Page 1

Installation Instructions

MP-Series and TL-Series Electric Cylinders Replacement Parts

Catalog Numbers MPAR-NA3210C, MPAR-NA323C, MPAR-NA4012C, MPAR-NA405C,

MPAR-NA6310C, MPAR-NA6320C

MPAR-NP3210B, MPAR-NP323B, MPAR-NP4012B, MPAR-NP405B, MPAR-NP6310B,

MPAR-NP6320B

TLY-A1xxx-B-X19x, TLY-A2xxx-B-X19x, TLY-A3xxx-B-Xxxx

MPL-x1520F-V-X20x, MPL-x1530F-V-X20x, MPL-x220F-V-X2xx, MPL-x330F-M-X21x,

MPL-x420F-M-X21x

MPAR-X1xxxB, MPAR-X1xxxE, MPAR-X2xxxC, MPAR-X2xxxF, MPAR-X3xxxE, MPAR-X3xxxH

Topi c Pag e

About the MP-Series and TL-Series Electric Cylinder Replacement Parts 1

Important User Information 2

Catalog Number Explanation 3

Before You Begin 6

Replace Inline-mount Electric Cylinder Motor 6

Replace Inline-mount Electric Cylinder Coupling or Actuator Cylinder 7

Replace a Parallel-mount Electric Cylinder Motor or Belt 12

Additional Resources 17

About the MP-Series and TL-Series Electric Cylinder Replacement Parts

Electric cylinders have three replaceable parts; the motor, actuator cylinder, and the transmission

component. For inline-mount electric cylinders, the transmission component is the coupler and

for parallel-mount electric cylinder, it is a belt. Instructions in this manual cover the replacement

of these components.

Page 2

2 MP-Series and TL-Series Electric Cylinders Replacement Parts

Important User Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for

the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

Automation sales office or online at http://www.rockwellautomation.com/literature/

between solid-state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the wide

variety of uses for solid-state equipment, all persons responsible for applying this equipment must satisfy themselves that each

intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibil ity or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNIN G: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from your local Rockwell

) describes some important differences

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard and recognize the

consequences.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, drive or motor, to alert people that

surfaces may reach dangerous temperatures.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Rockwell Automation Publication MPAR-IN002B-EN-P - September 2012

