

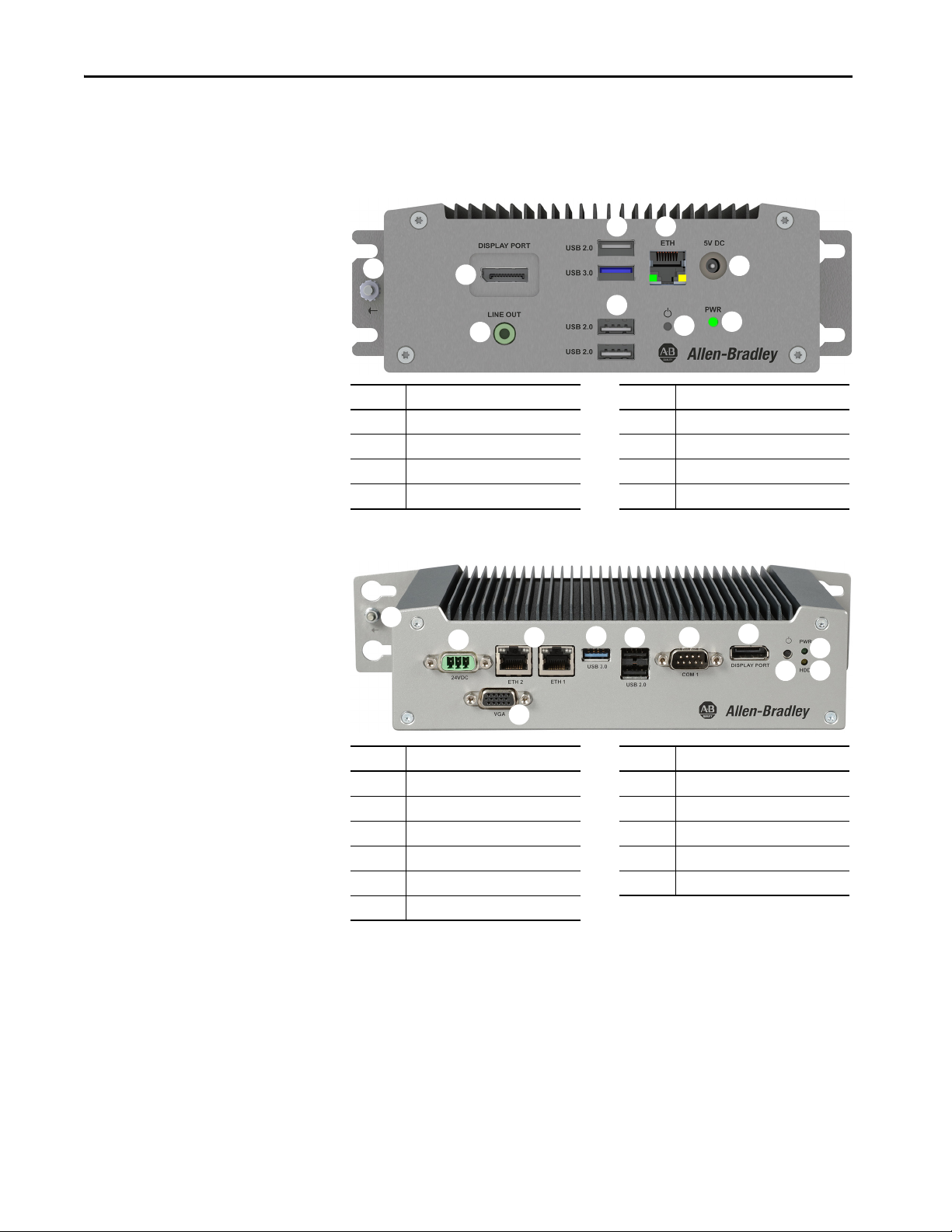

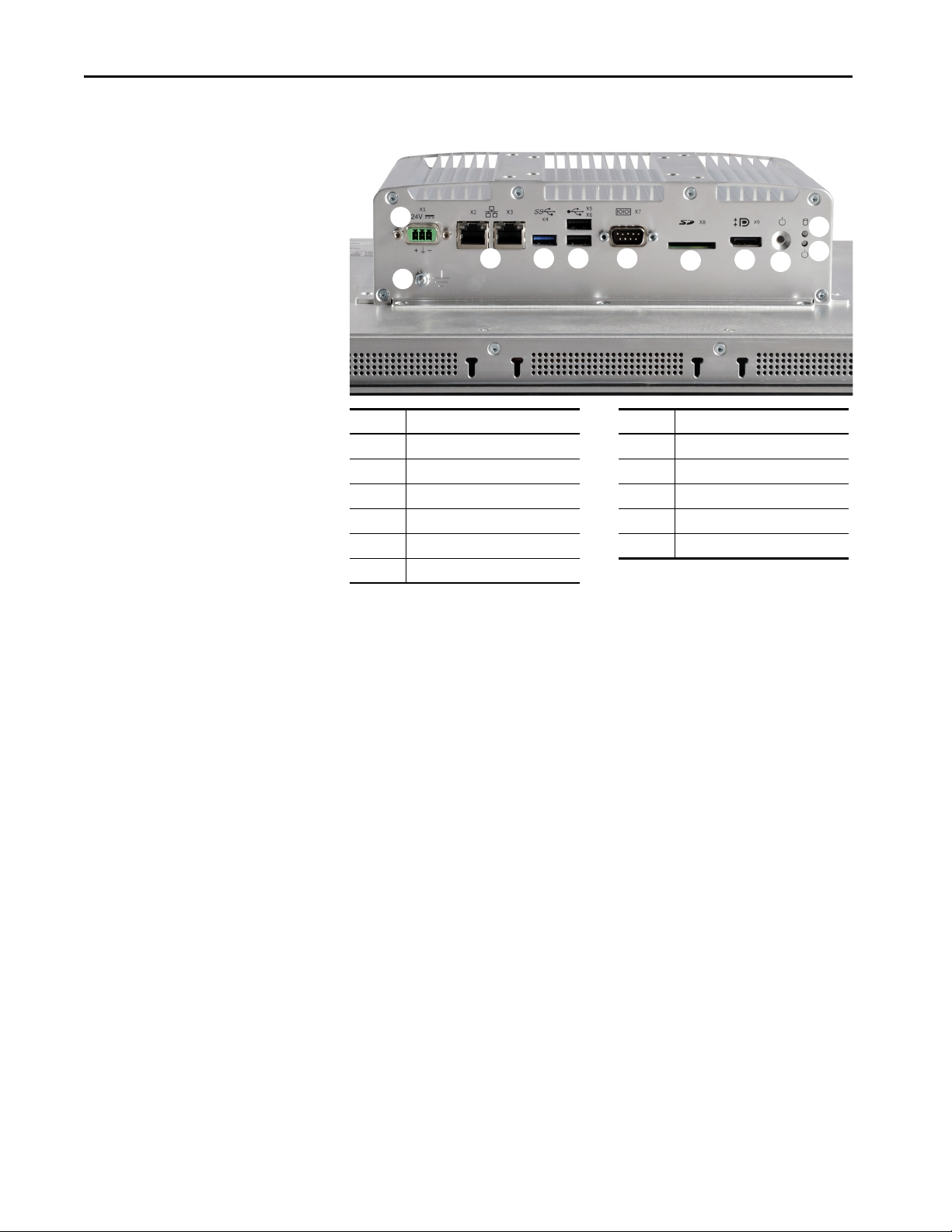

Hardware Features

The following figures show the hardware features of VersaView 5400 industrial

non-display and integrated display models.

Figure 1 - VersaView 5400 Industrial Non-display Models (cat. nos. 6200P-NS3x1)

Item Component Item Component

1 24V DC power input connection 7 Power LED

2 2 x Ethernet LAN port 8 SSD LED

3USB 3.0 port 9Power button

4 2 x USB 2.0 port 10 VGA port

5 Serial COM port, RS-232 11 Ground stud

6DisplayPort

(1) Audio output/line out supported.

(1)

Figure 2 - VersaView 5400 Industrial Integrated Display Models (cat. nos. 6200P-xxWS3x1)

Item Component Item Component

1 24V DC power input connection 7 DisplayPort

2 2 x Ethernet LAN port 8 Power button

3 USB 3.0 port 9 SSD LED

4 2 x USB 2.0 port 10 Power LED

5 Serial COM port, RS-232 11 Ground stud

6SD card

(1) Audio output/line out supported.

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 11

(1)

Page 12

Chapter 1 VersaView 5400 Industrial Computer Features

Notes:

12 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

Page 13

Chapter 2

VersaView 5200 ThinManager Thin Client

Features

Top ic Pa ge

Thin Client Options 13

Hardware Features 14

The Allen-Bradley® VersaView® 5200 ThinManager® thin clients work

exclusively with ThinManager software for centrally-managed content

delivery. Integrated display and non-display versions are available.

Thin Client Options

Ta b l e 2 describes what options ship currently with VersaView 5200 thin clients.

To identify your model’s configuration, compare the sticker on your model to

Ta b l e 2

.

A comparative summary of features is in publication IC-TD001

, Industrial

Computer and Monitors Specifications Technical Data.

