Page 1

ICS Regent+Plus

®

PD-6050

High Integrity Power Supply Assembly

110-240 VAC and 24 VDC

(T8060, T8062)

Issue 2,

The power supply assembly (see Figure 1) converts redundant main-line

voltages of either 110-240 VAC or 24 VDC to +15 VDC or +24 VDC

ou

tput power for ICS product power requirements.

March, 06

Industrial Control Services

Figure 1. Power Supply Assembly

Features

·

Redundant power inputs

·

250 W

·

Hot replaceable

·

Current sharing

·

Power factor correction

·

Front panel indicators for input, output voltage status and

output current level on each module

·

Ext

·

TÜV certified for safety, Risk Class 5

1

ernal status signals

Page 2

Catalog No.

Chassis Unit

Input Power Voltage

Configuratio

n

T8200

I/O Power Supply Chassis

110-240 VAC, 50/60 Hz

Straight Bussed

T8201

I/O Power Supply Chassis

110-240 VAC, 50/60 Hz

Cross Bussed

T8202

I/O Power Supply Chassis

24 VDC

Catalog

No.

Input

Type

Input Power

Voltage

Output Power

Voltage

T8220

Dual 110-240 VAC

15 VDC

T8222

Dual 24 VDC

15 VDC

T8223

Single 110-240 VAC

24 VDC

T8224

Single 110-240 VAC

15 VDC

T8225

Dual 110-240 VAC

24 VDC

T8226

Dual 24 VDC

24 VDC

I/O Power Supply Assembly (T8060,T8062)

Structure

The power supply assembly consists of a power supply chassis containing

up to six power supply modules. The chassis may be configured to

distribute power in various combinations. For example, a chassis containing

six power supply modules may be set up with three modules providing

triplicated power for Regent+Plus I/O assemblies and three modules

providing field power in a N+1 configuration.

Power Supply

Chassis

The power supply chassis houses a maximum of six power supply modules.

It may be mounted in a 19-inch rack or flush mounted on a panel. Table 1

identifies the available types of chassis.

Table 1. Chassis Types

Power Supply Modules

The power su

pply assembly modules are single (if redundant inputs are not

required) and dual input, hot swap, user-replaceable AC and DC units.

Table 2 identifies the available types of modules.

Table 2. Module Types

2

Industrial Control Services

Page 3

I/O Power Supply Assembly (T8060,T8062)

