Page 1

TrustedTM

PD-T8082

Introduction

Trusted

TM

Toolset Suite

This document describes the System Configuration Manager and the IEC1131 TOOLSET. Details of

the Trusted

Application Validators, which can be installed from the CD.

The IEC1131 TOOLSET is an enhanced version of the ISaGRAF Workstation. The toolset contains

on-line documentation describing application design. This document describes the following:

• Installation

• System Configuration Manager

• I/O Connection Editor

• Workstation Enhancements

• Intelligent Updates

The System Configuration Manager is used to manually create the System.INI file. This is a text file

used to configure the operational parameters within a controller. The System Configuration Manager is

an enhanced version of the System.INI File Transfer tool introduced with Version 1.2 of the Trusted

System.

The I/O Connection Editor is used establish a logical link between the I/O variables of the application

and the physical channels of the boards existing on the target machine.

The operating parameters of the I/O modules which may be used with a Trusted

in Complex I/O definitions for the I/O Connection Editor, are defined in the appropriate I/O module or

interface/bridge module PD.

The Toolset Suite is validated for use on Windows NT and Windows XP service pack 2. It will not run

on Windows Vista.

M

T

application validators are contained within a separate product description, PD-T8015

TM

System, as defined

TM

Issue 14 Feb 10 PD-T8082 1

Page 2

Trusted

Issue Record

Issue

Number Date Revised by Technical

1 K Mecklenburgh G Creech R Cockman

2 J Brinkman CCB Approved

3 TUV 3.4

4 G Creech

5 G Creech

6 July 04 J Bourn G Creech R Cockman

7 Jan 06 J W Clark Format/Release 3.5

8 Aug 06 N Owens I Vince P Stock Corrections

9 Sep 06 N Owens I Vince P Stock Template Editor

10 Oct 06 N Owens I Vince P Stock Intelligent Updates

11 Dec 06 N Owens I Vince P Stock No load threshold,

12 Mar 07 A Holgate N Owens P Stock

TM

Toolset Suite T8082

Authorised by Modification

Check

- ECN No 1491

password protections

Detail of Intelligent

online updates moved

to AN-T80009

13 Feb 08 N Owens A Holgate P Stock

14 Feb 10 S Blackett A Holgate N Owens Note added about

Capabilities

maximum expander

chassis added

Issue 14 Feb 10 PD-T8082 2

Page 3

Trusted

TM

Toolset Suite T8082

Table of Contents

1. Installation ...............................................................................................................................10

.1.

1

L

2. System Configuration Manager...............................................................................................14

2.1. Accessing the System Configuration Manager .......................................................................15

2.2. Menu Structure........................................................................................................................16

2.2.1. File Menu.................................................................................................................................16

2.2.2. Template Menu .......................................................................................................................16

2.2.3. Communications Menu ...........................................................................................................17

2.2.4. Help Menu...............................................................................................................................17

2.3. Template Editor .......................................................................................................................18

2.3.1. Menu Structure........................................................................................................................19

2.3.2. New Templates .......................................................................................................................19

2.3.3. Template Types ......................................................................................................................20

2.3.4. Threshold Templates ..............................................................................................................21

2.3.5. Threshold Template Editor......................................................................................................22

2.3.6. LED Templates .......................................................................................................................23

2.3.7. Module LED State Editor.........................................................................................................25

2.3.8. Channel LED State Editor .......................................................................................................26

icensing .................................................................................................................................11

2.3.9. Force Templates .....................................................................................................................27

2.3.10. Module System Information Templates...................................................................................28

2.3.11. Module System Information Template Editor ..........................................................................30

2.3.12. Module Flags Templates (Future Use Only) ...........................................................................30

2.3.13. Module Flags Template Editor ................................................................................................31

2.3.14. Module Filter Templates (Future Use Only) ............................................................................32

2.3.15. Module Filter Template Editor .................................................................................................33

2.3.16. Shutdown Templates ..............................................................................................................33

2.3.17. Shutdown Template Editor......................................................................................................34

2.3.18. Channel Type Templates ........................................................................................................34

2.3.19. Channel Type Template Editor................................................................................................35

2.3.20. De-energised Short Circuit Detection Templates....................................................................35

2.3.21. De-energised Short Circuit Detection Template Editor ...........................................................36

2.4. Configuring a SYSTEM .INI File..............................................................................................37

2.5. TrustedTM TMR Processor.......................................................................................................37

2.6. Modules and Chassis ..............................................................................................................38

2.7. TrustedTM TMR Communications Interface Module ( 8151 / 8151B ) .....................................41

2.8. TrustedTM I/O Modules ............................................................................................................43

2.8.1. Scanning Controls: Pre Release 3.5 .......................................................................................45

Issue 14 Feb 10 PD-T8082 3

Page 4

Trusted

.8.2.

2

2.9. Unused Slots ...........................................................................................................................46

2.10. Generating the SYSTEM.INI File ............................................................................................47

2.11. Displaying the SYSTEM.INI File..............................................................................................48

2.12. Example SYSTEM.INI File ......................................................................................................50

2.13. Generating the SYSTEM.INI File Diagram..............................................................................53

2.14. Downloading to the TMR Processor .......................................................................................54

2.15. Uploading to the EWS.............................................................................................................55

2.16. Archiving..................................................................................................................................56

2.16.1. Save Configuration..................................................................................................................56

2.16.2. Delete Current Configuration...................................................................................................56

2.16.3. Extract Configuration...............................................................................................................56

2.16.4. Archive Templates ..................................................................................................................56

2.16.5. Restore Templates..................................................................................................................56

3. The I/O Connection Editor.......................................................................................................57

3.1. Using the I/O Connection Editor.............................................................................................57

TM

Toolset Suite T8082

canning Controls: From Release 3.5 ....................................................................................45

S

3.2. Icons........................................................................................................................................58

3.3. Defining I/O Boards .................................................................................................................59

3.3.1. Selecting I/O board type .....................................................................................................59

3.3.2. Technical notes ..................................................................................................................59

3.3.3. Removing a board ..............................................................................................................59

3.3.4. Real boards and virtual boards ..........................................................................................59

3.4. Setting Board Parameters.......................................................................................................60

3.5. Connecting I/O Channels ........................................................................................................61

3.5.1. Connecting variables ..........................................................................................................61

3.5.2. Removing connected variables ..........................................................................................61

3.5.3. Comments...............................................................................................................................61

3.6. Directly Represented Variables...............................................................................................62

4. TrustedTM Board Definitions ....................................................................................................64

4.1. Process Historian ....................................................................................................................64

4.2. Sequence of Events ................................................................................................................64

5. TrustedTM workstation additions ..............................................................................................65

6. ISaGRAF Workstation Enhancements....................................................................................66

6.1. Tooltips Enabled......................................................................................................................66

6.2. Comment Variable Attachment ...............................................................................................66

6.3. Power Flow Debugging ...........................................................................................................67

6.4. I/O Forcing...............................................................................................................................68

6.5. Integer Interfacing Enhancements ..........................................................................................69

Issue 14 Feb 10 PD-T8082 4

Page 5

Trusted

.5.1.

6

6.5.2. Registers as Unsigned Integer................................................................................................69

6.5.3. Use Two Registers (32-bit) .....................................................................................................69

6.5.4. Least Significant Word First ....................................................................................................69

6.6. Printing ....................................................................................................................................70

6.7. Process Execution Timing Data ..............................................................................................71

7. Intelligent Online Updates .......................................................................................................73

7.1. Enabling Intelligent Online Updates ........................................................................................73

7.2. Manual function block matching (from release 3.5.1) .............................................................75

7.3. Operation.................................................................................................................................76

7.4. Important Information..............................................................................................................76

8. ISA.INI settings........................................................................................................................77

8.1. Decimal format for Modbus addresses ...................................................................................77

8.2. Configure an Internal variable or Constant with an Initial Value and the Retain attribute .......77

8.3. Change the documentation logo .............................................................................................78

9. System Capabilities.................................................................................................................78

TM

Toolset Suite T8082

rite Protect ...........................................................................................................................69

W

10. Password Permissions............................................................................................................80

Issue 14 Feb 10 PD-T8082 5

Page 6

Trusted

TM

Toolset Suite T8082

Table of Figures

Figure 1 Licensing Program ...................................................................................................................11

igure 2 License Type ............................................................................................................................12

F

Figure 3 Email license request ...............................................................................................................12

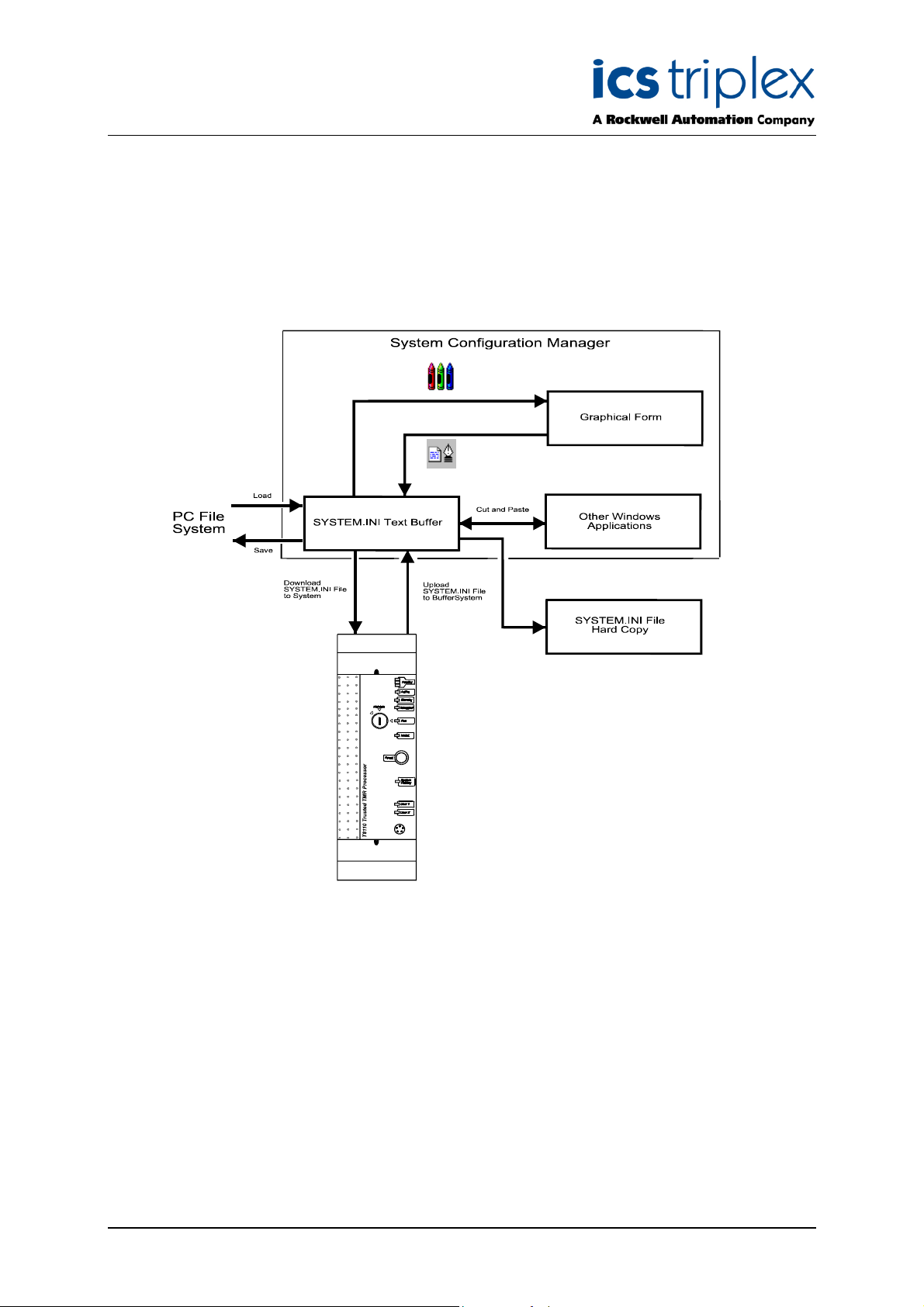

Figure 4 System Configuration Manager Facilities .................................................................................14