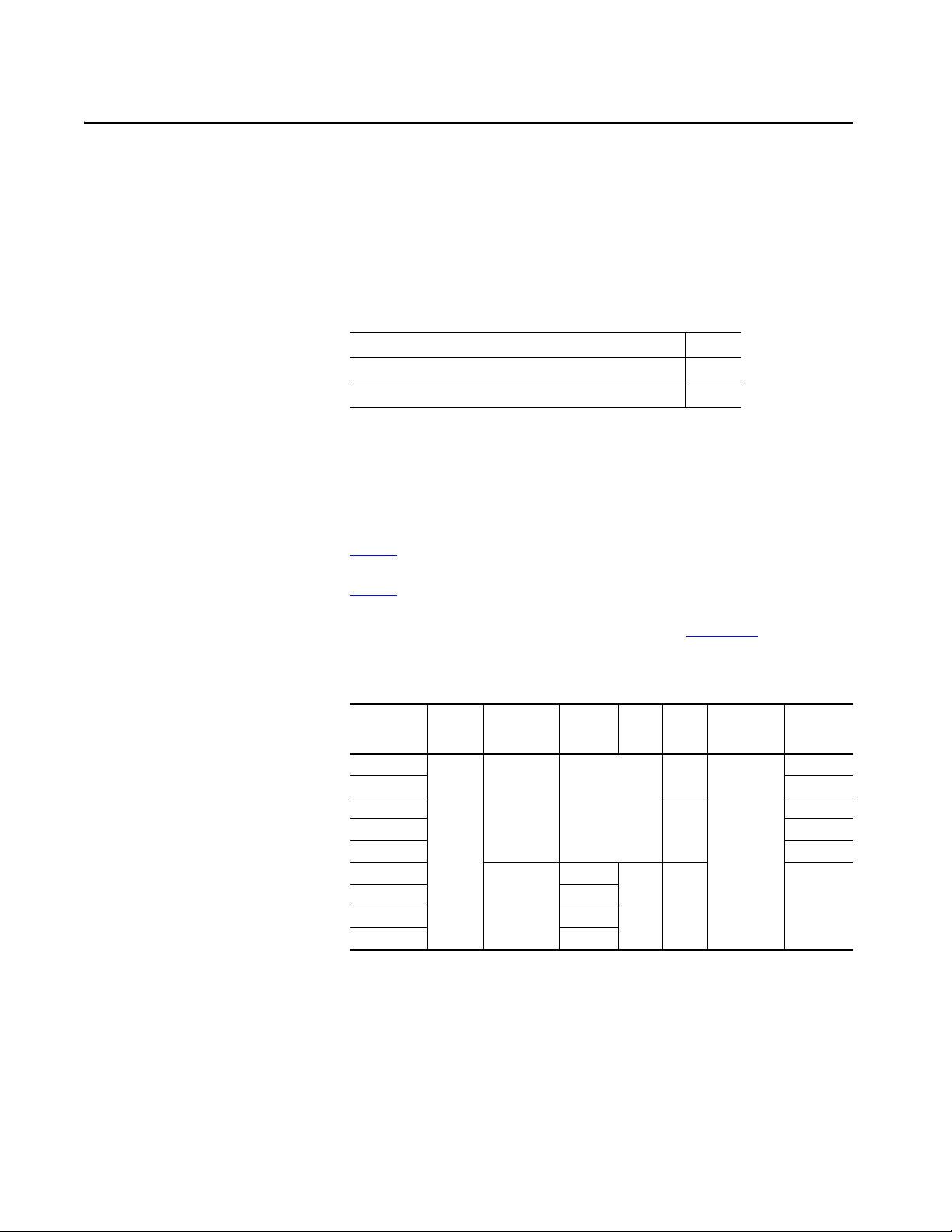

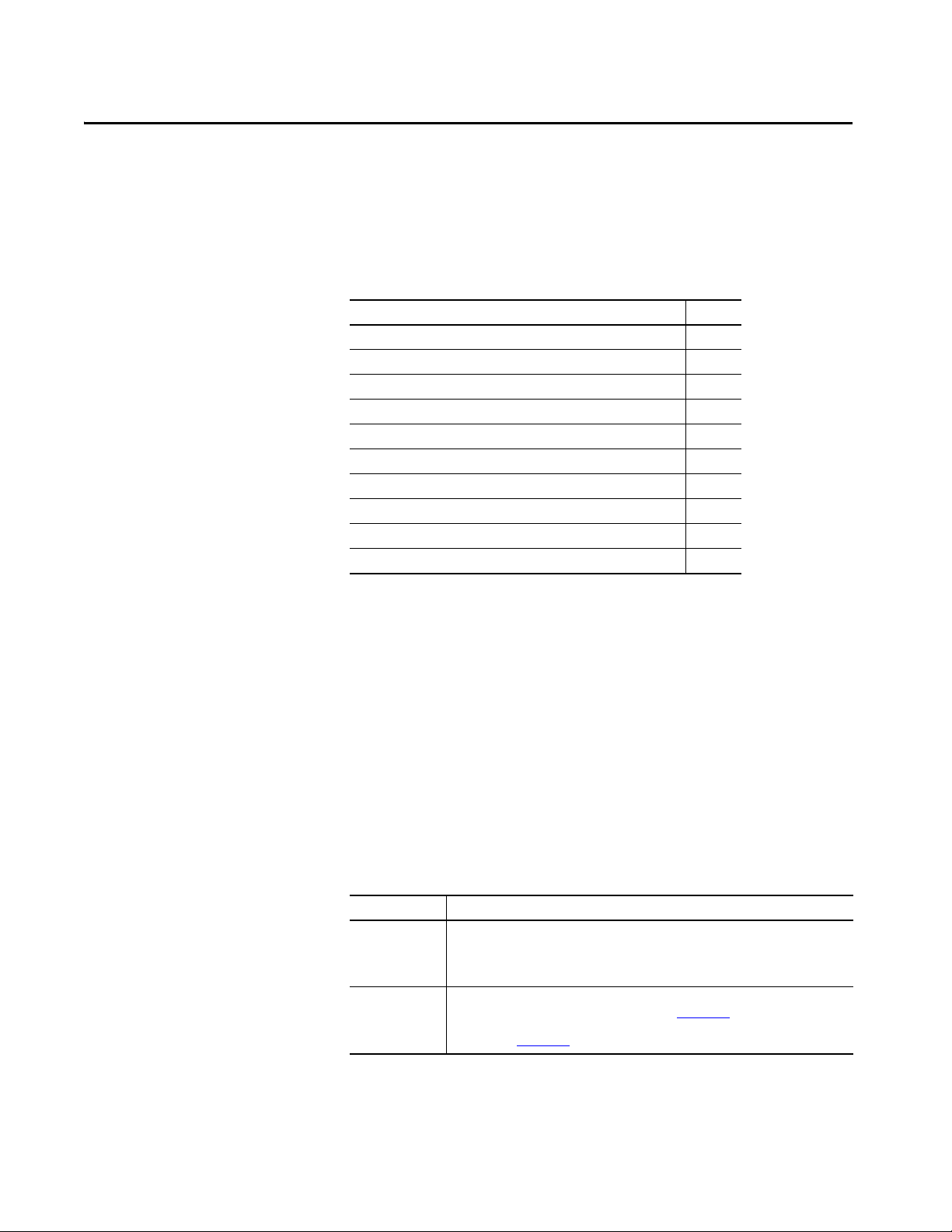

Table 2 - VersaView 5200 ThinManager Thin Client Non-display and Display Catalog Numbers

Cat. No.

6200T-BA — Non-display — Single — 1

6200T-NA 2

6200T-KB Quad 2

6200T-RC 3

6200T-RE 7

6200T-12WA Display 12.1 PCAP Single 1

6200T-15WA 15.6

6200T-19WA 18.5

6200T-22WA 21.5

(1) These external display ports support 4K resolution.

Windows OSThin Client

Model

Display

Size (in.)

Tou ch

Screen

CPU

Core

MLC SSD

Storage Size

(GB)

No. of

External

Displays

(1)

(1)

(1)

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 13

Page 14

Chapter 2 VersaView 5200 ThinManager Thin Client Features

1

2

3 4

5

6

7

3

8

1

2

3

4

5

6

10

9

7

8

11

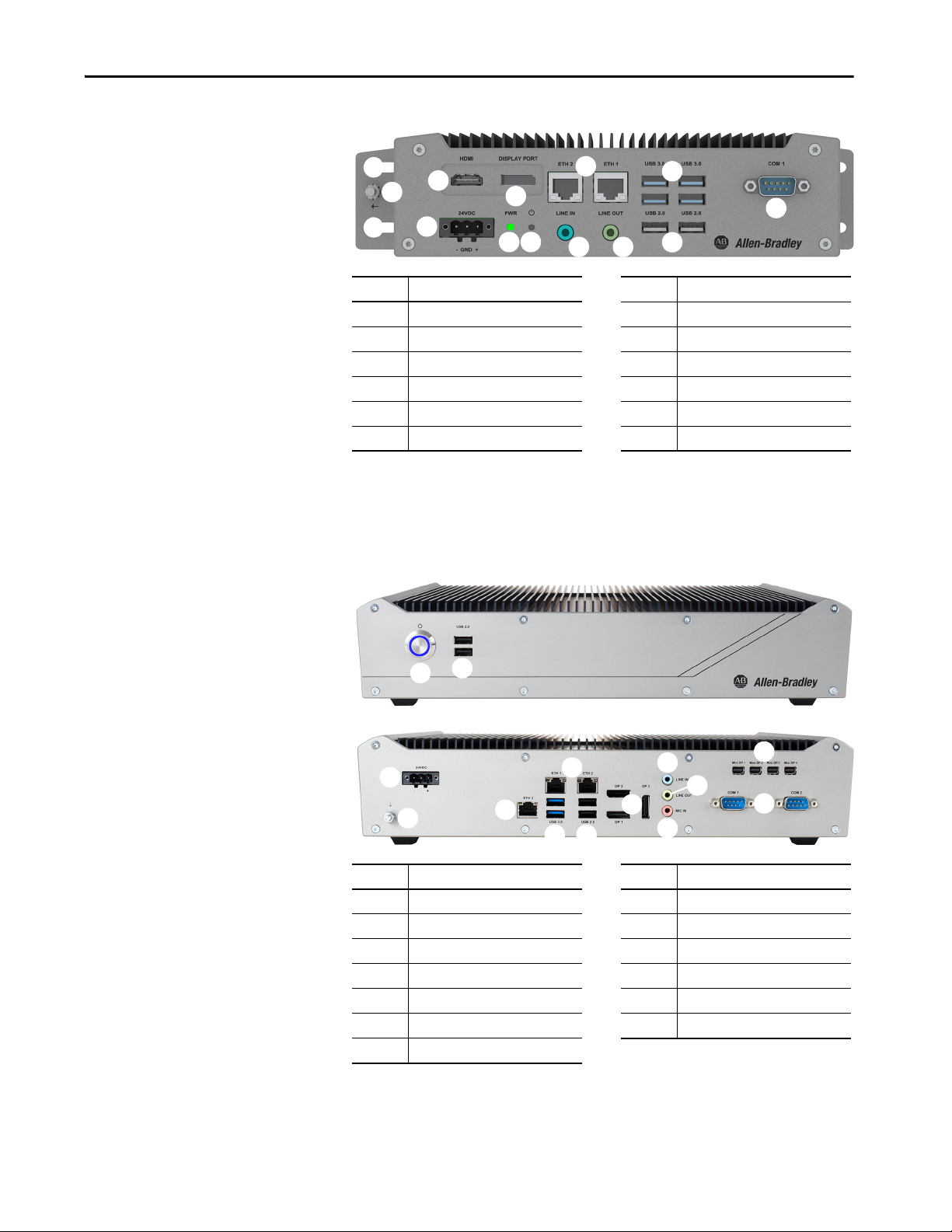

Hardware Features

The following figures show the hardware features of VersaView 5200

ThinManager thin client models.