PFC

PFC

Power Supply Module

PWM

Switching Regulator

T1:a

T1:c

T1:b

Rectifier

Rectifier

DC

Output

I/P Filter & Protection

I/P Filter & Protection

PFC A Off

I/P A Fail

PFC A Fail

Source

A

Source

B

Fail

High Tempterature

Reset

O/P Current

Status & Control

Remote Off

PFC B Off

I/P B Fail

PFC B Fail

Status & Control

Power Supply Module

DC

Output

I/P Filter & Protection

I/P Filter & Protection

PWM

Switching Regulator

T1:a

T1:b

I/P A Fail

Fail

High Tempterature

Reset

O/P Current

Status & Control

Remote OffI/P B Fail

Status & Control

Source

A

Source

B

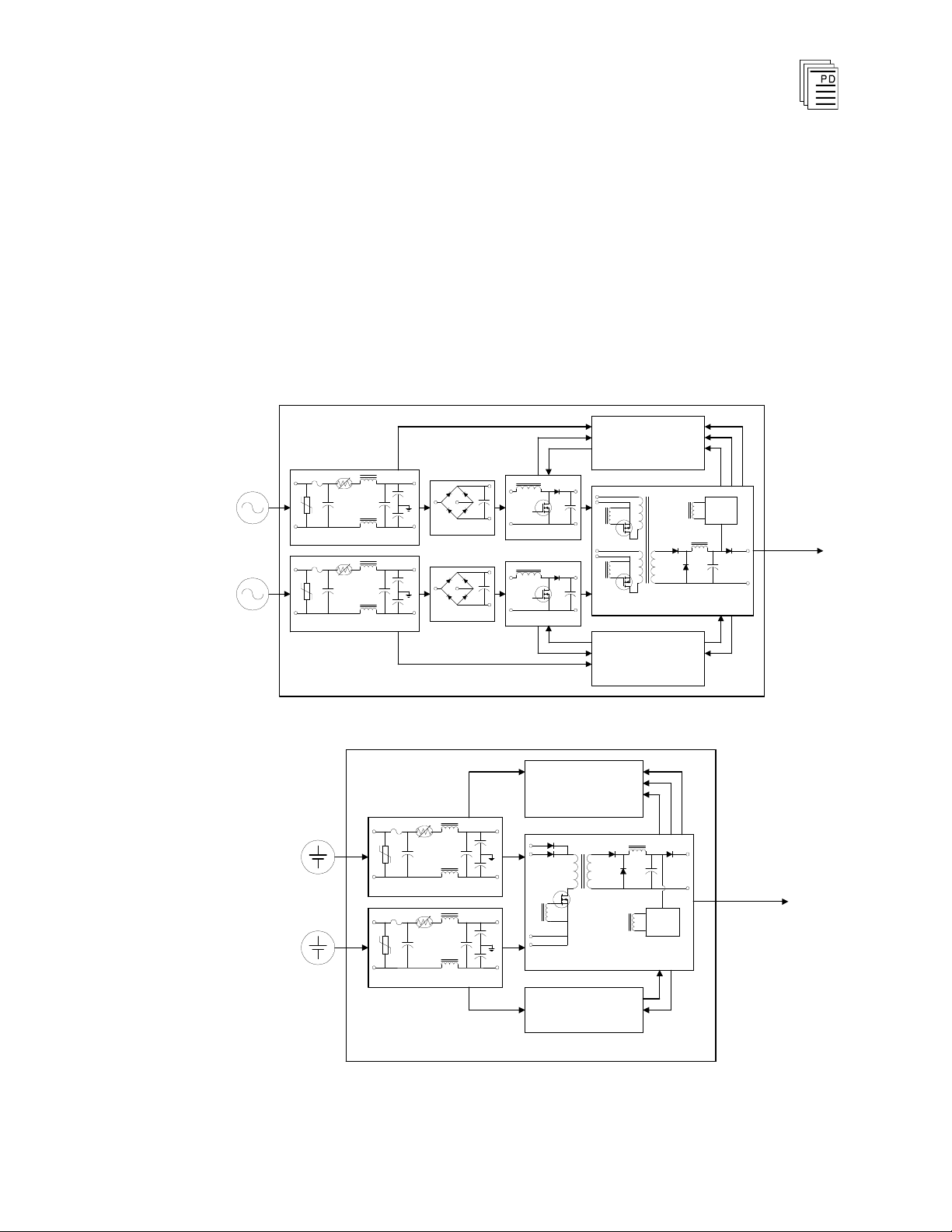

The dual inputs on the AC modules are galvanically isolated from each

other. The inputs on the DC modules are diode isolated and share a

common return.

Input Power Regulation

A block diagram of a typical dual AC input I/O power supply module is

shown in Figure 2. A block diagram of a typical dual DC input I/O power

supply module is shown in Figure 3.

Figure 2. Block Diagram of an AC I/O Power Supply Module

PD-6050

Figure3. Block Diagram of a DC I/O Power Supply Module.

Mar-06

3

Page 4

I/O Power Supply Assembly (T8060,T8062)

Each primary power input is individually fused and filtered with both

standard line filters and metal oxide varistors ( MOVs). The filters attenuate

any high-frequency common mode and normal mode noise present in the

power distribution system. The MOVs clamp high-voltage transients.

Filter, rectifier, and power factor correction circuits convert primary AC

input power to bulk DC voltage. The switching regulator converts bulk DC

power to regulated DC output voltage. Sensing, status, control, and timing

circuits provide for the following:

·

Input power failure - Active low status output. Indicates when the

input voltage is below 85 VAC or 18 VDC. There is a separate signal

for each input.

·

Bulk power failure - Active high status output on AC input modules

only. Indicates the DC bulk voltage (PFC output) is outside the

specified range. There is a separate signal for each input.

·

High-temperature warning alarm - Both an active high and active

low status output are provided. Indicates the module temperature

exceeds 75°C. The temperature is sensed near the air inle

the module.

·

High-temperature shutdown - Internal signal that will shut down the

t (bottom) of

switching regulator if module temperature is above 85 °C. The

temperature is sensed near the air inlet (bottom) of the module.

