Page 1

TrustedTM

PD-T8842

TM

Trusted

Versatile FTA

Introduction

The TrustedTM Versatile Field Termination Assembly (VFTA) T8842 is primarily designed to act as the

main interface between field devices associated with the detection and suppression of fire and gas

hazards, and the TrustedTM TMR Zone Interface Module T8448. It is also used as the interface for the

TrustedTM TMR Valve Monitor Module T8449, for which digital outputs to solenoid valves alternate with

valve position analogue inputs.

Each channel of the VFTA is configurable to enable a variety of field devices to be connected. These

include devices generating both analogue and digital input signals, and output devices requiring a

digital signal at up to 28V dc.

Features

40 channels per VFTA each configurable as inputs or outputs.

Industrial standard field device connections (2 or 3 wire).

Standard DIN rail compatibility.

Simple installation and connection.

Simple configuration using plug-in fuses and built-in resistors.

18-28Vdc operation.

Field power supply arranged in five groups of eight channels.

Option to supply power from a controllable output for each group.

Fused field power supply per channel.

Issue 8 Aug 12 PD-T8842 1

Page 2

Trusted

Issue Record

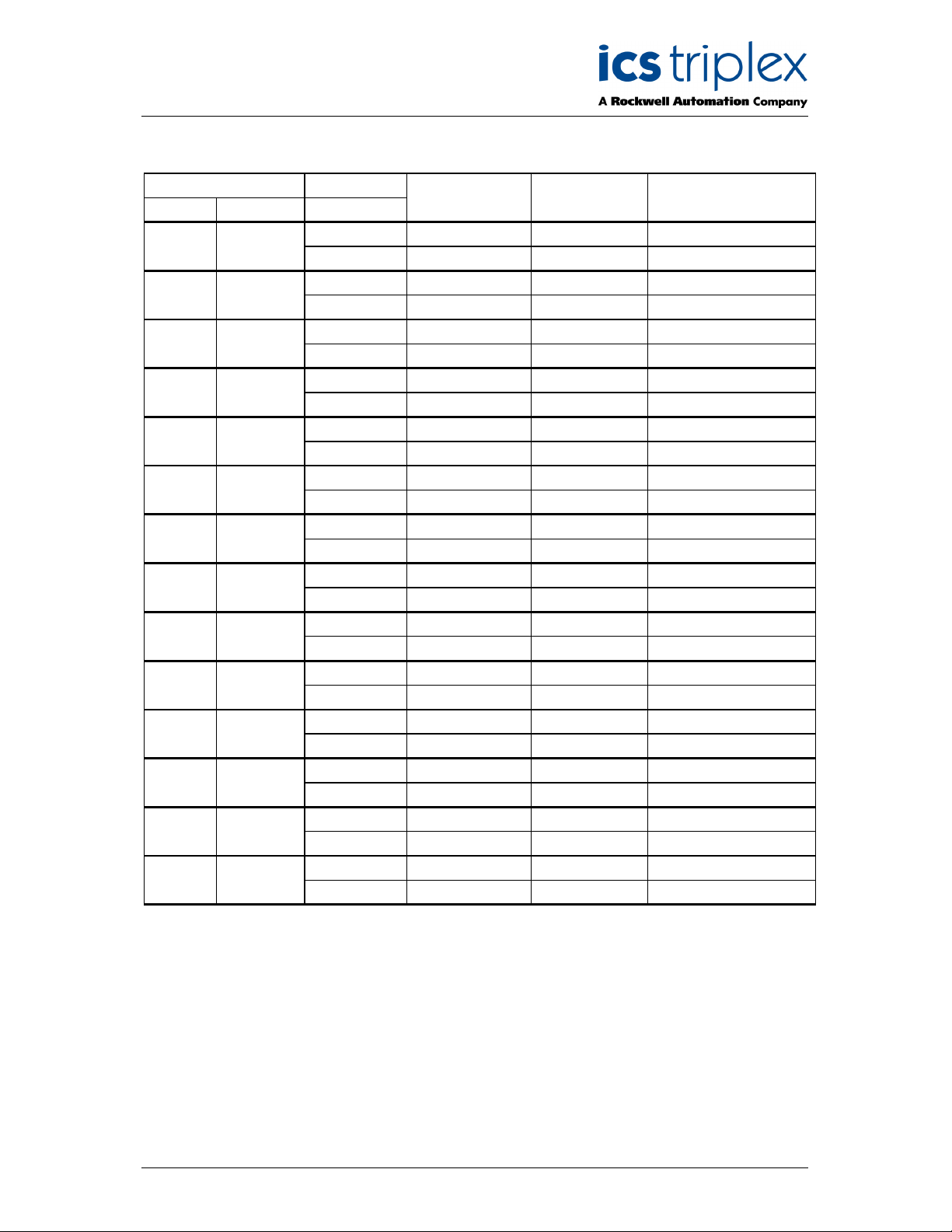

Issue

Number Date Revised by Technical Check Authorised by Modification

5 Sep 05 J W Clark Format

6 Aug 06 N Owens I Vince P Stock Corrections

7 Sep 07 N Owens I Vince P Stock Fire input advice

8 Aug 12 N Owens Correction to fig10;

switches reversed

TM

Versatile FTA T8842

Issue 8 Aug 12 PD-T8842 2

Page 3

Trusted

TM

Versatile FTA T8842

Figure 1 T8842 Layout

Issue 8 Aug 12 PD-T8842 3

Page 4

Trusted

TM

Versatile FTA T8842

Table of Contents

1. Description ................................................................................................................................... 8

1.1. Digital Inputs (Powered) ............................................................................................................. 10

1.2. Digital Inputs (Line Monitored) ................................................................................................... 11

1.3. Digital Output ............................................................................................................................. 12

1.4. Analogue inputs (4-20mA) ......................................................................................................... 13

1.5. Fire Input Loops ......................................................................................................................... 14

1.6. Monitored Valve Outputs ........................................................................................................... 15

2. Installation .................................................................................................................................. 16

3. Associated Cable Selection ....................................................................................................... 16

4. Assembly Pinout Connections ................................................................................................... 16

4.1. TBFP1 to TBFP5 Connections .................................................................................................. 17

4.2. TBG1 Connections .................................................................................................................... 17

4.3. TBG2 Connections .................................................................................................................... 18

4.4. TBG3 Connections .................................................................................................................... 18

4.5. TBG4 Connections .................................................................................................................... 19

4.6. TBG5 Connections .................................................................................................................... 19