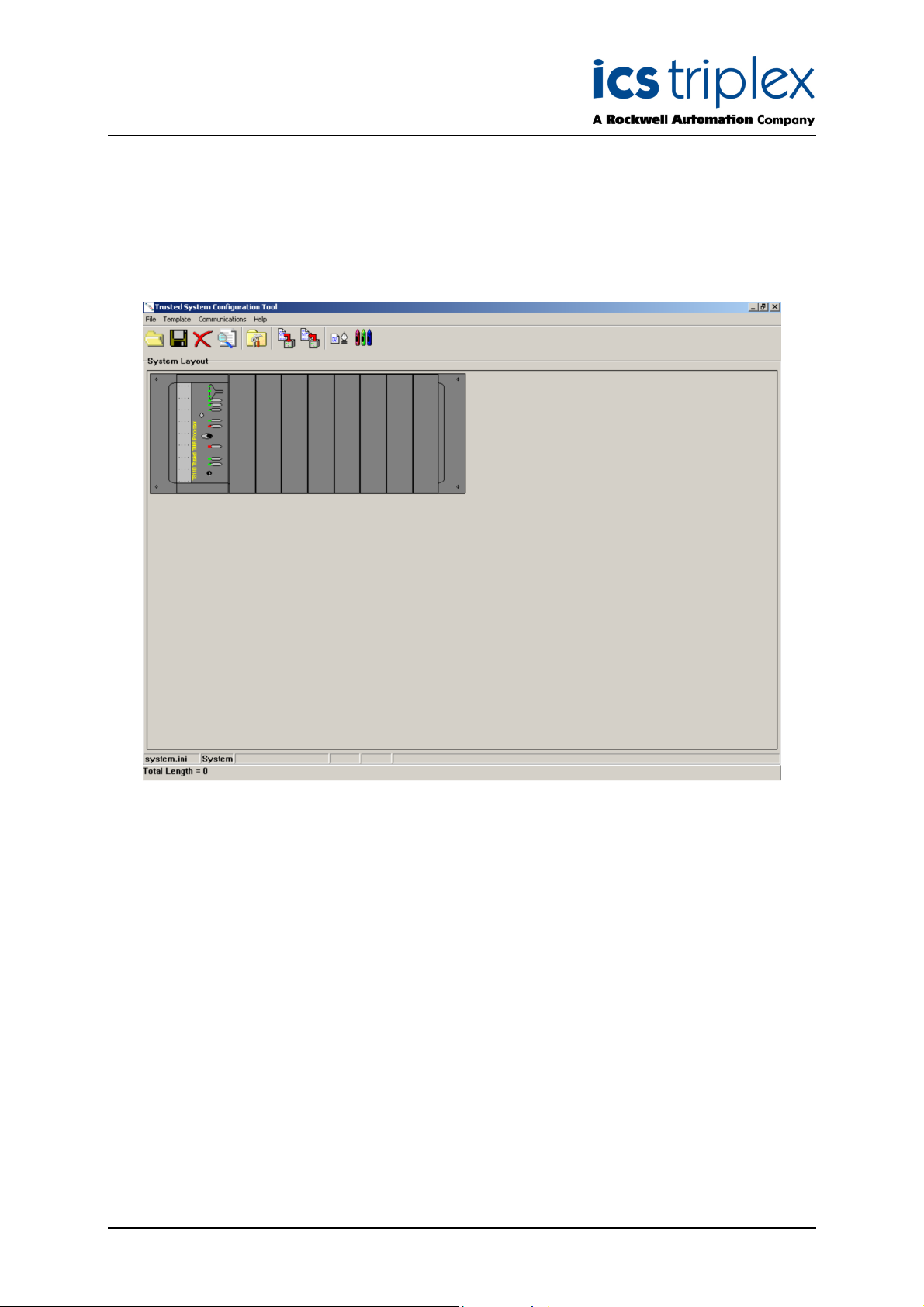

Figure 5 System Configuration Tool Opening Screen ............................................................................15

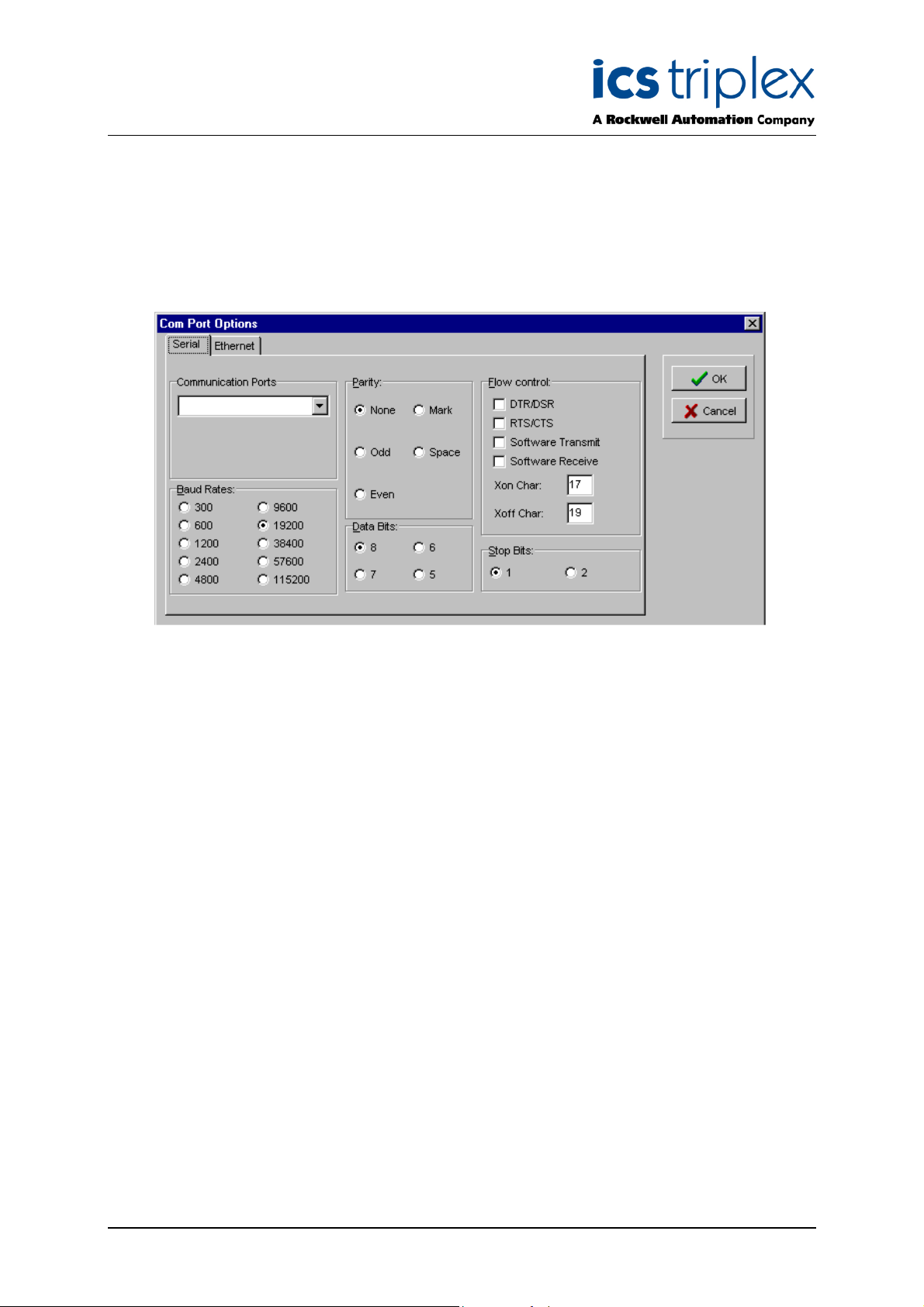

Figure 6 Com Port Options Window.......................................................................................................17

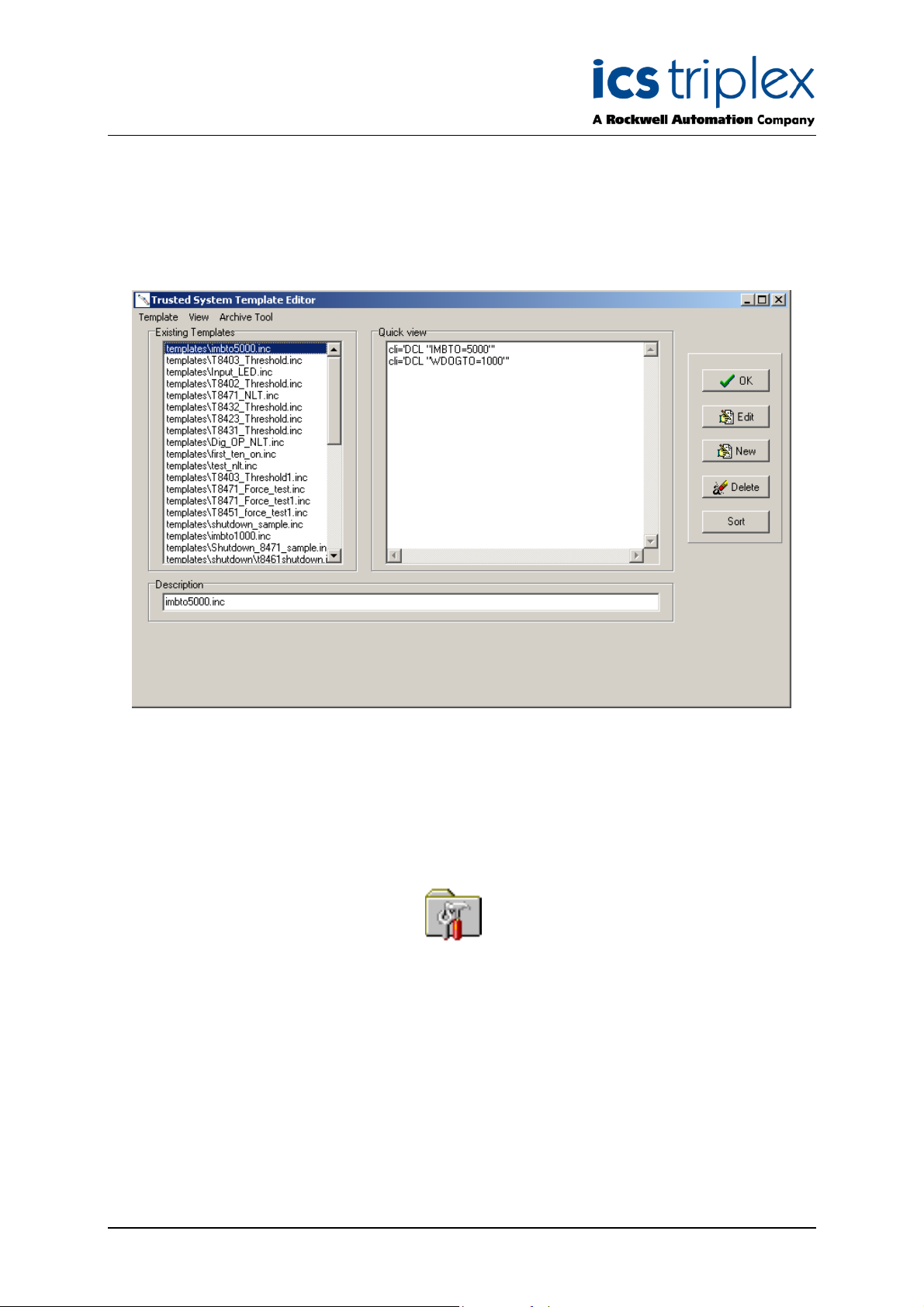

Figure 7 Template Editor Window ..........................................................................................................18

Figure 8 Template Editor Icon ................................................................................................................18

Figure 9 Template Creation Window.....................................................................................................19

Figure 10 Threshold Template Editor .....................................................................................................22

Figure 11 Module LED State Editor ........................................................................................................25

Figure 12 Channel LED State Editor ......................................................................................................26

Figure 13 Force Template Editor ............................................................................................................27

Figure 14 Module System Information Template Editor .........................................................................30

Figure 15 Module Flags Template Editor ...............................................................................................31

Figure 16 Module Filter Template Editor ................................................................................................33

Figure 17 Shutdown Template Editor (pre and post release 3.5)...........................................................34

Figure 18 Channel Type Template Editor...............................................................................................35

Figure 19 De-energised Short Circuit Detection Template Editor ..........................................................36

Figure 20 TMR Processor Configuration Window ..................................................................................37

Figure 21 ‘Replace Item in Slot’ Window ................................................................................................38

Figure 22 ‘Insert New Chassis’ Window.................................................................................................38

Figure 23 Configuration with one Expander Chassis..............................................................................39

Figure 24 Chassis Connection Window..................................................................................................39

Figure 25 Expander Interface Parameters Window ...............................................................................40

Figure 26 Chassis Connection Window..................................................................................................40

Figure 27 Switch Configuration Window.................................................................................................41

Figure 28 Expander Interface Parameters Window ...............................................................................41

Figure 29 Communications Interface Parameters Window....................................................................42

Figure 30 ‘Replace Item in Slot’ Window ................................................................................................43

Figure 31 Module Definition Window .....................................................................................................44

Figure 32 Disable Scanning....................................................................................................................46

Figure 33 INI Buffer Generation Icon......................................................................................................47

Figure 34 Version Control Information Editor Window ...........................................................................47

Figure 35 View INI Buffer Icon................................................................................................................48

Figure 36 INI Buffer Viewer ....................................................................................................................48

