Page 1

SDS-8449

T8449 Trusted TMR 24Vdc Valve Moni tor

OUT

IN

TrustedTM Industrial Control System

Trusted

TM

TMR 24Vdc Valve Monitor Module -T8449

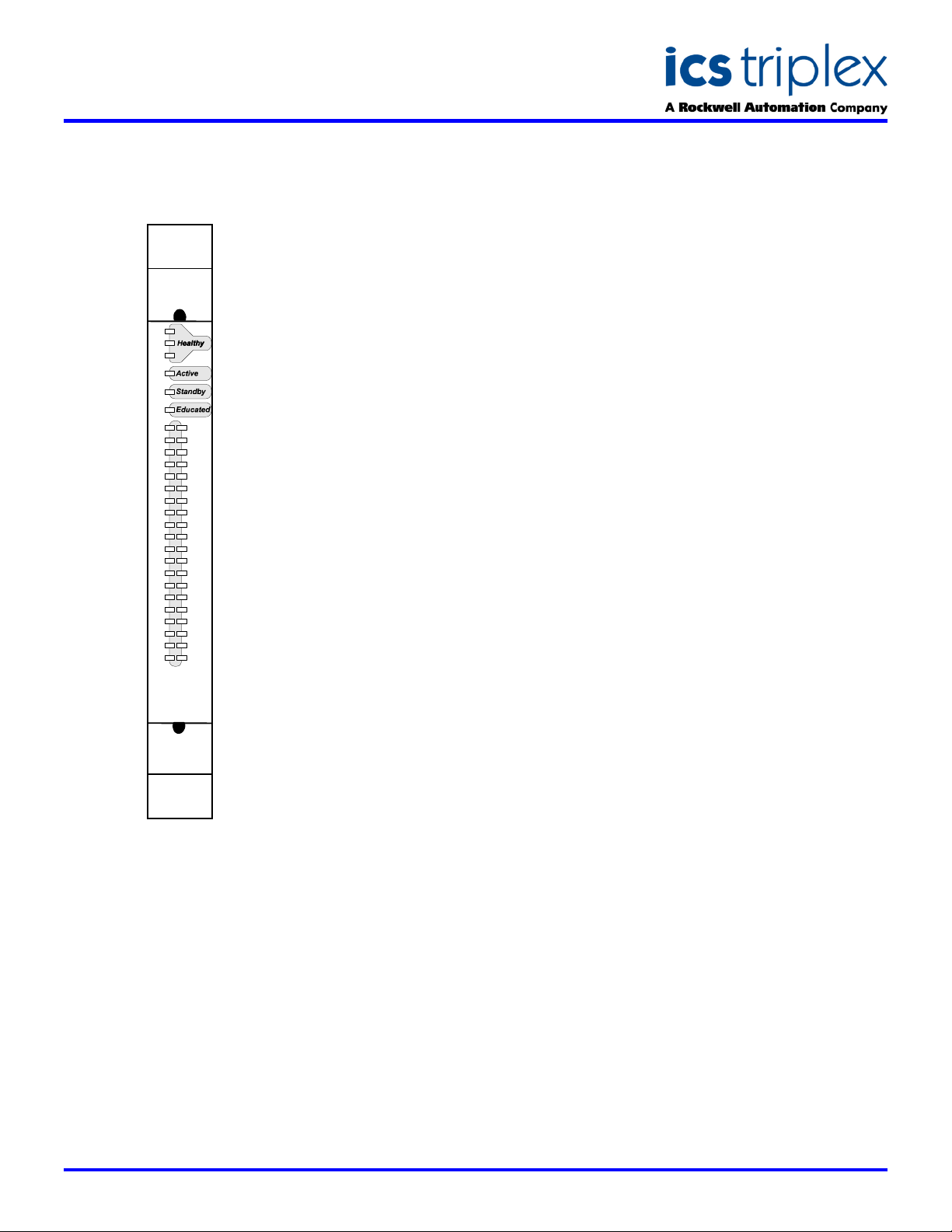

FRONT PANEL

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

DESCRIPTION

To meet the demanding requirements of

Safety Integrity Level (SIL) calculations,

final elements of a safety function such as

shutdown valves require regular testing.

The TUV approved (AK6, SIL3) Trusted

TMR Valve Monitor module, will control

any valve connected to it and test the

valve at regular intervals. It is used in

place of a normal controlling output

module where the automatic valve testing

function is required. The Valve Monitor

will perform the partial stroke tests,

monitor the results and pass on

information for display, alarm and

historical record via the application

program of the Trusted

TM

controller.

TM

Maximum test times are derived for each

valve to ensure the test can only move

the valve for a period which will not cause

disturbance to the process. This method

of partial stroke testing exercises the

entire shutdown path from safety system

logic to movement of the valve actuator.

The test verifies the ability of the valve to

perform its shutdown function.