Page 3

MP-Series and TL-Series Electric Cylinders Replacement Parts 3

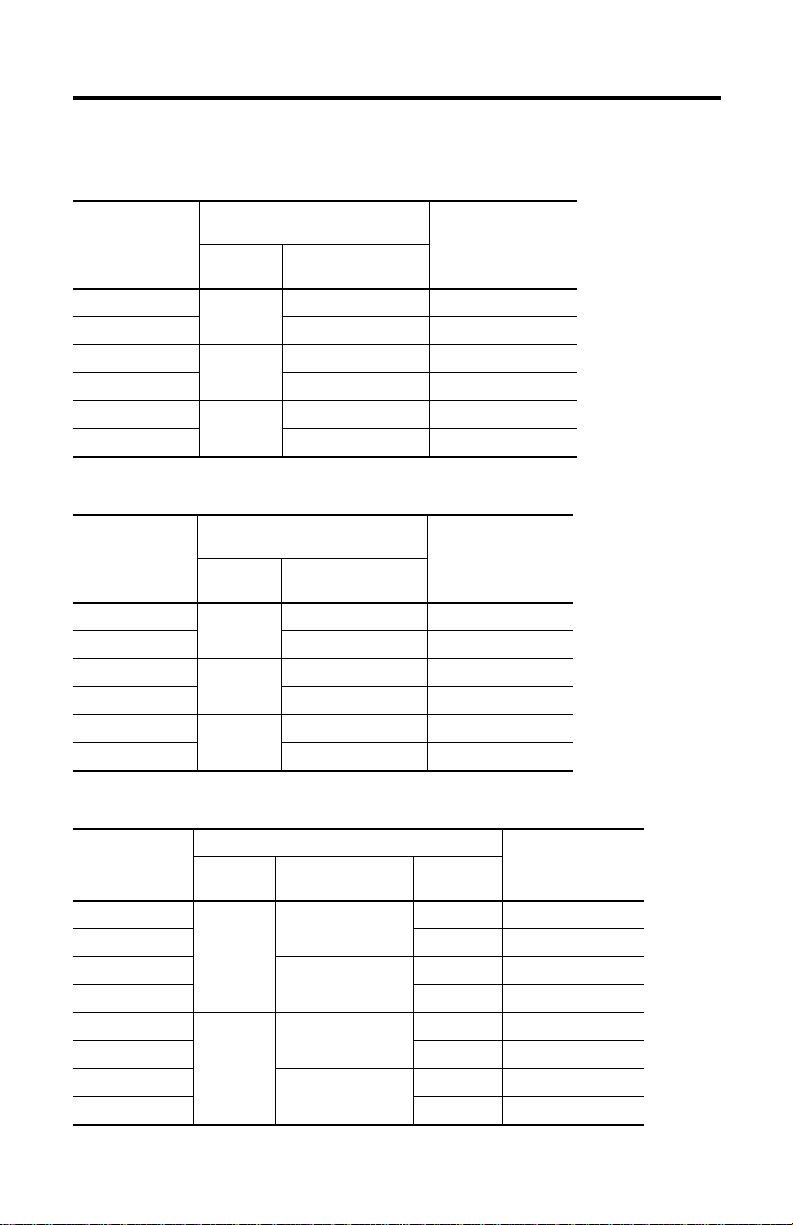

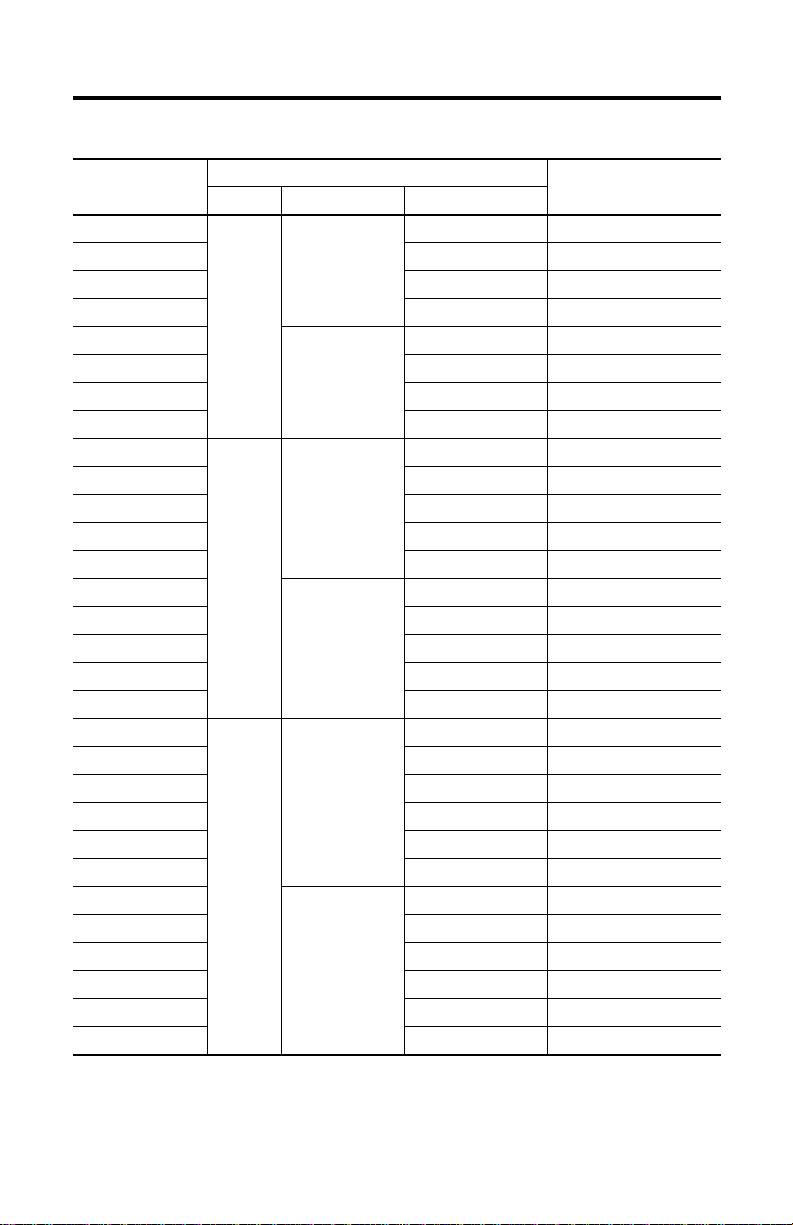

Catalog Number Explanation

Replacement Couplings

Electric Cylinder with Inline

Replacement Coupling

Cat. No.

MPAR-NA3210C

MPAR-NA323C 3.0 (0.118) MPAR-x1xxxB-xxA

MPAR-NA4012C

MPAR-NA405C 5.0 (0.197) MPAR-x2xxxC-xxA

MPAR-NA6310C

MPAR-NA6320C 20.0 (0.787) MPAR-x3xxxH-xxA

Frame Size

32

40

63

Replacement Belts

Replacement Belt

Cat. No.

MPAR-NP3210B

MPAR-NP323B 3.0 (0.118) MPAR-x1xxxB-xxB/D/E

MPAR-NP4012B

MPAR-NP405B 5.0 (0.197) MPAR-x2xxxC-xxB/D/E

MPAR-NP6310B

MPAR-NP6320B 20.0 (0.787) MPAR-x3xxxH-xxB/D/E

Frame Size

32

40

63

Motor Attributes

Ball Screw Pitch

mm/rev (in./rev)

10.0 (0.394) MPAR-x1xxxE-xxA

12.7 (0.500) MPAR-x2xxxF-xxA

10.0 (0.394) MPAR-x3xxxE-xxA

Electric Cylinder with Motor Mounted in

Parallel Attributes

Ball Screw Pitch

mm/rev (in./rev)

10.0 (0.394) MPAR-x1xxxE-xxB/D/E

12.7 (0.500) MPAR-x2xxxF-xxB/D/E

10.0 (0.394) MPAR-x3xxxE-xxB/D/E

Use with Electric Cylinder

Cat. No.

Use with Electric Cylinder

Cat. No.

Replacement Motors for TLAR-Series Electric Cylinders

Replacement Moto r

Cat. No.