Figure 37 Regenerate Graphic from INI Buffer Icon...............................................................................53

Issue 14 Feb 10 PD-T8082 6

Page 7

Trusted

igure 38 Updated Diagram ...................................................................................................................53

F

Figure 39 Download INI Buffer to MP Icon .............................................................................................54

Figure 40 Communications in Progress .................................................................................................54

Figure 41 Upload INI Buffer from MP Icon .............................................................................................55

Figure 42 Communication in Progress Window .....................................................................................55

Figure 43 I/O Connection Window..........................................................................................................57

Figure 44 Connect I/O Channel Dialogue Box........................................................................................61

Figure 45 Select Variable Dialogue ........................................................................................................62

Figure 46 Enabling Tooltips ....................................................................................................................66

Figure 47 Referencing variable comments .............................................................................................66

Figure 48 Power Flow Debugging Off.....................................................................................................67

Figure 49 Enable Power Flow Debugging ..............................................................................................67

Figure 50 Power Flow Debugging On.....................................................................................................67

Figure 51 Forced Data Point...................................................................................................................68

Figure 52 Extended Attributes ................................................................................................................69

Figure 53 Page Break Boundary ............................................................................................................70

TM

Toolset Suite T8082

Figure 54 SYS_PE_TIMES time data ranges.........................................................................................72

Figure 55 Starting the Intelligent Update Manager .................................................................................73

Figure 56 Intelligent Update Manager ....................................................................................................74

Figure 57 Intelligent Update Options ......................................................................................................74

Tables

Table 1 Digital Input Threshold Diagram ................................................................................................21

Table 2 8403 Input Module LED Default Settings...................................................................................23

Table 3 8451 Output Module LED Default Settings................................................................................24

Table 4 Analogue Input Module States...................................................................................................27

Table 5 OEM Parameters .......................................................................................................................64

Issue 14 Feb 10 PD-T8082 7

Page 8

Trusted

TM

Toolset Suite T8082

Notice

The content of this document is confidential to ICS Triplex Technology Ltd. companies and their

partners. It may not be given away, lent, resold, hired out or made available to a third party for any

purpose without the written consent of ICS Triplex Technology Ltd.

This document contains proprietary information that is protected by copyright. All rights are reserved.

Microsoft, Windows, Windows 95, Windows NT, Windows 2000, and Windows XP are registered

trademarks of Microsoft Corporation.

The information contained in this document is subject to change without notice. The reader should, in

all cases, consult ICS Triplex Technology Ltd. to determine whether any such changes have been

made. From time to time, amendments to this document will be made as necessary and will be

distributed by ICS Triplex Technology Ltd.

Information in this documentation set may be subject to change without notice and does not represent

a commitment on the part of ICS Triplex Technology Ltd..

The contents of this document, which may also include the loan of software tools, are subject to the

confidentiality and other clause(s) within the Integrator Agreement and Software License Agreement.

No part of this documentation may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and recording, for any purpose, without the express

written permission of ICS Triplex Technology Ltd.

Disclaimer

The illustrations, figures, charts, and layout examples in this manual are intended solely to illustrate the

text of this manual.

The user of, and those responsible for applying this equipment, must satisfy themselves as to the

acceptability of each application and use of this equipment.

This document is based on information available at the time of its publication. While efforts have been

made to be accurate, the information contained herein does not purport to cover all details or variations

in hardware or software, nor to provide for every possible contingency in connection with installation,

operation, or maintenance. Features may be described herein which are present in all hardware or

software systems. ICS Triplex Technology Ltd. assumes no obligation of notice to holders of this

document with respect to changes subsequently made.

ICS Triplex Technology Ltd. makes no representation or warranty, expressed, implied, or statutory with

respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness of

the information contained herein. No warranties of merchantability or fitness for purpose shall apply.

Issue 14 Feb 10 PD-T8082 8

Page 9

Trusted

TM

Toolset Suite T8082

Revision and Updating Policy

All new and revised information pertinent to this document shall be issued by ICS Triplex Technology

Ltd. and shall be incorporated into this document in accordance with the enclosed instructions. The

change is to be recorded on the Amendment Record of this document.

Precautionary Information

WARNING

Warning notices call attention to the use of materials, processes, methods, procedures or limits which

must be followed precisely to avoid personal injury or death.

CAUTION

Caution notices call attention to methods and procedures which must be followed to avoid damage to

the equipment.

Notes:

Notes highlight procedures and contain information to assist the user in the understanding of the

information contained in this document

Warning

RADIO FREQUENCY INTERFERENCE

Most electronic equipment is influenced by Radio Frequency Interference (RFI). Caution should be

exercised with regard to the use of portable communications equipment around such equipment.

Signs should be posted in the vicinity of the equipment cautioning against the use of portable

communications equipment.

MAINTENANCE

Maintenance must be performed only by qualified personnel, otherwise personal injury or death, or

damage to the system may be caused.

Caution

HANDLING

Under no circumstances should the module housing be removed.

Associated Documents

Product Descriptions (PD) provide product specific information.

The Safety Manual contains the recommended safety requirements for the safety system design.

The Operator and Maintenance Manual contains general guidelines on maintenance and diagnostic

procedures.

The Trusted IEC1131 Toolset Users Guide contains programming guidelines.

For technical support email: support@icstriplex.com

Issue 14 Feb 10 PD-T8082 9

Page 10

Trusted

TM

Toolset Suite T8082

1. Installation

M

The Trusted

following:-

IEC1131 Trusted

he System Configuration Manager

T

The Trusted

The Regent+Plus I/O Module Drivers

The Trusted

The Toolset Suite is validated for use on Windows NT and Windows XP service pack 2. It will not run

on Windows Vista.

Please ensure that previous installations of this product are removed before attempting to load this

product. If this product is being used to update an existing installation, all application files and registry

entries will be maintained.

Place the CD in the CD ROM drive of the computer.

If auto-run has been enabled for the CD ROM Drive, the installation program will automatically start.

T

Toolset Suite T8082B is a software suite supplied on CD ROM and includes the

TM

Toolset

TM

Application Validators

M

T

I/O Module Drivers

If auto-run has been disabled then run the program SETUP.EXE in the root folder of the CD.

The installation proceeds automatically apart from entry of user name.

Please note that the installation needs to be carried out with administrator privileges.

Issue 14 Feb 10 PD-T8082 10

Page 11

Trusted

TM

Toolset Suite T8082

1.1. Licensing

Before release 3.5, the toolset requires a parallel port dongle to be fitted to the computer’s parallel port.

This must be present during the final stages of application compilation, when saving the I/O connection

table and when downloading an application.

From release 3.5, there are three choices:

• An updated parallel port dongle, present at all times whilst the toolset is running (T8082P)

• A USB port dongle, present at all times whilst the toolset is running (T8082U)

• A software license, which will require the PC to have an Email client (T8082D)

A software license may be obtained using a separate program. From the Windows Start menu, select

All Programs | Trusted | Licensing.

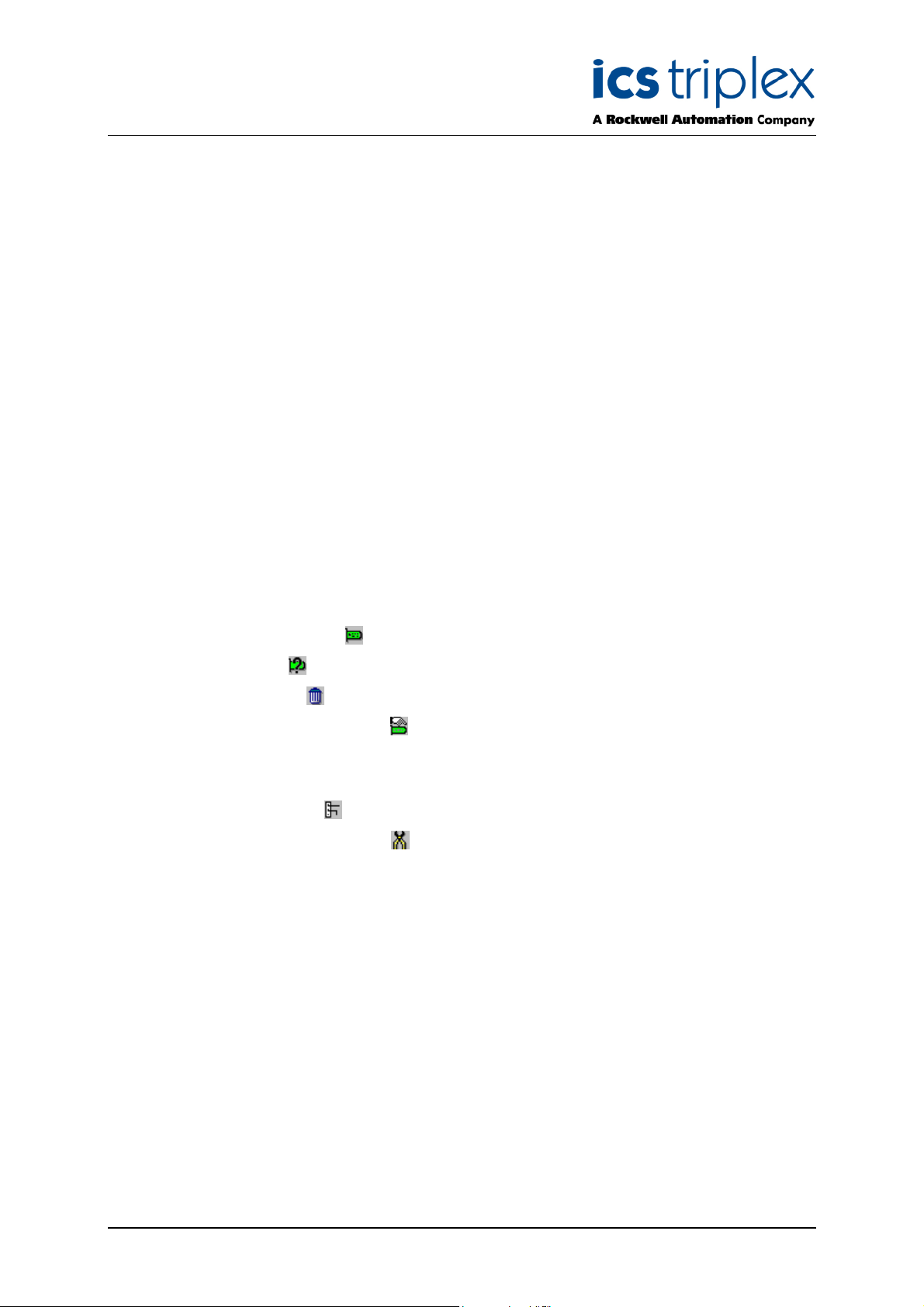

Figure 1 Licensing Program

If a parallel or USB dongle is present, then ‘ISaGRAF 3 Hardware Key’ will not be grey. To request a

license, click on ‘ISaGRAF 3 Software License’ and click Add.

