Page 1

Trusted

TM

PD-T8403

TM

Trusted

TMR 24V dc Digital Input

Module – 40 Channel

Introduction

The TrustedTM TMR 24V dc Digital Input module interfaces to 40 field input devices. Fault tolerance is

achieved through a Triple Modular Redundant (TMR) architecture within the module for each of the 40

input channels.

Each field input is triplicated and the input voltage is measured using a sigma-delta input circuit. The

resulting field voltage measurement is compared to user configurable threshold voltages to determine

the reported field input state. When a line-monitoring device is installed at the field switch, the module

can detect open and short-circuit field cables. Line monitoring functions are independently configured

for each input channel. The triplicated voltage measurement, coupled with on-board diagnostic testing,

provides comprehensive fault detection and tolerance.

The module provides on-board Sequence of Events (SOE) reporting with a resolution of 1ms. A

change of state triggers an SOE entry. States are determined by voltage thresholds that can be

configured on a per channel basis.

Features

• 40 Triple Modular Redundant (TMR) input channels per module.

• Comprehensive, automatic diagnostics and self-test.

• Selectable line monitoring per channel to detect open circuit and short circuit field wiring

faults.

• 2500V dc optical isolation barrier.

• On-board Sequence of Events (SOE) reporting with 1ms resolution.

• Configurable 50/60Hz digital filtering to eliminate field induced noise.

• Module can be hot-replaced on-line using dedicated Companion (adjacent) Slot or SmartSlot

(one spare slot for many modules) configurations.

• Front panel input status LEDs for each channel indicate input status and field wiring faults.

• Front panel module status LEDs indicate module health and operational mode (Active,

Standby, Educated)

• TϋV Certified IEC61508 SIL 3

Issue 15 Jun 13 PD-T8403 1

Page 2

Trusted

Issue Record

Issue

Number Date Revised by Technical Check Authorised by Modification

8 Jan 05 J Bourn Gerry Creech Russell

9 May 05 J.W. Clark G Creech R Cockman Reformat

10 June 05 J.W. Clark G Creech R Cockman Reformat

11 Dec 06 V Middleton N Owens P Stock Weights & Dims

12 Nov 07 N Owens A Holgate P Stock STATE descriptions

13 Dec 08 N Owens A Holgate P Stock Channel LEDs

14 Apr 10 S. Blackett A. Holgate P. Stock Table 7 change

15 Jun 13 N Owens S.Blackett P Stock States 0 and 6 removed

TM

Module T8403

Cockman

Issue 15 Jun 13 PD-T8403 2

Page 3

Trusted

TM

Module T8403

This page is intentionally blank

Issue 15 Jun 13 PD-T8403 3

Page 4

Trusted

TM

Module T8403

Table of Contents

1. Description ................................................................................................................................... 8

1.1. Field Termination Unit (FTU) ....................................................................................................... 9

1.2. Field Interface Unit (FIU) ............................................................................................................. 9

1.3. Host Interface Unit (HIU) ........................................................................................................... 10

1.4. Front Panel Unit (FPU) .............................................................................................................. 10

1.5. Line Monitoring Thresholds........................................................................................................ 11

1.6. Housekeeping ............................................................................................................................ 12

1.7. Fault Detection and Testing ....................................................................................................... 12

1.8. Sequence of Events Characteristics .......................................................................................... 12

2. Installation .................................................................................................................................. 13

2.1. Module Insertion/Removal ......................................................................................................... 13

2.2. Field Cable Selection ................................................................................................................. 13

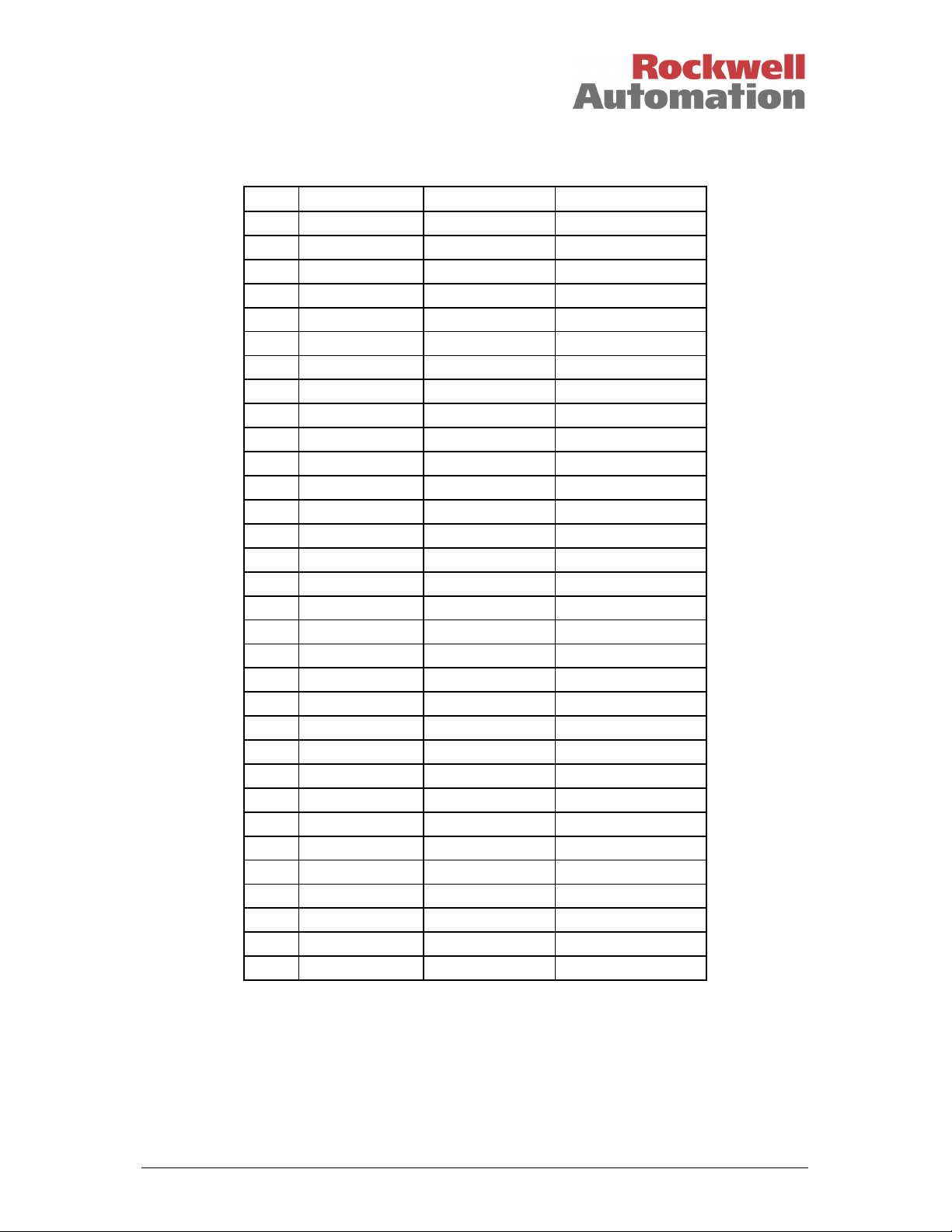

2.3. Module Pinout Connections ....................................................................................................... 14

2.4. TrustedTM Module Polarisation/Keying. ...................................................................................... 15

3. Application ................................................................................................................................. 16

3.1. Module Configuration ................................................................................................................. 16

3.2. T8403 Complex Equipment Definition ....................................................................................... 16

3.2.1. Rack 1: DI .................................................................................................................................. 17

3.2.2. Rack 2: STATE .......................................................................................................................... 17

3.2.3. Rack 3: AI .................................................................................................................................. 18

3.2.4. Rack 4: SPARE.......................................................................................................................... 19

3.2.5. Rack 5: LINE_FLT ..................................................................................................................... 19

3.2.6. Rack 6: DISCREP ...................................................................................................................... 19

