Page 1

Installation Instructions

TL-Series Servo Motors

Catalog Numbers TLY-A110, TLY-A120, TLY-A130, TLY-A220, TLY-A230,

TLY-A2530, TLY-A2540, TLY-A310

Topic Page

Catalog Number Explanation 3

Before You Begin 4

Installation and Maintenance Guidelin es 4

Install the TL-Series Motor 8

Requirements for Motor Mounting 8

Power Cable Shielding 9

Installing the Motor 10

Dimensions 12

Motor Load Force Ratings 17

Connector Data 19

Remove and Install a Shaft Key 21

Specifications 22

Accessories 23

Additional Resources 24

About This Publication

This publication provides installation instructions for the TL-Series motors categorized with a

TLY catalog number.

Use this document if you are responsible for installing these Allen-Bradley motor products. Please

read all instructions before installing this motor.

Page 2

2 TL-Series Servo Motors

Publication TL-IN003A-EN-P — June 2007

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines fo r the App lica ti on, Ins tal lati on an d Mai nte nanc e of Sol id S tat e Co ntro ls, pub lic atio n SG I-1. 1, avai labl e f rom

your local Rockwell Automation sales office or online at http://literature.rockwellautomation.com. It describes some

important differences between solid state equipment and hard-wired electromechanical devices. Because of this

difference, and al so because of the wide var i et y of us e s for solid state equipme nt, all persons res pon s ible for applying

this equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Roc kwel l Auto mati on, Inc. be respo nsib le or liab le fo r ind irec t or co nseque nt ial damage s resu lti ng from

the use or applicatio n of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables

and requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility

or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING

Identifies information about practices or circumstances that can cause an explosion in a

hazardous environment, which may lead to personal injury or death, property damage, or

economic loss.

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information that is critical for successful application and understanding of the

product.

Identifies information about practices or circumstances that can lead to personal injury or

death, property damage, or ec onomic loss. A ttentions help y ou identify a ha zard, avoid a

hazard and recognize the consequences.

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be p resent.

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Page 3

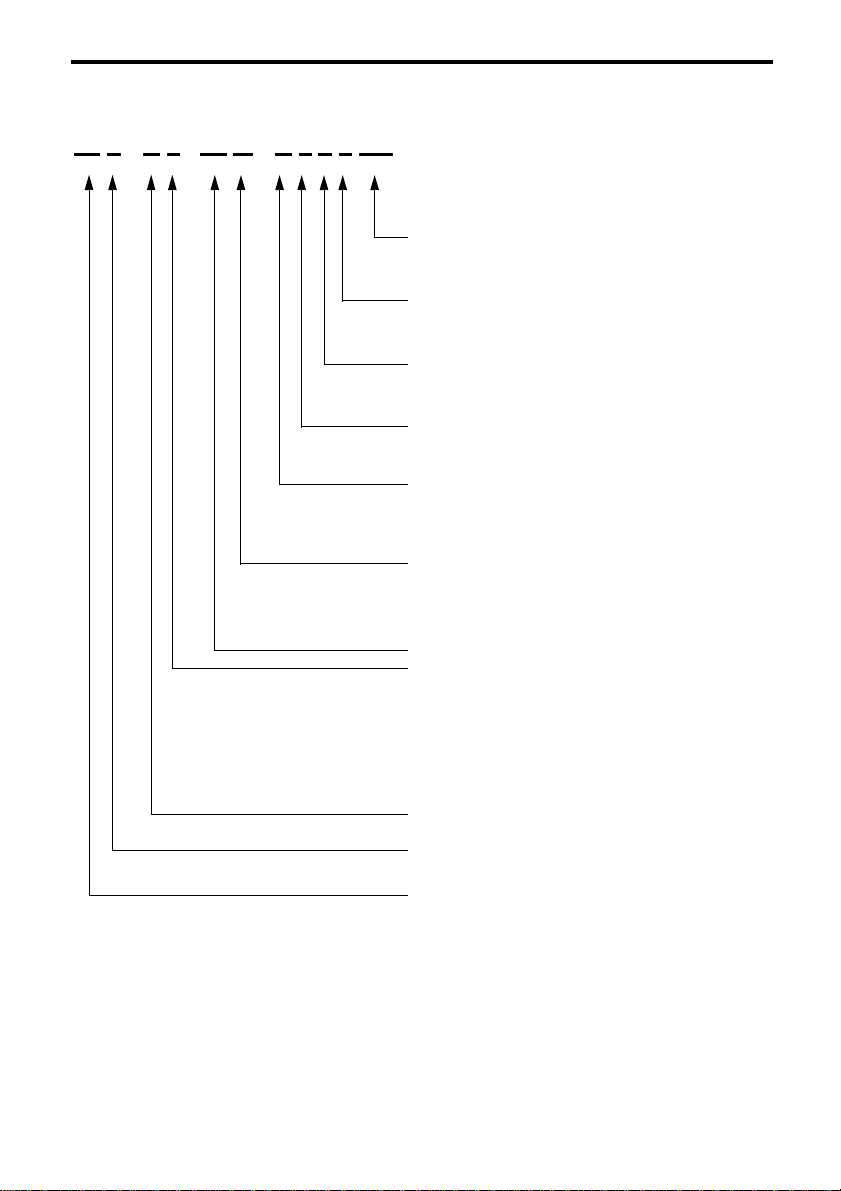

Catalog Number Explanatio n

TL Y

- A 3 10 M - B J 6 2 AA

TL-Series Servo Motors 3

FACTORY DESIGNATED OPTIONS

AA = Standard

AN = NEMA Mount i ng Fla nge/Shaft

BRAKE

2=No Brake

4 = 24V dc Brake

CONNECTORS

6 = 1m (39.4 in.) Leads with

Circular Plastic Connectors

ENCLOSURE/SHAFT KEY/SHAFT SEAL

J = IP65 Housing/Shaft Ke y / No Sh aft Seal

K = IP65 Housing/No Shaft Key/No Shaft Seal

FEEDBACK

B = Absolute Encoder, Battery-backed

Multi-turn

H = Incremental Encoder (2000 lines)

RATED SPEED

M = 4500 rpm

P = 5000 rpm

T = 6000 rpm

MAGNET STACK LENGTH DESIGNATOR

FLANGE SIZE

Diameter of Mounting Bolt Circle for Metric Motors,

or NEMA size

1 = 46 mm or NEMA 17

2 = 70 mm or NEMA 23

25 = 90 mm or NEMA 34

3 = 100 mm

VOLTAGE RATING

A = 230 V ac

TYPE

Y = Le ads with Circular Connector

SERIES DESIGNATOR

TL = Low Inertia

Publication TL-IN003A-EN-P — June 2007

Page 4

4 TL-Series Servo Motors

Publication TL-IN003A-EN-P — June 2007

Before You Begin

Before unpacking the product, inspect the shipping carton for damage. If damage is visible,

immediately contact the shipper and request assistance. Otherwise, proceed with unpacking.