Issue 14 Feb 10 PD-T8082 11

Page 12

Trusted

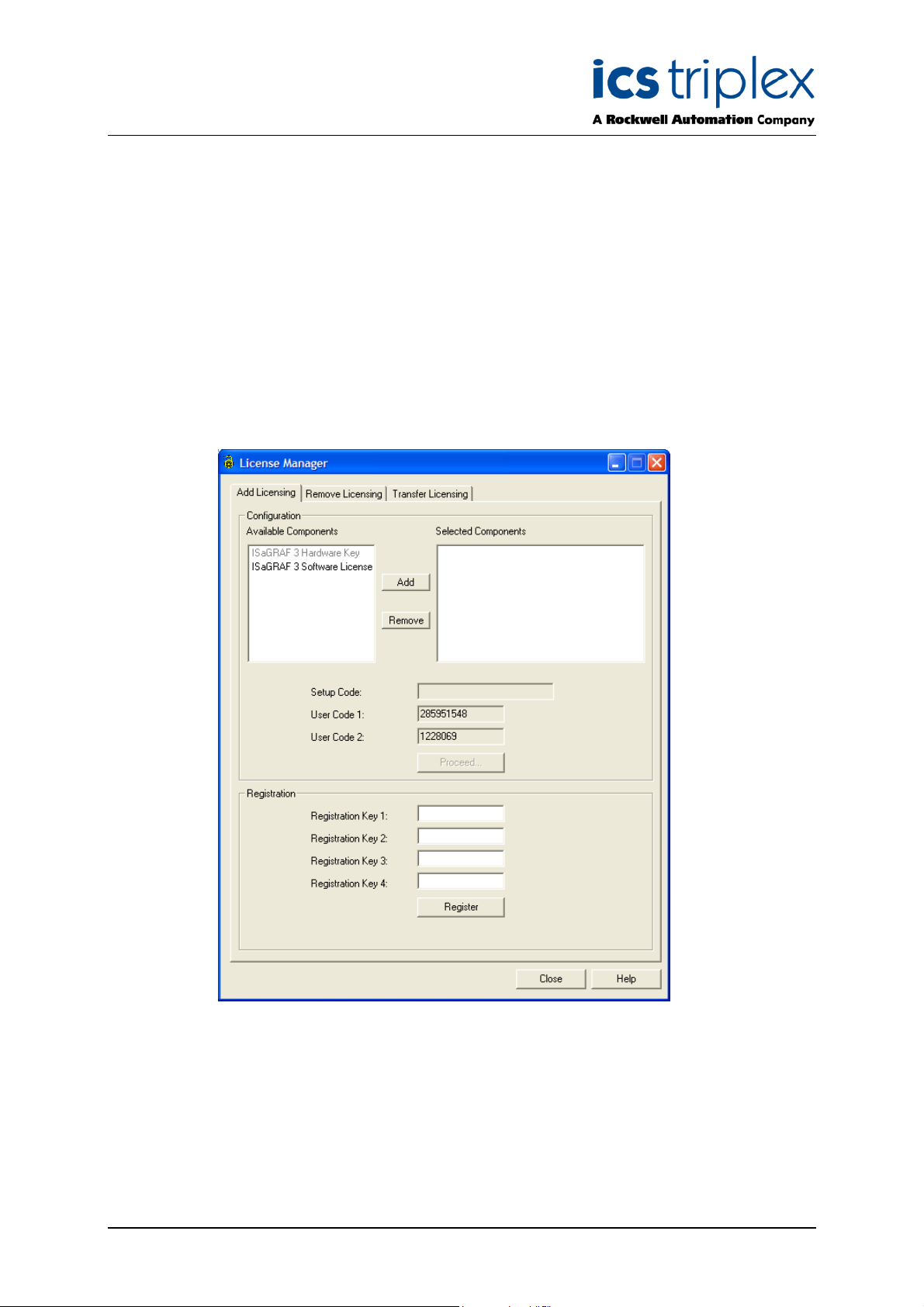

Select the required license size. Most live systems will need an unlimited license. The count of I/O

variables includes all those connected in the I/O Connection table. Click OK.

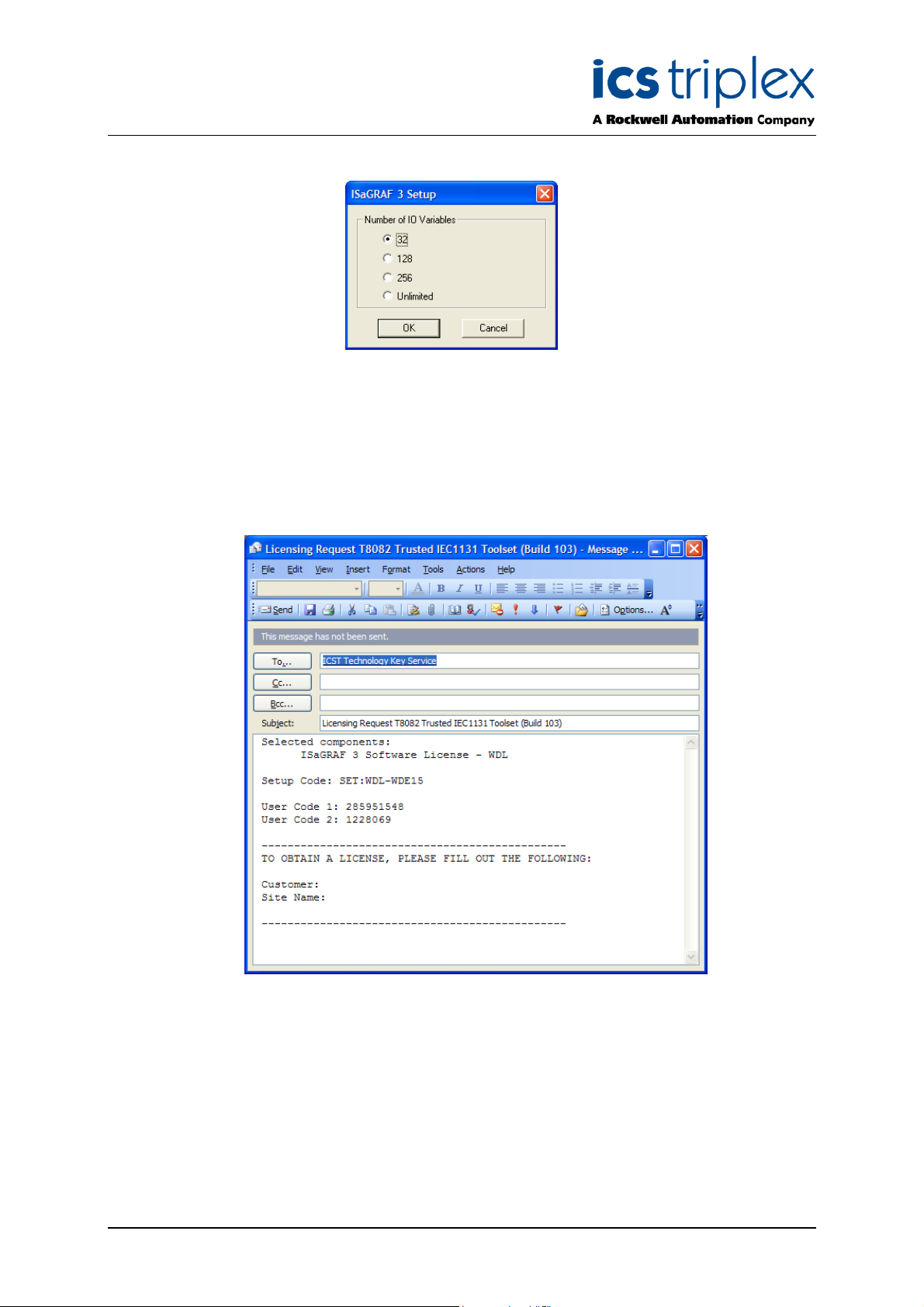

The appropriate setup code is now displayed. Click Proceed to request the license. The program

requests permission to register by Email; if there is no Email client (e.g. Outlook) present on the

computer, then either a hardware dongle is necessary, or the Email can be composed separately as

shown below on another computer and sent to the Email address keymaster@icstriplex.com .

TM

Toolset Suite T8082

Figure 2 License Type

Figure 3 Email license request

Enter a company name and site name as shown. The Email should also include the serial number

given on the Toolset packaging. Send the Email and close the licensing program. The request is

processed manually.

Issue 14 Feb 10 PD-T8082 12

Page 13

Trusted

The reply will include two sets of four registration key numbers. Reopen the Licensing program. In the

Registration area, enter the first four numbers and click Register. If successful, the number fields will

clear. Enter the next four numbers and click Register. The license should now be successfully

installed.

Other options in the Licensing program allow the surrendering of a license (Remove Licensing)

through a similar procedure, or the transfer of a license to another computer; the online Help gives

details on these processes.

Note: If the Toolset is uninstalled and reinstalled, the license will be lost. Transfer the license to

TM

Toolset Suite T8082

a removable disk before uninstalling.

Issue 14 Feb 10 PD-T8082 13

Page 14

Trusted

TM

Toolset Suite T8082

2. System Configuration Manager

The SYSTEM.INI file may be created manually, e.g. using ‘Notepad’, but it is best prepared with the aid

of the System Configuration Manager. The facilities available via the System Configuration Manager

are illustrated by Figure 4 below.

Figure 4 System Configuration Manager Facilities

TM

SYSTEM.INI files may be uploaded to or downloaded from the Trusted

System Configuration Manager. The Engineering Workstation (EWS) should be connected to the

Trusted

or via Ethernet using an 8153 Communications Interface Adapter (on the back of the slot containing a

Trusted

TM

TMR Processor front panel diagnostic port using the Serial Maintenance Cable TC-304-01,

TM

Communications Interface), providing the Maintenance Enable keyswitch on the front panel

TMR Processor using the

of the Processor is set to the Maintain position.

Issue 14 Feb 10 PD-T8082 14

Page 15

Trusted

TM

Toolset Suite T8082

2.1. Accessing the System Configuration Manager

The System Configuration Manager is used off-line to create/edit SYSTEM.INI files, and is accessed

by selecting the Tools / isa.mnu / System Config in the Toolset program folder. The opening screen

is shown in Figure 5 below.

Figure 5 System Configuration Tool Opening Screen

The opening screen shown above is used as an example only and depicts a single-chassis Trusted

System housing a single TMR Processor. Only one Processor will be displayed even if two are fitted.

Issue 14 Feb 10 PD-T8082 15

TM

Page 16

Trusted

TM

Toolset Suite T8082

2.2. Menu Structure

2.2.1. File Menu

The File menu from the opening screen allows the user to implement the following:

1. Load the Configurator text buffer with data held within a file on the Workstation. Note that the

buffer is separate from the diagram (graphical representation) of the system. The user is

prompted to build the diagram when loading the buffer.

2. Save the text buffer to a file on the Workstation. Since the buffer and diagram are separate,

the user is asked whether to save the existing buffer or rebuild it from the diagram.

TM

3. Upload the System.INI file held within the Trusted

prompted to build the diagram when uploading the buffer.

4. Download the text buffer contents to the System.INI file held in the Trusted

user is prompted to specify communications settings (see section 2.2.3 below) if not already

set, and also to verify that the buffer and diagram have been synchronised.

System to the text buffer. The user is

M

T

System. The

For example – to download the data held in a file called NEWSYS.INI to the System.INI, first load the

NEWSYS.INI file into the text buffer and then download the text buffer to the Trusted

TM

System.

1. Erase the contents of the buffer.

2. Copy the contents of the buffer to the clipboard.

3. Print the contents of the buffer and displayed graphic diagram.

4. Import a configuration. This opens a Toolset application file (‘appli.cnx’, the connection table

source code) and generates a graphical diagram of the Trusted

TM

System, representing

modules for each module found in the application.

The user is prompted to search for the application folder, which will be similar to

..\Toolset\apl\<application>\. On selecting the folder, the appli.cnx file is opened and the diagram is

built.

1. Note that this is only a first approximation to the configuration. Modules may be missing or

incorrectly chosen, the modules will have no templates assigned and the diagram should be

checked before continuing. This facility generates the diagram but does not create a buffer.

Exit from the System Configuration Manager.

2.2.2. Template Menu

Templates are segments of configuration. They can be viewed in text form, are referenced in the

System.INI and can be assigned to more than one module. Each template performs a specific

configuration of an Trusted

The Template menu contains one option - Manage Templates. This opens the Template Editor

window. The Template Editor shows all templates stored in the ‘Templates’ folder in the Toolset

directory. The ‘Templates’ folder is created automatically when the System Configuration Manager is

first initiated.

TM

module, such as trip thresholds and LED states.

The Template Editor is described in section 2.3 below.

Issue 14 Feb 10 PD-T8082 16

Page 17

Trusted

TM

Toolset Suite T8082

2.2.3. Communications Menu

The Communications menu allows the user to configure the communications port on the Engineering

Work Station (EWS) used to download the System.INI file to the TMR Processor. The

Communications menu contains one option - Configure Port. This opens the Com Port Options

window, shown in Figure 6 below.

Figure 6 Com Port Options Window

TM

The EWS may be connected to the Trusted

System either via a serial port to the front panel socket

of the TMR processor (using Maintenance Cable TC-304-01) or via Ethernet to a Communications

Module. Two tabs are provided to select these options.

On the ‘Serial’ tab, the Communications Ports’ drop-down menu lists all available serial ports on the

EWS. The remaining settings should be left at their defaults, unless the Trusted

TM

System

communications configuration has been changed. Selecting a serial port defines that port as the

communication channel, regardless of the settings on the ‘Ethernet’ tab.

TM

If the Trusted

System has previously been configured for Ethernet communications (using the

System.INI configuration) then further communications may be made quicker by Ethernet. On the

‘Ethernet’ tab, enter the TCP/IP address assigned to the socket used on the communications module.

Leave the port defined as 6000 unless changed in the System.INI configuration.

This options window is displayed if a System.INI file is downloaded without defining the

communications method.

2.2.4. Help Menu

The Help menu provides the user with two options; Introduction and About.

Selecting Introduction provides the user with access to all the available online help screens. These

are formatted as the normal HELP facilities found with any Windows based software package.

Selecting About provides the used with Version details of the System Configuration Manager.

Issue 14 Feb 10 PD-T8082 17

Page 18

Trusted

TM

Toolset Suite T8082

2.3. Template Editor

Selecting the Manage Templates option in the Template menu displays the window shown in Figure

7.

Figure 7 Template Editor Window

The Manage Templates option may also be initiated by selecting the command line button shown in

Figure 8 below.