Triple Modular redundancy (TMR) is used

to ensure fault tolerance. The system will

continue uninterrupted, safe operation in

the presence of one or more internal

discrepancies. Features typical of all

Trusted

TM

output modules are included,

such as, line monitoring, fuseless

protected outputs, 1msec sequence of

events (SOE) resolution, configurable

LED colours and field signal monitoring.

The Valve Monitor connects to 20 valves

by providing 20 control outputs and 20

monitoring inputs arranged together in

pairs. These pairs are in 5 isolated

groups with separate power feeds to

each. The outputs connect directly to the

Solenoid Operated Valve (SOV) or via an

Intrinsically Safe interface in the usual

way. Outputs can be normally energised

or de-energised, open or closed.

Feedback of valve position can be by limit

switches or an analogue position sensor.

The Valve Monitor connects to the field

circuits via a Versatile Field Termination

Assembly (VFTA). The VFTA allows the

user to link configure an appropriate

electrical loop for the control and

monitoring signals.

The signals that control valve open and

closed state, plus the requests to test, are

derived from the application program

running in the Trusted

TM

TMR Processor.

The IEC1131 Toolset uses a preconfigured function block to marshall

signals to and from the Valve Monitor.

The unique characteristics of each valve

such as test time, feedback thresholds

and alarm conditions, are also set in the

IEC 1131 Toolset and can be modified

online. Control of the testing can be

based on time of day, time interval or

manually initiated from the Valve Manager

operator interface.

The module has extensive automatic

diagnostics. Should a fault in the module

be detected, the Trusted

TM

TMR

Processor will flag the unhealthy

condition, indicating the need to replace

the module. Control continues until a

replacement (healthy) module is

available. Replacement modules can be

located in a Companion Slot next to the

faulty module or in a designated

SmartSlot with a temporary connection to

the faulty module.

Modules may be placed in any I/O slot in

a Trusted

TM

Processor Chassis or

Expander chassis. Mechanical keying

prevents insertion of the incorrect module.

