Page 1

Trusted

TM

Module T8310

TM

Trusted

TMR Expander Processor

Introduction

The TrustedTM TMR Expander Processor module resides in the processor slots of the TrustedTM

Expander Chassis and provides the ‘slave’ interface between the Expansion Bus and the Expander

Chassis backplane. The Expander Bus allows multiple chassis systems to be implemented using UTP

cable connections whilst maintaining the fault tolerant, high bandwidth IMB capabilities.

The module provides fault containment for the expander bus, the module itself and the expander

chassis, ensuring that the effects of these potential faults are localised and system availability

maximised. The module is fault tolerant with HIFT TMR architecture. Comprehensive diagnostics,

monitoring and testing provide rapid fault identification. Hot standby and module spare configurations

are supported, allowing automatic and manual repair strategies.

Features

• Triple Modular Redundant (TMR), fault tolerant (3-2-0) operation

• Hardware Implemented Fault Tolerant (HIFT) architecture

• Dedicated hardware and software test regimes which provide very fast

fault recognition and response times

• Automatic fault handling without nuisance alarming

• Hot replacement

• Front panel indicators that show module health and status.

Issue 12 Dec 06 PD-T8310 1

Page 2

Trusted

Issue Record

Issue

Number Date Revised by Technical CheckAuthorised by Modification

9 Oct 05 Format

10 Aug 06 N Owens I Vince P Stock Corrections

11 Nov 06 N Owens I Vince P Stock Specifications

12 Dec 06 N Owens I Vince P Stock Cable Distance

TM

Module T8310

Issue 12 Dec 06 PD-T8310 2

Page 3

Trusted

TM

Module T8310

This page is intentionally blank

Issue 12 Dec 06 PD-T8310 3

Page 4

Trusted

TM

Module T8310

Table of Contents

1. Description...................................................................................................................................8

1.1. Overview......................................................................................................................................9

1.2. Power Distribution........................................................................................................................9

2. Installation..................................................................................................................................10

2.1. Module Insertion and Removal ..................................................................................................11

2.2. Module Replacement .................................................................................................................11

2.3. Expander Bus Connection .........................................................................................................12

2.3.1. Cable Assembly Replacement...................................................................................................12

2.4. Expander Chassis IMB Connector (SK1) ..................................................................................13

2.5. Expander Chassis Bus Connector (PL4)...................................................................................14

2.6. TrustedTM Module Polarisation/Keying.......................................................................................15

3. Application .................................................................................................................................16

3.1. Message Forwarding .................................................................................................................16

3.2. Control Signal Forwarding .........................................................................................................16

3.3. Interface Module Selection ........................................................................................................16

3.4. IMB Power Generation...............................................................................................................17

3.5. IMB Clock Generation................................................................................................................17

3.6. 24V Supply Monitoring...............................................................................................................17

3.7. Module Information ....................................................................................................................17

3.8. Communication Busses .............................................................................................................18

3.8.1. Expander Bus ............................................................................................................................18

3.8.2. Inter-Module Bus........................................................................................................................18

3.9. Module Configuration.................................................................................................................18

3.10. I/O Complex Equipment Definition T8310 .................................................................................19

3.10.1. Voltage Level Format.................................................................................................................20

3.11. System Initialisation File ............................................................................................................20

4. Operation ...................................................................................................................................21

4.1. Standby......................................................................................................................................21

4.2. Active .........................................................................................................................................21

4.3. Expander Processor Module Active/standby Control.................................................................21

4.4. Front Panel ................................................................................................................................22

4.5. Module Status LEDs ..................................................................................................................23

5. Fault Finding and Maintenance..................................................................................................24

5.1. Fault Reporting ..........................................................................................................................24

5.2. Companion Slot .........................................................................................................................24

5.3. Troubleshooting.........................................................................................................................25

6. Specifications.............................................................................................................................27