Figure 8 Template Editor Icon

Issue 14 Feb 10 PD-T8082 18

Page 19

Trusted

TM

Toolset Suite T8082

2.3.1. Menu Structure

The Template menu allows the user to create new templates, edit existing templates and delete

templates that are no longer required. These facilities are replicated by the buttons on the right-hand

ide of the display.

s

The View menu allows the user to sort existing templates in alphabetical order. This facility is

replicated by a button on the right-hand side of the display.

The Archive Tool menu allows the user to save the template configuration, extract the template

configuration, completely delete template configuration, archive templates and restore templates.

These archives ensure that an entire System.INI configuration and associated templates are backed

up correctly and available to transfer to another Engineering Workstation. Refer to section 2.16 for

details. Note that from release 3.5, templates are extracted from the System.INI file itself, and so only

the System.INI file needs to be archived. However, if the configuration needs to be transferred to a

toolset issue before release 3.5, then a template archive is necessary.

All templates are listed in the Existing Templates window on the display. The contents of each

template may be viewed by selecting the required template. This will cause the contents of the selected

template to be displayed in the Quick View window of the display. Selecting Edit on the right hand side

of the window will allow modifications to be made to this existing template.

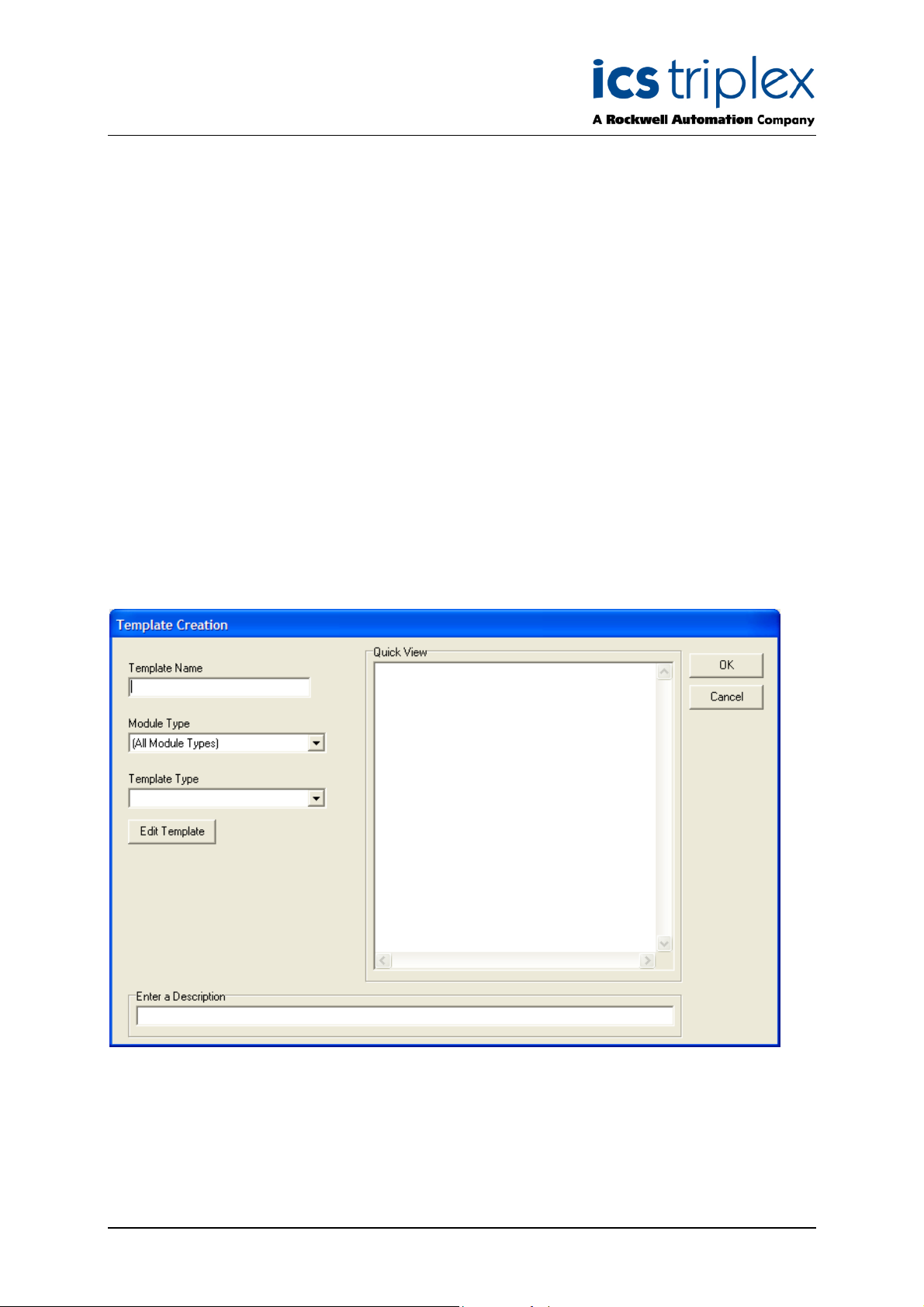

2.3.2. New Templates

To create a new template from the TrustedTM System Template Editor, select the New button on the

right-hand side of the display. The Template Creation window is displayed as shown in Figure 9 below.

Figure 9 Template Creation Window

From the Template Creation window shown above, select the module type. Each template created

can only be assigned to one module type. The available template types for that module are then

available in the menu below. If ‘[All Module Types]’ is selected, the templates available may be

Issue 14 Feb 10 PD-T8082 19

Page 20

Trusted

ssigned to any module, but are limited to these portable types. Enter a name for the template and a

a

TM

Toolset Suite T8082

description of its purpose or effect.

Select the Edit Template button on the window to design the template. This opens an editor

appropriate to the template type.

When all values have been entered, select the OK button. This will return to the Template Creation

window.

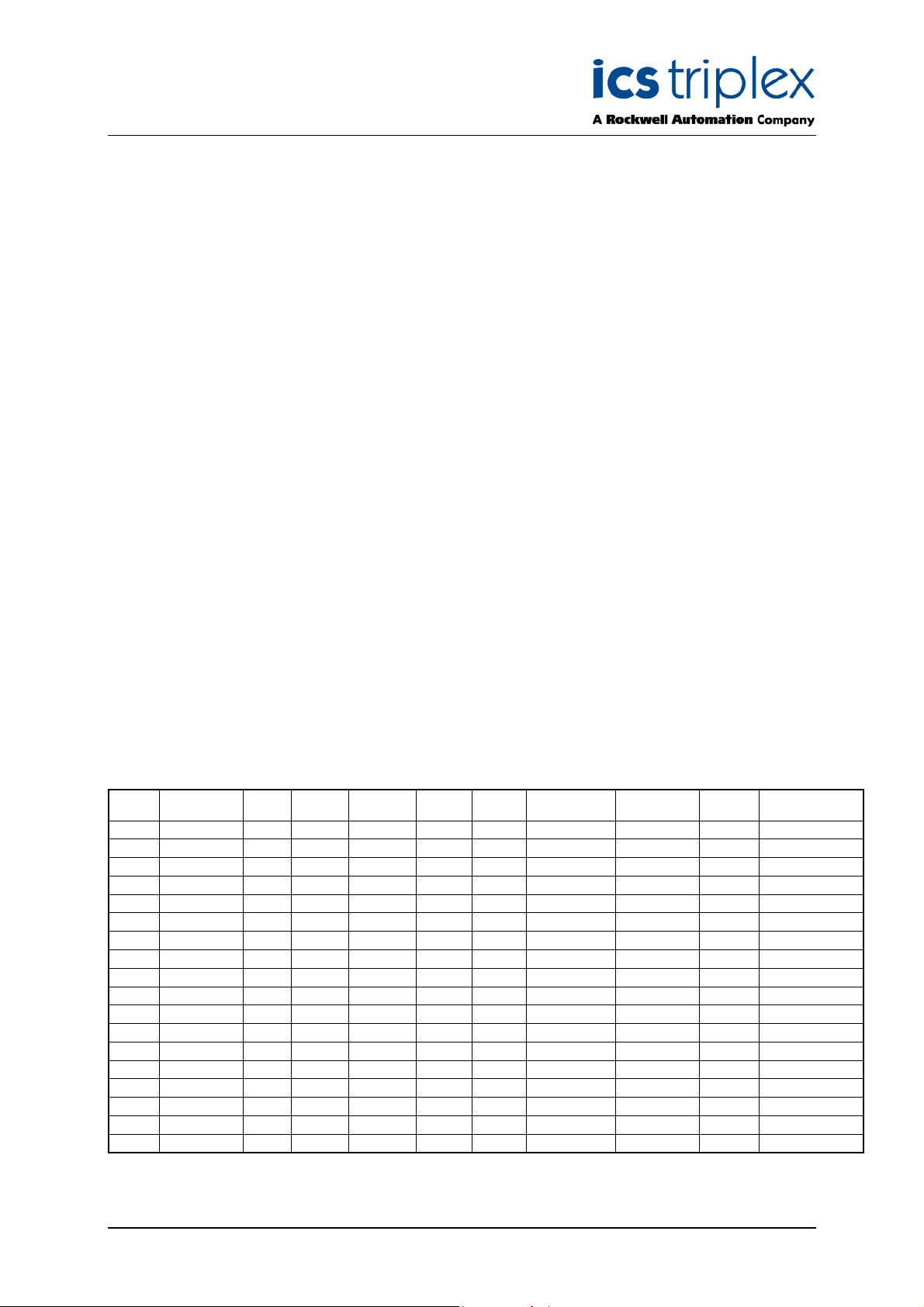

2.3.3. Template Types

There are ten types of template which may be created.

1. Threshold – defines the state of selected I/O module channels dependent upon the input signal to

the channel.

2. LED – defines the colour and mode (flashing, steady or off) for channel LEDs for different channel

states.

3. Channel Forcing – defines the state the unconnected channels must be forced into to provide a

healthy (unalarmed) system state.

4. Module System Information – defines the specific timeout periods allowed for the module

Watchdog and IMB (Inter-Modular-Bus ).

5. Module Flags – defines the flag settings for the I/O module.

6. Module Filter – defines the internal filtering values for the I/O module.

7. Additional – allows the user to define additional Command Line Interface (CLI) entries that are

external to the configuration data.

8. Shutdown – allows the user to define the output action required when the module enters the

shutdown state (for example when the application is stopped).

9. Channel Type – allows the user to configure a channels operation (input to output) for the 8448

module.

10. De-energised Short Circuit Detection – allows the user to enable short circuit detection for de-

energised outputs.

These are available for each module type as below.

8402

8403

8423

8424

8431

8432

8433

8442

8444

8448

8449

8451

8461

8471

8472

8473

8480

All

Threshold LED Force System Flags Filter

Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Speed monitor

Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes Yes Yes Channel

Yes Yes Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes

Yes Yes

Addition al

CLI Shutdown

De-en

SC Special

Issue 14 Feb 10 PD-T8082 20

Page 21

Trusted

TM

Toolset Suite T8082

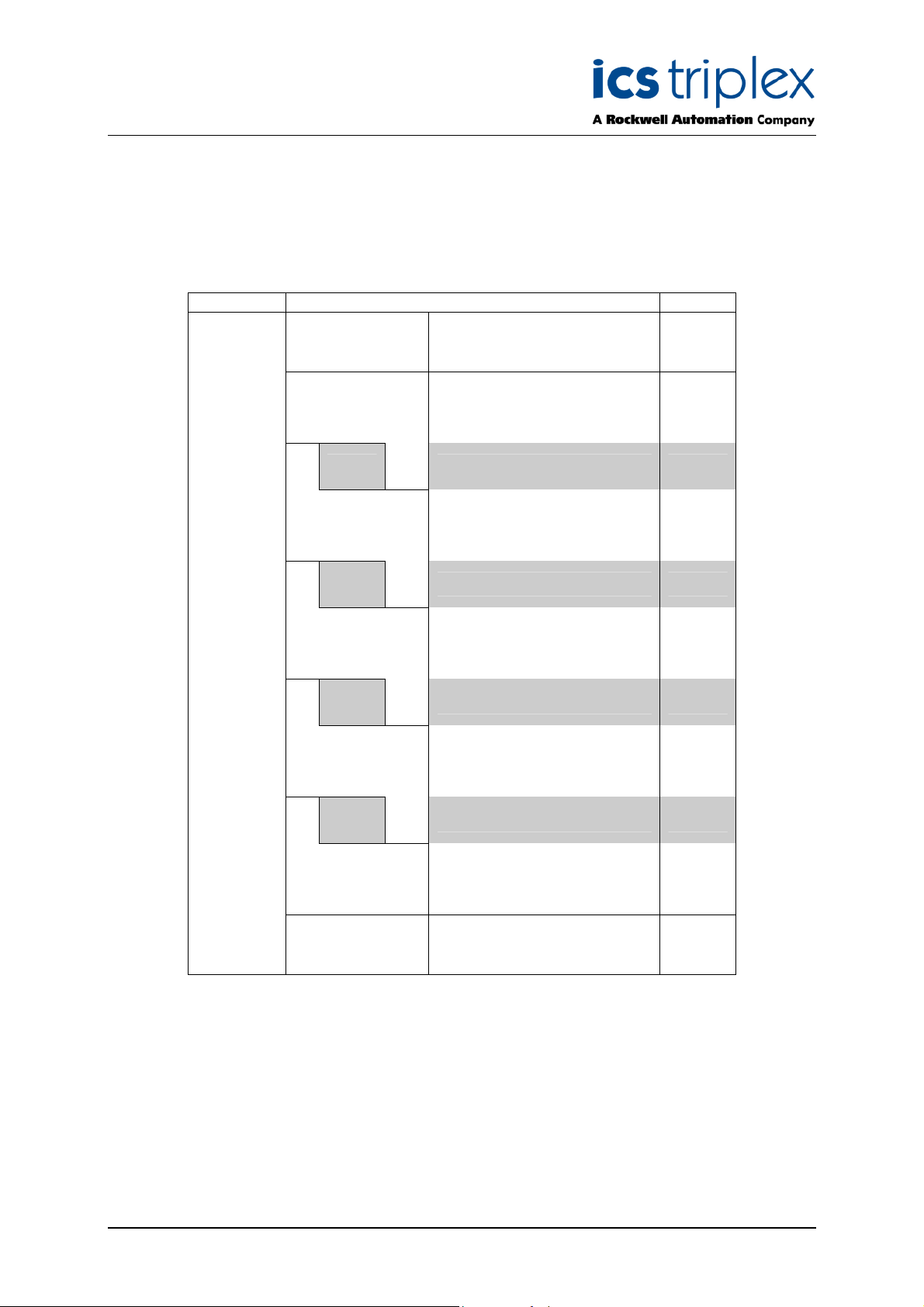

2.3.4. Threshold Templates

Input modules monitor and calculate the voltage level from the field at each channel to determine the