TLY-A130F-B-X191

TLY-A130F-B-X192 24V Brake TLAR-A1xxxB-x4x

TLY-A220F-B-X193

TLY-A220F-B-X194 24V Brake TLAR-A1xxxE-x4x

TLY-A220F-B-X195

TLY-A220F-B-X196 24V Brake TLAR-A2xxxC-x4x

TLY-A230F-B-X197

TLY-A230F-B-X198 24V Brake TLAR-A2xxxF-x4x

Frame Size

32

40

Electric Cylinder Attributes

Ball Screw Pitch

mm/rev (in./rev)

3.0 (0.118)

10.0 (0.394)

5.0 (0.197)

12.7 (0.5)

Brake

None TLAR-A1xxxB-x2x

None TLAR-A1xxxE-x2x

None TLAR-A2xxxC-x2x

None TLAR-A2xxxF-x2x

Use with Electric Cylinder

Cat. No.

Rockwell Automation Publication MPAR-IN002B-EN-P - September 2012

Page 4

4 MP-Series and TL-Series Electric Cylinders Replacement Parts

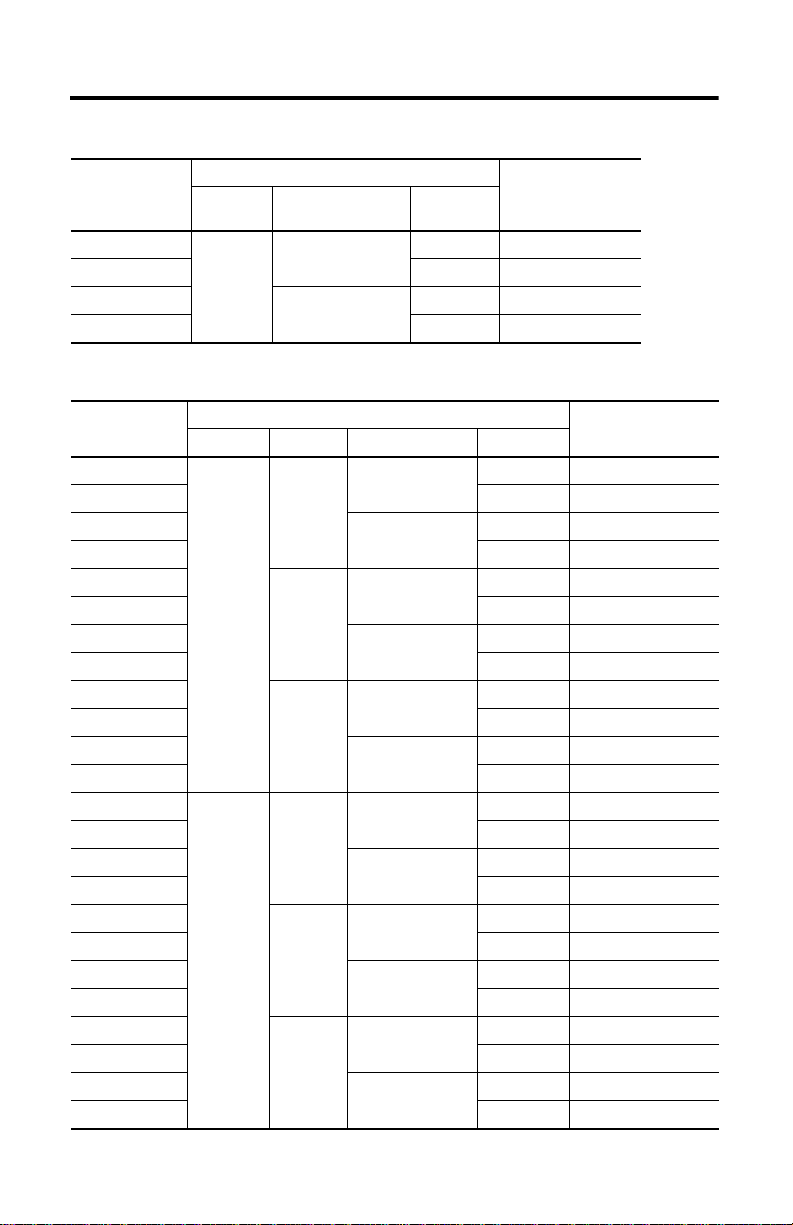

Replacement Motors for TLAR-Series Electric Cylinders (continued)

Replacement Motor

Cat. No.

TLY-A310F-B-X199

TLY-A310F-B-X200 24V Brake TLAR-A3xxxE-x4x

TLY-A310F-B-X201

TLY-A310F-B-X202 24V Brake TLAR-A3xxxH-x4x

Frame Size

63

Electric Cylinder Attributes

Ball Screw Pitch

mm/rev (in./rev)

10.0 (0.394)

20.0 (0.787)

Use with Electric Cylinder

Brake

None TLAR-A3xxxE-x2x

None TLAR-A3xxx H-x2x

Cat. No.

Replacement Motor for MPAR-Series Electric Cylinders

Replacement Motor

Cat. No.

