Page 1

AADvance Controller

Catalog Numbers T9110, T9300, T9310, T9401/2, T9431/2,

T9451, T9481/2

Configuration Guide Workbench R2.x Original Instructions

Page 2

AADvance Controller Configuration Guide Workbench R2.x

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WA RN I NG : Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

2 Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021

Page 3

Preface

About This Publication

This software technical manual defines how to configure an AADvance®

controller

using the AADvance® Workbench software version 2.x to satisfy your system

operation and application requirements.

In no event will Rockwell Automation be responsible or liable for indirect or

consequential damages resulting from the use or application of this

equipment. The examples given in this manual are included solely for

illustrative purposes. Because of the many variables and requirements related

to any particular installation, Rockwell Automation does not assume

responsibility or reliability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, with respect to use of

information, circuits, equipment, or software described in this manual.

All trademarks are acknowledged.

Disclaimer

It is not intended that the information in this publication covers every possible

detail about the construction, operation, or maintenance of a control system

installation. You should also refer to your own local (or supplied) system safety

manual, installation and operator/maintenance manuals.

Revision And Updating Policy

This document is based on information available at the time of its publication.

The document contents are subject to change from time to time. The latest

versions of the manuals are available at the Rockwell Automation Literature

Library under "Product Information" , “Critical Process Control & Safety

Systems".

Downloads

The product compatibility and download center is rok.auto/pcdc

Select the Find Downloads option under Download.

In the Product Search field enter "AADvance" and the AADvance option is

displayed.

Double-click on the AADvance option and the latest version is shown.

Select the latest version and download the latest version.

AADvance Release

.

This technical manual applies to AADvance system release 1.40

Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021 3

Page 4

Latest Product Information

For the latest information about this product review the Product Notifications

and Technical Notes issued by technical support. Product Notifications and

product support are available at the Rockwell Automation Support Center at

rok.auto/knowledgebase

.

At the Search Knowledgebase tab select the option By Product then scroll down

and select the ICS Triplex® product AADvance.

SM

Some of the Answer IDs in the Knowledge Base require a TechConnect

Support Contract. For more information about TechConnect Support Contract

Access Level and Features, click this link: Knowledgebase Document ID: IP622

- TechConnect Support Contract - Access Level & Features.

This will get you to the login page where you must enter your login details.

IMPORTANT A login is required to access the link. If you do not have an

account then you can create one using the "Sign Up" link at the

top right of the web page.

Purpose Of This Manual

Starting with a new panel and a software distribution DVD, this manual

explains how to install the AADvance Workbench. This manual defines the

process you must follow to configure your system. It includes background

information and step-by-step instructions for the following:

• Installing the software and setting up the software licensing

• Setting the controller IP Address and achieving communications with

the controller

• Defining the processor configuration

• Defining the application variables

• Configuring the I/O modules and channels

• Setting up MODBUS, CIP and SNCP

The instructions are based on using Release 2.1 of the AADvance Workbench

under the Windows XP operating system; other Windows operating systems

are supported - refer to the topic Chapter 2 "Planning the AADvance

Workbench Software Installation" for a full list of supported windows

operating systems.

This manual includes reference information about module status parameters

and I/O variables, to help you make a decision about which variable types to

use and full descriptions of the data values supplied by the I/O modules.

• If the information in this document does not agree with the applicable

project codes and standards, the system integrator must find a solution

for the mismatch.

• If AADvance is used for a safety function, the system integrator must

apply

4 Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021

Page 5

Who Should Use Manual

The data in this manual is written for system integrators who know about

building and setting up new systems. The system integrator must make sure

that the system complies with the local, national and international standards

for the application that AADvance is being used for.

Environmental Compliance

Rockwell Automation maintains current product environmental information

on its website at rok.auto/pec

.

Download Firmware, AOP, EDS, and Other Files

Summary of Changes

Download firmware, associated files (such as AOP, EDS, and DTM), and access

product release notes from the Product Compatibility and Download Center at

rok.auto/pcdc

.

This publication contains the following new or updated information. This list

includes substantive updates only and is not intended to reflect all changes.

Global changes

This table identifies changes that apply to all information about a subject in the

manual and the reason for the change. For example, the addition of new

supported hardware, a software design change, or additional reference

material would result in changes to all of the topics that deal with that subject.

Subject Reason

Applied latest publication template Marketing product change

New or enhanced features

This table contains a list of topics changed in this version, the reason for the

change, and a link to the topic that contains the changed information.

Additional Resources

Subject Reason

AADvance Release on page 3

Additional Resources on page 5

N on page 235 Removed NFPA 87.

proof test on page 236

Updated AADvance system release information.

Added reference to AADvance®-Trusted® SIS

Workstation software User Guide, publication

ICSTT-UM002.

Updated definition.

These documents contain additional information concerning related products

from Rockwell Automation.

Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021 5

Page 6

Resource Description

This technical manual defines how to safely apply AADvance controllers for a Safety

AADvance Controller Safety Manual, ICSTT-RM446

AADvance Controller System Build Manual, ICSTT-RM448

AADvance Controller Configuration Guide Workbench 1.x, ICSTT-RM405

AADvance-Trusted SIS Workstation Software User Guide, ICSTT-UM002

AADvance Controller OPC Portal Server User Manual, ICSTT-RM407

AADvance Controller PFH and PFDavg Data, ICSTT-RM449

AADvance Controller Solutions Handbook, ICSTT-RM447

AADvance Controller Troubleshooting and Maintenance Manual, ICSTT-RM406

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

Product Certifications website, rok.auto/certifications. Provides declarations of conformity, certificates, and other certification details.

Instrumented Function. It sets out standards (which are mandatory) and makes

recommendations to make sure that installations satisfy and maintain their required safety

integrity level.

This technical manual describes how to assemble a system, switch on and validate the

operation of your system.

This software technical manual defines how to configure an AADvance controller

using the AADvance Workbench software version 1.x to satisfy your system operation and

application requirements.

This publication provides how-to instructions for AADvance®-Trusted® SIS Workstation

software configuration and use.

This manual describes how to install, configure and use the OPC Server for an AADvance

Controller.

This document contains the PFH and PFD

examples on how to calculate the final figures for different controller configurations.

This technical manual describes the features, performance and functionality of the

AADvance controller and systems. It gives guidance on how to design a system to satisfy

your application requirements.

This technical manual describes how to maintain, troubleshoot and repair an AADvance

Controller.

Provides general guidelines for installing a Rockwell Automation industrial system.

Data for the AADvance Controller. It includes

avg

You can view or download publications at rok.auto/literature.

6 Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021

Page 7

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

About This Publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Download Firmware, AOP, EDS, and Other Files . . . . . . . . . . . . . . . . . . . . 5

Summary of Changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1

Quick Start Guide Creating Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Make a First Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Program Enable Key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Hardware Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Integrating the AADvance Controller with Other Systems. . . . . . . . . . . 16

Chapter 2

Software Installation and

Licensing

Planning the AADvance Workbench Software Installation . . . . . . . . . . 19

Upgrading from Release 1.x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Install the AADvance Workbench Software - Web Distribution . . . . . . 20

Install the AADvance Workbench Software - Full Product . . . . . . . . . . . 21

AADvance Workbench Licensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Set Up a Single User License or a Full License . . . . . . . . . . . . . . . . . . . . . . 23

Managing a Paid-for License . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Connecting the AADvance

Workbench to the Controller

Starting a Project and Defining

the Controller

Chapter 3

Controller IP Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Allocating IP Addresses for Network Communications . . . . . . . . . . . . . 26

AADvance Discover Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Configure the IP Address in the Controller . . . . . . . . . . . . . . . . . . . . . . . . 28

Configure the Controller Resource Number in the Controller . . . . . . . 31

Configure the IP Address of the Target Controller. . . . . . . . . . . . . . . . . . 33

System Security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Workbench Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Integrating the AADvance Controller with Other Systems. . . . . . . . . . . 38

Network Firewall. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Windows PC Firewall. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Save and Load a Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Save a Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Reload a saved Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Replace an Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Chapter 4

Reset Window Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021 7

Page 8

Make a New Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Import Existing Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Procedure to import an existing project. . . . . . . . . . . . . . . . . . . . . . . . 52

Procedure for Opening An Existing Project . . . . . . . . . . . . . . . . . . . . . . . . 54

To open a project from the Workbench. . . . . . . . . . . . . . . . . . . . . . . . . 54

To open a project from the Projects directory . . . . . . . . . . . . . . . . . . . 54

Equipment View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Communication View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Application View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Add a New Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Configure the Controller Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Configure Controller Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

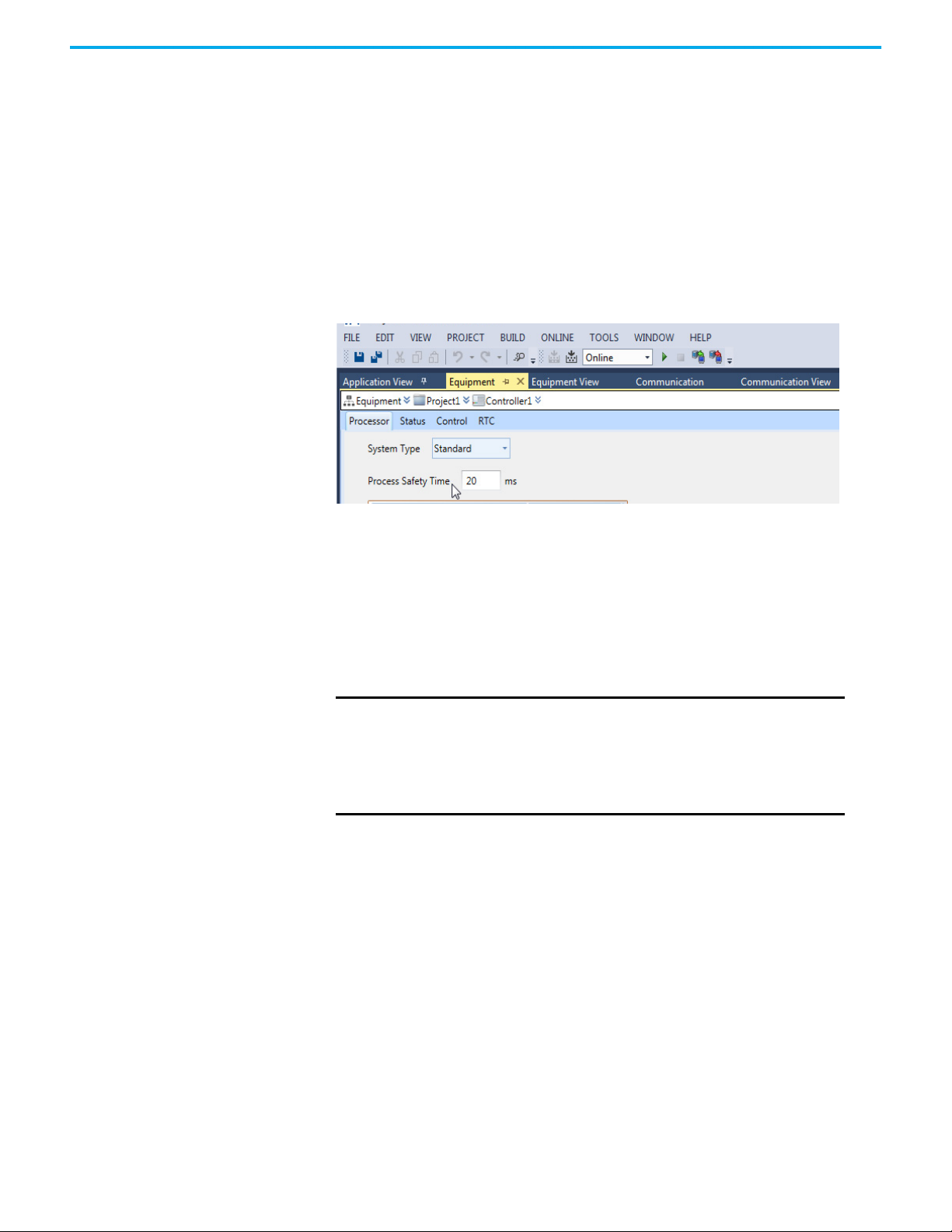

Controller Process Safety Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Configure the Top-level Process Safety Time. . . . . . . . . . . . . . . . . . . . . . . 65

