Page 1

8000 SERIES TMR SYSTEM

SAFETY MANUAL

T8094

ISSUE 27 – JUNE 2013

Page 2

SAFETY MANUAL

Copyright © Rockwell Automation 1998-2013

Printed in England

Doc Number T809 4

Issue 27 – J u n e 2013 Page ii

Page 3

SAFETY MANUAL

This page intentionally blank

Doc Number T809 4

Issue 27 – J u n e 2013 Page iii

Page 4

SAFETY MANUAL

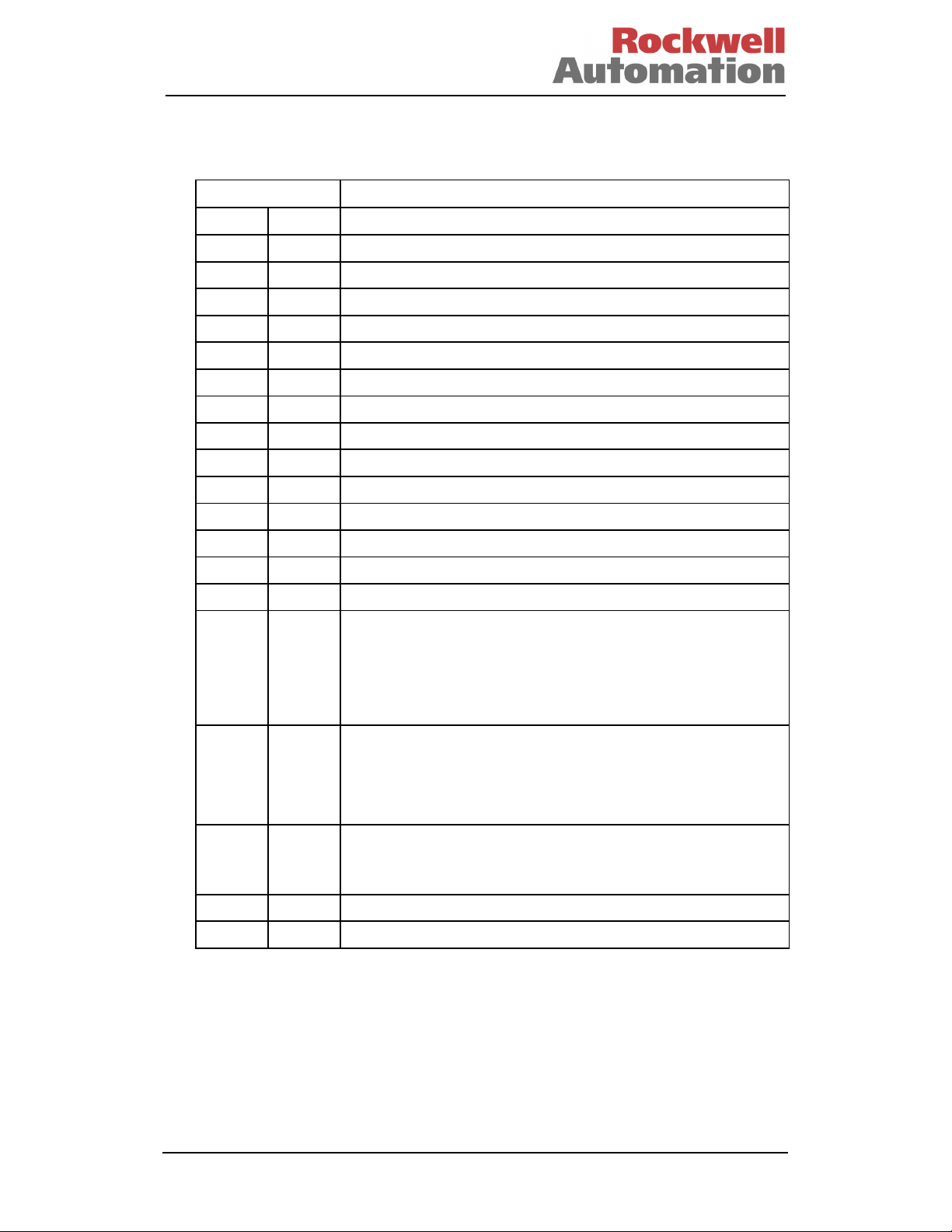

Issue Record and Record of Amendments

Issue Changes

Number Date

Issue 1 Sep 99

Issue 2 Sep 01

Issue 3 Nov 01

Issue 4 Mar-02

Issue 5 Mar-02

Issue 6 May-02

Issue 7 Jan-03

Issue 8 Jan-03

Issue 9 May-03

Issue 10 May-03

Issue 11 May-03

Issue 12

Issue 13

Issue 14

Issue 15 Mar-04

Issue 16 Nov 04

Issue 17 Nov 05

Issue 18 July 06

Issue 19

Initial Issue

Updated to reflect re-certification as of September, 2001

Updated to reflect 3.0 certification.

Updated to add new logo

Updated to correct table and figure numbering.

Updated to reflect 3.1 certification.

Updated to reflect 3.2 certification.

Updated to reflect EN 60204 stop categories. Reworded 3.5.1.2

Added IEC 61508, EN54, NFPA 85 and HFPA 86 requirements

Updated to reflect TUV comments

System release 3.3

Not released

Updated Section 3.12.11 For Intelligent Update

Added 3.7.1.6 & updated 3.22; System Release 3.4

Added Appendix B – Triguard (SC300e) support ; Added Application and

System Configuration archive to 3.12.1 and 3.12.2.; Added 8472 Output

Module to Table 5; Reworded 2.2.1.10.3 & 3.2.4; Removed item 4 from

section 3.13.3; Corrected reference in 3.11.3 to specify section 5; Added

“Grey Channel” to glossary; Corrected 3.6.2 paragraph 2 to refer to the

correct section.; 3.7.2 added ‘companion slot’ to a. and removed ‘pair’

from b.