Figure 3 - VersaView 5200 ThinManager Thin Client – Single Display (cat. no. 6200T-BA)

Item Component Item Component

1 DisplayPort 5 5V DC power input connection

2 Analog audio output 6 Power LED

3 3 x USB 2.0 port and 1 x USB 3.0 por t 7 Power button

4 Ethernet LAN port 8 Ground stud

Figure 4 - VersaView 5200 ThinManager Thin Client – Dual Display (cat. no. 6200T-NA)

Item Component Item Component

1 24V DC power input connection 7 Power LED

2 2 x Ethernet LAN port 8 SSD LED

3 USB 3.0 port 9 Power button

4 2 x USB 2.0 port 10 VGA port

5 Serial COM port, RS-232 11 Ground stud

6DisplayPort

(1) Audio output/line out supported.

14 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

(1)

Page 15

VersaView 5200 ThinManager Thin Client Features Chapter 2

1

2

3

4

5

6

11

9

7

8

10

12

1

13

3

4

5

6

11

9

7

8

10

2

12

5

Front View

Back View

Figure 5 - VersaView 5200 ThinManager Thin Client – Dual 4K Display (cat. no. 6200T-KB)

Item Component Item Component

1 24V DC power input connection 7 2 x USB 2.0 port

2HDMI port

3DisplayPort

4 2 x Ethernet LAN port 10 Power button

5 4 x USB 3.0 port 11 Power LED

6 Serial COM port, RS-232 12 Ground stud

(1) These ports support 4K resolution.

(2) Audio input is not supported currently with ThinManager software.

(1)

(1)

8 Analog audio output

9 Analog audio input

(2)

Figure 6 - VersaView 5200 ThinManager Thin Client – Multi-4K Display (cat. nos. 6200T-RC and

6200T-RE)

Item Component Item Component

1Power button

(1)

8 3 x full-sized DisplayPort

22 x USB 2.0 port 9Analog audio input

3 24V DC power input connection 10 Analog audio output

4 Ground stud 11 Microphone input

5 3 x Ethernet LAN port 12 2 x Serial COM port, RS-232

6 2 x USB 3.0 port 13 4 x Mini DisplayPort

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 15

7 2 x USB 2.0 port

(1) Button has a LED ring that is lit when power is on, which is shown in picture.

(2) These ports support 4K resolution.

(3) Audio input is not supported currently with ThinManager software.

(4) Only cat. no. 6200T-RE includes these four mini display ports; cat. no. 6200T-RC does not.

(2)

(3)

(3)

(2)(4)

Page 16

Chapter 2 VersaView 5200 ThinManager Thin Client Features

1

2 3 4 5

6

7

8

9

10

11

Figure 7 - VersaView 5200 ThinManager Thin Client Integrated Display Models

(cat. nos. 6200T-xxWA)

(1) Audio output/line out supported.

Item Component Item Component

1 24V DC power input connection 7 DisplayPort

2 2 x Ethernet LAN port 8 Power button

3 USB 3.0 port 9 SSD LED

4 2 x USB 2.0 port 10 Power LED

5 Serial COM port, RS-232 11 Ground stud

6SD card

(1)

16 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

Page 17

Install the Thin Client or Computer

Top ic Pa ge

Before You Begin 17

Parts List 17

Installation Precautions 18

Installation Guidelines 19

Mounting Clearance Requirements 20

Dimensions 21

Required Tools 23

Install the Thin Client or Computer 23

Connect Per ipherals 28

Connect Powe r 29

Chapter 3

Before You Begin

Parts List

Before you unpack your VersaView® 5000 ThinManager® thin client or

industrial computer, inspect the shipping carton for damage. If damage is

visible, immediately contact the shipper and request assistance. Otherwise,

proceed with unpacking.

Keep the original packing material in case you need to return the VersaView

thin client or computer for repair or transport it to another location. Use both

the inner and outer packing cartons to provide adequate protection for

equipment returned for service.

VersaView thin clients or computers ship with the following items.

Item Description

Hardware • Mounting clips

• DC terminal block

• AC-to-DC power adapter, cat. no. 6200V-MPS5

• Four rubber mount pads

Documents • VersaView 5100 Industrial Monitors, VersaView 5000 Thin Clients, Industrial Computers,

and Accessories Product Information, publication 6200-PC001

• VersaView 5000 Thin Client and Integrated Display Industrial Computers Cutout Template,

publication 6200-DS001

(1) Shipped only with VersaView thin client and industrial computers with integrated display models.

(2) DC terminal block does not ship with the cat. no. 6200T-BA ThinManager thin client model.

(3) Shipped only with the cat. no. 6200T-BA ThinManager thin client model.

(4) Shipped only with non-display industrial computers and non-display ThinManager thin client models.

(1)

(2)

(3)

(4)

(1)

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 17

Page 18

Chapter 3 Install the Thin Client or Computer

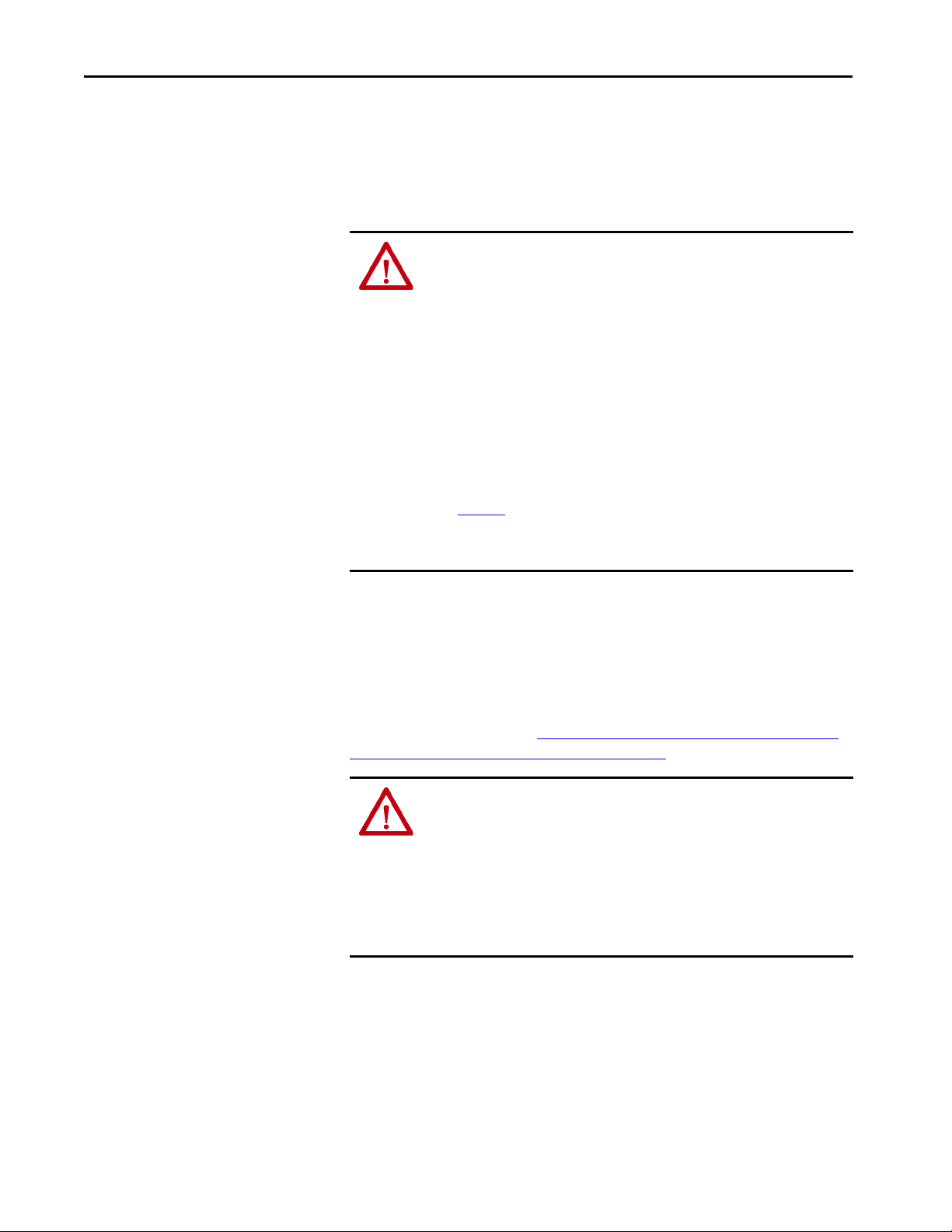

Installation Precautions

Read and follow these precautions before you install your VersaView thin client

or industrial computer.

Environment and Enclosure Information

ATT EN TI ON : This equipment is intended for use in a Pollution Degree 2

industrial environment, in overvoltage Category II applications (as defined in

IEC 60664-1), at altitudes up to 2000 m (6561 ft) without derating.

This equipment is UL Listed, and considered Group 1, Class A industrial

equipment according to IEC/CISPR 32. Without appropriate precautions, there

can be potential difficulties with electromagnetic compatibility in other

environments due to conducted as well as radiated disturbance.

All VersaView integrated display thin clients and industrial computers are

shipped with a gasketed bezel to meet specified NEMA, UL Type, and IEC IP

ratings only when mounted in a panel or enclosure with an equivalent rating.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication

1770-4.1

• NEMA 250 and IEC 60529, as applicable, for explanations of the degrees of

protection provided by enclosures

, for more installation requirements

European Union Directive

VersaView 5000 ThinManager thin client and industrial computers meet the

European Union Directive requirements when installed within the European

Union or EEA regions and have the CE marking. A copy of the declaration of

the conformity is available at https://www.rockwellautomation.com/global/

support/technical-documentation/overview.page.

ATT EN TI ON : This equipment is intended to operate in an industrial or

control room environment, which uses some form of power isolation from

the public low-voltage mains.

To comply with EN 55024 and EN 55032, all cables, with the exception of the

Ethernet cables, must be used indoors. These cables cannot exit the building at

any point and cannot directly connect to cables outside the building. All I/O

cables, with the exception of the Ethernet cables and serial port (COM) cables,

must be less than 3 m (9.842 ft).