Online Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Archiving and Restoring Repository Projects . . . . . . . . . . . . . . . . . . . . . . 67

To archive a repository project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

To restore a repository project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Processor Module Battery and Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Configure the Processor Battery Alarm . . . . . . . . . . . . . . . . . . . . . . . . 68

Remote Fault Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Chapter 5

Declaring Project Variables About Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Declare or Change Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Properties for AADvance Project Variables. . . . . . . . . . . . . . . . . . . . . . . . . 72

Standard IEC 61131-3 Data Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Built-in Data Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Chapter 6

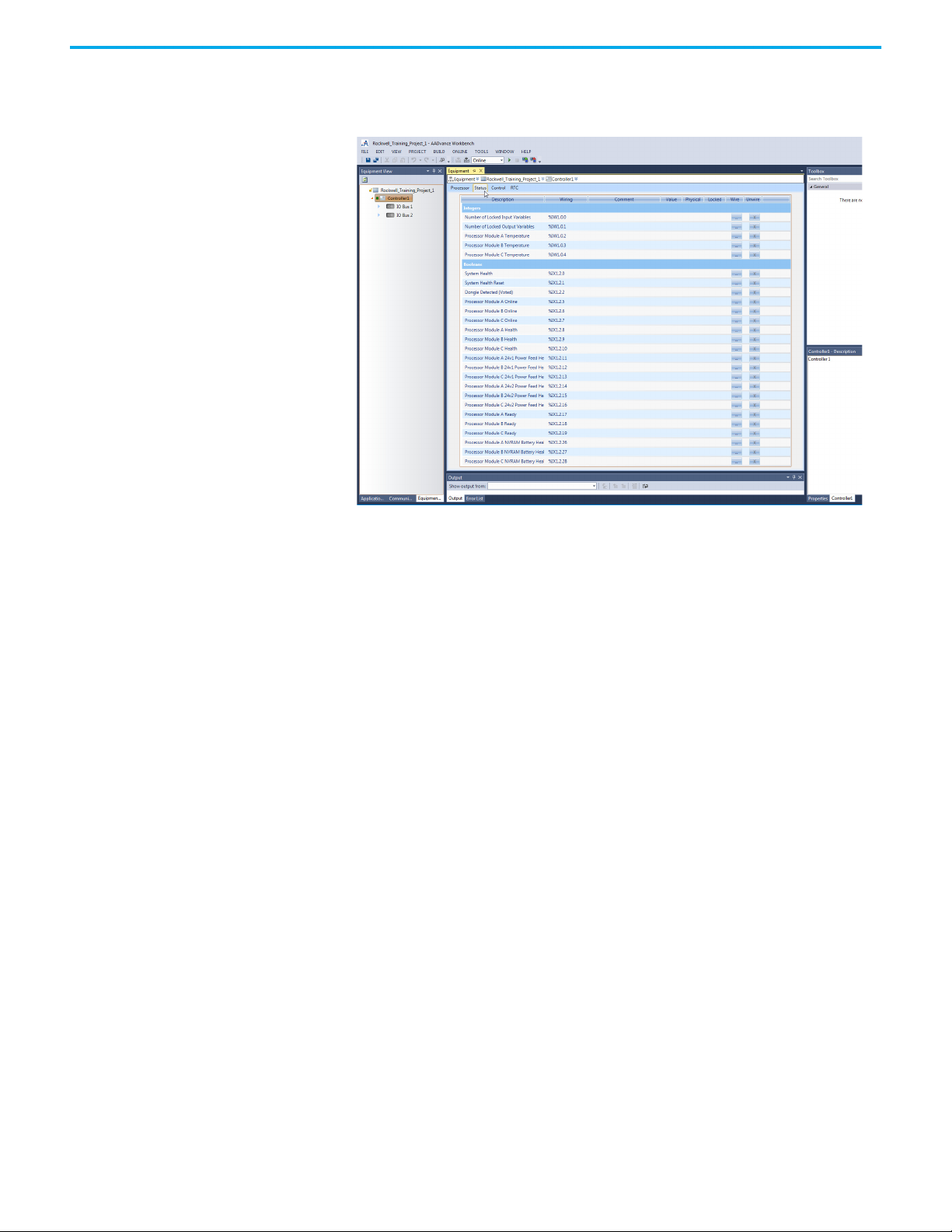

Setting Processor Variables Processor Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

To Wire a Processor Variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

To Unwire a Processor Variable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

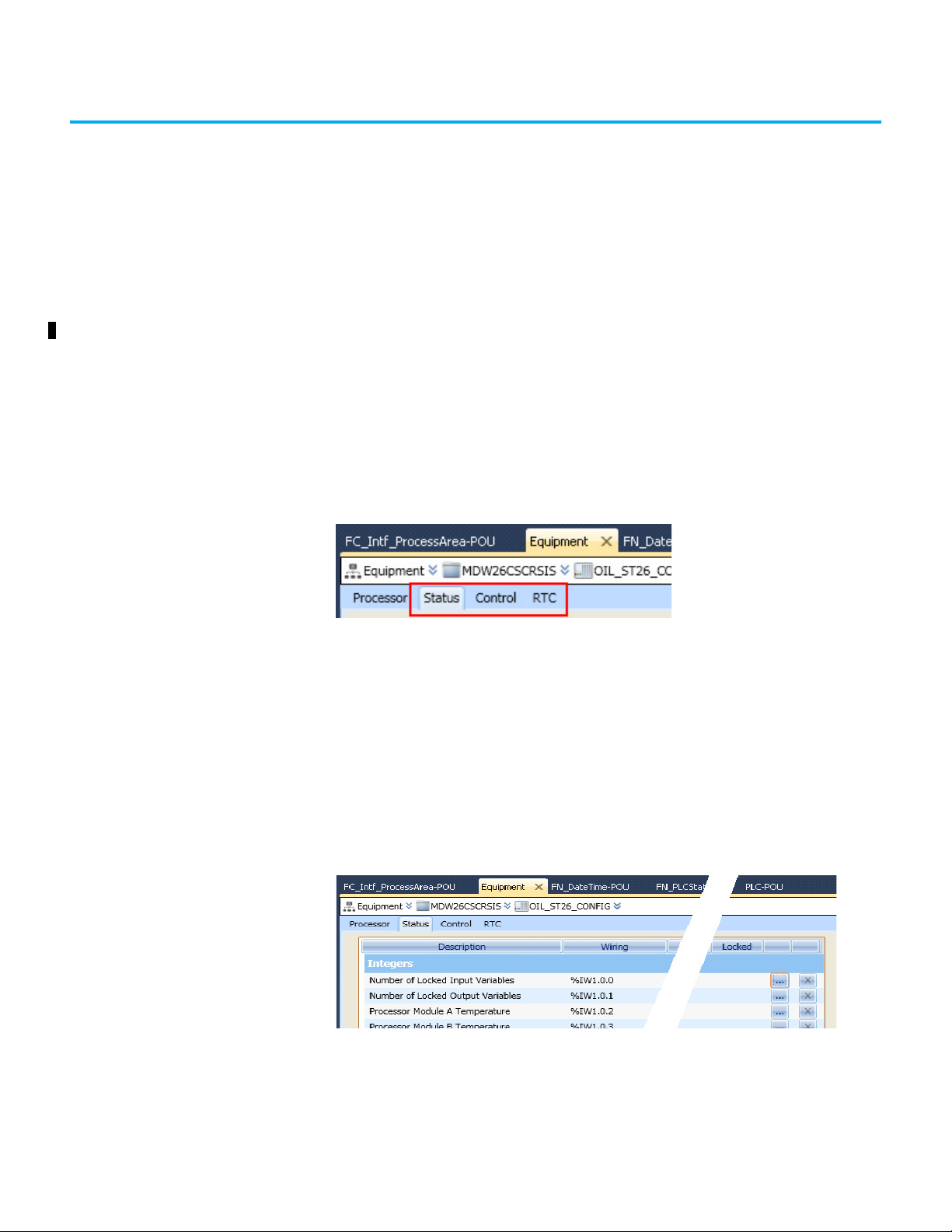

Status Variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Status Integers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Number of Locked Input Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Number of Locked Output Variables. . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Processor Module A Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Processor Module B Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Processor Module C Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Status Booleans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

System Health. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

System Health Reset (Voted 1oo3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Dongle Detected (Voted) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Processor Module A Online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Processor Module B Online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Processor Module C Online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Processor Module A Health . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Processor Module B Health . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8 Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021

Page 9

Processor Module C Health . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Processor Module A 24 V1 Power Feed Health. . . . . . . . . . . . . . . . . . . 84

Processor Module B 24 V1 Power Feed Health. . . . . . . . . . . . . . . . . . . 84

Processor Module C 24 V1 Power Feed Health . . . . . . . . . . . . . . . . . . 84

Processor Module A 24 V2 Power Feed Health . . . . . . . . . . . . . . . . . . 85

Processor Module B 24 V2 Power Feed Health . . . . . . . . . . . . . . . . . . 85

Processor Module C 24 V2 Power Feed Health . . . . . . . . . . . . . . . . . . 85

Processor Module A Ready. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Processor Module B Ready. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Processor Module C Ready. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Processor Module A NVRAM Battery Health. . . . . . . . . . . . . . . . . . . . 86

Processor Module B NVRAM Battery Health. . . . . . . . . . . . . . . . . . . . 87

Processor Module C NVRAM Battery Health. . . . . . . . . . . . . . . . . . . . 87

Control Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Control Integers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

AUX LED Colour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Allow Remote Fault Reset Most Significant Bits (MSB) . . . . . . . . . . 88

Allow Remote Fault Reset Least Significant Bits (LSB). . . . . . . . . . . 89

Control Booleans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Unlock All Locked Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Set System Health Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

HART Pass-Through . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Perform Remote Fault Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Perform Remote Fault Join . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Real-Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

RTC Processor Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

RTC Status Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

RTC Status: Year. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

RTC Status: Month . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

RTC Status: Day of Month . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

RTC Status: Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

RTC Status: Minutes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

RTC Status: Seconds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

RTC Status: Milliseconds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

RTC Program Variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

RTC Program: Year . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

RTC Program: Month . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

RTC Program: Day of Month. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

RTC Program: Hours. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

RTC Program: Minutes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

RTC Program: Seconds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

RTC Program: Milliseconds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

RTC Control Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

RTC Control: RTC Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

RTC Control: RTC Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

RTC Control: Year . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

RTC Control: Month . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

RTC Control: Day of Month. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

RTC Control: Hours. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

RTC Control: Minutes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021 9

Page 10

Configuring Timing and

Communications

RTC Control: Seconds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

RTC Control: Milliseconds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

To manually set the real-time clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Chapter 7

Synchronizing the Controller Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Choosing a Network Time Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Using the Controller as an SNTP Client . . . . . . . . . . . . . . . . . . . . . . . 102

Using the Controller as an SNTP Server. . . . . . . . . . . . . . . . . . . . . . . 102

Using the Controller as an SNTP Client and Server. . . . . . . . . . . . . 103

Time Synchronization SNTP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Configure the Controller as an SNTP Client . . . . . . . . . . . . . . . . . . . 103

Configure the Controller as an SNTP Server. . . . . . . . . . . . . . . . . . . 105

Using Serial Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Serial Port Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Configure the Serial Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Serial Port Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Chapter 8

Configuring the Controller I/O About Adding and Configuring I/O Modules. . . . . . . . . . . . . . . . . . . . . . . 111

Assign I/O Modules to a Configuration . . . . . . . . . . . . . . . . . . . . . . . 112

Resize a Group of Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Move a Module to a Different Slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Remove an I/O Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Enable I/O Online Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Change the I/O Configuration with an Online Update. . . . . . . . . . 120

About Wiring to and from I/O Channels . . . . . . . . . . . . . . . . . . . . . . 120

Configuring Digital Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Threshold Values for Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Configuring Analogue Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Threshold Values for Analogue Inputs . . . . . . . . . . . . . . . . . . . . . . . . 125