Updated to incorporate TUV comments to release 3.41; Record of

amendments for issue 15 had incorrect table reference for 8472 Output

module; Previously unlabelled figures and tables given references in

issue 15 and hence figure and table numbering changed.; Some points in

checklist 4.2.1 were changed in error and have been corrected in issue

16

Added T8442 Module (Table 6). Added T8424 Module (Table 4). Added

Enhanced Peer to Peer (Table 3 & section 3.10).; Updated Table 10,

forced air temperatures.; Changed suggested Global Protection to level 8

in table 8.; Corrected reference to NFPA86 & EN54 in 3.2.7 & 3.2.8

Modified table 3 regarding peer to peer

Not released

Doc Number T809 4

Issue 27 – J u n e 2013 P a g e i v

Page 5

SAFETY MANUAL

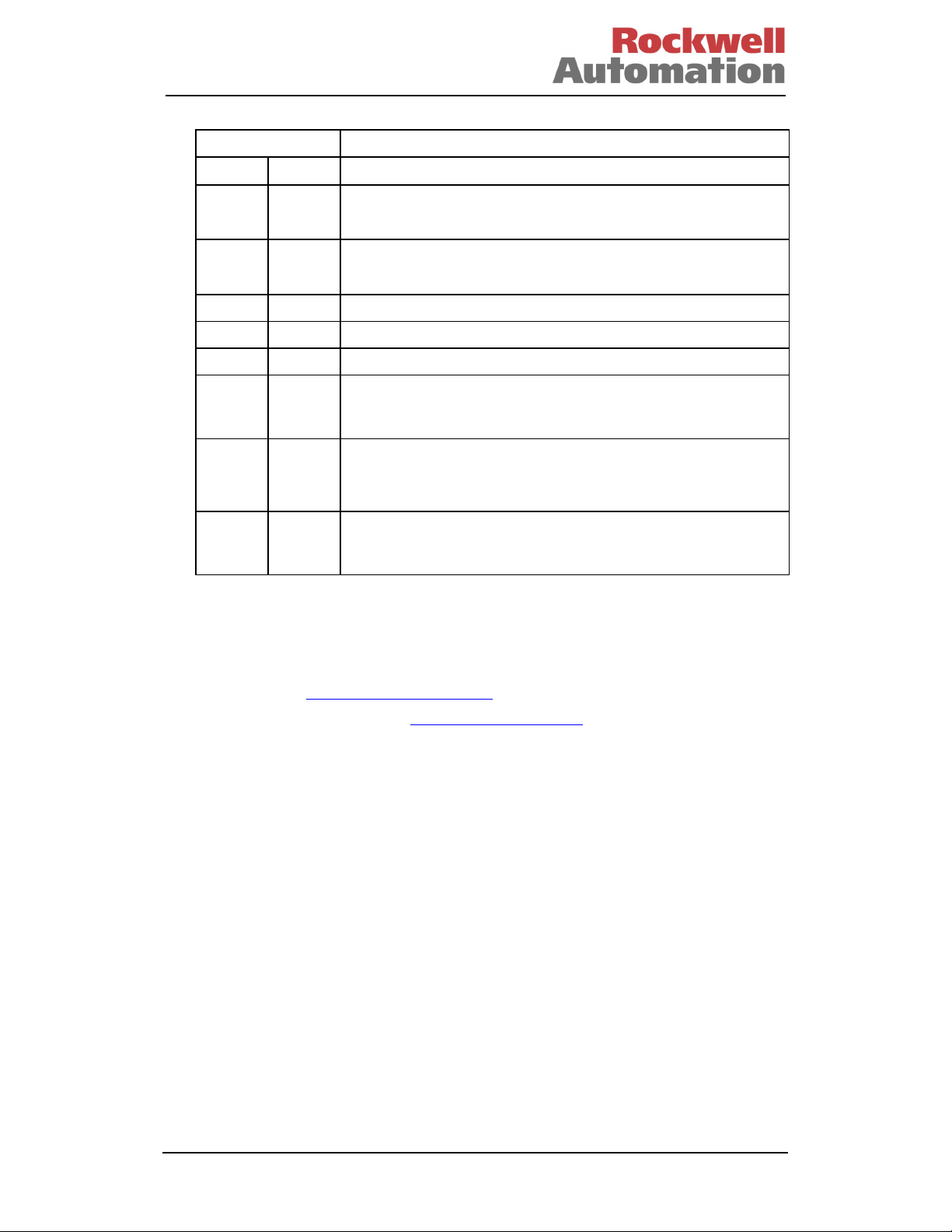

Issue Changes

Number Date

Issue 20 Feb 09

Issue 21 Oct 09

Issue 22 Nov 12

Issue 23 Nov 12

Issue 24 Jan 13

Issue 25 May 13

Issue 26

Issue 27 June 13

Company logo; master\slave replaced by active\standby; Section 3.7.2

corrected Companion Slot configuration; Added section 6 SYSTEM

SECURITY

Relevant sections revised due to updated standards; NFPA 72:2007,

NFPA 85:2007, NFPA 86:2007.; ICS Triplex Technology replaced with

ICST Triplex

Update for certification of release 3.5.3.

Obsolete – withdrawn.

Details of CS300 migration added in Appendix C.

Instructions for use of autotest management function blocks added in

Appendix C.

Additions and corrections to Appendix C for certification.

Not released.

Draft A – 21 May 2013

Draft B – 23 May 2013

Update for TUV certification of CS300 migration (Appendix C and

section 3.13)

Change of company name in text to Rockwell Automation

Note:

The latest issue of the Safety Manual is available by either:

- contacting icstsupport@ra.rockwell.com

- visiting the TUV website at www.tuv-fs.com/plcics.htm

Doc Number T809 4

Issue 27 – J u n e 2013 P a g e v

Page 6

SAFETY MANUAL

NOTICE

The content of this document is confidential to Rockwell Automation companies and their

partners. It may not be given away, lent, resold, hired out or made available to a third party for

any purpose without the written consent of Rockwell Automation.

This document contains proprietary information that is protected by copyright. All rights are

reserved.

Microsoft, Windows, Windows 95, Windows NT, Windows 2000, and Windows XP are

registered trademarks of Microsoft Corporation.

The information contained in this document is subject to change without notice. The reader

should, in all cases, consult Rockwell Automation to determine whether any such changes have

been made. From time to time, amendments to this document will be made as necessary and

will be distributed by Rockwell Automation.

Information in this documentation set may be subject to change without notice and does not

represent a commitment on the part of Rockwell Automation.

The contents of this document, which may also include the loan of software tools, are subject to

the confidentiality and other clause(s) within the Integrator Agreement and Software License

Agreement.

No part of this documentation may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and recording, for any purpose, without the

express written permission of Rockwell Automation.

DISCLAIMER

The illustrations, figures, charts, and layout examples in this manual are intended solely to

illustrate the text of this manual.

The user of, and those responsible for applying this equipment, must satisfy themselves as to

the acceptability of each application and use of this equipment.

This document is based on information available at the time of its publication. While efforts have

been made to be accurate, the information contained herein does not purport to cover all details

or variations in hardware or software, nor to provide for every possible contingency in connection

with installation, operation, or maintenance. Features may be described herein which are

present in all hardware or software systems. Rockwell Automation assumes no obligation of

notice to holders of this document with respect to changes subsequently made.

Rockwell Automation makes no representation or warranty, expressed, implied, or statutory with

respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

Doc Number T809 4

Issue 27 – J u n e 2013 P a g e v i

Page 7

SAFETY MANUAL

PREFACE

This Manual contains the recommended Safety Requirements a System Integrator must

consider and implement when designing and building a Safety System using the 8000 series

range of products.

The contents of this Manual have been reviewed by TÜV and all recommendations and

comments made by TÜV have been incorporated.

REVISION AND UPDATING POLICY

All new and revised information pertinent to this document shall be issued by Rockwell

Automation and shall be incorporated into this document in accordance with the enclosed

instructions. The change is to be recorded on the Amendment Record of this document.

PRECAUTIONARY INFORMATION

WARNING

Warning notices call attention to the use of materials, processes, methods, procedures or limits

which must be followed precisely to avoid personal injury or death.

CAUTION

Caution notices call attention to methods and procedures which must be followed to avoid

damage to the equipment.

Notes:

Notes highlight procedures and contain information to assist the user in the understanding of the

information contained in this document

Doc Number T809 4

Issue 27 – J u n e 2013 Page vii

Page 8

MAINTENANCE MUST BE PERFORMED ONLY BY QUALIFIED PERSONNEL.

SAFETY MANUAL

RADIO FREQUENCY INTERFERENCE

MOST ELECTRONIC EQUIPMENT IS INFLUENCED BY RADIO FREQUENCY

INTERFERENCE (RFI). CAUTION SHOULD BE EXERCISED WITH REGARD

TO THE USE OF PORTABLE COMMUNICATIONS EQUIPMENT AROUND

SUCH EQUIPMENT. SIGNS SHOULD BE POSTED IN THE VICINITY OF THE

EQUIPMENT CAUTIONING AGAINST THE USE OF PORTABLE

COMMUNICATIONS EQUIPMENT.

MAINTENANCE

OTHERWISE PERSONAL INJURY OR DEATH, OR DAMAGE TO THE

SYSTEM MAY BE CAUSED.

WARNING

CAUTION

STATIC SENSITIVE DEVICES

MODULES IN THE TMR SYSTEM MAY CONTAIN STATIC SENSITIVE

DEVICES WHICH CAN BE DAMAGED BY INCORRECT HANDLING OF THE

MODULE. THE PROCEDURE FOR MODULE REMOVAL IS DETAILED IN

RELEVANT PRODUCT DESCRIPTIONS AND MUST BE FOLLOWED. ALL

TMR SYSTEMS MUST HAVE LABELS FITTED TO THE EXTERIOR SURFACE

OF ALL CABINET DOORS CAUTIONING PERSONNEL TO OBSERVE ANTISTATIC PRECAUTIONS WHEN TOUCHING MODULES. THESE

PRECAUTIONS ARE DETAILED IN CHAPTER 3 OF THIS PACKAGE.

Doc Number T809 4

Issue 27 – J u n e 2013 Page viii

Page 9

SAFETY MANUAL

1-oo-2 One-out-of-two

1-oo-2D One-out-of-two with diagnostics

2-oo-2 Two-out-of-two

2-oo-3 Two-out-of-three

API Application Program Interface

DIN Deutsche Industrie-Norm (German Industrial Standard)

DIU Diagnostic Interface Utility

EMC Electromagnetic Compatibility

EMI Electromagnetic Interference

EUC Equipment Under Control

FB Function Block

FCR Fault Containment Region

HIFT Hardware Implemented Fault Tolerance

IL Instruction List

I/O Input/Output

IMB Inter-module Bus

LD Ladder Diagram

MMU Memory Management Unit

MTR Mean Time to Repair

PC Personal Computer

PST Process Safety Times

PSU Power Supply Unit

SFC Sequential Function Chart

SFOC Second Fault Occurrence Time

SIL Safety Integrity Levels

ST Structured Text

TMR Triple Modular Redundant

TÜV Technischer Überwachungs-Verein

UPS Uninterruptable Power Supply

ABBREVIATIONS

Doc Number T809 4

Issue 27 – J u n e 2013 P a ge ix

Page 10

h carry related data.

SAFETY MANUAL

Actuators Devices which cause an action (electrical,

Architecture Organisational structure of a computing system

ASCII The American Standard Code for Information

Availability The probability that a system will be able to

Asynchronous A data communications term describing the

Backplane A printed circuit board which supports bussed

Buffer A type of memory in which information is stored

Bus A group of conductors whic

CIE Control Indicating Equipment

Companion Slot Spare (standby) slot position adjacent (to the

Controller A Controller is the heart of any Rockwell

GLOSSARY

mechanical, pneumatic, etc.) to occur when

required within a plant component.

which describes the functional relationship

between board level, device level and system

level components.

Interchange. Uses seven bits to represent 128

characters. Both upper and lower case letters,

numbers, special symbols and a wide range of

control codes are included.

perform its designated function when required

for use – normally expressed as a percentage.

method by which signals between computers

are timed. Although the number of characters

to be sent per second is undefined, the rate at

which a character’s bits are sent is predetermined. Each character is preceded by a

start bit and terminated by a stop bit.

functions to connectors mounted on a printed

circuit board. Plug-in components and modules

are then able to connect to the bus pins.

temporarily during transfer from one device to

another, or one process to another. Normally

used to accommodate the difference in the rate

or time at which the devices can handle the

data.

