Page 1

Trusted

TM

PD-T8444

TM

Trusted

TMR Pulse Generator and

Monitoring Module

Introduction

The TrustedTM TMR Pulse Generator and Monitoring module interfaces through special Thyristor

Drivers, to two Stepper Motors, which form an integral part of a damper rod control system. The

module is based upon the Trusted

rod position is provided by the module as a % Movement figure and a series of fault signals.

Triplicated diagnostic tests are performed throughout the module in order to locate and annunciate

hardware failures. Inputs are treated as analogues and are fully tested by the nature of their operation.

Fault tolerance is achieved through a Triple Modular Redundant (TMR) architecture within the module.

The module has been configured to provide the control and interlock requirements for a high power

stepper motor control system which is used to position Damper Rods in a Nuclear reactor. The

functionality of this module is highly specialised and is detailed later in this PD.

Features

TM

T8461 Digital output module. Feedback of Thyristor activation and

• Two Stepper Motor controls

• Special control algorithms and fault diagnostics resident within the module

• Bi-directional Fast and slow movement

• Emergency stop and hold facility

• Rod position Indication

• Thyristor driver fault indications

• ESD Rod release

• 2500V dc optical isolation barrier

• Automatic over-current protection (per channel), no fuses required (outputs)

• Front panel status LEDs for each point indicate status and field wiring faults

• Front panel module status LEDs indicate module health and operational mode (Active,

Standby, Educated)

6V Certified IEC 61508 SIL 3

• T

Issue 9 Apr 10 PD-T8444 1

Page 2

Trusted

Issue Record

Issue

Number Date Revised by Technical CheckAuthorised by Modification

5 July 05 J W Clark Formatting

6 Dec 06 N Owens I Vince P Stock Weights and Dims

7 Sep 07 N Owens I Vince P Stock Tbl16 Chns rotated

8 Nov 09 S Blackett A Holgate N Owens Table 5 change

9 Apr 10 S Blackett A Holgate N Owens Rack 7 change

TM

Module T8444

Issue 09 Apr 10 PD-T8444 2

Page 3

Trusted

TM

Module T8444

This page is intentionally blank

Issue 09 Apr 10 PD-T8444 3

Page 4

Trusted

TM

Module T8444

Table of Contents

1. Description ...................................................................................................................................9

1.1. Field Termination Unit (FTU) .....................................................................................................10

.2.

1

1.3. Host Interface Unit (HIU) ...........................................................................................................11

1.4. Front Panel Unit (FPU) ..............................................................................................................11

1.5. Line Monitoring ..........................................................................................................................12

1.6. Housekeeping............................................................................................................................12

1.7. Fault Detection/Testing..............................................................................................................12

1.8. Sequence of Events Characteristics..........................................................................................13

1.9. Output Switch Structure .............................................................................................................14

1.9.1. Switch Diagnostics.....................................................................................................................15

1.9.2. Short Circuit Protection Issues. .................................................................................................16

1.9.3. Group Fail Safe Switches. .........................................................................................................16

1.10. Input interfaces ..........................................................................................................................16

2. Installation..................................................................................................................................17

2.1. Module Insertion/Removal .........................................................................................................17

2.2. Field Cable Selection .................................................................................................................17

2.3. Module Pinout Connections .......................................................................................................18

2.4. TrustedTM Module Polarisation/Keying.......................................................................................19

3. Application .................................................................................................................................20

3.1. Module Configuration.................................................................................................................20

3.2. T8444 Complex Equipment Definition .......................................................................................20

3.2.1. Rack 1: PG_CTRL .....................................................................................................................21

3.2.2. Rack 2: FIELD ............................................................................ Error! Bookmark not defined.

3.2.3. Rack 3: PI_CTRL .......................................................................................................................23

3.2.4. Rack 4: PG_FAULT ...................................................................................................................23

3.2.5. Rack 5: Line_Flt .........................................................................................................................24

3.2.6. Rack 6: Discrep .........................................................................................................................24

3.2.7. Rack 7: Housekeeping...............................................................................................................25

3.2.8. Rack 8: INFO .............................................................................................................................26

3.3. SYSTEM.INI File Configuration .................................................................................................26

4. Operation ...................................................................................................................................27

4.1. Front Panel ................................................................................................................................27

4.2. Module Status LEDs ..................................................................................................................28

4.3. I/O Status LEDs .........................................................................................................................29

4.3.1. Outputs and Gate Outputs .........................................................................................................29

4.3.2. Feedback Inputs ........................................................................................................................30

4.4. Output and Input separation/Channel allocation........................................................................31

5. Fault Finding and Maintenance..................................................................................................32

5.1. Fault Reporting ..........................................................................................................................32

5.2. Field Wiring Faults .....................................................................................................................32

5.3. Module Faults ............................................................................................................................32

5.4. Companion Slot .........................................................................................................................33

ield Interface Unit (FIU) ...........................................................................................................10

F

Issue 09 Apr 10 PD-T8444 4

Page 5

Trusted

5.5. SmartSlot ...................................................................................................................................33

5.6. Cold Start...................................................................................................................................33

5.7. Transfer between Active and Standby Modules ........................................................................34

6. Technical specification...............................................................................................................35

6.1. Introduction ................................................................................................................................35

6.2. Phase Rotation ..........................................................................................................................36

6.3. Fail Safe actions ........................................................................................................................37

6.4. Internal testing and Monitoring...................................................................................................37

6.5. Thyristor Driver interfaces/Stepper Motor Drives.......................................................................37

6.5.1. Module Start up..........................................................................................................................37

6.5.2. Minimum output Load ................................................................................................................37

6.5.3. Input Termination Resistance ....................................................................................................37

6.6. Operation with one thyristor driver removed ..............................................................................38

6.7. Detection of a missing pulse......................................................................................................38

6.8. Detection of an extra pulse ........................................................................................................38

6.9. Detection of a short/ long pulse .................................................................................................39

6.10. Analogue Feedback out of limits................................................................................................39

6.11. Motor Voltage Monitoring...........................................................................................................39

6.12. Inference of Position from Motor Pulses....................................................................................40

6.13. Number of Pulses for a full transition of a rod from End to End ................................................40

6.14. Synchronisation/External timing.................................................................................................40

6.15. Setting of Count Position ...........................................................................................................40

6.16. Analogue Input Discrepancy ......................................................................................................40

6.17. Output 2-oo-3 error ....................................................................................................................40

6.18. Module Temperature Measurement ..........................................................................................41

6.19. Diagnostics ................................................................................................................................41

6.20. FTA Output Schematic ..............................................................................................................42

6.21. FTA Input Schematic .................................................................................................................43

7. Specifications.............................................................................................................................44

TM

Module T8444

Issue 09 Apr 10 PD-T8444 5

Page 6

Trusted

TM

Module T8444

Figures

Figure 1 Module Architecture....................................................................................................................9

Figure 2 Functional Block Diagram ........................................................................................................10

igure 3 Output Switch Structure............................................................................................................14

F

Figure 4 Simplified Switch Circuit Diagram ............................................................................................15

Figure 5 Module polarisation ..................................................................................................................19

Figure 6 Module Front Panel ..................................................................................................................27

Figure 7 PG/M Functional Block Diagram ..............................................................................................35

Figure 8 Field Termination Output Schematic ........................................................................................42

Figure 9 Field Termination Input Schematic ...........................................................................................43

Tab l es

Table 1 Line Monitoring Fault Status ......................................................................................................12

Table 2 Field Connector Pinout ..............................................................................................................18

Table 3 Complex Equipment Definition ..................................................................................................20

Table 4 OEM Parameters .......................................................................................................................21

Table 5 Rack 1: PG_CTRL descriptions.................................................................................................21

Table 6 Rack 2: Field descriptions .........................................................................................................22

Table 7 Rack 3: PI_CTRL descriptions ..................................................................................................23

Table 8 Rack 4: PG_Fault descriptions ..................................................................................................23

Table 9 Rack 5: Line_Flt descriptions ....................................................................................................24

Table 10 Rack 6: Discrepancy descriptions ...........................................................................................24

Table 11 Rack 7: Housekeeping descriptions ........................................................................................25

Table 12 Rack 8: INFO descriptions.......................................................................................................26

Table 13 Module Status Indicators .........................................................................................................28

Table 14 Default I/O Status Indicators....................................................................................................29

Table 15 Feedback Inputs ......................................................................................................................30

Table 16 I/O separation/Channel allocation............................................................................................31

Issue 09 Apr 10 PD-T8444 6

Page 7

Trusted

TM

Module T8444

Notice

The content of this document is confidential to ICS Triplex Technology Ltd. companies and their

partners. It may not be given away, lent, resold, hired out or made available to a third party for any

purpose without the written consent of ICS Triplex Technology Ltd.

This document contains proprietary information that is protected by copyright. All rights are reserved.

Microsoft, Windows, Windows 95, Windows NT, Windows 2000, and Windows XP are registered

trademarks of Microsoft Corporation.

The information contained in this document is subject to change without notice. The reader should, in

all cases, consult ICS Triplex Technology Ltd. to determine whether any such changes have been

made. From time to time, amendments to this document will be made as necessary and will be

distributed by ICS Triplex Technology Ltd.

Information in this documentation set may be subject to change without notice and does not represent

a commitment on the part of ICS Triplex Technology Ltd..

The contents of this document, which may also include the loan of software tools, are subject to the

confidentiality and other clause(s) within the Integrator Agreement and Software License Agreement.

No part of this documentation may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and recording, for any purpose, without the express

written permission of ICS Triplex Technology Ltd.