appropriate state to report to the TMR Processor. After the module has calculated the input channel

voltage, a state is then determined based on the channel threshold settings. There are 8 possible

states (0 to 7). An example of these state thresholds is shown in Table 1 below.

Threshold Description State

The voltage is above the

Tmax

T8

T7

T6

T5

T

ax

m

maximum for the module (set

in manufacture ).

Short circuit. The voltage level

S/C

indicates a short circuit field

loop

CC Closed contact. 4

IND

Indeterminate, this voltage

indicates an error condition.

6

5

4 or 5

3 or 4

3

T4

2 or 3

T3

OC Open contact. 2

T2

1 or 2

T1

Open circuit. The voltage level

O/C

indicates an open circuit field

1

loop condition.

Tmin

T

min

The voltage is below the

minimum for the module ( set

0

in manufacture ).

Table 1 Digital Input Threshold Diagram

States 0 to 6 are based on the calculated voltage. One additional state (7) is reported when the

module has completely failed. The description of the states shown above is in terms of a line

monitored digital input switch configuration.

There are fixed minimum (Tmin) and maximum (Tmax) thresholds for the module, but each channel

has eight configurable thresholds as illustrated above. Each state transition has a hysteresis shown by

the grey areas in the diagram.

Issue 14 Feb 10 PD-T8082 21

Page 22

Trusted

The rules for configuring thresholds are as follows:

TM

Toolset Suite T8082

• Each threshold must be greater than or equal to the previous threshold, i.e. T2 must be greater

or equal to T1, T3T2 etc…

• The state associated with each threshold is between the threshold settings, except that the

lower threshold must be higher than Tmin (in the valid OC state range), and the upper

threshold must be lower than Tmax (in the valid SC state range).

• Threshold values are defined as fractions of a volt. For example, the 8403 Digital Input

Module, thresholds are represented as 512 counts per volt; e.g. a value of 8400 represents

16.406 volts (8400/512). The appropriate module Product Description defines the threshold

fraction used.

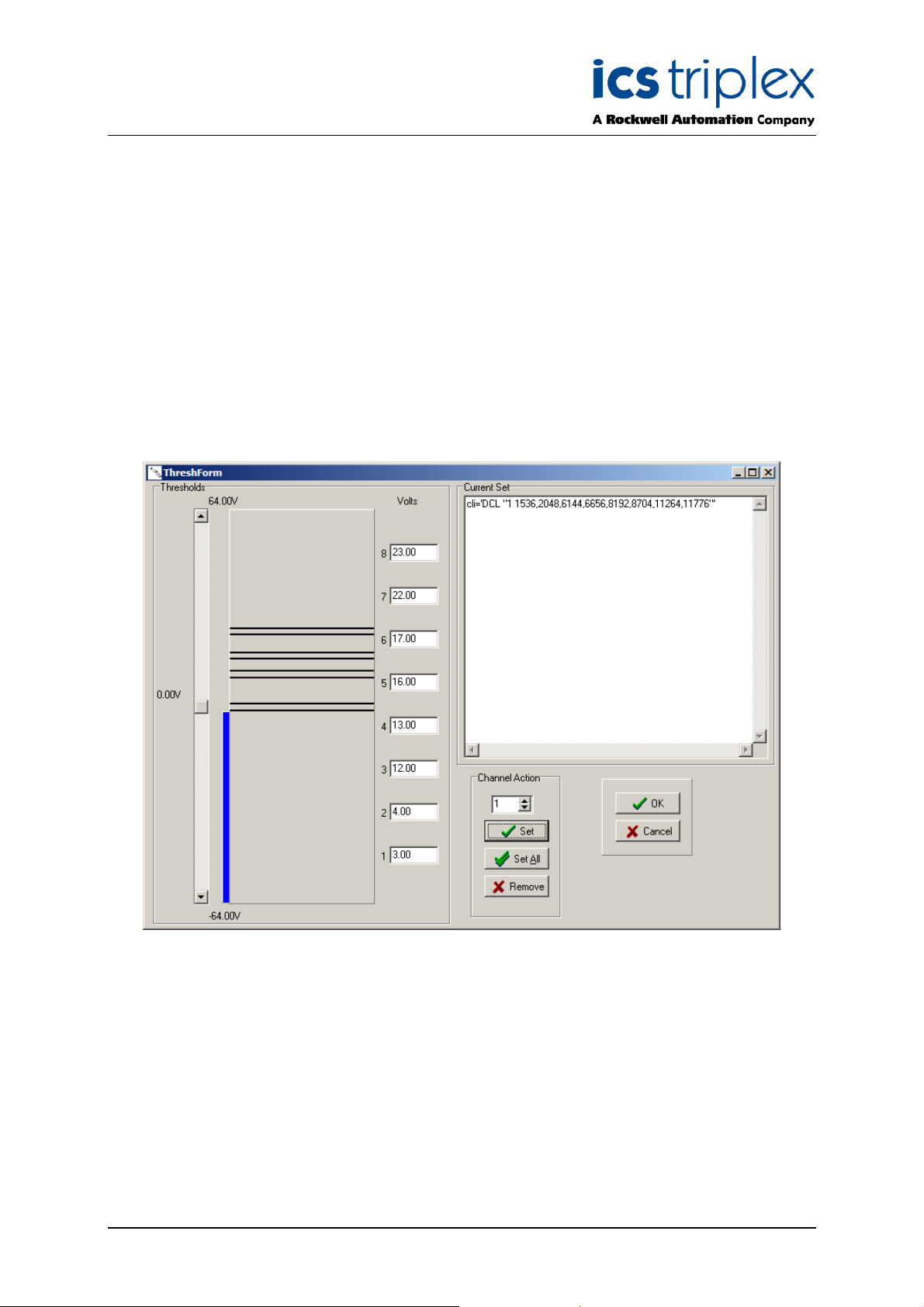

2.3.5. Threshold Template Editor

The Threshold Template Editor window is shown in Figure 10 below.

Figure 10 Threshold Template Editor

There are two types of entries for this section: default settings that apply to all channels not individually

configured, and individual channel settings.

The syntax for entering module default thresholds is:

default = <T1>, <T2>, <T3>, <T4>, <T5>, <T6>, <T7>, <T8>

The syntax for entering individual channel thresholds is:

channel# = <default> | <T1>, <T2>, <T3>, <T4>, <T5>, <T6>, <T7>, <T8>

Issue 14 Feb 10 PD-T8082 22

Page 23

Trusted

If no entries are made to customize the thresholds, the module sets all channels to default settings. For

example, in the 8403 Digital Input Module these are as follows:

default = -2304,-1971,3046,3072,7168,8192,14848,15872

The bar graph details the current voltage thresholds. These have been applied to Channel 1 of the I/O

module in Figure 10 above by selecting the Set button (part of the Channel Action group of buttons).

These values may be applied to all channels on the I/O module by selecting the Set All button.

Alternatively, the user may select individual channels by selecting the channel number and then

selecting the Set button.

The threshold values may be changed by dragging the horizontal lines on the bar graph. These values

may also be changed by entering the voltage values in the windows of the Volts area. The vertical

slider may be used to demonstrate the threshold settings.

Channels that have previously been Set but are no longer required may be deleted by selecting the

Remove button.

TM

Toolset Suite T8082

2.3.6. LED Templates

1. Input Modules

This template defines the mapping between the input state and the front panel indicators for the

specific module. The mapping defines the required operation for all input channels. An LED mapping

entry is made using the syntax shown below.

state# = <OFF | RED | GREEN [+FLASH]>

If no entries are made in this section, the module will operate with the default LED mapping. The

example in Table 2 below shows defaults for the 8403 Digital Input Module, which are suitable for

inputs without line monitoring devices installed.

0 =

1 =

2 =

3 =

4 =

5 =

6 =

7 =

8- = Red –

Note: States 8 through 15 all represent channel fault states.

LED templates define specific LED states. For example, if inputs are installed with line monitoring

devices, the LED mapping entries can be made to flash red for the corresponding states that indicate a

line fault condition, i.e. Open circuit, Indeterminate and Short circuit.

Red –Out of range

Off –Open circuit

Off –Open field contact

Off –Indeterminate contact state

Green –Closed field contact

Green –Short circuit

Green –Overrange

Off –

Table 2 8403 Input Module LED Default Settings

Issue 14 Feb 10 PD-T8082 23

Page 24

Trusted

TM

Toolset Suite T8082

2. Output Modules

This section defines the mapping between the output state and the front panel indicators for the

specific module. The mapping defines the required operation for all output channels. An LED mapping

entry is made using the syntax shown below.

state# = <OFF | RED | GREEN [+FLASH]>

f no entries are made in this section, the module will operate with the default LED mapping. The

I

example in Table 3 below shows defaults for the 8451 Digital Output Module, which are suitable for

outputs without line monitoring devices installed.

0 = Off – Not used

1 = Red – No field supply voltage

2 = Off – Output de-energised (off)

3 = Green – Line open circuit

4 = Green – Output energised (on)

5 = Red – Field short circuit

6 = Off – Not used

7 = Off – Not used

8- = Red –

Table 3 8451 Output Module LED Default Settings

Note: States 8 through 15 all represent channel fault states.

Input and Output Module LED templates are configured using the Module LED State Editor. On

creating an LED template, select ‘Module’ in the LED Config section. The Module LED State Editor is

described in section 2.3.7 below.

2. Zone Interface Modules

TrustedTM 8448 Zone Interface Modules can have each channel defined as an input or an output using

a Channel Template. In this case, one single LED definition for all channels is not appropriate. The

LED states for this module are configured using the Channel LED State Editor. On creating an LED

template, select ‘Channel’ in the LED Config section. The Channel LED State Editor is described in

section 2.3.8 below.