18 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

Page 19

Install the Thin Client or Computer Chapter 3

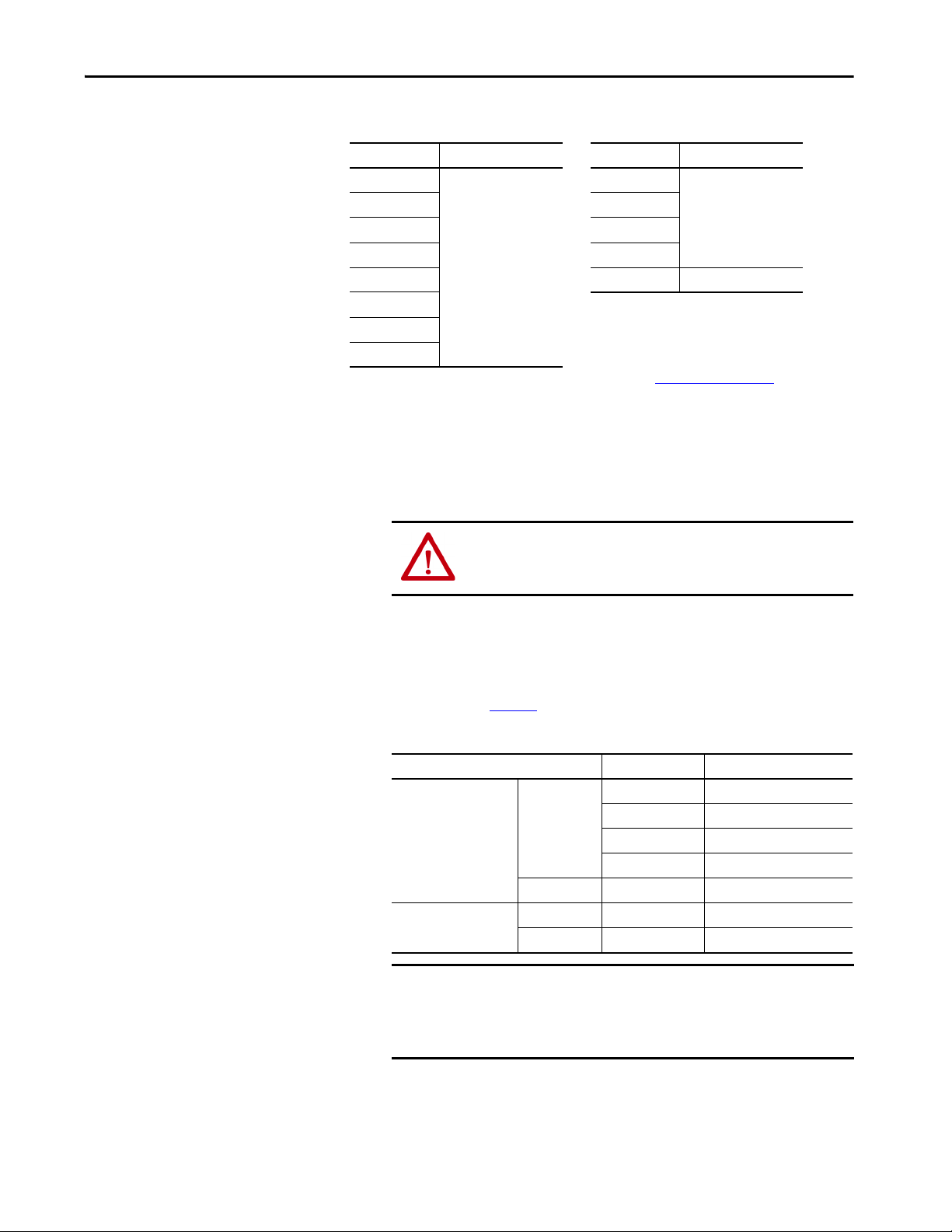

To comply with EN 55024 and EN 55032, use the following for cable types.

Cable Type Required Attribute Cable Type Required Attribute

LAN

USB Line-in

Serial RS-232 Microphone

DVI DC power

DisplayPort AC power Unshielded

Mini-DisplayPort

HDMI

VGA

(1) For the applicable power adapters, see the Power Connection table rows in Connect Peripherals on page 28.

Shielded

Line-out

Unshielded

(1)

Installation Guidelines

Follow these guidelines to make sure your VersaView thin client or industrial

computer provides service with excellent reliability:

• The installation site must have sufficient power.

ATTENTION: For applications with an AC power source, the shipped

or optional AC-to-DC power adapter must be plugged into a

grounded outlet to maintain an electrically safe installation.

• In dry environments, static charges can build up easily. Proper grounding

of the thin client or computer helps to reduce static discharges, which

can cause shock and damage electronic components.

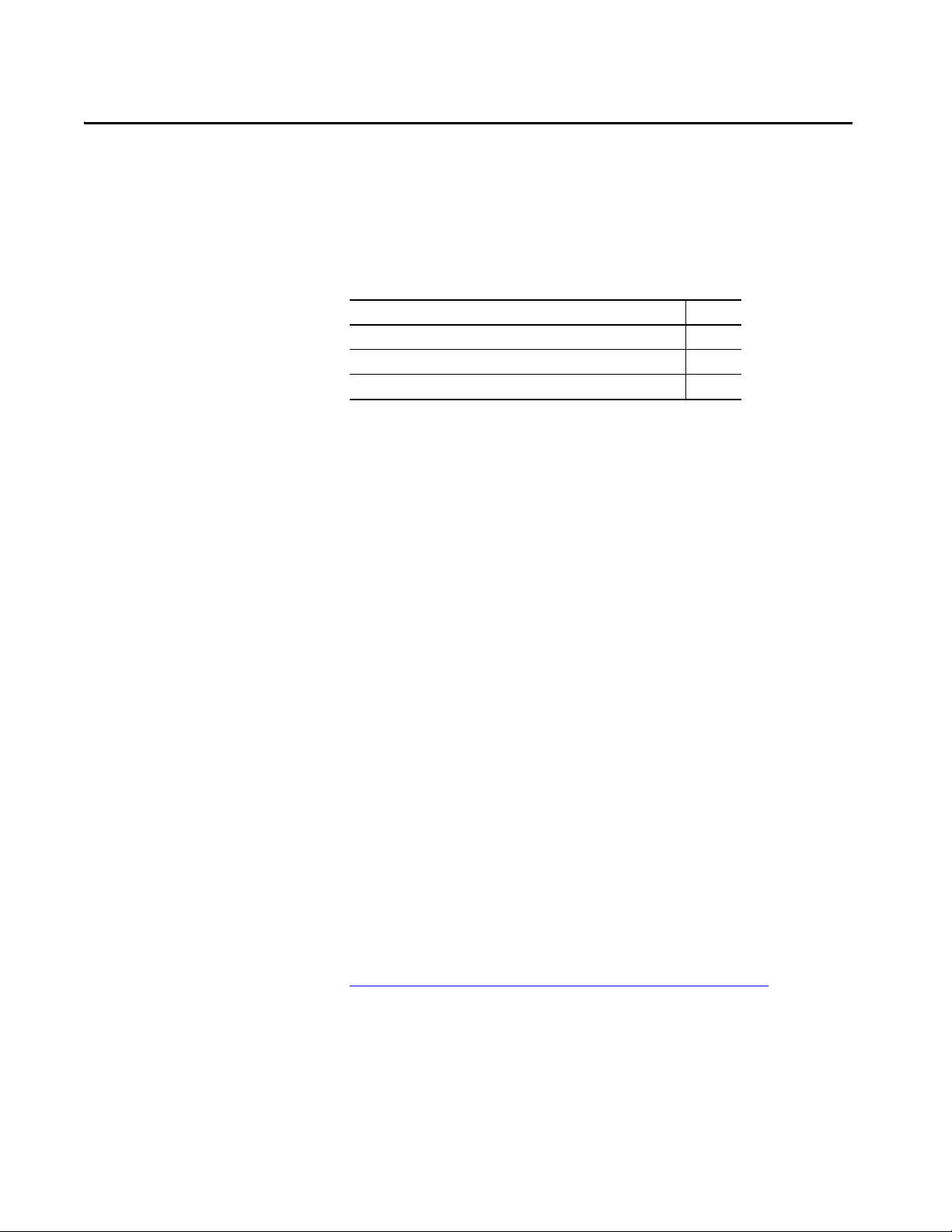

• The ambient air temperature must not exceed the maximum operating

temperature in Ta b l e 3

Table 3 - Maximum Operating Temperature Ranges

VersaView Model Cat. Nos. Temperature, max

5200

ThinManager thin client

5400 Industrial Computers Non-display 6200P-NSxA1 -20…+60 °C (-4…+140 °F)

.

Non-display 6200T-BA 0…50 °C (32…122 °F)

6200T-KB 0…55 °C (32…131 °F)

6200T-RC, 6200T-RE 0…45 °C (32…113 °F

6200T-NA -20…+60 °C (-4…+140 °F)

Display 6200T-xxWA 0…50 °C (32…122 °F)

Display 6200P-xxWS3x1 0…50 °C (32…122 °F)

IMPORTANT VersaView thin clients and industrial computers can operate at a

range of extremes. However, the life span of any elec tronic device is

shortened if you continuously operate it at its highest rated

temperature, which includes the touch screen and LCD panel.

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 19

Page 20

Chapter 3 Install the Thin Client or Computer

• The humidity of the ambient air must not exceed the following limits:

VersaView Model C at. Nos.

5200

ThinManager thin client

5400 Industrial Computers Non-display 6200P-NSxA1 95% at 40 °C (104 °F)

Non-display 6200T-BA 90% at 50 °C (122 °F)

6200T-KB 90% at 55 °C (122 °F)

6200T-RC, 6200T-RE 90% at 40 °C (104 °F)

6200T-NA 95% at 40 °C (104 °F)

Display 6200T-xxWA 93% at 40 °C (104 °F)

Display 6200P-xxWS3x1 93% at 40 °C (104 °F)

Humidity, max

(noncondensing)

• The thin client or computer cover must always remain in place during

operation. The cover provides protection against high voltages inside

the VersaView device and inhibits radio frequency emissions that can

interfere with other equipment.

Enclosure Guidelines

• The enclosure must allow sufficient space around air inlets and outlets to

provide the circulation necessary for cooling. See Mounting Clearance

Requirements on page 20 for further information. Never allow air

passages to become obstructed.

• Hot air rises. The temperature at the top of the enclosure is often higher

than the temperature in other parts of the enclosure, especially if air is

not circulating.

