Page 1

Triguard SC300E

THR

Hot Repair Adaptor

(THR)

Issue 6

INTRODUCTION

PURPOSE

The Hot Repair Adaptor kit enables the backplane field connectors of two adjacent I/O modules

to be bridged so that both are connected to a single set of field connections in a Dual Hot

Re

pair configuration. The kit comprises two Hot Repair Adaptor cards and the appropriate

hardware

shown in Figure 3-1.

This document is intended to provide a general understa

adaptor sufficient to enable basic maintenance operations to be effected in the field.

fittings. The assembly and fitting of one adaptor card to the chassis backplane is

nding of the function of the hot repair

October 2005

ASSOCIATED DOCUMENTATION

008-5097

Reference No

SPECIFICATION

Model

Connectors A and B

Current rating (per contact)

Insulation test voltage

Voltage rating

Overall size (mm)

Overall size (inches)

Weight

Title

Chassis User Manual

34 pin DIN41612. Connector A pins press

fitted.

1.6A max at 60°C

1.5kVdc

132Vac/dc maximum

102H x 51W x 28D

4.0H x 2.0W x 1.1D

0.65kg

THR

008-5106

Page 2

2THR

October

2005–

Issue 6

Triguard

SC300E

ENVIRONMENTAL SPECIFICATIONS

The maximum ambient temperature measured at the hottest point within the Triguard system

shall

not be greater than 60 degrees centigrade.

Temperature operating:

Temperature

Humidity

EMC/RFI

Vibration/Shock

Certification:

General Certification: Ref. SC300E Product Guide (ref 008-5209)

storage:

Immunity

+5°C to +60°C

-

25°C to +70°C

5% to 95

Tested and certified to IEC 1131-Part 2 1994

Tested and certified to IEC 1131-Part 2 1994

% non-condensing at ambient <40°C

TRANSPORT AND HANDLING

The hot repair adaptor must be transported and stored in its original packing material which

should be retained for this purpose.