4.7. TBSS Connections..................................................................................................................... 20

4.8. TB1 to TB40 Connections .......................................................................................................... 20

4.9. Links........................................................................................................................................... 21

5. Specifications ............................................................................................................................. 22

Issue 8 Aug 12 PD-T8842 4

Page 5

Trusted

TM

Versatile FTA T8842

Figures

Figure 1 T8842 Layout .............................................................................................................................. 3

Figure 2 Layout for single channel showing all components .................................................................... 8

Figure 3 Power Group Configuration ........................................................................................................ 9

Figure 4 Digital Inputs (with power) ........................................................................................................ 10

Figure 5 Digital Inputs (Line Monitored without power) .......................................................................... 11

Figure 6 Digital Outputs .......................................................................................................................... 12

Figure 7 Current Sourcing Analogue Inputs ........................................................................................... 13

Figure 8 Fire Inputs ................................................................................................................................. 14

Figure 9 Position Limit Switches and circuit ........................................................................................... 15

Figure 10 Voltage Input with Limit Switch Position ................................................................................. 15

Figure 11 Connector Locations............................................................................................................... 16

Figure 12 Link Detail (for first group) ...................................................................................................... 21

Figure 13 Resistor Forming .................................................................................................................... 21

Tables

Table 1 TBFP1 to TBFP5 Connections .................................................................................................. 17

Table 2 TBG1 Connections .................................................................................................................... 17

Table 3 TBG2 Connections .................................................................................................................... 18

Table 4 TBG3 Connections .................................................................................................................... 18

Table 5 TBG4 Connections .................................................................................................................... 19

Table 6 TBG5 Connections .................................................................................................................... 19

Table 7 TBSS Connections .................................................................................................................... 20

Table 8 TB1 to TB40 Connections ......................................................................................................... 20

Issue 8 Aug 12 PD-T8842 5

Page 6

Trusted

TM

Versatile FTA T8842

Notice

The content of this document is confidential to ICS Triplex Technology Ltd. companies and their

partners. It may not be given away, lent, resold, hired out or made available to a third party for any

purpose without the written consent of ICS Triplex Technology Ltd.