3.2.7. Rack 7: HKEEPING ................................................................................................................... 20

3.2.8. Rack 8: Information .................................................................................................................... 21

3.3. Sequence of Events Configuration ............................................................................................ 22

3.4. SYSTEM.INI File Configuration ................................................................................................. 22

4. Operation ................................................................................................................................... 23

4.1. Front Panel ................................................................................................................................ 23

4.2. Module Status LEDS .................................................................................................................. 24

4.3. I/O Status LEDs ......................................................................................................................... 25

5. Fault Finding and Maintenance .................................................................................................. 26

5.1. Fault Reporting .......................................................................................................................... 26

5.2. Field Wiring Faults ..................................................................................................................... 26

5.3. Module Faults ............................................................................................................................ 26

5.4. Companion Slot ......................................................................................................................... 27

5.5. SmartSlot ................................................................................................................................... 27

Issue 15 Jun 13 PD-T8403 4

Page 5

Trusted

5.6. Cold Start ................................................................................................................................... 27

5.7. Transfer between Active and Standby Modules ........................................................................ 28

6. Specifications ............................................................................................................................. 29

TM

Module T8403

Figures

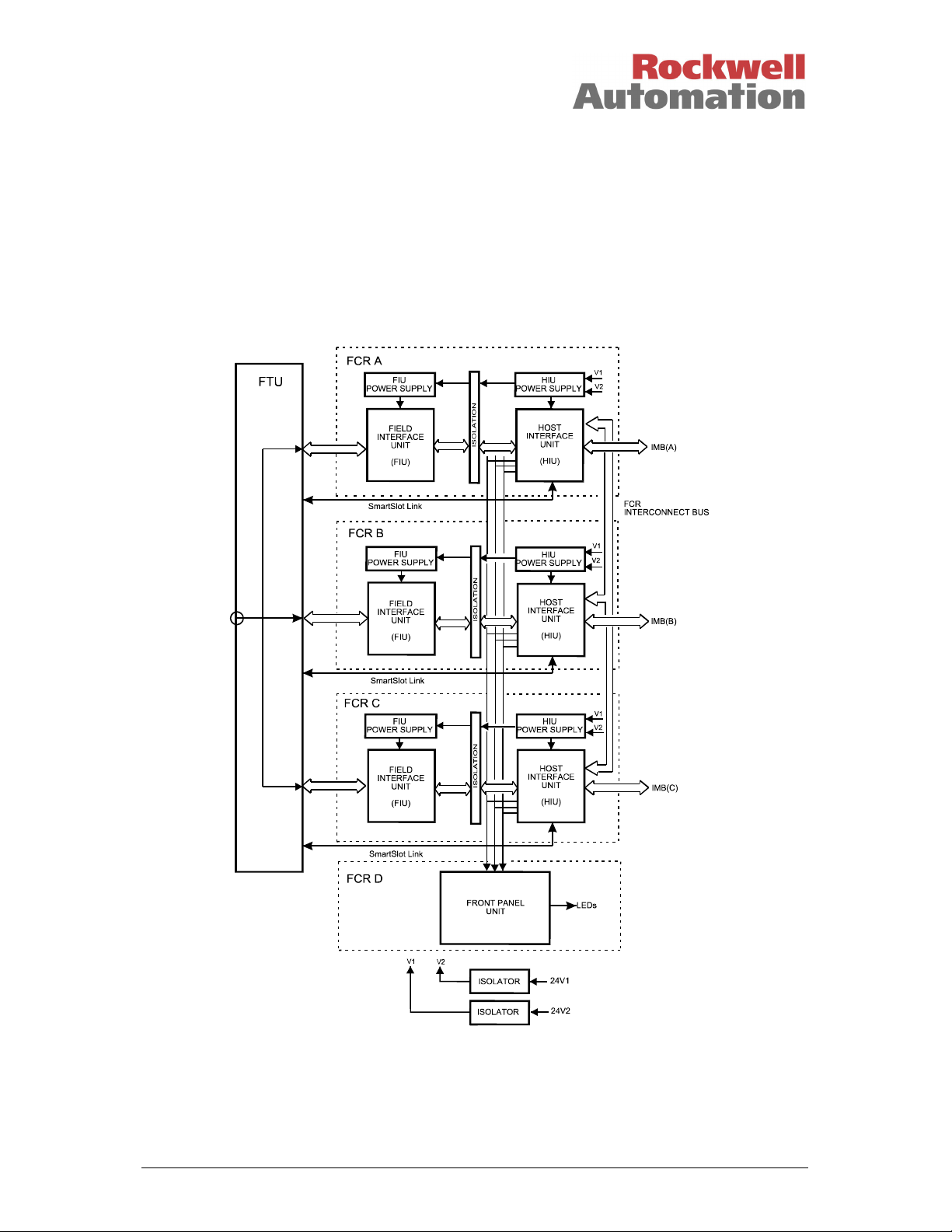

Figure 1 Module Architecture ................................................................................................................... 8

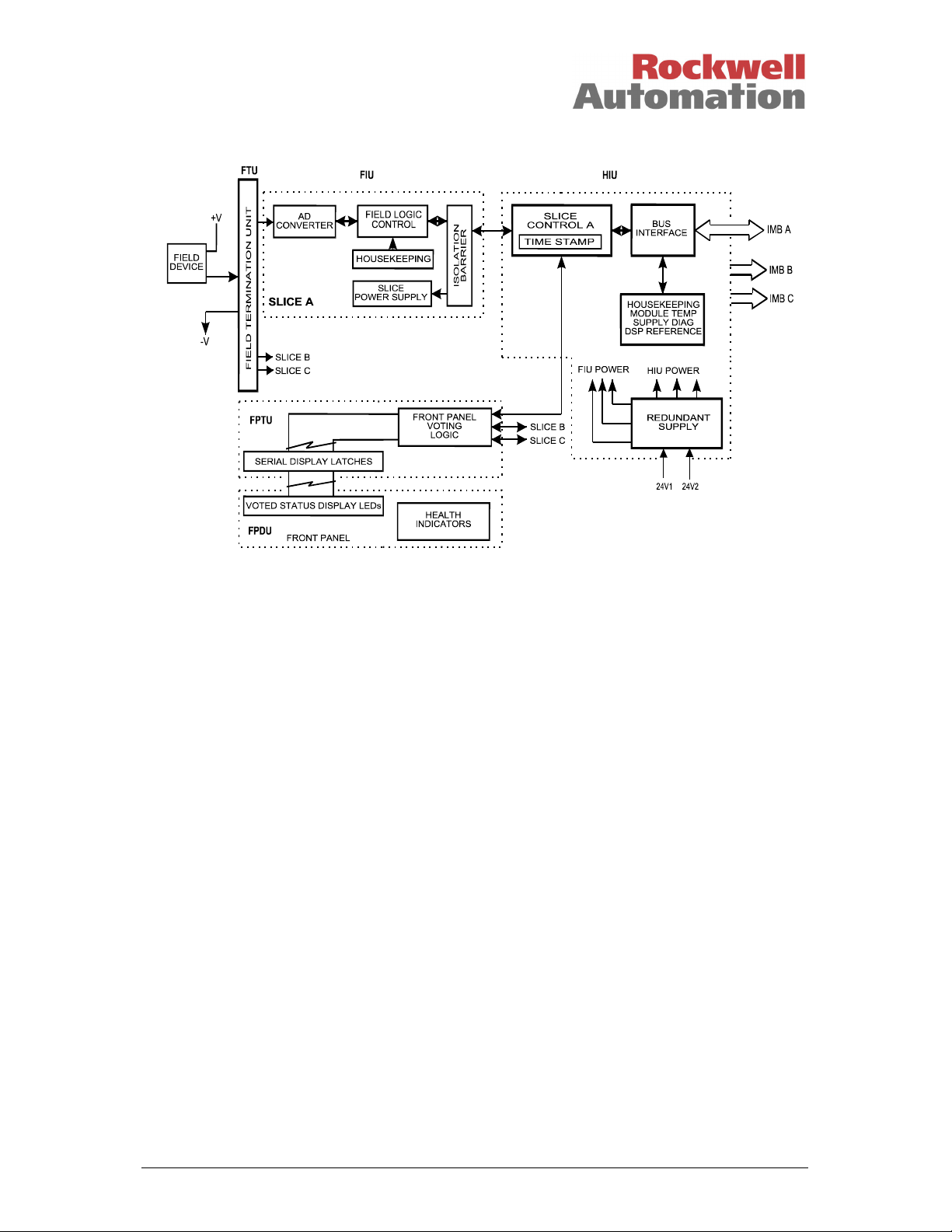

Figure 2 Functional Block Diagram ......................................................................................................... 9