MPL-A1520F-V-X203

MPL-A1520F-V-X204 24V Brake MPAR-A1xxxB-x4x

MPL-A1530F-V-X205

MPL-A1530F-V-X206 24V Brake MPAR-A1xxxE-x4x

MPL-A1530F-V-X207

MPL-A1530F-V-X208 24V Brake MPAR-A2xxxC-x4x

MPL-A220F-V-X209

MPL-A220F-V-X210 24V Brake MPAR-A2xxxF-x4x

MPL-A330F-M-X211

MPL-A330F-M-X212 24V Brake MPAR-A3xxxE-x4x

MPL-A420F-M-X213

MPL-A420F-M-X214 24V Brake MPAR-A3xxxH-x4x

MPL-B1520F-V-X215

MPL-B1520F-V-X216 24V Brake MPAR-B1xxxB-x4x

MPL-B1530F-V-X217

MPL-B1530F-V-X218 24V Brake MPAR-B1xxxE-x4x

MPL-B1530F-V-X219

MPL-B1530F-V-X220 24V Brake MPAR-B2xxxC-x4x

MPL-B220F-V-X221

MPL-B220F-V-X222 24V Brake MPAR-B2xxxF-x4x

MPL-B330F-M-X223

MPL-B330F-M-X224 24V Brake MPAR-B3xxxE-x4x

MPL-B420F-M-X225

MPL-B420F-M-X226 24V Brake MPAR-B3xxxH-x4x

Voltag e Class Frame Size Pitch mm/rev (in./rev) Brake

200

400

Electric Cylinder Attributes

32

40

63

32

40

63

3.0 (0.118)

10.0 (0.394)

5.0 (0.197)

12.7 (0.50)

10.0 (0.394)

20 (0.787)

3.0 (0.118)

10.0 (0.394)

5.0 (0.197)

12.7 (0.50)

10.0 (0.394)

20.0 (0.787)

None MPAR-A1xxxB-x2x

None MPAR-A1xxxE-x2x

None MPAR-A2xxxC-x2x

None MPAR-A2xxx F-x2x

None MPAR-A3xxxE-x2x

None MPAR-A3xxx H-x2x

None MPAR-B1xxxB-x2x

None MPARBA1xxxE-x2x

None MPAR-B2xxxC-x2x

None MPAR-B2xxxF-x2x

None MPAR-B3xxxE-x2x

None MPAR-B3xxxH-x2x

Use with Electric Cylinder

Cat. No.

Rockwell Automation Publication MPAR-IN002B-EN-P - September 2012

Page 5

Replacement Actuator

MP-Series and TL-Series Electric Cylinders Replacement Parts 5

Replacement Ac tuator

Cat. No.

MPAR-X1100B

MPAR-X1200B 200 TLAR/MPAR-x1xxxB-xxx

MPAR-X1300B 300 TLAR/MPAR-x1xxxB-xxx

MPAR-X1400B 400 TLAR/MPAR-x1xxxB-xxx

MPAR-X1100E

MPAR-X1200E 200 TLAR/MPAR-x1xxxE-xxx

MPAR-X1300E 300 TLAR/MPAR-x1xxxE-xxx

MPAR-X1400E 400 TLAR/MPAR-x1xxxE-xxx

MPAR-X2100C

MPAR-X2200C 200 TLAR/MPAR-x2xxxC-xxx

MPAR-X2300C 300 TLAR/MPAR-x2xxxC-xxx

MPAR-X2400C 400 TLAR/MPAR-x2xxxC-xxx

MPAR-X2600C 600 TLAR/MPAR-x2xxxC-xxx

MPAR-X2100F

MPAR-X2200F 200 TLAR/MPAR-x2xxxF-xxx

MPAR-X2300F 300 TLAR/MPAR-x2xxxF-xxx

MPAR-X2400F 400 TLAR/MPAR-x2xxxF-xxx

MPAR-X2600F 600 TLAR/MPAR-x2xxxF-xxx

MPAR-X3100E

MPAR-X3200E 200 TLAR/MPAR-x3xxxE-xxx

MPAR-X3300E 300 TLAR/MPAR-x3xxxE-xxx

MPAR-X3400E 400 TLAR/MPAR-x3xxxE-xxx

MPAR-X3600E 600 TLAR/MPAR-x3xxxE-xxx

MPAR-X3800E 800 TLAR/MPAR-x3xxxE-xxx

MPAR-X3100H

MPAR-X3200H 200 TLAR/MPAR-x3xxxH-xxx

MPAR-X3300H 300 TLAR/MPAR-x3xxxH-xxx

MPAR-X3400H 400 TLAR/MPAR-x3xxxH-xxx

MPAR-X3600H 600 TLAR/MPAR-x3xxxH-xxx

MPAR-X3800H 800 TLAR/MPAR-x3xxxH-xxx

Frame Size Pitch mm/rev (in./rev) Stroke Length mm (in.)

32

40

63

Electric Cylinder Attributes

3.0 (0.118)

10.0 (0.394)

5.0 (0.197)

12.7 (0.50)

10.0 (0.344)

20.0 (0.787)

Use with Electric Cylinder

Cat. No.

100 TLAR/MPAR-x1xxxB-xxx

100 TLAR/MPAR-x1xxxE-xxx

100 TLAR/MPAR-x2xxxC-xxx

100 TLAR/MPAR-x2xxxF-xxx

100 TLAR/MPAR-x3xxxE-xxx

100 TLAR/MPAR-x3xxxH-xxx

Rockwell Automation Publication MPAR-IN002B-EN-P - September 2012

Page 6

6 MP-Series and TL-Series Electric Cylinders Replacement Parts

IMPORTANT

Motor

Actuator Cylinder

X

1

Before You Begin

Before you begin, use the Catalog Number Explanation to verify that the replacement parts

match the electric cylinder that you are attempting to repair. Read through the procedure before

beginning repair or replacement.