This document contains proprietary information that is protected by copyright. All rights are reserved.

Microsoft, Windows, Windows 95, Windows NT, Windows 2000, and Windows XP are registered

trademarks of Microsoft Corporation.

The information contained in this document is subject to change without notice. The reader should, in

all cases, consult ICS Triplex Technology Ltd. to determine whether any such changes have been

made. From time to time, amendments to this document will be made as necessary and will be

distributed by ICS Triplex Technology Ltd.

Information in this documentation set may be subject to change without notice and does not represent

a commitment on the part of ICS Triplex Technology Ltd.

The contents of this document, which may also include the loan of software tools, are subject to the

confidentiality and other clause(s) within the Integrator Agreement and Software License Agreement.

No part of this documentation may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and recording, for any purpose, without the express

written permission of ICS Triplex Technology Ltd.

Disclaimer

The illustrations, figures, charts, and layout examples in this manual are intended solely to illustrate the

text of this manual.

The user of, and those responsible for applying this equipment, must satisfy themselves as to the

acceptability of each application and use of this equipment.

This document is based on information available at the time of its publication. While efforts have been

made to be accurate, the information contained herein does not purport to cover all details or variations

in hardware or software, nor to provide for every possible contingency in connection with installation,

operation, or maintenance. Features may be described herein which are present in all hardware or

software systems. ICS Triplex Technology Ltd. assumes no obligation of notice to holders of this

document with respect to changes subsequently made.

ICS Triplex Technology Ltd. makes no representation or warranty, expressed, implied, or statutory with

respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness of

the information contained herein. No warranties of merchantability or fitness for purpose shall apply.

Issue 8 Aug 12 PD-T8842 6

Page 7

Trusted

TM

Versatile FTA T8842

Revision and Updating Policy

All new and revised information pertinent to this document shall be issued by ICS Triplex Technology

Ltd. and shall be incorporated into this document in accordance with the enclosed instructions. The

change is to be recorded on the Amendment Record of this document.

Precautionary Information

WARNING

Warning notices call attention to the use of materials, processes, methods, procedures or limits which

must be followed precisely to avoid personal injury or death.

CAUTION

Caution notices call attention to methods and procedures which must be followed to avoid damage to

the equipment.

Notes:

Notes highlight procedures and contain information to assist the user in the understanding of the

information contained in this document

Warning

RADIO FREQUENCY INTERFERENCE

Most electronic equipment is influenced by Radio Frequency Interference (RFI). Caution should be

exercised with regard to the use of portable communications equipment around such equipment.

Signs should be posted in the vicinity of the equipment cautioning against the use of portable

communications equipment.

MAINTENANCE

Maintenance must be performed only by qualified personnel, otherwise personal injury or death, or

damage to the system may be caused.

Caution

HANDLING

Under no circumstances should the module housing be removed.

Associated Documents

Product Descriptions (PD) provide product specific information.

The Safety Manual contains the recommended safety requirements for the safety system design.

The PD8082B – Toolset Suite provides specific guidance on system configuration and application

generation.

The Operator and Maintenance Manual contains general guidelines on maintenance and diagnostic

procedures.

For technical support email: support@icstriplex.com

Issue 8 Aug 12 PD-T8842 7

Page 8

Trusted

Fuse Field Power

1

TM

Versatile FTA T8842

1. Description

The TrustedTM Versatile FTA T8842 provides termination for a maximum of 40 input or output channels

from various types of field devices. The input signals may be analogue (0-20mA) or digital, whilst

output signals are digital only with the T8448 Zone Interface Module. However, the Versatile FTA

T8842 may be used with the T8480 Analogue Output module using the Digital Output configuration

shown in this document.