Micro-based systems have an Address Bus,

Data Bus and a Control Bus.

right) to the slot occupied by the ‘active’

module. The slots are inter-connected to enable

the ‘active’ module to be ‘hot’ replaced as

necessary.

Automation microprocessor based system. It

performs central processing of user application

logic and controls the actions of input and

output hardware, as well as peripheral hardware

such as printers and Visual Display Units.

Doc Number T809 4

Issue 27 – J u n e 2013 Page x

Page 11

SAFETY MANUAL

Discrepancy A discrepancy exists if one or more of the

DRAM Dynamic Random Access Memory. A type of

Element A set of input conditioning, application

Engineering

Workstation

EPROM Erasable Programmable Read Only Memory. A

EUC Equipment Under Control. Equipment,

Fail Safe The capability to go to a pre-determined safe

Fault Tolerance Built-in capability of a system to provide

Field Devices Equipment connected to the field side of the I/O

Firmware Special purpose memory units containing

Fixed Frame An empty fixed metal surround, designed to

FBD Functional Block Diagram. A graphical IEC1131

Grey Channel A non-safety critical communication line

GUI Graphical User Interface

elements disagree.

volatile read/write memory where the data is

stored as a short-life capacitive charge. Though

high density and low cost are a feature of

DRAMs, they require each row address and

hence all data to be refreshed frequently.

processing and output conditioning.

Comprising rugged PC platform fitted with

IEC1131 TOOLSET.

non-volatile storage medium which is

electronically programmed. The EPROM device

may be erased by strong ultra-violet light.

machinery, apparatus or plant used for

manufacturing, process, transportation, medical

or other activities.

state in the event of a specific malfunction.

continued correct execution of its assigned

function in the presence of a limited number of

hardware and software faults.

terminals. Such equipment includes field

wiring, sensors, final control elements and

those operator interface devices hard-wired to

I/O terminals.

software embedded in protected memory

required for the operation of programmable

electronics.

contain 483mm (19”) standard equipment.

language for building complex procedures by

taking existing Functional Blocks from the

IEC1131 library and wiring them together on the

screen.

between two modules that are regarded as

safety critical. Communications sent across a

“grey channel” are viewed as subject to errors

induced by that channel which must be detected

and compensated be the safety related receiver.

Doc Number T809 4

Issue 27 – J u n e 2013 P a ge xi

Page 12

SAFETY MANUAL

Hot Swap Alternative term for Companion Slot

IEC 1131 TOOLSET Software used to configure and program the

8000 series TMR system.

IEC 61508 IEC61508 is an international standard that

covers functional safety, encompassing

electrical, electronic and programmable

electronic systems; hardware and software

aspects.

IEC 61511 IEC61511 is an international standard that

covers functional safety and Safety

Instrumented Systems for the process

industry, encompassing electrical, electronic

and programmable electronic systems,

hardware and software aspects.

EPROM A non-volatile storage medium which is

electronically programmed. The EPROM

device may be erased by strong ultra-violet

light.

IL Instruction List. A low level IEC1131 language,

similar to the simple textual PLC’s language.

Industrial Processor High performance processor for use in non

safety-related applications which can be used

in a simplex or dual-redundant configuration.

Input Module Interface that converts input signals from

external devices into signals that the control

system can utilise.

I/O Input/Output conditioning circuits (as distinct

from the central processing).

I/O Driver Essential software to allow the IEC1131

TOOLSET to configure and program unique

types of TMR system I/O interfaces.

LD Ladder Diagram. An IEC1131 language

composed of contact symbols representing

logical equations and simple actions. The

main function of the ladder diagram is to

control outputs based on input conditions.

MMI Man Machine Interface. The operator’s

window to monitoring and keys, knobs,

switches, Graphical User Interface of the

Operator Workstation, etc. for making

adjustments in the process.

Modbus An industry standard communications

protocol developed by Modicon. Used to

communicate with external devices such as

distributed control systems (DCSs) or operator

interfaces.

M-oo-N m-out-of-n. See Voting System

Module An electronic (generally pluggable) sub-

system.

Doc Number T809 4

Issue 27 – J u n e 2013 Page xii

Page 13

battery backed) form of read/write memory.

SAFETY MANUAL

MORSE Method for Object Reuse in Safety-critical

Output Module Interface that converts output signals from the

Peer-to-Peer

Communications

PCM PCI Mezzanine Card

Protocol A set of rules governing data flow in a

PSU Power Supply Unit.

RAM Random Access Memory. A volatile (unless

Environments. Programming and

configuration software tool for the Fastflex

range of Remote I/O.

control system into signals that can actuate

external devices.

Allows two or more TMR Controllers to

communicate with each other.

communication system. The protocol governs

such matters as the way a message is

addressed and routed, how often it is sent,

how to recover from transmission errors and

how much information is to be sent.

The time to access different locations is the

same. It may be static (SRAM - data held in a

flip- flop) or dynamic (DRAM – data held as a

capacitive charge).

Real Time A method of data processing in which the data

is acted upon immediately instead of being

accumulated and processed in batches.

Redundancy The employment of two or more devices, each

performing the same function, in order to

improve reliability.

RISC Reduced Instruction Set Computer

RS-232C,

RS-422,

RS-485

Standard interfaces introduced by the Energy

Industries Association covering the electrical

connection between data communication

equipment. RS-232C is the most commonly

used interface,. However, RS-422 allows for

high transmission rates over greatly increased

distances.

RTU Remote Telemetry Unit

Safety Where TÜV certification is a requirement, the

Safety Chapter prescribes how to use the TMR

system in a safety-related application.

SFC Sequential Function Chart. A IEC1131

language that divides the process cycle into a

number of well-defined steps separated by

transitions.

Doc Number T809 4

Issue 27 – J u n e 2013 Page xiii

Page 14

Software specific to the user application.

SAFETY MANUAL

SIL Safety Integrity Level. One of four possible

Slot A slot is the term given to the physical

SmartSlot Spare module slot position wired, and

SOE Sequence of Events

Software (Application

Software)

ST Structured Text. A high level IEC1131

Swingframe An empty hinged metal surround, designed to

Synchronous A data-communication term describing the

System Engineering

Toolset

TMR Triple Modular Redundancy.

TMR Interface An interface between the TMR Controller and 6U

8000 Series Certified family of products for use in a wide

discrete levels for specifying the safety integrity

requirements of the safety functions to be

allocated to the safety-related systems. SIL4

has the highest level of safety integrity; SIL1 has

the lowest.

allocation of a module within a 483mm (19 inch)

frame.

configured to enable any one of a number of

modules of the same type to be ‘hot’ replaced as

necessary.

Generally, it contains logic sequences,

permissives, limits, expressions, etc. that

control the appropriate input, output,

calculations and decisions necessary to meet

system safety functional requirements.

structured language with a syntax similar to

Pascal. Used mainly to implement complex

procedures that cannot be expressed easily

with graphical languages.

contain 483mm (19 inch) standard equipment.

method by which signals between computers

are timed. In synchronous communications, a

pre-arranged number of bits is expected to be

sent across a line per second. To synchronise

the sending and receiving machines, a clocking

signal is sent on the same line by the

transmitting computer. There are no start or

stop bits in synchronous communications.

Sophisticated software package which can be

used to reduce the time to perform applications

engineering, manufacturing, validation and

support of the TMR system

format TMR I/O Modules (Low Density I/O)

range of controls applications including safety,

continuous process, supervisory control/data

acquisition, and integrated control and safety.

Doc Number T809 4

Issue 27 – J u n e 2013 Page xiv

Page 15

SAFETY MANUAL

Communications

Interface

An intelligent communications module which

interfaces between a TMR Controller and an

Engineering Workstation, third party equipment

or other TMR Controllers.

TMR Processor A processor for use in safety-related

applications of the 8000 series system. Handles

application program execution, diagnostics and

reporting functions. The TMR Processor uses

three high performance RISC processors based

on patented TMR architecture arranged in a

lock-step configuration.

TÜV Certification Independent third party certification against a

defined range of International standards.

U Units of electronic module size (1-¾ inches).

Voting System Redundant system (e.g. m out of n, 1-oo-2, 2-oo-

3 etc.) which requires at least m of the n

channels to be in agreement before the system

can take action.

Watchdog Watchdog circuitry provides dynamic and/or

static monitoring of processor operation and is

used to annunciate processor or processor

related failures.