Replace Inline-mount Electric Cylinder Motor

This procedure applies to Bulletin MPAR-xxxxxx-xxA and TLAR-xxxxxx-xxA electric

cylinders.

Apply Loctite 222 to bolts M4 and Loctite 242 for bolts M5 during assembly steps.

Follow these steps to replace the motor.

1. Disconnect motor and feedback cables.

2. Remove the four bolts that secure the motor to the motor flange.

3. Remove the bolt from the coupling hub on the motor shaft.

4. Remove the coupling hub from the motor shaft.

5. Clean the replacement motor shaft with a soft cloth damped with isopropyl alcohol.

6. Position the coupling hub on the replacement motor’s shaft.

Use the dimension from the table on page 7

7. Torque the coupling bolt to the value listed in the table on page 7

.

.

Rockwell Automation Publication MPAR-IN002B-EN-P - September 2012

Page 7

MP-Series and TL-Series Electric Cylinders Replacement Parts 7

IMPORTANT

(1)

X

Cat. No.

MPAR-x1xxxB-xxA

MPAR-x1xxxE-xxATLAR-A1xxxE-BxA 28.8 (1.13)

MPAR-x2xxxF-xxA 22.3 (0.88) TLAR-A2xxxF-BxA

MPAR-x3xxxE-xxA 35.5 (1.40)

MPAR-x3xxxH-xxA 35.2 (1.38) TLAR-A3xxxH-BxA

(1) Tolerance is ± 0.25 mm (0.010 in.).

1

mm (in.)

18.5 (0.73)

Torq ue

N•m (lb•in)

4.0 (35.4)

8.0 (70.8)

Cat. No.

TLAR-A1xxxB-BxA 25.0 (0.98) 0.6 (5.31)

TLAR-A3xxxE-BxA

(1)

X

1

mm (in.)

29.8 (1.17)

30.5 (1.20) 8.0 (70.8)

Torq ue

N•m (lb•in)

4.0 (35.4)MPAR-x2xxxC-xxA 19.5 (0.77) TLAR-A2xxxC-BxA

8. Align the coupling, the motor, and the actuator cylinder, then push them together.

9. Attach the motor to the motor mount flange by using all four bolts.

10. Torque the bolts as follows.

Cat. No. Bolt Size

MPAR-x1xxxx-xxA

MPAR-x2xxxC-xxATLAR-A1xxx

MPAR-x3xxxE-xxA M6 x 25 9.9 (87.6) TLAR-A2xxxF-BxA

MPAR-x3xxxH-xxA M8 x 25 24.0 (212.4) TLAR-A3xxxE-BxA

M5 x 20 5.9 (52.2)

Torq ue

N•m (lb•in)

Cat. No. Bolt Size

TLAR-A1xxxB-BxA M4 x16 2.9 (25.6)

E-BxA

TLAR-A3xxxH-BxA

M5 x16 5.9 (52.2)MPAR-x2xxxF-xxATLAR-A2xxxC-BxA

M6 x 20 9.9 (87.6)

Torq ue

N•m (lb•in)

Replace Inline-mount Electric Cylinder Coupling or Actuator Cylinder

This procedure applies to Bulletin MPAR-xxxxxx-xxA and TLAR-xxxxxx-xxA electric

cylinders.

Follow these steps to replace the coupling or actuator cylinder.

Apply Loctite 222 to bolts M4 and Loctite 242 for bolts M5 during assembly steps.

1. Disconnect the motor and feedback cables.

Rockwell Automation Publication MPAR-IN002B-EN-P - September 2012

Page 8

8 MP-Series and TL-Series Electric Cylinders Replacement Parts

1

2

3

4

2

6

5

Gear Ring

Coupling Hubs

Actuato r Cylinder

Motor

2. Disassemble the motor, motor flange, and coupling housing, using the following

diagram.

Item Description Item Description

1Motor 4Coupling housing

2 Coupling hub 5 Gear ring

3Motor flange 6Actuator cylinder

Replace Only the Coupling

If you are replacing the coupling only, follow these steps. If replacing the actuator cylinder go to

Replace Only the Actuator Cylinder

on page 10.

1. Remove the coupling hubs from the

motor and actuator.

2. Pull apart the new coupling.

3. Insert the new gear ring in one of the

coupling hubs.

4. Position the coupling hub with

matching diameter on the motor.

5. Position the coupling hubs with matching diameter on the actuator cylinder shaft.

Rockwell Automation Publication MPAR-IN002B-EN-P - September 2012

Page 9

MP-Series and TL-Series Electric Cylinders Replacement Parts 9

Use the dimension from the table.

Motor

X

1

Y

1

Actuator Cylinder

6. Tighten the clamping bolts on both the coupling hubs to the specified torque.

Continue with Assemble the Electric Cylinder

on page 10.

(1)

X

Cat. No.

MPAR-x1xxxB

MPAR-x1xxxETLAR-x1xxxE

MPAR-x2xxxF

MPAR-x3xxxE 35.5 (1.4)

MPAR-x3xxxH

(1) Tolerance is ± 0.25 mm (0.010 in.).

1

mm (in.)

18.5

(0.73)

19.5

(0.77)

22.3

(0.88)

35.2

(1.38)

(1)

Y

1

mm (in.)

