Page 1

Installation Instructions

TL-Series Motor Transition Plate

(Catalog Numbers TL-TRPLAT-17-23, TL-TRPLAT-23-34, and

TL-TRPLAT-34-42)

This publication provides instructions to attach the TL-Series Transition

Plates to TL-Series NEMA motors.

The TL-Series Motor Transition Plate allows a TL-Series NEMA motor

to physically replace an N-Series motor. It converts the mounting bolt

hole pattern from a TL-Series NEMA pattern to an N-Series NEMA

bolt hole pattern. This allows the original mounting holes in the

machine to be used to mount the replacement motor.

This document applies to the transition plates, motors, and mounting

hardware identified by these catalog numbers:

Catalog Number Description

TL-TRPLAT-17-23 TL-Series Transition Plate, NEMA 17 to 23 N-22xx TL-A1xxP-xxxxN

TL-TRPLAT-23-34 TL-Series Transition Plate, NEMA 23 to 34 N-34xx TL-A2xxP-xxxxN

TL-TRPLAT-34-42 TL-Series Transition Plate, NEMA 34 to 42 N-42xx TL-A25xxP-xxxxN

Transition plates are not available for the N-56xx motors.

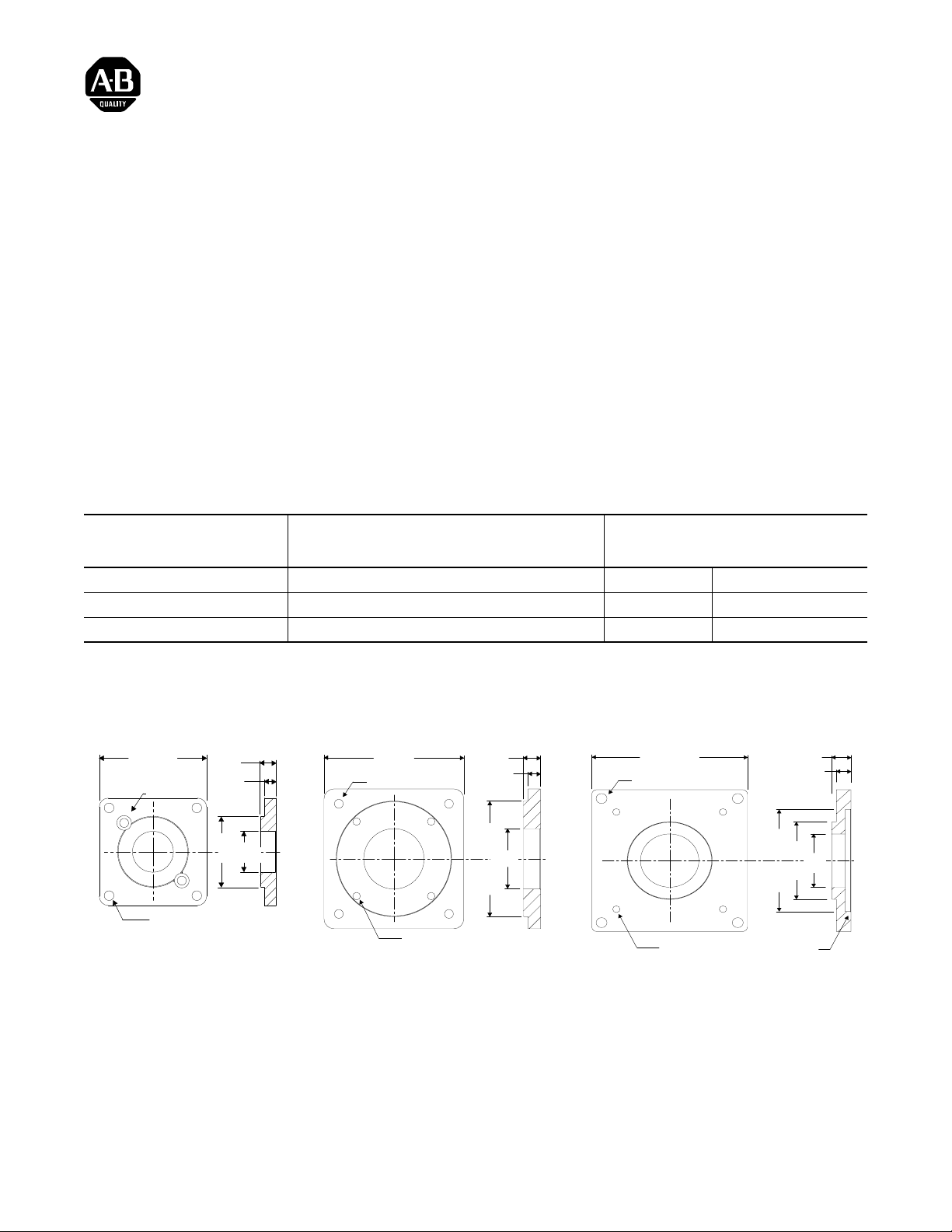

2.27 sq.

0.19 on

1.725 circle

0.205 on 2.625 circle

Note: 0.19 mounting holes (2) are

counterbored 0.31 to 0.18 depth.

0.34

0.25

1.50

0.867

3.48 sq.

0.22 on 3.875 circle

10-32 on 2.625 circle

0.43

0.31

2.875

1.50

Compatible Motors

From N-Series to TL-Series NEMA

TL-TRPLAT-34-42TL-TRPLAT-23-34TL-TRPLAT-17-23

4.0 sq.

0.28 on 4.95 circle

0.28 on 4.95 circle

2.875

2.188

10-32 on 3.875 circle

0.15 deep

0.50

0.375

1.50

Note: The standoff resulting from the transition plate depth reduces the shaft extension on the TL-Series NEMA motor to the nominal shaft extension of an N-Series motor.

Publication TL-IN002A-EN-P — December 2004

Page 2

Installation Instructions

!

To attach an transition plate to a TL-Series NEMA motor:

