Page 1

Trusted

TM

AN-T80003

Trusted

Application Note

TM

System Mechanical Build

This application note explains the mechanical fitting of the Trusted

19” rack. This includes mounting details for:

T8100 Processor Chassis

T8300 Expander Chassis

T8270 Fan Tray Rack Mounted

T824x Power Shelves

T8292 MCB Power Distribution Unit

T8290/T8297 Output Power Distribution Unit

TM

chassis and accessories into a

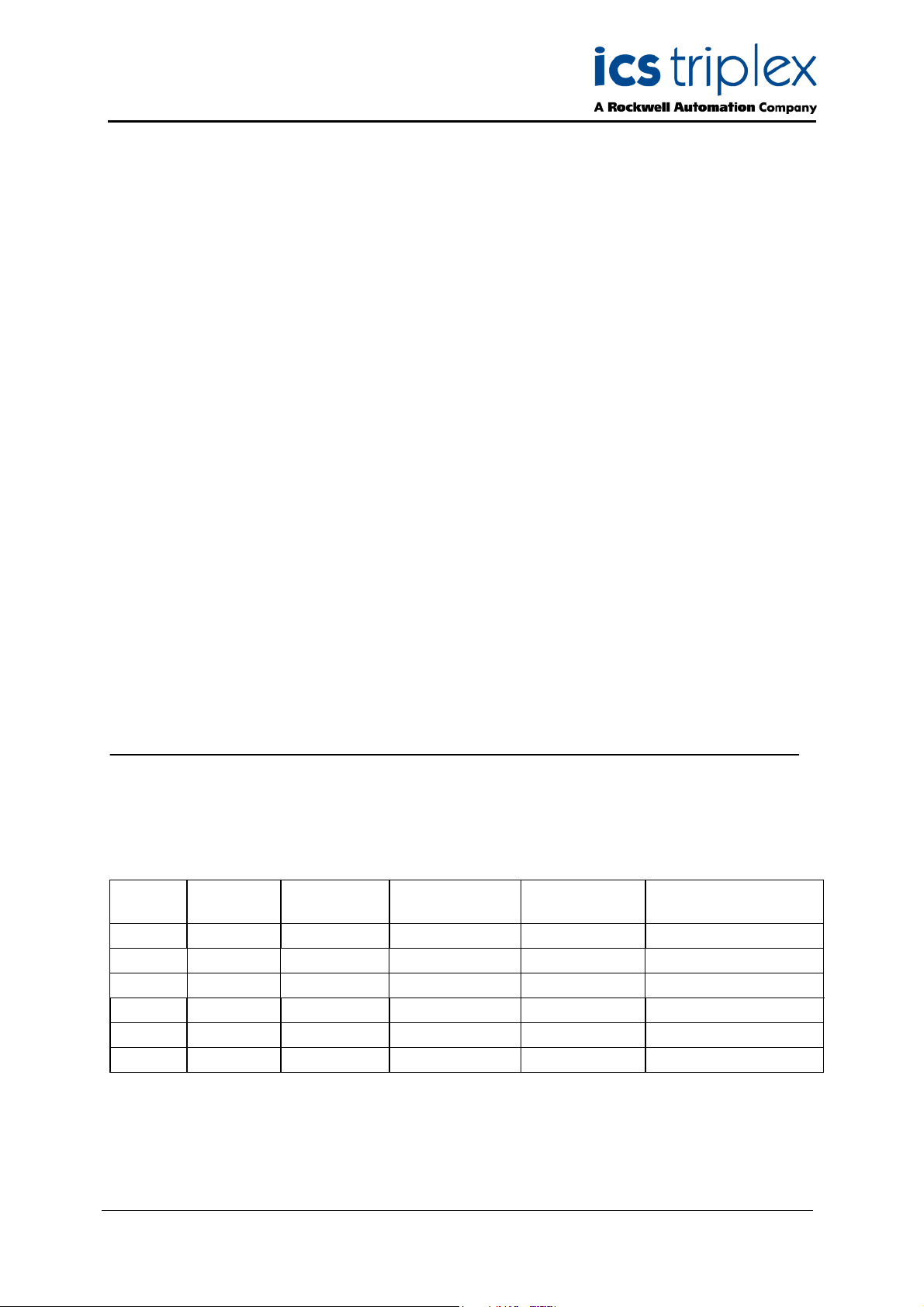

Issue Record

Issue

Number

1 Feb 07 Nick Owens Ray Brown Pete Stock Initial Issue

Issue 1 Feb 07 AN-T80003 1

Date Revised by Technical

Check

Authorised by Modification

Page 2

Trusted

TM

AN-T80003 TrustedTM System Mechanical Build

Mechanical Assembly

The following steps defines a recommended procedure for fitting TrustedTM chassis and accessories

into a 19” rack.