19.3

(0.76)

18.3

(0.72)

27.0

(1.06)

Torq ue

N•m (lb•in)

4.0 (35.4)

8.0 (70.8)

Cat. No.

TLAR-x1xxxB

TLAR-x2xxxC

TLAR-x2xxxF

TLAR-x3xxxE

TLAR-x3xxxH

(1)

X

1

mm (in.)

25.0

(0.98)

28.8

(1.13)

29.8

(1.17)

30.5

(1.20)

(1)

Y

1

mm (in.)

16.8

(0.66)

19.3

(0.76)

18.3

(0.72)

27.0

(1.06)

Torq ue

N•m (lb•in)

0.6 (5.31)

4.0 (35.4)MPAR-x2xxxC

8.0 (70.8)

Rockwell Automation Publication MPAR-IN002B-EN-P - September 2012

Page 10

10 MP-Series and TL-Series Electric Cylinders Replacement Parts

Coupling Housing

Actuator Cylinder

Coupling Housing

Actuator Cylinder

Motor Flange

Replace Only the Actuator Cylinder

1. Remove the coupling hub from the actuator cylinder.

2. Remove the bolt from the coupling hub.

3. Position the coupling hub on the shaft of the actuator cylinder.

Use the dimension shown on the table in step 6

on page 9.

4. Tighten the coupling hub bolt to the torque shown on the table in step 6

Continue with Assemble the Electric Cylinder

on page 10.

Assemble the Electric Cylinder

1. Attach the coupling housing by using four bolts.

2. Torque the bolts as shown in this table.

on page 9.

Cat. No.

MPAR-x1xxxx-xxA

MPAR-x2xxxC-xxA TLAR-A1xxxE-BxA

MPAR-x2xxxF-xxA TLAR-A2xxxC-BxA

MPAR-x3xxxE-xxA

MPAR-x3xxxH-xxA TLAR-A3xxxE-BxA

Bolt

Size

M6 x 30 4.2 (37.17)

M8 x 40 7.8 (69)

Torq ue

N•m (lb•in)

Cat. No.

TLAR-A1xxxB-BxA

TLAR-A2xxxF-BxA

TLAR-A3xxxH-BxA

3. Attach the motor flange by using the required number of bolts.

See table in following the step for the bolt quantity.

Rockwell Automation Publication MPAR-IN002B-EN-P - September 2012

Bolt

Size

M6 x 20 4.2 (37.17)

M8 x 40 7.8 (69)

Torq ue

N•m (lb•in)

Page 11

MP-Series and TL-Series Electric Cylinders Replacement Parts 11

Align Coupling Hubs

4. Torque the bolts as shown in this table.

Cat. No.

MPAR-x1xxxx-xxA

MPAR-x2xxxC-xxA TLAR-A1xxxE-BxA

MPAR-x2xxxF-xxA TLAR-A2xxxC-BxA

MPAR-x3xxxE-xxA

MPAR-x3xxxH-xxA 3 TLAR-A3xxxE-BxA

Bolt

Quantity

4

Torq ue

Bolt

N•m

Size

(lb•in)

2.9

M4 x 12

(25.6)

M6 x 20 9.9 (87.6)

Cat. No.

TLAR-A1xxxB-BxA

TLAR-A2xxxF-BxA

TLAR-A3xxxH-BxA

Bolt

Quantity

4

Bolt

Size

M3 x 12

M4 x 16

M6 x 16

5. Align the coupling, the motor, and the actuator cylinder and push them together.

Torq ue

N•m

(lb•in)

1.2

(10.6)

2.9

(25.6)

9.9

(87.6)

6. Attach the motor to the motor mount flange by using all four bolts.

7. Tor qu e b o lt s as fo ll ow s.

Cat. No.

MPAR-x1xxxx-xxA

MPAR-x2xxxC-xxATLAR-A1xxxE-BxA

MPAR-x3xxxE-xxA M6 x 25 9.9 (87.6) TLAR-A2xxxF-BxA

MPAR-x3xxxH-xxA M8 x 25 24.0 (212.42) TLAR-A3xxxE-B

Bolt

Size

M5 x 20 5.9 (52.2)

Torq ue

N•m (lb•in)

Cat. No. Bolt Size

TLAR-A1xxxB-BxA M4 x 16 2.9 (25.6)

xA

TLAR-A3xxxH-BxA

M5 x 16 5.9 (52.2)MPAR-x2xxxF-xxATLAR-A2xxxC-BxA

M6 x 20 9.9 (87.6)

Rockwell Automation Publication MPAR-IN002B-EN-P - September 2012

Torq ue

N•m (lb•in)

Page 12

12 MP-Series and TL-Series Electric Cylinders Replacement Parts

IMPORTANT

CAUTION

Hot surface.

Do not touch.

Belt Housing

Replace a Parallel-mount Electric Cylinder Motor or Belt

This procedure is for Bulletin MPAR-xxxxxx-xxB/D/E electric cylinders. These steps can be

used to change the motor or the actuator cylinder orientation.

Follow these steps to replace the belt, motor, or actuator cylinder.

Apply Loctite 222 to bolts M4 and Loctite 242 for bolts M5 during assembly steps.

1. Disconnect the motor and feedback cables.

2. If the motor has brake, release the brake on motor so that the rod moves freely.

3. Position the rod to the center of travel.

4. Remove the cover from belt housing.

ATTENTION: Exposed moving parts can cause severe injury. Do not the operate electric c ylinder

without the cover in place. Follow the lock-out procedures before servicing the machine.