Disclaimer

The illustrations, figures, charts, and layout examples in this manual are intended solely to illustrate the

text of this manual.

The user of, and those responsible for applying this equipment, must satisfy themselves as to the

acceptability of each application and use of this equipment.

This document is based on information available at the time of its publication. While efforts have been

made to be accurate, the information contained herein does not purport to cover all details or variations

in hardware or software, nor to provide for every possible contingency in connection with installation,

operation, or maintenance. Features may be described herein which are present in all hardware or

software systems. ICS Triplex Technology Ltd. assumes no obligation of notice to holders of this

document with respect to changes subsequently made.

ICS Triplex Technology Ltd. makes no representation or warranty, expressed, implied, or statutory with

respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness of

the information contained herein. No warranties of merchantability or fitness for purpose shall apply.

Issue 09 Apr 10 PD-T8444 7

Page 8

Trusted

TM

Module T8444

Revision and Updating Policy

All new and revised information pertinent to this document shall be issued by ICS Triplex Technology

Ltd. and shall be incorporated into this document in accordance with the enclosed instructions. The

change is to be recorded on the Amendment Record of this document.

Precautionary Information

WARNING

Warning notices call attention to the use of materials, processes, methods, procedures or limits which

must be followed precisely to avoid personal injury or death.

CAUTION

Caution notices call attention to methods and procedures which must be followed to avoid damage to

the equipment.

Notes:

Notes highlight procedures and contain information to assist the user in the understanding of the

information contained in this document

Warning

RADIO FREQUENCY INTERFERENCE

Most electronic equipment is influenced by Radio Frequency Interference (RFI). Caution should be

exercised with regard to the use of portable communications equipment around such equipment.

Signs should be posted in the vicinity of the equipment cautioning against the use of portable

communications equipment.

MAINTENANCE

Maintenance must be performed only by qualified personnel, otherwise personal injury or death, or

damage to the system may be caused.

Caution

HANDLING

Under no circumstances should the module housing be removed.

Associated Documents

Product Descriptions (PD) provide product specific information.

The Safety Manual contains the recommended safety requirements for the safety system design.

The PD8082B – Toolset Suite provides specific guidance on system configuration and application

generation.

The Operator and Maintenance Manual contains general guidelines on maintenance and diagnostic

procedures.

For technical support email: support@icstriplex.com

Issue 09 Apr 10 PD-T8444 8

Page 9

Trusted

TM

Module T8444

1. Description

The TMR Pulse Generator and Monitoring module is a member of the TrustedTM range of Input/Output

(I/O) modules. All Trusted

level, all I/O modules interface to the Inter-Module Bus (IMB) which provides power and allows

ommunication with the TMR Processor. In addition, all modules have a field interface that is used to

c

connect to module specific signals in the field. All modules are Triple Modular Redundant (TMR).

TM

I/O modules share common functionality and form. At the most general

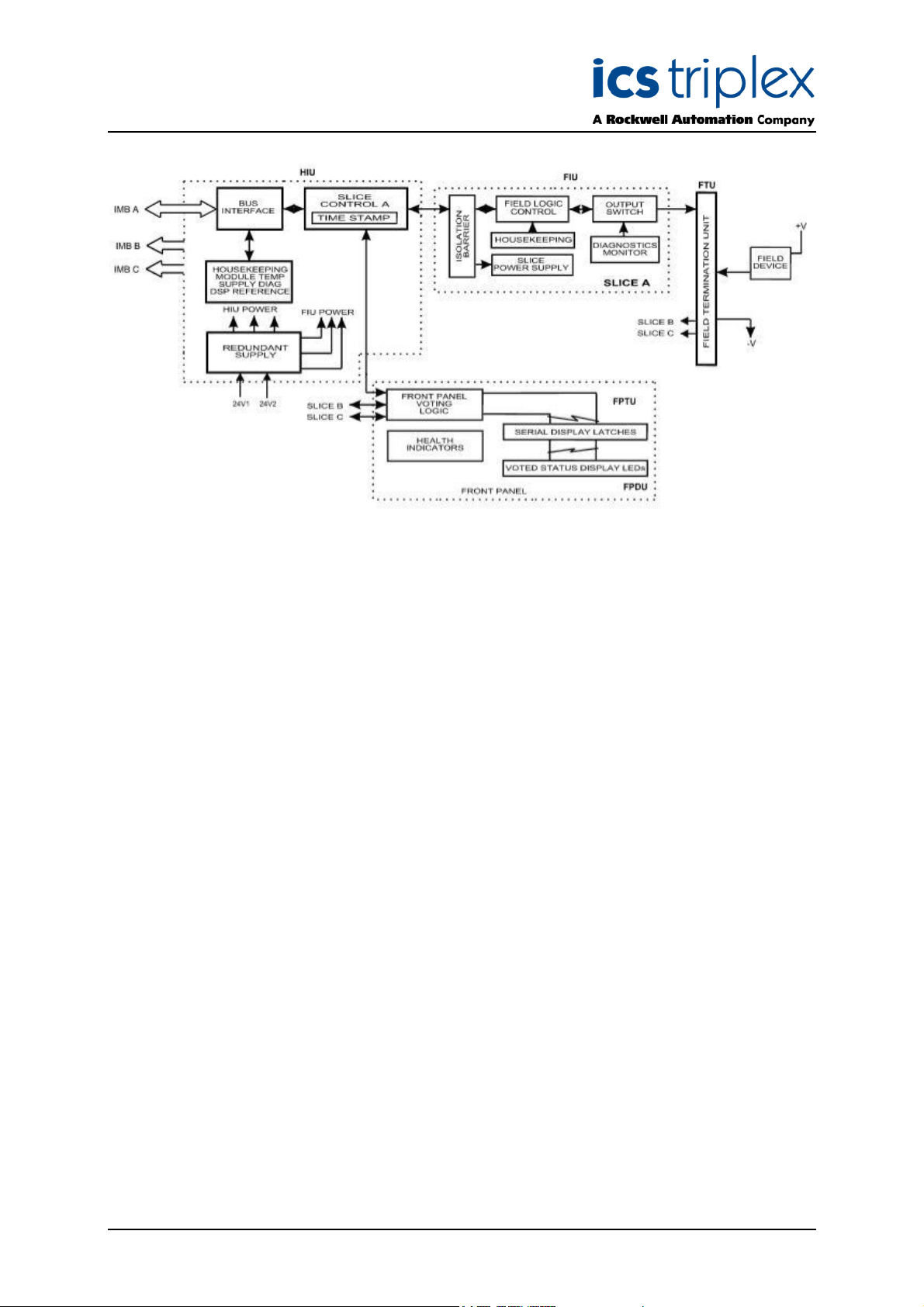

Figure 1 Module Architecture

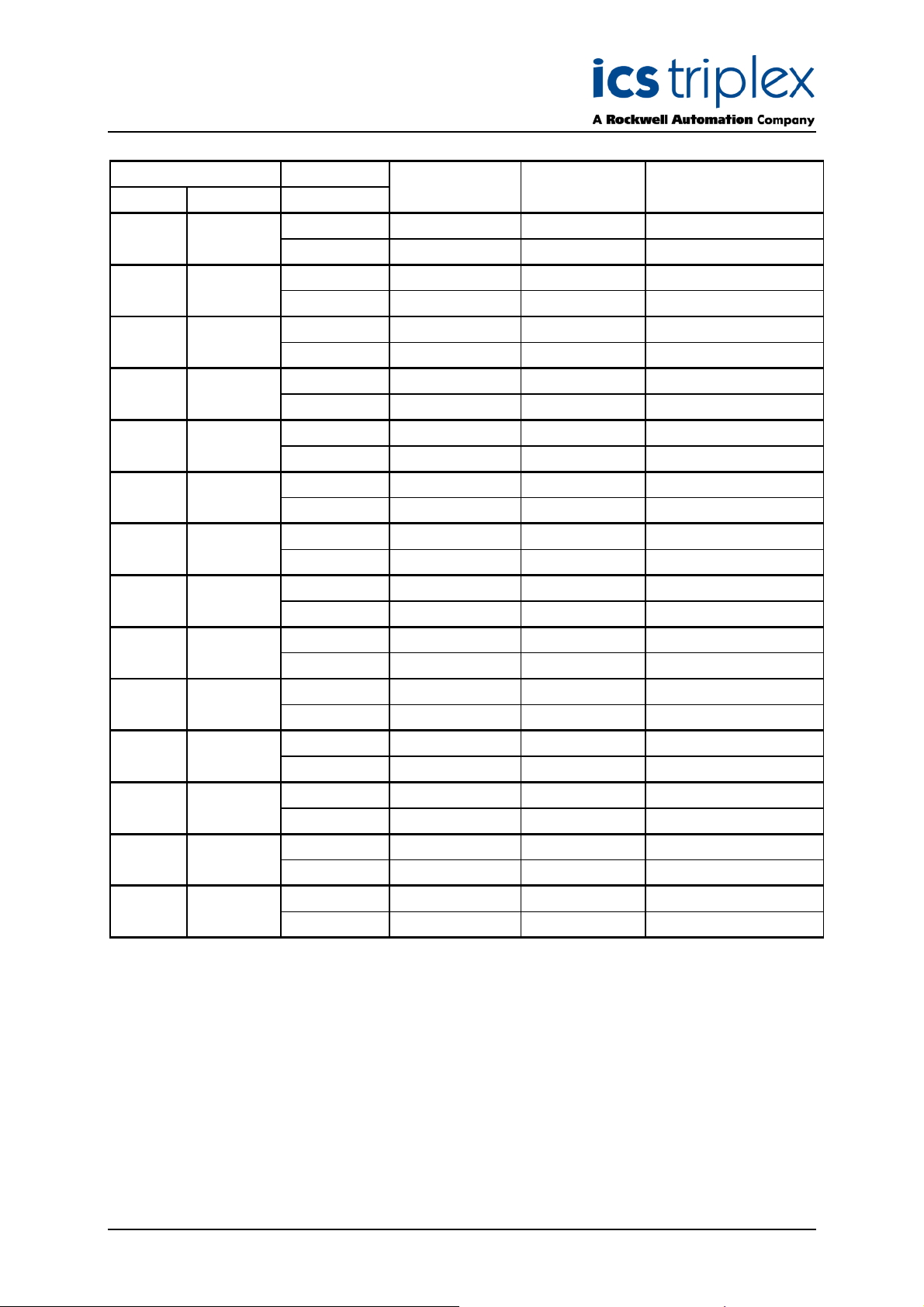

All High Integrity I/O modules are made up of 4 sections: Host Interface Unit (HIU), the Field Interface

Unit (FIU), the Field Termination Unit (FTU), and the Front Panel Unit (or FPU).

