Page 1

TD200 AC Drive

Installation and Operation Manual

Version 1.0

0.3 to 20V RMS, 3-Phase Output

63 A (Maximum Continuous Motor Amps)

Instruction Manual

D2-3462

Page 2

The information in this manual is subject to change without notice.

Throughout this manual, the following notes are used to alert you to safety considerations:

ATTENTION:Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss.

!

Important: Identifies information that is critical for successful application and understanding of the product.

ATTENTION:Only personnel familiar with the drive and associated machinery should plan or

implement the installation, start-up and subsequent maintenance of the system. Failure to comply

!

may result in bodily injury and/or damage to the equipment.

Reliance is a trademark of Rockwell Automation.

©2000 Rockwell International Corporation

Page 3

Chapter 1 Introduction to the Drive

1.1 Drive Description .............................................................................................1-1

1.2 Identifying the Drive by Model Number ...........................................................1-1

1.3 Getting Assistance from Reliance Electric.......................................................1-1

Chapter 2 Setting the Drive Jumpers

2.1 Removing the Drive Cover ..............................................................................2-1

2.2 Setting the Speed Reference Jumper (J1) ......................................................2-2

2.3 Setting the Maximum Speed Jumpers (J2 through J8) ...................................2-2

2.4 Setting the V/Hz Curve Jumpers (J9 through J12) .......................................... 2-3

2.5 Setting the Current Rating Jumpers (J13 through J16)...................................2-4

2.6 Setting the External Speed Control Jumpers (J17 through J19) ..................... 2-5

2.7 Reattaching the Cover..................................................................................... 2.6

Chapter 3 Mounting the Drive

3.1 Planning the Installation ..................................................................................3-1

3.2 Mounting the Drive .......................................................................................... 3-1

Chapter 4 Wiring the Drive

4.1 Wiring the External Control Inputs and Outputs .............................................. 4-2

4.2 Wiring the Output Power to the Motor .............................................................4-2

4.3 Wiring Input Power to the Drive.......................................................................4-3

CONTENTS

Chapter 5 Checking the Installation

5.1 Checking the Installation with the Power Off...................................................5-1

5.2 Checking the Direction of Motor Rotation........................................................ 5-1

5.3 Testing the Drive under Load ..........................................................................5-2

Chapter 6 Operating the Drive ................................................................................................ 6-1

Chapter 7 Diagnostics and Troubleshooting

7.1 Drive Faults and Corrective Actions ................................................................7-1

Appendix A Technical Specifications........................................................................................A-1

Contents

I

Page 4

II

TD200 AC Drive Installation and Operation

Page 5

LIst of Figures

Figure 1.1 – Identifying the Drive Model Number .....................................................1-1

Figure 2.1 – Location of Drive Jumpers....................................................................2-1

Figure 2.2 – V/Hz Curve ........................................................................................... 2-3

Figure 3.1 – Drive Mounting Dimensions.................................................................. 3-1

Figure 4.1 – Drive External Wiring Diagram .............................................................4-1

Contents

III

Page 6

IV

TD200 AC Drive Installation and Operation

Page 7

List of Tables

Table 2.1 – Maximum Speed Jumper Settings.........................................................2-2

Table 2.2 – V/Hz Curve Jumper Settings ................................................................. 2-3

Table 2.3 – Current Rating Jumper Settings ............................................................ 2-4

Table 2.4 – External Speed Control Jumper Settings...............................................2-5

Table 2.5 – Output Frequencies for Input Voltage Reference

or External Resistance..........................................................................2-5

Table 4.1 – External Control Inputs and Ouputs.......................................................4-2

Table 4.2 – Output Power Connections....................................................................4-2

Table 4.3 – Output Power Connections....................................................................4-3

Table 6.1 – Operating the Drive................................................................................6-1

Table 7.1 – Drive Status Indicators...........................................................................7-1

Contents

V

Page 8

VI

TD200 AC Drive Installation and Operation

Page 9

CHAPTER 1

Introduction to the Drive

This chapter describes the drive and how to identify it using the model number matrix.

It also provides an illustration of the drive showing the locations of major components.