Rockwell Automation Publication MPAR-IN002B-EN-P - September 2012

Page 13

MP-Series and TL-Series Electric Cylinders Replacement Parts 13

Motor Mount Bolts (4X)

Spacer Ring

Belt

Pulleys

5. Loosen, but do not remove the four blots that hold the motor to the belt housing.

This relieves the tension on the belt.

6. Remove the pulleys and the belt.

Use a wrench to hold the pulley in place while turning the collar clockwise with a hex

driver.

The pulley has a left hand thread.

7. If you are changing the motor or actuator cylinder orientation, follow steps 7a through

7e; if not, go to step 8

.

Rockwell Automation Publication MPAR-IN002B-EN-P - September 2012

Page 14

14 MP-Series and TL-Series Electric Cylinders Replacement Parts

IMPORTANT

a. Remove the bolts from the motor or actuator cylinder.

Be sure to collect all the square nuts if you are removing the motor.

b. Reposition the motor and or actuator cylinder.

If you are mounting the motor with the connectors between the actuator cylinder

and the motor, rotate the motor connec tors so they exit 180° away from the shaft.

c. Attach the actuator cylinder with four bolts.

d. Torque the actuator cylinder bolts to values shown in this table.

Cat. No.

MPAR-x1xxxB-xxB/D/E

MPAR-x1xxxE-xxB/D/E

MPAR-x2xxxC-xxB/D/E

MPAR-x2xxxF-xxB/D/E

MPAR-x3xxxE-xxB/D/E

MPAR-x3xxxH-xxB/D/E

Bolt

Size

M6 x 18 4.2 (37.17

M8 x 20 7.8 (69)

Torq ue

N•m (lb•in)

e. Attach the motor by using four bolts and four square nuts.

Do not tighten bolts at this time.

8. Place the spacer rings, belt, and pulleys on the shafts.

Bottom out pulleys to make them parallel.

Rockwell Automation Publication MPAR-IN002B-EN-P - September 2012

Page 15

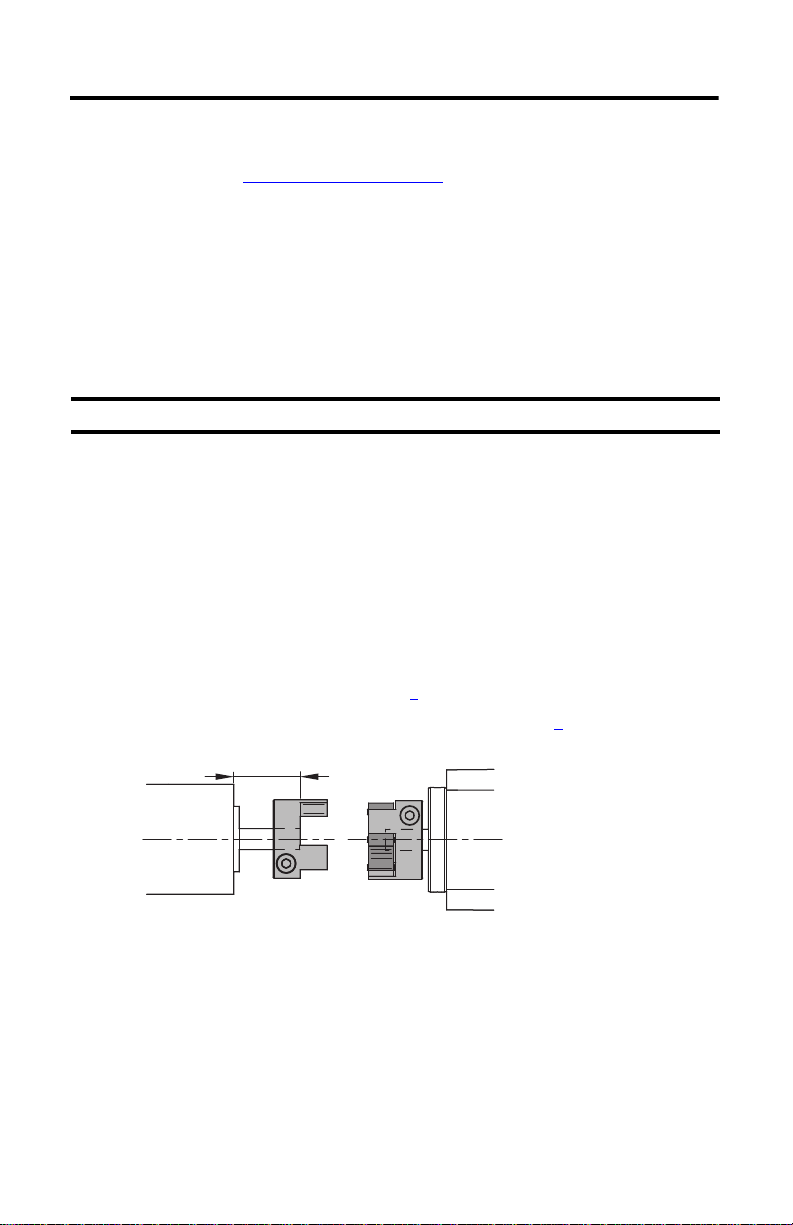

MP-Series and TL-Series Electric Cylinders Replacement Parts 15

IMPORTANT

X

Y

XY

Fv

Fv

Untensioned: X <Y

Tensioned: X = Y

9. Hold the pulleys with a wrench and tighten the collar by turning the hex key

counter-clockwise to the torque shown in this table.