Mounting Clearance Requirements

Consider a user-supplied fan, heat exchanger, or air conditioner for heat

generated by other devices in the enclosure. See Installation Guidelines

on page 19 for the acceptable temperature ranges for these computers.

To help prevent overheating and to provide access to the thin client or

computer I/O ports for cable connections, leave at least 5 cm (2 in.) of free

space around the device.

Do not obstruct the air intake, exhaust openings, or cooling fins of the thin

client or computer cover.

IMPORTANT VersaView thin clients and industrial computers generate heat. Therefore,

do not operate either device in an enclosure with the minimum clearances

unless adequate ventilation or other cooling methods are used to lower the

temperature within the enclosure.

20 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

Page 21

Install the Thin Client or Computer Chapter 3

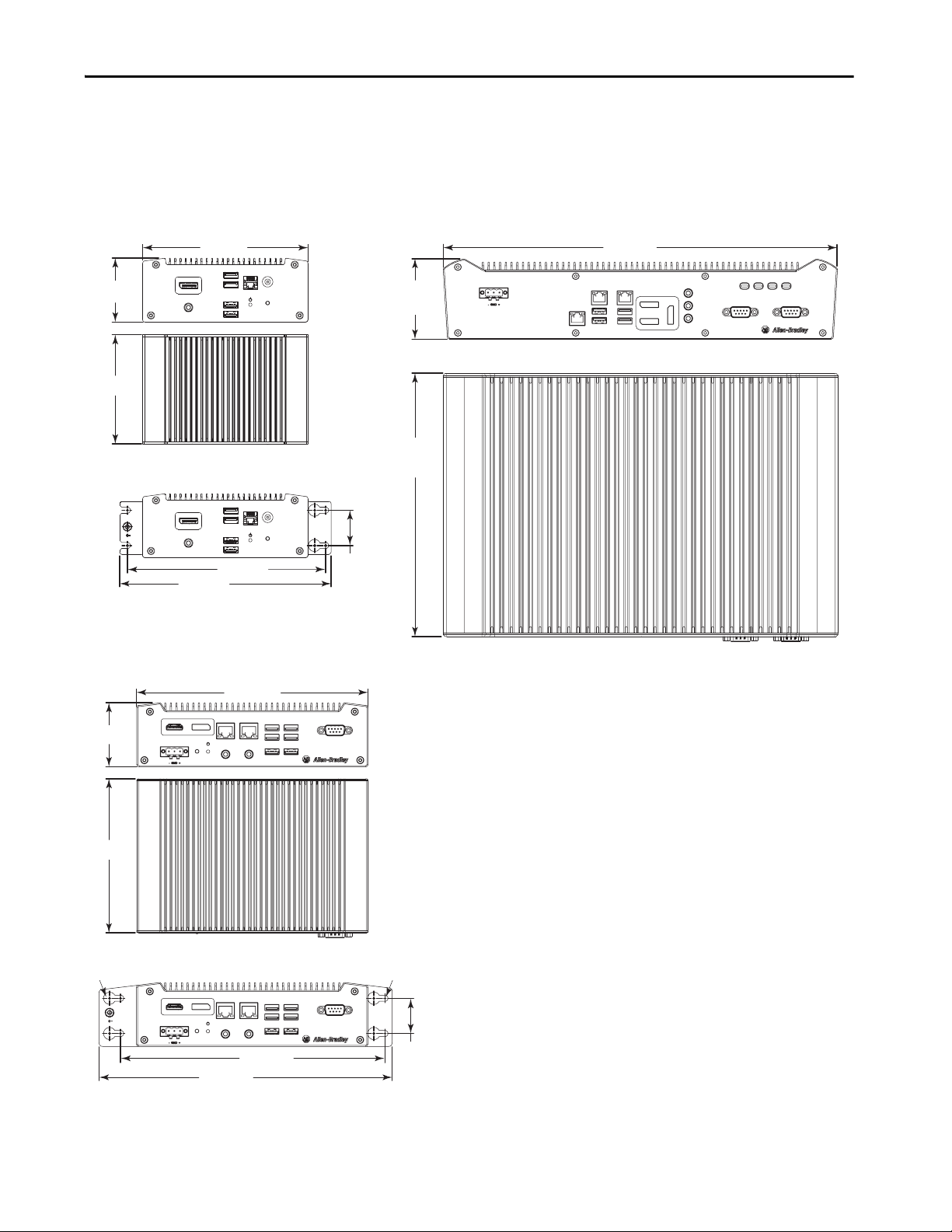

210 (8.27)

140 (5.51)

63 (2.48)*

Without the Factory-installed Bookshelf Mounting Plate

With the Factory-installed Bookshelf Mounting Plate

Cat. No. 6200T-BA

Cat. Nos. 6200T-KB, 6200T-NA, and 6200P-NS3x1

(cat. no. 6200T-KB shown in illustration)

Without the Fac tory-installed Bookshelf Mounting Plate

With the Factory-installed Bookshelf Mounting Plate

150 (5.9)

58 (2.28)*

240 (9.45)

99.5 (3.92)

4 x Ø11

(0.43)

32

(1.26)

4 x Ø5.5

(0.22)

266 (10.47)

4 x Ø5.5

(0.22)

180 (7.01)

192 (7.56)

32

(1.26)

* Add 2.6 mm (0.1 in.) to the height if you install the supplied rubber foot pads.

Cat. Nos. 6200T-RC and 6200T-RE

350 (13.78)

248.5

(9.78)

71.4

(2.81)*

Dimensions

Figure 8 - Dimensions for Non-display Models

Review the following dimensions to estimate the clearance necessary to install

your thin client or computer. Dimensions are given in mm (in.).

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 21

Page 22

Chapter 3 Install the Thin Client or Computer

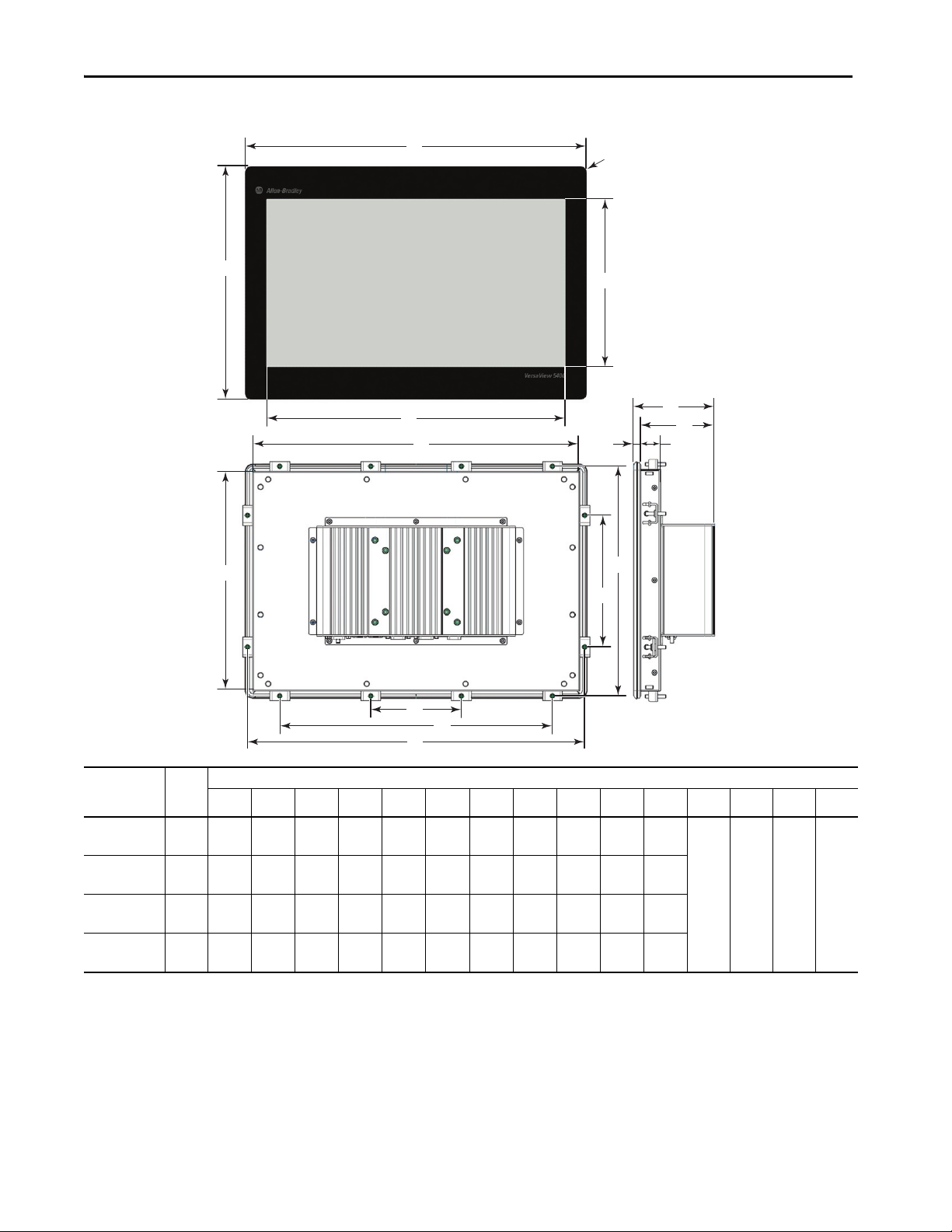

B

A

C

D

E

F

G

H

I

J

K

M

N

L

O

Radius 10

(0.4 in.)

Figure 9 - Dimensions for Integrated Display Models

Display

Size

Cat. Nos.

6200P-12WS3x1,

6200T-12WA

6200P-15WS3x1,

6200T-15WA

6200P-19WS3x1,

6200T-19WA

6200P-22WS3x1,

6200T-22WA

(1) Metric dimension is ±0.5, and the English dimension is ±0.02.

(2) Metric dimension is ±1.0, and the English dimension is ±0.04.

(in.)

12.1 266

(10.47)

15.6 298

(11.73)

18.5 337

(13.27)

21.5 373

(14.68)

ABCDEFGHI J KL

328

414

(16.3)

480

(18.9)

545

163.2

(6.43)

193.5

(7.61)

230

(9.07)

268

(10.55)

(12.91)

(21.46)

261

(10.28)

344.2

(13.55)

410

(16.13)

476.6

(18.76)

248

(9.76)

280

(11)

319

(12.56)

355

(14)

310

(12.2)

396

(15.6)

462

(18.19)

527

(20.75)

Dimensions, mm (in.)