Issue 12 Dec 06 PD-T8310 4

Page 5

Trusted

TM

Module T8310

Figures

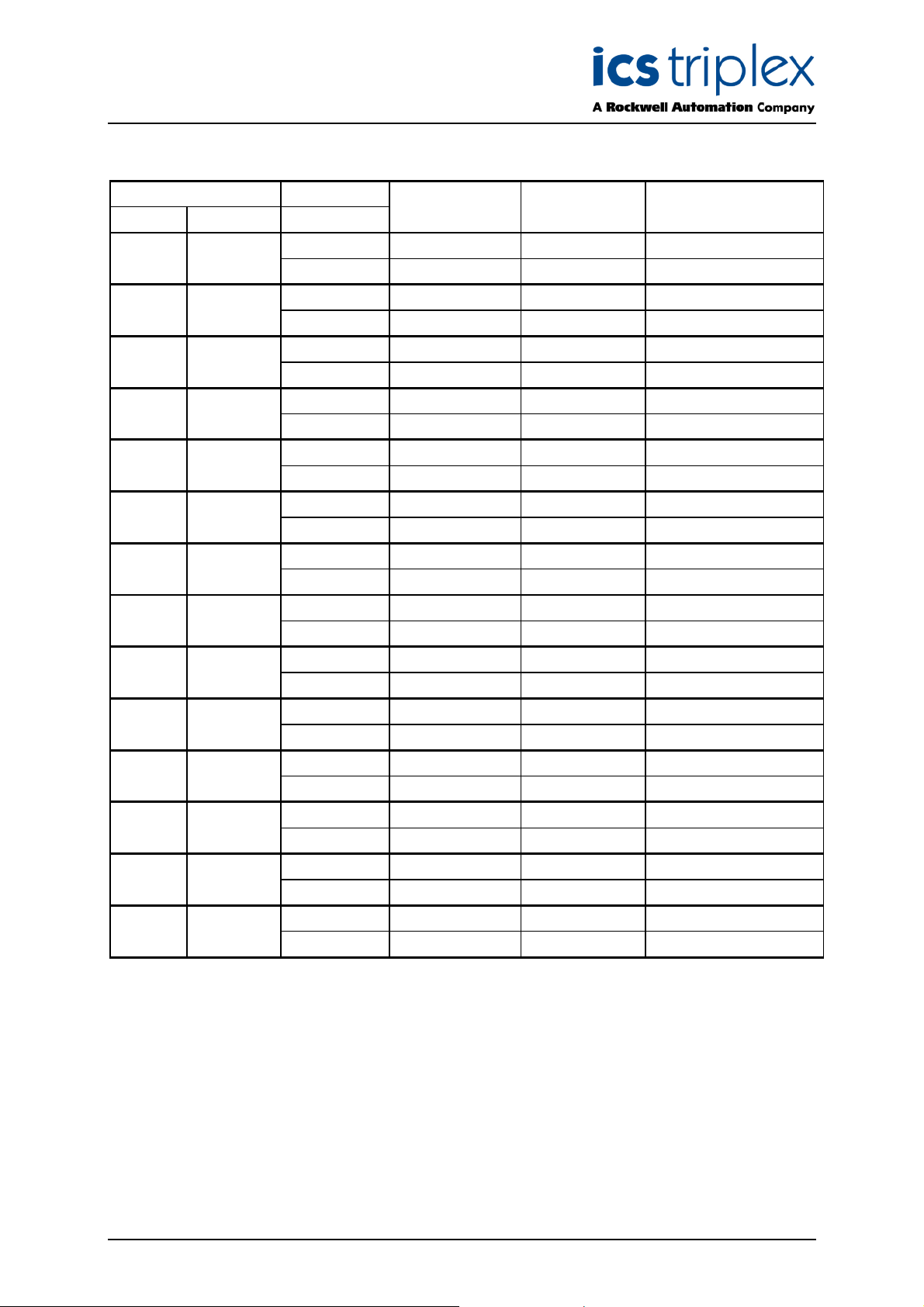

Figure 1 Simplified Block Diagram ...........................................................................................................8

Figure 2 Expander Processor Slots ........................................................................................................10

Figure 3 Expander Processor Cable ......................................................................................................10

Figure 4 Module Polarisation ..................................................................................................................15

Figure 5 Module Configuration ...............................................................................................................18

Figure 6 Front Panel ...............................................................................................................................22

Tables

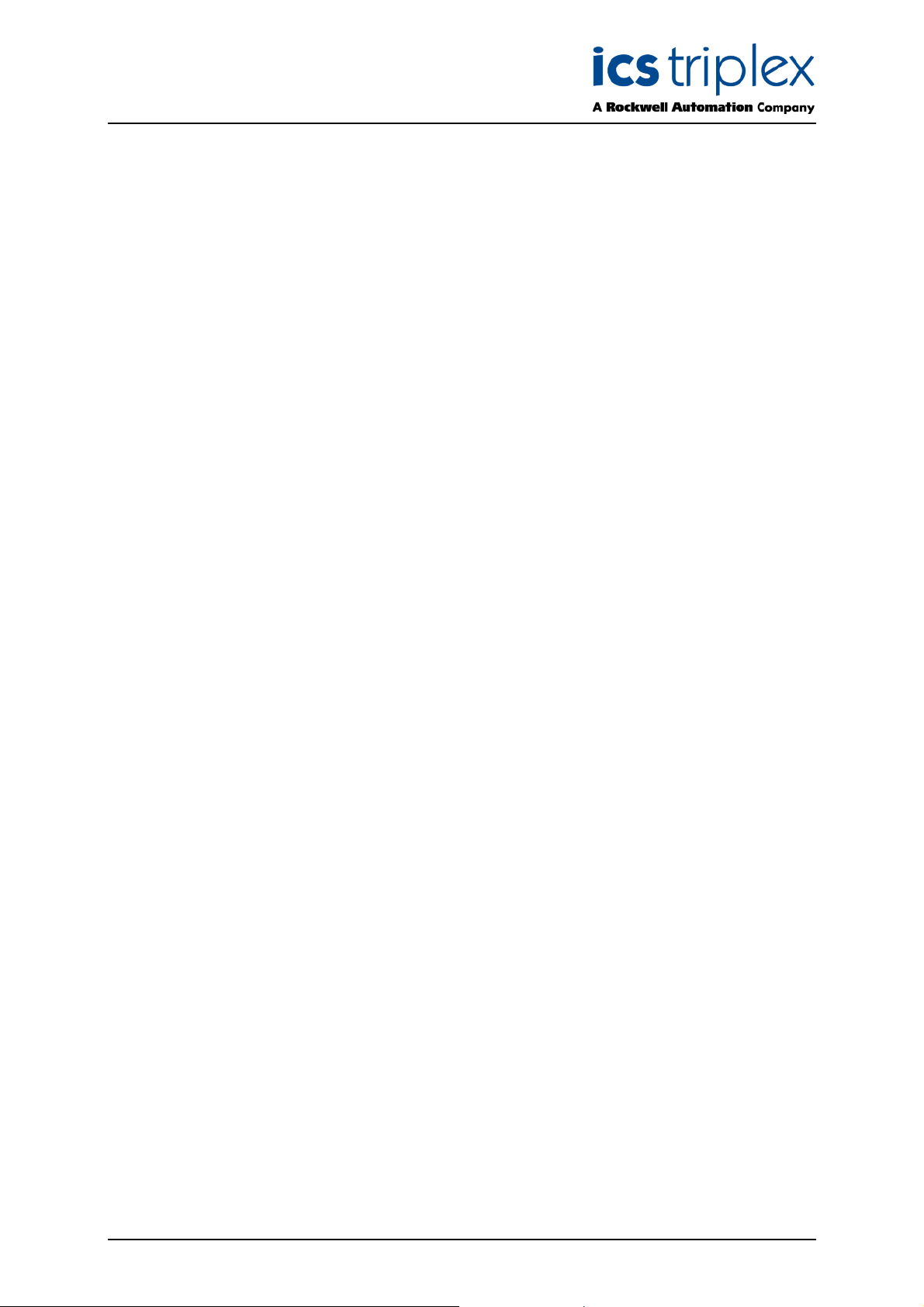

Table 1 IMB SK1 Pinout Connections ....................................................................................................13

Table 2 PL4 Pinout Connections ............................................................................................................14

Table 3 Module Status Indicators ...........................................................................................................23

Issue 12 Dec 06 PD-T8310 5

Page 6

Trusted

TM

Module T8310

Notice

The content of this document is confidential to ICS Triplex Technology Ltd. companies and their

partners. It may not be given away, lent, resold, hired out or made available to a third party for any

purpose without the written consent of ICS Triplex Technology Ltd.

his document contains proprietary information that is protected by copyright. All rights are reserved.

T

Microsoft, Windows, Windows 95, Windows NT, Windows 2000, and Windows XP are registered

trademarks of Microsoft Corporation.

The information contained in this document is subject to change without notice. The reader should, in

all cases, consult ICS Triplex Technology Ltd. to determine whether any such changes have been

made. From time to time, amendments to this document will be made as necessary and will be

distributed by ICS Triplex Technology Ltd.