Page 3

THROctober

2005–

Issue 6

3

Triguard

SC300E THR Hot Repair Adaptor

TECHNICAL DESCRIPTIO

N

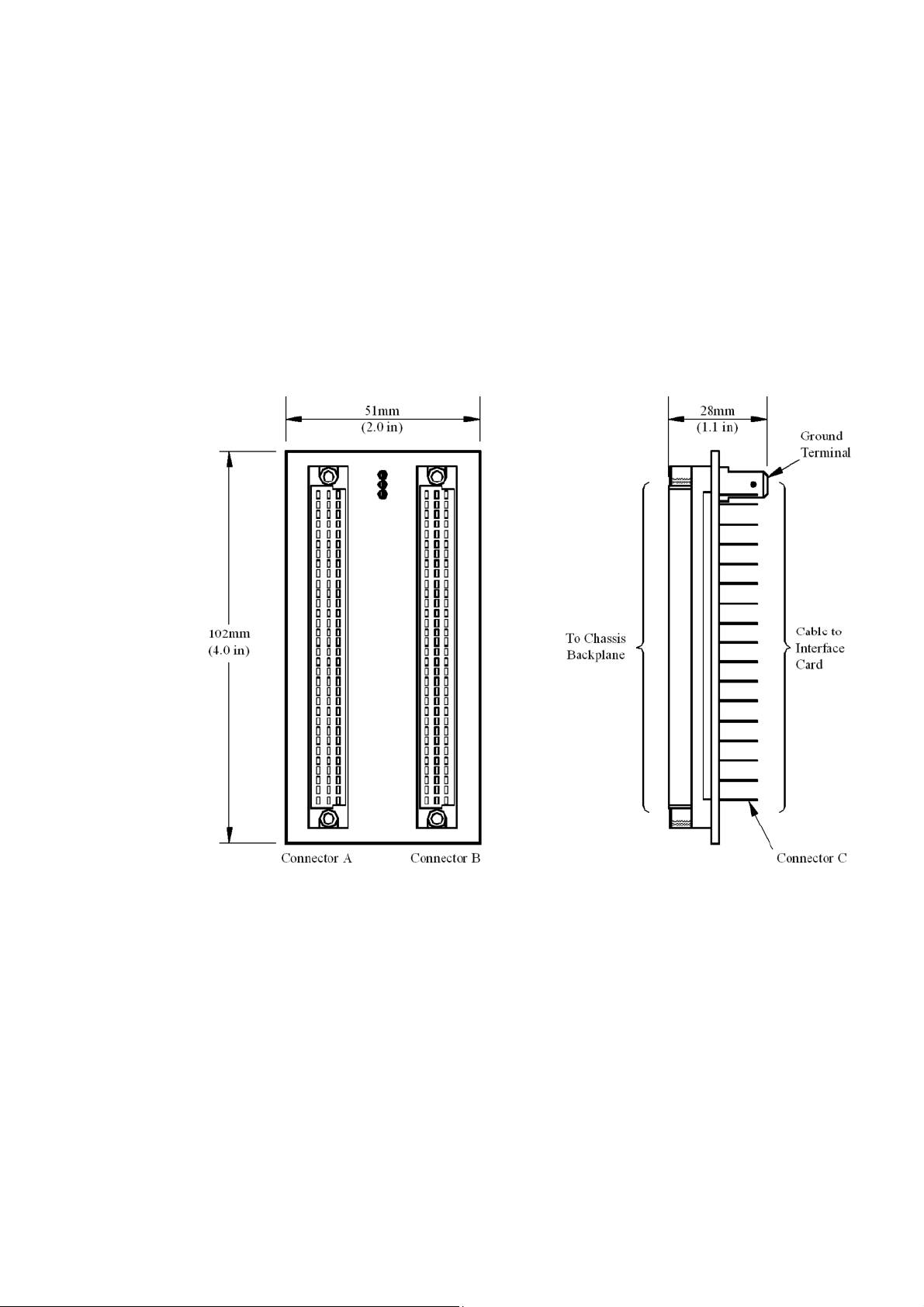

PHYSICAL

The Hot Repair Adaptor kit comprises two adaptor cards and hardware fittings

The tracks in each adaptor card connect corresponding pins of the two sockets that mate with

the backplane connectors. The rear of Connector ‘A’ is unused, the pins are cut short and

protected by the shell and cover (items 7 and 6 respectively). The pins of the left hand socket

protrude through a shroud which enables the connection of the field DIN connector.

Figure 2-1. THR Front and side views

Page 4

4THR

October

2005–

Issue 6

Triguard

SC300E

SERVICING

SCOPE

No servicing is necessary, repair is by replacement of the faulty adaptor.

ASSEMBLY AND FITTING

The Hot Repair Adaptor kit comprises two adaptor cards and hardware fittings.

Item No

(refer to Figure 3-1)

1 099-1245

2 600-1079

3 525-7625

4 507-0175

5 525-7619

Table 3-1. Contents of Hot Repair Adaptor kit

Part No.

Description

Hot repair adaptor card

M3 x 3mm spacer

M2.5 x 25mm screw

M2.5 x spring washer

M2.5 x 19mm screw

No. off

2

4

4

8

4

6 442-1016

7 442-1015

Incorrect fitting of an adaptor may result in irreparable damage to the chassis backplane

Prior to the connection of any system cables, fit the Hot Repair Adaptors in the following

manner.

Refer to Figure 3-1.

1.

2.

3.

4.

Check the contents of the Hot Repair Adaptor kit against the list in Table 3-1.

Identify the two adjacent slots to be configured for hot repair.

Remove the four black shrouds from the slot field outlets. Retain two of the shrouds.

Check that none of the backplane connector pins are bent or misaligned.

Cover

Shell

CAUTION

2

2

5.

Carefully position one of the adaptor cards the right way up over two of the backplan

connectors by aligning the top screw holes and gently entering the two top pins into

each connector.

e

Page 5

THROctober

2005–

Issue 6

5

6.

7.

8.

9.

Triguard

Attempt to fully engage the adaptor card but if excessive resistance is felt remove the

card and check for bent pins or any other obstructions.

U

sing items 2, 3 and 4 fit one of the shrouds to the card over the pins of the left hand

connector;

Note that the two spacers (item 2) fit between the shroud and the card. Do not over

tighten the screws.

Using items 4 and 5 fit the shell (item 7) to the card over the short pins of the right

hand connector. Do not over tighten the screws.

Insert the cover (item 6) into the shell (item 7).

ensure that the shroud is correctly oriented (keys on the left, Figure 3-1. ).

SC300E THR Hot Repair Adaptor

10.

Repeat steps e) to i) to fit the other adaptor card to the remaining two field connectors.

Page 6

6THR

October

2005–

Issue 6

Triguard

SC300E

Figure 3-1. THR Exploded view

Page 7

THROctober

2005–

Issue 6

7

Triguard

SC300E THR Hot Repair Adaptor

SERVICE SUPPORT

SPARE PARTS

Spare parts and technical advice can be obtained from your local area offices

.

Loading...

Loading...