The 40 channels are arranged in five power groups each comprising eight channels. Each channel

circuit includes two resistors.

High power 250R 7W 1% resistors to limit short circuit current

Precision 250R 0.25W 0.1% resistors to measure analogue field current

Each circuit contains a set of link positions and can be configured with the following components

supplied with the VFTA to enable the user to set the channel for the required input or output

configuration.

50mA plug-in TE5 series fuses to protect analogue current inputs

315mA plug-in TE5 series fuses to protect digital inputs

2A plug-in TE5 series fuses to protect digital outputs or act as low resistance links

The first channel of each power group may be configured as a power source for the other seven

channels of the group, to allow fire loops to be hard reset by the application.

The cable linking the 40 channels on the TrustedTM Module to the VFTA is terminated at five 10-way

connectors (TBG1 to TBG5). The dual 24Vdc power supplies are connected to the VFTA via five 4-way

connectors (TBFP1 to TBFP5). Forty 3-way connectors are used for the field loops (TB1 to TB40).

Field

Power

TBFPn

Channel 1

Signal

TBGn

B

2

3

4

2

F

E

0V

D

C

Precision Resistor

Power Resistor

A

Signal

0V

1

Field

2

Terminals

TBn

3

m

Figure 2 Layout for single channel showing all components

Issue 8 Aug 12 PD-T8842 8

Page 9

Trusted

TM

Versatile FTA T8842

Figure 3 Power Group Configuration

The diagram above shows the full wiring for one power group of eight channels. This circuit is repeated

for each of the five power groups.

In the diagram, odd-numbered resistors are precision 250 ohms and even numbered resistors are

power 250 ohms. Links E and F cannot be fitted simultaneously, and links C and D cannot be fitted

simultaneously.

Note that 24V field power is required for a Zone Interface Module even if all channels are configured as

volt-free inputs. This may be connected via the plug at the chassis end of the cable to a T8290 or

T8297 distribution unit (for cables without power wires) or at the VFTA (for integral power cables).

Each power group is supplied from dual 24Vdc feeds which are ‘commoned’ via diodes on the VFTA.

The supply is then fed to each channel within the group. The feeds are rated at 3 amps maximum and

are designed for input circuit power.

The following sub-paragraphs detail each type of input or output configuration.

Issue 8 Aug 12 PD-T8842 9

Page 10

Trusted

Fuse Field Power

1

TM

Versatile FTA T8842

Digital Inputs (Powered)

Figure 4 shows a channel configured to accept digital input signals from the field from devices which

require power from the loop, e.g. fire input devices.

Field

Power

TBFPn

Channel 1

Signal

TBGn

B

Precision Resistor

Power Resistor

0V

F

E

2A

D

C

2

3

4

2

A

315 mA

Signal

m

0V

1

Field

2

Terminals

TBn

3

Figure 4 Digital Inputs (with power)

The configuration shown above enables powered digital input devices to be interfaced to the TrustedTM

TMR Zone Interface module. The channel is configured by fitting a 315mA fuse in position A, which

provides circuit protection. Power for the field loop is derived from the dual 24Vdc source via the 2A

fuse in position D, which acts as a link. The 250R resistor (7W 1%) allows the field device status to be

monitored via the resistor voltage drop. It also acts as a field current limiter (96mA at 24V). The

voltage at the field side of the resistor is detected by the module and used to determine the

healthy/alarm state from the field device.

For inputs which directly short the input or apply a fixed voltage (e.g. zener diode line monitoring), to a

Zone Interface or Valve Monitor module, a 1k 0.6W resistor is required in position A. This is because

the module requires an impedance to allow internal testing. Note that this will change the voltages seen

by the module.

Issue 8 Aug 12 PD-T8842 10

Page 11

Trusted

Fuse Field Power

1

TM

Versatile FTA T8842

Digital Inputs (Line Monitored)

Figure 5 shows a channel configured to accept line monitored digital input signals.