Wire a Channel Variable to an Analogue Input . . . . . . . . . . . . . . . . 127

T9K_AI_COMPACT and T9K_AI_FULL. . . . . . . . . . . . . . . . . . . . . . . . 128

HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

HART Pass-Through . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Use FactoryTalk Asset Center with an Analogue Module . . . . . . . . 136

Configure HART Pass-Through Monitoring . . . . . . . . . . . . . . . . . . . 139

Configuring Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Variables for a Digital Output Module . . . . . . . . . . . . . . . . . . . . . . . . 140

Wire a Channel Variable to a Digital Output. . . . . . . . . . . . . . . . . . . 143

T9K_DO_COMPACT and T9K_DO_FULL. . . . . . . . . . . . . . . . . . . . . . 144

The State Variable for Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . 145

Protection for Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Faulted State for Digital Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Configure the Channel Advanced Settings . . . . . . . . . . . . . . . . . . . . 147

Configuring Analogue Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Configure the Channel Advanced Settings . . . . . . . . . . . . . . . . . . . . 149

T9K_AI_COMPACT and T9K_AI_FULL. . . . . . . . . . . . . . . . . . . . . . . . 150

10 Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021

Page 11

Chapter 9

Sharing Data between

ControlLogix and AADvance

Using AADvance for CIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Connection Requirements of a Produced or Consumed Tag . . . . . . . . 154

Example: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Memory Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Data Types for CIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Setting Up Variables for CIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Define the CIP Producer Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

CIP and its Producer and Consumer Variables. . . . . . . . . . . . . . . . . 158

Define a CIP Consumer Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

With Status Produce and Consume Variables . . . . . . . . . . . . . . . . . . . . . 161

Obtaining the Connection Status for a Consumed Variable . . . . . . . . 161

AADvance Producer RunMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

About the RSLogix 5000 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Set the RSLogix UNICAST Configuration . . . . . . . . . . . . . . . . . . . . . 164

Chapter 10

Configuring MODBUS MODBUS Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

MODBUS Master Hardware and Physical Connections . . . . . . . . . . . . 165

Planning for MODBUS Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

MODBUS Master Command Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

MODBUS Data Types and Addressing. . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

MODBUS Message Scheduling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Configure MODBUS Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Physical Connections for MODBUS RTU . . . . . . . . . . . . . . . . . . . . . . . . . 171

Physical Connections for MODBUS TCP . . . . . . . . . . . . . . . . . . . . . . . . . 172

MODBUS Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Create a MODBUS Slave Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Configure a MODBUS Slave Object. . . . . . . . . . . . . . . . . . . . . . . . . . . 172

MODBUS Slave Exception Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

MODBUS Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

MODBUS Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Handling MODBUS Communication Errors . . . . . . . . . . . . . . . . . . 176

MODBUS Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

MODBUS Exception Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

AADvance Objects for MODBUS Master . . . . . . . . . . . . . . . . . . . . . . 176

MODBUS Master Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Create a MODBUS Master Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Configure for MODBUS RTU/TCP . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Create Links to MODBUS Slaves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Configure a MODBUS Slave - General Tab . . . . . . . . . . . . . . . . . . . . 181

Configure a MODBUS Master Slave - Messages. . . . . . . . . . . . . . . . 183

Remove a MODBUS Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

OPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Configure OPC Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Sequence of Events (SOE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Configure SOE Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021 11

Page 12

Chapter 11

SNCP Bindings and the SNCP Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Create a Binding Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

SNCP Link Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Bindings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Configure Bindings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

SNCP Binding Error Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Chapter 12

Peer-to-Peer Network Peer-to-Peer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Peer-to-Peer Configuration Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Create a Peer-to-Peer Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Peer-to-Peer Subnet Controller Configuration . . . . . . . . . . . . . . . . . . . . 204

Set up the Peer IP Addresses and Status Variable . . . . . . . . . . . . . . 206

Peer-to-Peer Data Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Configure Data Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Configure Analog Input Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Configure Digital Input Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Configure Analogue Output Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Configure Digital Output Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Peer-to-Peer Configuration Example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Peer-to-Peer Controller Setting Summary. . . . . . . . . . . . . . . . . . . . . 221

Peer-to-Peer Data Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Appendix A

History of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

12 Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021

Page 13

Chapter 1

Quick Start Guide

Creating Applications The AADvance® Workbench is the software development environment for the

AADvance controller. It lets you make one comprehensive control solution and

then target parts of the solution to individual controllers. Interaction between

resources is automatic, eliminating the need to have different synchronous

schemes.

The AADvance Workbench supports the Function Block (FB), Structured Text

(ST) and Ladder Diagrams (LD) languages of IEC 61131-3. The Instruction List

(IL) language is not supported by Workbench 2.1 and the Sequential Function

Chart (SFC) language is not supported by Workbench 2.1 in a safety related

application. You can use one language or a combination of languages

depending on what is applicable to the application and your programming

style.

The AADvance Workbench runs on a Windows computer. You simulate and

test programs on the computer before downloading them to the controller. The

AADvance Workbench then works online to give you real-time monitoring,

online updates and other features. Connectivity between the AADvance

Workbench, the controller and between individual controllers, is through a

standard Ethernet network.

Make a First Application It only takes minutes to create the first application. If you have not already

installed and licensed the AADvance Workbench, do this now. Installation

instructions are provided in Chapter 2

Begin by creating a project and defining the type of hardware for the

controller:

1. Launch the software by clicking Start All Programs Rockwell

Automation AADvance 2.1 AADvance 2.1.

The application will open and display the following screen.

Default Start-Up Screen

Software Installation and Licensing.

Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021 13

Page 14

Chapter 1 Quick Start Guide

For subsequent use of the Workbench application, the layout for the screen

presented on start-up is the same as the view displayed on the previous closure

of the application. For further detail refer to Reset Window Layout

on page 45.

2. Create a new project (File New Project) and move to the Application

View, Communication View or Equipment View.

• the AADvance Workbench places a controller into the project

• the controller is named Controller1.

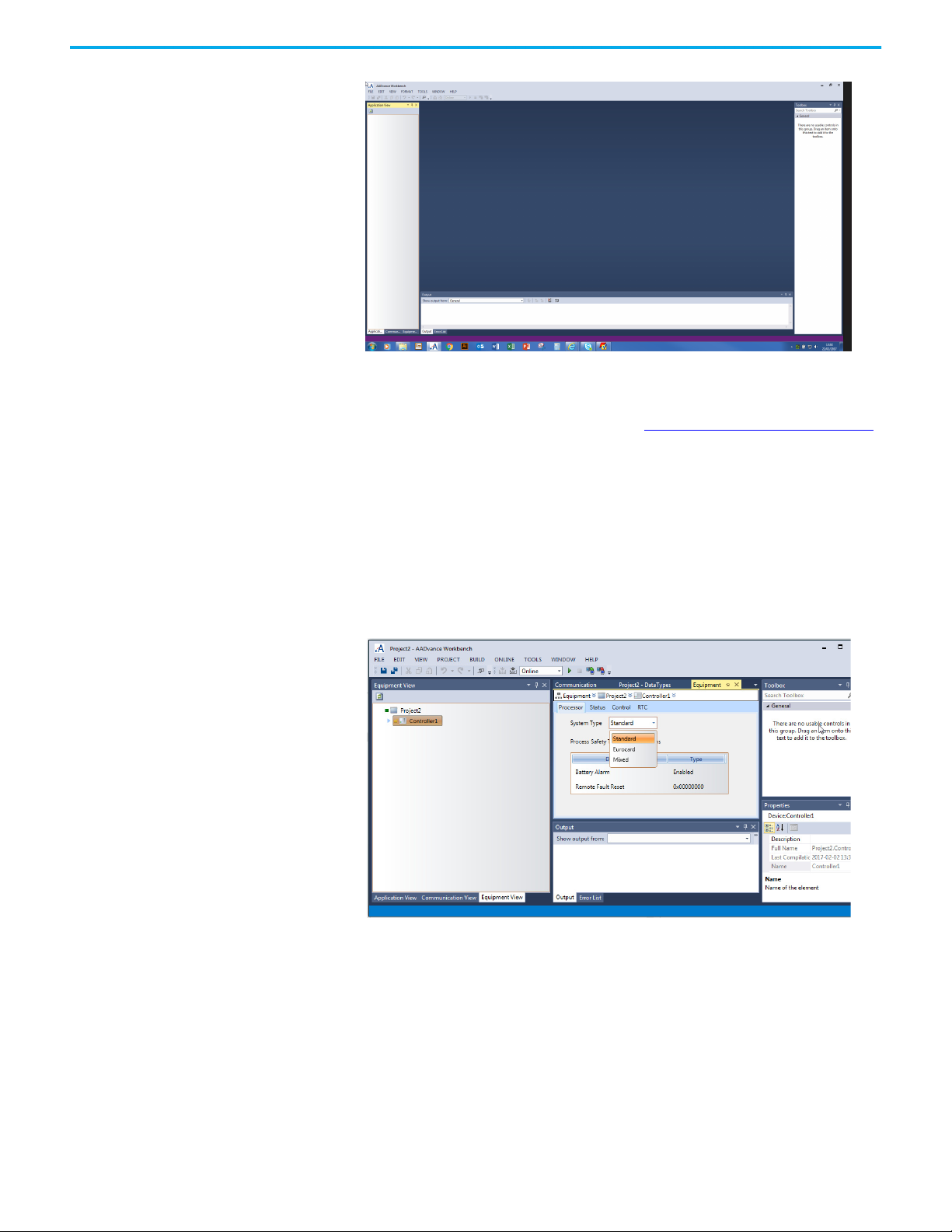

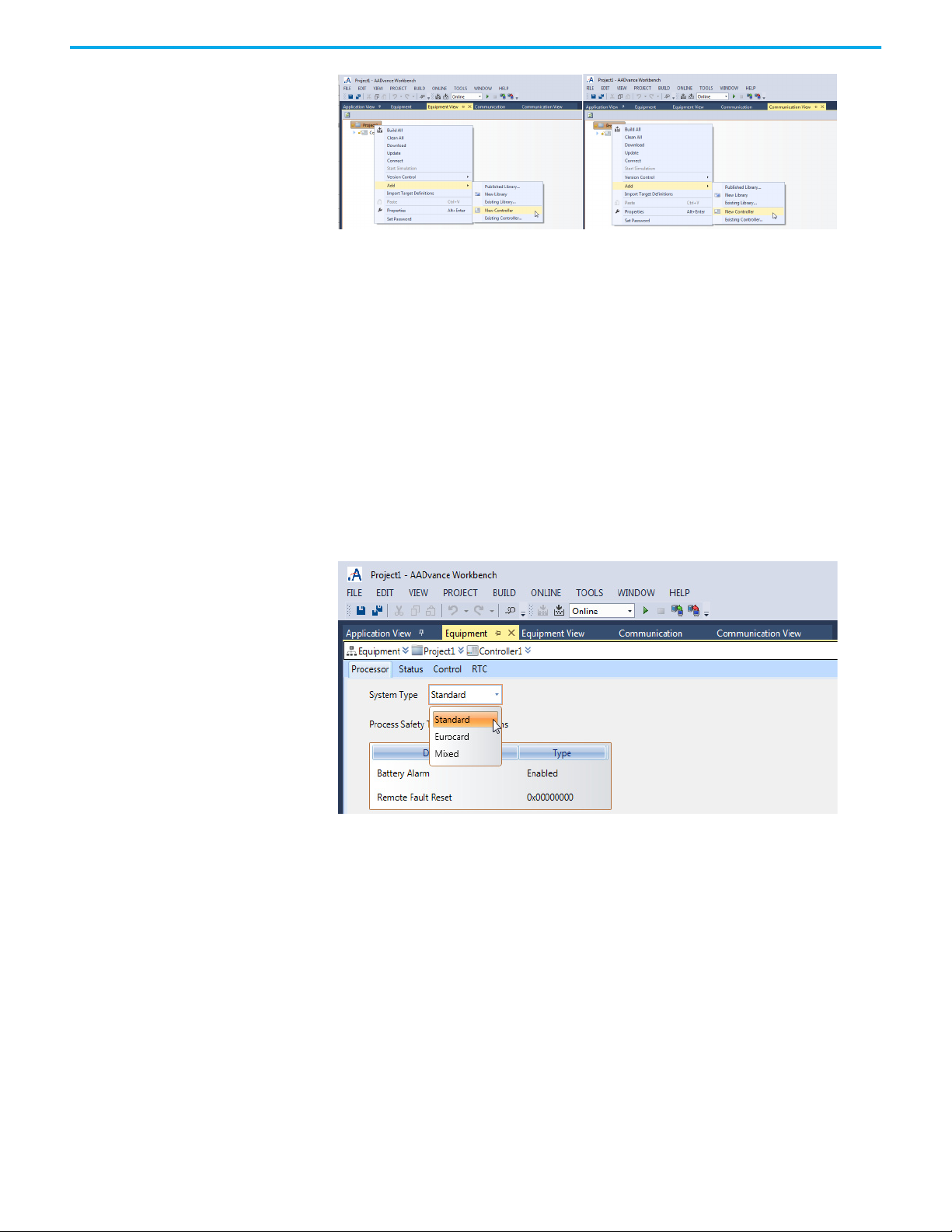

3. Select Equipment View Controller1 identify the system type of the

controller. The three options for system type are:

• Standard

• Eurocard

•Mixed.