Cat. No.

MPAR-x1xxxB-xxB/D/E

MPAR-x2xxxC-xxB/D/E

MPAR-x2xxxF-xxB/D/E

MPAR-x3xxxH-xxB/D/E

Torq ue

N•m (lb•ft)

16.95 (13)MPAR-x1xxxE-xxB/D/E

67.79 (50) MPAR-x3xxxE-xxB/D/E

10. Apply pressure to the base of the motor to tension the belt.

Observe the distance a X and Y and determine this transition precisely.

This table shows the recommend belt tension values.

Cat. No.

MPAR-x1xxxB-xxB/D/E 30 (6.75)

MPAR-x1xxxE-xxB/D/E 61 (13.73)

MPAR-x2xxxC-xxB/D/E 67 (15.10)

MPAR-x2xxxF-xxB/D/E 90 (20.23)

MPAR-x3xxxE-xxB/D/E 162 (36.4)

MPAR-x3xxxH-xxB/D/E 224 (50.4)

Recommend Belt Tension

N (lb)

A low pretension force is better than a high pretension force.

Excessive pretension on the belt results in:

• impermissible radial loads causing shaft to break

• increased wear in the axis and motor gearings

• reduction of the service life of the belt

Rockwell Automation Publication MPAR-IN002B-EN-P - September 2012

Page 16

16 MP-Series and TL-Series Electric Cylinders Replacement Parts

11. While a maintaining on tension on the belt, torque the motor bolts to value specified in

this table.

Cat. No. Bolt Size

MPAR-x1xxxB-xxB/D/E

MPAR-x1xxxE-xxB/D/E

MPAR-x2xxxC-xxB/D/E

MPAR-x2xxxF-xxB/D/E M5 x 20

MPAR-x3xxxE-xxB/D/E M6 x 18 9.8 (87.6)

MPAR-x3xxxH-xxB/D/E M8 x 20 24.0 (212.0)

M5 x 16

Torq ue

N•m (lb•in)

5.9 (52.2)

12. Secure the cover to the belt housing with five bolts.

Rockwell Automation Publication MPAR-IN002B-EN-P - September 2012

Page 17

MP-Series and TL-Series Electric Cylinders Replacement Parts 17

Additional Resources

These documents contain additional information concerning related products from Rockwell

Automation.

Resource Description

MP-Series Electric Cylinders Installation Instructions,

publication MPAR-IN001

TL-Series Electric Cylinders Installation Instructions,

publication TLAR-IN001

MP-Series Brushless Servo Motor Installation Instruc tions,

publication MP-IN001

MP-Series Brushless Servo Motor Installation Instruc tions,

publication MP-IN006

Product Certifications website http://www.ab. com Provides declarations of conformity, certificates, and other

You can view or download publications at http://www.rockwellautomation.com/literature. To

order paper copies of technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Information on installing MP-Series electric cylinders

Information on installing TL-Series electric cylinders

Information on installing, medium frame (100…165 mm)

MP-Series low-inertia motors

Information on installing small frame (<75 mm) MP-Series

low-inertia motors

certification details

Rockwell Automation Publication MPAR-IN002B-EN-P - September 2012

Page 18

18 MP-Series and TL-Series Electric Cylinders Replacement Parts

Notes:

Rockwell Automation Publication MPAR-IN002B-EN-P - September 2012

Page 19

Notes:

MP-Series and TL-Series Electric Cylinders Replacement Parts 19

Rockwell Automation Publication MPAR-IN002B-EN-P - September 2012

Page 20

Rockwell Automation Support

Rockwell Automation provides tec hnical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

links to software service packs, and a MySupport feature that you can customize to make the best use of these tools. You c an also visit

our Knowledgebase at http://www.rockwellautomation.com/knowledgebase

forums, software updates, and to sign up for product notification updates.

For an additional level of technical phone support for installation, configuration and troubleshooting, we offer TechConnect

support programs. For more information, contact your local distributor or Rockwell Automation representative, or visit

http://www.rockwellautomation.com/support/

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review the information that's contained in this manual.

You can also contact a special Customer Support number for initial help in getting your product up and running.

United States or Canada 1.440.6 46.3434

Outside United States or

Canada

Use the Wor ldwi de Loc ator

http://www.rockwellautomation.com/support/americas/phone_en.html

Rockwell Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all o f its products to ensure that they are fully operational when shipped from the manufacturing facility.

However, if your produc t is not functioning and needs to be returned, follow these procedures.

, you can find technical manuals, technical and application notes, sample code and

for FAQs, technical information, support chat and

SM

.

at

, or contact your local

United States

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

Contact your distributor. You must provide a Customer Support case number (call the phone number

above to obtain one) to your distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete this form, publication RA-DU002

Allen-Bradley, MP-Series, Rockwell Software, Rockwell Automation, and TL-Series are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to R ockwell Automation are property of their respective companies.

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Publication MPAR-IN002B-EN-P - September 2012 814069

Supersedes Publication MPAR-IN002A-EN-P - April 2010 Copyright © 2012 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

, available at http://www.rockwellautomation.com/literature/.

Loading...

Loading...