Information in this documentation set may be subject to change without notice and does not represent

a commitment on the part of ICS Triplex Technology Ltd.

The contents of this document, which may also include the loan of software tools, are subject to the

confidentiality and other clause(s) within the Integrator Agreement and Software License Agreement.

No part of this documentation may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and recording, for any purpose, without the express

written permission of ICS Triplex Technology Ltd.

Disclaimer

The illustrations, figures, charts, and layout examples in this manual are intended solely to illustrate the

text of this manual.

The user of, and those responsible for applying this equipment, must satisfy themselves as to the

acceptability of each application and use of this equipment.

This document is based on information available at the time of its publication. While efforts have been

made to be accurate, the information contained herein does not purport to cover all details or variations

in hardware or software, nor to provide for every possible contingency in connection with installation,

operation, or maintenance. Features may be described herein which are present in all hardware or

software systems. ICS Triplex Technology Ltd. assumes no obligation of notice to holders of this

document with respect to changes subsequently made.

ICS Triplex Technology Ltd. makes no representation or warranty, expressed, implied, or statutory with

respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness of

the information contained herein. No warranties of merchantability or fitness for purpose shall apply.

Issue 12 Dec 06 PD-T8310 6

Page 7

Trusted

TM

Module T8310

Revision and Updating Policy

All new and revised information pertinent to this document shall be issued by ICS Triplex Technology

Ltd. and shall be incorporated into this document in accordance with the enclosed instructions. The

change is to be recorded on the Amendment Record of this document.

Precautionary Information

WARNING

Warning notices call attention to the use of materials, processes, methods, procedures or limits which

must be followed precisely to avoid personal injury or death.

CAUTION

Caution notices call attention to methods and procedures which must be followed to avoid damage to

the equipment.

Notes:

Notes highlight procedures and contain information to assist the user in the understanding of the

information contained in this document

Warning

RADIO FREQUENCY INTERFERENCE

Most electronic equipment is influenced by Radio Frequency Interference (RFI). Caution should be

exercised with regard to the use of portable communications equipment around such equipment.

Signs should be posted in the vicinity of the equipment cautioning against the use of portable

communications equipment.

MAINTENANCE

Maintenance must be performed only by qualified personnel, otherwise personal injury or death, or

damage to the system may be caused.

Caution

HANDLING

Under no circumstances should the module housing be removed.

Associated Documents

Product Descriptions (PD) provide product specific information.

The Safety Manual contains the recommended safety requirements for the safety system design.

The PD8082B – Toolset Suite provides specific guidance on system configuration and application

generation.

The Operator and Maintenance Manual contains general guidelines on maintenance and diagnostic

procedures.

For technical support email: support@icstriplex.com

Issue 12 Dec 06 PD-T8310 7

Page 8

Trusted

TM

Module T8310

1. Description

Figure 1 Simplified Block Diagram

Issue 12 Dec 06 PD-T8310 8

Page 9

Trusted

TM

Module T8310

1.1. Overview

The TMR Expander Processor is a fault tolerant design based on TMR architecture arranged in a lockstep configuration. Figure 1 shows, in simplified terms, the basic structure of the TMR Expander

Processor.

he module has three main fault containment regions (FCR A, B and C). Each of the main FCRs

T

contains interfaces to the Expander Bus and Inter-Module Bus (IMB), an active/standby interface to the

other TMR Expander Processor in the chassis, control logic, communications transceivers and power

supplies.

Communication between the module and the TMR Processor is via the TMR Expander Interface

Module and the triplicated Expander Bus. The Expander Bus is triplicated, point-to-point architecture.

Each channel of the Expander Bus comprises separate command and response media. Voting is

provided at the Expander Bus Interface to ensure that cable faults are tolerated, and the remainder of

the Expander Processor operates in a fully triplicated mode, even in case of cable faults occurring.

Communication between the module and the I/O modules in the Expander Chassis is via the IMB on

the backplane of the Expander Chassis. The IMB is identical to that within the Controller Chassis,

providing the same fault tolerant, high bandwidth communications between the interface modules and

the TMR Processor. As with the Expander Bus Interface all transactions are voted, localising faults to

the IMB should they occur.

A fourth FCR (FCR D) provides the non-critical monitoring and display functions and is also part of the

inter-FCR Byzantine voting structure.

Isolation is provided between FCRs wherever interfaces are required, to ensure that faults can not

propagate between them.

1.2. Power Distribution

The TMR Expander Processor Module derives its internal voltages from dual redundant +24V dc

power supplied via the module connector from the Trusted

derives the required supplies independently.

TM

Expander Chassis backplane. Each FCR

Issue 12 Dec 06 PD-T8310 9

Page 10

Trusted

TM

Module T8310

2. Installation

The Expander Processor module always resides in one of the two processor (left most - PL1 and PL2)

slots within the Expander Chassis. The Expander Processor must NOT be installed in these other

module locations, as this may cause damage to the module.

Figure 2 Expander Processor Slots

The two processor slots must be interconnected using the Cable Hood Assembly shown below.

Figure 3 Expander Processor Cable

The Expander Processor Modules are connected to the Expander Interface modules by the Expander

Interface Hot Link Cable TC-301 via the Trusted

Remote Expander Processor Modules are connected to the Trusted

TM

Expander Interface Adaptor Unit T8312.

TM

Fibre Optic Tx/Rx Unit T8314 by

the Fibre Tx/Rx Unit to Expander Processor (Remote Expanders) Cable TC-303.

TM

The connection to the Trusted

Trusted

TM

Expander Interface Adaptor Unit using the Expander Interface Adaptor to Fibre Tx/Rx Unit

Fibre Optic Tx/Rx Unit from the Expander Interface Modules is via the

(Remote Expanders) Cable TC-302.

Issue 12 Dec 06 PD-T8310 10

Page 11

Trusted

TM

Module T8310

2.1. Module Insertion and Removal

CAUTION:

The module contains static sensitive parts. static handling precautions must be observed. Specifically

nsure that exposed connector pins ARE NOT TOUCHED. Under no circumstances should the

e

module housing BE REMOVED.

Before installation, visually inspect the module for damage. Ensure that the module housing appears

undamaged and inspect the I/O connector at the back of the module for bent pins. If the module

appears damaged or any pins are bent, do not install the module. Do not try to straighten bent pins.

Return the module for replacement.

Ensure that the module is of the correct type.

Record the module type, revision and serial number of the module before installation.

If the module is to reside in a new chassis, or the system is being configured for the first time, ensure

that the chassis address has been set correctly before installing the modules. See Expander Chassis

Product Description (PD-8300) for further details.