TM

1. Mount the Trusted

Shelves require T8247 support brackets to be fitted first and secured by fitting the first power shelf

with M5 x 12 Pan Head Taptite screws and large plain and crinkle washers through the support

brackets. The power shelf must then be secured to the support bracket using four M3 x 6 slotted

cheesehead screws or similar with a plain washer.

2. Mount the Trusted

height above and below each controller and expander chassis must be provided to allow the

installation of fan trays and vents. The chassis are secured in position using M5 x 12 Pan Head

Taptite screws and large plain and crinkle washers through the inner pair of holes on each chassis

mounting flange.

3. Mount a Trusted

ears using 4-off M5 x Pan Head 12 Taptite screws, crinkle and M5 plastic cup washers. Fan tray

units must be fitted AFTER the module chassis to avoid fouling of the chassis power connector.

Power Supply (T8240) into the swingframe as required. The T8240 Power

M

T

Controller and Expander Chassis into the swingframe as required. 2U of rack

M

T

Fan Tray Unit above each chassis. Fixings are through the fan tray grille and

4. Check the alignment of the chassis and fan tray units on the front of the swingframe.

5. Fit plastic facia ears over the mounting ears of each module chassis. Fixings are M5 x 12 Pan

Head Taptite screws and crinkle washers.

6. Fit blanking plates to mask off unused rack space.

Swingframe

1. If a swingframe is used, it is possible to fit equipment

to the side of the assembly. Fit 5-off 220mm trunking

brackets to the handle side of the swingframe.

Fixings are M5 x 8 Pan Head Taptite screws with

large plain and crinkle washers. Example 220mm and

60mm brackets are shown right.

2. Fit 80W x 60H trunking to the brackets fitted in the

above step. Fixings are M5 x 8 Pan Head Taptite

screws with large plain and crinkle washers. The rear

edge of the trunking should align with the rear edge

of the brackets.

3. Fit a busbar to the trunking brackets, for DC

distribution.

Note: The busbar should be mounted as close as

possible to the power supply that is supplying

it. The length of the busbar is determined by

the requirements of the system. This may

result in additional trunking brackets being

required.

When determining the length of busbar required, note

the following:

a For output field power, each output Versatile

Field Termination Assembly (VFTA) and each

Field Termination Assembly (FTA) will require five busbar terminations.

b PSU to busbar feeds will require three busbar terminations.

Issue 1 Feb 07 AN-T80003 2

Page 3

Trusted

TM

AN-T80003 TrustedTM System Mechanical Build

4. Fit 5-off 60mm trunking brackets to the pivot side of the swingframe. Fixings are M5 x 8 Pan Head

Taptite screws with large plain and crinkle washers.

5. Fit 60W x 40H x 1775mm long trunking to the brackets fitted above. Locate the trunking as close to

the front of the swingframe as possible. Fixings are M5 x 8 Pan Head Taptite screws with large

plain and crinkle washers. This trunking will be used for the power supply chassis incoming

feeders.

6. Fit a saddle to the rear end bracket at the required position for the power supply chassis incoming

power supply feeders ‘swing point’.

7. Fit a TS35 DIN Rail 1775mm long to the trunking brackets on the handle side of the swingframe.

Fixings are M5 x 8 Pan Head Taptite screws with large plain and crinkle washers.

8. Check that the ‘Top Hat’ bracket on the rear of the controller and expander chassis are fitted to the

pivot side of the swingframe.

9. Fit saddles to each of the ‘Top Hat’ brackets on the rear of the controller and expander chassis.

These are ‘swing points’ to carry I/O cables etc. from each chassis to the back of panel ‘swing

points’.

Output Power Distribution

The following procedures must be implemented where the controller or expander chassis contain

Trusted

Fit Trusted

T8292) as required to the TS35 DIN Rail fitted to the handle

side of the swingframe and retain in position with 2-off end stops. Note that the units should be

positioned as close as possible to the PSU.