Remove the motor carefully from its shipping container, and visually inspect the motor for any

damage. Carefully examine the motor frame, front output shaft, and mounting pilot for any defects.

Keep the original packing material in case you need to return the product for repair or transport it to

another location. Use both the inner and outer packing cartons to verify adequate protection for a

unit returned for service.

ATTENTION

Do not attempt to open and modify the motor. Modifications that can be performed in

the field are described in this manual, ot her changes should not be attempted.

Only a qualified Allen-Br adl ey employee can service this type of motor.

Failure to observe these safety procedures could result in personal injury or damage to

equipment.

Installation and Maintenance Guidelines

This section advises you on how to install your product so it provides safe and reliable service.

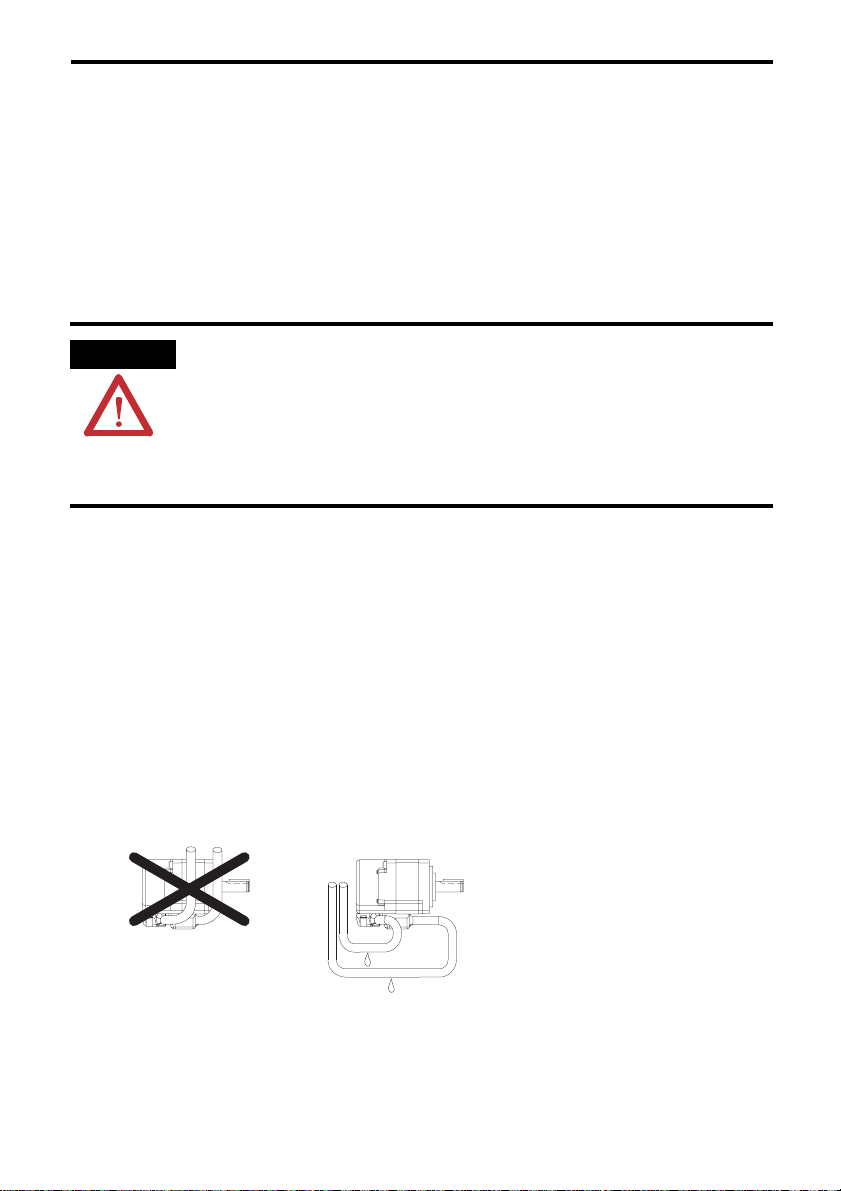

T o Prolong Motor Life

Thoughtful design and proper maintenance can increase the life of a servo motor.

• Always install the motor with the cable entry point(s) positioned underneath the motor

housing, and provide a drip loop in each cable. A drip loop is a downward bend in the cable

that lets water gather and drip off the cable rather than continue to flow along the cable.

These two installation practices greatly reduce the potential for moisture related problems.

Recommended Connector Orientation with Drip Loop

Motor is position ed so ca ble

enters from above, and

cable lacks drip loop.

• Avoid installing the motor with the shaft pointing upward. This orientation increases the risk

of contaminant ingress.

• Avoid spraying liquids under pressure directly on the junction of the motor shaft, housing,

and connectors, as well as the enclosure joints. Fluids under pressure can be forced around

worn seals, and contaminate the motor bearings. Bearing contamination will significantly

shorten the life of a servo motor.

Cable enter s beneath the motor,

and drip loop is formed.

Page 5

TL-Series Servo Motors 5

• If design requirements permit, provide shields that protect the motor housing, shaft, seals and

their junctions from product conta mination, caustic agent s, and high pressure fluids.

• Replace the optional shaft seal at or before its expected twelve-month lifetime elapses.

Refer to Remove and Install a Shaft Key on page 21 for more information on sha ft seals.

• Inspect the motor and seals for damage or wear on a regular basis. If damage or adverse wear

is suspected, replace the item.

• If desired, the motor front flang e may be sealed to the driven equipment by a bead of RTV

around the periphery of the motor to equipment joint. Use of a gasket or RTV on the mating

surfaces may cause misalignment of the shaft and result in damage to the motor and driven

equipment.