To install the module:

1. Ensure that the cable assembly is correctly located.

2. Release the ejector tabs on the module using the release key. Ensure that the ejector tabs

are fully open.

3. Holding the ejectors, carefully insert the module into the intended slot.

4. Push the module fully home by pressing on the top and bottom of the module fascia.

5. Close the module ejectors, ensuring that they click into their locked position.

2.2. Module Replacement

The replacement module must be inserted in to the vacant processor slot, ensuring that the module is

correctly located and the ejector tabs are closed (see Module Insertion ands Removal). The newly

installed module will perform its power-up sequence.

Ensure that the LED indicators on the newly installed module are as follows:

LED 1 Healthy A Steady Green

LED 2 Healthy B Steady Green

LED 3 Healthy C Steady Green

If the original module has reported faults, the TMR Processor may automatically initiate the

changeover to the newly installed module. Manual changeover may be initiated either using the ejector

tabs on the original module or using commands via the diagnostic interface. To initiate the changeover

using the ejector tabs use the following sequence:

1. Release both the top and bottom ejector tabs on the original module using the ejector release

tool. DO NOT remove the module.

2. Wait until the original module indicates that it is in the standby mode of operation and the

newly installed module is in the active mode.

3. Remove the original module.

Note: Under no circumstances remove a module that is indicating ACTIVE mode. Removal of an

active module may result in modules within the chassis adopting their default (shutdown) state,

and initiate shutdown states via the application program.

Issue 12 Dec 06 PD-T8310 11

Page 12

Trusted

In Hot-standby configurations, with both Expander Processor Modules installed, the faulted module

may be either the active or the standby module. In most cases the system will automatically switch to

the healthiest module, therefore only the standby module will require replacement. To replace the

active module follow the steps described above. To replace the standby module:

In Hot-standby configurations, the replacement module should then be installed in the position where

the previous module was removed. This module will become the standby module.

TM

Module T8310

1. Release both the top and bottom ejectors tabs on the standby module using the ejector

release tool.

2. Ensure that the other module is indicating the active mode of operation.

3. Remove the standby module.

2.3. Expander Bus Connection

Further details of the Expander Bus cable assembly are provided in the associated Product Description

PD-TC300.

2.3.1. Cable Assembly Replacement

It is not intended that the cable should need replacement, however this may be achieved by

replacement of the complete cable assembly that requires that the system be shutdown. To remove a

cable:

1. Ensure that the correct chassis and slot positions are selected.

2. Ensure the associated chassis slots are not occupied by modules.

3. Press in the hood release button and slide the hood downwards.

4. Remove the hood from the chassis slot by sliding down and rearward.

To insert a new or replacement cable:

1. Ensure that the correct chassis and slot positions are selected.

2. Ensure that the associated chassis slots are not occupied by modules.

3. Present the connector to the chassis backplate slot, taking care to align the lugs of the

connector with the cut-outs of the slot.

4. Push the connector hood in and upwards into the slot until the latch engages with the

backplate lip.

5. Ensure that the connector hood is secure in its position.

Where it is critical to maintain system operation additional chassis may be installed and on-line

operation maintained by transferred control to modules within that chassis using the I/O modules

SmartSlot capability.

Issue 12 Dec 06 PD-T8310 12

Page 13

Trusted

TM

Module T8310

2.4. Expander Chassis IMB Connector (SK1)

SK1 is a 185-way DIN41642 type connector.