1.1 Drive Description

The drive is powered by a nominal +28 VDC input, and provides a three-phase AC

variable frequency and voltage output to control a 63 amp AC motor (maximum

continuous amps).

1.2 Identifying the Drive by Model Number

Each 2 HP AC drive can be identified by its model number. See figure 1.1. This

number appears on the shipping label and on the drive’s nameplate. The drive’s model

number includes the Power Module and the regulator version.

1 TD 20 002

Catalog Number

TD = Universal

Input Voltage

20 = +28 VDC

Horsepower Rating

002 = 2 HP

Figure 1.1 – Identifying the Drive Model Number

1.3 Getting Assistance from Reliance Electric

If you have any questions or problems with the products described in this instruction

manual, contact your local Reliance Electric sales office. For technical assistance, call

1-800-726-8112.

Introduction to the Drive

1-1

Page 10

1-2

TD200 AC Drive Installation and Operation

Page 11

Setting the Drive Jumpers

Before the drive can be mounted and wired, you must set the drive jumpers to match

your drive application.

2.1 Removing the Drive Cover

ATTENTION:This drive contains ESD (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are required

!

You must remove the drive cover to provide access to the drive jumpers.

Step 1. Place the drive with the six cover screws facing up.

Step 2. Remove the six M4 machine screws that hold the cover in place.

Step 3. Remove the cover.

when installing, testing, servicing or repairing this assembly . Component

damage may result if ESD control procedures are not followed. Failure

to observe this precaution could result in damage to the equipment.

CHAPTER 2

Important: Note that the gasket inside the cover is glued to the inside of the cover . Do

not disturb the gasket.

4

5

0

1

3

2

1

2

J

J

0

1

5

3

J

6

4

J

J

S1

J7J

1

1

1

8

9

J

J

1

J

J

J

J

S2

6

8

7

1

1

1

J

J

J

9

1

1

1

J

J

J

0

1

S3

Setting the Drive Jumpers

Figure 2.1 – Location of Drive Jumpers

2-1

Page 12

2.2 Setting the Speed Reference Jumper (J1)

Jumper J1 is used to select between the external speed reference or the internal

speed jumpers. When this jumper is set (J1 = 1), the motor speed can be externally

adjusted from the POT1 and POT2 terminals (see section 2.6). When J1 is reset

(J1 = 0), the internal speed jumpers (J2 through J8 ) are used to set the maximum

speed. In either configuration, the "HI/LO" external input is active (see section 4.1).

Note that if the drive input power drops below a nominal 25 VDC, the speed will drop

to 3/4 of HI speed.

2.3 Setting the Maximum Speed Jumpers (J2 through J8)

Jumpers J2 through J8 set the maximum speed when jumper J1 (Speed Reference

Jumper) is in the "Speed Jumpers" position (J1 = 1). The range of values for output

frequency is 0 to 127 Hz in 1 Hz steps (see table 2.1). The speed selected by totalling

the values of these jumper settings is the nominal speed. The actual output frequency

will be within -0.5 to +1.3 Hz tolerance. Actual motor speed will depend on load and

associated slip.

Table 2.1 – Maximum Speed Jumper Settings

Jumper Position Maximum Speed Level

J2 1 Adds 0 Hz to speed reference

0 Adds 64 Hz to speed reference

J3 1 Adds 0 Hz to speed reference

0 Adds 32Hz to speed reference

J4 1 Adds 0 Hz to speed reference

0 Adds 16 Hz to speed reference

J5 1 Adds 0 Hz to speed reference

0 Adds 8 Hz to speed reference

J6 1 Adds 0 Hz to speed reference

0 Adds 4 Hz to speed reference

J7 1 Adds 0 Hz to speed reference

0 Adds 2 Hz to speed reference

J8 1 Adds 0 Hz to speed reference

0 Adds 1 Hz to speed reference

2-2

TD200 AC Drive Installation and Operation

Page 13

2.4 Setting the V/Hz Curve Jumpers (J9 through J12)

Jumpers J9 through J12 set the frequency break point for the V/Hz Curve . The

breakpoint is the frequency at which the output voltage reaches the maximum voltage.