Doc Number T809 4

Issue 27 – J u n e 2013 P a ge xv

Page 16

SAFETY MANUAL

Paragraph Page

1. INTRODUCTION ............................................................................................ 1

1.1 PURPOSE OF SAFETY ............................................................................ 1

1.2 ASSOCIATED DOCUMENTS ................................................................... 2

1.3 TERMINOLOGY ........................................................................................ 2

1.3.1 Safety and Functional Safety ........................................................... 3

1.3.2 Safety Integrity and Risk Class Levels ............................................ 3

1.3.3 Process Safety Time (PST) ............................................................. 4

1.4 THE 8000 SERIES OVERVIEW ................................................................ 7

2. SAFETY PRINCIPLES .................................................................................... 8

2.1 INTRODUCTION ....................................................................................... 8

2.2 SAFETY MANAGEMENT .......................................................................... 8

2.2.1 Safety Lifecycle ................................................................................ 9

2.3 FUNCTIONAL SAFETY ASSESSMENT ................................................. 16

2.3.1 Competency................................................................................... 17

3. SYSTEM RECOMMENDATIONS ................................................................. 18

3.1 INTRODUCTION ..................................................................................... 18

3.2 I/O ARCHITECTURES ............................................................................ 18

3.2.1 Safety-Related Configurations ....................................................... 19

3.2.2 High-Density I/O ............................................................................ 23

3.2.3 Analog Input Safety Accuracy ........................................................ 25

3.2.4 Energise to Action Configurations ................................................. 25

3.2.5 EN 60204 Category 0 & 1 Configurations ...................................... 26

3.2.6 NFPA 72 Requirements ................................................................. 26

3.2.7 NFPA 85 Requirements ................................................................. 26

3.2.8 NFPA 86 Requirements ................................................................. 27

3.2.9 EN54 Requirements ...................................................................... 28

3.3 SENSOR CONFIGURATIONS ................................................................ 30

3.4 ACTUATOR CONFIGURATIONS ........................................................... 31

3.5 PFD CALCULATIONS ............................................................................. 31

3.6 PROCESSOR CONFIGURATION ........................................................... 32

3.6.1 Timing ............................................................................................ 32

3.6.2 Diagnostic Access ......................................................................... 33

3.6.3 Configuration File Verification ........................................................ 33

3.7 HIGH DENSITY I/O MODULE CONFIGURATION .................................. 33

3.7.1 Module Characteristics .................................................................. 33

3.7.2 Module Replacement Configuration .............................................. 35

3.8 INPUT AND OUTPUT FORCING ............................................................ 36

3.9 MAINTENANCE OVERRIDES................................................................. 37

3.10 PEER COMMUNICATIONS CONFIGURATION ..................................... 38

3.11 APPLICATION PROGRAM DEVELOPMENT ......................................... 38

3.11.1 IEC1131 Workbench Configuration ............................................... 40

3.11.2 Language Selection ....................................................................... 41

3.11.3 Testing of New or Previously Untested Functions ......................... 42

3.11.4 Application Development ............................................................... 44

TABLE OF CONTENTS

Doc Number T809 4

Issue 27 – J u n e 2013 Page xvi

Page 17

SAFETY MANUAL

3.11.5 Communications Interaction .......................................................... 45

3.11.6 Program Testing ............................................................................ 46

3.12 ON-LINE MODIFICATION ....................................................................... 47

3.12.1 Application Program ...................................................................... 47

3.12.2 System Configuration .................................................................... 48

3.13 ENVIRONMENTAL REQUIREMENTS .................................................... 48

3.13.1 Climatic Conditions ........................................................................ 48

3.13.2 Electromagnetic Compatibility (EMC) ............................................ 50

3.13.3 Physical Installation Design ........................................................... 50

3.13.4 System Power Requirements ........................................................ 51

3.14 ELECTROSTATIC HANDLING PRECAUTIONS .................................... 52

4. CHECKLISTS ............................................................................................... 53

4.1 PRE-ENGINEERING CHECKLISTS ....................................................... 53

4.1.1 Scope Definition Checklist ............................................................. 53

4.1.2 Functional Requirements Checklist ............................................... 54

4.1.3 Safety Requirements Checklist ..................................................... 55

4.2 ENGINEERING CHECKLISTS ................................................................ 56

4.2.1 I/O Architecture Checklist .............................................................. 56

4.2.2 Language Selection Checklist ....................................................... 57

4.2.3 Override Requirements Checklist .................................................. 58

4.2.4 High Density Module Configuration Checklist................................ 59

4.2.5 Processor and Other Configuration ............................................... 59

4.2.6 Testing ........................................................................................... 60

5. PREVIOUSLY ASSESSED FUNCTIONS ..................................................... 61

6. SYSTEM SECURITY .................................................................................... 63

APPENDIX A ...................................................................................................... 64

7. LOW-DENSITY I/O ....................................................................................... 64

7.1.1 Effect of Input Architectures .......................................................... 64

7.1.2 Effect of Output Architectures ....................................................... 64

7.1.3 TX and DX Low Density module types in Safety applications. ...... 67

APPENDIX B ...................................................................................................... 69

8. TRIGUARD I/O ............................................................................................. 69

8.1 AFFECT OF THE INPUT AND OUTPUT STATES ................................. 69

8.1.1 Effect of Input States ..................................................................... 69

8.1.2 Effect of Output States .................................................................. 69

8.2 SAFETY RELATED INPUTS AND OUTPUTS ........................................ 72

8.2.1 Inputs ............................................................................................. 72

8.2.2 Outputs .......................................................................................... 74

APPENDIX C ..................................................................................................... 76

9. MIGRATING A CS300 CONTROLLER ........................................................ 76

9.1 OVERVIEW ............................................................................................. 76

9.2 GLOSSARY ............................................................................................. 77

9.3 ASSOCIATED DOCUMENTS ................................................................. 77

9.3.1 Specifications ................................................................................ 77

9.3.2 TUV Certification ........................................................................... 77

9.4 LIST OF MODULES FOR SAFETY-RELATED APPLICATIONS ............ 77

9.5 REQUIREMENTS FOR THE TRUSTEDTM SYSTEM .............................. 78

9.6 SYSTEM ARCHITECTURE FEATURES ................................................. 79

Doc Number T809 4

Issue 27 – J u n e 2013 Page xvii

Page 18

SAFETY MANUAL

9.6.1 T8162 CS300 Bridge Module ........................................................ 80

9.6.2 CS300 Equipment Power Supplies................................................ 81

9.6.3 PI-616/PI-716 Digital Input Board .................................................. 81

9.6.4 PI-632/PI-732 Analogue Input Board ............................................. 81

9.6.5 PI-626/PI-726 Digital Output Board ............................................... 82

9.6.6 PI-627/727 Digital Output Board .................................................... 82

9.6.7 TM118-TWD Watchdog Module .................................................... 82

9.7 SITE PLANNING AND INSTALLATION DESIGN ................................... 83

9.7.1 Operational Environment ............................................................... 83

9.7.2 Installation Design ......................................................................... 83

9.8 PLANNING THE MIGRATION ................................................................. 83

9.9 REPLICATING THE APPLICATION ........................................................ 83

9.9.1 Prerequisites .................................................................................. 83

9.9.2 Choosing Application Logic ........................................................... 84

9.9.3 Detecting and Handling Faults....................................................... 84

9.10 USING THE AUTOTEST MANAGEMENT FUNCTION BLOCKS ........... 84

9.10.1 Function Block Library ................................................................... 84

9.10.2 Hardware Arrangements ............................................................... 85

9.10.3 Quick Reference Guide ................................................................. 85

9.10.4 Choosing and Using Function Blocks ............................................ 86

9.10.5 Function Block Specifications ........................................................ 92

9.10.6 Parameter Specifications ............................................................... 94

9.10.7 Connecting F&G and ESD Systems .............................................. 98

9.10.8 Retaining the CD901 Diagnostic Panel ......................................... 98

9.10.9 TM117-DMX Matrix Driver Interface Module ................................. 98

9.10.10 Making Printouts of Alarm and Diagnostic Data ............................ 99

9.11 PREPARING FOR ENTRY INTO SERVICE ........................................... 99

9.12 MAINTAINING THE MIGRATED SYSTEM ............................................. 99

9.12.1 Maintenance Schedule .................................................................. 99

9.13 COMPLETION ......................................................................................... 99

Doc Number T809 4

Issue 27 – J u n e 2013 Page xviii

Page 19

SAFETY MANUAL

Figure 1 - Simple Triplicated System ................................................................... 5

Figure 2 – TMR Architecture ................................................................................ 6

Figure 3 - Single High Density TMR I/O Module Architecture ............................ 23

Figure 4 - SmartSlot or Adjacent Slot TMR Module Configuration .................... 24

Figure 5 – 2-oo-3 voting logic with discrepancy reporting .................................. 67

Figure 6 – Discrepancy error bit latch and manual reset logic ........................... 68

Figure 7 - Current to Voltage Conversion .......................................................... 73

Figure 8 – System Architecture Features using T8162 Bridge Module ............. 79

Figure 9 - Wiring for CS300 digital inputs using a simplex digital input module100

Figure 10 - Wiring for CS300 digital inputs using duplex digital input modules 101

Figure 11 - Wiring for CS300 analogue inputs ................................................. 102

Figure 12 - Wiring for CS300 digital outputs .................................................... 103

ILLUSTRATIONS

TABLES

Table 1 - Referenced documents ......................................................................... 2

Table 2 - Central Modules .................................................................................. 19

Table 3 - Input Modules High Density I/O .......................................................... 20

Table 4 - Output Modules High Density I/O ....................................................... 20

Table 5 - Multi-purpose Modules, High Density I/O ........................................... 21

Table 6 - Auxiliary Modules ................................................................................ 22

Table 7 - IEC1131 Workbench Recommended Access Levels ......................... 40

Table 8 - Safety Related Programming Language ............................................. 41

Table 9 - Climatic Condition Requirements ....................................................... 49