• Brakes on these servo motors are holding brakes. The brakes are spring-set, and release when

voltage is applied to the brake coil. A power source, either external or internal to the servo

drive, is required to disengage the brake. The power source may be applied by the machine

controller.

If system main power fails, holding brakes can withstand occasion al use as stopping brakes.

However, this is potentially damaging to the system, increases brake wear, and reduces brake

life.

IMPORTANT

Holding brakes are not designed to stop rotation of the motor shaft, nor are

they intended to be used as a safety device. They are designed to hold a motor

shaft at 0 rpm for up to the rated brake holding torque.

Follow these steps to prevent shaft rotat ion.

1. Command the servo drive to 0 rpm.

2. Verify the motor is at 0 rpm.

3. Engage the brake.

4. Disable the drive.

Disabling the drive removes the pot ent ial for brake wear caused by a badly

tuned servo system oscillating the shaf t .

Publication TL-IN003A-EN-P — June 2007

Page 6

6 TL-Series Servo Motors

Publication TL-IN003A-EN-P — June 2007

Mechanical Connections

Mechanical connections to the motor shaft, such as couplings and pulleys, require a torsionally rigid

coupling or a reinforced timing belt. The high dynamic performance of servo motors can cause

couplings, pulleys, or belts to loosen or slip over time. A loose or slipping connection will cause

system instability and may damage the motor shaft. All connections between the machine and the

motor shaft must be rigid to achieve acceptable system response. Periodically inspect connections to

verify their rigidity.

When mounting couplings or pulleys to the shaft, verify that the connections are properly aligned and

that axial and radial loads are within the specifications of the motor.

Refer to Motor Load Force Ratings on page 17 for guidelines on how to achieve 20,000 hours of

motor bearing life.

ATTENTION

Do not strike the shaft, key, couplings, or pulleys with tools dur ing installation or

removal.

Damage may occur to the motor bearings and the feedback device if sharp impact to the

shaft is applied during installation of couplings and pulleys, or a shaft key. Damage to

the feedback device also may result by applying leverage from the faceplate to remove

devices mounted on the motor shaft.

Apply a constant pressure, with a wheel puller for example, to the user end of the shaft

to remove a friction fit or a stuck device.

Failure to observe these safety procedur es could result in damage to the motor and its

components.

A shaft key provides a rigid mechanical connection with the pot ential for self-alignment, but the key

must be properly installed in the keyway. Refer to these sections for additional information:

• Dimensions on page 12 for dimensional information about the key and shaft keyway.

• Remove and Install a Shaft Key on page 21 for recommendations on how to remove and

install a shaft key.

Page 7

TL-Series Servo Motors 7

Interconnect Cables

Knowledgeable cable routing improves system electromagnetic compatibility (EMC). Refer to

Shielding of Brake Wires Within the Power Cable on page 9 for cable shield grounding at the servo

drive.

Follow these steps to install the cables.

1. Keep wire lengths as short as physically possible.

2. Route signal cables away from motor and power wiring. Typical signal cables transmit

encoder, serial, or analo g data at low vo lt ages.

3. Separate cables by 0.3 m (1 ft) minimum for every 9 m (30 ft) of parallel run.

4. Ground both ends of the cable shield and twist the signal wire pairs to prevent

electromagnetic interference (EMI) from other equipment.

ATTENTION

High voltage can be present on the shields of a power cable, if the shields are

not grounded.

Verify there is a connection to ground for all shields in the power cable.

Failure to observe these safety procedures could result in per s onal injury or

damage to equipment.

Electrical Noise

ElectroMagnetic Interference (EMI), commonly called noise, adversely impacts motor performance

by inducing stray signals. Effective techniques to counter EMI include filtering the ac power,

shielding and separating signal carrying lines, and practicing good grounding techniques. Effective ac

power filtering can be achieved by using isolated ac power transformers or prop erly installed ac line

filters.

To reduce EMI follow these guidelines:

• Physically separate signal lines from mo t or cabling and power wiring. Do not route signal

wires with motor and power wires, and do not route signal wires over the vent openings of

servo drives or other electrical power sources.

• Ground all equipment by using a single-point parallel ground system that employs ground bus

bars or large straps. If necessary, use additional electrical noise reduction techniques to reduce

EMI in noisy environments.

Publication TL-IN003A-EN-P — June 2007

Page 8

8 TL-Series Servo Motors

Publication TL-IN003A-EN-P — June 2007

Shaft Seals

You may install the optional shaft seal to protect the front bearing from fluids or fine dust that could

contaminate the motor bearing and reduce its lifetime. The IP rating for the motor depends on the

usage of shaft seal s.

Refer to these sections for additional information:

• Shaft Seal Kits on page 23 lists catalog numbers of seal kits available for your motor.

• Specifications on page 22 briefly describes IP ratings.

Install the TL-Series Motor

Before installing the motor, review and become familiar with the following instructions:

• Requirements for Motor Mounting

• Power Cable Shielding

• Installing the Motor

• Dimensions

• Motor Load Force Ratings

• Connector Data

Requirements for Motor Mounting

All TL-Series motors include a mounting pilot for aligning the motor on a machine. Preferred

fasteners are stainless steel. The installation must comply with all local regulations and use of

equipment and installation practices that promote electromagnetic compatibility and safety.

ATTENTION

Unmounted motors, disconnected mechanical couplings, loose shaft keys, and

disconnected cables are dangerous if power is applied.

Disassembled equipment should be app ropriately identified (t agged-out) and

have access to electrical power restricted (locked-out).

Before applying power to the motor, remove the shaft key and other mechanical

couplings that could be thrown from the shaft.

Failure to observe these safety procedures could result in per s onal injury.

Page 9

TL-Series Servo Motors 9

Power Cable Shielding

Power cables must be shielded, and the cable shield must connect to a ground.

ATTENTION

Verify the separate brake wire shield connects to the overall chassis ground by looping back this brake

wire pair as shown in the figure Shielding of Brake Wires Within the Power Cable.

High voltage can be present on the shields of a power cable, if the shields are not

grounded.

Verify there is a connection to ground for all shields in the power cable.

Failure to observe these safety procedures could result in personal injury or damage to

equipment.

Shielding of Brake Wires Within the Power Cable

Factory supplied

Power cable conta i ns br ak e wi r es wi t h

separate ground shield.

}

Cable insulation is removed to expose

Field Modified

overall power cable shield.

Loop brake wires and signal shielding to contact

the overall po wer cable shield.