Below this point the output voltage and frequency increase together. This feature is

required to allow the drive to work with motors rated at various frequencies. Figure 2.2

shows a general V/Hz curve.

V

V

max

Boost

F (Hz)

Figure 2.2 – V/Hz Curve

Table 2.2 – V/Hz Curve Jumper Settings

Jumpers

Frequency at Maximum VoltsJ9 J10 J11 J12

1 1 1 1 42 Hz

0111 46 Hz

1 0 1 1 50 Hz

0011 53 Hz

1 1 0 1 56 Hz

0101 60 Hz

1 0 0 1 63 Hz

0001 66 Hz

1 1 1 0 70 Hz

0110 74 Hz

1 0 1 0 77 Hz

0010 81 Hz

1 1 0 0 85 Hz

0100 88 Hz

1 0 0 0 92 Hz

0000 95 Hz

Setting the Drive Jumpers

2-3

Page 14

2.5 Setting the Current Rating Jumpers (J13 through

J16)

Jumpers J13 through J16 set the maximum continuous current rating and the

associated current limit level of the drive’s output current. The four jumpers are binary

weighted and scaled so that the current limit level is adjustable from 30 to 70 amps

RMS in approximate 3 amp RMS steps. Table 2.3.6 shows the nominal current limit

level for each possible jumper setting.

Table 2.3 – Current Rating Jumper Settings

Jumpers

Rated

Continuous

Current

Current Limit

Threshold1

Current Limit

(A RMS)

(1 minute

Instantaneous

Overcurrent Trip

J13 J14 J15 J16 (A RMS) (A RMS) allowable) (A Peak)

0 0 0 0 30 >30 39 68

0001 33 >33 42 75

0 0 1 0 35 >35 46 80

0011 38 >38 49 86

0 1 0 0 41 >41 53 93

0101 43 >43 56 98

0 1 1 0 46 >46 59 105

0 1 1 1 49 >49 63 112

1 0 0 0 51 >51 66 116

1 0 0 1 54 >54 70 123

1 0 1 0 57 >57 73 130

1 0 1 1 59 >59 76 134

1 1 0 0 62 >62 80 141

1101

1 1 1 0

1111

1

Eventual drive shutdown if sustained

2

The user must verify that the application does not e xceed the maximum continous rating of 63 A RMS. Exceeding this rating could cause

overtemperature protection to shut down the drive. For maximum system protection, it is recommended that the current limit jumpers be

set to a value not greater than the application demands.

63

63

63

2

2

2

>65 83 148

>67 87 153

>70 90 160

2-4

TD200 AC Drive Installation and Operation

Page 15

2.6 Setting the Ex ternal Speed Contr o l Jumpers (J17

through J19)

The motor speed can be manually adjusted between minimum speed and full speed

with 0 to 4.5 volt voltage reference, or a 1000 ohm potentiometer. To make the

external speed control inputs (POT1, POT2) active, jumper J1 (Speed Reference

Jumper) must be in the Speed Ref position (J1 = 1), as described in section 2.2.

Jumpers J17 through J19 configure the external speed control function for either an

external 1 Kohm pot control or a 0 to 4.5 VDC voltage control (see table 2.4). Zero

ohms and zero volts are minimum speed. For the voltage control, the positive input is

into the POT1 terminal, the return being POT2. In either configuration, the "HI/LO"

external input is active.

Table 2.4 – External Speed Control Jumper Settings

Jumpers

External Speed Control Min/Max SpeedJ1 J17 J18 J19

1 0 0 0 External 1 Kohm pot 0 ohm / 1 kohm

1 1 1 1 External 0 to 4.5 V control 0 VDC / 4.5 VDC

Table 2.5 shows what the output frequency is for a given input voltage reference or

external resistance. When driving the input with an external voltage source, the source

sees a 200 Kohm input impedance. When driving an external potentiometer, the drive

input circuit sources 5 mA. When configured for external speed control (pot), an open

circuit condition will cause the drive to default to 128 Hz. For the pot control selection,

a resistor should be installed across the input if 128 Hz is beyond a safe operational

speed. For voltage source control, an open circuit will cause the drive to default to

2Hz.