Issue 09 Apr 10 PD-T8444 9

Page 10

Trusted

TM

Module T8444

Fig 2 shows a simplified block diagram of the Trusted

M

T

PG/M Module.

Figure 2 Functional Block Diagram

1.1. Field Termination Unit (FTU)

The Field Termination Unit (FTU) is the section of the I/O module that connects all three FIUs to a

single field interface. The FTU provides the Group Fail-safe switches and passive components

necessary for signal conditioning, over-voltage protection, and EMI/RFI filtering. When installed in a

Trusted

TM

Controller or Expander Chassis, the FTU field connector interconnects to the Field I/O Cable

Assembly attached at the rear of the chassis.

The SmartSlot link is passed from the HIU to the field connections via the FTU. These signals go

directly to the field connector and maintain isolation from the I/O signals on the FTU. The SmartSlot

link is the intelligent connection between active and standby modules for co-ordination during module

replacement.

1.2. Field Interface Unit (FIU)

The Field Interface Unit (FIU) is the section of the module that contains the specific circuits necessary

to interface to the particular types of field I/O signals. Each module has three FIUs, one per slice. For

the TMR Pulse Generator and Monitoring Module, the FIU contains one stage of the output switch

structure, and A/D monitoring circuits for each of the channels. Two additional A/D circuits provide

optional monitoring of the external field I/O supply voltage.

The FIU receives isolated power from the HIU for logic. The FIU provides additional power conditioning

for the operational voltages required by the FIU circuitry. An isolated serial link connects each FIU to

one of the HIU slices.

The FIU also measures a range of on-board “house-keeping” signals that assist in monitoring the

performance and operating conditions of the module. These signals include power supply voltages,

current consumption, on-board reference voltages, board temperature, and condensation

Issue 09 Apr 10 PD-T8444 10

Page 11

Trusted

ng I/O

Redundant power sharing of dual 24V dc chassis supply voltage and power regulation for logic

ordination during module

board housekeeping, which monitors reference voltages, current consumption and board

TM

Module T8444

1.3. Host Interface Unit (HIU)

The HIU is the point of access to the Inter-Module Bus (IMB) for the module. It also provides power

distribution and local programmable processing power. The HIU is the only section of the I/O module

to directly connect to the IMB backplane. The HIU is common to most high integrity I/O types and has

type dependent and product range common functions. Each HIU contains three independent slices,

commonly referred to as A, B, and C.

All interconnections between the three slices incorporate isolation to prevent any fault interaction

between the slices. Each slice is considered a Fault Containment Region (FCR), as a fault on one

slice has no effect on the operation of the other slices.

The HIU provides the following services common to the modules in the family:

• High Speed Fault-Tolerant Communications with the TMR Processor via the IMB interface.

• FCR Interconnect Bus between slices to vote incoming IMB data and distribute outgoi

module data to IMB.

• Optically isolated serial data interface to the FIU slices.

•

power to HIU circuitry.

• Magnetically Isolated power to the FIU slices.

• Serial data interface to the FPU for module status LEDs.

• SmartSlot link between active and standby modules for co-

replacement.

• Digital Signal Processing to perform local data reduction and self-diagnostics.

• Local memory resources for storing module operation, configuration, and field I/O data.

• On-

temperature.

1.4. Front Panel Unit (FPU)

The Front Panel Unit (FPU) contains the necessary connectors, switches, logic, and LED indicators for

the front panel. For every module, the FPU contains the Slice Healthy, Active/Standby, the Educated

indicators (LEDs), and the module removal switches. Additional bi-colour LEDs provide status

indication for the individual I/O signals. Serial data interfaces connect the FPU to each of the HIU

slices to control the LED status indicators and monitor the module removal switches.

.

Issue 09 Apr 10 PD-T8444 11

Page 12

Trusted

TM

Module T8444

1.5. Line Monitoring

The module automatically monitors the channel line fault status. These are reported back to the

application and are represented below.

Description Line Fault Status

Field Short Circuit 1

Output Energised (On) 0

No Load, Field Open Circuit 1

Output De-energised (Off) 0

No Field Supply Voltage 1

Table 1 Line Monitoring Fault Status

1.6. Housekeeping

The module automatically performs local measurements of several on-board signals that can be used

for detailed troubleshooting and verification of module operating characteristics. Measurements are

made within each slice’s HIU and FIU to determine the condition of the power supplies and common

services such as the temperature of the HIU.

1.7. Fault Detection/Testing

From the IMB to the field connector, the I/O module contains extensive fault detection and integrity

testing. Most testing is performed in a non-interfering mode. Data input from the IMB is stored in

redundant error-correcting RAM on each slice portion of the HIU. Received data is voted on by each

slice. All data transmissions include a confirmation response from the receiver.

Periodically, the TMR Processor commands the onboard DSPs to perform a Safety Layer Test. The

SLT results in the DSP verifying with the TMR Processor its ability to process data with integrity. In

addition, the DSP uses Cyclical Redundancy Checks (CRC) to verify the variables and configuration

stored in Flash memory.

Between the HIU and FIU are a series of optically isolated links for data and power. The data link is

synchronised and monitored for variance. Both FIU and HIU have onboard temperature sensors to

characterise temperature-related problems. Each FIU is also fitted with a condensation sensor.

The power supplies for both the HIU and FIU boards are redundant, fully instrumented and testable.

Together these assemblies form a Power Integrity Sub System.

Issue 09 Apr 10 PD-T8444 12

Page 13

Trusted

TM

Module T8444

1.8. Sequence of Events Characteristics

Each Boolean Variable can be configured for automatic Sequence of Events (SOE) logging. This

applies to the Input/Output Status and Line Fault Status variables. A Boolean variable is configured for

SOE during the variable definition in the Data Dictionary Editor. To select SOE, press the Extended

Button in the Boolean Variable Definition Dialog Box to open the Extended Definition Dialog. Then

check to box for Sequence of Events to enable the variable for automatic SOE logging.

During operation, the module automatically reports time-stamped change of state information for the

output data. The TMR Processor automatically logs change of state for configured SOE variables into

the system SOE Log. The SOE Log can be monitored and retrieved using the SOE and Process

Historian Package running on the EWS. This software package is described in PD-8013.

