Page 1

TrustedTM

PD-T8019

TM

Trusted

Process Control Algorithm

Software Package

Introduction

M

The system architecture of the Trusted

interlock applications as is possible. The control algorithms detailed in this Product Description are

primarily intended to support the limited process control capabilities required for Floating Production,

Storage and Offloading (FPSO) installations. The algorithms may also be used for other process

control applications as required.

Control functions require the use of floating point values. This ultimately limits the integrity that can be

attributed to these functions because of the introduction of an element of “loss of precision” and the

general inability to exhaustively verify floating-point capabilities.

T

is intended to cover as large a cross section of control and

The functions are integrated into the IEC1131 TOOLSET execution environment. This environment is

“Commercial-Off-The-Shelf (COTS)” and designed to commercial standards. The overall system

achieves higher levels of integrity by the use of additional on-line monitoring and internal state control.

The combination of the above factors indicate that the target integrity for the basic process control

functions should be SIL1 (AK3). These functions should therefore NOT be used within elements of

application programs intended for SIL3 (AK6) use.

TM

The control algorithms are executed within the Trusted

program and are divided into ‘functions’ and ‘function blocks’.

‘Functions’ are those algorithms with no internal state, or time dependent operation, i.e. they have no

storage element. The functions process the defined number of parameters and return a single

resultant state or value. Functions, therefore, have only a single operating mode, always performing

the same operation.

The ‘function blocks’ include retentive information and may return multiple values. Function blocks will

have an initial state or value for each of their outputs. The initial value may be maintained for a single

or multiple application iterations, depending on the detail of the algorithms.

Controller as part of the standard application

Issue 8 Sep 07 PD-T8019 1

Page 2

Trusted

Issue Record

Issue

Number Date Revised by Technical CheckAuthorised by Modification

6 Oct 05 J W Clark Format

7 Dec 06 N Owens I Vince P Stock Example PID loop

8 Sep 07 N Owens I Vince P Stock Corrections

TM

Process Control Algorithms T8019

Issue 8 Sep 07 PD-T8019 2

Page 3

Trusted

TM

Process Control Algorithms T8019

This page is intentionally blank

Issue 8 Sep 07 PD-T8019 3

Page 4

Trusted

TM

Process Control Algorithms T8019

Table of Contents

1. Description...................................................................................................................................7

1.1. Functions .....................................................................................................................................8

1.1.1. Square Root Extraction................................................................................................................8

1.2. BCD Translation...........................................................................................................................9

1.3. Analogue Select.........................................................................................................................10

1.4. Multiple Value Averaging ...........................................................................................................10

1.5. Drum Level Control....................................................................................................................11

1.6. Mass Flow Computation ............................................................................................................11

2. Function Blocks .........................................................................................................................12

2.1. Analogue Scaling .......................................................................................................................12

2.2. Analogue Value Clamping .........................................................................................................13

2.3. Low Value Select .......................................................................................................................13

2.4. High Value Select ......................................................................................................................14

2.5. Median Value Select ..................................................................................................................14

2.6. Proportional PID Function..........................................................................................................15

2.7. Incremental PID Function ..........................................................................................................17

2.8. Deviation Alarm..........................................................................................................................19

2.9. Manual Tracking ........................................................................................................................19

2.10. Time Averaged Value ................................................................................................................20

2.11. Rate of Change Detection..........................................................................................................22

2.12. Analogue Value Slew.................................................................................................................24

3. Other Functions .........................................................................................................................25

3.1. Lead/Lag Control .......................................................................................................................25

4. Sample Application Program .....................................................................................................26

Figures

Figure 1 PID Function.............................................................................................................................16

Figure 2 IPID Function............................................................................................................................18

Figure 3 Sample Application Program ....................................................................................................26

Tables

Table 1 Error Statistics .............................................................................................................................7

Table 2 BCD Translation ..........................................................................................................................9

Table 3 Example Time Average .............................................................................................................21

Issue 8 Sep 07 PD-T8019 4

Page 5

Trusted

TM

Process Control Algorithms T8019

Notice

The content of this document is confidential to ICS Triplex Technology Ltd. companies and their

partners. It may not be given away, lent, resold, hired out or made available to a third party for any

purpose without the written consent of ICS Triplex Technology Ltd.

his document contains proprietary information that is protected by copyright. All rights are reserved.