Table 2.5 – Output Frequencies for Input Voltage Reference or External Resistance

Volt Reference (V)

J17 J18 J19 = 1 1 1

02 0 3

0.45 15 50 16

0.90 28 100 26

1.35 41 250 54

1.80 54 300 62

2.25 67 393 75

2.70 80 500 88

3.15 93 750 113

3.60 106 825 119

4.05 118 910 125

4.50 128 1000 128

Output

Frequency (Hz)

External Resistance (

J17 J18 J19 = 0 0 0

Ω)

Output

Frequency (Hz)

Setting the Drive Jumpers

2-5

Page 16

2.7 Reattaching the Cover

Follow these steps to reattach the drive cover.

Step 1. Position the cover on the back of the drive.

Step 2. Reinstall the six M4 machine screws finger tight, beginning with the two

middle screws, then the four corner screws.

Step 3. Beginning with the two middle screws, torque all of the screws to 4 to 6 lb-in (

.45 to .68 Nm). Do not overtighten.

2-6

TD200 AC Drive Installation and Operation

Page 17

3.1 Planning the Installation

The drive should be installed in a location where high airflow and low ambient

temperatures are present. The jumpers must be configured before installation,

because their access is from the bottom of the unit.

3.2 M ounting the Drive

Use the following steps to mount the drive.

Step 1. Prepare the mounting surface based on the dimensions shown in figure 3.1.

Step 2. Position the drive in the enclosure. Choose the mounting surface (horizontal

or vertical) to provide maximum airflow through the fin area.

Step 3. Attach the drive to the mounting surface using four fasteners.