260

292

331

367

125

(4.92)

160

(6.3)

250

(9.84)

250

(9.84)

(10.24)

(11.5)

(13.03)

(14.45)

200

(7.87)

110

(4.33)

130

(5.12)

150

(5.91)

— 322.5

330

(13)

390

(15.35)

450

(17.71)

(12.7)

408

(16)

474

(18.66)

539

(21.22)

(1)

7.6

(0.3)

(2)

M

97.1

(3.82)

NO

89.5

24.5

(3.52)

(0.97)

22 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

Page 23

Install the Thin Client or Computer Chapter 3

Required Tools

Install the Thin Client or Computer

These tools are required to install all VersaView 5000 models:

• #2 cross-head screwdriver

• Panel cutout tools (for wall and panel mounting)

• 2 mm Allen wrench (for mounting clips on integrated display models)

• Drill motor and drill bit (for wall, machine, and table mounting)

• T10 Torx key or screwdriver (to install optional brackets)

• Anti-static wriststrap

The computers support the following mounting options:

• Panel mount (for integrated display models)

• Wall mount (for non-display models)

TIP All non-display models ship with a factory-installed mounting plate for

wall mounting, except for cat. nos. 6200T-RC and 6200T-RE.

Instructions for other available mounting plates and mounting options

are detailed in Appendix A, Install Accessories

, starting on page 51.

Panel Mounting Guidelines

Observe these guidelines when you install an integrated display thin client or

computer in a panel.

ATTENTION: Failure to follow these guidelines can result in personal

injury or damage to the panel components.

• Remove all electrical power from the panel before you make the cutout.

• Confirm that there is adequate space behind the panel. For specific

information, refer to Mounting Clearance Requirements

• Cut supporting panels to specifications before installation. Take

precautions so metal cuttings do not enter components already installe

panel.

in

The supplied mounting hardware accommodates panel thickness

between 1.5…6 mm (0.06…0.24 in.).

• Make sure the area around the panel cutout is clear.

• The only acceptable mounting position is in the horizontal positi

w

ith the I/O ports at the bottom.

• For VESA mounting of non-display thin clients or computers, th

i

nstallation must provide sufficient mechanical stability to minimize the

effects from vibration and shock. The mounting means must be firm

at

tached to the supporting surface with the appropriate hardware.

on page 20.

on

e

ly

d

IMPORTANT VESA mounting reduces the computer IP rating from IP65 to IP20.

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 23

Page 24

Chapter 3 Install the Thin Client or Computer

Panel Cutout Dimensions

The VersaView 5000 Cutout Template, publication 6200-DS001, is shipped

with all VersaView 5000 integrated display thin client or computer models.

All integrated display thin client or computer models must be mounted to

meet these panel cutout dimensions.

Display Size (in.) Cutout Dimensions (H x W), approx.

12.1 250 x 312 mm (9.84 x 12.28 in.)

15.6 282 x 398 mm (11.1 x 15.67 in.)

18.5 321 x 464 mm (12.64 x 18.27 in.)

21.5 357 x 529 mm (14.06 x 20.83 in.)

Mount an Integrated Display Model in a Panel

Mounting clips secure an integrated display model to the panel. The number of

clips varies by model.

Display Size (in.) Clips (qty.) Cat. No. Description

12.1 8 6200V-MCLPS4 Replacement mounting clips (14)

15.6 12

18.5 14

21.5

Follow these steps to mount an integrated display model in a panel.

1. Remove power from the panel.

2. Verify that the panel surface around the area to be cut is clean and free of

be debris.

ATTENTION: Take precautions so metal fragments do not enter

components already installed in the panel to avoid personal injury or

damage to the panel components.

3. Cut an opening in the panel by using the appropriate panel cutout

dimensions.

4. Attach cables to the integrated display model before installation if rear

access to the model is limited after installation.

For where to attach cables, see Connect Peripherals

5. Make sure the sealing gasket is properly positioned on the integrated

display model.

This gasket forms a compression-type seal. Do not use sealing compounds.

6. Place the integrated display model in the panel cutout.

24 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

on page 28.

Page 25

Install the Thin Client or Computer Chapter 3

4

3

6

18

27

12.1 in. Integrated Display Models

18.5 in. and 21.5 in. Integrated Display Models

8

3

4

7

10 1 5

11 6 2

13

8

7

14

3

4

10 1 5

11 6 2 9

12

12

9

15.6 in. Integrated Display Models

5

I/O Ports

I/O Ports

I/O Ports

7. Slide the mounting clips into the holes on the top, bottom, and sides of

the integrated display model.

8. Hand-tighten the mounting clips around the bezel by following the

tighten sequence in Figure 10

.

9. Repeat this process at least three times until the clips are hand-tight and

the gasket is compressed uniformly against the panel.

10. With a 2 mm Allen wrench, tighten the mounting clips to a torque of

0.4 N•m (3.5 lb•in) by following the torque sequence in Figure 10

. Do

not overtighten.

11. Repeat this process at least three times until the clips are properly torqued

0.7 N•m (6.2 lb•in)

to

. Verify that the gasket is compressed uniformly

against the panel.

ATTENTION: Tighten the mounting clips to the specified torque to

provide a proper seal and to help prevent product damage. Rockwell

Automation assumes no responsibility for water or chemical damage

to the integrated display model or other equipment within the

enclosure because of improper installation.

Figure 10 - Tightening and Torquing Sequence for Mounting Clips

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 25

Page 26

Chapter 3 Install the Thin Client or Computer

VESA Mounting

You can use an optional bench/tabletop adapter to mount a VersaView 5000

thin client or industrial computer on a bench or tabletop.

For installation instructions, see Install the VESA Mounting Plate

IMPORTANT If you choose to VESA mount an integrated display model, its IP rating is

reduced from IP65 to IP20.

on page 54.

Mount a Non-display Model

Follow these steps to mount a VersaView 5000 non-display model.

IMPORTANT Depending on the bracket, certain restrictions apply when you mount a

non-display model. See Figure 11

For other available non-display mounting brackets and their orientations,

see Appendix

1. Verify that the power is disconnected.

2. Depending on your application, drill holes to accommodate customersupplied M5 pan head screws.

See Figure 8 on page 21

3. Mount the non-display model by using four customer-supplied M5 pan

head screws.

A.

for mounting hole locations and dimensions.

for details.

Tighten to a torque that is appropriate for the screw and material.

26 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

Page 27

Install the Thin Client or Computer Chapter 3

For cat. nos. 6200T-KB, 6200T-NA, and

6200P-NS3xx with factory-installed

mounting bracket

For cat. no. 6200T-BA with

factory-installed mounting

bracket

6200V-BXMACH machine mounting for cat. nos. 6200T-KB, 6200T-NA, and 6200P-NS3x1

I/O Ports

I/O Ports

I/O

Port s

I/O

Port s

6200V-BXMACH2 machine mounting for cat. nos. 6200T-RC and 6200T-RE

I/O Ports

I/O Ports

I/O Ports I/O Ports

Figure 11 - Acceptable Mounting Positions for Non-display VersaView Thin Clients and Industrial Computer Models

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 27

Page 28

Chapter 3 Install the Thin Client or Computer

Connect Peripherals

See Hardware Features on page 11 or page 14 for what ports are available to

connect peripherals. Use the table below for accessories to connect peripherals

to VersaView 5000 thin clients or industrial computers.

IMPORTANT For optimal performance, use only Rockwell Automation-approved active

DisplayPort adapters.

Category Cat. No. Description For Cat. No.

Mounting

hardware

Cables a nd

adapters

Power

connection

(1) Power adapters ship with a power cord that has an IEC 60320 C14 receptacle and a NEMA 5-15P three-prong plug

6200V-BXMACH Machine mounting bracket 6200P-NS3x1

6200T-KB

6200T-NA

6200V-BXMACH2 Machine mounting bracket for ThinManager thin client

6200V-DPVGA2 DisplayPort to VGA active adapter All

6200V-DPDVI2 DisplayPort to DVI-D active adapter

6200V-DPHDMI4K DisplayPort to HDMI active adapter

6200V-DPCBL2M DisplayPort to DisplayPort cable, 2 m (6.5 ft) long

6200V-DVICBL2M DVI-D to DVI-D cable, 2 m (6.5 ft) long

6200V-MDP2 Mini DisplayPort to Mini DisplayPort cable, 2 m (6.5 ft) long 6200T-RC

6200V-MDPDP Mini DisplayPort to HDMI adapter

6200VMDPHDMI4K30

6200V-VGACBL2M VGA to VGA cable, 2 m (6.5 ft) long All

6200V-USBCBL2M USB touch screen cable, 2 m (6.5 ft) long

6200V-MPS4 AC to 90 W, 24V DC power adapter

6200V-MPS5 Replacement AC to DC power adapter

6200V-MPS6 AC to 40 W, 24V DC power adapter

6200V-DCCONN DC power mating connector housing kit All except

6200V-DCCONN2 Replacement DC terminal block 6200T-KB

for North American applications. Any IEC 60320 C13 power cord can be used for other international applications.

multi-4K display models

Mini DisplayPort to DisplayPor t adapter

(1)

(1)

(1)

6200T-RC

6200T-RE

6200T-RE

All except

6200T-BA

6200T-BA

All except

6200T-BA

6200P-22WS3x1

6200T-BA

6200T-KB

6200T-RC

6200T-RE

6200T-RC

6200T-RE

28 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

Page 29

Install the Thin Client or Computer Chapter 3

Connect Power

VersaView 5000 thin clients and industrial computers are factory shipped to be

connected to a 24V DC power source, except for the 6200T-BA VersaView

ThinManager thin client model, which uses an included AC to 5V DC

adapter. For applications with an AC power source, see AC Power Options

on

page 31.

ATTENTION:

When you connect power to the thin client or computer for the

first time, these actions occur:

• The default UEFI setting automatically starts the computer after it is plugged

into a power source.

• For VersaView 5400 industrial computers with a Windows operating system

(OS), you must read and accept an End User Setup procedure.

Do not disconnect power from the system until after the Windows Setup

procedure is completed. If power is disconnected during this procedure, it

can result in a corrupted system image.

Operate the VersaView thin client or industrial computer in an industrial or

control room environment, which uses some form of power isolation from the

public low-voltage mains.

ATTENTION:

Supply the thin client or computer circuit with its own disconnect.

Use an uninterruptible power source (UPS) to help protect against unexpected

power failure or power surges.