Issue 09 Apr 10 PD-T8444 13

Page 14

Trusted

TM

Module T8444

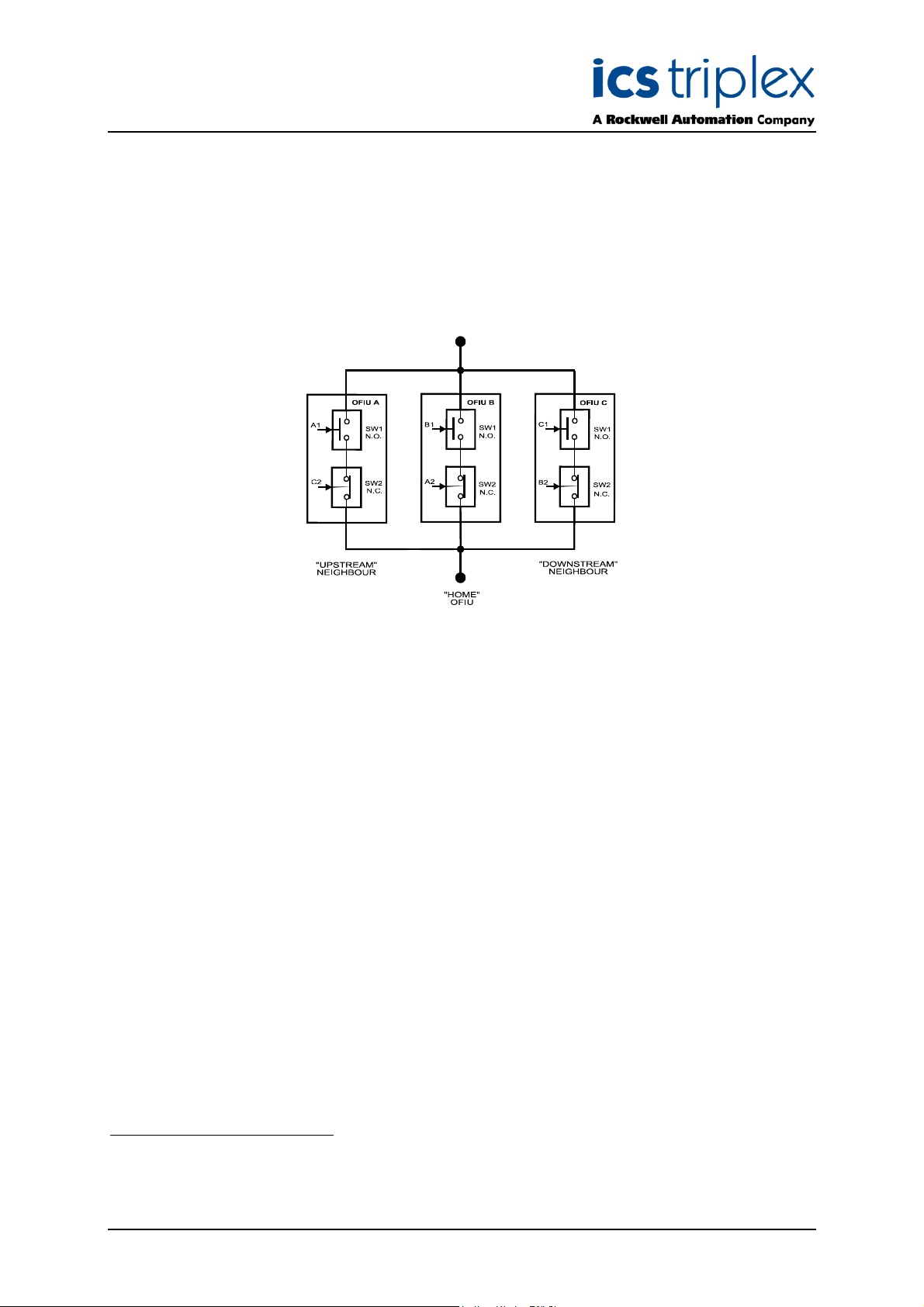

1.9. Output Switch Structure

The outputs of the Pulse Generator and Monitoring Module provides a TMR switch topology where the

load is driven by a total of three fully monitored, fail-safe (6 element) switch channels, one physically

resident on each OFIU in the module. Any single switch or entire slice failure is designed to leave two

of the three fail-safe switch channels operational to power the load.

Figure 3 Output Switch Structure

The upper switches as shown in are denoted as N.O. (Normally Open), and are controlled by the FIU

1

on which they are physically resident.

and are controlled by the “upstream” neighbouring FIU.

The lower switches are depicted as N.C. (Normally Closed),

2

Note:

In this context, N.O. is defined as being in the off state in the absence of control signal power,

and similarly, N.C. is the on state in the absence of control signal power. These switches are

constructed from enhancement mode MOSFETs and are both guaranteed to be off in the

3

absence of module power to create gate voltage signals to bias them on

(unlike

electromechanical relays for example).

The reason that the lower switches are specified to be on in the absence of control signal power is to

allow two channels to power the load should an entire slice fail. Even if an entire slice fails, the

surviving output circuits will carry the necessary control. The structure of each OFIU output is shown

below:

1

Their “home” FIU.

2

The home FIU, supplies an independent control signal for the “downstream” FIU FSS.

3

For an un-faulted transistor.

Issue 09 Apr 10 PD-T8444 14

Page 15

Trusted

A resistor provides a means of continuously monitoring the switch current. A signal transistor is used

to drive the gate of Switch 2. It provides Switch 2 with a negative gate voltage, to minimise it’s on

resistance, and serves to hold Switch 2 on in the event that the secondary gate control loses power.

The zener diode between the gate of Switch 2 and source is only required to protect the gate from

large voltage spikes on the drain that might capacitively couple through when Switch 1 and Switch 2

are in the off state.

The resistors in series with the gate of Switch 1 and the signal transistor serve to protect the drive logic

in the event of a malicious switch failure. The pull-up resistors define the gate voltages in the absence

of power.

TM

Module T8444

Figure 4 Simplified Switch Circuit Diagram

1.9.1. Switch Diagnostics.

During normal operation, Switch 1 and Switch 2 are maintained on. In this state, Switch 1 and Switch 2

exhibit less than 0.5L of resistance each.

To determine the ability of the system to control the load via Switch 1 and Switch 2, their gate voltages

are modulated, one at a time. As the gate voltages are modulated, the monitoring signals

synchronously change in a predictable fashion. The local DSP analyses the relative amplitude and

phase of these small AC signals, to determine the on resistance and threshold voltages of each switch.

The current to the load does not need to be completely interrupted in order to obtain a level of

confidence in the ability of the transistors to turn off. For the TMR switch configuration in the on state,

only one fail-safe switch at a time needs to be modulated, while the other two bear the load current.

Issue 09 Apr 10 PD-T8444 15

Page 16

Trusted

TM

Module T8444

1.9.2. Short Circuit Protection Issues.

In a fuse-free design such as in the Trusted

event of an over-current or over-power situation. In fact, this protection scheme offers advantages to

fuses in both automatic recovery and speed of action.

The topology of the channel provides a natural limit to the instantaneous current flow, giving the

module time to respond. Furthermore, the over-current protection circuitry is inherently self-testable,

ince the threshold can be a programmable value.

s

The P-channel architecture of Switch 1 and Switch 2 utilises an open-drain output structure. Under

short-circuit conditions the maximum instantaneous current with a 24V field voltage is naturally limited

to less than 5A per channel. This is because high output currents cause the gate-source voltages of

the two transistors to be reduced, tending to turn them off.

The output current is monitored by the DSP and sustained over current conditions result in a latched

over-current condition and de-energise the associated output. After removing the fault condition, the

latched over-current condition can be reset by either pressing the system fault reset button or turning

off the logical output signal to the module. The output also includes a non-replaceable fusible link for

absolute protection.

TM

System, the module is required to respond rapidly in the

1.9.3. Group Fail Safe Switches.

To ensure safe operation, each output from the module is equipped with a series of switches that

provide source power to a group of 8 channels. The module Group Fail Safe Switch (GFSS) is

intended as a final control switch which can de-energise any outputs that cannot be de-energised in the

normal way. For safety, the presence of two or more faults within the module will cause the Group Fail

Safe Switches to de-energise, resulting in all of the outputs in its group to de-energise.

There are three switches in parallel, which comprise the GFSS, one associated with each 'slice' of the

power group. The GFSS’ are controlled via a signal from one of the other two neighbouring slices.

This means that if one slice determines from the output states that an output is not in a de-energised

state when it should be, then it can command its own GFSS and those of the other slices GFSS to deenergise. This results in two of the three elements of the GFSS structure to de-energise, leaving only

one GFSS element energised. If two slices do the same thing then the last GFSS output will deenergise. For example, this would occur if two or more output switch elements fail in a 'stuck-on' state

such that the output cannot de-energise.

The GFSS control signal is generated by a charge pump driven from the comms clock to the slice

power group. If the clock fails then the GFSS bias collapses. This means that even if the ability of the

slice to communicate with a power group is lost, the GFSS can still be de-energised by stopping the

comms clock. If a slice fails, the watchdog on the HIU will time out and reset the slice, this will

shutdown the OFIU power supply and the associated GFSS control signal will also de-energise.

1.10. Input interfaces

Each input channel is provided with three A/D converters which monitor the voltage at the input

connection. Each input is a high impedance channel which measures from 0 to 30 V. If current is to

be measured the input must be conditions with an external resistor. The module uses its TMR

architecture to provide fault tolerance in the event of a hardware failure. No particular dynamic testing

is provided on the inputs because of the continuous dynamic nature of the signal being interfaced and

the duality of the thyristor drives which are providing the input signals.

Issue 09 Apr 10 PD-T8444 16

Page 17

Trusted

TM

Module T8444

2. Installation

2.1. Module Insertion/Removal

CAUTION:

The module contains static sensitive parts. static handling precautions must be observed. Specifically

ensure that exposed connector pins ARE NOT TOUCHED. Under no circumstances should the

module housing BE REMOVED.

Before installation, visually inspect the module for damage. Ensure that the module housing appears

undamaged and inspect the I/O connector at the back of the module for bent pins. If the module

appears damaged or any pins are bent, do not install the module. Do not try to straighten bent pins.

Return the module for replacement.

Ensure that the module is of the correct type.

Record the module type, revision and serial number of the module before installation.

To install the module:

1. Ensure that the field cable assembly is installed and correctly located.

2. If I/O module keys are used, verify that all keys are installed in the correct positions and

properly seated in their slots.

3. Release the ejector tabs on the module using the release key. Ensure that the ejector tabs

are fully open.

4. Holding the ejectors, carefully insert the module into the intended slot.

5. Push the module fully home by pressing on the top and bottom of the module fascia.

Close the module ejectors, ensuring that they click into their locked position.

The module should mount into the chassis with a minimum of resistance. If the module does not

mount easily, do not force it. Remove the module and check it for bent or damaged pins. If the pins

have not been damaged, try reinstalling the module.

2.2. Field Cable Selection

I/O cables suitable for use with the TrustedTM TMR Pulse Generator and Monitoring Module are

detailed in the following Product Descriptions.