Figure 3 Module polarisation ................................................................................................................. 15

Figure 4 Module Front Panel ................................................................................................................. 23

Tables

Table 1 Example Threshold data ............................................................................................................ 11

Table 2 Field Connector Pinout .............................................................................................................. 14

Table 3 Complex Equipment Definition .................................................................................................. 16

Table 4 OEM Parameters ....................................................................................................................... 17

Table 5 Rack 1: DI descriptions .............................................................................................................. 17

Table 6 Rack 2: STATE descriptions...................................................................................................... 17

Table 7 Rack 2: STATE Output descriptions .......................................................................................... 18

Table 8 Rack 3: Channel Field Voltage .................................................................................................. 18

Table 9 Rack 3: Channel Field Voltage bit definitions ............................................................................ 18

Table 10 Rack 5: LINE_FLT ................................................................................................................... 19

Table 11 Rack 6: DISCREP bit descriptions .......................................................................................... 19

Table 12 Rack 7: Housekeeping ............................................................................................................ 20

Table 13 Rack 8: INFO Descriptions ...................................................................................................... 21

Table 14 Rack 8: INFO bit Descriptions ................................................................................................. 21

Table 15 Rack 8: FCR bit Descriptions .................................................................................................. 22

Table 16 Module Status LEDs ................................................................................................................ 24

Table 17 Default I/O status Indicators .................................................................................................... 25

Issue 15 Jun 13 PD-T8403 5

Page 6

Trusted

TM

Module T8403

Notice

The content of this document is confidential to ICS Triplex Technology Ltd. companies and their

partners. It may not be given away, lent, resold, hired out or made available to a third party for any

purpose without the written consent of ICS Triplex Technology Ltd.

This document contains proprietary information that is protected by copyright. All rights are reserved.

Microsoft, Windows, Windows 95, Windows NT, Windows 2000, and Windows XP are registered

trademarks of Microsoft Corporation.

The information contained in this document is subject to change without notice. The reader should, in

all cases, consult ICS Triplex Technology Ltd. to determine whether any such changes have been

made. From time to time, amendments to this document will be made as necessary and will be

distributed by ICS Triplex Technology Ltd.

Information in this documentation set may be subject to change without notice and does not represent

a commitment on the part of ICS Triplex Technology Ltd.

The contents of this document, which may also include the loan of software tools, are subject to the

confidentiality and other clause(s) within the Integrator Agreement and Software License Agreement.

No part of this documentation may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and recording, for any purpose, without the express

written permission of ICS Triplex Technology Ltd.

Disclaimer

The illustrations, figures, charts, and layout examples in this manual are intended solely to illustrate the

text of this manual.

The user of, and those responsible for applying this equipment, must satisfy themselves as to the

acceptability of each application and use of this equipment.

This document is based on information available at the time of its publication. W hile efforts have been

made to be accurate, the information contained herein does not purport to cover all details or variations

in hardware or software, nor to provide for every possible contingency in connection with installation,

operation, or maintenance. Features may be described herein which are present in all hardware or

software systems. ICS Triplex Technology Ltd. assumes no obligation of notice to holders of this

document with respect to changes subsequently made.

ICS Triplex Technology Ltd. makes no representation or warranty, expressed, implied, or statutory with

respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness of

the information contained herein. No warranties of merchantability or fitness for purpose shall apply.

Issue 15 Jun 13 PD-T8403 6

Page 7

Trusted

TM

Module T8403

Revision and Updating Policy

All new and revised information pertinent to this document shall be issued by ICS Triplex Technology

Ltd. and shall be incorporated into this document in accordance with the enclosed instructions. The

change is to be recorded on the Amendment Record of this document.

Precautionary Information

WARNING

Warning notices call attention to the use of materials, processes, methods, procedures or limits which

must be followed precisely to avoid personal injury or death.

CAUTION

Caution notices call attention to methods and procedures which must be followed to avoid damage to

the equipment.

Notes:

Notes highlight procedures and contain information to assist the user in the understanding of the

information contained in this document

Warning

RADIO FREQUENCY INTERFERENCE

Most electronic equipment is influenced by Radio Frequency Interference (RFI). Caution should be

exercised with regard to the use of portable communications equipment around such equipment.

Signs should be posted in the vicinity of the equipment cautioning against the use of portable

communications equipment.

MAINTENANCE

Maintenance must be performed only by qualified personnel, otherwise personal injury or death, or

damage to the system may be caused.

Caution

HANDLING

Under no circumstances should the module housing be removed.

Associated Documents

Product Descriptions (PD) provide product specific information.

The Safety Manual contains the recommended safety requirements for the safety system design.

The PD8082B – Toolset Suite provides specific guidance on system configuration and application

generation.

The Operator and Maintenance Manual contains general guidelines on maintenance and diagnostic

procedures.

For technical support email: support@icstriplex.com

Issue 15 Jun 13 PD-T8403 7

Page 8

Trusted

TM

Module T8403

1. Description

The TrustedTM TMR 24V dc Digital Input module is a member of the TrustedTM range of Input/Output

(I/O) modules. All TrustedTM I/O modules share common functionality and form. At the most general

level, all I/O modules interface to the Inter-Module Bus (IMB) which provides power and allows

communication with the TrustedTM TMR Processor. In addition, all modules have a field interface that

is used to connect to module specific signals in the field. All modules are Triple Modular Redundant

(TMR).

Figure 1 Module Architecture

All TrustedTM I/O modules comprise four sections: Host Interface Unit (HIU), the Field Interface Unit

(FIU), the Field Termination Unit (FTU) and the Front Panel Unit (or FPU).

Issue 15 Jun 13 PD-T8403 8

Page 9

Trusted

Figure 2 shows a simplified functional block diagram of the TrustedTM 24V dc Digital Input module.

TM

Module T8403

Figure 2 Functional Block Diagram

1.1. Field Termination Unit (FTU)

The Field Termination Unit (FTU) is the section of the I/O module that connects all three FIUs to a

single field device. The FTU primarily contains passive components necessary for front-end signal

conditioning, field signal over-voltage protection, and EMI/RFI filtering. W hen installed in a TrustedTM

Controller or Expander Chassis, the FTU field connector interconnects to the I/O cable assembly

attached at the rear of the chassis.

The SmartSlot link is passed from the HIU to the field connections via the FTU. These signals go

directly to the I/O cable assembly and maintain isolation from the I/O signals on the FTU. The

SmartSlot link is the intelligent connection between active and standby modules for co-ordination

during module replacement.

1.2. Field Interface Unit (FIU)

The Field Interface Unit (FIU) is the section of the module that contains the specific circuits necessary

to interface to the particular types of field I/O signals. Each module has three FIUs, one per slice. For

the TMR 24V dc Digital Input module, the FIU contains an individual analogue to digital (A/D) converter

for each of the 40 field inputs.

The FIU receives isolated power from the HIU for logic. The FIU provides additional power

conditioning for the operational voltages required by the FIU circuitry. An isolated 6.25Mbit/sec serial

link connects each FIU to one of the HIU slices.