Connect shields to power cabl e ground clamp on drive

Clamp should c ontact both (overall and brak e) cable shield s.

Publication TL-IN003A-EN-P — June 2007

Page 10

10 TL-Series Serv o Motors

Publication TL-IN003A-EN-P — June 2007

Installing the M o to r

Follow these procedures and recommendations to install a TL-Series motor.

ATTENTION

Servo motors are not for direct connection to an ac power line.

Servo motors are designed for connection to a servo drive that control s the application

of ac power.

Failure to observe these safety proce dur es could result in damage to the motor and

equipment.

ATTENTION

Do not strike the shaft, couplings, or pulleys with tools during installation or removal.

Damage may occur to the motor bearings and the feedback device if sharp impact to the

shaft is applied during installation of couplings and pulleys.

Failure to observe these safety procedur es could result in damage to the motor and its

components.

1. Allow sufficient clearances in the area of the motor for it to stay within its specified operating

temperature range.

• Obtain the specified motor thermal rating by mounting the motor on a surface with heat

dissipation equivalent to an aluminum heatsink of the following dimensions.

Motor Frame Size Heatsink Dimensio ns (H x W x D) Approx.

millimeters (inches)

TLY-A1xx 203.0 x 203.0 x 6.4 (8 x 8 x 0.25)

TLY-A2xx 254.0 x 254.0 x 6.4 (10 x 10 x 0.25)

TLY-A25xx, TLY-3xx 305.0 x 305.0 x 12.7 (12 x 12 x 0.5)

(1)

Ambient temperature of the specified heatsink is 40 °C (104 °F).

(1)

• Refer to Specifications on page 22 for the operating range.

• Do not install the motor in an area with restricted airflow , and keep other heat producing

devices away from the motor.

Page 11

TL-Series Servo Motors 11

ATTENTION

Outer surfaces of the motor can reach high temperatures, 110 °C (230 °F) during

motor operation.

Take precautions to prevent accidental contact with hot surfaces. Locate the

motor and route cable connections to avoid contact with hot surfaces.

Failure to observe these safety procedures could result in personal injury or

damage to equipment.

2. Position the motor with the cable connections beneath the motor.

Refer to Recommended Connector Orientation with Drip Loop on page 4 for a visual

reference of correct motor and cab le positioning.

3. Properly mount and align the motor.

• Refer to Dimensions on page 12 to properly locate and size motor mounts.

• Do not exceed the Motor Load Force Ratings on page 17. The tables list the radial and

axial shaft load limitations of your motor.

4. Connect the feedback, and the combined power and brake cables after the motor is mounted.

ATTENTION

Mount the motor so exposure to dust and liquids is mi nimized for both the

motor and its cable connections, and restrain cables to prevent uneven tension

or flexing at the connectors.

ATTENTION

Short circuits in the feedback, power, or brake circuits may result from

exposure of the unsealed motor cable connectors to dust or liquids, or by

uneven forces at the connector housing.

Failure to observe these safety procedures could result in personal injury or

damage to the motor and equipment.

Servo drive power must be turned off before connecting or disconnecting the

cables to the motor, and if a cable is left disconnected at the motor end.

Arcing or unexpected motion could occur if the feedback, power or brake

cables are connected or disconnected while power is applied to the servo

drive.

Failure to observe these safety procedures could result in personal injury or

damage to the motor and equipment.

Publication TL-IN003A-EN-P — June 2007

Page 12

12 TL-Series Serv o Motors

Publication TL-IN003A-EN-P — June 2007

Dimensions

Dimensions are supplied for non-brake motors. Footnotes provide additional dimensions for brake

motors, and tolerances for common dimensions. All dimensions are approximate.

References for Motor Dimensions

Mounting pattern has two

holes for A110 through A130

(shown). All others have four

holes.

AD

L

LB

HD

L-LB

T

TB

Key (supplied) for

motors with key slot.

S dia. holes on

D

M dia. bolt circle.

P

N

NB

BE

Motor Dimensions for

Metric Frame

Mounting pattern has two

threaded hol es for A120 and

A130 (shown). All others have

four holes.

AC

AD

BE

Motor Dimensions for

NEMA Mount

LE

HD

LA

G

F

CAB

L

LB

L-LB

T

S dia. holes on

M dia. bolt circle.

D

P

N

Key supplied with

TLY-A2xx and TLY-A25xx

LE

CAB

LA

(NEMA 23 and 34) only.

TLY-A120 or TLY-A130

(NEMA 17) is not available

with key slot.