6.50

3.00

CHAPTER 3

Mounting the Drive

3.75

0.25

Mounting the Drive

.33

4 Places

Dimensions in inches

Front View

12.95

12.25

Figure 3.1 – Drive Mounting Dimensions

4.12

Side View

0.25

3-1

Page 18

3-2

TD200 AC Drive Installation and Operation

Page 19

CHAPTER 4

Wiring the Drive

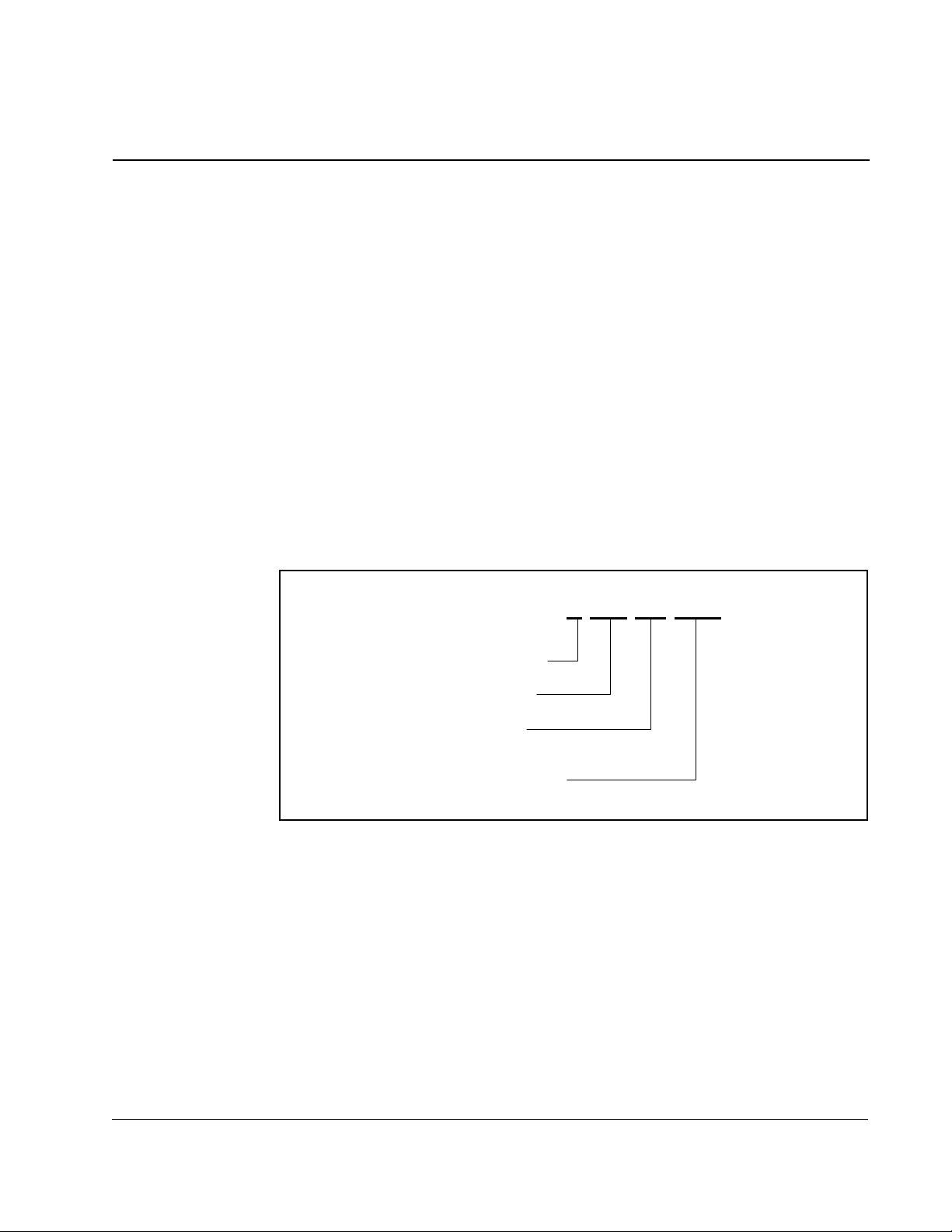

Figure 4.1 shows the wiring scheme for the drive’s e xternal control inputs and outputs.

Sections 4.1 through 4.3 provide information for wiring the drive circuits.

Lamp or Relay

(500 mA max.)

FAULT

+

–

Open = OFF

Closed = ON

Open = HI

Closed = LO

2

3

1K Potentiometer or

External Voltage Source

2

28 Volt Batte ry

ON/OFF

HI/LO

POT1 (+)*

1

POT2 (-)*

1

+28 V

GND

U

V

W

Drive

Drive

Wiring the Drive

T1 T2 T3

20 VAC Motor

1

When using 0 to 4.5 VDC external voltage source, POT1 is +.

2

Fuse or circuit breaker, value dependent on application.

3

Contact your local Reliance Electric sales office for motor availability.

Figure 4.1 – Drive External Wiring Diagram

3

4-1

Page 20

4.1 Wiring the External Control Inputs and Outputs

Table 4.1 describes the external control circuits shown in figure 4.1. All control circuits

should be wired as follows:

• use 12 to 18 AWG wire terminated with ring lugs sized for a #8 stud.

• torque all connections between 11 to 13 in-lb.

Table 4.1 – External Control Inputs and Ouputs

Terminal

Label Function

ON/OFF ON = Closed to run motor

OFF = Open to stop motor

There is an approximate delay of 1.0 second at startup.

Peak input current = 0.2 A, approximate 0.02 A average continuous

HI/LO LO (speed) = Closed for 3/4 of maximum speed.

HI (speed) = Open for maximum speed.

Nominal input current = 50 mA

POT1

POT2

Analog speed reference input. POT1 is the signal and POT2 is the

return.

The input signal range is 0 to 4.5 VDC.

May also be used with a 1000 ohm pot between POT1 and POT2 if

appropriate jumpers are selected.

F AULT Output fault indication. The fault output will sink up to 500 mA when

operating normally, and sink 0 A when the drive is faulted or not

activated.

4.2 Wiring the Output Power to the Motor

Table 4.2 describes the drive output power connections shown in figure 4.1. All output

power connections should be wired as follows:

• Minimum 6 AWG wire terminated with ring lugs sized for a 3/8” stud (drive end).

• torque all connections between 90 to 100 in-lb.

Table 4.2 – Output Power Connections

Terminal Label Function

U Connect to motor terminal “U”

V Connect to motor terminal “V”

W Connect to motor terminal “W”

4-2

TD200 AC Drive Installation and Operation

Page 21

4.3 Wiring Input Power to the Drive

ATTENTION:The input power of this drive is not internally fused. The

user is responsible for external fusing. Failure to observe this precaution

!