The FIU also measures a range of on-board “house-keeping” signals that assist in monitoring the

performance and operating conditions of the module. These signals include power supply voltages,

current consumption, on-board reference voltages, board temperature, and condensation.

Issue 15 Jun 13 PD-T8403 9

Page 10

Trusted

s between slices to vote incoming IMB data and distribute outgoing I/O

Redundant power sharing of dual 24V dc chassis supply voltage and power regulation for logic

ordination during module

board housekeeping, which monitors reference voltages, current consumption and board

TM

Module T8403

1.3. Host Interface Unit (HIU)

The HIU is the point of access to the Inter-Module Bus (IMB) for the module. It also provides power

distribution and local programmable processing power. The HIU is the only section of the I/O module

to directly connect to the IMB backplane. The HIU is common to most TrustedTM I/O types and has

type dependent and product range common functions. Each HIU contains three independent slices,

commonly referred to as A, B, and C.

All interconnections between the three slices incorporate isolation to prevent any fault interaction

between the slices. Each slice is considered a Fault Containment Region (FCR), as a fault on one

slice has no effect on the operation of the other slices.

The HIU provides the following services common to the modules in the family:

• High Speed Fault Tolerant Communications with the TMR Processor via the IMB interface.

• FCR Interconnect Bu

module data to the IMB.

• Optically isolated serial data interface to the FIU slices.

•

power to HIU circuitry.

• Magnetically Isolated power to the FIU slices.

• Serial data interface to the FPU for module status LEDs.

• SmartSlot link between active and standby modules for co-

replacement.

• Digital Signal Processing to perform local data reduction and self-diagnostics.

• Local memory resources for storing module operation, configuration, and field I/O data.

• On-

temperature.

1.4. Front Panel Unit (FPU)

The Front Panel Unit (FPU) comprises a Front Panel Termination Unit (FPTU) and a Front Panel

Display Unit (FPDU). The overall FPU contains the necessary connectors, switches, logic, and LED

indicators for the front panel. For every type of TrustedTM I/O module, the FPU contains the Slice

Healthy, Active/Standby and Educated indicators (LEDs), and the module removal switches.

Additional bicolour LEDs provide status indication for the individual I/O signals. Serial data interfaces

connect the FPU to each of the HIU slices to control the LED status indicators and monitor the module

removal switches.

Issue 15 Jun 13 PD-T8403 10

Page 11

Trusted

TM

Module T8403

1.5. Line Monitoring Thresholds

The module determines the contact state and line fault status by comparing the input voltage level to

four user programmed thresholds and two fixed (minimum and maximum) thresholds. A “Contact

Indeterminate” region is defined between the contact Closed and Open states to account for marginal

faults in the external wiring or in the IFIU. Hysteresis is provided on the thresholds by up-scale and

downscale values, corresponding to the thresholds for increasing and decreasing values respectively.

Typical

voltage

threshold

values

Over-range 7 0 1

Tmax 36.00

T8 22.00

T7 21.00

T6 12.75

T5 12.25

T4 11.75

T3 11.25

T2 3.00

T1 2.00

Tmin -8.00

Short Circuit 5

Contact Closed 4 ‘1’ 0

3 or 4 0/1 0/1

Contact Indeterminate 3 0 1

2 or 3 0

Contact Open 2

1 or 2 0/1

Open Circuit 1 1

Under-range 7

Input

Channel

State

4 or 51

DI

Status

Line

Fault

Status

0/1 0/1

Table 1 Example Threshold data

When a module is inserted into the standby slot in a line-monitored application, then the field

terminations for all the input channels are paralleled, resulting in a drop in the input voltages for the

active module. Therefore the recommended components for line monitoring are zener diodes, one in

parallel with the field switch which is across the supply and signal, the other in series with the signal.

1

The channel state value returned is dependent on the previous state value. If the input level is

increasing then the lower state value will be returned. If the input level is decreasing the higher state

value will be returned.

Issue 15 Jun 13 PD-T8403 11

Page 12

Trusted

The module biases each input channel by means of a 5kΩ (typical for 24V dc digital inputs) termination

resistor to the 0V reference of the module input circuitry. In the absence of any line fault, the zener

diodes used for line monitoring purposes form a voltage divider with this termination resistor in the

module. Typically, the values are chosen so that the open contact voltage at the input terminal is about

1

/3 of the field supply; with the user contact closed the voltage is about 2/3 of the field supply, illustrated

in the previous threshold table, default threshold values used for non line monitored inputs are as

follows (in raw units)

Default = -4096, -2305, -1971, 3046, 3072, 7168, 8192, 14848, 15872, 19456

TM

Module T8403

1.6. Housekeeping

The input module automatically performs local measurements of several on-board signals that can be

used for detailed fault finding and verification of module operating characteristics. Measurements are

made within each slice’s HIU and FIU.

1.7. Fault Detection and Testing

From the IMB to the field connector, the input module contains extensive fault detection and integrity

testing. As an input device, all testing is performed in a non-interfering mode. Data input from the IMB

is stored in redundant error-correcting RAM on each slice portion of the HIU. Received data is voted

on by each slice. All data transmissions include a confirmation response from the receiver.

Between the HIU and FIU, there are a series of optically isolated links for data and power. The data

link is synchronised and monitored for variance. Both the FIU and HIU have onboard temperature

sensors to characterise temperature-related problems. Each FIU is also fitted with a condensation

sensor.

The power supplies for both the HIU and FIU boards are redundant, fully instrumented and testable.

Together, these assemblies form a Power Integrity Sub System.

The module field input is connected to a single bit ADC known as the Σ∆ input circuit. These circuits,

one per channel on each slice, produce a digital output which naturally transitions between on and off.

Any failure in the circuit causes the output to saturate to stuck-on or stuck-off which is automatically

detected. As the conversion process is dynamic and not gated like traditional ADCs, failures are

rapidly diagnosed and located.

By using the Σ∆ circuit, the analogue path in the module is short and does not involve many

components. This results in analogue failures being contained to a single channel on a single slice

instead of causing a group of eight or more inputs to fail.

1.8. Sequence of Events Characteristics

The input module automatically measures the field-input voltage, compares the value to the

configurable thresholds, and determines the state of the field input. An event occurs when the input

transitions from one state to another. When an input changes state, the on-board real-time clock value

is recorded. When the TMR Processor next reads data from the input module, the input state and realtime clock values are retrieved. The TMR Processor uses this data to log the input state change into

the system Sequence of Events (SOE) log. The user may configure each input to be included in the

system SOE log. Full details of SOE are contained in PD-8013 – TrustedTM SOE And Process

Historian.

Issue 15 Jun 13 PD-T8403 12

Page 13

Trusted

TM

Module T8403

2. Installation

2.1. Module Insertion/Removal

CAUTION:

The module contains static sensitive parts. Static handling precautions must be observed. Specifically

ensure that exposed connector pins are not touched. Under no circumstances should the module

housing be removed.

Before installation, visually inspect the module for damage. Ensure that the module housing appears

undamaged and inspect the I/O connector at the back of the module for bent pins. If the module

appears damaged or any pins are bent, do not install the module. Do not try to straighten bent pins.

Return the module for replacement.

Ensure that the module is of the correct type.

Record the module type, revision and serial number of the module before installation.

To install the module:

1. Ensure that the field cable assembly is installed and correctly located.

2. Release the ejector tabs on the module using the release key. Ensure that the ejector tabs

are fully open.

3. Holding the ejectors, carefully insert the module into the intended slot.

4. Push the module fully home by pressing on the top and bottom of the module fascia.

5. Close the module ejectors, ensuring that they click into their locked position.

The module should mount into the chassis with a minimum of resistance. If the module does not

mount easily, do not force it. Remove the module and check it for bent or damaged pins. If the pins

have not been damaged, try reinstalling the module.

2.2. Field Cable Selection

I/O cables suitable for use with the TrustedTM TMR 24V dc Digital Input Module are detailed in the

following Product Descriptions.