4. If the project needs more controllers, use the contextual menu on the

project node (the first node in the tree) to add the controllers to the

project. Then identify the class of each new controller.

After having identified the controller class you can configure the controller

and place I/O modules with slots on the processor bus. Place input modules in

simplex, duplex and triplex arrangements, output modules in simplex and

duplex arrangements. The duplex and triplex arrangements use adjacent slots

in groups of two or three.

Proceed to the Application View, Communication View or Equipment View.

14 Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021

Page 15

Chapter 1 Quick Start Guide

IMPORTANT

1. Use a spreadsheet or equivalent tool to assign tag names to the variables

you want to use. If you chose structured variables for I/O channels, the

AADvance Workbench generates a set of other variable elements with the

same tag name for each element type.

2. Declare variables for I/O channels and module status parameters. An

extensive range of variable types is available including a set of structured

variables. You can subsequently add new variables if applicable.

3. Connect (wire) each I/O channel to variables to get input channel states

and set output data values.

4. Set up the serial ports, process safety time, and SNTP and MODBUS

services.

5. Allocate the IP addresses for communication with the AADvance

controllers and configure the network communications parameters.

The controller configuration must be exactly the same as the

hardware arrangement. If you change the physical arrangement

of the hardware, remember to change the Workbench

configuration to match the new arrangement.

Program Enable Key The standard AADvance controller has a program enable key which plugs into

the KEY connector on the 9100 processor base unit. When the key is removed,

the controller application is protected from unwanted changes. You must fit

the program enable key before performing a download to the application,

adjusting the application and setting or changing the controller IP address.

If the program enable key is not installed before performing a download to the

application, adjusting the application and setting or changing the controller IP

address will produce an error message. The error message will vary depending

on the application status, running or stopped.

Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021 15

Page 16

Chapter 1 Quick Start Guide

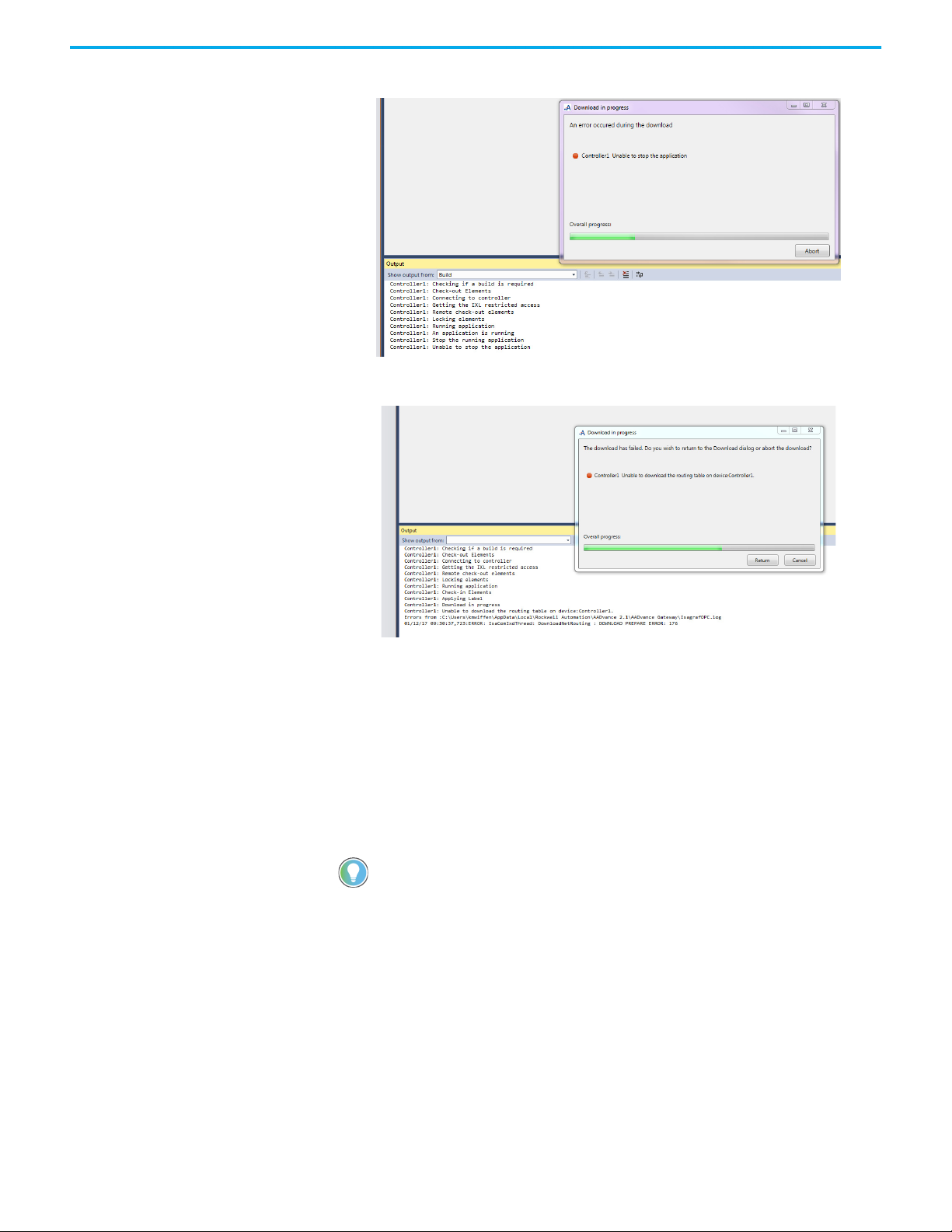

Figure 1 - With the application running the following error message occurs.

Figure 2 - With the application stopped the following error message occurs.

Hardware Redundancy You create hardware redundancy in the AADvance Workbench when you

identify the hardware configuration from the Equipment View. During the

allocation of I/O modules to empty slots, you have the option of adding two or

three modules. When you use the two or three option the AADvance

Workbench automatically allocates the modules to a group of adjacent slots.

The AADvance Workbench then only allows you to configure one set of I/O

channels to the group.

You do not need to define redundancy for AADvance processors. The

AADvance Workbench automatically connects to each processor when the

network connection is set up.

Integrating the AADvance

Controller with Other

The AADvance controller connects to existing control systems and plant

monitoring equipment. This connection enables a third-party control system

to read the state of sensors connected to the controller.

Systems

The connection interfaces are through the controller network ports and serial

ports, and use the following protocols:

• CIP™ over Ethernet/IP™

•Modbus RTU

• Open Modbus/TCP

16 Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021

Page 17

• OLE for Process Control (OPC).

Chapter 1 Quick Start Guide

IMPORTANT

In order to support the integrity of the AADvance system,

activation of network firewalls and Windows operating system

firewalls is strongly advised.

Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021 17

Page 18

Chapter 1 Quick Start Guide

Notes:

18 Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021

Page 19

Planning the AADvance Workbench Software Installation

Chapter 2

Software Installation and Licensing

The AADvance® Workbench software is a 32-bit application based on the

Microsoft Visual Studio Shell that runs on all common Windows platforms.

This chapter provides the instructions to install and license the AADvance

Workbench software.

IMPORTANT

The AADvance Workbench software uses the Microsoft Visual Studio 2010

with Service Pack 1. The installer automatically installs Microsoft Visual Studio

2010 Shell (isolated mode) and Microsoft .NET 4.0, but only if these are not

already installed on the computer. This reduces the time necessary for updates

of the AADvance Workbench, where the Microsoft Visual Studio and .NET are

already on the computer.

If you have not installed the AADvance Workbench software

before, read all of this section before starting the installation.

The specification of the computer where you install the software must have the

following specification, or better:

Operating system (32- bit or 64-bit):

• Microsoft Windows XP

•Windows Vista

•Windows 7

• Microsoft Windows Server 2003

• Microsoft Windows Server 2008.

Hardware:

•1.6 GHz CPU

• 1 GB RAM (32-bit) or 2 GB RAM (64-bit) (add 512 MB if running in a

virtual machine)

• DirectX 9 capable video card running at 1024 x 768 resolution display

•5,400 RPM hard disk

• 3 GB available hard disk space

• DVD drive or network connection, to read software distribution files

• Network port (10/100 Base T Ethernet), for communications with the

controller.

It is recommended that the computer has a 2.2 GHz or higher CPU; 1,024 MB

or more RAM, a 1,280 x 1,024 display and a 7,200 RPM or higher hard disk.

Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021 19

Page 20

Chapter 2 Software Installation and Licensing

It is also recommended that the hard disk has at least 10 GB free space. This

provides sufficient space to hold the distribution zip file, the unzipped source

files and the installed program files, and also sufficient space for Windows to

operate reasonably quickly. You can retrieve a lot of this space by deleting the

source files after finishing the installation.

Upgrading from Release 1.x If you are upgrading to AADvance 2.x from AADvance 1.x, and you mean to

migrate one or more existing projects to AADvance 2.x, do the following:

IMPORTANT

1. Make sure that the repository for the AADvance 1.x AADvance

Workbench is on a local disk drive. The AADvance 2.x Workbench does

not permit opening AADvance 1.x projects from a repository when no

local copy exists.

2. If the project is stored as only an AADvance 1.x archive, put back the

archive as a project in the AADvance 1.x Workbench.

3. Make sure that the AADvance 1.x project compiles fully.

4. Make sure that all users record all on-going modifications.

• When you open a project from an AADvance 1.x repository in

AADvance 2.x, the repository is upgraded to the current version and is

no longer available in the previous version.

• If you do not record all on-going modifications, the modifications

become local and cannot be integrated into the repository.

5. Write down the ID of each MODBUS Slave set up for Ethernet

communications. AADvance 2.x automatically assigns a value of 255 to a

MODBUS Slave ID for which Ethernet was specified.

6. Write down which Ethernet ports are assigned to CIP binding groups.

AADvance 2.x does not assign Ethernet ports to CIP binding groups, and

you have to specify Ethernet ports for individual groups after the

upgrade.

IMPORTANT

You must do these steps before installing AADvance 2.x.

The Instruction List (IL) language is not supported by Workbench

2.0 and the Sequential Function Chart (SFC) is not supported by

Workbench 2.0 in a safety related application.

Install the AADvance Workbench Software - Web Distribution

20 Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021

If you need to update an existing installation, use the web distribution version

of the AADvance Workbench software. The installation is smaller and quicker

than the full product because the Microsoft .NET Framework and Visual

Studio products which the software needs are already installed on the

computer.

IMPORTANT

The installation of the web distribution version takes about 10 minutes on a

computer with the recommended specification and will take longer if the

machine has less than 1,024 MB RAM.

To install the AADvance Workbench software (web distribution) do the

following:

If the AADvance Workbench has not been installed on the

computer, you must install the full product first. Following the

initial installation you can use the web distribution version to

update the installation.

Page 21

Chapter 2 Software Installation and Licensing

1. Log onto the computer using an account with administrator

permissions.

2. Close all programs and do not run them until the installation is

completed.

3. The software is supplied as a compressed archive. Make a local copy of

the archive on the hard disk. Then put the archive into a temporary folder

on the hard disk. Find the file named setup.exe and run it.