315 mA

B

Field

Power

TBFPn

2

3

4

F

E

0V

D

Precision Resistor

Power Resistor

A

Signal

2A

0V

1

Field

2

Terminals

TBn

3

Channel 1

Signal

TBGn

2

m

C

Figure 5 Digital Inputs (Line Monitored without power)

The configuration shown above enables line monitored digital input devices to be interfaced to the

TrustedTM TMR Zone Interface module (or a TMR Digital Input module). The channel is configured by

fitting a 315mA fuse in position B, which provides circuit protection. Power for the field loop is derived

from the dual 24Vdc source. The input signal is returned via a 2A fuse in position A, which acts as a

link.

For inputs without line monitoring components or using zener diodes, to a Zone Interface or Valve

Monitor module, a 1K 0.6W resistor is required in position A. This is because the module requires an

impedance to allow internal testing. Note that this will change the voltages seen by the module.

Issue 8 Aug 12 PD-T8842 11

Page 12

Trusted

Fuse Field Power

1

TM

Versatile FTA T8842

Digital Output

Figure 6 shows the configuration required to provide digital outputs to the field.

Field

Power

TBFPn

Channel 1

Signal

TBGn

B

2

3

4

2

m

F

E

0V

D

C

Precision Resistor

Power Resistor

A

Signal

2A

0V

1

Field

2

Terminals

TBn

3

Figure 6 Digital Outputs

Powered digital outputs to the field may be provided by fitting a 2A fuse in fuse position A, acting as

circuit protection. Note: The maximum output power from any single power group (8 outputs) is 8

Amps.

Issue 8 Aug 12 PD-T8842 12

Page 13

Trusted

Fuse Field Power

1

TM

Versatile FTA T8842

Analogue inputs (4-20mA)

Figure 7 below shows the configurations required to accept input signals from current sourcing

analogue field devices.

315 mA

Field

Power

TBFPn

B

Precision Resistor

Power Resistor

0V

F

E

2A

D

2

3

4

A

50 mA

Signal

0V

1

Field

2

Terminals

TBn

3

Channel 1

Signal

TBGn

2

m

C

Figure 7 Current Sourcing Analogue Inputs

The (optional) field power for each channel configured for analogue inputs is derived from the dual

24Vdc supplies via a 315mA fuse fitted in fuse position B, which provides circuit protection.

Current sourcing analogue field devices may be interfaced to the VFTA by fitting a 2A fuse in fuse

position E, which acts as a link, and a 50mA fuse in fuse position A, for circuit protection. This enables

current detection through the 250R resistor (high precision 0.1%). The fuse in fuse position A limits the

signal current to 50mA.

Current sinking analogue field devices may only be interfaced to the VFTA using a current mirror

interface. This interface may also include I.S. protection, e.g. MTL5040.

Issue 8 Aug 12 PD-T8842 13

Page 14

Trusted

Fuse Field Power

1

TM

Versatile FTA T8842

Fire Input Loops

Figure 8 below shows the configuration required to accept input signals from fire input loops. This

configuration may be used for both I.S. and non-I.S. applications.

Field

Power

TBFPn

Channel 1

Signal

TBGn

B

2

3

4

2

F

E

0V

D

C

2A

Precision Resistor

Power Resistor

A

315 mA

Signal

m

0V

1

Field

2

Terminals

TBn

3

Figure 8 Fire Inputs

Latching fire detectors are reset by the removal of field power. Using this Fire Input configuration, fire

loops can have their field power supplied from the TrustedTM module, using the first channel of a power

group as a power supply, configured as a digital output. This provides control of the field loop from the

application with no added components. The first channel must be wired as shown in Figure 6.

The supply voltage to the field loop is derived from the first channel in each power group and fed via

the 2A fuse located in fuse position C, which acts as a link. Position C is commoned to the remaining

7 channels in the associated power group. Each channel in the power group with a fire input loop

connected requires a 315mA fuse fitted in fuse position A, which provides circuit protection, and a 2A

fuse in position C, to connect to the switched field power. The 250R resistor (7W 1%) allows the field

device status to be monitored via the resistor voltage drop. It also acts as a field current limiter. The

voltage at the field side of the resistor is detected by the module and used to determine the

healthy/alarm state from the field device.