G

F

Page 13

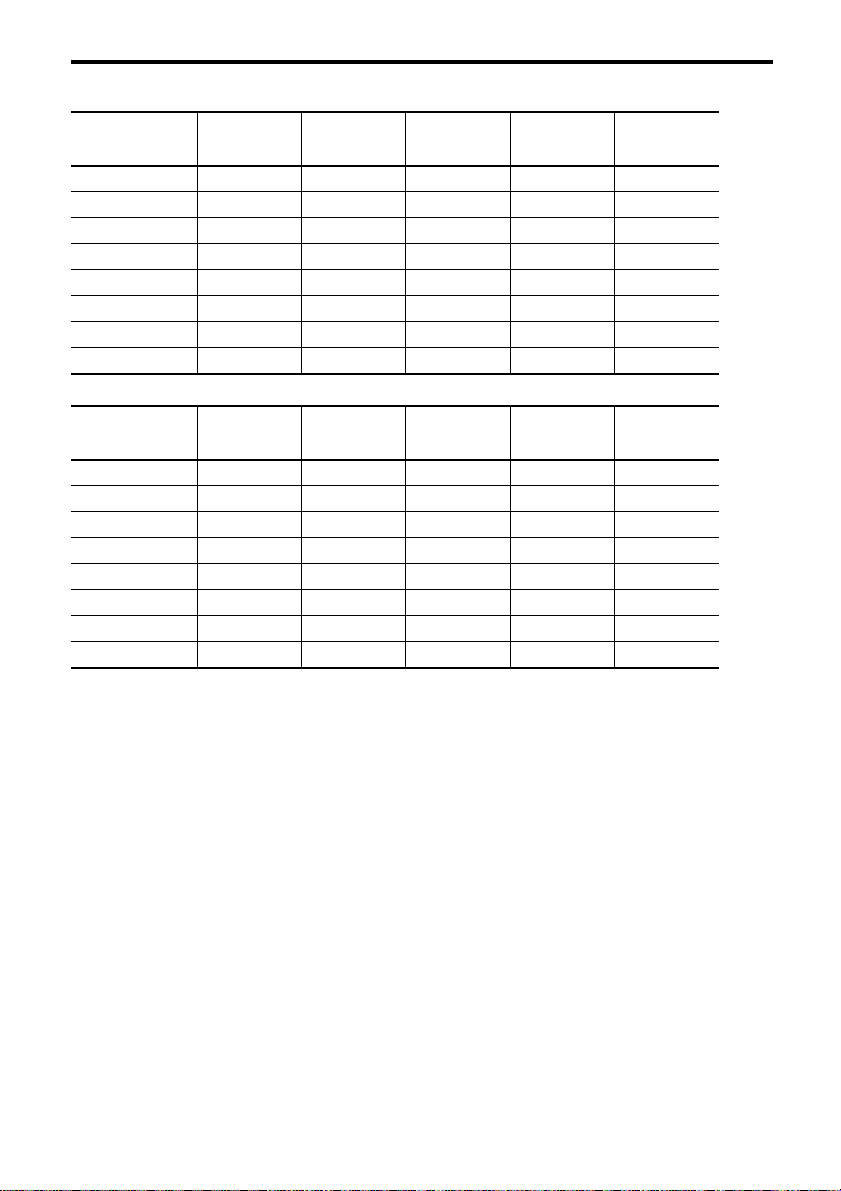

Metric Frame Dimensions, Approx.

TL-Series Servo Motors 13

Motor

Series

TLY

-A

110

130

220

230

2530

2540

310

Metric motor frames are designed to metric dimensions. Inch dimensions are a mathematical conversion.

AD

mm

(in.)

31.1

(1.22)

43.0

(1.69)

53.0

(2.09)

56.0

(2.20)

BE

mm

(in.)

21.0

(0.83)

27.6

(1.09)

D 1

mm

(in.)

8.0

(0.315)

12.0

(0.4724)

16.0

(0.6299)

HD

mm

(in.)

51.1

(2.01)

73.0

(2.87)

93.0

(3.66)

99.0

(3.90)

L 2

mm

(in.)

78.5

(3.09)

84.5

(3.33)

98.5

(3.88)

106.1

(4.18)

128.1

(5.04)

134.7

(5.30)

143.7

(5.66)

179.2

(7.06)

L-LB

mm

(in.)

25.0

(0.984)

30.0

(1.181)

35.0

(1.378)

3

LA

mm

(in.)

(0.20)

(0.24)

(0.32)

5.0

6.0

8.0

LB 2

mm

(in.)

53.5

(2.11)

59.5

(2.34)

73.5

(2.89)

76.1

(3.00)

98.1

(3.86)

99.7

(3.93)

108.7

(4.28)

144.2

(5.68)

LE 2

mm

(in.)

39.1

(1.54)

42.8

(1.69)

43.8

(1.72)

57.1

(2.25)

M

mm

(in.)

46.0

(1.811) 120

70.0

(2.76)

90.0

(3.54)

100.0

(3.94)

1 Tolerance f or this dimension is : TL Y-A1xx -0.009 mm (-0.0004 in.); TLY-A2xx -0.011 mm (-0.0004 in.); TLY-A25xx -0.011 mm (-0.0004 in.);

TLY-A310 -0.011 mm (-0.0004 in.).

2 TLY-A110, TLY-A120, or TLY-A130 motor with brake, add 35.6 mm (1.40 in.) to L, LB, and LE.

TLY-A220 and TLY-A230 motor with brake, add 34.6 mm (1.36 in.) to L, LB, and LE.

TLY-A2530, or TLY-A2540 motor with brake, add 36.6 mm (1.44 in.) to L, LB, and LE.

TLY-310 motor with brake, add 23.0 mm (0.90 in.) to L, LB, and LE.

3 Tolerance for this dimension is: ±1.0 mm (±0.039 in.).

Publication TL-IN003A-EN-P — June 2007

Page 14

14 TL-Series Serv o Motors

Publication TL-IN003A-EN-P — June 2007

Metric Frame Dimensions, Approx. (cont.)

Motor

Series

TLY-A

4

N

mm

(in.)

NB

P

S 5

T

TB

CAB 6

G 7

F 8

mm

mm

mm

mm

mm

mm

mm

mm

(in.)

(in.)

(in.)

(in.)

(in.)

(in.)

(in.)

(in.)

110

30.0

20.0

120

(1.1811)

(0.79)

40.0

(1.57)

4.5

(0.177)

2.5

(0.10)

4.5

(0.18)

6.2

(0.244)

3.0

(0.118)

130

220

50.0

(1.9685)

27.0

(1.06)

60.0

(2.36)

5.5

(0.217)

1000

(39.4)

9.5

(0.374)

4.0

(0.157)

230

3.0

7.0

2530

2540

310

Metric motor frames are designed to metric dimensions. Inch dimensions are a mathematical conversion.

70.0

(2.7556)

80.0

(3.15)

34.0

(1.34)

80.0

(3.15)

(0.260)

86.0

(3.39)

6.6

(0.12)

(0.28)

13.0

(0.512)

5.0

(0.197)

9

Key

mm

(in.)

3 x 3 x 15

(0.118 x 0.118 x

0.59)

4 x 4 x 15

(0.158 x 0.158 x

0.59)

5 x 5 x 20

(0.197 x 0.197 x

0.79)

4 Tolerance for this dimension is: TLY-A1xx -0.021 mm (-0.0008 in.); TLY-A2xx -0.025 mm (-0.001 in.); TLY-A25xx -0.03 mm (-0.0012 in.);

TLY-A310 -0.03 mm (-0.0012 in.).

5 TLY-A1xx has two mounting holes, TLY-A2xx…TLY-A310 have four mounting holes.

Mounting holes are S diameter on M diameter bolt circle.

6 Tolerance for cable length is ±50.0 mm (±1.97 in.). Minimum bend radius is 15.00 mm (0.59 in.).

7 Tolerance for this dimension is: -0.20 mm (-0.008 in.).

8 Tolerance for this dimension is: TLY-A1xx -0.006…-0.031 mm (-0.0002…-0.0012 in.); TLY-A2xx, TLY-A25xx and TLY-A3xx

-0.012…-0.042 mm (-0.0005…-0.0017 in.).