CONNECTOR SK1 PINOUT

PIN E D C B A

2 CHASSIS_GND CHASSIS_GND CHASSIS_GND CHASSIS_GND CHASSIS_GND

3

4 IMB_+24V_RTN IMB_+24V_RTN IMB_+24V_RTN IMB_+24V_RTN IMB_+24V_RTN

5

6 IMB_+24V_1 IMB_+24V_1 IMB_+24V_1 IMB_+24V_1 IMB_+24V_1

7

8 IMB_+24V_2 IMB_+24V_2 IMB_+24V_2 IMB_+24V_2 IMB_+24V_2

9

10 IMBA_CHAS_ID_3 IMBA_CHAS_ID_2 IMBA_CHAS_ID_1 IMBA_CHAS_ID_0 IMBA_MN/IX_ID

11 IMBA_CMDN_RSP GND IMBA_XIM_SEL_OUTNIMBA_XIM_SEL_INN IMBA_IOM_SELN_1

12 IMBA_D0 GND IMBA_D1 IMBA_IOM_SELN_2 IMBA_IOM_SELN_3

13 IMBA_D2 GND IMBA_D3 IMBA_IOM_SELN_4 IMBA_IOM_SELN_5

14 IMBA_D4 GND IMBA_D5 IMBA_IOM_SELN_6 IMBA_IOM_SELN_7

15 IMBA_D6 GND IMBA_D7 IMBA_IOM_SELN_8 IMBA_IOM_SELN_9

16 IMBA_CK_OUT GND IMBA_XIM_CLK_IN IMBA_IOM_SELN_10IMBA_IOM_SELN_11

17 IMBA_IOM_CK1 GND IMBA_SFTY_WDOG IMBA_IOM_SELN_12

18 IMBA_IOM_CK2 GND IMBA_PWR_FAIL IMBA_+6.5V

19 IMBB_CHAS_ID_3 IMBB_CHAS_ID_2 IMBB_CHAS_ID_1 IMBB_CHAS_ID_0 IMBB_MN/IX_ID

20 IMBB_CMDN_RSP GND IMBB_XIM_SEL

OUTN

21 IMBB_D0 GND IMBB_D1 IMBB_IOM_SELN_2 IMBB_IOM_SELN_3

22 IMBB_D2 GND IMBB_D3 IMBB_IOM_SELN_4 IMBB_IOM_SELN_5

23 IMBB_D4 GND IMBB_D5 IMBB_IOM_SELN_6 IMBB_IOM_SELN_7

24 IMBB_D6 GND IMBB_D7 IMBB_IOM_SELN_8 IMBB_IOM_SELN_9

25 IMBB_CK_OUT GND IMBB_XIM_CLK_IN IMBB_IOM_SELN_10IMBB_IOM_SELN_11

26 IMBB_IOM_CK1 GND IMBB_SFTY_WDOG IMBB_IOM_SELN_12

27 IMBB_IOM_CK2 GND IMBB_PWR_FAIL IMBB_+6.5V

28 IMBC_CHAS_ID_3 IMBC_CHAS_ID_2 IMBC_CHAS_ID_1 IMBC_CHAS_ID_0 IMBC_MN/IX_ID

29 IMBC_CMDN_RSP GND IMBC_XIM_SEL_OU

TN

30 IMBC_D0 GND IMBC_D1 IMBC_XIM_SELN_2 IMBC_IOM_SELN_3

31 IMBC_D2 GND IMBC_D3 IMBC_XIM_SELN_4 IMBC_IOM_SELN_5

32 IMBC_D4 GND IMBC_D5 IMBC_XIM_SELN_6 IMBC_IOM_SELN_7

33 IMBC_D6 GND IMBC_D7 IMBC_XIM_SELN_8 IMBC_IOM_SELN_9

34 IMBC_CK_OUT GND IMBC_XIM_CLK_IN IMBC_XIM_SELN_10 IMBC_IOM_SELN_11

35 IMBC_IOM_CK1 GND IMBC_SFTY_WDOG IMBC_IOM_SELN_12

36 IMBC_IOM_CK2 GND IMBC_PWR_FAIL IMBC_+6.5V

37

38 CHASSIS_GND CHASSIS_GND CHASSIS_GND CHASSIS_GND CHASSIS_GND

IMBB_XIM_SEL_INN IMBB_IOM_SELN_1

IMBC_XIM_SEL_INN IMBC_IOM_SELN_1

Table 1 IMB SK1 Pinout Connections

Issue 12 Dec 06 PD-T8310 13

Page 14

Trusted

TM

Module T8310

2.5. Expander Chassis Bus Connector (PL4)

PL4 is a 96-way DIN41612, C-type connector.

Pin

10

11 GND GND GND

12 TXB+

13 TXB-

14

15

16 RXB1+ LB_B_ACTN/STB_OUT

17 RXB1- LB_B_ACTN/STB_IN

18

19

20

21

22

23 TXC+

24 TXC-

25

26

27 RXC1+ LB_C_ACTN/STB_OUT

28 RXC1- LB_C_ACTN/STB_IN

29

30

31

32

CONNECTOR PL4 PINOUT

A B C

1 TXA+

2 TXA-

3

4

5 RXA1+ LB_A_ACTN/STB_OUT

6 RXA1- LB_A_ACTN/STB_IN

7

8

9

Table 2 PL4 Pinout Connections

Issue 12 Dec 06 PD-T8310 14

Page 15

Trusted

TM

Module T8310

2.6. TrustedTM Module Polarisation/Keying

M

All Trusted

The polarisation comprises two parts. The module and the associated field cable.

ach module type has been keyed during manufacture. The organisation responsible for the

E

integration of the Trusted

so that they correspond with the bungs fitted to the associated module prior to fitting.

T

Modules have been Keyed to prevent insertion into the wrong position within a chassis.

TM

system must key the cable by removing the keying pieces from the cable

Cable Exit

1

Polarising/Keying

Pins.

(Remove using

side cutters

where identified

TrustedTM

Cable hood

below)

12

Release button

Figure 4 Module Polarisation

For Cables with Companion slot installations both keying strips must be polarised.

For This Module (T8310) remove keying pins 1,2,5.

Smart

Swap

Connect

or if

Fitted

Issue 12 Dec 06 PD-T8310 15

Page 16

Trusted

TM

Module T8310

3. Application

3.1. Message Forwarding

The primary function of the Expander is to provide a method of extending the IMB beyond a single

processor chassis. The active TMR Expander Interface Module receives messages from the

processor chassis IMB/backplane and forwards them to the Expander Bus when its slot position is

enabled. Similarly, the active TMR Expander Processor Module forwards all messages received from

the Expander Bus to the Expander Chassis IMB.

Messages addressed to the Expander Processor module itself, i.e. those command messages with

chassis and slot address fields matching those of the module, result in the message being handled

locally and the appropriate response message being generated. For other command messages the

response message received by the active Expander Processor from the addressed module is passed

to the Expander Bus and hence to the TMR Expander Interface Module. The active TMR Expander

Interface Module then passes the message to the Processor Chassis IMB, subject to the prevailing

IMB control signals.

The messages received from the controller chassis IMB at the TMR Expander Interface Module are

re-synchronised and majority voted before being passed to the triplicated Expander Bus. Similarly,

messages received by the TMR Expander Processor Module from the Expander Chassis IMB are

re-synchronised and majority voted before onward transmission.

Messages received from the Expander Bus at both the TMR Expander Interface Module and TMR

Expander Processor Module are re-synchronised and majority voted (Byzantine voted) before being

passed to the associated IMB.

Errors in messages are corrected, and therefore masked using this method. This, however, makes it

important that discrepancies in faults in these signals are detected and the information made available

for fault reporting purposes to avoid latent fault issues.

3.2. Control Signal Forwarding

The active TMR Expander Interface Module continually monitors and transmits the state of the

following signals:

• Power Failure Warning

• System Watchdog

• Command Response Control

All three signals are fully triplicated. These signals are distributed to all of the attached Expander

Busses. The TMR Expander Processor Modules forward the received state of these signals to the

Expander Chassis IMB. The direction of these signals is always from TMR Processor to TMR

Expander Interface to TMR Expander Processor to interface (I/O) module.

As with the message forwarding, these signals are re-synchronised and majority voted, i.e. Byzantine

voted at the TMR Expander Interface and TMR Expander Processor Modules. The signals are

synchronous within the Expander Chassis even in the case of a fault within the Processor Chassis.

3.3. Interface Module Selection

The active TMR Expander Processor Module monitors the received command messages and decodes

chassis and slot information where the message’s chassis number matches that set by the local

switches.

Issue 12 Dec 06 PD-T8310 16

Page 17

Trusted

Expander Bus link quality, including receive error counts for each communications link and link

TM

Module T8310

3.4. IMB Power Generation

The TMR Expander Processor Modules (both active and standby) generate three independent IMB

power supplies. These supplies are provided via a diode to the IMB/backplane. These supplies are

used to power the triplicated IMB interfaces within the interface modules within the Expander Chassis.

These supplies have a common return, commoned with the module’s internal 0V. Failure of any of

these supplies will not affect the remaining supplies. Similarly, overload conditions on a supply will not

affect the continued operation of the other supplies.

3.5. IMB Clock Generation

The active TMR Expander Processor Module provides synchronised IMB clock signals at the standard

IMB rate of 12.5M symbols/second. To minimise clock loading, the IMB connection provides

independent signals for odd and even module positions and for the other TMR Expander Processor

Module. All of these signals are driven synchronously.