For VersaView 5400 industrial computers, always shut down the Windows OS

before you disconnect power to the computer to minimize performance

degradation and operating system failures.

Connect DC Power

DC power models support operation from a SELV

common (DC-) can be connected together to the functional ground screw to

support some SELV cases where grounding at the computer is required by the

end user.

IMPORTANT This section does not apply to the cat. no. 6200T-BA thin client single display

model, which is supplied with an AC to 5V DC power adapter and cord.

The power supply is internally protected against reverse polarity.

ATT EN TI ON : Use a SELV isolated and ungrounded power supply as input

power to the computer. This power source provides protection so that under

normal and single fault conditions, the voltage between the conductors and

Functional Earth/Protective Earth does not exceed a safe value.

(1) Where safety extra low voltage (SELV) is as defined in IEC 61010-2-201.

(1)

power source. The DC

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 29

Page 30

Chapter 3 Install the Thin Client or Computer

Non-display Computer or Thin Client Models (above)

(1)

Photo 1 is the DC power input connector on the bottom of cat. nos. 6200P-NS3x1

and 6200T-NA. Photo 2 is the supplied DC terminal block installed in the same DC

power input connector (shown without wires connected).

Photo 3 is the DC power input connector on the bottom of cat. nos. 6200T-KB,

6200T-RC, and 6200T-RE. Photo 4 is the supplied DC terminal block installed in the

same DC power input connector (shown without wires connected).

Integrated Display Computer or thin client Models (at right)

Photo 5 is the DC power input connector on the bottom of all integrated display thin

client or computer models. Photo 6 is the sup plied DC terminal block installed in the

DC power input connector (shown without wires connected).

(1) Excludes cat. no. 6200T-BA.

23 41

56

Follow these steps to connect the thin client or computer to a DC power

source.

TIP The following steps are to wire and attach

the DC terminal block that is supplied

with the computer.

The optional DC connector shown at right,

cat. no. 6200V-DCCONN, can be used

instead of the DC terminal block.

1. Turn off the main power switch or breaker.

2. Verify that the DC power wires meet these requirements:

•Material: Stranded copper

• Wire gauge: 0.326…3.31 mm (22…12 AWG)

3. Insert each DC power wire into the correct terminal on the supplied

DC terminal block.

See the DC power input connector on the bottom of the thin client or

computer for which wires to connect to the DC terminal block.

30 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

4. Connect the DC terminal block to the DC power input.

5. Connect the thin client or computer to earth ground by using a

1.5 mm

2

(16 AWG) or larger external wire.

Use a ground wire with an insulation color that is approved by local

inspection authority.

Page 31

Install the Thin Client or Computer Chapter 3

TIP Integrated display thin clients and computers have a ground stud

on the computer base. See page 11

or page 16 for its location.

On non-display thin clients and

computers with bookshelf

mounting brackets, a ground screw

is on one end of the bracket, as

shown at right.

Use this ground screw to connect

the thin client or computer to earth ground.

6. Apply 24V DC power to the thin client or computer.

AC Power Options

The following options are available to connect AC to 24V DC power for

VersaView 5000 thin clients or industrial computers, except for the

6200T-BA thin client single display model

separately.

• An AC to 90 W, 24V DC power adapter and power cord

(cat. no. 6200V-MPS4)

(2)

• An AC to 40 W, 24V DC power adapter and power cord

(cat. no. 6200V-MPS6)

(2)

• Allen-Bradley® switched mode power supplies:

https://ab.rockwellautomation.com/Power-Supplies/Switched-ModePower-Supplies

(1)

. These options must be ordered

Both power adapters ship with a power cord that has an IEC 60320 C14

receptacle and a standard NEMA 5-15P three-prong plug for use in North

America. Any IEC 60320 C13 power cord can be used for other international

applications.

Follow these steps to connect a separately purchased AC to DC power adapter

to an AC power source.

1. Connect the AC to DC power adapter to the DC power input on the

computer. See Hardware Features on page 11

or page 14 for the DC

power input location.

2. Connect the receptacle end of the power cord to the power adapter.

3. Connect the three-prong plug end of the power cord to an AC power

source.

SHOCK HAZARD: Connect the power cord to an AC power source with

an earth ground. Failure to follow this warning can result in electrical

shock.

(1) The 6200T-BA thin client model is supplied with an AC to 5V DC power adapter and cord. To order a replacement, see

Connect Peripherals

(2) See Connect Peripherals

on page 28.

on page 28 for which VersaView models work with each power adapter.

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 31

Page 32

Chapter 3 Install the Thin Client or Computer

Notes:

32 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

Page 33

Operate the Thin Client or Computer

Top ic Pa ge

Operating Guidelines 33

Touch Screen Precautions 34

Start the Thin Client or Computer 34

Restart the Thin Client or Computer 36

Shut Down the Thin Client or Computer 36

Chapter 4

Operating Guidelines

Follow these operating guidelines for your VersaView® thin client or computer:

• When the thin client or computer is panel mounted, operator access is

limited to the front of the thin client or computer, which includes the

display and the touch screen.

IMPORTANT Access to components behind the panel where the thin client or

computer is installed is restricted to authorized and properly

trained personnel.

• When the thin client or computer is mounted in an enclosure, keep the

enclosure door closed during operation so dust and other airborne

contamination do not infiltrate the thin client or computer. Open the

door only for routine maintenance.

SHOCK HAZARD: Do not operate the thin client or computer with

the covers removed. An electric shock hazard exists. All covers are

required to maintain EMI shield.

• Always use the proper power down procedures as required by your

operating system, such as the Shut Down command in the Microsoft

Windows operating system (OS).

• After you shut down the thin client or computer, do not apply power

again until shutdown is complete.

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 33

Page 34

Chapter 4 Operate the Thin Client or Computer

Touch Screen Precautions

WARNING: If the LCD screen darkens or if the backlight is not functioning

properly, the screen may be difficult to read and use of this screen could

result in a potentially hazardous outcome. Do not use the LCD touch screen

under these circumstances.

The design of the system must take into account the possibility of the LCD screen

or LCD touch screen losing functionality and unable to be used to maintain or

change control of the system. The touch screen shall not be the single point of

control of critical functions and is not intended to replace an E-stop.

Design of the system should follow all applicable code and good engineering

practice. Factors to consider include the following:

• The possibility of an unreadable LCD screen

• The possibility of an inoperable touch screen

• Unexpected communication errors or delays

• Operator error in the control of the system

• Proper use of E-stops and other safety practices

The user shall provide means to achieve a safe state during anomalies and verify

that the system has adequate redundancy for critical functions.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Touch Screen Driver Software

VersaView 5400 integrated display industrial computers are factory calibrated and

do not need field calibration. They are shipped with a specialized touch screen

driver (eGalaxTouch) and configuration utility that are optimized for single-touch

mouse emulation applications such as FactoryTalk® View.

VersaView 5200 integrated display thin clients must be configured and calibrated

via ThinManager® software. For more information on how to configure and

calibrate, see

IMPORTANT ThinManager software only supports single-touch operation.

https://thinmanager.com/support/manuals/

The USB touch screen driver module must be added to the terminal

configuration.

.

34 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

Page 35

Operate the Thin Client or Computer Chapter 4

Reinstall the Microsoft HID Driver on VersaView 5400 Integrated Display Computers

The factory-installed eGalaxTouch screen driver on VersaView 5400 integrated

display industrial computers is for single touch applications. By default, the

Windows OS on

available for this Display’ for multi-touch operation.

If you want the Windows OS to recognize the native Microsoft HID multitouch driver, then you must first uninstall the eGalaxTouch screen driver.

To uninstall the eGalaxTouch screen driver, perform the following steps.

these computers

report that ‘No Pen or Touch Input is

Start the Thin Client or Computer

1. On your Windows task bar, cl

2. Click Control Panel.

3. In the Control Panel menu, click Programs and Features.

4. In the Programs list, find and highlight eGalaxTouch software.

5. Right-click the highlighted program name, and select Uninstall.

6. After you uninstall eGalaxTouch software, restart your computer.

Windows automatically installs the native Microsoft HID touch screen

driver, and then reports the computer as having ‘Touch Input Avai

with 10 Touch Points.’

TIP To reinstall the eGalaxTouch screen driver, access the Rockwell Automation®

Product Compatibility and Download Center (PCDC) at

https://compatibility.rockwellautomation.com/Pages/home.aspx

If you must reinstall the touch screen driver, the touch screen utility

automatically detects the USB port used by the touch screen controller.

Follow these steps to start your VersaView thin client or computer.

IMPORTANT The following steps apply to when the thin client or computer must be

manually started. See Connect Power on page 29 for when power is applied

to the thin client or computer for the first time.

ick .

lable

.

1. Make sure all necessary peripheral devices are connected to the

corresponding I/O ports on the thin client or computer.

2. Make sure any connected components with separate power supplies

(such as an external display) are turned on first.

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 35

Page 36

Chapter 4 Operate the Thin Client or Computer

3. Install power to the power input of the thin client or computer.

Restart the Thin Client or Computer

AC powered models: See AC Power Options

on page 31 for how to

install an AC-to-DC power adapter to the DC power input on the thin

client or computer.

DC powered models: See Connect DC Power

on page 29 for how to

install DC power to the DC power input on the thin client or computer.

4. Apply power to the thin client or computer.

5. Press the power switch on the thin client or computer.

See Hardware Features on page 11

or page 14 for the power switch

location.

The thin client or industrial computer performs certain actions when it is

started or reset. See Restart the Thin Client or Computer

on page 36 for what

is done.

If your system does not start or you notice other anomalies, refer to

Troubleshoot the System

starting on page 45.

Use any of the following methods to restart the thin client or computer.

• From the Start menu, choose Restart.

• Press Ctrl+Alt+Delete on an attached keyboard and click Restart.

Shut Down the Thin Client or Computer

During a restart, the thin client or computer does the following:

• Clears the RAM.

• Starts the POST.

• Initializes peripheral devices such as drives and printers.

• Loads the operating system (except for VersaView ThinManager® thin

client computers).

If a display is available, use it to view the progress of the POST, the initialization of

accessory devices, and the startup dialogs for any operating system that is installed.

Use either of the following methods to shut down the thin client or computer.

Method Actions

Windows O S IMPORTANT: Applies only to VersaView 5400 integrated display industrial

Power switch Momentarily press the power switch to shut down the thin client or computer. See

computers.

With an attached mouse and keyboard, do one of the following.

• Press Ctrl+Alt+Delete and click Shut Down.