TM

1. PD-TC200 – Trusted

2. PD-TC500 – Trusted

The Product Descriptions detailed above also detail the types of Field Termination Assembly (FTA) or

Versatile Field termination Assembly (VFTA) which may be used with type of module

I/O Companion Slot Cables

TM

I/O SmartSlot Cables

Issue 09 Apr 10 PD-T8444 17

Page 18

Trusted

TM

Module T8444

2.3. Module Pinout Connections

1 Smart Slot Link C Smart Slot Link B Smart Slot Link A

2

3 Rod 1 Phase C Pwr Group 1 (+) Rod 1 Phase A

4 Rod 1 Phase CC Pwr Group 1 (+) Rod 1 Phase AA

5 Pwr Group 1 Rtn Pwr Group 1 (+) Pwr Group 1 Rtn

6 Rod 1 Gate A Pwr Group 1 (+) Rod 1 Phase B

7 Rod 1 Gate B Pwr Group 1 (+) Rod 1 Phase BB

8

9 Mon Rod 1 Phase C power supply A Pwr Group 2 (+) Mon Rod 1 Phase A power supply A

10 Mon Rod 1 Phase AA power supply A Pwr Group 2 (+) Mon Rod 1 Phase CC power supply A

11 Pwr Group 2 Rtn Pwr Group 2 (+) Pwr Group 2 Rtn

12 Mon Rod 1 Phase A power supply B Pwr group 2 (+) Mon Rod 1 Phase B power supply A

13 Mon Rod 1 Phase CC power supply B Pwr Group 2 (+) Mon Rod 1 Phase BB power supply A

14

15 Mon Rod 2 Phase A power supply A Pwr Group 3 (+) Mon Rod 1 Phase B power supply B

16 Mon Rod 2 Phase CC power supply A Pwr Group 3 (+) Mon Rod 1 Phase BB power supply B

17 Pwr Group 3 Rtn Pwr Group 3 (+) Pwr Group 3 Rtn

18 Mon Rod 2 Phase B power supply A Pwr Group 3 (+) Mon Rod 1 Phase C power supply B

19 Mon Rod 2 Phase BB power supply A Pwr Group 3 (+) Mon Rod 1 Phase AA power supply B

20

21 Mon Rod 2 Phase B power supply B Pwr Group 4 (+) Mon Rod 2 Phase C power supply A

22 Mon Rod 2 Phase BB power supply B Pwr Group 4 (+) Mon Rod 2 Phase AA power supply A

23 Pwr Group 4 Rtn Pwr Group 4 (+) Pwr Group 4 Rtn

24 Mon Rod 2 Phase C power supply B Pwr Group 4 (+) Mon Rod 2 Phase A power supply B

25 Mon Rod 2 Phase AA power supply B Pwr Group 4 (+) Mon Rod 2 Phase CC power supply B

26

27 Rod 2 Phase C Pwr Group 5 (+) Rod 2 Phase A

28 Rod 2 Phase CC Pwr Group 5 (+) Rod 2 PhaseAA

29 Pwr Group 1 Rtn Pwr Group 5 (+) Pwr Group 1 Rtn

30 Rod 2 Gate A Pwr Group 5 (+) Rod 2 Phase B

31 Rod 2 Gate B Pwr Group 5 (+) Rod 2 Phase BB

32

C B A

Table 2 Field Connector Pinout

Issue 09 Apr 10 PD-T8444 18

Page 19

Trusted

identified below)

TM

Module T8444

2.4. TrustedTM Module Polarisation/Keying.

M

All Trusted

The polarisation comprises two parts. The module and the associated field cable.

Each module type has been keyed during manufacture. The organisation responsible for the

integration of the Trusted

so that they correspond with the bungs fitted to the associated module prior to fitting.

T

Modules have been Keyed to prevent insertion into the wrong position within a chassis.

TM

system must key the cable by removing the keying pieces from the cable

Cable Exit

1

Polarising/Keying

Pins.

(Remove using

side cutters where

Trusted Cable

hood

12

Release button

Smart

Swap

Connector

if Fitted

Figure 5 Module polarisation

For Cables with Companion slot installations both keying strips must be polarised.

For This Module (T8444) remove keying pins 1,7,8

Issue 09 Apr 10 PD-T8444 19

Page 20

Trusted

TM

Module T8444

3. Application

3.1. Module Configuration

There is no configuration required to the physical module. All configurable characteristics of the

module are performed using tools on the EWS and become part of the application or system.ini file

that is loaded into the TMR Processor. The TMR Processor automatically configures the module after

applications are downloaded and during Active/Standby changeover.

The IEC1131 TOOLSET provides the main interface to configure the module. Details of the

configuration tools and configuration sequence are provided in PD-8082B Trusted

There are three procedures necessary to configure the module. These are:

1. Define the necessary I/O variables for the field data and module status data using the

Dictionary Editor of the IEC1131 TOOLSET.

2. Create an I/O module definition in the I/O Connection Editor for each I/O module. The I/O

module definition defines physical information, e.g. Chassis and Slot location, and allows

variables to be connected to the I/O channels of the module.

M

T

3. Using the Trusted

System Configuration Manager, define custom LED indicator modes,

per-channel default or fail-safe states, and other module settings.

TM

Toolset Suite.

3.2. T8444 Complex Equipment Definition

The T8444 I/O Complex Equipment Definition includes 8 I/O boards, referenced numerically

by Rack number. There are two OEM parameters included in the first rack (DO Board).

These OEM parameters define the primary module position; declaring the module’s chassis

and slot location. There is no need to define the secondary module position within the

IEC1131 TOOLSET. Where systems may be required to start-up with modules in the

secondary position as the active module, e.g. primary module is not installed when

application is started, the secondary module’s position should be declared in the module

definition of the System Configuration Manager.