3.6. 24V Supply Monitoring

The TMR Expander Processor Modules monitor each of the 24V supplies and generates status

information accessible by the TMR Processor.

3.7. Module Information

The following information is recorded by the TMR Expander Processor Module and made available to

the TMR Processor.

•

status.

• Received message error, on a per link/FCR basis, including frame error, checksum error and

discrepancy.

• HIFT Clock, master and slave clock status, and master/slave switching.

• FCR watchdog status.

• Current active/standby status.

• IMB status information.

• 24V supply levels

• Module type code and serial number.

• Module removed flap status

Issue 12 Dec 06 PD-T8310 17

Page 18

Trusted

TM

Module T8310

3.8. Communication Busses

3.8.1. Expander Bus

ach TMR Expander Processor Module contains a Bus Interface, isolation components and

E

transceivers to the Expander Bus. The triplicated Expander Bus provides communication

interconnection between the TMR Processor Chassis and the Expander Chassis at a data transfer rate

of 1.5Gbps via UTP cables.

3.8.2. Inter-Module Bus

Each TMR Expander Processor Module FCR contains a Bus Interface to the Inter-Module Bus. The

triplicated Inter-Module Bus provides communication interconnection between modules in the TMR

Expander Chassis, at a data transfer rate of up to 12.5Mbps.

The Inter-Module Bus handles the following triplicated signals:

Data

Control

System Watchdog

8-bit, bi-directional bus.

-

Bus clocks, module enables and bus direction control.

-

System Watchdog signal to the I/O modules.

-

System power fail warning to I/O modules.

Power Fail

Slot

Chassis ID

-

Indicating the left or right TrustedTM TMR Expander Processor slot

position to the Trusted

a 4-bit code indicating the chassis number or id.

-

TM

TMR Processor.

3.9. Module Configuration

The Expander Processor requires no configuration to the module itself. The module provides status

information that available to the application programmer. The IEC1131 TOOLSET provides the

interface to configure and use this status information.

Figure 5 Module Configuration

Issue 12 Dec 06 PD-T8310 18

Page 19

Trusted

TM

Module T8310

3.10. I/O Complex Equipment Definition T8310

M

Each module fitted in a Trusted

chassis and slot number. The I/O Complex Equipment Definition allows control of the module’s

functions, and provides information on its status. For information on editing the I/O Connection table,

refer to PD-8082B. The definition for this module is described below.

OEM PARAMETERS

OEM parameter Valid numbers Description

TICS_CHASSIS

TICS_SLOT

2 – 15

13 and 14 (Expander Chassis)

CONFIGURATION

PHYSICAL MODULE:

RACK 1: [XPM_0] 16 ANALOGUE

RACK 2: (INFO) 11 INTEGER inputs Channel 1:Chassis position of AM

inputs

T

system requires an entry in the I/O Connection table, specifying its

The TICS chassis & slot number where the T8310 module

is placed. Expander processor modules cannot be placed

in a processor chassis.

By definition, the primary module is placed in the left-hand

slot (13) and the secondary in the right-hand slot (14).

Channel 1: Not used

Channel 2: 24V dc Feed 1

Channel 3: 24V dc Feed 2

Channel 4: Not used

Channel 5: Not used

Channel 6: Not used

Channel 7: Slice A Rx error count

Channel 8: Slice B Rx error count

Channel 9: Slice C Rx error count

Channels 10 to 16 – Not used.

Channel 2:Slot position of AM

Channel 3:Indication of global health of AM

1 – No slice errors and module is responding

0 – Some error has been found

Channel 4:Current state of AM

Channel 5:Chassis position of SM

0 – No partner exists

Channel 6:Slot position of SM

0 – No partner exists

Channel 7:Indication of global health of SM

1 – No slice errors and module is responding

0 – Some error has been found

Channel 8:Current state of SM

Channel 9:Slice information of SM. See Note

Channel 10 Is AM the Primary Module

1 – Yes 0 – Not

Channel 11:Not used

Issue 12 Dec 06 PD-T8310 19

Page 20

Trusted

TM

Module T8310

APPENDIX :

Note:

Bit 1 AM slice B:

Bit 0 AM slice A:

1 - Slice is responding and there are no slice errors.

0 - Slice is either NOT responding or there is a slice error.

1 - Slice is responding and there are no slice errors.

0 - Slice is either NOT responding or there is a slice error.

Bit 2 AM slice C:

1 - Slice is responding and there are no slice errors.

0 - Slice is either NOT responding or there is a slice error.

Bit 3 AM ejectors open:

1 - AM ejectors open.

0 - AM ejectors closed.

Bit 4 SM slice A:

1 - Slice is responding and there are no slice errors.

0 - Slice is either NOT responding or there is a slice error.

Bit 5 SM slice B:

1 - Slice is responding and there are no slice errors.

0 - Slice is either NOT responding or there is a slice error.

Bit 6 SM slice C:

1 - Slice is responding and there are no slice errors.

0 - Slice is either NOT responding or there is a slice error.

Bit 7 SM ejectors open:

1 – SM ejectors open.

0 - SM ejectors closed.

3.10.1. Voltage Level Format

The voltage level is reported as an integer, with the units being 1/

scaled arithmetically or scaled using the conversion tables.

When used directly the value may be considered as a fixed-point binary value, i.e.:

Bit

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Sign Integer ·Fractional

To scale the value arithmetically simply divide the returned ‘integer’ by 512 to return the voltage as

either a REAL or INTEGER as required.

The input conversion tables may be used to convert the input value to engineering units, in this case

voltage. This is the recommended method where the value is not to be used directly. The full-scale

range for this number format is decimal ±256, corresponding to physical range –32768 to +32767.

V. This may be used directly,

512

3.11. System Initialisation File

There is no System INI File entry for this module. The module’s existence is assumed for every

expander chassis defined in the System INI configuration.

Issue 12 Dec 06 PD-T8310 20

Page 21

Trusted

TM

Module T8310

4. Operation

4.1. Standby

Standby is the default mode of operation for the module, once internal supply levels are established. In

this mode the module may receive messages addressed to the module itself over the IMB or Expander

Bus. Response messages over the Expander Bus will only be transmitted following a transition to the

Active mode. The module does not provide the capability of passing messages to and from other

modules within the Expander Chassis in this mode.

4.2. Active

In the active mode, the module is responsible for the forwarding of messages from the Expander Bus

to the Expander Chassis IMB, and response messages from the Expander Chassis IMB to the

Expander Bus. The module also provides all of the functions available within the Standby mode of

operation.