·

Output overvoltage - Internal signal that will shut down the switching

regulatorif the output voltage exceeds +18 VDC or +28 VDC for 15

volt and 24 volt modules respectively. Over-voltage protection circuitry

activation is a permanent error condition, requiri

to return module to normal operation.

·

DC output fail - Active high status output indicates the DC output

ng manual intervention

voltage has gone out of regulation. The DC output fail threshold is

13.75 VDC and 21.75 VDC (±0.25 VDC) for the 15 and 24 volt

module respectively.

·

Output current limiting - Internal signal limits output current in

excessive current demand situations.

4

Industrial Control Services

Page 5

I/O Power Supply Assembly (T8060,T8062)

·

POWER FAIL - Active high status signal that indicates impending loss

of output power due to one

-

Both inputs have indicated power failure

-

Remote off control signal activated

-

Thermal shutdown

-

Output overvoltage

·

RESET - Active high status signal that is generated a minimum of 10

of the following:

ms (AC input module) or 0.5 ms (DC input module) after a POWER

FAIL signal. RESET remains asserted for 200 ms (minimum) after

module power-up.

·

PFC off - Active low input that turns off the power factor correction of

an individual input. This signal provides the capability to test the input

circuitry

monitoring the module fail signal

of a module by turning off each input independently while

·

Remote off - Active low input that turns off the output power of a

module.

Note: Bulk Power Fail, PFC Off and Remote Off are accessed through the

monitor module connector on the chassis backplane. The monitor module

connector allows for a future development of a monitor card that would

provide remote control and enhanced monitoring of the power supply

chassis.

Active low signals are not maintained while RESET is act

signals are open collector and require external pull-up resistors.

ive. All status

RESET is used in the Regent I/O transceivers for power system interlocking

within the I/O system. A power failure (either input power or module fault)

activates RESET and turns off the DC output front panel indicator.

The POWER FAIL and RESET signals are required for proper operation

of Regent I/O transceivers and I/O modules during power up, power down,

and loss of power. Refer to

connect these signals to a Regent I/O chassis.

Assembly Installation

for details on how t

o

PD-6050

Mar-06

Front Panel Indicators

The front panel of each I/O power supply module contains the following

indicators:

5

Page 6

I/O Power Supply Assembly (T8060,T8062)

· Input Power Voltage Indicator

Each green INPUT POWER indicator is lighted when the associated

input (Input A, Input B) is above the lower input voltage threshold.

· Output Power Display

The 10-segment LED indicator bar displays the approximate output

current level percentage (0 - 100%)

· Output Power Indicator

The DC Output indicator is lighted when the I/O p

ower supply

module's DC output is within tolerance. Out-of-tolerance conditions,

loss of input power or brown-out, and module failures turn off this

indicator.

6

Industrial Control Services

Page 7

I/O Power Supply Assembly (T8060,T8062)

TB3

J13

J15

TB1

J14

19"

10.5"

J1 J2 J3 J4 J6J5

J7 J8 J12J11J9 J10

Input

Crossover

Patch

TB4

TB2

Installation

Chassis Mounting

Figures 4 and 5 show the front and rear views of the power supply chassis.

Figure 4. Power Supply Chassis Front View

Figure 5. Power Supply Chassis Rear View

PD-6050

Mar-06

7

Page 8

Input Crossover Patch configured for no crossover,

source 1 and source 2 are connected to input A and

input B respectively for all modules slots.

6E5 6E6

6E7 6E8

6E3 6E4

6E1 6E2

Input Crossover Patch configured to swap source 1

and source 2 for modules slots 4 through 6. Source 1

and source 2 are connected to input A and input B

respectively for slots 1-3. Source 1 and source 2 are

connected to input B and input

A respectively for slots

4-6.

Terminal

No.

T8200

T8202

Source

1 N DC- B

2

L

DC+

3 N DC- A

4

L

DC+

6E6

6E5

6E7 6E

6E3 6E

6E1

I/O Power Supply Assembly (T8060,T8062)

Mounting flanges can be attached to either the rear or the front of the

chassis. This allows flush mounting the chassis to a panel or mounting in a

19-inch rack.

The input crossover patch is on the T8200 chassis only.