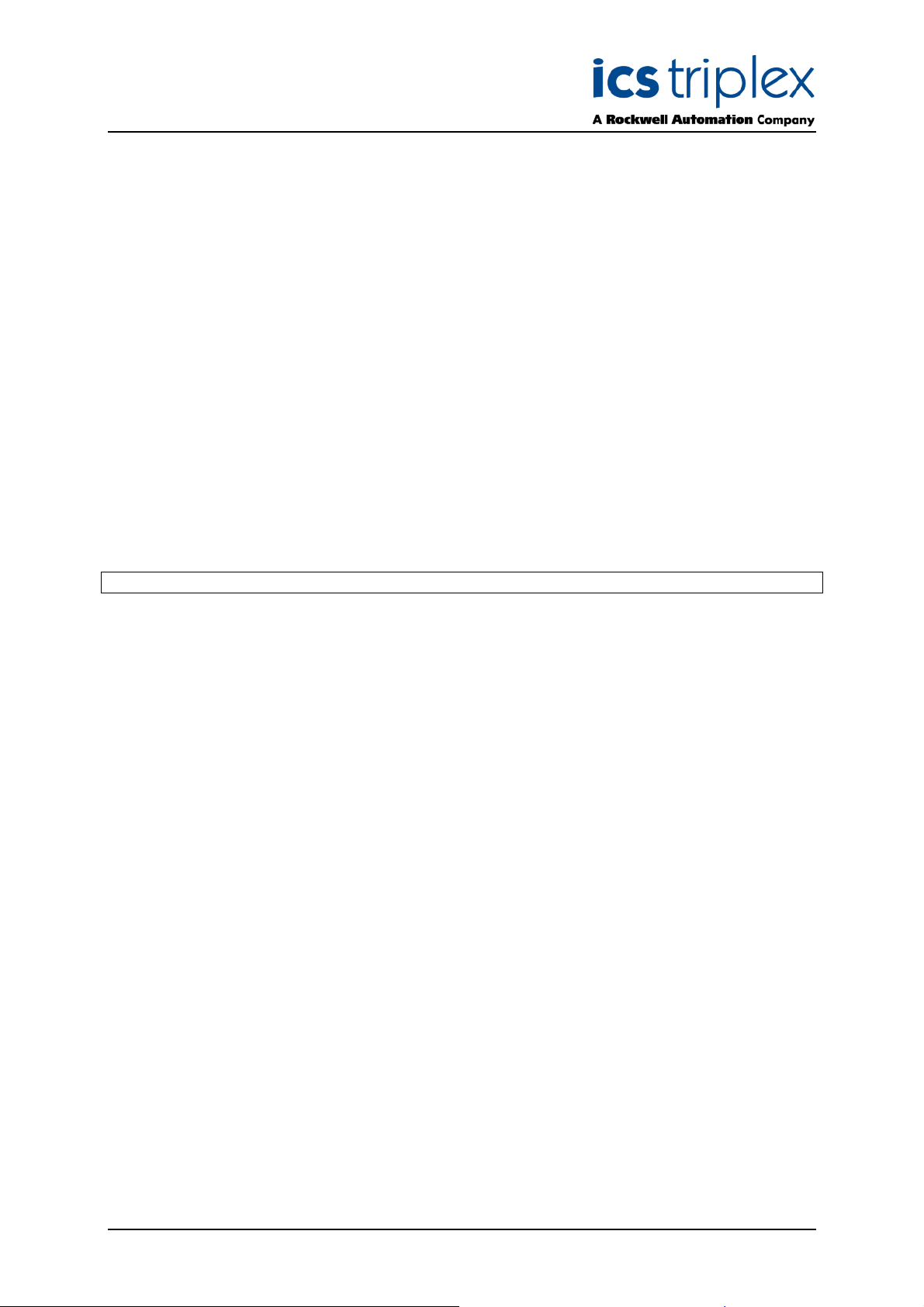

Rack I/O Board Description Data Type Direction No. of Channels

1 PG_CTRL

2 FIELD Field State Integer In 26

3 PI_CTRL Position Indicator controls Integer Out 12

4 PG_FAULT Pulse Generator faults Boolean In 16

5 LINE_FLT Line Fault Status Boolean In 40

6 DISCREP Channel Discrepancy Integer In 3

7 HKEEPING Housekeeping Registers Integer In 57

8 INFO I/O Module Information Integer In 11

OEM Parameters - - -

Pulse Generator controls Boolean Out 16

Table 3 Complex Equipment Definition

Issue 09 Apr 10 PD-T8444 20

Page 21

Trusted

TM

Module T8444

OEM Parameter Description Default

TICS_CHASSIS The number of the TrustedTM

Chassis where the Primary I/O

module is installed

TICS_SLOT The slot number in the chassis

where the Primary I/O module

is installed

Value

1 The TrustedTM Controller Chassis is 1, and Trusted

1 The I/O module slots in the TrustedTM Controller

Table 4 OEM Parameters

3.2.1. Rack 1: PG_CTRL

Channel Description

1 JOG control signal for Rod 1

2 RUN control signal for Rod 1

3 IN control signal for Rod 1

4 OUT control signal for Rod 1

5 ROD_TRIP control signal for Rod 1

6 PG_INHIBIT_RESET control signal for Rod 1

7 GD_A_INHIBIT_RESET control signal for Rod 1

8 GD_A_INHIBIT_RESET control signal for Rod 1

9 JOG control signal for Rod 2

10 RUN control signal for Rod 2

11 IN control signal for Rod 2

12 OUT control signal for Rod 2

13 ROD_TRIP control signal for Rod 2

14 PG_INHIBIT_RESET control signal for Rod 2

15 GD_A_INHIBIT_RESET control signal for Rod 2

16 GD_A_INHIBIT_RESET control signal for Rod 2

17 GD_A_INHIBIT_RESET control signal for Rod 2

18 GD_B_INHIBIT_RESET control signal for Rod 2

19 GD_A_INHIBIT control signal for Rod 2

20 GD_B_INHIBIT control signal for Rod 2

Notes

Expander Chassis are 2 to 15

chassis are numbered from 1 to 8. The I/O Module slots

in the TrustedTM Expander Chassis are numbered from

1 to 12

Table 5 Rack 1: PG_CTRL descriptions

Issue 09 Apr 10 PD-T8444 21

Page 22

Trusted

TM

Module T8444

3.2.2. Rack 2: FIELD

Channel Description

1 Phase A voltage feedback on Motor A of Rod 1

2 Phase B voltage feedback on Motor A of Rod 1

3 Phase C voltage feedback on Motor A of Rod 1

4 Phase AA voltage feedback on Motor A of Rod 1

5 Phase BB voltage feedback on Motor A of Rod 1

6 Phase CC voltage feedback on Motor A of Rod 1

7 Phase A voltage feedback on Motor B of Rod 1

8 Phase B voltage feedback on Motor B of Rod 1

9 Phase C voltage feedback on Motor B of Rod 1

10 Phase AA voltage feedback on Motor B of Rod 1

11 Phase BB voltage feedback on Motor B of Rod 1

12 Phase CC voltage feedback on Motor B of Rod 1

13 Position Indicator value for Rod 1

14 Phase A voltage feedback on Motor A of Rod 2

15 Phase B voltage feedback on Motor A of Rod 2

16 Phase C voltage feedback on Motor A of Rod 2

17 Phase AA voltage feedback on Motor A of Rod 2

18 Phase BB voltage feedback on Motor A of Rod 2

19 Phase CC voltage feedback on Motor A of Rod 2

20 Phase A voltage feedback on Motor B of Rod 2

21 Phase B voltage feedback on Motor B of Rod 2

22 Phase C voltage feedback on Motor B of Rod 2

23 Phase AA voltage feedback on Motor B of Rod 2

24 Phase BB voltage feedback on Motor B of Rod 2

25 Phase CC voltage feedback on Motor B of Rod 2

26 Position Indicator value for Rod 2

Table 6 Rack 2: Field descriptions

Issue 09 Apr 10 PD-T8444 22

Page 23

Trusted

TM

Module T8444

3.2.3. Rack 3: PI_CTRL

Channel Description

1 RESET control signal for PI for Rod 1

2 PULSER control signal for PI for Rod 1

3 COUNT_UP control signal for PI for Rod 1

4 COUNT_DOWN control signal for PI for Rod 1

5 LOAD control signal for PI for Rod 1

6 NewPosition integer value for PI for Rod 1

7 RESET control signal for PI for Rod 2

8 PULSER control signal for PI for Rod 2

9 COUNT_UP control signal for PI for Rod 2

10 COUNT_DOWN control signal for PI for Rod 2

11 LOAD control signal for PI for Rod 2

12 NewPosition integer value for PI for Rod 2

Table 7 Rack 3: PI_CTRL descriptions

3.2.4. Rack 4: PG_FAULT

Channel Description

1 Missing pulse fault on Motor A of Rod 1

2 Extra pulse fault on Motor A of Rod 1

3 Missing pulse fault on Motor B of Rod 1

4 Extra pulse fault on Motor B of Rod 1

5 <2 or >3 phases on fault on Rod 1

6 Pulse Generator inhibit on Rod 1

7 Gate Drive A inhibit on Rod 1

8 Gate Drive B inhibit on Rod 1

9 Missing pulse fault on Motor A of Rod 2

10 Extra pulse fault on Motor A of Rod 2

11 Missing pulse fault on Motor B of Rod 2

12 Extra pulse fault on Motor B of Rod 2

13 <2 or >3 phases on fault on Rod 2

14 Pulse Generator inhibit on Rod 2

15 Gate Drive A inhibit on Rod 2

16 Gate Drive B inhibit on Rod 2

Table 8 Rack 4: PG_Fault descriptions

Issue 09 Apr 10 PD-T8444 23

Page 24

Trusted

TM

Module T8444

3.2.5. Rack 5: Line_Flt

Channel Description

1 Field output channel 1 line fault

2 Field output channel 2 line fault

40 Field output channel 40 line fault

Table 9 Rack 5: Line_Flt descriptions

The line fault input state is reported as true (logic ‘1’) for a line fault condition (open circuit, short circuit, and no

field supply voltage). The logic state is the majority voted value.

3.2.6. Rack 6: Discrep

Channel Description

1 Discrepancy status outputs 1 to 16 (output 1 is LSB)

2 Discrepancy status outputs 17 to 32 (output 17 is LSB)

3 Discrepancy status outputs 33 to 40 (output 33 is LSB)

Table 10 Rack 6: Discrepancy descriptions

Each of the words reports the discrepancy status of 16 output channels. The corresponding bit within the word is

set to ‘1’ when a discrepancy condition is detected on that output channel’s output state (rack 2).

Issue 09 Apr 10 PD-T8444 24

Page 25

Trusted

Description

FCR

Units (Full Scale Range)

1A2B3

C

4A5B6

C

7A8B9

C

10A11B12

C

13A14B15

C

16A17B18

C

19A20B21

C

22A23B24

C

25A26B27

C

28A29B30

C

31A32B33

C

34A35B36

C

37A38B39

C

40A41B42

C

43A44B45

C

46A47B48

C

49A50B51

C

52A53B54

C

55A56B57

C

TM

Module T8444

3.2.7. Rack 7: Housekeeping

Channel

24V2 Output Voltage -32768 32767 mV

Internal supply voltage (post regulator) -32768 32767 mV

Internal supply current (post regulator) 0 65535 mA

Output voltage (post isolation) -32768 32767 mV

24V1 Output Voltage -32768 32767 mV

HIU Board Temperature

(Note: Temperature, ºC = input value / 256)

Front Panel Load Current 0 65535 mA

SmartSlot Link Voltage -32768 32767 mV

FIU Output Group 1 Field Supply Voltage -32768 32767 mV

FIU Board Temperature, Output Group 1

(Note: Temperature, ºC = input value / 256)

FIU Output Group 2 Field Supply Voltage -32768 32767 mV

FIU Board Temperature, Output Group 2

(Note: Temperature, ºC = input value / 256)

FIU Output Group 3 Field Supply Voltage -32768 32767 mV

FIU Board Temperature, Output Group 3

(Note: Temperature, ºC = input value / 256)

-32768 32767 -

-32768 32767 -

-32768 32767 -

-32768 32767 -

Issue 09 Apr 10 PD-T8444 25

FIU Output Group 4 Field Supply Voltage -32768 32767 mV

FIU Board Temperature, Output Group 4

(Note: Temperature, ºC = input value / 256)

FIU Output Group 5 Field Supply Voltage -32768 32767 mV

FIU Board Temperature, Output Group 5

(Note: Temperature, ºC = input value / 256)

Diagnostic error code

-32768 32767 -

-32768 32767 -

Table 11 Rack 7: Housekeeping descriptions

Page 26

Trusted

Each input within the housekeeping rack is reported as an integer. In general, the application engineer will not

normally require these inputs. They are provided to aid fault finding and diagnosis and may be used for reporting

and display purposes.

TM

Module T8444

3.2.8. Rack 8: INFO

Channel Description

1 Active Module chassis number

2 Active Module slot number

3 Active Module Healthy

4 Active Module Mode

5 Standby Module Chassis Number

6 Standby Module Slot Number

7 Standby Module Healthy

8 Standby Module Mode

9 FCR Status

10 Primary module is active

11 Active module is simulated

Table 12 Rack 8: INFO descriptions

The active module chassis and slot numbers indicate the position of the currently active module.

These values will change to match the primary or secondary module position, depending on their active

status, i.e. active/standby changeover will “swap” the values for the active module chassis and slot

number channels with those in the standby module chassis and slot number channels. The chassis

and slot numbers are set to zero if the module is not present.

