Page 1

SDS-8030

TM

Trusted

Industrial Control System

TrustedTM OPC Server-T8030

OPC DISPLAY

DESCRIPTION

OPC ( OLE for Process Control ) is an industry

standard for transferring process data between

a server and one or more client applications.

The Trusted

link between a Trusted

OPC clients. Using Ethernet Interface cards

within the Servers host PC, it connects to one

or more Trusted

applications can connect to the server using

Microsoft COM ( or DCOM over a network ).

Each client can browse the server to view the

available tag references. Using these

references, the clients can then arrange for

groups of tags to be synchronously updated at

defined intervals. Values may also be written

asynchronously to the server.

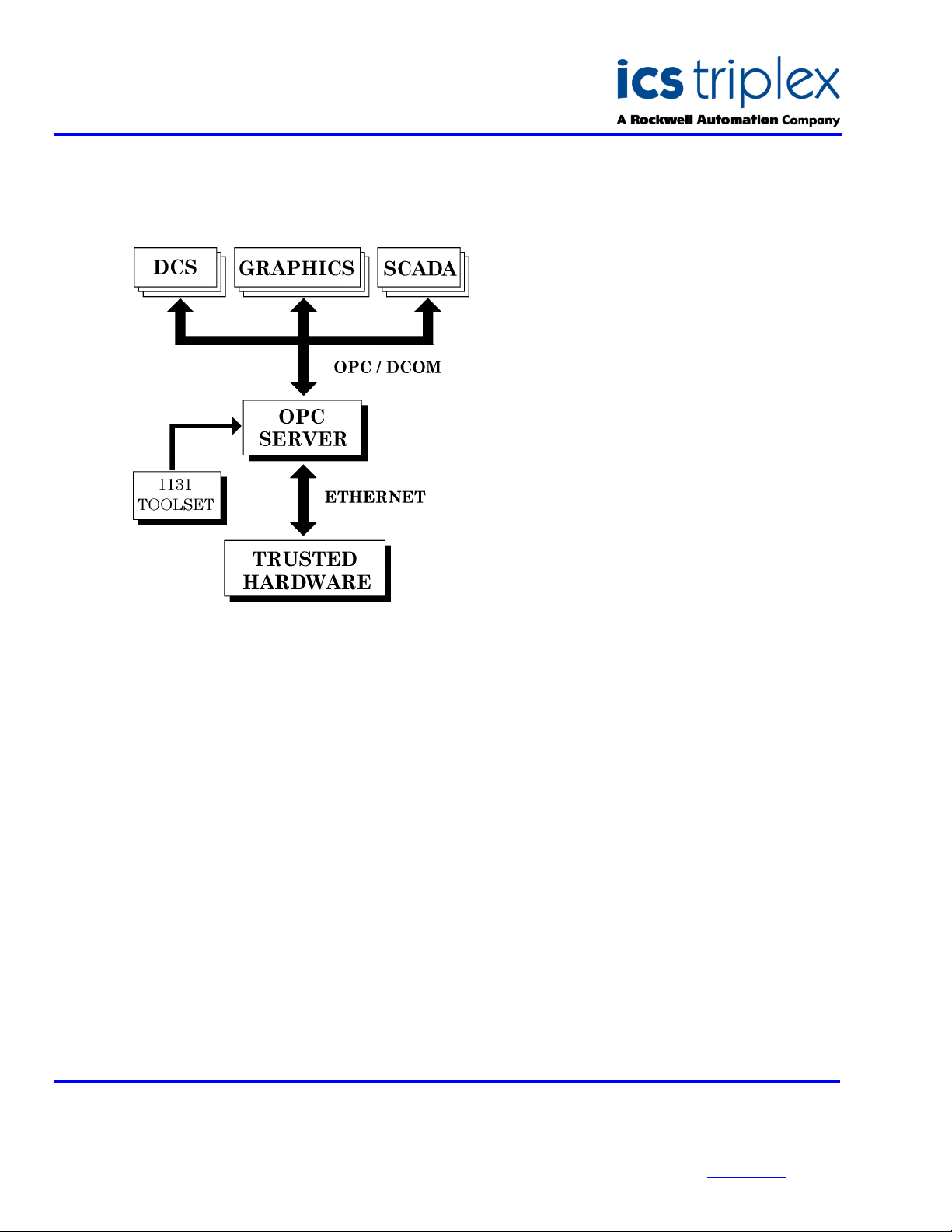

The block diagram overleaf shows how the

OPC Server fits between the Trusted

hardware and one or more OPC client

applications.

The server OPC Server may be considered to

comprise three main functions. These are; the

Browse Interface, the OPC Server Group

Interface and the Communications Interface.

TM

OPC Server provides an OPC

TM

TM

and one or more

Controllers. OPC client

TM

The server provides a list of tag

references that OPC clients can browse

in a standard manner. The root node is

the Trusted

sub-items are groups, which are used to

configure and locate the tag names,

which may be located within them.

These tags are then identified by the full

path name of the tree.

When a client attaches to the server, a

unique server object is created within

the main Trusted

client can create and edit groups within

this server object. Each group has a

number of tag references and an update

rate. Every time the tags are to be

updated, the server will inform the client

of the new values, quality, time, etc.

When the groups within an OPC server

request tag data is to be updated, the

tag references are passed to the

communications interface. This will

read the values from the appropriate

Trusted

tag data back to the server groups.

Data can also be written to the tags.

The tag references and values are

passed to the communications interface,

which will then send the data to the

appropriate Trusted

TM

Ethernet Interface. All

TM

OPC server. The

TM

Controller and will supply the

TM

Controller.

FEATURES

Industry standard

interface (OLE for

Process Control

V2.0)

Single or Dual

redundant link to a

Trusted

Handles multiple

Trusted

Controllers

TM

System

TM

Update rate of up to

10ms

Events time

stamped to a

resolution of 1ms

Collects SOE and

Process Historian

data

Automatically

interfaces to

TOOLSET

tag references in

Trusted

Controllers

IEC1131

to obtain

TM

On-line monitoring

of tag values

Customised tree

view of available

controllers

Runs as a Windows

Service

Issue 6 Jan 2006

Page 2

SDS-8030

Trusted

TM

Industrial Control System

TrustedTM OPC Server-T8030

BLOCK DIAGRAM

MECHANICAL

SPECIFICATION

There are no Mechanical

Specifications associated

with this Product

ENVIRONMENTAL

There are no

Environmental

Specifications associated

with this Product

ELECTRICAL SPECIFICATION

There are no Electrical Specifications associated with this Product.

ICS Triplex

Technical data sheets are intended for

information and guidance. The Company

has a policy of continual product

development and improvement.

Specifications are subject to change

without notice. For latest information, visit

our Websi te:- www.icstr iple x.com

Loading...

Loading...