The maximum switched field supply current is 2 amps in each power group, distributed across

channels 2 to 8. The maximum loop current per channel is 96mA at 24V.

Note that the power supply channel 1 needs to be connected to a load of at least 50mA to protect the

output from no-load shutdown.

For inputs without line monitoring components or using zener diodes, to a Zone Interface or Valve

Monitor module, a 1K 0.6W resistor is required between the Signal connection and the module (in

series with the I/O cable). This is because the module requires an impedance to allow internal testing.

Note that this will change the voltages seen by the module.

Issue 8 Aug 12 PD-T8842 14

Page 15

Trusted

TM

Versatile FTA T8842

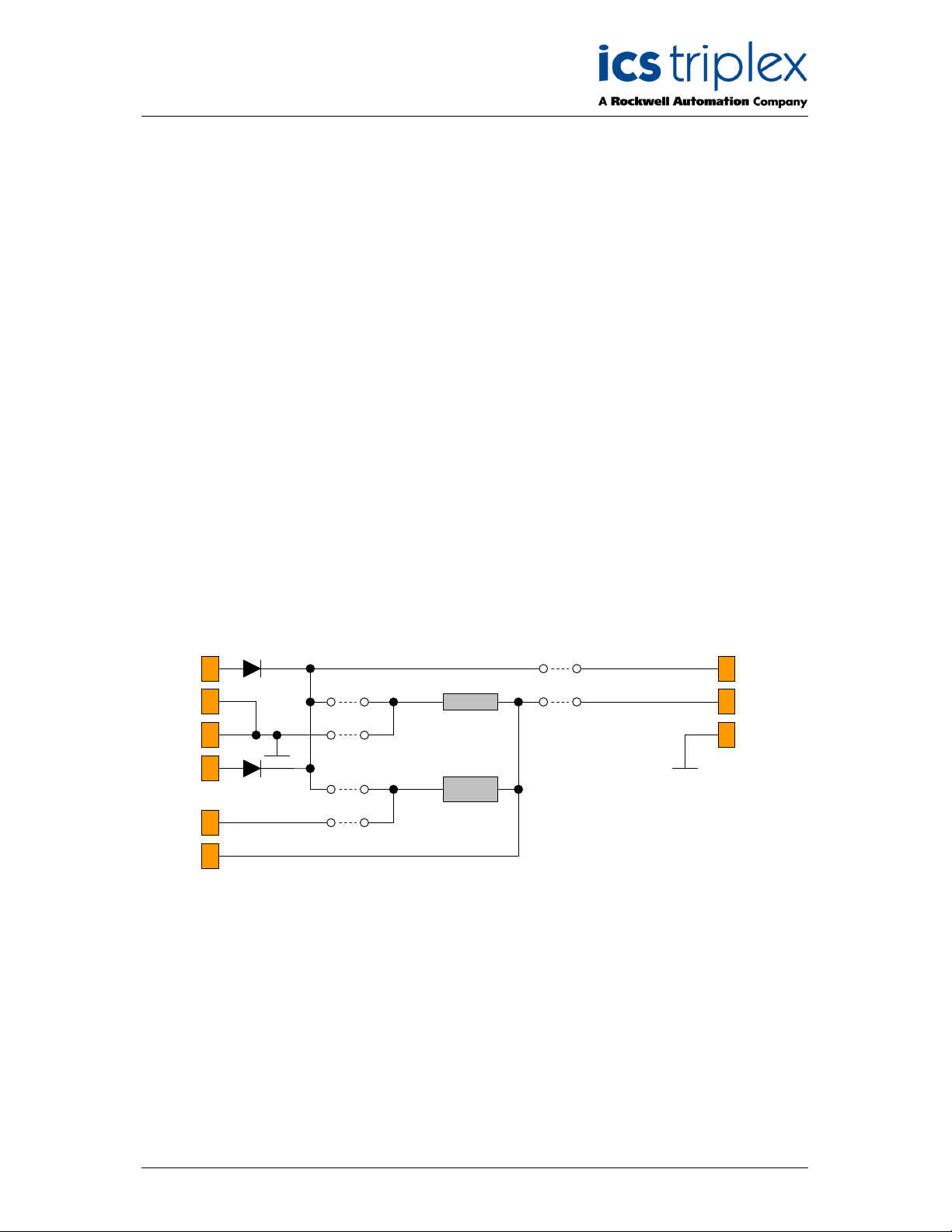

Monitored Valve Outputs

For a TrustedTM TMR Valve Monitor Module T8449, an output configuration as shown in Figure 6 is