9 X-Y tolerance for this dimension is: TLY-A1xx -0.025 mm (-0.001 in.); TLY-A2xx, TLY-A25xx and TLY-A3xx -0.03 mm (-0.0012 in.). Lengt h

is untoleranced.

Page 15

NEMA Mount Dimensions, Approx.

TL-Series Servo Motors 15

Motor

Series

TLY-A

AC

mm

(in.)

AD

mm

(in.)

BE

D 1

HD

L 2

L-LB

mm

mm

mm

mm

(in.)

(in.)

(in.)

(in.)

mm

(in.)

91.5

120

130

—

31.10

(1.22)

21.0

(0.83)

6.35

(0.25)

52.0

(2.05)

(3.603)

105.5

(4.153)

27.0

(1.063)

137.9

220

230

60

(2.36)

43.0

(1.69)

12.70

(0.50)

27.6

(1.09)

2530

—

53.0

(2.09)

15.875

(0.625)

2540

NEMA motor fl an ges and shafts are designed to inc h dimensions. Other frame area s are designed to metric dimensions.

Conversions are mathematically calculated.

1 Tolerance for this dimension is: TLY-A1xx -0.009 (-0.0004); TLY-A2xx -0.011 (-0.0004); TLY-A25xx -0.011 (-0.0004).

2 TLY-A120, or TLY-A130 motor with brake, add 35.6 mm (1.40 in.) to L, LB, and LE.

73.0

(2.87)

96.0

(3.78)

(5.43)

159.9

(6.30)

149.2

(5.872)

158.2

(6.205)

38.1

(1.50)

44.5

(1.752)

3

LA

LB 2

mm

mm

(in.)

(in.)

LE

mm

(in.)

2

M

mm

(in.)

64.5

5.0

(0.20)

(2.54)

78.5

39.1

(1.54)

43.8

(1.725)

(3.09)

99.8

(3.93)

6.0

(0.24)

121.8

43.3

(1.70)

66.7

(2.625)

(4.80)

104.7

(4.12)

8.0

(0.32)

113.7

43.8

(1.72)

98.4

(3.875)

(4.48)

TLY-A220, or TLY-A230 motor with brake, add 34.6 mm (1.36 in.) to L, LB, and LE.

TLY-A2530, or TLY-A2540 motor with brake, add 36.6 mm (1.44 in.) to L, LB, and LE.

3 Tolerance for this dimension is: ±1.0 mm (±0.039 in.).

Publication TL-IN003A-EN-P — June 2007

Page 16

16 TL-Series Serv o Motors

Publication TL-IN003A-EN-P — June 2007

NEMA Mount Dimensions, Approx. (cont.)

Motor

Series

TLY-A

120

4

N

mm

(in.)

22.0

(0.8661)

NB

mm

(in.)

—

P

mm

(in.)

42.0

(1.65)

5

S

mm

(in.)

8-32

Thread

T

mm

(in.)

2.0

(0.08)

TB

mm

(in.)

—

CAB

mm

(in.)

1000

(39.4)

6

7

8

G

mm

(in.)

F

Key 9

mm

(in.)

mm

(in.)

— — —

130

220

38.1

(1.50)

—

56.4

(2.22)

5.5

(0.217)

1.5

(0.06)

—

1000

(39.4)

10.92

(0.43)

3.175

(0.125)

(0.125 x 0.125

x 0.9375)

230

2530

73.02

(2.875)

—

86.0

(3.39)

5.5

( 0.217)

1.6

(0.06)

—

1000

(39.4)

13.13

(0.517)

4.763

(0.1875)

(0.187 x 0.187

x 1.156)

2540

NEMA motor flanges and shafts are designed to inch dimensions. Other frame areas are designed to metric

dimensions. Conversions are mathematically calculated.

4 Tolerance for this dimension is: TLY-A1xx -0.021 mm (-0.0008 in.); TLY-A2xx -0.025 mm (-0.001 in.); TLY-A25xx -0.03 mm (-0.0012 in.).

5TLY-A1xx has two threaded holes, TLY-A2xx and TLY-A25xx have four mounting holes.

Mounting holes are S diameter on M diameter bolt circle.

6 Tolerance for cable length is ±50.0 mm (±1.97 in.). Minimum bend radius is 15.00 mm (0.59 in.).

7 Tolerance for this dimension is: -0.38 mm (-0.015 in.).

8 Tolerance for this dimension is: +0.051 mm (+0.002 in.).

9 X-Y tolerance for this dimension is: TLY -0.051 mm (-0.002 in.). Length is untoleranced.

Page 17

TL-Series Servo Motors 17

Motor Load Force Ratings

Motors are capable of operating with a sustained shaft load. The radial and axial load force location,

and maximum values are provided.

Load Forces on the Shaft

Radial load forc e is ap plied at the mid point of the sh aft ext ension .

Axial load force is applied at the center of the shaft diameter.

The following tables represent 20,000- hour L10 bearing fatigue life at various loads and speeds. The

20,000-hour life does not account for application-specific life reduction that can occur due to bearing

grease contaminati on from external sources.

Loads are measured in pound s. Kilograms are a mathematical conversion.

Radial Load Force Ratings

Motor 1000 rpm 2000 rpm 3000 rpm 4500 rpm 5000 rpm

kg (lb) kg (lb) kg (lb) kg (lb) kg (lb)

TLY-A110 11 (24) 9 (19) 7 (16) – – 6 (14)

TLY-A120 12 (26) 10 (21) 8 (18) – – 7 (15)

TLY-A130 13 (29) 10 (23) 9 (20) – – 8 (17)

TLY-A220 27 (60) 22 (48) 19 (42) – – 16 (35)

TLY-A230 31 (68) 24 (54) 21 (47) – – 18 (40)

TLY-A2530 48 (106) 38 (84) 34 (74) – – 28 (62)

TLY-A2540 50 (110) 39 (87) 34 (76) – – 29 (64)

TLY-A310 80 (177) 64 (140) 56 (123) 47 (103) – –

Publication TL-IN003A-EN-P — June 2007

Page 18

18 TL-Series Serv o Motors

Publication TL-IN003A-EN-P — June 2007

Axial Load Force Ratings (maximum radial load)

Motor 1000 rpm 2000 rpm 3000 rpm 4500 rpm 5000 rpm

kg (lb) kg (lb) kg (lb) kg (lb) kg (lb)