Backplane Versions and Module Keying

Connector placement on AC input modules and backplanes differ from DC

modules and backplanes. This prohibits insertion of the wrong input module

type into a backplane.

Module slots in a chassis can be individually keyed to only accept a module

of an particular output voltage.

Input Power Terminals: TB1, TB2 (#8 screw terminals)

8

Industrial Control Services

Page 9

I/O Power Supply Assembly (T8060,T8062)

Terminal No.

Module Slot

T8200, T8202

12 6

11 5

10 4

+ DC Output

9 3

8 2

7 1

6

5

4 1-6 DC Return

3

(terminals 1-6 are

2

Connected together on

1 Backplane)

Pin

J14

J15

Slot Signal

Slot Signal

1

2

All

Input ‘A’ Fail

3

All

Input ‘B’ Fail

4

All

Hi Temperature

5

1

Reset 4

Reset

6

1

Power Fail

6

Reset

7

2

Reset 4

Power Fail

Output Power Terminals: TB3, TB4 (

#6 screw terminals)

Status Connectors: J14, J15

Type: 10 pin Shrouded Header, Double-Row, 0.100 x

0.100 Centers

Mfg.: AMP P/N: 102618-3

Mating Connector: AMP 87631-5

Pin Out:

PD-6050

Mar-06

9

Page 10

8

3

Power Fail

6

Power Fail

9

2

Power Fail

5

Power Fail

10 3

Reset 5

Reset

Available Load Units (for a set of 3 power supplies)

Number of I/O Units (Chassis):

Load Unit Capacity:

1 2

3

4

82 78 74 70

I/O Power Supply Assembly (T8060,T8062)

Monitor Connector: J13

Configuration

Current Sharing

The modules are capable of current sharing by connecting their outputs

together in parallel. This can be done external to the chassis or by using a

shorting bar that mounts directly to the output terminals on the chassis

backplane. This allows separate gro

chassis to have their outputs configured as: Single, Dual or N+1. The

module uses a passive “droop” method of current sharing and will share to

within 25% of the rated load.

Regent Power Supply Load Units

Type: 72 pin Edge Connector, 0.125” centerline

Mfg.: AMP

Mfg. P/N: 1Pin Out: TBD

530844-9

ups of modules from within a single

When using the power supply system with Regent and Regent+Plus , power

supply loading is based on the number of I/O modules in the I/O chassis

and the load imposed by each I/O module. Load units for each I/O module

are shown in that module’s product description and spec

under the

will provide the following load units:

10

Safetybus Power

ification sheet

heading. A set of three power supply modules

Industrial Control Services

Page 11

I/O Power Supply Assembly (T8060,T8062)

Calculating the number of load units in your system helps you to determine

the number of I/O power supplies your system needs. For economic power

distribution, and to avoid overloading individual power supply units,

calculate power supply loa

ding when configuring systems.

Regent I/O Triplicated Power Distribution

A chassis can contain two sets of triple-redundant power supplies for

Regent I/O. Each of the triple-redundant I/O power supply modules within

the I/O power supply chassis provides power for one leg of the three

redundant legs of the I/O Safetybus transceivers, and provides power to all

the I/O modules within its associated I/O chassis. Each I/O module contains

a diode OR power-sharing circuit that receives power from all three I/O

pow

er supply modules.

Should any I/O power supply module fail, only one leg of the transceiver

modules loses power: the two remaining legs maintain proper Regent

operation. In addition, all the I/O modules continue to operate properly by

drawing their current from the two remaining power supplies within the I/O

power supply assembly.

I/O transceivers and I/O modules require power fail and reset status signals

for proper operation.

PD-6050

Mar-06

11

Page 12

TB3

J15

J14

6

6

{

Two Sets of Triplicated Power

and Status to Regent I/O

Chassis

{

IInput

Crossover

Patch

123

45678

91011

12

T8200 Chassis

Source B

Source A

TB3

J15 J14

10

{

Triplicated 15 Volt Power and

Status for Regent I/O Chassis

Input

Crossover

Patch

1

2

3

4

5

6

7

8

9

10

11

12

T8201 Chassis

Source B

Source A

T8220 Dual AC Input, 15 VDC Output

T8220 Dual AC Input, 15 VDC Output

T8225 Dual AC Input, 24 VDC Output

T8223 Single AC Input, 24 VDC Output

Dual 24 V Power and Status for

Trusted ICS

24 V Power for Field Devices

{

{

6

4

T8220 Dual AC Input, 15 VDC Output

T8225 Dual AC Input, 24 VDC Output

TB3

J15

J14

6

{

{

IInput

Crossover

Patch

121110

98765

432

1

T8200 Chassis

Source B

Source A

N+1 Power For Field Devices

Triplicated Power and Status

For Regent I/O Chassis

I/O Power Supply Assembly (T8060,T8062)