4.3. Expander Processor Module Active/standby Control

The TMR Expander Processor Modules transition between active and standby (and vice-versa) is

controlled locally by negotiation between two TMR Expander Processor Modules. Interlocks are

incorporated within the TMR Expander Processor module to ensure that both modules within an

active/standby configuration can not assume active mode operation.

Where both modules are healthy, the active operation defaults to the left-most module.

Issue 12 Dec 06 PD-T8310 21

Page 22

Trusted

TM

Module T8310

4.4. Front Panel

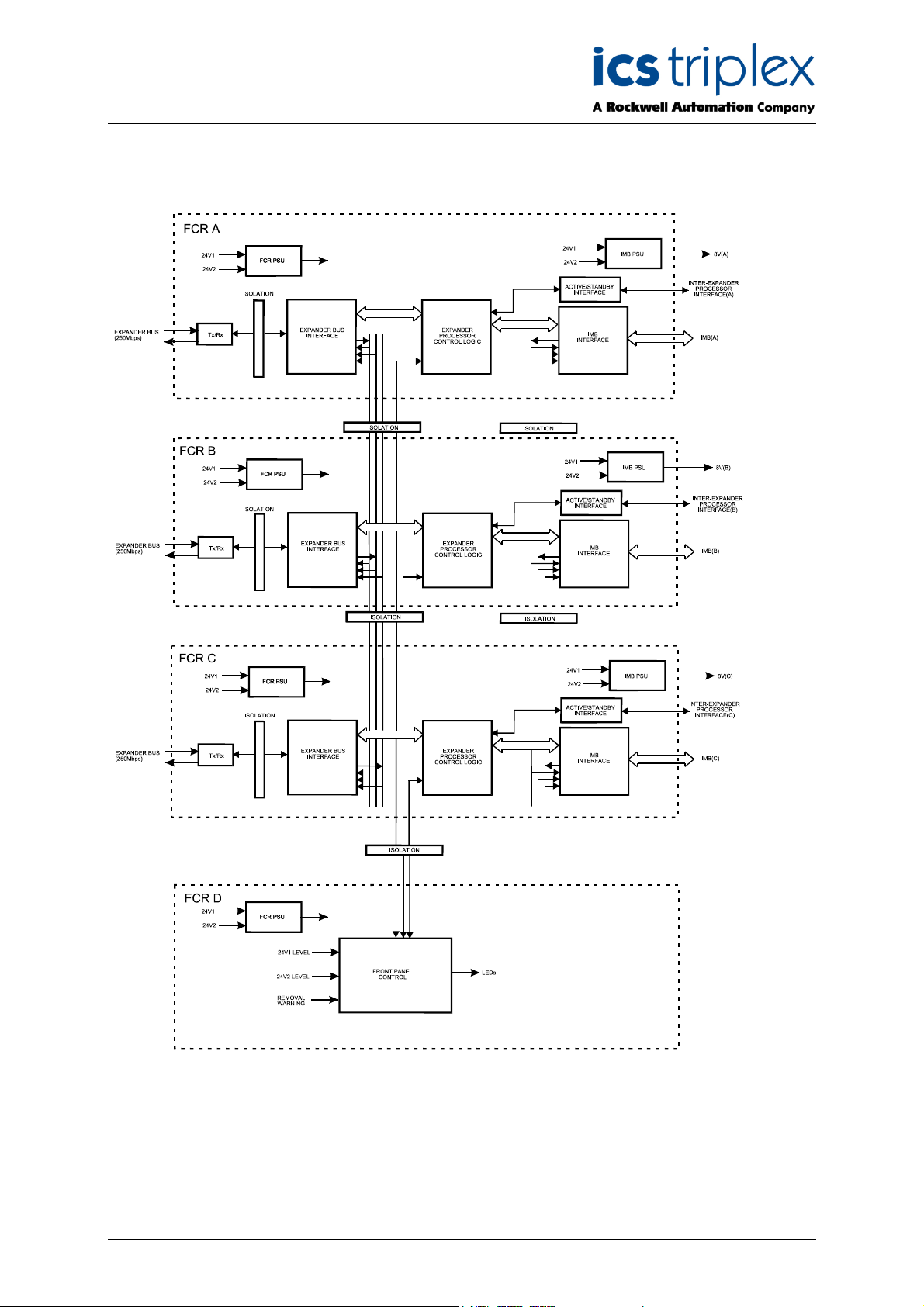

Figure 6 Front Panel

Issue 12 Dec 06 PD-T8310 22

Page 23

Trusted

TM

Module T8310

4.5. Module Status LEDs

LED State Description

Healthy On Steady Green The Module is healthy.

Flashing Red Fault on the corresponding Chanel

Active Green Module is in the Active state.

Standby On Steady Green Module is in the Standby state.

Communications Activity Off

Green

Red Transmit activity.

Table 3 Module Status Indicators

When the module is in standby, no Transmit activity (Red LED) will be observed

No activity or failed

Receive activity`.

Issue 12 Dec 06 PD-T8310 23

Page 24

Trusted

TM

Module T8310

5. Fault Finding and Maintenance

5.1. Fault Reporting

Input module faults are reported to the user through visual indicators (LEDs) on the front panel of the

module. Faults are also reported via status variables which may be automatically monitored in the

application programs, and external system communications interfaces. There are generally two types

of faults that must be remedied by the user; external wiring and module faults. External wiring faults

require corrective action in the field to repair the fault condition. Module faults require replacement of

the module.

5.2. Companion Slot

The Expander Processor operates in a Companion Slot configuration. Two adjacent slots in a

Trusted

other a unique secondary (or spare) slot. The two slots are joined at the rear of the Trusted

with a double-width Interface Cable that connects both slots to common IMB connections. During

normal operations, the primary slot contains the active module as indicated by the Active indicator on

the front panel of the module. The secondary slot is available for a spare module that will normally be

the standby module as indicated by the Standby indicator on the front panel of the module.

Depending on the installation, a hot-spare module may already be installed, or a module blank will be

installed in the standby slot. If a hot-spare module is already installed, transfer to the standby module

occurs automatically if a module fault is detected in the active module. If a hot spare is not installed,

the system continues operating from the active module until a spare module is installed

TM

Chassis are configured for the same module function. One slot is the primary slot and the

TM

Chassis

Issue 12 Dec 06 PD-T8310 24

Page 25

Trusted

TM

Module T8310

5.3. Troubleshooting

Symptom Possible Cause Solution

All front

panel

indicators off

Single FCR

indicator

flashing RED

Multiple FCR

indicating

flashing RED

Flashing

standby

indicator

Both active

or standby

LEDs OFF

All Comms

activity LEDs

off

Lack of power If all other modules within the chassis also show no indicators, check

Front panel interface

(FCR D) failure

Single main FCR

failure.