required to drive the safety valve. The valve position is monitored by the next channel configured as an

input. This input may be an analogue position sensor, which is wired as shown in Figure 7. This input

expects a 4-20mA current loop from the position sensor. It may also be wired from a set of limit

switches arranged in a resistor network. This network is powered from 24V and received as a voltage

input as in Figure 5. The network should be arranged so that the voltage seen at the channel input

passes through a series of steps as the switches are activated in turn. The steps should continue in

one direction through the whole valve travel, or the valve monitor module will not be able to determine

the valve position.

The diagrams below shows an example switched voltage circuit, using Open, Nearly Open and Closed

switches. Each switch is wired to close to the clockwise side of travel (note: ‘O’ will close when ‘not

open’). The resistor values shown will ensure that the lowest value resistor will override the state of the

others. The thresholds are programmed into the module System.INI and set the target states for the

valve test. They also allow room for open and short circuit detection.

24V

1

2

0V

3

O

NO C

O

NO

20.4

12.8

5.7

2.2

C

10K

1K2

220R 4K7

1K

Figure 9 Position Limit Switches and circuit

V

Figure 10 Voltage Input with Limit Switch Position

closed

Threshold 18V

travel

Threshold 10V

nearly open

Threshold 4V

open

Issue 8 Aug 12 PD-T8842 15

Page 16

Trusted

TBG1 TBG2 TBG3 TBG4 TBG5 TBSS

TB1

TB2

TB3

TB4

TB5

TB6

TB7

TB8

TB9

TB10

TB11

TB12

TB13

TB14

TB15

TB16

TB17

TB18

TB19

TB20

TB21

TB22

TB23

TB24

TB25

TB26

TB27

TB28

TB29

TB30

TB31

TB32

TB33

TB34

TB35

TB36

TB37

TB38

TB39

TB40

TM

Versatile FTA T8842

2. Installation

The TrustedTM Versatile FTA 8842 is designed to be mounted on either of the TS32 or TS35 DIN rails

in the horizontal or vertical positions as required.

3. Associated Cable Selection

Note that 24V field power is required even if all channels are configured as inputs. This may be

connected via the plug at the chassis end of the cable to a T8290 or T8297 distribution unit (for cables

without power wires) or at the VFTA (for integral power cables).

Refer to the product descriptions detailed below:

PD-TC000 TrustedTM Power Cables

PD-TC200 TrustedTM I/O Companion Slot Cables

PD-TC500 TrustedTM I/O SmartSlot Cables

4. Assembly Pinout Connections

1 2 3

Figure 11 Connector Locations

TBFP1

TBFP2

TBFP3

TBFP4

TBFP5

4 3 2 1

Issue 8 Aug 12 PD-T8842 16

Page 17

Trusted

TM

Versatile FTA T8842

TBFP1 to TBFP5 Connections

The pin connections of TBFP1 to TBFP5 are identical and are detailed below:

Pin Service

1 24V-1

2 0V

3 0V

4 24V-2

Table 1 TBFP1 to TBFP5 Connections

Note that the 0V for each group are interconnected on the VFTA.