Issue 14 Feb 10 PD-T8082 24

Page 25

Trusted

TM

Toolset Suite T8082

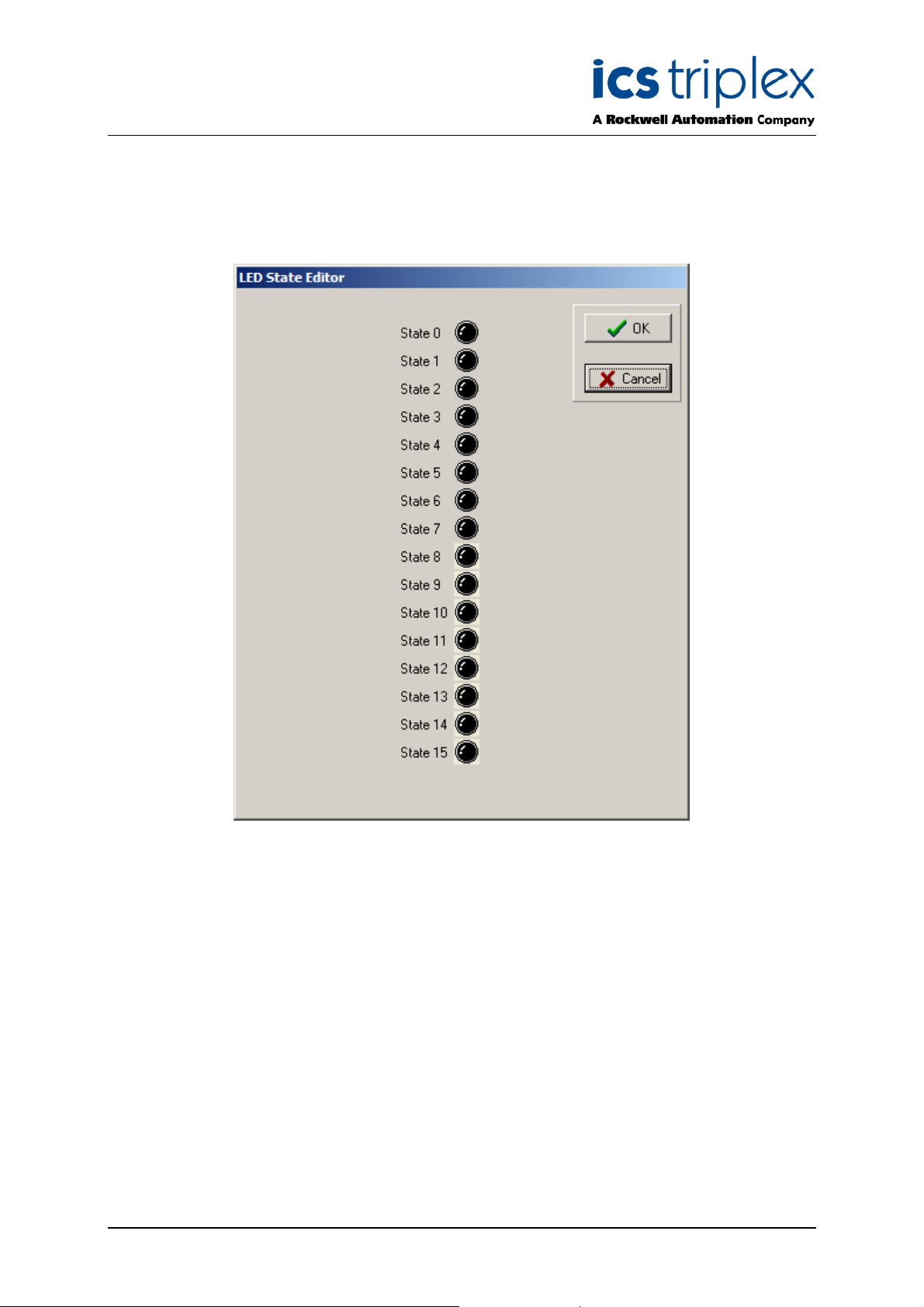

2.3.7. Module LED State Editor

From the Template Creation window, select LED Template and select Module in the LED Config

section. Select the Edit button. This will cause the Module LED Editor window to be displayed, as

shown in Figure 11 below.

Figure 11 Module LED State Editor

To change the colour and operating mode of the LED, point and click the left-hand mouse button on

the required State LED icon. These changes will apply to all channel LEDs on the I/O modules that

this template is applied to. The LED appearance for each state is then animated on the editor window.

When the correct LED states have been entered, the user must select the OK button. This will return

the user to the Template Creation window which permits the newly created template to be saved. The

filename must not include any spaces. Underscores are recommended.

Note that state 7 is a module fault. States 8 to 15 are not used for modules except the 8449 Valve

Monitor Module. For this module, valve outputs and position inputs are grouped in pairs. States 0 to 7

are the output states 0 to 7 described in section 2 above. States 8 to 15 are the position input states 0

to 7 described in section 1 above.

Issue 14 Feb 10 PD-T8082 25

Page 26

Trusted

TM

Toolset Suite T8082

2.3.8. Channel LED State Editor

From the Template Creation window, select LED Template and select Channel in the LED Config

section. Select the Edit button. This will cause the Channel LED Editor window to be displayed, as

shown in Figure 12 below.

Figure 12 Channel LED State Editor

Each channel can be individually configured with an LED state/colour map. To change the colour and

operating mode of a channel LED, first select the channel to edit. Several channels may be selected at

once using Ctrl-click or Shift-click. To change the LED appearance in a particular state, point and click

the left-hand mouse button on the required State LED icon. The LED appearance for each state is

then animated on the editor window. These changes will apply to the selected channel LEDs on the I/O

modules that this template is applied to.

The channels may also be assigned to the default LED state/colour map. Channels with a D

symbol as shown left use the default map. To define whether a channel uses the default map or

a specific map, select ‘Use Default’ or ‘Use Editor’ in the ‘Channel Options’ section. To edit the default

map, select ‘Default’ at the top of the channel list and edit the LED colours.

A channel LED map may be assigned as the default by selecting the channel and selecting ‘Default <Current’ in the ‘Default LED State’ section. A channel specific map may be changed to the current

default by selecting the channel and selecting ‘Current <- Default’ in the ‘Default LED State’ section.

The channel still has a specific LED map but it now matches the default.

Issue 14 Feb 10 PD-T8082 26

Page 27

Trusted

When the correct LED states have been entered, the user must select the OK button. This will return

the user to the Template Creation window which permits the newly created template to be saved. The

filename must not include any spaces. Underscores are recommended.

TM

Toolset Suite T8082

2.3.9. Force Templates

Refer to the safety manual.

These templates allow forcing of the input or output channel states on-board the module to a specific

value irrespective of the value that may be present. Channels may be forced to a specified state on a

per-channel basis. The states that exist on a module are specific to that module. For example,

channels on the 8431 Analogue Input Module may be any one of eight states detailed in Table 4 below.

0 - Under range

1 - Low-Low

2 - Low

3 - Normal

4 - High

5 - High-High

6 - Over Range

7 - Fail Safe

Table 4 Analogue Input Module States

Force Template Editor

From the Template Creation window, select Channel Forcing Template, select the Module Group

and Number of channels, then select the Edit button. This will cause the Forcing Editor window

shown in Figure 13 below to be displayed.

Figure 13 Force Template Editor

The Forcing Editor window above shows Channels 1, 11, 22 and 31 forced to the ‘High’ state

described in section 2.3.9 above. The LEDs displaying the channel status will be steady green (if set

to the default colours) because they are indicating state 4.

To add a channel force to the template, the user must select the appropriate channel number in the

Channel Select window, enter the required channel state in the Channel State window, then select

the Add button.

To remove a channel from the template, the user must select the channel, then select the Remove

button. A warning message is shown to ensure the correct force is removed.

To change the entered state for a channel, the user must select the appropriate channel, enter the new

value in the Channel State window, then select the Change button.

Issue 14 Feb 10 PD-T8082 27

Page 28

Trusted

When the correct channel and force states have been entered, the user must select the OK button.

This will return the user to the Template Creation window which permits the newly created template to

be saved. The filename must not include any spaces. Underscores are recommended.

TM

Toolset Suite T8082

2.3.10. Module System Information Templates

The typical entries for this template, include; NLthresh, IMBTO, WDOGTO, PWRFAILTO, and

BYPASSTO. The syntax and function of each entry is defined below.

nlthresh = < group1 >, < group2 >,< group3 >,< group4 > [,< group5 >]

nlthresh (‘no-load threshold’) is a template that is used on output modules. It sets the current per slice

(in milliamps) below which an output will signal state 3 (no load), and each of the parameters sets the

threshold for an entire power group of eight digital outputs. Without this template, the defaults are

10mA, i.e. at least 30mA is required for the load to be recognised.

Outputs do not share current evenly across the three TMR slices and there may be a significant

difference between slices. As an example, the 8451 output module has a minimum on state load

current of 50 mA per channel. With a load of 51mA, the load may be spread across the slices as

follows:

Channel 1 Slice A 26mA

Channel 1 Slice B 16mA

Channel 1 Slice C 9mA

Whilst the channel total is greater than the nominal minimum, slice C is below the default no-load

threshold (10mA) and would therefore signal a no-load state whilst the other two slices will record an

acceptable load. This causes a discrepancy alarm. In earlier firmware versions this may lead to a

module shutdown.

It is recommended to group comparatively high and low power loads on different power groups. This

prevents potential noise from a higher powered output affecting the lower powered signals. The

following no-load threshold settings are recommended for each group:

25 to 80 mA nlthresh = 5

80 to 150mA nlthresh = 10

150 to 300mA nlthresh = 15

300mA to limit nlthresh = 20

As an example, if groups 1 and 2 (channels 1 to 16) are approximately 100mA per channel and the

rest are 50mA per channel, the no-load thresholds should be set as:

nlthresh = 10,10,5,5,5

Output modules such as the 8471 (120Vdc) only have 4 output groups and the template is written, for

example, as:

nlthresh = 5, 5, 5, 5

Whilst some output modules have a minimum on state load current of 20 or 25 mA per channel, it is

still recommended to use the nlthresh template for these modules.

For the 8473, it is recommended to set nlthresh = 20, 20 because it will not accurately detect the noload condition below this value.

Issue 14 Feb 10 PD-T8082 28

Page 29

Trusted

MBTO = < value >

I

TM

Toolset Suite T8082

The IMBTO (Inter-Modular Bus Timeout) is a timer run internally within each I/O module from start-up.

If the TMR Processor does not scan the module within the programmed time, the module adopts the

shutdown mode. In the majority of Trusted

n systems that are very large, or for test purposes, e.g. to allow the application program to be paused,

I

Systems, this entry may be omitted and the default used.

it may be necessary to adjust the timeout period. The timeout period is defined in milliseconds; a value

of zero disables the timeout.

Note: This value MUST NOT be set to zero for operational systems.

WDOGTO = < value >

The WDOGTO (System Watchdog Timeout) is a timer run internally within each I/O module from

start-up. If the TMR Processor does not pet the module’s watchdog within the programmed time, the

module adopts the shutdown mode. However this parameter adjusts the system watchdog timeout

interval. Again, it is not normally necessary to adjust this parameter, unless the system is very large or

to allow certain tests to be performed. The timeout value is entered in milliseconds, and a value of

zero disables the timeout.

Note: This value MUST NOT be set to zero for operational systems.

PWRFAILTO = < value >

The PWRFAILTO (Power Fail Timeout) adjusts the interval between the system detecting loss of both

24V power feeds to the module initiating its power-down sequence and fail-safe operation. Only in

exceptional cases will it be necessary to adjust this setting. The timeout value is entered in

milliseconds, and a value of zero disables the timeout.

Note: This value MUST NOT be set to zero for operational systems.

BYPASSTO = < value >

The BYPASSTO (Bypass Timeout) is used internally in the module to bypass the other timeouts during

an Active/Standby changeover. Only in exceptional cases will it be necessary to adjust this setting.

The timeout value is entered in milliseconds, and a value of zero disables the timeout.

Note: This value MUST NOT be set to zero for operational systems.

Issue 14 Feb 10 PD-T8082 29

Page 30

Trusted

TM

Toolset Suite T8082

2.3.11. Module System Information Template Editor

From the Template Creation window, select Module System Information, then select the Edit

button. This will cause the Module window shown in Figure 14 below to be displayed.

Figure 14 Module System Information Template Editor

The window above shows arbitrary values in the IMB Timeout and Watchdog Timeout windows.

These may be changed and added by selecting Add as required.

It is recommended to set the above timeouts so that the module is polled at least four times at the

normal scan time within the timeout, taking scheduled polling into account. For example, if the ‘current’

scan time is 200 milliseconds (as reported in the Toolset Debugger window), and the module is set for

scheduled polling every 5

200 x 5 x 4 = 4000ms minimum. Ensure that the timeouts are still safe, i.e. less than half the process

safety time.

The Miscellaneous window will normally be blank when initially editing this template. Timeout values

for Power Fail and Bypass must be entered using this window, in the syntax shown in section 2.3.10.

When the correct timeout values have been entered, the user must select the OK button. This will

return the user to the Template Creation window which permits the newly created template to be

saved. The filename must not include any spaces. Underscores are recommended.

The Pulse Train Module is discontinued and its associated tab should not be used.

th

scan, then both timeouts (they operate in a similar way) need to be set to

2.3.12. Module Flags Templates (Future Use Only)

Input Modules

There are two possible entries for this template; Currentsink and Ratiometric. The syntax and function

of each entry is described below. These settings apply to the entire module.

Currentsink = < TRUE | FALSE (default) >

Issue 14 Feb 10 PD-T8082 30

Page 31

Trusted

he input configuration option defines if the inputs are high or low side switching, i.e. switch to +V or

T

0V (return). The default option is for high-side switch (to +V). Setting this option to TRUE will select

the switch operation to 0V (return).

Ratiometric = < TRUE | FALSE (default) >

This option allows the input thresholds to be defined either in terms of their absolute voltage or

normalised to the nominal field supply voltage. The default operation is for the thresholds to be defined

in absolute voltage.