1. PD-TC200 – TrustedTM I/O Companion Slot Cables

2. PD-TC500 – TrustedTM I/O SmartSlot Cables

The Product Descriptions detailed above also detail the types of Field Termination Assembly (FTA) or

Versatile Field termination Assembly (VFTA) which may be used with type of module.

Issue 15 Jun 13 PD-T8403 13

Page 14

Trusted

TM

Module T8403

2.3. Module Pinout Connections

1 Smart Slot Link C Smart Slot Link B Smart Slot Link A

2

3 Chan 28 (+) Chan 14 (+) Chan 0 (+)

4 Chan 28 (+) Chan 14 (+) Chan 0 (+)

5 Chan 29 (+) Chan 15 (+) Chan 1 (+)

6 Chan 29 (+) Chan 15 (+) Chan 1 (+)

7 Chan 30 (+) Chan 16 (+) Chan 2 (+)

8 Chan 30(+) Chan 16 (+) Chan 2 (+)

9 Return Return Return

10 Chan 31 (+) Chan 17 (+) Chan 3 (+)

11 Chan 31 (+) Chan 17 (+) Chan 3 (+)

12 Chan 32 (+) Chan 18 (+) Chan 4 (+)

13 Chan 32 (+) Chan 18 (+) Chan 4 (+)

14 Chan 33 (+) Chan 19 (+) Chan 5 (+)

15 Chan 33 (+) Chan 19 (+) Chan 5 (+)

16 Chan 34 (+) Chan 20 (+) Chan 6 (+)

17 Chan 34 (+) Chan 20 (+) Chan 6 (+)

18 Chan 35 (+) Chan 21 (+) Chan 7 (+)

19 Chan 35 (+) Chan 21 (+) Chan 7 (+)

20 Return Return Return

21 Chan 36 (+) Chan 22 (+) Chan 8 (+)

22 Chan 36 (+) Chan 22 (+) Chan 8 (+)

23 Chan 37 (+) Chan 23 (+) Chan 9 (+)

24 Chan 37 (+) Chan 23 (+) Chan 9 (+)

25 Chan 38 (+) Chan 24 (+) Chan 10 (+)

26 Chan 38 (+) Chan 24 (+) Chan 10 (+)

27 Chan 39 (+) Chan 25 (+) Chan 11 (+)

28 Chan 39 (+) Chan 25 (+) Chan 11 (+)

29 Chan 40 (+) Chan 26 (+) Chan 12 (+)

30 Chan 40 (+) Chan 26 (+) Chan 12 (+)

31 Chan 41 (+) Chan 27 (+) Chan 13 (+)

32 Chan 41 (+) Chan 27 (+) Chan 13 (+)

C B A

Table 2 Field Connector Pinout

Note: The letters appended to the channel numbers indicate the destination slice on the module for

the incoming signal from the field.

Issue 15 Jun 13 PD-T8403 14

Page 15

Trusted

1

12

Cable Exit

Release button

TM

Module T8403

2.4. TrustedTM Module Polarisation/Keying.

All TrustedTM Modules have been Keyed to prevent insertion into the wrong position within a chassis.

The polarisation comprises two parts. The module and the associated field cable.

Each module type has been keyed during manufacture. The organisation responsible for the

integration of the TrustedTM system must key the cable by removing the keying pieces from the cable

so that they correspond with the bungs fitted to the associated module prior to fitting.

Polarising/Keying

Pins.

(Remove using

side cutters

where identified

below)

Trusted Cable

hood

Smart

Swap

Connect

or if

Fitted

Figure 3 Module polarisation

For Cables with Companion slot installations both keying strips must be polarised.

For This Module (T8403) remove keying pins 1,3,5

Issue 15 Jun 13 PD-T8403 15

Page 16

Trusted

TM

Module T8403

3. Application

3.1. Module Configuration

There is no configuration required to the physical input module. All configurable characteristics of the

module are performed using tools on the EWS and become part of the application or system.ini file

that is loaded into the TMR Processor. The TMR Processor automatically configures the input module

after applications are downloaded and during Active/Standby changeover.

The IEC1131 TOOLSET provides the main interface to configure the input module. Details of the

configuration tools and configuration sequence are provided in PD-8082B. There are three procedures

necessary to configure the input module. These are:

1. Define the necessary I/O variables for the field input data and module status data using the

Dictionary Editor of the IEC1131 TOOLSET.

2. Create an I/O module definition in the I/O Connection Editor for each I/O module. The I/O

module definition defines physical information, e.g. Chassis and Slot location, and allows

variables to be connected to the I/O channels of the module.

3. Using the TrustedTM System Configuration Manager, define custom LED indicator modes,

per-channel threshold levels and noise filtering, and other module settings.

3.2. T8403 Complex Equipment Definition

The T8403 I/O Complex Equipment Definition includes 8 I/O boards, referenced numerically by Rack

number:

Rack I/O Board Description Data Type Direction No. of

Channels

1 DI

2 STATE Field Input State Integer In 40

3 AI Input voltage Integer In 40

4 SPARE Not used Integer - 16

5 LINE_FLT Line Fault Status Boolean In 40

6 DISCREP Channel Discrepancy Integer In 3

7 HKEEPING Housekeeping Registers Integer In 51

8 INFO I/O Module Information Integer In 11

There are two OEM parameters included in the first rack (DI Board). These OEM parameters define

the primary module position; declaring the module’s chassis and slot location. There is no need to

define the secondary module position within the IEC1131 TOOLSET. Where systems may be required

to start-up with a module in the secondary position as the active module, e.g. primary module is not

installed when application is started, the secondary module’s position should be declared in the module

definition of the System Configuration Manager.

OEM Parameters - - -

Field Input Status Boolean In 40

Table 3 Complex Equipment Definition

Issue 15 Jun 13 PD-T8403 16

Page 17

Trusted

OEM Parameter Description Notes

TICS_CHASSIS The number of the

TICS_SLOT The slot number in the

TM

Module T8403

TrustedTM Chassis where

the primary I/O module is

installed

chassis where the primary

I/O module is installed

The TrustedTM Controller Chassis is 1, and

TrustedTM Expander Chassis are 2 to 15

The I/O module slots in the TrustedTM Controller

chassis are numbered from 1 to 8. The I/O

Module slots in the TrustedTM Expander Chassis

are numbered from 1 to 12

Table 4 OEM Parameters

3.2.1. Rack 1: DI

This board provides the logical input state for each of the field inputs.

Channel Description

1 Field input channel 1 logical state

2 Field input channel 2 logical state

40 Field input channel 40 logical state

Table 5 Rack 1: DI descriptions

The input state is reported as true (logic ‘1’) for a closed contact input, and false (logic ‘0’) for an open

contact input. The logic state is the majority voted value.

3.2.2. Rack 2: STATE

This board provides the majority voted numerical input state. This input channel state indicates the

threshold band within which the input voltage lies.

Channel Description

1 Field input channel 1 state

2 Field input channel 2 state

40 Field input channel 40 state

Table 6 Rack 2: STATE descriptions

Issue 15 Jun 13 PD-T8403 17

Page 18

Trusted

TM

Module T8403

Value Description

7 Unknown

5 Short circuit

4 Closed contact

3 Indeterminate

2 Open contact

1 Open circuit

Table 7 Rack 2: STATE Output descriptions

The input channel has a value 7 (Unknown) when:

1. The input channel cannot be correctly measured by two or more slices of the TMR input

module.

2. The TMR Processor detects a 2oo3 channel discrepancy between the three slices of the

TMR input module.

3. The module is simulated (not installed or the TMR Processor cannot communicate with 2oo3

slices of the module).

3.2.3. Rack 3: AI

The AI board returns the field loop voltage at the input.

Channel Description

1 Field input channel 1 voltage

2 Field input channel 2 voltage

40 Field input channel 40 voltage

Table 8 Rack 3: Channel Field Voltage

The voltage is the median value taken from the triplicated module. The voltage level is reported as an

integer, with the units being 1/

V. This may be used directly, scaled arithmetically or scaled using the

512

IEC1131 TOOLSET conversion tables.