ATTENTION

1. Align the mounting holes in the transition plate with those in the

TL-Series NEMA motor.

2. Insert the mounting screws from the proper direction, and then torque

each screw to the appropriate value.

• TL-TRPLAT-17-23 requires two screws through the face of the

transition plate and into the front of the motor mount.

• TL-TRPLAT-23-34 and TL-TRPLAT-34-42 require four screws

through the back of the motor mount and into the rear of the

transition plate.

Energy may be stored in a drive system after power is

removed.

Before disconnecting mechanical or electrical connections

to a motor, remove power from the drive system and allow

the bus capacitance to discharge for the time indicated on

the front of the drive.

Failure to observe safety procedures could result in personal

injury or equipment damage.

Catalog Number of Transition Plate Mounting Hardware Torque Requirements

TL-TRPLAT-17-23 Two 8-32 cap screws 3.0 - 3.7 Nm (27 - 33 lb-in.)

TL-TRPLAT-23-34

TL-TRPLAT-34-42

Refer to the TL-Series Servo Motor Installation Instructions (publication

TL-IN001x-EN-P) for detailed information on mounting, maintaining, and

troubleshooting a TL-Series NEMA motor. To obtain a copy, contact your

local Rockwell Automation office or distributor, or access the document

on-line at http://

For more information refer to our web site: www.ab.com/motion

For Allen-Bradley Technical Support information refer to: www.support.rockwellautomation.com or Tel: (1) 440.646.5800

Allen-Bradley, and A-B are registered tradema rks of Rockwell Automation.

www.rockwellautomation.com

Four 10-32 cap screws 6.1 - 7.5 Nm (54 - 66 lb-in.)

/literature.

Publication TL-IN002A-EN-P — December 2004 P/N 9101-0465-001

Copyright © 2004 Rockwell Automation. All rights reserved. Printed in USA.

Loading...

Loading...