4. If there is an older version of the software on the machine, the software

will find it. Click Yes to update the existing version.

5. When the first window of the AADvance installer to opens, click Next.

6. Before proceeding, read the Release Notes.html file. This file is located in

the same folder as setup.exe.

7. Return to the installer window. The installer window shows the license

agreement. Accept the license agreement, click Next. The installation will

start.

8. If the installer offers you the opportunity to make a backup, click Yes.

Accept the default location for the backup files, and then wait for the

installer to make the backup. The installer displays a message showing

the location of the backup. Write down the location, then click OK.

9. If the computer has a repository of projects from AADvance release 1.x,

use a repository path which is different from the one used for AADvance

1.x.

10. Wait for the installer to finish, then click Finish.

11. The installation of the AADvance Workbench is now complete.

12. Select No, just reset settings, overwrite my current settings, click Next.

13. Select CurrentSettings.vssettings, click Finish.

Install the AADvance Workbench Software - Full Product

If you need to install the software on a computer where the software has not

been installed before, use the AADvance Workbench software full product.

Make sure that you have at least 10 GB free space on the local hard disk before

you install the software.

The full installation takes about 40 minutes on a computer having the

recommended specifications and will take a longer time (typically 3 or 4 hours)

if the machine has less than 1,024 MB RAM.

If the installation seems to have stopped (especially during the stages for

Microsoft Visual Studio), let the installer run for at least ten minutes before

investigating a possible problem.

IMPORTANT

To install the AADvance Workbench software (full product) do the following:

1. Log onto the computer using an account with administrator

permissions.

2. If you have Microsoft Visual Studio 2010 already installed on the

computer (this is likely only if you are a software developer), make sure

that it has Service Pack 1.

3. Close all programs and do not run them until the installation is

completed.

4. The software is supplied as a compressed archive and on a DVD:

You must install the Microsoft .NET Framework to use the

Workbench.

Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021 21

Page 22

Chapter 2 Software Installation and Licensing

• If the software has been supplied as a compressed archive (such as a

zip file), make a local copy of the archive on the hard disk. Then put the

archive into a temporary folder on the hard disk. Locate the file named

setup.exe and run it.

• If the software has been supplied on a DVD, place the disk into the

DVD-ROM drive and wait for the disk to Autorun. If the installer does

not start (typically because the Autorun feature has been disabled on

the computer), find the file named setup.exe on the DVD and run it.

5. Wait for the first window of the AADvance installer to open.

6. Before proceeding, read the Release Notes.html. This file is located in the

same folder as setup.exe.

7. Return to the installer window. The installer window shows the license

agreement. Accept the license agreement, click Next.

8. Accept the Complete setup type (this is the default), click Next.

9. If you are upgrading from AADvance release 1.x, use a repository path

which is different to the one used for AADvance 1.x.

10. If the Microsoft .NET Framework is not already installed on the

computer, the installer will ask for your permission to install it. Click

Install.

11. Wait for the Microsoft Visual Studio 2010 Isolated Shell English

installation to run.

12. Wait for the Microsoft Visual Studio 2010 Service Pack 1 Setup to run.

13. Wait for Help Viewer Verification process to run.

14. Wait for the installer to configure the software and do a module file

check.

15. Wait for the InstallShield Wizard Complete window to open, click

Finish.

16. The installer places a shortcut on the Windows desktop.

17. The installation of the AADvance Workbench is now complete. If the

software was supplied on a DVD, remove the DVD.

AADvance Workbench Licensing

The AADvance Workbench is licensed software. There are three types of

license: full, single controller and demo.

• The single controller license is applicable for applications which use only

one controller. The software features which add a second or subsequent

controller to the project are disabled, and you cannot open an existing

project which uses more than one controller.

• The full license supplies all of the features of the AADvance Workbench.

It is applicable for applications with one or more controllers.

• The demo license is a like a full license, but with a time limit. You can use

all of the features of the AADvance Workbench for up to 30 days after

first running the AADvance Workbench is first run.

A demo license is supplied free of charge for a first installation on a computer.

You change the demo license to a single controller license or a full license by

purchasing an unlock code from Rockwell Automation, and entering the code

into the software. When you use the demo license, the AADvance Workbench

displays a Demo License window each time you try to open a project. The

window includes the contact details at Rockwell Automation required for

purchasing a license.

If you try to use the demo license for more than 30 days, the license expires.

You cannot open a project or create a new one until you purchase a license.

22 Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021

Page 23

Chapter 2 Software Installation and Licensing

Set Up a Single User License or a Full License

Managing a Paid-for License

You have to set up a single user license or a full license if you want to use the

AADvance Workbench after the demo license expires.

To set up a single user license or a full license, do the following:

1. Click Help Licensing, a Licensing window is displayed.

2. Copy the three user codes into an email stating the type of license

necessary (this is a single user license or a full license) and send the email

to keymaster@ra.rockwell.com or keymaster@icstriplex.com.

3. Rockwell Automation will reply to the email and will send you two

registration keys.

• These registration keys are only valid for the provider user codes.

These codes might have changed since the last time they were

displayed, if they did you will need to resend the new user codes.

4. Enter the registration keys into the Licensing window, click Validate.

5. The software license can now be used.

6. Repeat this procedure on each other computer where you have installed

and want to use the AADvance Workbench.

After purchasing a paid-for license, the license persists through all Workbench

updates and uninstall/re-install operations on the same computer.

A paid-for license is specific to the computer for which it is purchased. If you

need to move the license to a different computer, or you change the hard disk

drive, contact Rockwell Automation for advice.

Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021 23

Page 24

Chapter 2 Software Installation and Licensing

Notes:

24 Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021

Page 25

Chapter 3

Connecting the AADvance Workbench to the

Controller

The AADvance® system uses Internet Protocol (IP) for communication/data

transfer between the controller and the AADvance Workbench. This chapter

describes how to connect the AADvance Workbench to the controller.

AADvance Processor Modules are mounted on a Processor Base Unit. Up to

three Processor Modules can be mounted on the Processor Base Unit as shown

below:

The Processor Base Unit connects to Input/Output (I/O) Base Units to form an

interlocking backplane. The combined Processor and I/O Module assemblies

comprise the Controller. The interlocked backplane is latched securely against

a metal DIN rail. See also, Configuring the Controller I/O

Processor Modules can be mounted in any order onto any of the slots on the

Processor Base Unit. However, for the controller to communicate with

Workbench, the correct Internet Protocol (IP) address of the occupied position

on the Processor Base Unit must be selected. For explanation, see below.

on page 109 .

Controller IP Address The AADvance controller stores its IP address data in non-volatile memory in

the 9100 processor base unit. The data is independent of the 9110 processor

modules in the controller, and so the controller keeps the address information

when you remove a processor module.

Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021 25

Page 26

Chapter 3 Connecting the AADvance Workbench to the Controller

You must set up the IP address data when you create a new system, or if you fit

a new processor base unit.

After having set up the IP address data in the controller, you can configure the

AADvance Workbench to find the controller on the network.

Allocating IP Addresses for Network Communications

For some systems, the administrator of the local area network will allocate the

IP address for the controller. If this has not occurred, use an address from the

ranges allocated to private networks:

• 10.0.0.0 to 10.255.255.255 (10/8 prefix)

• 172.16.0.0 to 172.31.255.255 (172.16/12 prefix)

• 192.168.0.0 to 192.168.255.255 (192.168/16 prefix).

Each controller on a local area network must have a unique IP address.

IMPORTANT

Make sure that the two Ethernet ports on each 9110 processor

module are on different subnets.