3.3. SYSTEM.INI File Configuration

There are many operating characteristics of the module that can be customised for a particular

application. The System Configuration Manager is a tool that allows the user to configure the specific

operating characteristics for each module. Descriptions of the items that may be configured for the

Trusted

Certain characteristics apply to the entire module and are considered Module Configurable Items.

Other characteristics apply to individual output channels and are considered Channel Configurable

Items. There are specific default settings for each of the configurable items. If the default settings are

appropriate for a given application, then customisation of the module definition in the System

Configuration Manager is not required.

TM

Pulse Generator and Monitoring Module T8444 are contained in PD-8082B.

Issue 09 Apr 10 PD-T8444 26

Page 27

Trusted

TM

Module T8444

4. Operation

4.1. Front Panel

Status indicators on the front panel of the module provide visual indications of the module’s operational

status and field status. Each indicator is a bicolour LED. Located at the top and bottom of each

module is an ejector lever that is used to remove the module from the chassis. Limit switches detect

the open/closed position of the ejector levers. The ejector levers are normally latched closed when the

module is firmly seated into the Controller or Expander Chassis.

Module

Removal

Latch

Module

Status LEDs

Channel

Status LEDs

Module

Removal

Latch

Figure 6 Module Front Panel

Issue 09 Apr 10 PD-T8444 27

Page 28

Trusted

TM

Module T8444

4.2. Module Status LEDs

There are six module status indicators on the module front panel: three Healthy, one Active, one

Standby, and one Educated. The Healthy indicators are controlled directly by each module slice. The

Active, Standby, and Educated indicators are controlled by the FPU. The FPU receives data from

each of the module slices. The FPU performs a 2-oo-3 vote on each data bit from the slices and sets

the indicators accordingly.

The module status indicator modes and their meanings are described as follows:

INDICATOR STATE DESCRIPTION

Healthy Off No power applied to the module.

Amber Slice is in the start-up state (momentary after

installation or power-up)

Green Slice is healthy.

Red – flashing Fault present on the associated slice but the slice is still

operational.

Red (momentary) On installation – power applied to the associated slice.

Red The associated slice is in the fatal state. A critical fault

has been detected and the slice disabled..

Active Off Module is not in the Active state.

Green Module is in the Active (or Maintain) state.

Red – flashing Module is in the shutdown state if the Standby LED is

off.

Red – flashing Module is in the fatal state if the Standby LED is also

flashing.

Standby Off Module is not in the Standby state.

Green Module is in the Standby state.

Red – flashing Module is in the fatal state. The Active LED will also be

flashing red.

Educated Off Module is not educated.

Green Module is educated.

Green – flashing Module is recognised by the Processor but education is

not complete.

Amber - Flashing Active/standby changeover in progress

Table 13 Module Status Indicators

Issue 09 Apr 10 PD-T8444 28

Page 29

Trusted

TM

Module T8444

4.3. I/O Status LEDs

There are 40 channel status indicators on the module front panel, one for each field input/output.

These indicators are controlled by the FPU. The FPU receives data from each of the module slices.

The FPU performs a 2-oo-3 vote on each data bit from the slices and sets the indicators accordingly.

The input/output status indicator mode is dependent upon the numerical state of the channel. Each

state can be defined to have a particular indicator mode: off, green, red, flashing green, or flashing red.

The configurable indicator modes allow users to customise the status indications to suit individual

application requirements. Without customisation, the default indicator modes are suitable for damper

control installations as described below. Each channel is provided with a Bicolour Led. The channel

LED’s illuminate as follows.

4.3.1. Outputs and Gate Outputs

Function Off Green

Output off no

faults

Output Off with

Module Fault

Output Off with

field Fault

Output off with

Module and

Field Fault

Output on No

Faults

Output On with

Module Fault

Output On with

Field Fault

Output on with

Module and

field Fault

Yes Not

Yes Not

Not

Not

Not

Not

Not

Not

Steady

allowed

allowed

allowed

allowed

allowed

allowed

allowed

allowed

Green

Flash

Not

allowed

Not

allowed

Not

allowed

Not

allowed

Not

allowed

Not

allowed

Not

allowed

Not

allowed

Red

Steady

Slice LED’s Green

Slice LED’s Red

Yes Slice LED’s Green

Yes Slice LED’s Red

Yes Slice LED’s Green

Yes Slice LED’s Red

Yes Slice LED’s Green

Yes Slice LED’s Red

Red

Flash

Amber

Steady

Amber

Flash

Note

Table 14 Default I/O Status Indicators

Issue 09 Apr 10 PD-T8444 29

Page 30

Trusted

TM

Module T8444

4.3.2. Feedback Inputs

Function Off Green

Input off no

faults

Input off with

Module fault

Input off with

Field Fault

Input Off with

Module and

Field Fault

Input On no

Fault

Input on with

Module fault

Input on with

Field Fault

Input on with

both Module

and field fault

Yes Not

Yes Not

Not

Not

Yes Not

Yes Not

Not

Not

Steady

Green

Flash

Red

Steady

allowed

allowed

allowed

allowed

allowed

allowed

allowed

allowed

Red Flash Amber

Not

allowed

Not

allowed

Not

allowed

Not

allowed

Not

allowed

Not

allowed

Not

allowed

Not

allowed

Steady

Slice LED’s

Slice LED’s Red

Yes Slice LED’s

Yes Slice LED’s Red

Slice LED’s

Slice LED’s Red

Yes Slice LED’s

Yes Slice LED’s Red

Amber

Flash

Notes

Green

Green

Green

Green

Table 15 Feedback Inputs

Note: The LEDs indicating channel status may be configured to suit user requirements by

implementing the procedure for configuring the System.INI file detailed in PD-8082B.

Issue 09 Apr 10 PD-T8444 30

Page 31

Trusted

TM

Module T8444

4.4. Output and Input separation/Channel allocation

The Module has 6 pulse outputs 12 pulse inputs and 2 control signals per motor drive. The output

module has 5 power groups protected by Group Fail safe switches. In order to minimise the effect of a

single group failure the I/O is segregated as shown below.

Power

Group

1 1 Rod 1 Phase A 3 21 Mon Rod 2 Phase A power supply A

1 2 Rod 1 Phase CC 3 22 Mon Rod 2 Phase CC power supply A

1 3 Rod 1 Phase B 3 23 Mon Rod 2 Phase B power supply A

1 4 Rod 1 Phase BB 3 24 Mon Rod 2 Phase BB Power supply A

1 5 Rod 1 Phase C 4 25 Mon Rod 2 Phase C power supply A

1 6 Rod 1 Phase AA 4 26 Mon Rod 2 Phase AA power supply A

1 7 Rod 1 Gate A 4 27 Mon Rod 2 Phase A power supply B

1 8 Rod 1 Gate B 4 28 Mon Rod 2 Phase CC Power supply B

2 9 Mon Rod 1 Phase A

2 10 Mon Rod 1 Phase CC

2 11 Mon Rod 1 Phase B

2 12 Mon Rod 1 Phase BB

2 13 Mon Rod 1 Phase C

2 14 Mon Rod 1 Phase AA

2 15 Mon Rod 1 Phase A

2 16 Mon Rod 1 Phase CC

3 17 Mon Rod 1 Phase B

3 18 Mon Rod 1 Phase BB

3 19 Mon Rod 1 Phase C

3 20 Mon Rod 1 Phase AA

Channel Function Power

Group

4 29 Mon Rod 2 Phase B power supply B

power supply A

4 30 Mon Rod 2 Phase BB power supply B

power supply A

4 31 Mon Rod 2 Phase C power supply B

power supply A

4 32 Mon Rod 2 Phase AA Power supply B

Power supply A

5 33 Rod 2 Gate A

power supply A

5 34 Rod 2 Gate B

power supply A

5 35 Rod 2 Phase A

power supply B

5 36 Rod 2 Phase CC

Power supply B

5 37 Rod 2 Phase B

power supply B

5 38 Rod 2 Phase BB

power supply B

5 39 Rod 2 Phase C

power supply B

5 40 Rod 2 Phase AA

Power supply B

Channel Function

Table 16 I/O separation/Channel allocation

Issue 09 Apr 10 PD-T8444 31

Page 32

Trusted

TM

Module T8444

5. Fault Finding and Maintenance

5.1. Fault Reporting

Module faults are reported to the user through visual indicators on the front panel of the module and

through status variables which may be automatically monitored in the application programs and

external system communications interfaces. There are generally two types of faults that must be

remedied by the user: external wiring and module faults. External wiring faults require corrective action

in the field to repair the fault condition. Module faults require replacement of the module.

5.2. Field Wiring Faults

By measuring the channel voltage and current, the module automatically detects field-wiring and load

faults. When a field signal fails open circuit, short circuit or there is no field supply voltage connected,

the status indicator will display the configured LED mode and the line fault status for that channel will

be set to ‘1’. All other channels will be unaffected, except in the case of common cause wiring and

supply voltage faults in the field.

The field voltage and current variables can be monitored to determine the actual operating conditions

of each channel. This additional information assists the user in determining the specific type of wiring

fault.

Once the specific field-wiring fault has been identified and corrected, the status variables and status

indicator will display the normal on/off status of the field device.

5.3. Module Faults

Extensive diagnostics provide the automatic detection of module faults. The TMR architecture of the

module and the diagnostics performed ensure the validity of all critical circuits. Using the TMR

architecture provides a Fault Tolerant method to withstand the first fault occurrence on the module and

continue normal control without interruption in the system or process. Faults are reported to the user

through the Healthy status indicators on the front panel of the module and through the INFO and

HKEEPING variables. Under normal operations all three Healthy Indicators are green. When a fault

occurs, one of the Healthy Indicators will be flashing red. It is recommended that this condition is

investigated and if the fault is within the module, it should be replaced .