TM

Output modules:

a Fit 2-off chassis trunking brackets to the fixing points

on the rear of the chassis. Fixings are M5 x 6 CSK

screws. Use only one screw per bracket. An example

trunking bracket is shown right. These allow trunking

to be mounted above the chassis, with clearance

away from the fan tray.

b Fit a TS35 DIN Rail 440mm long to the brackets on

the rear of the chassis using the second chassis

mounting points. Fixings are M5 x 8 Pan Head

Taptite screws with large plain and crinkle washers.

c Fit 40W x 40H x 385mm long trunking to the brackets

fitted in a. above, using any of the three holes on the

top of each bracket. The trunking should be mounted

such that it is in line with the rear end of the chassis

on the pivot side of the swingframe. Fixings are M5 x

8 Pan Head Taptite screws with large plain and

crinkle washers.

d Fit Output Distribution Units on the TS35 DIN Rail as

required, and retain in position with 2-off end stops.

The units must be fitted with insulated covers if the

voltage exceeds 24V dc.

TM

Power Distribution Unit(s) MCB 24V dc (Part No.

Issue 1 Feb 07 AN-T80003 3

Page 4

Trusted

TM

AN-T80003 TrustedTM System Mechanical Build

Completed Assembly

The picture below shows a part assembled swingframe with three system chassis, three fan trays,

trunking and rails fitted to brackets, MCBs for power distribution and T8290 power distribution units.

Issue 1 Feb 07 AN-T80003 4

Page 5

Trusted

TM

AN-T80003 TrustedTM System Mechanical Build

I/O Connectors

The I/O connectors to the chassis backplane are DIN 41612 type connectors, and are mounted in

ither a single or a double connector hood. The double connector hood enables Trusted

e

Interfaces (of the same type) to be installed in a Companion Slot configuration in adjacent slots.

To install an I/O connector in the chassis backplane:

1. Ensure the correct connector and chassis backplane slot are selected

2. Ensure the associated chassis slot is not occupied by a module

3. Present the I/O connector to the chassis backplane slot, taking care to align the four lugs of the

connector with the four cut-outs of the slot

4. Push the I/O connector in and upwards into the slot until the I/O connector latch engages with the

chassis slot backplane-lip

5. Ensure that the I/O connector is secure in its chassis slot

Connection at the other end of the cable may be via a similar connection or via a flying lead – see the

appropriate Product Descriptions for full details of I/O cable types.

M

T

/O

I

Module Installation

Before initial module installation, ensure that the supply voltage levels have been checked and are

within tolerance, and that the I/O connector and hood are correctly latched in place. Ensure that an

anti-static wrist strap is worn and that it is suitably earthed.

To install the module:

1. Insert the release key to disengage the ejector levers.

2. Move the upper and lower ejector levers in an upward and downward direction respectively to

disengage the levers.

3. Holding the ejector levers, carefully insert the module into its chassis slot (the modules are selfaligning);

4. Push the module fully home;

5. Press the ejector levers to the housed position until they click onto the ejector lever retaining clip,

This ensures that the module is correctly secured.

Trusted

Trusted

chassis where module slots are unoccupied.

All unoccupied module slots MUST be fitted with Trusted

1. T8191 – Single-width slots.

2. T8193 – Triple-width slots.

TM

Shields

TM

Shields are fitted with baffle plates designed to assist and direct the flow of air through the

TM

Shields detailed as follows:

Issue 1 Feb 07 AN-T80003 5

Page 6

ICS Triplex technologies and services are available worldwide.

Regional Headquarters:

Americas:

4325 West Sam Houston

arkway North, Suite 100

P

Houston

Texas 77043-1219

USA

Tel: +1 713 353 2400

Fax: +1 713 353 2401

Europe, ME & Africa:

Hall Road

Maldon Essex

CM9 4LA

UK

Tel: +44 1621 854444

Fax: +44 1621 851531

Asia Pacific:

Unit 2/12 Keegan Street

O’Connor

Western Australia

Tel: +61 89 314 7787

Fax: +61 89 314 7786

www.icstriplex.com

For technical support email: support@icstriplex.com

Sales enquiries: sales@icstriplex.com

Technology Driven Customer Led

Loading...

Loading...