TLY-A110 8(18) 6(14) 5(10) ––4(9)

TLY-A120 9(20) 7(16) 5(12) ––5(10)

TLY-A130 10 (22) 8 (17) 6 (13) – – 5 (11)

TLY-A220 15 (32) 11 (24) 9 (20) – – 7 (16)

TLY-A230 15 (34) 12 (26) 10 (21) – – 8 (17)

TLY-A2530 18 (39) 13 (29) 11 (24) – – 9 (19)

TLY-A2540 18 (39) 13 (29) 11 (25) – – 9 (20)

TLY-A310 24 (54) 18 (4 0) 15 (34) 12 (27) – –

Axial Load Force Ratings (zero radial load)

Motor 1000 rpm 2000 rpm 3000 rpm 4500 rpm 5000 rpm

kg (lb) kg (lb) kg (lb) kg (lb) kg (lb)

TLY-A110 12 (26) 9 (20) 7 (16) – – 6 (13)

TLY-A120 12 (26) 9 (20) 7 (16) – – 6 (13)

TLY-A130 12 (26) 9 (20) 7 (16) – – 6 (13)

TLY-A220 19 (41) 14 (30) 11 (25) – – 9 (20)

TLY-A230 19 (41) 14 (30) 11 (25) – – 9 (20)

TLY-A2530 23 (50) 17 (37) 14 (31) – – 11 (25)

TLY-A2540 23 (50) 17 (37) 14 (31) – – 11 (25)

TLY-A310 29 (65) 22 (4 8) 19 (41) 15 (32) – –

Page 19

TL-Series Servo Motors 19

Connector Data

These tables provide signal descriptions for servo motors with TLY catalog numbers.

Absolute Encoder Connector Pinouts Incremental Encoder

Feedback Connections Feedback Connector Feedback Connections

Pin Signal Tyco AMP 206152-1 Pin Signal

1…5 Reserved — 1…8 Reserved —

6 BAT+ Brown 9 AM+ Green

7…12 Reserved — 10 AM- Green/blk

13 DATA+ Blue 11 BM+ Blue

14 DATA- Blue/black 12 BM- Blue/blk

15…21 Reserved — 13 IM+ Yellow

22 EPWR 5V Red 14 IM- Yellow/blk

23 ECOM & BAT- Black 15 S1+ Grey/blk

24 SHIELD Drain wire 16 S1- Grey

25…28 Reserved — 17 S2+ Brown/blk

Power and Brake Connections Power and Brake Connector Power and Brake Connections

Pin Signal Tyco AMP 206705-2 Pin Signal

1 U phase Red 1 U phase Red

2 V phase White 2 V phase Black

3 W phase Black 3 W phase White

4 Reserved — 4 Reserved —

5 Ground Yellow/grn &

drain wires

6 Reserved — 6 Reserved —

7 MBRK+ Yellow 7 MBRK+ Yellow

8 Reserved — 8 Reserved —

9 MBRK- Blue 9 MBRK- Blue

1

4

9

15

21

26

1

4

7

3

8

14

20

25

28

18 S2- Brown

19 S3+ White/blk

20 S3- White

21 Reserved —

22 EPWR 5V Red

23 ECOM Black

24 SHIELD Drain wire

25…28 Reserved —

3

6

9

5 Ground Yellow/grn &

drain wires

ATTENTION Be sure that cables are installed and restrained to prevent uneven tension or flexing at

the cable connectors. Excessive and uneven force at the cable connector may result in

damage to the housing and contacts as the cable f lexes. Failure to observe these safety

procedures could result in damage to th e motor and its components.

Publication TL-IN003A-EN-P — June 2007

Page 20

20 TL-Series Serv o Motors

Publication TL-IN003A-EN-P — June 2007

Connector Type Feedback - 28 Position Power - 9 Position

Motor Connectors

Connector housing 206152-1 206705-2

Connector backshell 206070-8 206966-7

Signal and powe r c ontact pins

Reel

Loose

Ground contact pi ns

Reel

Loose

Brake contact pins

Reel

Loose

(3)

Compatible Connectors for Mating Cables

Connector housing 205839-3 206708-1

Connector backshell 206070-8 206966-7

Contact sockets

Reel

Loose

Tools for Motor Connectors or Compatible Connectors

Hand crimp tool 91503-1 58495-1

Contact tool

Extraction and insertion - feedback

Extraction - power and brake

Extraction - ground

Insertion - power, brake, and ground

(1)

(2)

1658540-4

1658540-5

(5)

(5)

—

A110…A130

(7)

66102-9

66103-4

(7)

A220…A310

66098-9

66099-4

164161-4

164164-2

—

66106-8

66107-4

1658538-2

66505-9

91285-1

(6)

(6)

66100-9

66101-4

(8)

(8)

305183

(4)

725840-1

91002-1

(8)

(8)

Tyco AMP specifies wire sizing in AWG, mm2 is a conversion from AWG in the footnotes.

(1)

For U, V, and W power phases in the power connector.

(2)

For motor frame ground in the power connector.

(3)

For motor brake in the power connector.

(4)

Use of the contact insertion tool is optional, as contacts are readily pushed by hand into the connector housing. After

contacts are inserted into the connector housing, gently pull backward on each wire to be sure that contacts are

fully seated and latched into position.

(5)

Wire range is 0.08…0.2 mm2 (28…24 AWG).

(6)

Contacts and wire gauge used in Rockwell cables may vary by cable conductor. For reference only, the wire range of these

contacts is 0.08…0.2 mm

(7)

Wire range is 0.2…0.6 mm2 (24…20 AWG).

(8)

Wire range is 0.8…1.4 mm2 (18…16 AWG).

2

(28…24 AWG).

Page 21

TL-Series Servo Motors 21

Remove and Install a Shaft Key

Shaft keys are constructed of carbon steel. Keys for metric mount motors are toleranced for

interference fit (slightly larger than the opening) to be sure of a secure and rigid fit with the mating

connection. Keys for NEMA mount motors are toleranced for a slightly loose (slip) fit.

ATTENTION

To remove a shaft key, perform one of the following acti ons.

• Lift the key by grasping it with a plier or similar tool.

• Lever the key with a flat-blade screwdriver inserted between the key and the slot.

To install a shaft key, follow these steps.

1. Verify that the replacement key matches the keyway in the shaft and the mating mechanical

connection (for example, a coupling or pulley) before proceeding.