When used directly the value may be considered as a signed, fixed-point binary value, i.e.:

Bit

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Sign Integer Fractional

Table 9 Rack 3: Channel Field Voltage bit definitions

To scale the value arithmetically, simply divide the input value by 512 to return the voltage as either a

REAL or INTEGER as required.

The IEC1131 TOOLSET conversion tables may be used to convert the input value to engineering

units, in this case voltage. The full-scale range for this number format is decimal ±64, corresponding

to physical range –32768 to +32767. Other units may be chosen depending on the numeric resolution

and span of the desired result.

Issue 15 Jun 13 PD-T8403 18

Page 19

Trusted

When the TMR Processor detects a 2oo3 channel fault or discrepancy, or if the input module is

simulated, the input voltage numeric value is reported as –2048.

TM

Module T8403

3.2.4. Rack 4: SPARE

This rack is reserved for future used and is included to promote consistency with other TrustedTM I/O

modules.

3.2.5. Rack 5: LINE_FLT

Channel Description

1 Field input channel 1 line fault

2 Field input channel 2 line fault

40 Field input channel 40 line fault

Table 10 Rack 5: LINE_FLT

The line fault input is reported as true (logic ‘1’) for a line fault condition (open circuit, indeterminate, or

short circuit condition). The logic state is the majority voted value.

When the TMR Processor detects a 2oo3 channel fault or discrepancy, or if the input module is

simulated, the line fault input is set to True.

3.2.6. Rack 6: DISCREP

Channel Description

1 Discrepancy status inputs 1 to 16 (input 1 is LSB, bit 0)

2 Discrepancy status inputs 17 to 32 (input 17 is LSB, bit 0)

3 Discrepancy status inputs 33 to 40 (input 33 is LSB, bit 0)

Table 11 Rack 6: DISCREP bit descriptions

Each of the integers reports the discrepancy status of 16 input channels. The corresponding bit within

the integer is set to ‘1’ when a discrepancy condition is detected on that input channel’s input state

(rack 2). For example, if slice B of the input module reports the state of channel 4 as state 5, while

slices A and C report channel 4 as state 2, then Slice B has a channel discrepancy for channel 4. In

this case, bit 3 of channel 1 on the Discrepancy board would be set to ‘1’.

Issue 15 Jun 13 PD-T8403 19

Page 20

Trusted

1 A

2 B

3 C

4 A

5 B

6 C

7 A

8 B

9 C

10 A

11 B

12 C

13 A

14 B

15 C

16 A

17 B

18 C

19 A

20 B

21 C

22 A

23 B

24 C

25 A

26 B

27 C

28 A

29 B

30 C

31 A

32 B

33 C

34 A

35 B

36 C

37 A

38 B

39 C

40 A

41 B

42 C

43 A

44 B

45 C

46 A

47 B

48 C

49 A

50 B

51 C

TM

Module T8403

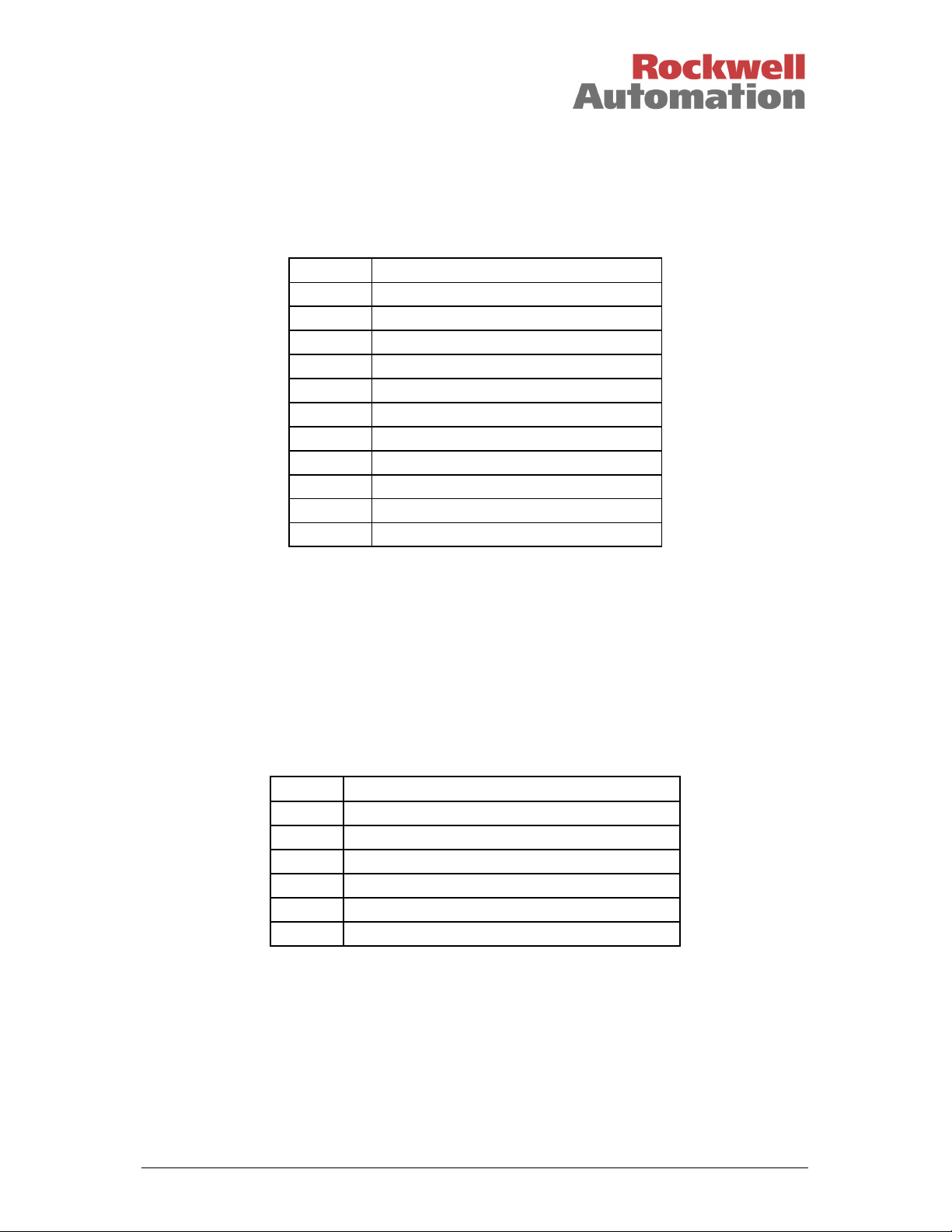

3.2.7. Rack 7: HKEEPING

Channel

Description

FCR Units (Full Scale Range)

Internal supply voltage (post regulator) -32768 32767 mV

Internal supply current (post regulator) -32768 32767 mA

24V2 Input Voltage -32768 32767 mV

Input voltage (post isolation) -32768 32767 mV

24V1 Input Voltage -32768 32767 mV

(Note: Temperature, ºC = input value / 256)

HIU Board Temperature

Front Panel Load Current -32768 32767 mA

SmartSlot Link Voltage -32768 32767 mV

Reserved for FIU condensation sensor 0 0 -

FIU Internal Supply Voltage -32768 32767 mV

FIU Internal Supply Current -32768 32767 mA

FIU Unregulated input voltage -32768 32767 mV

FIU Board Temperature

(Note: Temperature, ºC = input value / 256)

FIU Reference Voltage, DAC_X1 -32768 32767 mV

-32768 32767 -

-32768 32767 -

FIU Reference Voltage, DAC_X2 -32768 32767 mV

FIU Reference Voltage, DAC_X3 -32768 32767 mV

Diagnostic error code

Table 12 Rack 7: Housekeeping

Issue 15 Jun 13 PD-T8403 20

Page 21

Trusted

Each input within the housekeeping rack is reported as an integer. In general, the application engineer

will not normally require these inputs. They are provided to aid fault finding and diagnosis and are

often used for reporting and display purposes. If a slice is Fatal, then all reported housekeeping inputs

are set to zero.