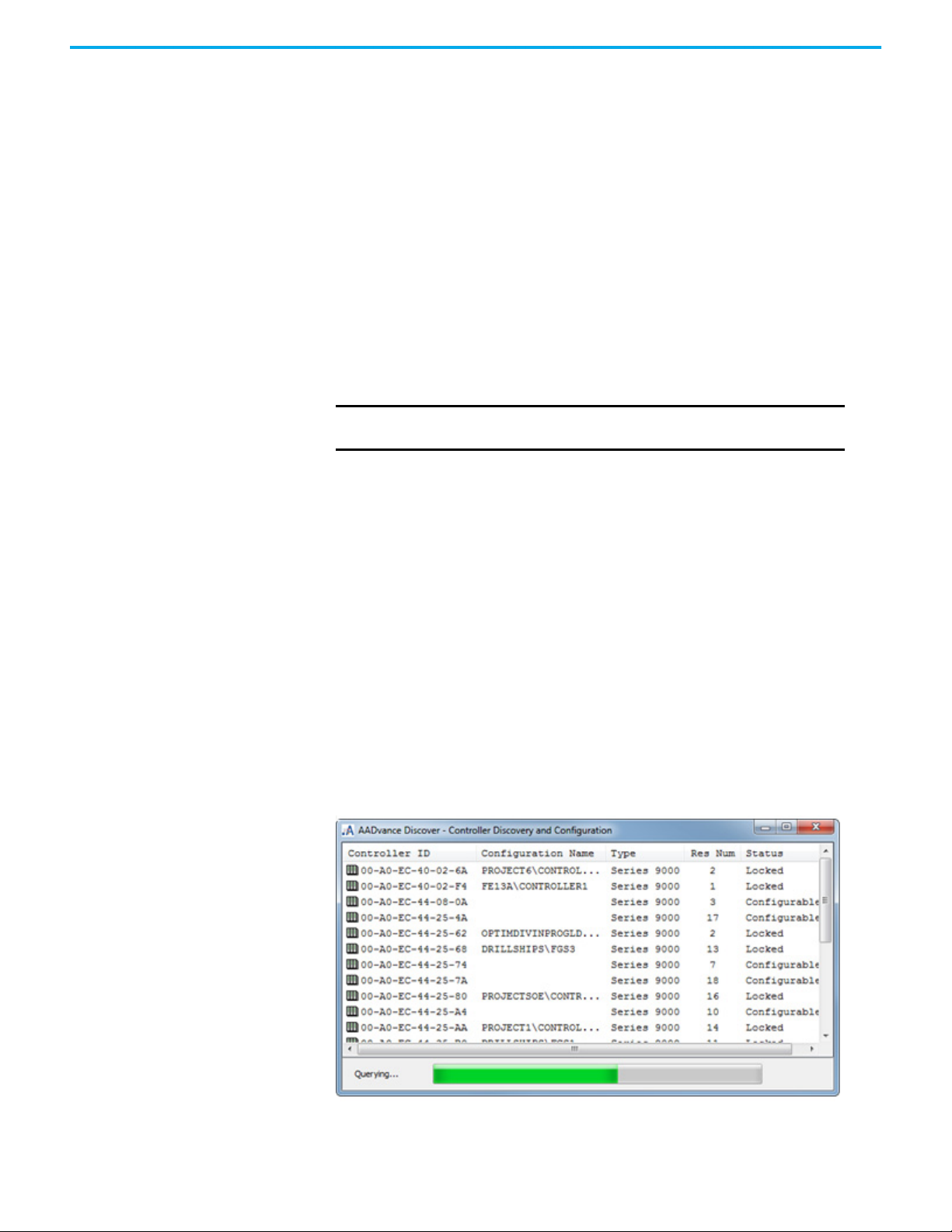

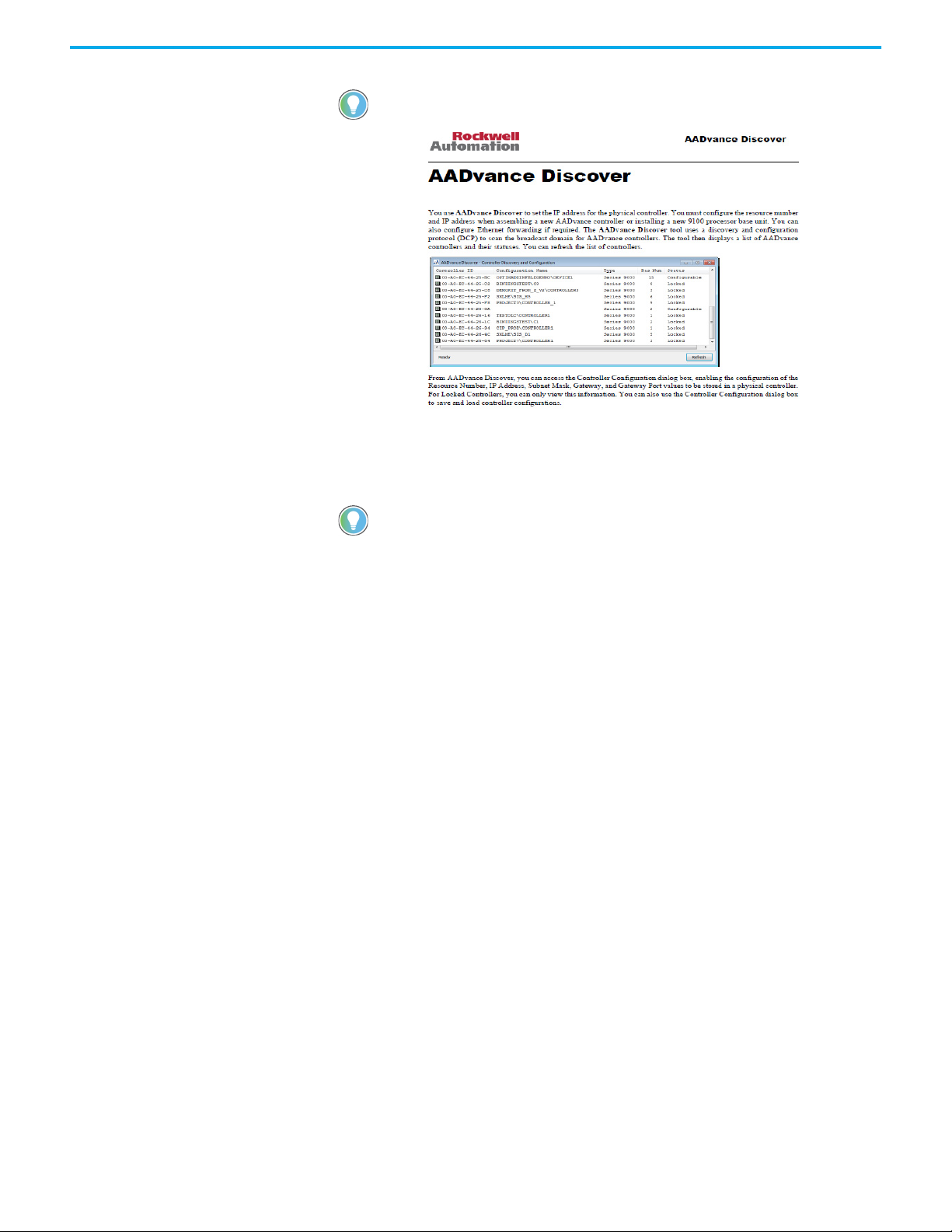

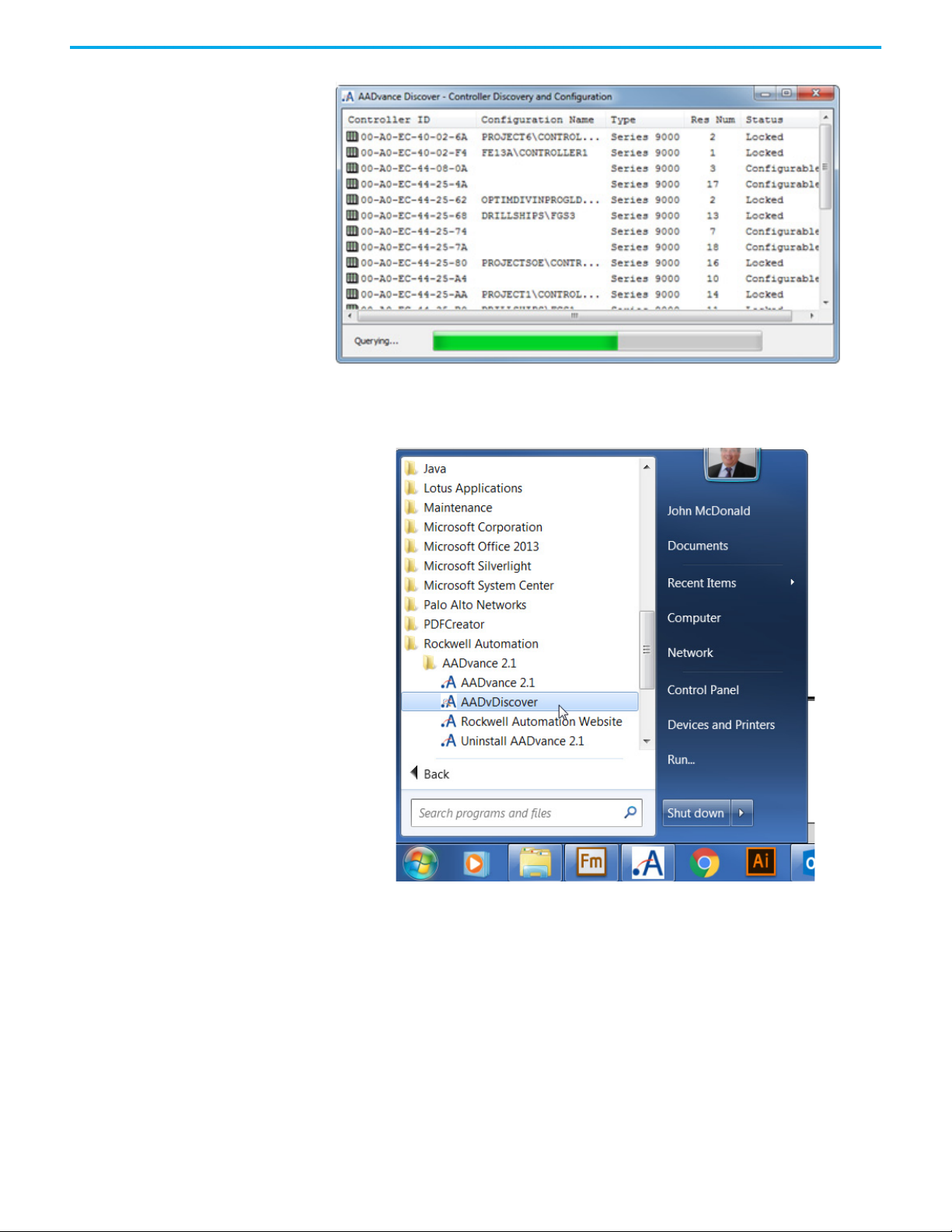

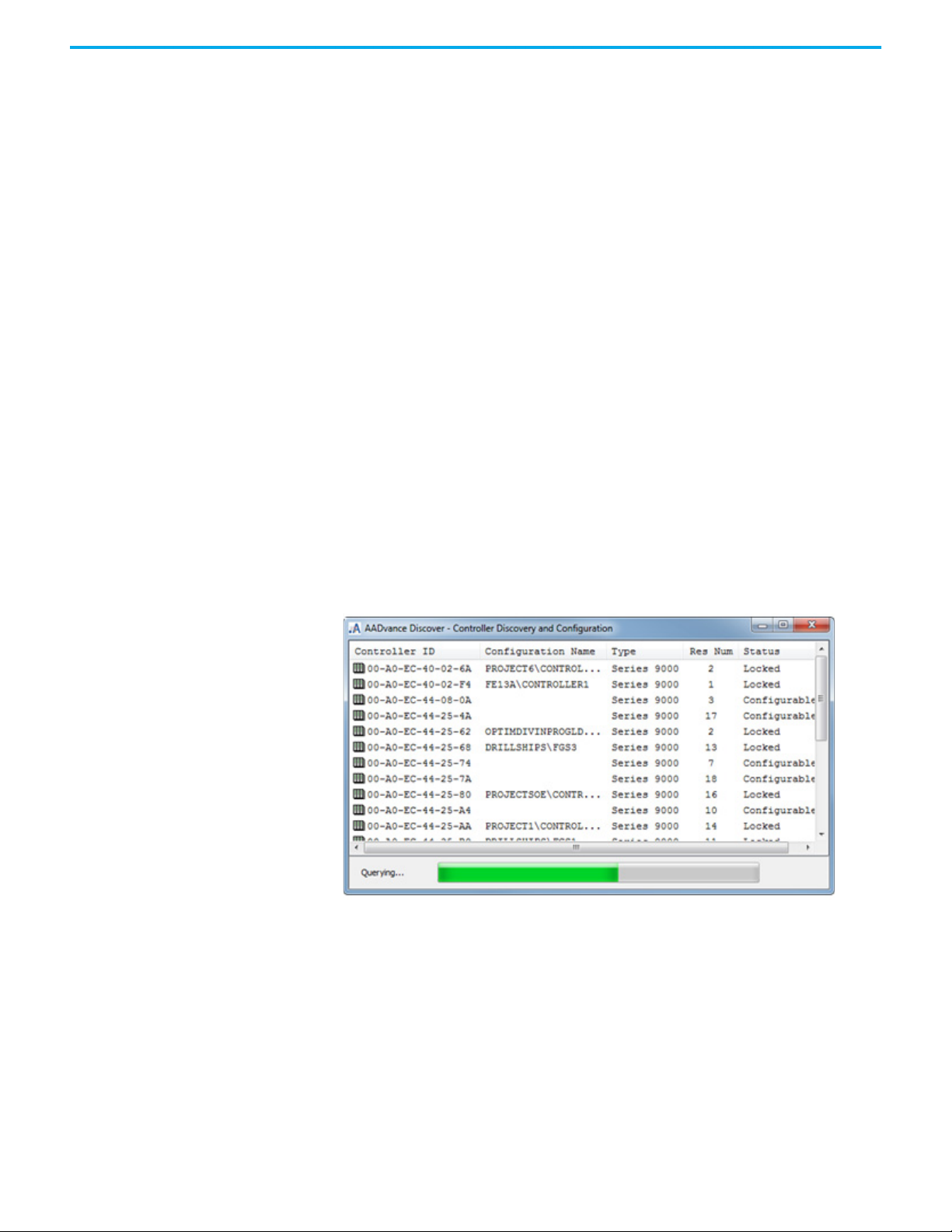

AADvance Discover Utility You use the AADvance Discover utility to set up the controller IP address. The

utility uses a discovery and configuration protocol (DCP) to perform a scan of

the broadcast domain for AADvance controllers and enables you to configure

the resource number and IP Address to be stored in a controller. You can use

the utility to save configurations and load them again in the future.

The AADvance Discover utility is part of the AADvance Workbench

installation. It appears on the drop-down list in the View menu, which is a tab

on the main menu bar.

There is also a feature on the Windows Start menu:

Click “Windows Start” “All Programs”. “Rockwell Automation”

“AADvance 2.1” “AADvDiscover” to start the utility.

The utility displays a list of the AADvance controllers on the broadcast

network, and reports a status for each one.

26 Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021

Page 27

Chapter 3 Connecting the AADvance Workbench to the Controller

If the The AADvance discover utility is selected and the [F1] key is pressed on

the keyboard a .pdf help-file is opened.

Double-clicking on an entry in the list enables examining the resource and IP

address settings for a controller. A Refresh button enables a scan of the

network and creates a new list.

If a controller known to be on the network does not show in the list, look for

communication blocking or miss-routing by Windows or by other network

devices. DCP communications will not go through network bridges and

routers.

The DCP is proprietary to Rockwell Automation. It uses the first MAC address

of the 9100 processor base unit to identify each individual controller - the MAC

address is the 'Controller ID' in the list.

The controller status will be 'No Response', 'Locked' or 'Configurable':

• 'No response' means that the controller is turned off, or the

communications between the computer running the utility and the

controller have failed.

• 'Locked' means that the utility has established communications with the

controller, but one or more of the criteria for 'Configurable' status is not

present.

• 'Configurable' means that the controller can be configured with its IP

address. The utility has established communications with the controller,

the program enable key is present (this plugs into the KEY connector on

the 9100 processor base unit) and either no application is loaded or an

application is loaded but not running.

The status must be shown as 'Configurable' before you can set the controller

configuration. If you change the configuration of a controller, click the

Refresh button to make a new list.