Multiple failure. This condition may be indicated briefly during module power-up, but in

Software detected

fault

LED failure This condition may be indicated briefly during module power-up.

Expander Interface

Module failure or

missing

Expander Bus fault Check the Expander Bus cable assembly is correctly installed at both

TMR Processor fault If the module is indicating active mode, check that the module is

Front panel interface

(FCR D) failure

the power distribution and connection to the chassis.

Check if other modules within the chassis have LEDs illuminated.

Check if it is possible to communicate with other modules within the

chassis – using either the chassis board type (T8300) or the diagnostic

utility. If communications is possible and this is the only Expander

Processor installed, the failure is within FCRD and the module should

be replaced,

If another Expander Processor module is installed, check its status

indication. If the other module is indicating active mode, check if

communications with the potentially faulty module is possible (again

using either the Expander Chassis board or diagnostic utility). If

communications is possible, note the information returned as part of

the Expander Processor board and then initiate the module

replacement.

The module will continue to provide communications between the

expander bus and the modules within the chassis. However, the

module should be replaced as soon as practical.

other circumstances, this indicates a failure beyond the modules fault

tolerant capabilities.

If the failed module is not the active module, it should be removed

immediately. A replacement module should be installed as soon as

practical.

If the module was the active module, the system will attempt to switch

to the standby, if it is installed and if the failures do not occur

simultaneously.

This indicates that the TMR Processor has detected a fault within the

module and has switched to the previously standby module. The

faulted module should be removed as soon as possible and a

replacement installed as soon as practical.

If another Expander Processor module is installed within the same

chassis, use its indicators to verify the active/standby mode of this

module. To avoid confusion it is recommended that this module be

replaced at some convenient time, initiating the active/standby

changeover to the other module if necessary.

Check for the presence and healthy state of the Expander Interface

module within the controller chassis.

the expansion and controller chassis.

Check that there are no faults within the expander bus cabling, replace

any cables found to be defective.

Check that the Expander Processor Module is installed in the correct

slot.

reported as not installed/responding using the diagnostic utility. If

reported as not responding then replace the module immediately,

otherwise replace the module as soon as practical.

If the module is indicating standby mode of operation, replace the

module as soon as practical.

Verify that the module is continuing to respond using the chassis board

type or the diagnostic utility. Replace the module as soon as practical.

Issue 12 Dec 06 PD-T8310 25

Page 26

Trusted

TM

Module T8310

Symptom Possible Cause Solution

Single

activity LED

off

Comms Error

counters

incrementing

24V Supply

Level

All other

modules

within the

chassis

indicate

standby

mode.

Minor BIU

errors

counters

incrementing

Expander Interface

Module fault

Expander Bus Fault Check the Expander Bus cable assembly is correctly installed at both

Expander Processor

receiver fault

Front panel interface

(FCR D) failure

Poor cable condition Check the Expander Bus cabling for damage and replace as

Extreme levels of

interference (EMI)

Poor/missing supply The Expander Processor monitors and reports the 24V supply levels

Monitoring fault If the voltage reported by the module differs significantly from the

TMR Processor not

running (faulted, or

application not

started).

Expander Processor

Fault

Expander Bus Fault Verify that the fault is not the result of a failed Expander Processor

Expander Processor

not installed.

Interface Module Fault The error counters for a single module will be incrementing. Check the

Expander Processor

Fault

Verify that there is a fault within the Expander Interface Module (within

the controller chassis). Replace the faulted module as soon as

possible.

the expansion and controller chassis.

Check that there are no faults within the expander bus cabling, replace

any cables found to be defective.

Check the communications receive error counters reported as part of

the Expander Processor board. If these are rapidly increasing then

initiate the changeover to the standby module or replace the module as

soon as possible.

If the fault is within the standby module replace the module as soon as

convenient.

If the module is the current active module, install the spare module (if

not already installed) and initiate the changeover to the standby

module.

If the module is in standby mode, replace the module when convenient.

necessary.

Ensure that the maximum/minimum cable distances have been met.

If the condition is permanent then measures should be taken to reduce

the levels to which the expander bus is exposed. The design provides

high levels of immunity; this condition will only occur if the system has

not been installed within the defined environmental conditions.

provided at least one of the supplies is within tolerance. If the reported

level is below acceptable levels, verify the supply level to the chassis

(using either a DVM or by verifying the level reported by other

modules). Correct the supply if necessary.

measured voltage, or that reported by other modules, replace the

module when convenient.

Verify the condition of the TMR processor and start the application as

necessary.

Verify the Expander Processor is faulty by checking the reported

condition within the T8300 chassis board or the diagnostic utility. If the

module is shown not to be responding, replace the module

immediately.

(see above).

Check that the Expander Bus is connected correctly at both the

Processor and Expander Chassis.

Check that the Expander Processor(s) are installed in the correct

slot(s).

Ensure a healthy Expander Processor module is installed in the correct

slot.

values using the diagnostic utility. If the count exceeds a defined limit,

the system will attempt to indicate this fault by setting the

corresponding healthy LED on the module to red flashing.

Replace the faulty interface module.

The error counters for all the modules within the corresponding chassis

will be incrementing. Check the values using the diagnostic utility. If

the count exceeds a defined limit, the system will attempt to indicate

this fault by setting the corresponding healthy LED on the module to

red flashing.

Replace the faulty Expander Processor module as soon as possible.

Issue 12 Dec 06 PD-T8310 26

Page 27

Trusted

TM

Module T8310

6. Specifications

Voltage Range

Maximum Load

Heat Dissipation

Use with Chassis

Module Clocks

Expander Bus Data Rate

I/O Interface

Expander Comms Max Distance

Using TC-301 copper cable

Using fibre converters

Operating Temperature

Non-operating Temperature

Operating Humidity

Environmental Specifications

Dimensions

Height:

Width

Depth:

Weight

20 to 32V dc

40W

40W

T8300

50MHz

250Mbps

Expander Chassis backplane

30m

10km

-5°C to 60ºC (23°F to 140°F)

-25°C to 70ºC (-25°F to 158°F)

5 to 95% RH

Refer to Document 552517

266mm (10.5ins)

31mm (1.2ins)

303mm (12.0ins)

1.33kg (2.9lbs.)

Issue 12 Dec 06 PD-T8310 27

Page 28

Loading...

Loading...