TM

Module T8403

3.2.8. Rack 8: Information

Channel Description

1 Active module chassis number

2 Active module slot number

3 Active module healthy

4 Active module state

5 Standby module chassis number

6 Standby module slot number

7 Standby module healthy

8 Standby module state

9 Fault Containment Region (FCR) status

10 Primary module is active

11 Active module is simulated

Table 13 Rack 8: INFO Descriptions

The active module chassis and slot numbers indicate the position of the currently active module.

These values will change to match the primary or secondary module position, depending on their active

status, i.e. active/standby changeover will “swap” the values for the active module chassis and slot

number channels with those in the standby module chassis and slot number channels.

The active and standby module healthy channel is returned as an integer. A value of 0 indicates that a

fault has been detected, a value of ‘1’ indicates that the module is healthy.

The active and standby module state is an integer indicating the current operating mode of the

associated module. The value indicates the current internal operating mode of the module.

Value Module State

5 Shutdown

4 Maintain

3 Active

2 Standby

1 Configuration

0 Unknown, no module present, or module is Fatal

Table 14 Rack 8: INFO bit Descriptions

The FCR status channel reports the fault status of each slice of the active and standby modules. The

value is bit-packed as shown below, the least significant byte is used with the most significant 8-bits set

to zero:

Issue 15 Jun 13 PD-T8403 21

Page 22

Trusted

The ‘Primary Module is active’ channel is set to non-zero if the primary module is the current active

module, i.e. the active module is in the chassis and slot numbers defined within the OEM parameters.

The ‘Active Module is simulated’ channel is set to ‘1’ if the active module is being simulated, this will

only be set if the module is not present or non-operational and the simulation enable has been set

within the module’s configuration in the System.INI file.

TM

Module T8403

Bit

7 6 5 4 3 2 1 0

Standby Module Active Module

Ejector

open

FCR C

Healthy

FCR B

Healthy

Table 15 Rack 8: FCR bit Descriptions

FCR A

Healthy

Ejectors

open

FCR C

Healthy

FCR B

Healthy

FCR A

Healthy

3.3. Sequence of Events Configuration

Each Boolean Input Variable can be configured for automatic Sequence of Events (SOE) logging. This

applies to the Input Status and Line Fault Status variables. A Boolean variable is configured for SOE

during the variable definition in the Data Dictionary Editor. To select SOE, press the Extended Button

in the Boolean Variable Definition Dialog Box to open the Extended Definition Dialog. Then check the

box for Sequence of Events to enable the variable for automatic SOE logging.

During operation, the input module automatically reports time-stamped change of state information for

the input data. The TMR Processor automatically logs change of state for configured SOE variables

into the system SOE Log. The SOE Log can be monitored and retrieved using the SOE and Process

Historian Package running on the EWS. This software package is described PD-8013.

3.4. SYSTEM.INI File Configuration

There are many operating characteristics of the input module that can be customised for a particular

application. The System Configuration Manager is a tool that allows the user to configure the specific

operating characteristics for each module. Descriptions of the items that may be configured for the

TrustedTM 24V dc Digital Input Module T8403 are contained in PD-8082B.

Certain characteristics apply to the entire module and are considered Module Configurable Items.

Other characteristics apply to individual input channels and are considered Channel Configurable

Items. There are specific default settings for each of the configurable items. If the default settings are

appropriate for a given application, then customization of the module definition in the System

Configuration Manager is not required.

Issue 15 Jun 13 PD-T8403 22

Page 23

Trusted

Module

Status

Module

Latch

Input

Status

Indicators

Module

Latch

TM

Module T8403

4. Operation

4.1. Front Panel

Status LEDs on the front of the module provide visual indications of the module’s operational status

and field input status. Each LED is a tri-colour LED of which for normal operation, only two colours are

used; red and green. Located at the top and bottom of each module is an ejector lever that is used to

remove the module from the chassis. Limit switches detect the open/closed position of the ejector

levers. The ejector levers are normally latched closed when the module is firmly seated into the

Controller or Expander Chassis.

Indicators

Figure 4 Module Front Panel

Issue 15 Jun 13 PD-T8403 23

Page 24

Trusted

TM

Module T8403

4.2. Module Status LEDS

There are six module status LEDs on the module front panel; three Healthy, one Active, one Standby,

and one Educated. The Healthy indicators are controlled directly by each module slice. The Active,

Standby, and Educated indicators are controlled by the FPU. The FPU receives data from each of the

module slices. The FPU performs a 2-oo-3 vote on each data bit from the slices and sets the

indicators accordingly.

The module status LED states and their meanings are described as follows:

LED STATE DESCRIPTION

Healthy Off No power applied to the module.

Amber Slice is in the start-up state (momentary after

installation or power-up).

Green Slice is healthy.

Red – flashing Fault present on the associated slice but the slice is

still operational, or one 24V feed to the chassis has

failed

Red (momentary) On installation – power applied to the associated

slice.

Red The associated slice is in the fatal state. A critical

fault has been detected and the slice disabled..

Active Off Module is not in the Active state.

Green Module is in the Active (or Maintain) state.

Red – flashing Module is in the shutdown state if the Standby LED is

off.

Red – flashing Module is in the fatal state if the Standby LED is also

flashing.

Standby Off Module is not in the Standby state.

Green Module is in the Standby state.

Red – flashing Module is in the fatal state. The Active LED will also

be flashing red.

Educated Off Module is not educated.

Green Module is educated.

Green – flashing

Amber - Flashing Active/standby changeover in progress

Module is recognised by the Processor but education

is not complete.

Table 16 Module Status LEDs

Issue 15 Jun 13 PD-T8403 24

Page 25

Trusted

TM

Module T8403

4.3. I/O Status LEDs

There are 40 input channel status LEDs on the module front panel, one for each field input. These

indicators are controlled by the FPU. The FPU receives data from each of the module slices. The

FPU performs a 2-oo-3 vote on each data bit from the slices and sets the indicators accordingly.

The input status LED mode is dependent upon the voltage level of the field I/O signal. Each field input

voltage is measured and compared to six threshold levels (four configurable and two fixed) which

produce seven threshold bands. Each threshold band can be defined to have a particular indicator

mode: off, green, red, flashing green, or flashing red.

The configurable voltage thresholds and LED modes allow users to customise the input measurement

and status indications to suit individual application requirements. Without customisation, the default

indicator modes are suitable for digital inputs without line monitoring as described below:

Indicator State Description

Off Open field switch (contact) or open circuit or indeterminate

between open and closed (states 1,2,3).

Green Closed field contact (contact) or short circuit (states 4,5).

Red – flashing Channel Fault (state 7).

Table 17 Default I/O status Indicators

Note: The LEDs indicating channel status may be configured to suit user requirements by

implementing the procedure for configuring the System.INI file detailed in PD-8082B.

Issue 15 Jun 13 PD-T8403 25

Page 26

Trusted

TM

Module T8403

5. Fault Finding and Maintenance

5.1. Fault Reporting

Input module faults are reported to the user through visual indicators (LEDs) on the front panel of the

module. Faults are also reported via status variables which may be automatically monitored in the

application programs, and external system communications interfaces. There are generally two types

of faults that must be remedied by the user; external wiring and module faults. External wiring faults

require corrective action in the field to repair the fault condition. Module faults require replacement of

the input module.

5.2. Field Wiring Faults

The input circuits of the module may be used to detect field wiring faults in addition to alarm states. To

achieve this, line monitoring components must be fitted to the field device.

By comparing the input signal from the field with pre-configured alarm thresholds, the module can

automatically detect field-wiring faults. When a field signal fails open or short-circuit, or to an

intermediate value, the input channel status LED will flash red (default setting). The corresponding

input state will be reported and the line fault status for that channel will be set to ‘1’. All other input

channels will be unaffected, except in the case of common cause wiring faults in the field.