When the ratiometric threshold operation is enabled the field supply must be connected to the

monitoring terminals on the field termination unit. In ratiometric mode the range of voltages for the

thresholds is 0 to 24V, the value will be re-scaled according to the current field supply voltage, e.g. a

threshold value of 12V with an actual field supply of 30V will result in an actual threshold of 15V. If the

field supply voltage is out of range, a line fault condition will be generated.

Output Modules

There is one possible entry for this template; LOGICAL. The syntax and function is described below.

These settings apply to the entire module.

LOGICAL = < TRUE | FALSE (default) >

This configuration option defines how the module timestamps changes of state for the output channel.

When set to True, the module will timestamp an output change when it receives a change of state to

the logical output control signal. When set to False (default) the module will timestamp an output

change of state when the measured voltage and current reflect an actual change of state in the output

control circuit. Propagation delay between receiving the logic control signal and driving the output

control signal is typically less than 1 millisecond. It is usually unnecessary to change this setting in

most applications.

TM

Toolset Suite T8082

2.3.13. Module Flags Template Editor

From the Template Creation window, select Module Flags, then select the Edit button. This will

cause the Command Line Interface (CLI) Entry window shown in Figure 15 below to be displayed.

Figure 15 Module Flags Template Editor

The Current CLI Entries area of the CLI Entry window will normally be blank when initially editing this

template. If there are entries in this area, they may be deleted by highlighting them and selecting the

Remove Entry button. Each entry must be deleted individually.

New instructions are entered in the Please Enter CLI Instruction area in the format shown above,

then added to the template by selecting the Add Entry button.

Issue 14 Feb 10 PD-T8082 31

Page 32

Trusted

When the correct instructions have been entered, the user must select the OK button. This will return

the user to the Template Creation window which permits the newly created template to be saved. The

filename must not include any spaces. Underscores are recommended.

TM

Toolset Suite T8082

2.3.14. Module Filter Templates (Future Use Only)

The Module Filter template is used to configure the filter type to use for each of the 40 channels on an

input module. There are two types of entries for this template; default and channel settings.

The default entry sets the default filter type for all channels on the module. It has the following syntax.

Default = < 0 | 1 | 2 | 3 >

Input filtering for individual channels can be configured using the following

channel# = < default > | < 0 | 1 | 2 | 3 >

The module supports 4 input filter types, relating to the numbers in the syntax above.

0 4ms filter

1 4ms filter, same as 0

2 50Hz notch filter

3 60Hz notch filter

Note: 50Hz and 60Hz filters can not be mixed on the same module.

4ms Filter

The samples are passed straight through with only a 4ms signal averaging filter. The

sampling frequency depends on whether another filter has been selected for any other

channels. The default sampling frequency is 1.0ms.

50Hz Filter (default)

This will filter out a 50Hz signal in the sample data. The module sampling frequency is

set to 1ms, the filtering is performed by a moving boxcar average over 20 samples.

The time is delayed for the channel by 20*1.0=20ms to accommodate for the filter.

This is the default line filter used.

60Hz Filter

This will filter out a 60Hz signal in the sample data. The module sampling frequency is

set to 1.04ms, the filtering is performed by a moving boxcar average over 16 samples.

The time is delayed for the channel by 16*1.04=16.64ms.

Since the propagation delays of the filters are a known constant, when a change of input state passes

through the filter, the corresponding SOE event time stamp is adjusted by the propagation delay.

Issue 14 Feb 10 PD-T8082 32

Page 33

Trusted

TM

Toolset Suite T8082

2.3.15. Module Filter Template Editor

From the Template Creation window, select Module Filter, then select the Edit button. This will

cause the CLI Entry window shown in Figure 16 below to be displayed.

Figure 16 Module Filter Template Editor

The Current CLI Entries area of the CLI Entry window will normally be blank when initially editing this

template. If there are entries in this area, they may be deleted by highlighting them and selecting the

Remove Entry button. Each entry must be deleted individually.

New instructions are entered in the Please Enter CLI Instruction area in the format shown above,

then added to the template by selecting the Add Entry button.

When the correct instructions have been entered, the user must select the OK button. This will return

the user to the Template Creation window which permits the newly created template to be saved. The

filename must not include any spaces. Underscores are recommended.

2.3.16. Shutdown Templates

This template is used to configure individual shutdown states for each channel of an output module.

Output channels are driven to the default, fail-safe, state when the module enters the shutdown mode.

Typically the module will enter the shutdown mode when any of the system timeouts occur, or when

commanded by the TMR Processor. A channel may be configured to enter a specific shutdown state

other than the default using this template.

A shutdown entry is made using the syntax shown below.

channel#=< ON | OFF | HOLD >

The three available shutdown modes are:

ON: Energize the output

OFF : De-energise the output

HOLD: Hold, or maintain the output in the last commanded state

Note: All output channels used for safety critical applications must be configured with shutdown mode

that places the process in the safe state.

Issue 14 Feb 10 PD-T8082 33

Page 34

Trusted

TM

Toolset Suite T8082

2.3.17. Shutdown Template Editor

From the Template Creation window, select Shutdown (Output Modules Only), then select the Edit

button. This will cause the Shutdown Editor window shown in Figure 17 below to be displayed.

Figure 17 Shutdown Template Editor (pre and post release 3.5)

For earlier versions, the Shutdown Template Data area of the Shutdown Editor window will normally

be blank when initially editing this template. If there are entries in this area, they may be deleted by

highlighting them and selecting the Remove button to delete individual entries, or the Remove All

button to globally delete entries. For later versions, all channels are unassigned by default.

The template is configured using the options and facilities available in the Editor area of the

Shutdown Editor window (earlier versions) or by right clicking on each channel (later versions). The

above displays show that channels 4 and 7 have been set to the Energise The Output option. All

module outputs may be forced to a pre-determined state by selecting the Set All button in the Global

Entry area.

When the correct option and channels have been selected, the user must select the OK button. This

will return the user to the Template Creation window which permits the newly created template to be

saved. The filename must not include any spaces. Underscores are recommended.

2.3.18. Channel Type Templates

This template defines the TrustedTM Zone Interface Module channel configuration. Each channel on a

Zone Interface Module can either be an input or output. The default configuration is with all channels

set as inputs.

Issue 14 Feb 10 PD-T8082 34

Page 35

Trusted

TM

Toolset Suite T8082

2.3.19. Channel Type Template Editor

From the Template Creation window, select Channel Type (ZIM Only). Enter a description for the

template, then select the Edit button. This will cause the Channel Type Editor window shown below to

be displayed as shown in Figure 18 below.

Figure 18 Channel Type Template Editor

To change the channel type, point and click right-hand mouse button on the channel required to get the

Type selection menu. Click on the desired channel type. The icon in the channel list will show I or O for

input or output as requested.

When the correct channel Types have been entered, the user must select the OK button. This will

return the user to the Template Creation window which permits the newly created template to be

saved. The filename must not include any spaces. Underscores are recommended.

2.3.20. De-energised Short Circuit Detection Templates

Output modules by default do not detect for short circuit faults when de-energised. Using this template,

they may be configured to detect de-energised short circuit faults on some or all channels. The

impedance below which a de-energised short circuit fault is reported is 40 ohms. Note that the cold

resistance of small incandescent lamps may be less than this threshold.

Issue 14 Feb 10 PD-T8082 35

Page 36

Trusted

ote that de-energised short circuit templates will not work on older 5V HIU hardware builds. An

N

attempt to swap from a 3.3V module with this template, to a 5V module, will fail.

TM

Toolset Suite T8082

2.3.21. De-energised Short Circuit Detection Template Editor

From the Template Creation window, select the De-energised Short Circuit Detection option,

module voltage and number of channels. Enter a description for the template. Select the Edit button on

the display. This will cause the De-Energised Short Circuit Detection editor window to be displayed as

shown in Figure 19 below.

Figure 19 De-energised Short Circuit Detection Template Editor

To change the channel line monitoring, point and click right-hand mouse button on the channel

required to get the line monitor selection menu. Select either 40 or off. Selecting Select All (or Ctrl–A

or the Select All icon) allows all channels to be set together.

When the correct channel selections have been entered, the user must select the OK button. This will

return the user to the Template Creation window which permits the newly created template to be

saved. The filename must not include any spaces. Underscores are recommended.

Issue 14 Feb 10 PD-T8082 36

Page 37

Trusted

TM

Toolset Suite T8082

2.4. Configuring a SYSTEM .INI File

Once the user has configured all required templates for the Trusted

TM

System, the communications

port on the EWS has been configured and communications with the Processor are open, the user may

configure/edit the System.INI file as necessary. For the purpose of clarity, this Product Description will

describe the full configuration of the System.INI file with the basic module tray as shown in the opening

screen.

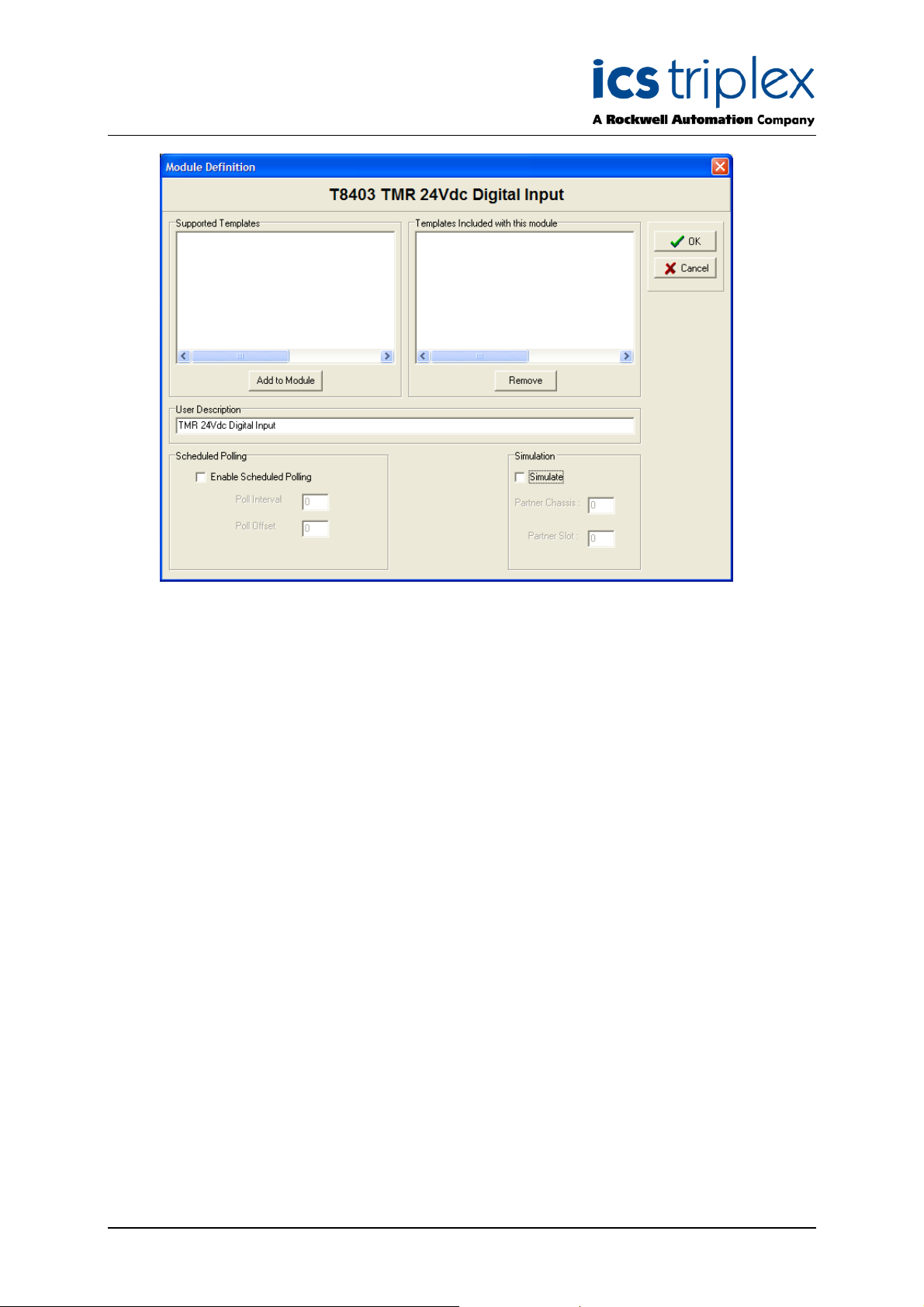

2.5. TrustedTM TMR Processor

Configuration of the TrustedTM TMR Processor is necessary at initial start-up of the Trusted

This is achieved by clicking the left-hand mouse button on the Processor module shown on the

opening screen. This will cause the dialogue box shown in Figure 20 below to appear.

TM

System.

Figure 20 TMR Processor Configuration Window

The values shown in the display above are the defaults for the Trusted