• From the Start menu, click or choose Shut Down.

Hardware Features on page 11

or page 14 for the power switch location.

36 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

Page 37

Configure the UEFI (BIOS) Settings

Top ic Pa ge

Set-up Utility Overview 37

Access the Set-up Utility 38

UEFI Overview 38

H/W Monitor 38

Security 38

Restore the OS Image 39

Upgrade to a New UEFI 40

Chapter 5

Set-up Utility Overview

The set-up utility is a hardware configuration program built into the

extensible firmware interface (UEFI)

Input/Output System (BIOS) to describe the system firmware except where

BIOS is specifically used, such as on a graphical interface

You can run the set-up utility to do the following:

• Change the system configuration.

• Set the time and date as part of a commissioning step.

TIP A commissioning step is one of the following situations:

• When the thin client or computer is powered up initially

• When the Windows OS image is restored (on VersaView® 5400

computers)

• When the UEFI set-up utility is upgraded

• Redefine communication ports to help prevent any conflicts.

• Read the current amount of system memory.

• Change the boot drive order.

• Set or change the password or make other changes to the security

settings.

.

In this chapter, UEFI replaces Basic

.

universal

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 37

Page 38

Chapter 5 Configure the UEFI (BIOS) Settings

UEFI for All Cat. Nos. Except 6200T-KB, 6200T-RC, and 6200T-RE UEFI for Cat. Nos. 6200T-KB, 6200T-RC, and 6200T-RE

Help Window Help Window

Access the Set-up Utility

UEFI Overview

Follow these steps to access the set-up utility in your thin client or computer.

IMPORTANT An external keyboard must be connected to the computer to perform these

steps.

1. Start or restart your computer.

2. During POST, press F2 to access the UEFI set-up utility.

The main tab is the default screen whenever you access the UEFI interface.

Depending on the UEFI, there are other tabs with configurable menu items

Help Window

When you select a menu or submenu item, a corresponding help menu displays

to the right of the item. As you toggle between menu items, the help menu

updates automatically.

H/W Monitor

Security

You can view various hardware parameters from the H/W Monitor menu. It

shows the temperature and system voltage measurements. This menu is

beneficial to identify possible computer issues.

The Security tab of the UEFI set-up utility provides password protection for

applications where security is preferred or needed.

You can set a supervisor password that is required to access the UEFI set-up

utility. You can set a user password that is required for computer startup.

38 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

Page 39

Configure the UEFI (BIOS) Settings Chapter 5

Restore the OS Image

Perform the following steps to restore your computer with a backed-up OS image

on an external USB storage drive.

1. Attach the following external peripherals to your computer:.

• Display (for non-display computers)

•USB Keyboard

• USB drive (16 GB or larger)

2. Access the Rockwell Automation® PCDC website at

https://compatibility.rockwellautomation.com/Pages/home.aspx

3. On the home page, click Find Downloads.

4. On the Find Downloads page, use your computer model as the sear

cri

teria.

5. Follow the instructions on the PCDC site to find your OS image.

TIP You must be registered with the Rockwell Automation PCDC

website to download files.

You must accept a User Agreement before files can be downloaded.

6. Download the OS Image file to your USB drive.

7. After the file downloads, restart the computer.

.

ch

8. During POST, press F5 to access the Boot menu.

9. Toggle down the Boot menu to select RecoveryDISK and press Enter.

10. To apply the image, follow the onscreen instructions.

11. The OS image file on the USB drive copies to the system.

WARNING: Do not interrupt power to the computer during the OS

image restore.

Sudden power loss can render the computer inoperable.

12. After the OS image

13. When you restore the OS image, it is identical to starting the computer

for the first time.

See Connect Power on page 29 for what actions occur.

restore is complete, restart the computer.

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 39

Page 40

Chapter 5 Configure the UEFI (BIOS) Settings

Upgrade to a New UEFI

Sometimes a new UEFI (BIOS) is released to enhance the performance of your

computer or to correct a anomaly. In such cases, you can download BIOS

upgrades at the Rockwell Automation PCDC website at

https://compatibility.rockwellautomation.com/Pages/home.aspx

drive upgrade is available.

. A USB

For All VersaView 5000 ThinManager® Thin Client and Industrial Computers Except Cat. No. 6200T-BA

For instructions to upgrade the BIOS for cat. no. 6200T-BA, see page 42.

To upgrade the BIOS for other VersaView 5000 ThinManager thin client and

industrial computers, perform the following steps.

1. Attach the following external peripherals to your computer:

• Display (for non-display computers)

•USB keyboard

• USB drive (1 GB or larger)

2. Access the Rockwell Automation PCDC website.

3. On the home page, click Find Downloads.

4. On the Find Downloads page, use your computer model as the search

criteria.

5. Follow the instructions on the PCDC site to find your BIOS.

TIP You must be registered with the Rockwell Automation PCDC

website to download files.

You must accept a User Agreement before files can be downloaded.

6. Download the BIOS file to your USB drive.

7. Open the file and extract the folder to the root directory of your USB

drive.

8. After the folder is extracted, restart the computer.

9. During POST, press F5 to access the Boot menu.

40 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

Page 41

Configure the UEFI (BIOS) Settings Chapter 5

For All Cat. Nos. Except 6200T-KB, -RC, and -RE For Cat. Nos. 6200T-KB, 6200T-RC, and 6200T-RE

A

B

C

10. Toggle down the Boot menu to select Internal Shell and press Enter.

The internal shell displays.

IMPORTANT Depending on what other drives are attached to your system, the

attached USB drive can be mapped as the fs1 or fs2 drive, and as a

removable hard disk.

11. Type fsX: (where ‘X’ is the number shown for your mapped USB drive)

and press Enter (A).

12. To navigate to the folder where the BIOS is stored, use a DOS-type

command to identify the folder (for example, cd <folder_name>) and

press Enter (B).

13. Type update.nsh and press Enter (C).

The BIOS update procedure starts automatically.

IMPORTANT Ignore any ‘PDR Region does not exist’ messages.

WARNING: Do not disconnect power from the computer until after

the BIOS flash procedure is completed. If power is disconnected

during this procedure, it can render the computer inoperable.

14. Once the BIOS flash procedure is completed, restart the computer.

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 41

Page 42

Chapter 5 Configure the UEFI (BIOS) Settings

A

B

C

D

For VersaView 5200 ThinManager Thin Client Cat. No. 6200T-BA

To upgrade the BIOS for VersaView 5200 ThinManager thin client cat. no.

6200T-BA, perform the following steps.

1. Attach the following external peripherals to your computer:

•Display

•USB keyboard

• USB drive (1 GB or larger)

2. Access the Rockwell Automation PCDC website:

https://compatibility.rockwellautomation.com/Pages/home.aspx

3. On the home page, click Find Downloads.

4. On the Find Downloads page, use your computer model (6200T-BA) as

the search criteria.

5. Follow the instructions on the PCDC site to find your BIOS.

TIP You must be registered with the Rockwell Automation PCDC

website to download files.

You must accept a User Agreement before files can be downloaded.

6. Download the BIOS file to your USB drive.

7. Open the file and extract the folder to the root directory of your USB

drive.

8. After the folder is extracted, restart the computer.

9. During POST, press F11 to access the internal shell.

The internal shell displays.

IMPORTANT Depending on what other drives are attached to your system, the

attached USB drive can be mapped as the fs1 or fs2 drive, and as a

removable hard disk (A).

10. Type fsX: (where ‘X’ is the number shown for your mapped USB drive)

and press Enter (B).

11. To navigate to the folder where the BIOS is stored, use a DOS-type

command to identify the folder (for example, cd <folder_name>) and

press Enter (C).

42 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

Page 43

Configure the UEFI (BIOS) Settings Chapter 5

12. Type update.nsh and press Enter (D).

The BIOS update procedure starts automatically.

IMPORTANT Ignore any ‘Cannot find any ESP partition!’ messages during the

update.

WARNING: The computer automatically restarts twice during the

update. Do not disconnect power from the computer until after the

second restart, which is when the BIOS flash procedure is completed.

If power is disconnected before the second restart, it can render the

computer inoperable.

13. Once the BIOS flash procedure is completed, the computer

automatically restarts.

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 43

Page 44

Chapter 5 Configure the UEFI (BIOS) Settings

Notes:

44 Rockwell Automation Publication 6200-UM001C-EN-P - July 2018

Page 45

Troubleshoot the System

Top ic Pa ge

Hardware (H/W) Monitoring 45

Troubleshooting 46

Load the System Defaults 46

Ship or Transport the Computer 47

Dispose of the Computer 47

Chapter 6

Hardware (H/W) Monitoring

The built-in hardware monitor of the computer tracks the operating threshold

levels of the voltage and temperature sensors.

Follow these steps to determine whether an operating threshold has been reached.

1. Shut down the computer by using the appropriate method for the

installed operating system.

See Shut Down the Thin Client or Computer on page 36 for more

information.

2. Apply power to the computer.

3. During POST, press F2 to access the UEFI set-up utility:

4. On the Main screen, click Advanced.

5. On the Advanced screen, click H/W Monitor.

Use this menu to determine if there is an issue with internal voltages

or component temperatures.

Rockwell Automation Publication 6200-UM001C-EN-P - July 2018 45

Page 46

Chapter 6 Troubleshoot the System

Troubleshooting

Follow these steps to identify and isolate an issue with the computer’s operation.

1. Shut down the computer by using the appropriate method for the

installed operating system.

See Shut Down the Thin Client or Computer on page 36 for more

information.

2. Disconnect power to the computer.

3. Disconnect all peripheral devices from the computer.

4. If a keyboard and mouse are used, verify that they are properly

connected.

5. If an external display is used, verify that it is properly connected.

6.

Connect power to the computer. During POST, one of three events

occurs:

• The startup process is completed.

• A nonfatal error occurs and the related error message is displayed.

• A fatal error occurs and the startup process terminates.

If Then

The computer starts Reconnect all peripheral devices one at a time until the

The issue is with a specific software or driver Reinstall the software or driver.

issue occurs.

Load the System Defaults

If the computer fails after you make changes in the set-up menus, load the

system default settings to correct the error. These default settings have been

selected to optimize computer performance.

Follow these steps to load the system defaults.

IMPORTANT An external keyboard and mouse must be connected to the computer to

perform these steps.

1. Restart the computer as specified in Restart the Thin Client or

Computer on page 36.

2. During POST, press F2 to access the UEFI set-up u

3. On the main UEFI screen, click the

Exit tab.

tility.