TBG1 Connections

Pin Service

1 0V

2 Channel 1

3 Channel 2

4 Channel 3

5 Channel 4

6 Channel 5

7 Channel 6

8 Channel 7

9 Channel 8

10 0V (Not used)

Table 2 TBG1 Connections

Issue 8 Aug 12 PD-T8842 17

Page 18

Trusted

TM

Versatile FTA T8842

TBG2 Connections

Pin Service

1 0V

2 Channel 9

3 Channel 10

4 Channel 11

5 Channel 12

6 Channel 13

7 Channel 14

8 Channel 15

9 Channel 16

10 0V (Not used)

Table 3 TBG2 Connections

TBG3 Connections

Pin Service

1 0V

2 Channel 17

3 Channel 18

4 Channel 19

5 Channel 20

6 Channel 21

7 Channel 22

8 Channel 23

9 Channel 24

10 0V (Not used)

Table 4 TBG3 Connections

Issue 8 Aug 12 PD-T8842 18

Page 19

Trusted

TM

Versatile FTA T8842

TBG4 Connections

Pin Service

1 0V

2 Channel 25

3 Channel 26

4 Channel 27

5 Channel 28

6 Channel 29

7 Channel 30

8 Channel 31

9 Channel 32

10 0V (Not used)

Table 5 TBG4 Connections

TBG5 Connections

Pin Service

1 0V

2 Channel 33

3 Channel 34

4 Channel 35

5 Channel 36

6 Channel 37

7 Channel 38

8 Channel 39

9 Channel 40

10 0V (Not used)

Table 6 TBG5 Connections

Issue 8 Aug 12 PD-T8842 19

Page 20

Trusted

TM

Versatile FTA T8842

TBSS Connections

Pin Service

1 Auxiliary Input (Not used)

2 Auxiliary Input (Not used)

3 Smart Slot A (Not used)

4 Smart Slot B (Not used)

5 Smart Slot C (Not used)

6 Channel 41

7 Channel 0

Table 7 TBSS Connections

TB1 to TB40 Connections

The pin connections of TB1 to TB40 are identical and are detailed below:

Pin Service

1 Field power

2 Signal in

3 0V

Table 8 TB1 to TB40 Connections

Issue 8 Aug 12 PD-T8842 20

Page 21

Trusted

TM

Versatile FTA T8842

Links

Links 1 to 6 are not used in this configuration and should be fitted in position B or removed.

Links 1 to 5 wire power from each group to the unused TBSS terminals 2 and 7. Link 6 wires TBSS

terminals 1 and 6 to zero volts. SmartSlot operation is no longer performed on the VFTA and therefore

the links should not be fitted.

Each channel has a set of links to configure the conditioning circuit, as referenced on the previous

pages. These are detailed below.

Links F1 to F8

Links E1 to E8

Links D1 to D8

Links C1 to C8

Links B1 to B8

Links A1 to A8

1 2 3 4 5 6 7 8

Figure 12 Link Detail (for first group)

Note: The pitch and spacing of the links prevent invalid configuration if the fuses supplied with the

VFTA are used.

Groups 2 to 5 are arranged in the same way. The channel links are numbered on the PCB.

Where 1K resistors are required as described in this document, the resistor leads should be formed as

shown below.

Figure 13 Resistor Forming

Issue 8 Aug 12 PD-T8842 21

Page 22

Trusted

TM

Versatile FTA T8842

5. Specifications

Voltage Range (Field Supply)

Fuses

Maximum Current (Field Supply)

Recommended Operating Current (Field Supply)

Power Consumption (Field Supply)

Signal Input Range

Operating Temperature

Non-operating Temperature

Operating Humidity

Environmental Specifications

Dimensions

Height

Width

Depth (including mounting rail and connectors)

Weight

18 to 28Vdc

40-off 2A plug-in TE-5 series, ICS part

number 813409

40-off 315mA plug-in TE-5 series, ICS

part number 813407

40-off 50mA plug-in TE-5 series, ICS

part number 813405

2.52A per power group

220mA per channel

9W maximum

0-20mA

-50C to 600C (230F to 1400F)

-250C to 700C (-130F to 1580F)

5 to 95% RH non-condensing

Refer to Document. 552517

110mm (4.33ins)

360mm (14.17ins)

68mm (2.67ins)

950gms (2.1lbs)

Issue 8 Aug 12 PD-T8842 22

Page 23

Trusted

TM

Versatile FTA T8842

This page is intentionally blank

Issue 8 Aug 12 PD-T8842 23

Page 24

Loading...

Loading...