A status bar is displayed at the bottom of the window, below the list. This will

show the message 'Initializing' as the tool starts followed by 'Searching',

locating all the controllers connected to the network, then 'Querying' and

finally 'Ready':

• 'Querying' scans the network for controllers and creates a list

• 'Ready' means the controller status and IP addresses are displayed ready

for new settings.

Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021 27

Page 28

Chapter 3 Connecting the AADvance Workbench to the Controller

A Refresh button allows you to repeat the Querying process.

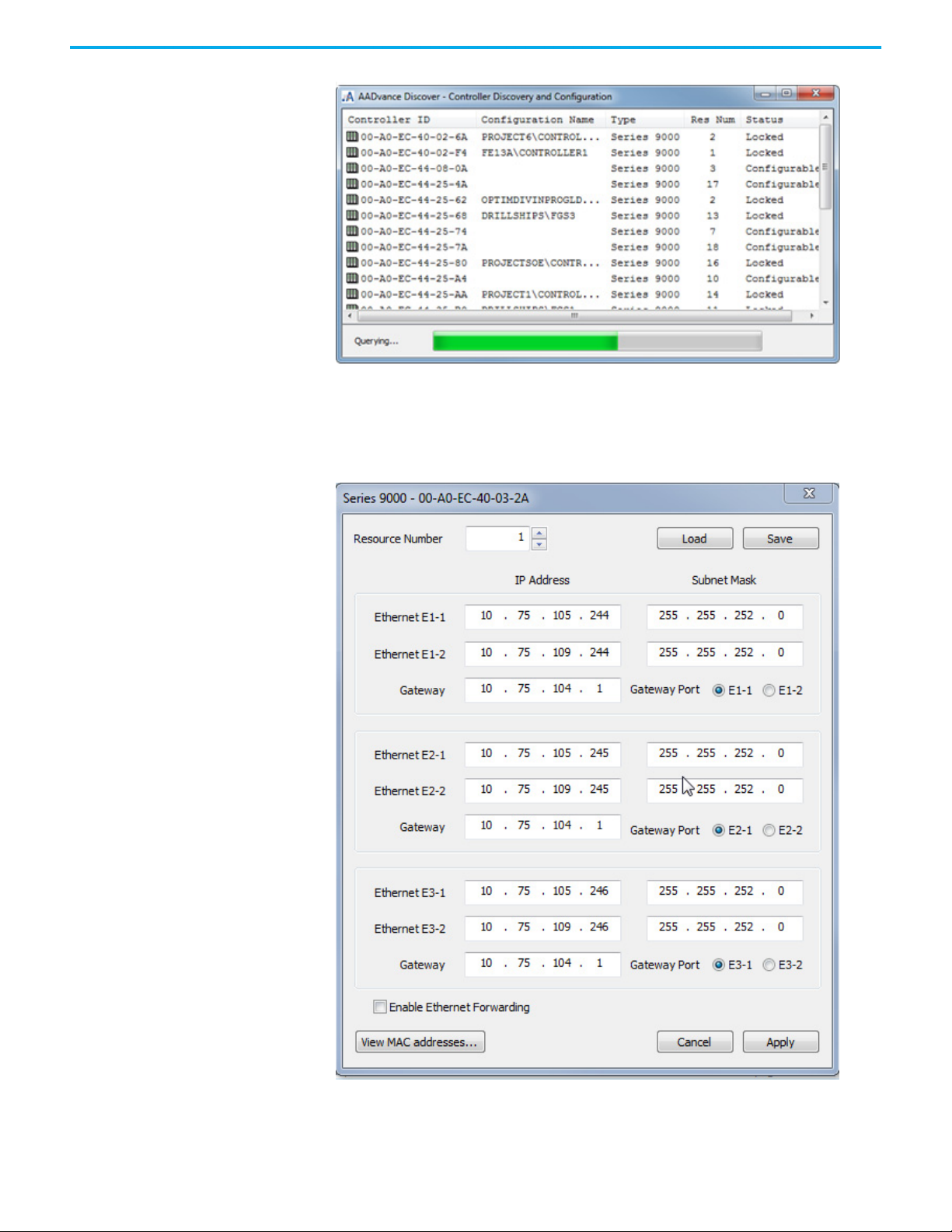

Configure the IP Address in the Controller

When you assemble a new AADvance controller, or install a new 9100

processor base unit, you have to configure the IP Address stored in the

controller.

The procedure to configure the IP Address uses the AADvance Discover utility.

Changes occur immediately and you do not have to start the controller again.

To set the IP Address do the following:

1. Write down the controller's first MAC address (the Controller ID)

displayed on a label on the processor base unit. Install at least one 9110

processor module into the processor base unit.

2. Make sure the program enable key is inserted in the KEY connector on

the processor base unit.

3. The AADvance Discover utility may be opened, either from the view tab

on the menu bar, or through the Windows Start menu.

• To start the AADvance Discover tool from the view tab on the menu bar

within Workbench 2.1:

Click View AADvance Discover as shown below.

The AADvance Discover utility scans the network for controllers, and creates a

list.

28 Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021

Page 29

Chapter 3 Connecting the AADvance Workbench to the Controller

• Alternatively start the AADvance Discover tool from the Windows

Start menu:

Start All Programs Rockwell Automation AADvance 2.1

AADvDiscover as shown below.

The AADvance Discover tool above scans the network for controllers, and

creates a list.

Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021 29

Page 30

Chapter 3 Connecting the AADvance Workbench to the Controller

4. Locate the controller in the list and make sure that the status of the

controller is Configurable.

5. Double-click on the MAC address in the Controller ID field.

• The Resource Number, IP Address and Subnet Mask dialog boxes are

displayed.

6. Enter the IP Address and Subnet Mask into the fields for each Ethernet

port.

7. Enter the Gateway values for each processor module, then click Apply.

30 Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021

Page 31

Chapter 3 Connecting the AADvance Workbench to the Controller

• Returning to the main window of the utility, the controller status will

show In Progress and then Configurable.

• The controller uses the new settings.

Configure the Controller Resource Number in the Controller

When assembling a new AADvance controller or installing a new 9100

processor base unit, the resource number stored in the controller must be

configured. The resource number is a type of device address, and it must also

be configured in the application.

The procedure to configure the resource number uses the AADvance Discover

utility. To set the resource number do the following:

1. Write down the controller's first MAC address (the Controller ID)

displayed on a label on the processor base unit. Install at least one 9110

processor module into the processor base unit.

2. Make sure the program enable key is inserted in the KEY connector on

the processor base unit.

3. Start the AADvance Discover tool:

a. Either from the view tab on the main menu bar within Workbench 2.1:

•Click View AADvance Discover

b. Or from the Start menu:

•Start All ProgramsRockwell Automation AADvance2.1

AADvDiscover.

The AADvance Discover utility scans the network for controllers and

creates a list.

4. Locate the controller in the list and make sure that the status of the

controller is Configurable.

5. Double-click the MAC address in the Controller ID field.

• The Resource Number, IP Address and Subnet Mask dialog boxes are

displayed.

Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021 31

Page 32

Chapter 3 Connecting the AADvance Workbench to the Controller

6. Enter the resource value into the Resource Number field, then click

Apply.

• Returning to the main window of the utility, the controller status will

show Pending Restart.

7. To finish the update, turn off the power to the controller.

8. Start the controller. Refresh the screen to make sure that the new

resource number is shown in the resource field and that the controller

status is configurable.