FEATURES

40 TMR channels to control

and test 20 shutdown valves

Partial stroke testing

embedded in TMR safety

system

Tests valves to AK6 or SIL3

application requirements

Use with single or dual SOV’s

for maximum process

availability

No added hardware so no

increase in MTBF

spurious

Line monitoring

Automatic over-current

protection – no fuses required

Hot replaceable

Can be installed as retrofit

using existing field installation

Maximum increase to safety

integrity for minimum cost

On-board 1ms resolution

Sequence of Events reporting

Issue 3 Jan 2006

Page 2

SDS-8449

Trusted

TM

Industrial Control System

Trusted

TM

TMR 24Vdc Valve Monitor Module -T8449

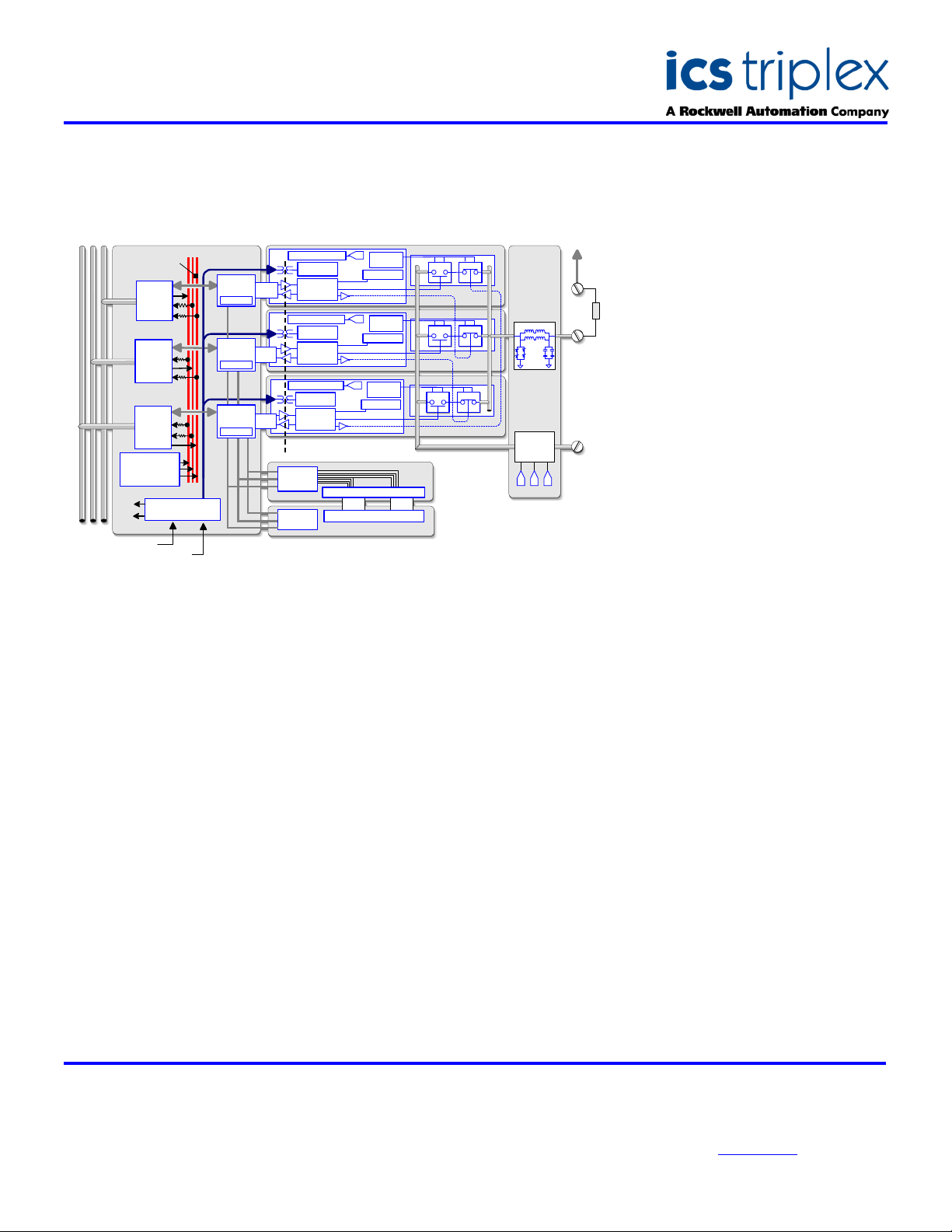

BLOCK DIAGRAM

OFIUHIU

I

nternal Voting Bus

TMR Intermodule Bus

Housekeeping

Module Temp

DSP reference

Back Plane

B

ack Plane Power Bus 1

Power Bus

Back Plane Power Bus 2

1

Bus

Interface

Bus

Interface

Bus

I

nterface

Supply Diag

Redundant Supply

S

lice

Control

ime Stamp

T

A

S

lice

Control

Time Stamp

B

Slice

Control

ime Stamp

T

B

Failsafe Bia s Control

S

lice Power

upply

S

Field Logic

Control

F

ailsafe Bias Control

S

lice Power

Supply

Field Logic

Control

F

ailsafe Bias Control

S

lice Power

Supply

Field Logic

Control

Opto Isolat ion Boundary

Front Panel

oting Logic

V

Indicators

Health

Voted Status Display LEDs

Serial Dis play Latches

F

A

D

iagnostic

onitor

M

ousekeeping

H

B

D

iagnostic

Monitor

Housekeeping

C

D

iagnostic

Monitor

Housekeeping

ront Panel

N.O.

N.O.

N.O.

FPIU

FPDU

Slice A

N

S

lice B

N.C.

Slice C

N.C.

ELECTRICAL SPECIFICATION

Number of channels

No. of Independent Power Groups

Field Common Isolation

Sustained Working ±250V dc

Maximum Withstanding ±2.5kV dc

Field Supply Voltage

Measurement Range 0 to 32V dc

Maximum Withstanding -1 to 40V dc

Output Current Rating

Continuous 2 A

Minimum 50ma

Output Off Resistance (effective

leakage)

Power Consumption at 24V (1A per

channel)

Output Turn On/Off Delay

Self-Test Interval

Output Short Circuit Protection

Fusing

Intrinsic Safety

Circuit Type

40 Channels – 20 control, 20

monitoring

5, each of 4 outputs & 4 inputs

33k>

24W

0.5ms

2 minutes

Automatic

Not required

External barrier

Fault tolerant, fully triplicated with

optional line monitoring

OFTU

.C.

F

ield Interfa ce

rotection C ircuit

P

G

roup

Fail-Safe

Switch

A B C

-

V

MECHANICAL

SPECIFICATION

Dimensions (HxWxD):

241mm x 30mm x 300mm

(9.5ins x 1.2ins x 11.8ins)

Weight:

1.13kg

(2.5lbs)

ENVIRONMENTAL

+V

Operating Temperature:

-5°C to 60°C

(23°F to 140°F)

Operating Humidity:

5 to 95%, noncondensing

Vibration:

10 to 57Hz ±0.075mm

57 to 150Hz 1.0g

Shock:

15g, ½ sine wave, 11ms

EMI (IEC 801):

ESD

Air discharge to 15kV

Contact discharge to 8kV

Radiated Fields

10V/m, 27MHz to

500MHz

Transients and Bursts

2kV, 2.5kHz for

t=60 seconds

ICS Triplex

Technical data sheets are intended for

information and guidance. The Company

has a policy of continual product

development and improvement.

Specifications are subject to change

without notice. For latest information, visit

our Websi te:- www.icstr iple x.com

Loading...

Loading...