Table 10 - Electromagnetic Compatibility ........................................................... 50

Table 11 - Input Module, Low Density I/O .......................................................... 65

Table 12 - Output Modules, Low Density I/O ..................................................... 66

Table 13 - Central Modules ................................................................................ 70

Table 14- Input Module, Triguard I/O ................................................................. 70

Table 15- Output Modules, Triguard I/O ............................................................ 71

Table 16 – Triguard Multi-purpose Modules ...................................................... 71

Table 17 – Auxiliary Chassis and PSUs ............................................................. 71

Table 18 - List of CS300 Modules Suitable for Safety-Related Applications ..... 77

Table 19 - TrustedTM Items Needed for the Migration ........................................ 79

Table 20 - Summary of Function Blocks ............................................................ 85

Table 21 - Summary of Function Block Parameters .......................................... 85

Doc Number T809 4

Issue 27 – J u n e 2013 Page xix

Page 20

SAFETY MANUAL

Doc Number T809 4

Issue 27 – J u n e 2013 Page xx

Page 21

SAFETY MANUAL

This page intentionally blank

Doc Number T809 4

Issue 27 – J u n e 2013 Page xxi

Page 22

SAFETY MANUAL

SAFETY MANUAL

1. INTRODUCTION

1.1 PURPOSE OF SAFETY

The 8000 series TMR system has been designed and certified for use in safety related

applications. To ensure that systems build upon these foundations, it is necessary to

impose requirements on the way such systems are designed, built, tested, installed

and commissioned, operated, maintained and de-commissioned. This Manual sets

out the requirements to be met during the lifecycle stages of safety-related systems to

ensure that the safety objectives of the safety system are achieved

This Manual is intended primarily for system integrators. It is assumed that the reader

has a thorough understanding of the intended application and can translate readily

between the generic terms used within this Manual and the terminology specific to the

integrator’s or project’s application area.

The TMR system has been independently certified by the German certification

authority Technischer Überwachungs-Verein (TÜV) to meet the requirements of IEC

61508 SIL 3.

The content of this Manual has been reviewed by TÜV and it represents the

requirements that shall be fulfilled to achieve certifiable safety-related systems up to

SIL 3. Conditions and configurations that shall be adhered to if the system is to remain

in compliance with the requirements of SIL 3 are clearly marked.

The information contained in this Manual is intended for use by engineers and system

integrators and is not intended to be a substitute for expertise or experience in safetyrelated systems. Requirements for quality systems, documentation and competence

are included within this document; these are requirements, and NOT replacements, for

an operating company’s or integrator's quality systems, procedures and practices. The

system integrator remains responsible for the generation of procedures and practices

applicable to its business, and shall ensure that these are in accordance with the

requirements defined herein. The application of such procedures and practices is also

the responsibility of the system integrator, however, these shall be considered

mandatory for systems for SIL 3 applications.

Doc Number T809 4

Issue 27 – J u n e 2013 Page 1 of 1 0 3

Page 23

SAFETY MANUAL

1.2 ASSOCIATED DOCUMENTS

The following documents are associated with the safety requirements applicable to the

TMR system or provide supporting information via TUV web Site.

Document Title

"Maintenance Override" by TÜV

Süddeutschland / TÜV Product Service

GmbH and TÜV Rheinland

IEC61508 Functional Safety of Programmable

Electronic Systems

IEC61511 Functional safety: Safety Instrumented

Systems for the process industry sector

EN54-2 Fire Detection and Fire Alarm Systems

NFPA 72:2007 National Fire Alarm Code

NFPA 85:2007 Boiler and Combustion Systems Hazards

Code

NFPA 86:2007 Standard for Ovens and Furnaces

An understanding of basic safety and functional safety principles and the content of

these standards in particular are highly recommended. The principles of these

standards should be thoroughly understood before generating procedures and

practises to meet the requirements of this Safety Manual.

1.3 TERMINOLOGY

The terms ‘certification’ and ‘certified’ are used widely within this Manual. Within the

context of this Manual, these terms refer to the functional safety certification of the

product to IEC 61508 SIL 3. The 8000 series as a product is certified to a wider range

of standards that are outside the scope of this Safety Manual.

This Manual contains rules and recommendations:

Rules are mandatory and must be followed if the resulting system is to be a SIL 3

compliant application. These are identified by terms such as ‘shall’.

Recommendations are not mandatory, but if they are not followed, extra safety

precautions must be taken in order to certify the system. Recommendations are

identified by terms such as `it is strongly recommended’.

Table 1 - Referenced documents

Doc Number T809 4

Issue 27 – J u n e 2013 Page 2 of 1 0 3

Page 24

SAFETY MANUAL

1.3.1 Safety and Functional Safety

Safety: The expectation that a system will not lead to risk to human life or health.

Safety is traditionally associated with the characteristics or hazards resulting from the

system itself; including fire hazards, electrical safety, etc. The requirements to be

satisfied by the integrator here include wiring, protective covers, selection of materials,

etc.

Functional Safety: The ability of a system to carry out the actions necessary to

achieve or to maintain a safe state for the process and its associated equipment.

Functional safety is considered the ability of the system to perform its required safety

function. The requirements on the integrator here are to take the steps necessary to

ensure that system is free from faults, errors, and correctly implements the required

safety functions.

This Manual concentrates on functional safety; it is assumed that the reader is familiar

with the methods of achieving basic safety.

1.3.2 Safety Integrity and Risk Class Levels

The TMR system is certified for use for applications to SIL 3 for subsections of the

system using low density I/O.

A Safety Integrity Level (SIL) is defined in IEC61508/IEC61511 as one of four possible

discrete levels for specifying the safety integrity requirements of the safety functions to

be allocated to the safety-related system. SIL 4 has the highest level of safety

integrity; SIL 1 has the lowest.

However, IEC61508 requires that the complete installation meet these requirements in

order to achieve an overall SIL. The system covered by this technical manual forms

only a part of such requirements.

Doc Number T809 4

Issue 27 – J u n e 2013 Page 3 of 1 0 3

Page 25

SAFETY MANUAL

1.3.3 Process Safety Time (PST)

Every process has a safety time that is the period that the process can be controlled by

a faulty control-output signal without entering a dangerous condition. This is a function

of the process dynamic and the level of safety built into the process plant. The

Process Safety Time1 (PST) can range from seconds to hours, depending on the

process. In instances where the process has a high demand rate and/or highly

dynamic process the PST will be short, for example, turbine control applications may

dictate process safety times down to around 100ms

The PST dictates the response time for the combination of the sensor, actuators and

each realised control or safety function. For demand or event-driven elements of the

system, the response time of the system shall be considerably less than:

(PST- Sensor and actuator delay)

For convenience within this document, we will refer to the element of the PST relevant

to the system’s response time as PSTE, effective PST.

For cyclic elements of the system, the system’s scan time shall be considerably

less than of the effective PST, i.e.:

½ (PST- Sensor and actuator delay), or

The response time in the context of the process safety time must consider the

system’s ability to respond, i.e. its probability of failure on demand (including its ability

to fulfil the required function within the required time). The probability of failure on

demand is a function of the system’s architecture, its self-test interval and its β-factor2.

If the system architecture provided no fault tolerance, it would be necessary to ensure

that the sum of the response times (including sensors and actuators) and the fault

detection time does not exceed the process safety time.

In practice, many of a system’s self-test intervals vary from seconds to hours

depending on the element of the system under test. For higher requirements, the

system architecture shall provide sufficient fault tolerance, or faults shall result in failsafe actions, i.e. there shall be no potential covert failures for those safety-related

elements of the system. Degraded Operation

Non-fault tolerant (simplex) systems, by definition, do not have the ability to continue

their operation in the presence of fault conditions. If we consider a digital point, the

state may be 0, 1, or undefined (X). In the case of a fault within a non-fault tolerant

system we would normally assume that the state becomes undefined in the presence

of faults. For safety applications, however, it is necessary to be able to define how the

system will respond in the presence of faults and as faults accumulate, this is the

system’s defined degraded operation. Traditionally, 0 is considered the fail-safe state,

and 1 considered the operable condition. A standard non-fault tolerant system would

therefore be 1 channel operating (or 1-out of-1), degrading to undefined (X) in the case

of a fault. Obviously, this would be undesirable for safety applications, where we

require a fail-safe reaction in the case of a fault, a system providing this operation

would be 1-oo-1 fail-safe, or 1→0.

The additional element in the degradation path is that the fault may occur but may be

hidden, or covert. The fault could be such that it prevents the system from responding

when required to do so. Obviously, this would also be unacceptable for safety

½ (PSTE)

1

The only source of information about the PST is the designer’s Loss Prevention Engineer. This data is not

normally supplied at bid or at the manufacturing stage, so a direct request for information should be made.

This data must form part of the safety considerations for the system and design reviews must be a

fundamental part of safety engineering.

2

The β-factor is a measure of common cause failure and is dependent on the equipment’s original design,

which is assessed and certified independently, and the implementation of the guidance providing within

this Safety Chapter. The compact nature of the TMR system provides a β-factor of better than 1%.