IMPORTANT

The unique number identifying a resource within a project must

also be configured in the Properties/Properties Window for the

specified controller. See Configure Controller Properties on

page 58

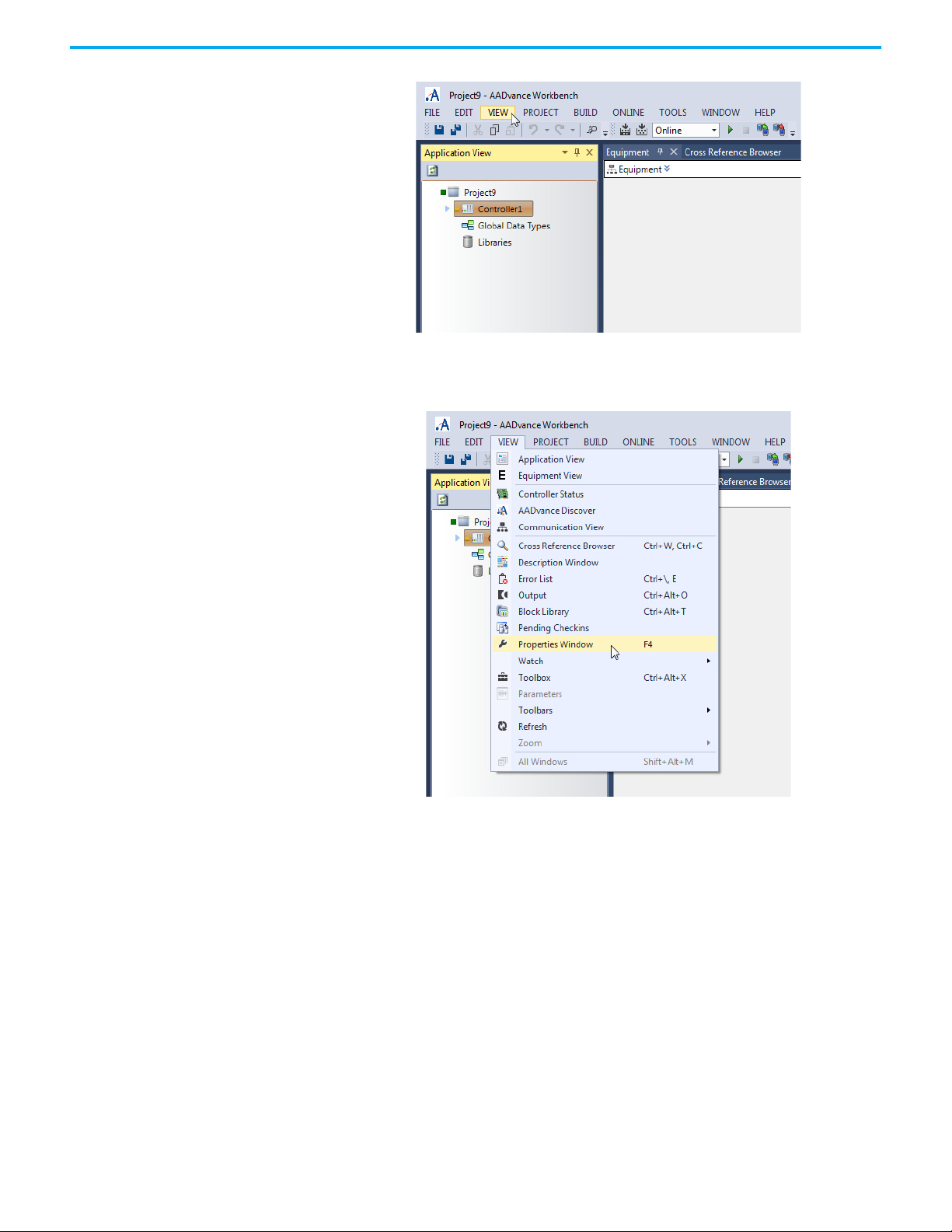

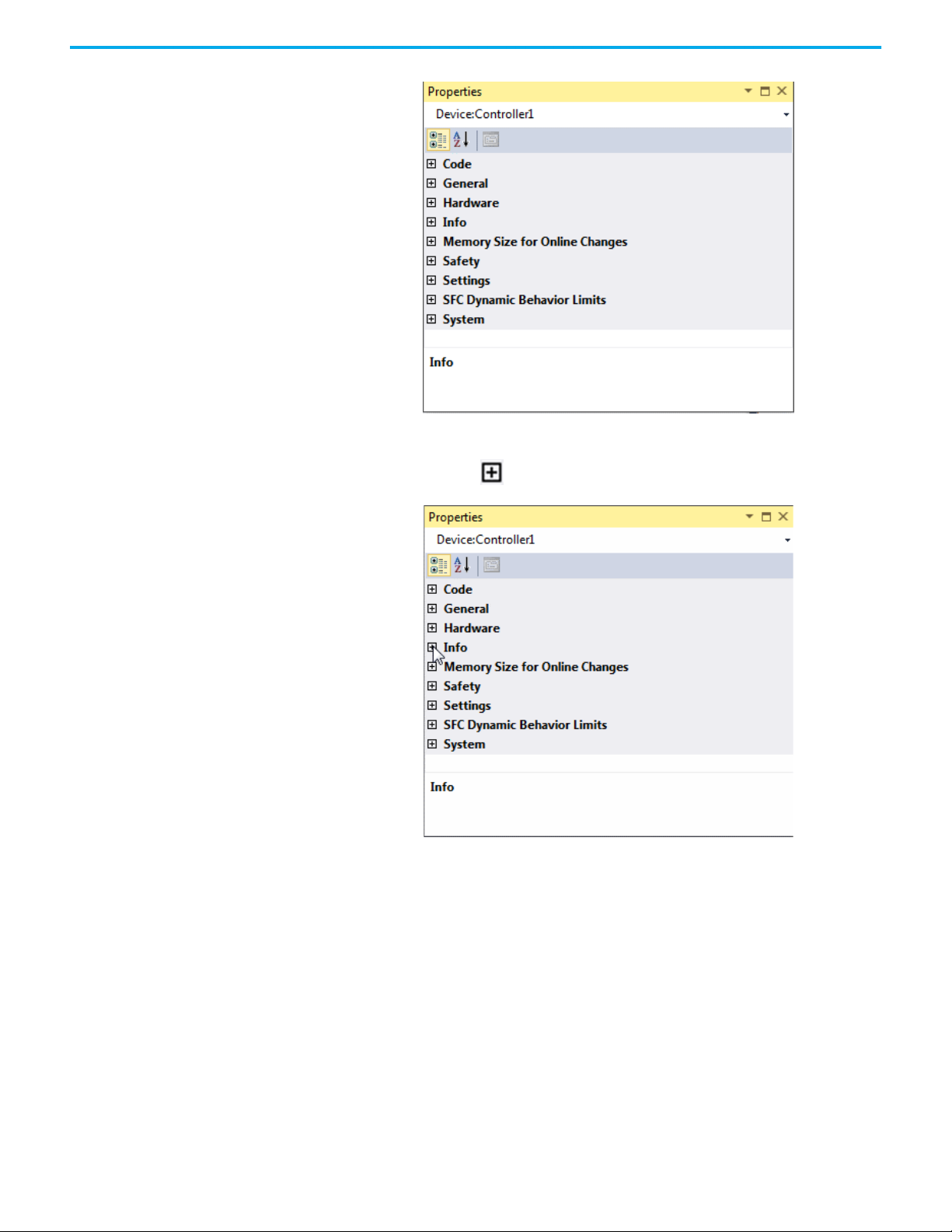

This can be seen, in the following screen-shot, as legend “Number” in the Properties box for “Device Controller1” in Application View.

32 Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021

Page 33

Chapter 3 Connecting the AADvance Workbench to the Controller

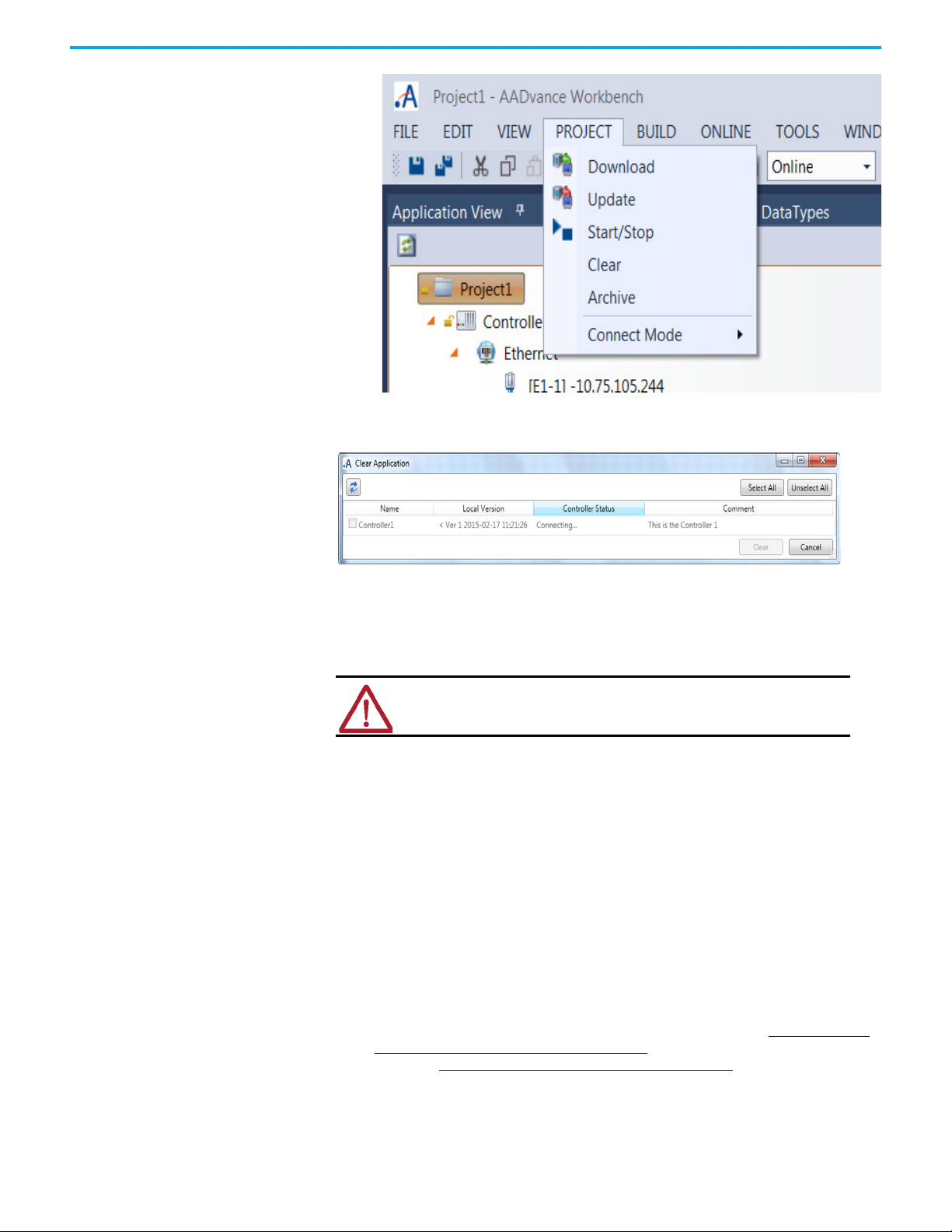

Configure the IP Address of the Target Controller

To connect the AADvance Workbench project to the target controller you have

to indicate the IP addresses allocated for the controller to the project.

1. Select the Communication View.

2. Double-click the Ethernet node. The Ethernet Ports table screen is

displayed.

3. Enter the IP Address for each port

• Where a port has been left "Not Configured" the port can be

configured individually.

4. Select the "Not Configured" port.

5. Enter the IP Address for the port.

Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021 33

Page 34

Chapter 3 Connecting the AADvance Workbench to the Controller

System Security An AADvance system, with its workstations and DCS interfaces, whether using

Ethernet networks or Serial links is likely part of a larger corporate network

which may expose the system to accidental or malicious infection, attack or

less obvious security vulnerabilities. If appropriate (or defined in the SRS), a

security risk assessment should be carried out and the appropriate level of risk

mitigation applied.

The following general security steps should be used to verify that the system is

secure:

WARNING: Network and workstation security must be set up when

installing and setting up the system. As a minimum use the following

security measures:

• The AADvance system must not be connected to a network with open

unsecured access to the Internet.

• A router firewall must be active on the Workstation, helping prevent

access to the unused Ethernet ports on each communication interface.

• Anti-virus software must be installed and be kept updated.

IMPORTANT

• If the workstation is a laptop, it must be kept locked when not in use.

• The Workbench software must be password protected. This can be done

when the Workbench is installed.

• The application must be password protected if a program enable key is

not used on the system.

Firewalls have been known to affect the operation of the

AADvance Discover utility so it may be necessary to

temporarily disable the Firewall when using this tool.

Workbench Access

Passwords are used to protect Project access and target AADvance Controller

access.

34 Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021

Page 35

Chapter 3 Connecting the AADvance Workbench to the Controller

Setting Project Access Control

For project security, access control may be set using a password for projects,

controllers, programs, libraries, and library functions and function blocks.

Password definitions are limited to eight characters and can consist of letters,

digits, and symbols. When projects are password-protected they cannot be

opened for editing. Project sub-elements, can have their own level of access

control. For example, a program having its own password remains locked and

cannot be modified without entering its password.

NOTE Because programs are encrypted, password definitions must be

retained.

In Application View, the following indicates the security state for elements:

The closed padlock indicates that a lock is applied to the element.

When opening a project having password-protected elements, the prompt to

enter the password is only offered once for each element. Password-protected

elements have the following modification restrictions:

Password-Protected Element Modification Restrictions

Project Opening the project

Controller

Program Viewing the program

Library Adding, editing and deleting a library function or function block

Library Function Viewing the function

Library Function Block Viewing the function block

Adding, editing and deleting a program, modifying the communication

protocols, modifying the system type and controller properties, wiring

variables and adding, editing and deleting input / output modules

Existing passwords may be edited for projects and project sub-elements.

Existing passwords may also be removed. When copying, pasting, importing

and exporting elements which have access control, password definitions are

retained.

Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021 35

Page 36

Chapter 3 Connecting the AADvance Workbench to the Controller

To set a password

1. In the Application View, right-click the controller instance, and then click

Set Password.

2. In the Set Password dialog box, enter the required information, then

click OK.

• In the New Password field, type the required password.

• In the Confirm Password field, re-type the required password.

To edit a password

1. In the Application View, right-click the required element, and then click

Set Password.

2. In the Change Password dialog box, enter the required information, then

click OK.

• In the Old Password field, type the current password.

• In the New Password field, type the required password.

• In the Confirm Password field, re-type the required password.

To remove a password

1. In the Application View, right-click the required element, and then click

Set Password.

2. In the Change Password dialog box, enter the required information, then

click OK.

• In the Old Password field, type the current password.

• The New Password and Confirm Password fields must remain blank.

The element is no longer password-protected.

36 Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021

Page 37

Chapter 3 Connecting the AADvance Workbench to the Controller

Setting Target Access Control

For controller security, access control may be set by defining a password for

the target AADvance controller. Password definitions are limited to eight

characters and can consist of letters, digits, and symbols. The target password

protects the following operations:

• stopping the application

• downloading the application

• updating the application

•locking variables

• modifying the value of a variable.

Existing passwords may be edited for targets. Existing passwords can also be

removed for target controllers. When setting, editing, and deleting the

password for a controller target, the attached target must be running.

To set a password for a target

1. In the Application View, right-click the controller instance, and then click

Set Target Password.

2. In the Set Password dialog box, enter the required information, then

click OK.

• In the New Password field, type the required password.

• In the Confirm Password field, re-type the required password.

To edit a password for a target

1. In the Application View, right-click the required controller, and then

click Set Target Password.

2. In the Set Password dialog box, enter the required information, then

click OK.

• In the Old Password field, type the current password.

• In the New Password field, type the required password.

• In the Confirm Password field, re-type the required password.

Rockwell Automation Publication ICSTT-RM458D-EN-P - February 2021 37

Page 38

Chapter 3 Connecting the AADvance Workbench to the Controller

To remove a password for a target

1. In the Application View, right-click the required controller, and then

click Set Target Password.

2. In the Set Password dialog box, enter the required information, then

click OK.

• In the Old Password field, type the current password.

• The New Password and Confirm Password fields must remain blank.

The target is no longer password-protected.

Threat Analysis

A system threat analysis must be performed and all high risk threats mitigated

before the system is commissioned.

Integrating the AADvance Controller with Other Systems

The AADvance controller connects to existing control systems and plant

monitoring equipment. This connection enables a third-party control system

read the state of sensors connected to the controller.