Sample Chassis Configurations

Two Sets of Triplicated 15 V Regent Power

12

Triplicated 15 V Regent and Redundant 24 V Trusted ICS Power

Industrial Control Services

Page 13

I/O Power Supply Assembly (T8060,T8062)

Triplicated 15 V Regent and 24 V N+1 Field Power

Maintenance

No periodic maintenance or calibration is required for I/O power supply

modules. There are no user-replaceable parts.

A failed I/O power supply module can be hot-replaced without disrupting

system operations. Main power wiring and I/O power cables (connected

to the chassis) are not disturbed during module replacement.

Safety Considerations

The power sup

Risk Class 5 safety critical applications.

ply modules and chassis are TÜV certified for

PD-6050

Mar-06

13

Page 14

Voltage Range

T8220, T8223, T8224, T8225

T8222, T8226

85 to 264 VAC

20 to 30 VDC

Frequency Range

T8220, T8223, T8224, T8225

47 to 63 Hz

Inrush Current

(120/260 Vac)

T8220, T8223, T8224, T8225

20/40A (peak) Cold,

35/65A (peak) Hot

Power Factor

0.95 min.

Efficiency

70%

Use with Chassis

T8220, T8223, T8224, T8225

T8222, T8226

T8200

T8202

Fusing (Internal to module)

T8220, T8223, T8224, T8225

T8222, T8226

6A, 250 V, 3AG Slow Blow

20 A, 250 V, 3AB Slow Blow

Output Voltage

T8220, T8223, T8224, T8225

T8222, T8226

+15 volts

+24 volts

Output Power

250W, per module

Power Hold-up Time

T8220, T8223, T8224, T8225

T8222, T8226

20 msec, minimum

1 msec, minimum

Operating Temperature

Natural Convection

Forced Air (>20 lf/min)

-20°

to 50° C

-20°

to 70° C

Storage Temperature

-40°

to 85° C

(-40° to 185° F)

I/O Power Supply Assembly (T8060,T8062)

Specifications

14

Industrial Control Services

Page 15

I/O Power Supply Assembly (T8060,T8062)

Operating Humidity

0 to 95% relative humidity, non

-

condensing

Vibration

10 to 55 Hz:

±0.15mm

Shock

Operating:

15 g, ½ sine wave, 11 msec

Electromagnetic Interference

•

IEC 801 Part 2 - Electrostatic

Discharges

•

IEC 801

Part 3 - Radiated

Electromagnetic Fields

•

IEC 801 Part 4 - Transients

and Bursts

•

IEC 801 Part 5 - Surge

Immunity

•

ANSI/IEEE C37.90 - Surge

Withstand Capability

Level 3: Contact discharge of

6 kV

Level 3: 10 V/M, 27 MHz

-

500 MHz

Level 4: 2 kV, 2.5 kHz for

t = 60 sec

Level 3: 2 kV

2.5 kV damped 1 MHz sine

wave

4 kV bi-directional impulse, 10

nsec rise time, fast tran

sient

Safety

Certified to DIN V VDE 0801

for Risk Class 5. Also designed

to meet UL 508 and CSA 22.2,

No. 142-M1981

Module Dimensions

Height:

Width:

Depth:

10.47" ( 266 mm)

2.38" ( 61 mm)

12.5" (318 mm)

Chassis Dimensions

Height:

Width:

Depth:

10.47" ( 266 mm)

19" ( 483 mm)

13.5" (343 mm)

Specifications (Continued)

PD-6050

Mar-06

15

Page 16

Module Weight

6.9 lbs (3.2 kg)

I/O Power Supply Assembly (T8060,T8062)

16

Industrial Control Services

Loading...

Loading...