Doc Number T809 4

Issue 27 – J u n e 2013 Page 4 of 1 0 3

Page 26

SAFETY MANUAL

applications. To detect the presence of these covert faults, it is necessary to perform

tests, or diagnostics on the system. Detection of the covert fault is then used to force

the system to its fail-safe condition. For a non-fault tolerant (simplex) system with

diagnostics, this is referred to as 1-oo-1D.

Fault tolerant systems have redundant elements that allow the system to continue

operation or to ensure that the system fails safety in the presence of faults. For

example, a dual system may be 1-oo-2 (also known as 2v2), with either channel able

to initiate the fail-safe reaction, or 2-oo-2 (1v2) requiring both channels to initiate the

fail-safe reaction. The 1-oo-2 system provides a greater period between potential

failure to respond to a hazard, but a higher probability of spurious responses. The 2oo-2 system providing a greater period between spurious responses, but a higher

chance of not responding when required. It is also possible to have dual systems with

diagnostics to address covert failures and help redress the balance between failure to

respond and spurious response. A dual system could therefore be 2-oo-2D reverting

to 1-oo-1D reverting to fail-safe, or 2→1→0.

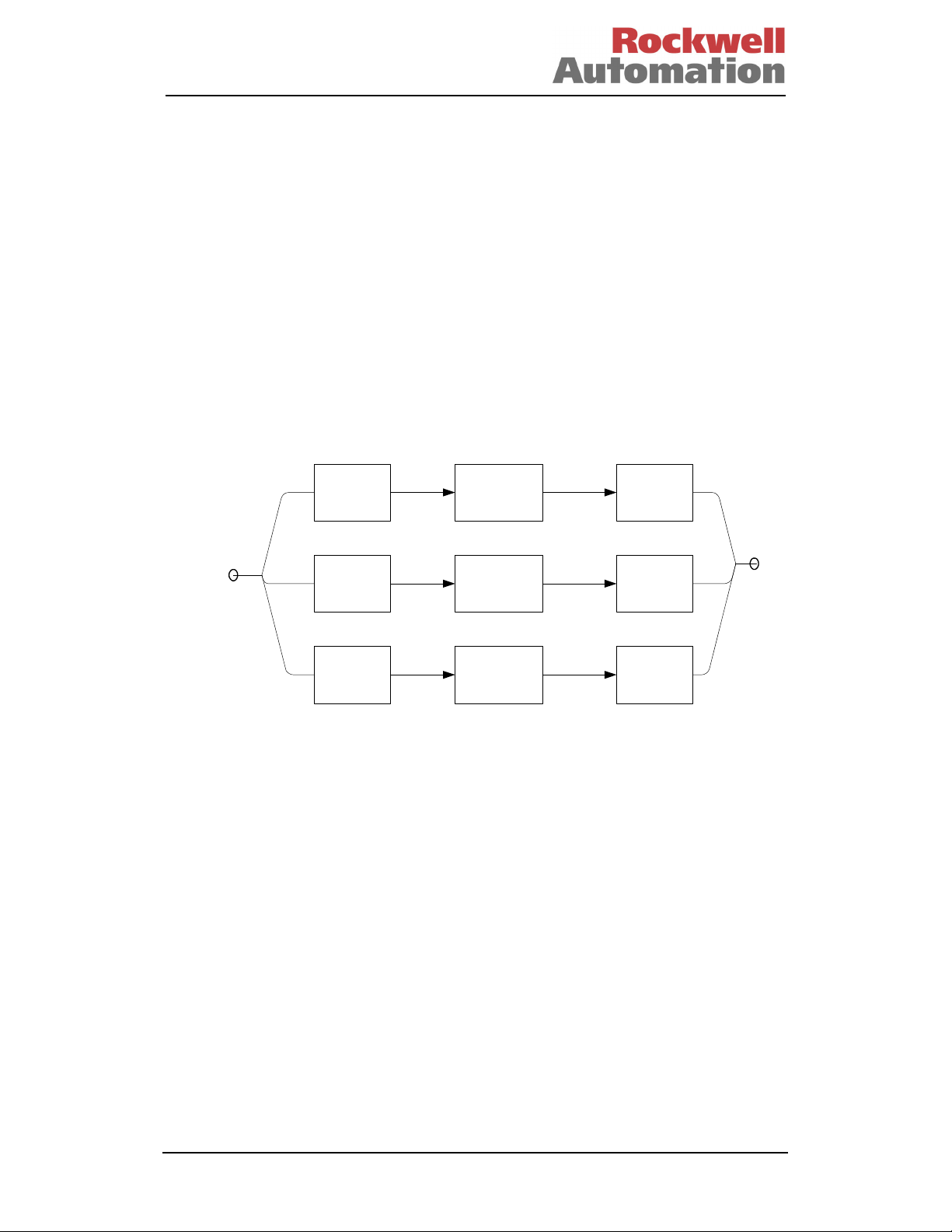

Consider a simple triplicated system, as shown in Figure 1. The input and output

devices are assumed to be simply wired to the input and output channels to provide

the requisite distribution and voting. We have assumed that the output vote is a simple

majority vote for this purpose. Note with non-8000 series systems there may be a

need for a common output-voting element.

INPUT

(Ch. A)

1

INPUT

(Ch. B)

1

INPUT

(Ch. C)

1

PROCESSOR

(Ch. A)

1

PROCESSOR

(Ch. B)

1

PROCESSOR

(Ch. C)

1

Figure 1 - Simple Triplicated System

OUTPUT

(Ch. A)

1

OUTPUT

(Ch. B)

1

OUTPUT

(Ch. C)

1

Doc Number T809 4

Issue 27 – J u n e 2013 Page 5 of 1 0 3

Page 27

SAFETY MANUAL

A failure in any element of each channel, e.g. Ch. A Input, will result in that complete

channel’s failure. If this failure is fail-safe, only 1 of the remaining channels needs to

respond to a demand condition to generate the safe reaction. If a second channel fails

safe then the overall system will fail-safe. This is therefore a 3-2-0 architecture.

Typically diagnostics are used to ensure that the fail-safe state can be assured, the

operation is therefore 2-oo-3D, reverting to 1-oo-2D, reverting to fail-safe.

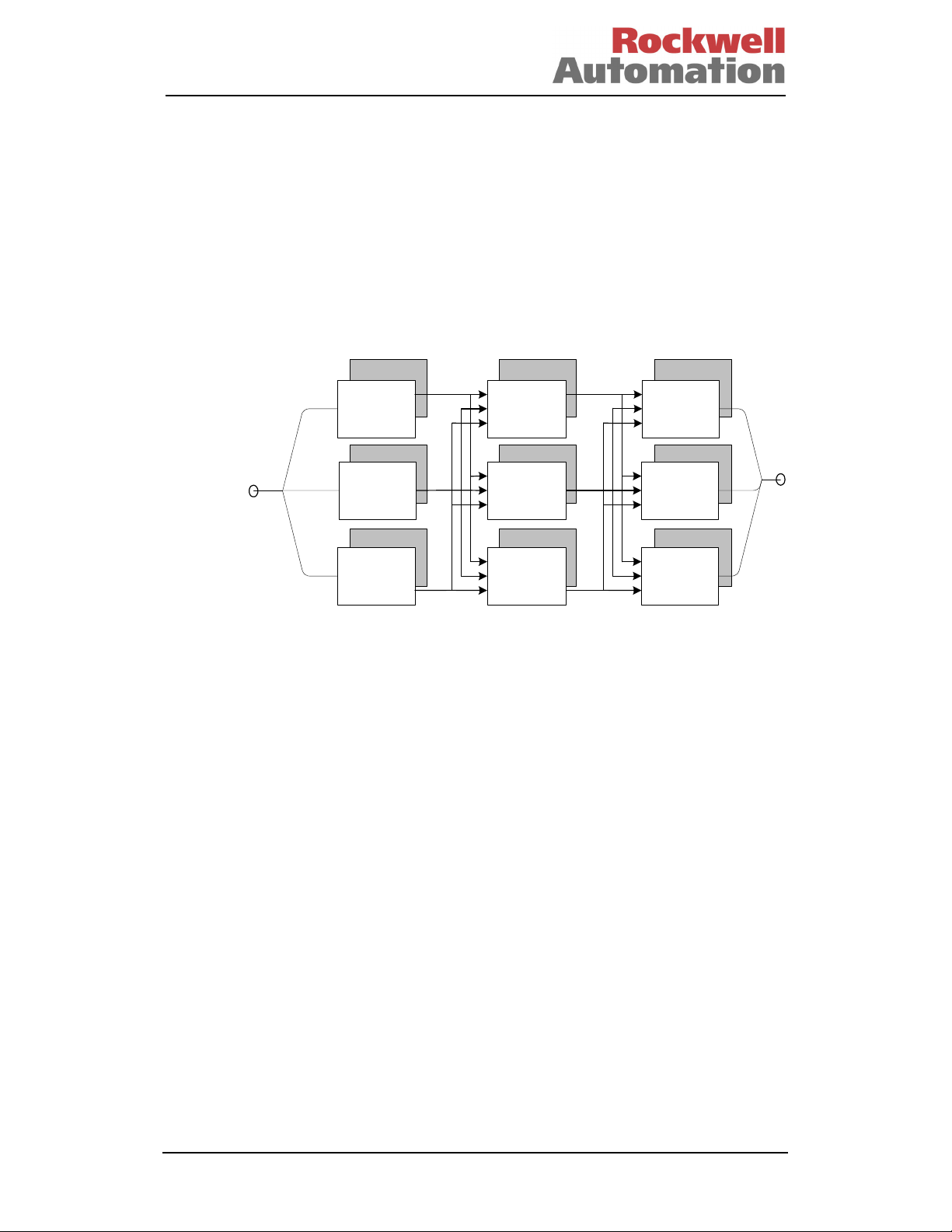

The 8000 series is a TMR system; this means that each stage of the system is

triplicated, with the results from each preceding stage majority voted to provide both

fault tolerance and fault detection. Diagnostics are also used to ensure that covert

failures are detected and result in the correct fail-safe reaction. For example, a fault

within Input Ch. A will be localised to that input, and unlike the standard triplicated

system, will allow Processor Ch. A and Output Ch. A to continue operation, i.e. the

input is now operating 1-oo-2D whilst the remainder of the system continues to operate

2-oo-3.