Once the field-wiring fault has been identified and corrected, the input status and the input status LED

will display the normal on/off status of the field device and field wiring.

5.3. Module Faults

Extensive diagnostics provide the automatic detection of module faults. The TMR architecture of the

input module and the diagnostics performed ensure the validity of all critical circuits. Using the TMR

architecture provides a fault tolerant method to withstand the first fault occurrence on the module and

continue normal input measurements without interruption in the system or process. Faults are

reported to the user through the Healthy status LEDs on the front panel of the module and through the

INFO and HKEEPING variables. Under normal operations all three Healthy LEDs are green. When a

fault occurs, one of the Healthy LEDs will flash red. It is recommended that this condition is

investigated and if the fault is within the module, it should be replaced.

Module replacement activities depend on the type of spare module configuration chosen when the

system was configured and installed. The module may be configured with a dedicated Companion Slot

or with a SmartSlot for a spare replacement module.

Issue 15 Jun 13 PD-T8403 26

Page 27

Trusted

TM

Module T8403

5.4. Companion Slot

For a Companion Slot configuration, two adjacent slots in a TrustedTM Chassis are configured for the

same input module function. One slot is the primary slot and the other a unique secondary (or spare)

slot. The two slots are joined at the rear of the TrustedTM Chassis with a double-wide I/O Interface

Cable that connects both slots to common field wiring terminations. During normal operations, the

primary slot contains the active module as indicated by the Active indicator on the front panel of the

module. The secondary slot is available for a spare module that will normally be the standby module

as indicated by the Standby indicator on the front panel of the module.

Depending on the installation, a hot-spare module may already be installed, or a module blank will be

installed in the standby slot. If a hot-spare module is already installed, transfer to the standby module

occurs automatically when a module fault is detected in the active module. If a hot spare is not

installed, the system continues operating from the active module until a spare module is installed.

5.5. SmartSlot

For a SmartSlot configuration, the secondary slot is not unique to each primary slot. Instead, a single

secondary slot is shared among many primary slots. This technique provides the highest density of

modules to be fitted in a given physical space. At the rear of the TrustedTM Chassis, a single-wide input

jumper Cable connects the secondary slot directly to the I/O Cable connected to the failed primary

module. With a spare module installed in the SmartSlot and the SmartSlot I/O Cable connected to the

failed primary module, the SmartSlot can be used to replace the failed primary module.

Input module Smart Slot jumper cable TC-306-02

Smart Slot between chassis can be performed if the chassis are version 2 (or higher). These have the

connector fitted to enable connection of a TC-006 that ensures the 0 Volt of each chassis is at the

same potential.

5.6. Cold Start

If an I/O module has shut down (due, for example, to two existing faults), the three Healthy LEDs will

be red, the Active and Standby LEDs will be flashing red and the Educated LED will be flashing amber.

The I/O functions provided by this module will have been lost if a hot swap partner has not taken over

control. The module can only be restarted by removing it from its slot and re-inserting it.

If an I/O module is inserted into a functional system slot which previously had no active module (e.g.

removing and reinserting as above), then the processor will educate the module once it has booted.

Once educated, the Educated LED will be steady green and the Active LED will be red flashing.

Input modules will now be reading and reporting their inputs. Output modules have not yet energised

their outputs. To activate outputs and to set the module’s Active LED and the processor’s System

Healthy LED steady green, press the processor Reset pushbutton.

Issue 15 Jun 13 PD-T8403 27

Page 28

Trusted

The user must define the primary, and optionally the secondary, I/O module location for each I/O

module pair. Each primary module location must be unique and is defined as part of the

. Secondary module locations can

be unique or shared between multiple secondary modules and are defined within the module’s

section within the System.INI file. The system will automatically determine the secondary

up, if the primary module is installed, it will become the active module by default.

If the secondary module has been defined within the System.INI file and no primary module is

module location is unique, the secondary module will become the

active module by default. If the secondary module is installed with no primary module present,

and the secondary module location is not unique (as in a SmartSlot configuration), then NO

In order for a module to become the active module, the TMR Processor will verify that the

module is the correct I/O module type and that both Module Removal switches are closed. At

When a fault occurs on the active module, the TMR Processor will be informed. Once it

An active/standby changeover starts with the TMR Processor checking to see if a standby I/O

module is installed. If no standby I/O module is available, the TMR Processor will continue to

e to check for an available standby I/O module. Once a

standby module is found, the TMR Processor will verify that the I/O module is of the correct type,

that both Module Removal switches are closed, and that the I/O module is a part of the correct

pair by using the SmartSlot link. At this point, the TMR Processor will configure the

standby I/O module with the same configuration information as the currently active I/O module

e is then placed in

the maintain state (which suspends field loop testing), and any module specific changeover data

is transferred. The educated light flashes amber before the active/standby changeover takes

er data (COD). The previous standby module

then becomes the active module and the original module becomes standby. If the currently

tests, the TMR Processor will revert it to

When both Module Removal switches are opened on an active module, regardless of the

module fault status, the TMR Processor will treat it as a request to perform an active/standby

TM

Module T8403

5.7. Transfer between Active and Standby Modules

The TMR Processor is responsible for managing a pair of I/O modules through an active/standby

changeover. The following rules apply to active/standby changeovers, though the TMR Processor and

not the I/O module enforce them:

•

complex equipment definition within the IEC1131 TOOLSET

module position if the primary module is installed and is operable.

• On initial start-

present, and if the secondary

module for that module pair will become active.

•

this point the I/O module is configured and eventually placed in the active state.

• A module in the active state should never be removed.

•

becomes aware of the fault, the TMR Processor will attempt an active/standby changeover.

•

utilise the active module and will continu

module

and place the standby I/O module into the standby state. The active modul

place, to indicate transfer of dynamic change ov

active module does not successfully complete the selfthe standby state, and the module in the maintain state will revert back to the active state.

•

changeover.

Under normal conditions, an active/standby changeover will only occur if the new active module is

fault-free. Under some circumstances, it is desirable to be able to force a changeover to a known

faulted module. This can be accomplished by opening the Module Removal switches on the currently

active module and pressing the push-button reset on the TMR Processor. This will force the

changeover to proceed even if the new active module is not fault free.

Issue 15 Jun 13 PD-T8403 28

Page 29

Trusted

TM

Module T8403

6. Specifications

System Supply Voltage Range 20 to 32V dc

Number of Inputs 40 Channels

Input Voltage

Measurement Range ±40V dc

Maximum Withstanding ±50V dc

Input voltage monitor absolute accuracy 0.5V dc Full Scale

Sample Update Time 0.5ms

Turn-on/off Voltage Configurable

Circuit Type Fault tolerant, fully triplicated

Fusing None, external if required

Intrinsic Safety External barrier

Sequence of Events

Event Resolution

Time-stamp Accuracy

Field Common Isolation

Sustained Working

Maximum Withstanding

Channel to Channel Crosstalk -40 to –60 dB

Power Consumption 15 – 18W

External Power

Expected current consumption @ 24V dc

Input Impedance 5K ohm

Self-Test Interval 2 minutes

Operating Temperature

Non-operating Temperature

Temperature change 0.5ºC/min

Operating Humidity 5 – 95% RH non-condensing

Environmental Specification Refer to Document 552517

Dimensions

Height

Width

Depth

Weight 1.18kg (2.6lbs)

Real Time Clock Resolution

with optional line monitoring

1ms

±0.5 ms

±250V dc

±2.5kV dc

4.8mA per channel

-5°C to 60°C (23°F to 140°F)

-25°C to 70°C (-13°F to 158°F)

266mm (10.5ins)

31mm (1.2ins)

303mm (12ins)

100µSec

Issue 15 Jun 13 PD-T8403 29

Page 30

Loading...

Loading...