Issue 09 Apr 10 PD-T8444 32

Page 33

Trusted

TM

Module T8444

5.4. Companion Slot

M

For a Companion Slot configuration, two adjacent slots in a Trusted

same input module function. One slot is the primary slot and the other a unique secondary (or spare)

slot. The two slots are joined at the rear of the Trusted

TM

Chassis with a double-wide I/O Interface

T

Chassis are configured for the

Cable that connects both slots to common field wiring terminations. During normal operations, the

primary slot contains the active module as indicated by the Active indicator on the front panel of the

module. The secondary slot is available for a spare module that will normally be the standby module

as indicated by the Standby indicator on the front panel of the module.

Depending on the installation, a hot-spare module may already be installed, or a module blank will be

installed in the standby slot. If a hot-spare module is already installed, transfer to the standby module

occurs automatically if a module fault is detected in the active module. If a hot spare is not installed,

the system continues operating from the active module until a spare module is installed.

5.5. SmartSlot

For a SmartSlot configuration, the secondary slot is not unique to each primary slot. Instead, a single

secondary slot is shared among many primary slots. This technique provides the highest density of

modules to be fitted in a given physical space. At the rear of the Trusted

Cable connects the secondary slot directly to the I/O Cable connected to the failed primary module.

With a spare module installed in the SmartSlot and the SmartSlot I/O Cable connected to the failed

primary module, the SmartSlot can be used to replace the failed primary module.

Output module Smart Slot jumper cable TC-308-02

Smart Slot between chassis can be performed if the chassis are version 2 (or higher). These have the

connector fitted to enable connection of a TC-006 that ensures the 0 Volt of each chassis is at the

same potential.

TM

Chassis, a single-wide I/O

5.6. Cold Start

If an I/O module has shut down (due, for example, to two existing faults), the three Healthy LEDs will

be red, the Active and Standby LEDs will be flashing red and the Educated LED will be flashing amber.

The I/O functions provided by this module will have been lost if a hot swap partner has not taken over

control. The module can only be restarted by removing it from its slot and re-inserting it.

If an I/O module is inserted into a functional system slot which previously had no active module (e.g.

removing and reinserting as above), then the processor will educate the module once it has booted.

Once educated, the Educated LED will be steady green and the Active LED will be red flashing.

Input modules will now be reading and reporting their inputs. Output modules have not yet energised

their outputs. To activate outputs and to set the module’s Active LED and the processor’s System

Healthy LED steady green, press the processor Reset pushbutton.

Issue 09 Apr 10 PD-T8444 33

Page 34

Trusted

the secondary, I/O module location for

each I/O module pair. Each primary module location must be unique and is defined as

. Secondary

ltiple secondary modules and are

defined within the module’s section within the System.INI file. The system will

automatically determine the secondary module position if the primary module is installed

module is installed, it will become the active module by

default. If the secondary module has been defined within the System.INI file and no

primary module is present, and if the secondary module location is unique, the

tive module by default. If the secondary module is

installed with no primary module present, and the secondary module location is not

unique (as in a SmartSlot configuration), then NO module for that module pair will

o become the active module, the TMR Processor will verify that

the module is the correct I/O module type and that both Module Removal levers (and

hence micro switches) are closed. At this point the I/O module is configured and

When a fault occurs on the active module, the TMR Processor will be informed. Once it

becomes aware of the fault, the TMR Processor will attempt an active/standby

by changeover starts with the TMR Processor checking to see if a

standby I/O module is installed. If no standby I/O module is available, the TMR

Processor will continue to utilise the active module and will continue to check for an

odule. Once a standby module is found, the TMR Processor will

verify that the I/O module is of the correct type, that both Module Removal switches are

closed, and that the I/O module is a part of the correct module pair by using the

is point, the TMR Processor will configure the standby I/O module

with the same configuration information as the currently active I/O module and place the

standby I/O module into the standby state. The active module is then placed in the

hich suspends field loop testing), and any module specific changeover

data is transferred. The educated light flashes amber before the active/standby

changeover takes place, to indicate transfer of dynamic change over data (COD). The

ule then becomes the active module and the original module

becomes standby. If the currently active module does not successfully complete the

tests, the TMR Processor will revert it to the standby state, and the module in the

When both Module Removal switches are opened on an active module, regardless of the

module fault status, the TMR Processor will treat it as a request to perform an

TM

Module T8444

5.7. Transfer between Active and Standby Modules

The TMR Processor is responsible for managing a pair of I/O modules through an active/standby

changeover. The following rules apply to active/standby changeovers, though the TMR Processor and

not the I/O module enforce them:

• The user must define the primary, and optionally

part of the complex equipment definition within the IEC1131 TOOLSET

module locations can be unique or shared between mu

and is operable.

• On initial start-up, if the primary

secondary module will become the ac

become active.

• In order for a module t

eventually placed in the active state.

• A module in the active state should never be removed.

•

changeover.

• An active/stand

available standby I/O m

SmartSlot link. At th

maintain state (w

previous standby mod

selfmaintain state will revert back to the active state.

•

active/standby changeover.

Under normal conditions, an active/standby changeover will only occur if the new active module is

fault-free. Under some circumstances, it is desirable to be able to force a changeover to a known

faulted module. This can be accomplished by opening the Module Removal switches on the currently

active module and pressing the push-button reset on the TMR Processor. This will force the

changeover to proceed even if the new active module is not fault free

Issue 09 Apr 10 PD-T8444 34

Page 35

Trusted

TM

Module T8444

6. Technical specification

6.1. Introduction

The Pulse Generator and Monitoring module is required to be high integrity but it is not in itself

intended to be a safety system.

The design concept maintains the advantages of TMR systems while retaining a simple

implementation of a Damper Rod control system by the use of redundant paths.

The PG/M generates a series of waveforms which rotate a stepper motor in either a clockwise or anti

clockwise direction. The phasing of the outputs determines the direction of rotation while the frequency

determines the speed.

Figure 7 PG/M Functional Block Diagram

Issue 09 Apr 10 PD-T8444 35

Page 36

Trusted

TM

Module T8444

6.2. Phase Rotation

PHASE 1 _|WWWWW|_______|WWWWW|_______|WW

PHASE 2 ___|WWWWW|_______|WWWWW|_______|

PHASE 3 _____|WWWWW|_______|WWWWW|______

PHASE 4 _______|WWWWW|_______|WWWWW|____

PHASE 5 WW|_______|WWWWW|_______|WWWWW|__

PHASE 6 WWWW|_______|WWWWW|_______|WWWWW|

TIME

T

2

| T

| T

TIME

T

1

FREQ. 1

(1.33 HZ)

FREQ. 2

(13.3 HZ)

NOTE : TIMING IS SHOWN FOR CLOCKWISE ROTATION OF STEPPING MOTOR.

FOR COUNTER-CLOCKWISE ROTATION PHASE 6 WOULD LEAD PHASE 5 WHICH WOULD

LEAD PHASE 4

437.5 MS 312.5 MS 125.0 MS

43.75 MS 31.25 MS 12.5 MS

1

2

| T3|

TIME

T

3

Issue 09 Apr 10 PD-T8444 36

Page 37

Trusted

TM

Module T8444

6.3. Fail Safe actions

This is not a safety system. Other equipment must be supplied for removing the power from the motor

drive circuits in an emergency. Fail safe action in this case is to maintain control of the rods whenever

possible even if a fault is detected in the control Module. For example a slice fault will be logged and

annunciated to the Trusted

This is not a safety critical design and has been classified as Sil0 however it can reside in a system

which is capable of maintaining AK6 on some of its signals.

M

T

controller but it will not result in the module entering the “Fatal” state.

6.4. Internal testing and Monitoring

Maintaining control of the Damper Rods/Stepper Motors is the primary aim of this system. Fail danger

faults detected by any diagnostics do not lead to the module releasing the Damper rods except in the

manner specified in Framatome Spec 08-5011407-00.

Monitoring which detects faults provides alarm indication but unless totally unavoidable does not

release control of the damper rods.

6.5. Thyristor Driver interfaces/Stepper Motor Drives

6.5.1. Module Start up

When a module is powered up it will maintain all outputs Off. Gate signals will be off and Output

Drives will be off.

TM

The education process is automatic and follows the Trusted

Once the boot and education sequence is complete the module will turn on Outputs A and B for each

Motor. The fault detection will operate and the fault bits will be determined depending upon the field

state.

The Gate drives will remain latched until commanded to reset by the application program.

Should the motor poll pieces not be aligned with A&B it is assumed that a recovery procedure will be

initiated by the application to engage the threaded rod.

After a successful start the Position counters will be set to Zero. This value can be amended using the

INI file if required.

Should a module detect a problem with booting and education the start up will be aborted and the

module will not energise any of its outputs. Restart will be by removal and re insertion of the module.

standard procedure.

6.5.2. Minimum output Load

The Pulse Generator and Monitoring Module requires a minimum current to be drawn from each

energised output. If the load to which it is connected is not sufficient. It is suggested that the

termination resistor of 500Ohms should be fitted

6.5.3. Input Termination Resistance

Input circuits accept 0 to 10V analogue values. Circuits which are interfacing to 4 to 20mA signals

should be conditioned with a 500 Ohm resistor.

Issue 09 Apr 10 PD-T8444 37