Diagnostics

INPUT

(Ch. A)

1

Diagnostics

INPUT

(Ch. B)

1

INPUT

(Ch. C)

1

Diagnostics

PROCESSOR

(Ch. A)

1

Diagnostics

PROCESSOR

(Ch. B)

1

DiagnosticsDiagnostics

PROCESSOR

(Ch. C)

1

Diagnostics

OUTPUT

(Ch. A)

1

Diagnostics

OUTPUT

(Ch. B)

1

Diagnostics

OUTPUT

(Ch. C)

1

Figure 2 – TMR Architecture

The 8000 Series utilises this Triple Modular Redundant architecture with diagnostics,

supporting a 2-oo-3D reverting to 1-oo-2D reverting to fail-safe, or 3-2-0 operation.

The 1-oo-2D operation is a transient mode of operation where active and standby

modules are installed; in this case, the degradation is 3-2-3-2-0.

The architecture, and hence degradation modes for low density I/O may be selected as

required, see para. 3.2 in this Manual for further details.

Doc Number T809 4

Issue 27 – J u n e 2013 Page 6 of 1 0 3

Page 28

SAFETY MANUAL

1.4 THE 8000 SERIES OVERVIEW

The TMR system is based on a triplicated microprocessor with internal redundancy of

all critical circuits. The system controls complex and often critical processes in real

time - executing programs that accept external sensor signals, solving logic equations,

performing calculations for continuous process control and generating external control

signals. These user-defined application programs monitor and control real-world

processes in the oil and gas, refining, rail transit, power generation and related

industries across a wide range of control and safety applications. The TMR system is

certified for use in safety-related applications such as fire and gas detection, and

emergency shutdown up to requirements of IEC 61508 SIL 3.

Application programs for the TMR system are written and monitored using the

IEC1131 TOOLSET , a Microsoft® Windows NT™, Windows 2000™, or Windows

XP™, based software suite running on a personal computer.

The TMR architecture provides a flexibility that allows each system to be easily

adapted to the different needs of any installation. This flexibility permits the user to

choose from different levels of I/O fault protection and provides a variety of I/O

interfacing and communications methods, thereby allowing the system to communicate

with other equipment and field devices.

Those elements of the system that are to be used in safety-related operations are

certified to IEC 61508 SIL 3. The remaining elements of the system are certified for

non-interfering operation.

This manual covers the release as specified in the certified module list.

Doc Number T809 4

Issue 27 – J u n e 2013 Page 7 of 1 0 3

Page 29

SAFETY MANUAL

2. SAFETY PRINCIPLES

2.1 INTRODUCTION

This paragraph provides an overview of generic safety principles with emphasis on the

system integration process. These principles are applicable to all safety-related

systems, including, but not limited to, the 8000 series system.

2.2 SAFETY MANAGEMENT

A prerequisite for the achievement of functional safety is the implementation of

procedural measures applicable to the safety lifecycle; these are collectively referred to

as a Safety Management System. The Safety Management System defines the

generic management and technical activities necessary for functional safety. In many

cases, the Safety Management and Quality systems will be integrated within a single

set of procedures. It is highly recommended that the integrator have a quality

management system in accordance with ISO9000.

The safety management system shall include:

• A statement of the policy and strategy to achieving functional safety.

• A Safety Planning Procedure. This shall result in the definition of the safety

lifecycle stages to be applied, the measures and techniques to be applied at

each stage, and responsibilities for completing these activities.

• Definitions of the records to be produced and methods of managing these

records, including change control. The change control procedures shall

include records of modification requests, the impact analysis of proposed

modifications and the approval of modifications. The baseline for change

control shall be defined clearly.

• Configuration items shall be uniquely identified and include version

information, e.g. system and safety requirements, system design

documentation and drawings, application software source code, test plans,

test procedures and results.

• Methods of ensuring that persons are competent to undertake their activities

and fulfil their responsibilities.

Expansion of these requirements is included within the following sub-paragraphs.

Doc Number T809 4

Issue 27 – J u n e 2013 Page 8 of 1 0 3

Page 30

SAFETY MANUAL

2.2.1 Safety Lifecycle

The Safety Lifecycle is designed to structure a system’s production into defined stages

and activities, and should include the following elements:

• Scope definition

• Functional requirements specification

• System safety requirements specification

• System engineering

• Application programming

• System production

• System integration

• System safety validation

• System installation and commissioning

• System operation and maintenance procedures

• System modification

• Decommissioning

The definition of each lifecycle stage shall include its inputs, outputs and verification

activities. It is not necessary to have stages within the lifecycle addressing each of

these elements independently; it is important that all of these stages be covered within

the lifecycle. Specific items that need to be considered for each of these lifecycle

elements are described in the following sub-paragraphs.

2.2.1.1 Scope Definition

The initial step in the system lifecycle should establish the bounds of the safety-related

system and a clear definition of its interfaces with the process and all third party

equipment. This stage should also establish the requirements resulting from the

intended installation environment, including climatic conditions, power sources, etc.

In most cases, the client will provide this information. It is necessary to review this

information and establish a thorough understanding of the intended application, the

bounds of the system to be provided and its intended operating conditions. An

example checklist for the review of the scope definition is given in para. 4.1.1.

2.2.1.2 Functional Requirements

This stage is to establish the complete set of functions to be implemented by the

system. The timing requirements for each of the functions are also to be established.

Where possible, the functions should be allocated to defined modes of operation of the

process.

For each function, it is necessary to identify the process interfaces involved in each of

the functions. Similarly, where the function involves data interchanged with third party

equipment, the data and interface are to be clearly identified. Where non-standard

field devices, communications interfaces or communications protocols are required, it

is important that the detailed requirements for these interfaces be established and

recorded at this stage. In general, the client will provide the functional requirements. It

is, however, necessary to collate these requirements into a document, or document

set, including any clarification of the functional requirements. In cases where the client

provides the functional requirements in an ambiguous form it will be necessary to

clarify, document and establish agreement on the requirements with the client. It is

recommended that logic diagrams be used to represent the required functionality. An

example checklist for the review of the functional requirements is given in para. 4.1.2.

Doc Number T809 4

Issue 27 – J u n e 2013 Page 9 of 1 0 3

Page 31

SAFETY MANUAL

2.2.1.3 Safety Requirements

The functional requirements shall be analysed to determine their safety relevance.

Where necessary, additional requirements shall be established to ensure that the plant

will fail-safe in the case of failures within the plant, the safety-related system, external

equipment and communications or the safety-related system’s environment.

For each safety-related function the required safety requirements class and safetyrelated timing requirements shall be defined. The client should supply this information.

Where this information is not supplied it shall be established and agreed with the client

as part of this phase. It is highly recommended that the client approve the resulting

safety requirements. An example checklist for the review of the safety requirements is

given in para. 4.1.3.

2.2.1.4 Systems Engineering

This stage realises the safety-related system design. It is recommended that the

engineering comprise two stages, the first defining the overall system architecture, and

the second detailing the engineering of the architectural blocks.

The overall system architecture shall identify the individual systems. The architecture

for these systems and for their sub-systems shall include any diverse or other

technology elements.

The architectural definition shall include the required safety requirements class for

each architectural element and identify the safety functions allocated to that element.

Additional safety functions resulting from the selected system architecture shall be

defined at this stage. The detailed engineering shall refine the architectural elements

and culminate in detailed information for system build. The detailed design shall be in

a form that is readable, readily understood and allows for simple inspection/review.

Tools used within the system engineering process are to be carefully selected, with

due consideration of the potential of introduction of error and the required safety

requirements class. Where there remains the possibility of error, procedural methods

of detecting such errors shall be included within the process.

2.2.1.4.1 Safety Requirements Allocations

The overall system architecture shall define the individual system. The architecture for

these systems, and for their sub-systems, shall include any diverse or other technology

elements. The architectural definition shall also define the required safety

requirements class for each architectural element and identify the safety functions

allocated to that element. Additional safety functions resulting from the selected

system architecture will be defined at this stage.

The detailed engineering shall refine the architectural elements and culminate in

detailed information for system build. The detailed design shall be in a form that is

readable, readily understood and allows for simple inspection/review.

