Page 1

Triguard SC300E

TBT

Bus Terminator

INTRODUCTION

(TBT

Issue 2

October 2005

)

PURPOSE

The Bus Terminator (TBT) is a passive end

TBT is to minimise line ringing and pulse reflections in order to eliminate transmission data

erro

rs.

This document is intended to provide a general understanding of the TBT sufficient to enable

basic

maintenance procedures to be effected in the field.

-of-

line I/O data bus terminator. The purpose of the

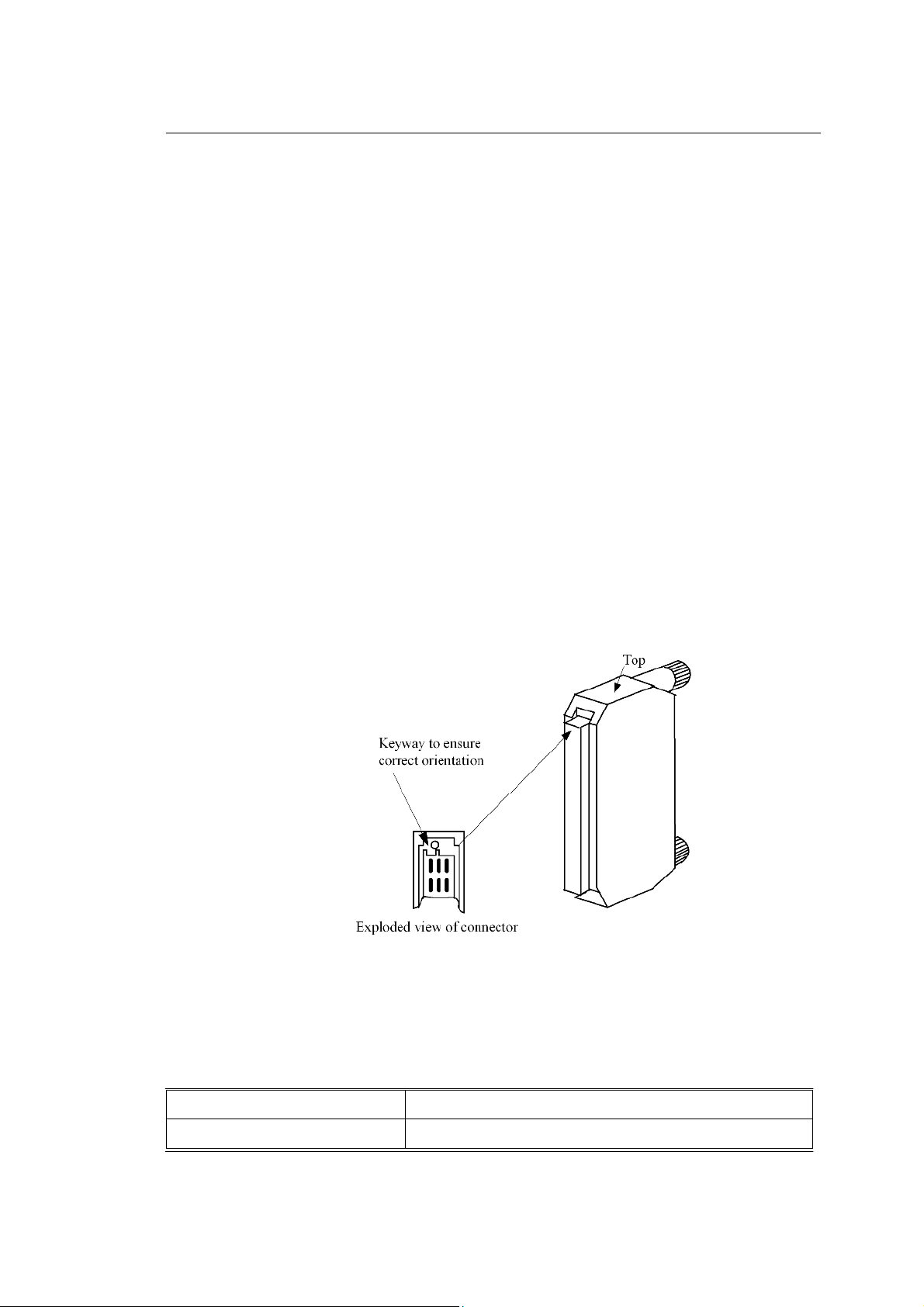

Figure 1-1. TBT Bus terminator-General view

ASSOCIATED DOCUMENTATION

008-5115

Reference No

TBA Bus Expansion Adaptor User Manual

008-5217

Title

Page 2

2

TBT

October

2005–

Issue 2

Triguard

SC300E

Page 3

TBT

October

2005–Issue 2

3

SPECIFICATION

Model

Triguard

TBT

SC300E TBT Bus Terminator

Connector

Overall size (mm)

Overall size (inches)

Weight (per set of three)

ENVIRONMENTAL SPECIF

The maximum ambient temperature measured at the hottest point within the Triguard system

shall

Temperature operating:

Temperature

Humidity

Certification:

General Certification: Ref. SC300E TMR Product Guide (ref 008-5209)

ICATIONS

not be greater than 60 degrees centigrade.

storage:

+5°C to +60°C

-

25°C to +70°C

5% to 95% non-condensing at ambient <40°C

DIN41612 style ‘c’ 64-way

100H x 18W x 40D

3.94H x 0.7W x 1.57D

0.21kg

TRANSPORT AND HANDLING

The TBT must be transported and stored in its original packing material, which should be

retained for this purpose.

Page 4

4

TBT

October

2005–

Issue 2

Triguard

SC300E

TECHNICAL DESCRIPTIO

N

PHYSICAL

The TBT bus terminator consists of a DIN41612 connector with two fixing screws to fit to the

bus

expansion adaptors (TBA) fitted to the SC300E chassis.

THEORY OF OPERATION

If the SC300E chassis are arranged with the MPPs at one end of the bus then the TBTs must

be fitted at at the other end of the bus as shown in Figure 2-1

the bus is arranged with the MPPs in the middle of the bus then TBTs will be required at both

If

ends

of

the bus as shown in Figure 2-2

.

.

Figure 2-1 TBT termination diagram -

Main chassis at one end of the bus

Page 5

TBT

October

2005–Issue 2

5

Triguard

SC300E TBT Bus Terminator

Figure 2-2 TBT termination diagram -

Main chassis at not an end of the bus

Page 6

6

TBT

October

2005–

Issue 2

Triguard

SC300E

SERVICING

SCOPE

System repair is by replacement of the faulty device. Faulty devices are not repairable in the

field. They should be re

repair.

The fitting or removal of these devices on a running system could result in a plant shutdown.

placed by a serviceable spare and the faulty device returned to for

WARNING 1

FUNCTIONAL TESTING

There are no functional tests for this device available on-line.

NOTE

Continued inexplicable errors occurring on one channel may mean that the TBT

is faulty. This fact can only be established if a replacement cures the problem

.

Page 7

TBT

October

2005–Issue 2

7

Triguard

SC300E TBT Bus Terminator

SERVICE SUPPORT

SPARE PARTS

Spare parts and technical advice can be obtained from your local area offices

.

Loading...

Loading...