Table 4.3 describes the input power connections to the drive as shown in figure 4.1. All

input power connections should be wired as follows:

• Minimum 6 AWG wire terminated with ring lugs sized for a 3/8” stud (drive end).

• torque all connections between 90 to 100 in-lb.

could result in damage to, or destruction of, the equipment.

ATTENTION:Applying reverse polarity at the drive input terminals will

allow unlimited input current to flow. A user-supplied fast-acting fuse or

circuit breaker should be installed in the drive input circuit to prevent

damage to the drive. Failure to observe this precaution could result in

damage to, or destruction of, the equipment.

Table 4.3 – Output Power Connections

Terminal Label Function

+28 V Connect to power source +28 VDC terminal

GND Connect to power source ground terminal

Wiring the Drive

4-3

Page 22

4-4

TD200 AC Drive Installation and Operation

Page 23

CHAPTER 5

Checking the Installation

ATTENTION:Only qualified electrical personnel, familiar with the

construction and operation of this equipment and the hazards involved,

!

To ensure safe operation, check the installation with the power off before operating the

unit. When power is first applied, the direction of rotation, operator speed reference,

and operation under load should be tested.

5.1 Checking the Installation with the Power Off

Perform the following installation checks of the unit with the power off:

Step 1. Disconnect DC input power to the unit.

Step 2. Check that the wiring to the power terminals and to the external control

should install, adjust, operate, and/or service this equipment. Read and

understand this manual in its entirety before proceeding. Failure to

observe this precaution could result in severe bodily injury or loss of life.

inputs and outputs are correct (refer to figure 4.1 and sections 4.1 through

4.3).

Step 3. Check that incoming DC power is correctly rated.

Step 4. Where applicable, check that a properly sized ground wire is installed and

that a suitable earth ground is used. Verify that all ground leads are run

unbroken.

5.2 Checking the Direction of Motor Rotation

ATTENTION:The following procedures require rotating parts and/or

electrical circuits to be exposed. Stay clear if the motor must be running.

!

Important: If any problems occur while the drive is running, refer to chapter 7,

After verifying that the drive installation is correct, check the direction of rotation of the

motor using the following procedure:

Step 1. Disconnect DC input power to the unit.

Step 2. Uncouple the driven equipment from the motor, if possible.

Step 3. Connect input power to the unit.

Step 4. Start the drive.

Disconnect, lockout, and tag the power source if contact must be made.

Failure to observe this precaution could result in severe bodily injury or

loss of lif e.

Diagnostics and Troubleshooting.

Checking the Installation

5-1

Page 24

Step 5. Visually check the direction of motor shaft rotation. If shaft rotation is correct,

proceed to the next section, Testing the Drive under Load. If shaft rotation is

incorrect, continue to step 7.

Step 6. Disconnect DC input power to the unit.

Step 7. Reverse any two of the three motor power leads (U, V, and W).

5.3 Testing the Drive under Load

Use the following procedure to test the drive under load:

Step 1. Turn off, lockout, and tag power to the drive.

Step 2. Couple the driven equipment to the motor.

Step 3. Turn power on and start the drive.

Step 4. Run the drive across the required speed range under load.

Step 5. If the drive does not operate the motor properly, refer to chapter 7,

Diagnostics and Troubleshooting.

5-2

TD200 AC Drive Installation and Operation

Page 25

CHAPTER 6

Operating the Drive

The following table describes how to start and stop the drive, and how to change the

motor speed. This table assumes that the drive is wired as shown in figure 4.1.

Table 6.1 – Operating the Drive

Function Process

Start the drive Apply 28 VDC to the ON/OFF terminal.

Stop the drive Remove 28 VDC to the ON/OFF terminal.

Adjust motor speed Motor speed can be controlled by:

• jumper settings (see section 2.3).

• speed potentiometer (see section 2.6).

• external voltage control (see section 2.6).

• application of 28 VDC to HI/LO terminal. This will

reduce motor speed by 75%.