Tools used within the system engineering process are to be carefully selected, with

due consideration of the potential for the possibility of introduction of error and the

required safety requirements class. Where there remains the possibility of error,

procedural methods of detecting such errors shall be included within the process.

Doc Number T809 4

Issue 27 – J u n e 2013 Page 10 of 1 0 3

Page 32

SAFETY MANUAL

2.2.1.5 Application Programming

An overall Application Program software architecture is to be defined. This

architecture will identify the software blocks and their allotted functions.

The application architectural design shall be used to define the additional requirements

resulting from the system hardware design. Specifically, methods for addressing

system specific testing, diagnostics and fault reporting are to be included.

It is highly recommended that simulation testing be performed on each software block.

This simulation testing should be used to show that each block performs its intended

functions and does not perform unintended functions.

It is also highly recommended that software integration testing be performed within the

simulation environment before hardware-software integration. The software

integration testing will show that all software blocks interact correctly to perform their

intended functions and do not perform unintended functions.

The development of the application software shall follow a structured development

cycle; the minimum requirements of which are:

• Architectural definition. The application program shall be divided into

largely self-contained ‘blocks’ to simplify the implementation and testing.

Safety and non-safety functions should be separated as far as possible at

this stage.

• Detailed design and coding. This stage details the design, and implements

each of the blocks identified during the architectural definition.

• Testing. This stage verifies the operation of the application; it is

recommended that the application blocks first be tested individually and then

integrated and tested as a whole. This should be initially undertaken within

the simulation environment.

The resultant Application Programs shall be integrated with the system hardware and

integration testing performed.

2.2.1.6 System Production

The system production stage implements the detailed system design. The production

techniques, tools and equipment used within the production testing of the system shall

be commensurate with the required safety requirements class.

2.2.1.7 System Integration

This stage shall integrate the Application Programs with the target systems. Where

multiple systems are used to meet the overall requirement, it is suggested that each

system undergoes individual application program and target system integration before

overall system integration is performed. To meet the requirements of the intended

safety requirements class, the system integration shall ensure the compatibility of the

software and hardware.

Doc Number T809 4

Issue 27 – J u n e 2013 Page 11 of 1 0 3

Page 33

SAFETY MANUAL

2.2.1.8 Installation and Commissioning

The system installation stage shall define the steps to be undertaken to ensure that the

system is installed correctly and commissioned on the plant. These steps shall include

the physical and electrical installation of the system.

The installation environment is a potential source of common cause failure. Therefore,

it is vital that compatibility of the equipment is established. The `environment` for

these purposes includes the climatic, hazardous area, power, earthing and EMC

conditions. In many cases, there may not be a single installation environment.

Elements of the system may be installed in differing location, i.e. central control room,

equipment rooms and field installations. In these cases, it is important to establish the

equipment and environment compatibility for each site.

The first step in the installation sequence is typically the physical installation of the

system. Where the system comprises a number of physically separate units, it is

important that the sequence of installation be established. This may include the

installation of termination facilities before the remaining elements of the system. In

these cases, it is important to establish that independent installation and testing

facilities are available.

Each installation shall be designed to ensure that the control equipment is not

operated in environments that are beyond its design tolerances. Therefore,

consideration should be given to the proper control of temperature, humidity, vibration

and shock, as well as adequate shielding and earthing to ensure that exposure to

electromagnetic interference and electrostatic discharge sources are minimised.

The commissioning stage is to establish the system hook-up and verify its correct ‘endto-end’ functionality, including the connection between the TMR system and the

required sensors and final elements. It is likely that groups of functions are

commissioned rather than the system as a whole, i.e. accommodation area functions

before production functions. In these cases, it is important to establish the

commissioning sequence and the measures to be taken to ensure safe operation

during periods of partial commissioning. These measures shall be system specific and

shall be defined clearly before commissioning. It is important to establish that any

temporary measures implemented for test purposes or to allow partial commissioning

are removed before the system, as a whole, becomes live.

Records shall be maintained throughout the commissioning process. These records

shall include records of the tests completed, problem reports and resolution of these

problems.

Doc Number T809 4

Issue 27 – J u n e 2013 Page 12 of 1 0 3

Page 34

SAFETY MANUAL

2.2.1.9 Safety System Validation

Safety system validation shall test the integrated system to ensure compliance with the

requirements specification at the intended safety requirements class. The validation

activities should include those necessary to establish that the required safety functions

have been implemented under normal start-up, shutdown and abnormal fault modes.

The validation shall ensure that each functional safety requirement has been

implemented at the required safety integrity level, and that the realisation of the

function achieves its performance criteria, specifically that the process safety time

requirements have been met. The validation shall also consider the potential external

common cause failures, i.e. power sources, environmental conditions, and ensure that

the system will provide fail-safe operation in the event of conditions exceeding its

capabilities.

2.2.1.10 Operation and Maintenance Plan

This Operation and Maintenance requirement ensures that functional safety continues

beyond the design, production, installation and commissioning of the system. The inservice operation and maintenance is normally beyond the system integrator

responsibility. However, guidance and procedures shall be provided to ensure that the

persons or organisations responsible for Operation and Maintenance maintain the

intended safety levels.

The Operating and Maintenance Plan shall include the following:

• Although the TMR product requires no specific power-up and power-down

requirements, it is possible that the project specific implementation will

dictate specific action sequences. These sequences shall be clearly defined,

ensuring that the sequences cannot result in periods of the system’s inability

to respond safely whilst a hazard may be present.

• The Maintenance Plan shall detail the procedures to be adopted when

re-calibrating sensors, actuators and I/O modules. The recommended

calibration periods shall also be included.

• The Maintenance Plan shall include the procedure to be adopted for testing

the system, and the maximum intervals between manual testing.

• Sensor and actuator maintenance will require the application of overrides in

certain circumstances. Where these are required, they shall be implemented

in accordance with the guidance provided within this document.

2.2.1.10.1 Planned Maintenance

In most system configurations there will be some elements that are not tested by the

system’s internal test facilities. These may be the final passive elements in some I/O

modules types, the sensors and actuators themselves and the field wiring. A regime of

Planned Maintenance testing shall be adopted to ensure that faults do not accumulate

within those elements that could ultimately lead to the system’s inability to perform its

required safety functions. The maximum interval between these tests shall be defined

during the system design, i.e. before installation. It is highly recommended that the

test interval be less than 12 months.

Doc Number T809 4

Issue 27 – J u n e 2013 Page 13 of 1 0 3

Page 35

SAFETY MANUAL

2.2.1.10.2 Field Device Maintenance

During the lifetime of the system, it will be necessary to undertake a number of field

maintenance activities that will include re-calibration, testing and replacement of

devices. Facilities should be included within the system design to allow these

maintenance activities to be undertaken. Similarly, the operating and maintenance

plan needs to include these maintenance activities, and their effect on the system

operation and design. In general, adequate provision for these measures will be

defined by the client, and provided the facilities, i.e. maintenance overrides, are

implemented within the requirements specified within this document. No further safety

requirements will be required.

It is highly recommended that the I/O forcing capability NOT be used to support field

device maintenance; this facility is provided to support application testing only. Should

this facility be used, the requirements defined in para. 3.8 shall be applied.

2.2.1.10.3 Module Fault Handling

When properly configured and installed, the TMR system is designed to operate

continuously and correctly even if one of its modules has a fault. When a module does

have a fault it should be replaced promptly to ensure that faults do not accumulate,

thereby causing multiple failure conditions that could cause a plant shutdown. All

modules permit live removal and replacement, and modules within a fault-tolerant

configuration can be removed with no further action. Modules that do not have a

partner slot or smart slot configured and have a fail-safe configuration will require the

application of override or bypass signals for the period of the module removal to

ensure that unwanted safety responses are not generated inadvertently.

On-site repair of modules is not supported; all failed modules should be returned for

repair and/or fault diagnosis. The return procedure for modules should include

procedures to identify the nature and circumstances of the failure and the system

response. Records of module failures and repair actions shall be maintained.

2.2.1.10.4 Monitoring

In order to establish that the safety objectives have been met through the lifetime of

the system it is important to maintain records of the faults, failures and anomalies.

This requires the maintenance of records by both the end-user and the system

integrator. The records maintained by the end-user are outside the scope of this

document; however, it is highly recommended that the following information be

included:

• Description of the fault, failure or anomaly

• Details of the equipment involved, including module types and serial

numbers where appropriate

• When the fault was experienced and any circumstances leading to its

occurrence

• Any temporary measures implemented to correct or work around the problem

• Description of the resolution of the problem and reference to remedial action

plans and impact analysis

Each system integrator should define the field returns, repair and defect handling

procedure. The information requirements placed on the end user because of this

procedure should be clearly documented and provided to the end user. The defect

handling procedure shall include:

• Method of detecting product related defects and the reporting of these to the

original designers.

Doc Number T809 4

Issue 27 – J u n e 2013 Page 14 of 1 0 3

Page 36

SAFETY MANUAL

• Methods for detecting systematic failure that may affect other elements of the

system or other systems, and links to the satisfactory resolution of the

issues.

• Procedures for tracking all reported anomalies, their work around and/or

resultant corrective action where applicable.

2.2.1.11 System Modification

Design changes will inevitably occur during the system lifecycle; to ensure that the