2. Align the front of the key with the front of the motor shaft. This prevents the radiused

end-of-cut at the motor end of the keyway from interfering with correct seating of the key.

Do not strike the shaft, key, couplings, or pulle ys wit h t ools during installation or

removal.

Damage may occur to the motor bearings and the feedback device if sharp impact to

the shaft is applied during installation of couplings and pul leys, or a shaft key.

Damage to the feedback device also may result by applying leverage from the

faceplate to remove devices mounted on t he mot or shaf t .

Apply a constant pressure, wit h a wheel puller, to the user end of the shaft to

remove from the motor shaft any friction fit or stuck device.

Failure to observe these safety procedures could result in da mage t o th e mot or and

its components.

3. Support the underside of the shaft diam eter with a fixture, and use a controlled press device

to apply a constant force across the top surface to press the key into the shaft.

IMPORTANT

Check the motor shaft and surrounding surfaces. Remove any nicks,

burrs, or surface damage. Significant grooving or damage will require

service by Rockwell Automation to provide appropriate seal performance.

Publication TL-IN003A-EN-P — June 2007

Page 22

22 TL-Series Serv o Motors

Publication TL-IN003A-EN-P — June 2007

Key Alignment and Shaft Support

Key aligns to front of shaft.

Shaft

Mill cut rounds

end of keyway.

Support for Shaft an d Mo tor

For clarity,

shaft is rotated

90° clockwise between

the drawings.

Specifications

The exterior surfaces of servo motors with TLY catalog numbers are made from the following

materials. Always store a motor in a clean and dry location within these environmenta l conditions.

Surface Material

Shaft carbon steel

Shaft key carbon steel

Housing of TLY-A1xx, T LY-A2 xx, and TLY-A25xx. aluminum and potting compound

Housing of TLY-A3xx aluminum

Requirement

Temperature, operating 0 … 40 °C (32 … 104 °F)

Temperature, storage -10 … 85 °C (14 … 185 °F)

Relative humidity 20% … 85% non-condensing

Atmosphere non-corrosive

Motor with optional shaft seal

Motor without a shaft seal, and

mounted in this direction.

shaft down

shaft horizontal

shaft up

Cable connectors IP30 protected from objects greater than 2.5 mm (0.1 in.) in

(1)

An optional shaft seal kit is required to provide the IP65 rating (excludes lower rating for cable connectors).

See Additional Resources on page 24 for Shaft Seal Installation Instructions.

(2)

IP rating descriptions are for reference only. Refer to the international standards for more complete rating descriptions.

(1)

IP65 dust tight, water jets

IP53

IP51

IP50

Description

dust protected, spraying water

dust protected, vertically falling water

dust protected, no special moisture protection

diameter, no special moisture protection

(2)

Page 23

TL-Series Servo Motors 23

Accessories

Accessories available from the factory include the following items.

Motor Cables

Factory manufactured feedback and power cables are available in standard cabl e lengths. Transition

cables are available to allow connection of ser vo motors wit h TLY catalog numbers to existing

N-Series power, feedback, and brake cables. Factory cables provide proper shield termination, which

reduces the potential for EMI.

For a complete listing of available cables refer to your drive’s installation manual, contact your nearest

Rockwell Automation sales office, or access the information from the website references in

Additional Resources on page 24.

Connector Kits

Each connector kit includes the appropriate connector housing, pins, and backshell.

Connector Kit Catalog Number Connector Kit Catalog Number

Feedback Connector 2090-KFBM6-00AA Power Connector 2090-KPBM6-16AA

Shaft Seal K its

Catalog numbers and dimensions for shaft seals are shown below.

Motor

TLY-A110, TLY-A120, TLY-A130 TL-SSN-1 8.9 (0.35) 16 (0.71) 3 (0.12)

TLY-A220, TLY-A230 TL-SSN-2 14.0 (0.55) 24 (0.95) 5 (0.20)

TLY-A2530, TLY-A2540, TLY-A310 TL-SSN-3 19.8 (0.78) 30 (1.18) 5 (0.20)

(1)

Shaft seals require a lubricant to reduce wear. Lubricant is provided with kit.

Catalog

Number

Inside Diameter Outside Diameter Width

(1)

mm (in.) mm (in.) mm (in.)

Transition Cables

Transition cables interface between N-Series motor cables and the cables on servo motors with TLY

catalog numbers with incremental encoders. The cables are 500 mm (20.0 in.)in leng th.

Feedback Cable

Catalog Number

2090-CFBM6CN-04AA 2090-CPBM6CN-16AA 2090-CPWM6CN-16AA

Power and Brake Cable

Catalog Number

Power Only Cable

Catalog Number

Publication TL-IN003A-EN-P — June 2007

Page 24

Transition Plates

Transition mounting plates allow a TL-Series NEMA motor to physically replace an N-Series motor.

Catalog Number Descriptio n Compatible Motors

N-Series TL-Series NEMA

TL-TRPLAT-17-23 TL Transition Plate, NEMA 17 to 23 N-23xx TLY-A1xxx-xxxxN

TL-TRPLAT-23-34 TL Transition Plate, NEMA 23 to 34 N-34xx TLY-A2xxx-xxxxN

TL-TRPLAT-34-42 TL Transition Plate, NEMA 34 to 42 N-42xx TLY-A25xxx-xxxxN

Transition plates are not available for the N-56xx motors.

Additional Resources

For additional information about motors and compatible Rockwell Automation drives, refer to these

publications.

For Read this document Pub li cat ion Number

Connecting to a drive. Kinetix 2000 User Manual

Mounting TL-Series moto r transition

plates

Installing a shaft seal Shaft Seal Installation Instructions 2090-IN012

Information about Kinetix products Kinetix Motion Control Selection Guide GMC-SG001

A glossary of industrial automation terms

and abbreviations

Kinetix 6000 User Manual

Ultra3000 Installation Manual

Ultra3000 Integration Manual

TL-Series Installation Instructions TL-IN002

Allen-Bradley Industrial Automation

Glossary

2093-UM001

2094-UM001

2098-IN003

2098-IN005

AG-7.1

You can view or download publications at http://literature.rockwellautomation.com

. To order paper

copies of technical documentation, conta ct your local Rockwell Automation distributor or sales

representative.

Publication TL-IN003A-EN-P - June 2007 PN-13218

Copyright © 2007 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...