Operating the Drive

6-1

Page 26

6-2

TD200 AC Drive Installation and Operation

Page 27

CHAPTER 7

Diagnostics and Troubleshooting

7.1 Drive Faults and Corrective Actions

The drive has two status LEDs that can be used to diagnose drive faults. Table 7.1

lists some possible drive faults and their corrective actions.

Table 7.1 – Drive Status Indicators

Status

Drive is

running

Drive runs,

but not at

commanded

speed

Drive is

stopped

Motor

LED

(M)

ON ON Drive is running (normal status).

ON ON Internal speed reference set

ON ON Overtemperature - result of

ON OFF Internal Drive Fault Cycle power. If fault repeats, replace drive.

OFF ON Overcurrent - sustained overload

Drive

LED

(D) Possible Cause Corrective Action

improperly

External peed refere nce not present

HI/LO input has voltage applied

Current limit set too low

V/Hz jumpers set improperly

Excessive load

Input voltage too low (< 25 VDC,

nominal)

Power source not delivering enough

current

inadequate air flow, excessive

ambient temperature, and/or

excessive load current

Overvoltage - voltage exceeds 32

VDC

exceeding limits in table 2.3.

Check jumper settings (J1 - J8).

Check speed r ef erenc e jum pers (J 1, J17 - J19),

POT1 and POT2.

Remove input voltage.

Increase J13 - J16 settings.

Set J9 - J12 to proper motor setting.

Reduce load.

Increase input voltage.

Supply app ropriate input current.

Let drive cool down, then cycle ON/OFF input.

Unit will automatically restart when voltage

returns to normal input levels.

Reduce current load.

OFF OFF Input power is too low or ON/OFF

To reset a fault, toggle the ON/OFF switch to OFF. When the switch is returned to the

ON position, the drive will attempt to restart.

Diagnostics and Troubleshooting

Instantaneous Overcurrent (IOC) short circuit or other fault applied to

the output

Ground Fault

input is low (OFF).

Check output circuitry; reduce current load.

Check motor and motor wiring.

7-1

Page 28

7-2

TD200 AC Drive Installation and Operation

Page 29

APPENDIX A

Technical Specifications

Drive Dimensions

Height: 12.95 inches

Width: 6.50 inches

Depth: 4.12 inches

Weight: 7.88 pounds

Input Voltage

Nominal: +28 VDC

Operating Range: +20 to +32 VDC

Maximum Non-operating Transient: +60 V peak., 0.1 seconds

Source: battery, battery & alternator, stand-alone alternator, or DC power supply

Note: Negative voltage should not be applied to the drive.

Input Current

Nominal: +65 A DC (@ 28 VDC input and rated HP)

Output Voltage

Nominal: 0.3 to 20 V RMS, 3-phase (@ 28 VDC input)

Output Current (per phase)

Maximum Continuous: 63 A RMS, (jumper-selectable range from 30 A to 63 A)

Instantaneous Overcurrent Trip (IOC Trip):160 A peak @ 63 A jumper setting (any

phase). This value is proportional to jumper setting.

Horsepower Rating

Maximum motor size: 2 HP. Maximum continuous output current must not be

exceeded.

Efficiency

Minimum: 93% (@ 28 V input and maximum continuous output current)

Humidity and Water Splash

The drive is suitable for wash down. The drive is not submersible.

A-1

Page 30

Shock and Vibration

Will withstand 3-axis sinusoidal vibration from 20 to 200 Hz @ 2 g.

Will withstand 3-axis, 10 g shock pulse with a duration of 8 msec.

Cooling Air Requirements

Minimum air velocity: 1000 linear ft/min (LFM) referenced to standard conditions of

° C and 760 mm Hg, directed through base areas of the unit’s cooling fins.

25

Electromagnetic Interference (EMI)

This product has been tested for immunity to electrostatic discharges, radiated

interference, and electrical fast transients. The IEC1000-4- 2, 3, 4 standards were

used to establish compliance.

A-2

TD200 AC Drive Installation and Operation

Page 31

Page 32

U.S. Drives Technical Support

Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, Email: support@drives.ra.rockwell.com, Online: www.ab.com/support/abdrives

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication D2-3462- October 2000 Copyright © 2000 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Loading...

Loading...