T

Microsoft, Windows, Windows 95, Windows NT, Windows 2000, and Windows XP are registered

trademarks of Microsoft Corporation.

The information contained in this document is subject to change without notice. The reader should, in

all cases, consult ICS Triplex Technology Ltd. to determine whether any such changes have been

made. From time to time, amendments to this document will be made as necessary and will be

distributed by ICS Triplex Technology Ltd.

Information in this documentation set may be subject to change without notice and does not represent

a commitment on the part of ICS Triplex Technology Ltd.

The contents of this document, which may also include the loan of software tools, are subject to the

confidentiality and other clause(s) within the Integrator Agreement and Software License Agreement.

No part of this documentation may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and recording, for any purpose, without the express

written permission of ICS Triplex Technology Ltd.

Disclaimer

The illustrations, figures, charts, and layout examples in this manual are intended solely to illustrate the

text of this manual.

The user of, and those responsible for applying this equipment, must satisfy themselves as to the

acceptability of each application and use of this equipment.

This document is based on information available at the time of its publication. While efforts have been

made to be accurate, the information contained herein does not purport to cover all details or variations

in hardware or software, nor to provide for every possible contingency in connection with installation,

operation, or maintenance. Features may be described herein which are present in all hardware or

software systems. ICS Triplex Technology Ltd. assumes no obligation of notice to holders of this

document with respect to changes subsequently made.

ICS Triplex Technology Ltd. makes no representation or warranty, expressed, implied, or statutory with

respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness of

the information contained herein. No warranties of merchantability or fitness for purpose shall apply.

Issue 8 Sep 07 PD-T8019 5

Page 6

Trusted

TM

Process Control Algorithms T8019

Revision and Updating Policy

All new and revised information pertinent to this document shall be issued by ICS Triplex Technology

Ltd. and shall be incorporated into this document in accordance with the enclosed instructions. The

change is to be recorded on the Amendment Record of this document.

Precautionary Information

WARNING

Warning notices call attention to the use of materials, processes, methods, procedures or limits which

must be followed precisely to avoid personal injury or death.

CAUTION

Caution notices call attention to methods and procedures which must be followed to avoid damage to

the equipment.

Notes:

Notes highlight procedures and contain information to assist the user in the understanding of the

information contained in this document

Warning

RADIO FREQUENCY INTERFERENCE

Most electronic equipment is influenced by Radio Frequency Interference (RFI). Caution should be

exercised with regard to the use of portable communications equipment around such equipment.

Signs should be posted in the vicinity of the equipment cautioning against the use of portable

communications equipment.

MAINTENANCE

Maintenance must be performed only by qualified personnel, otherwise personal injury or death, or

damage to the system may be caused.

Caution

HANDLING

Under no circumstances should the module housing be removed.

Associated Documents

Product Descriptions (PD) provide product specific information.

The Safety Manual contains the recommended safety requirements for the safety system design.

The PD8082B – Toolset Suite provides specific guidance on system configuration and application

generation.

The Operator and Maintenance Manual contains general guidelines on maintenance and diagnostic

procedures.

For technical support email: support@icstriplex.com

Issue 8 Sep 07 PD-T8019 6

Page 7

Trusted

TM

Process Control Algorithms T8019

1. Description

Several of the basic control algorithms may generate error conditions at run-time as all function

arameters are variable. This may result in reversed parameters, e.g. max < min, overflow and

p

underflow conditions, divide by zero errors, etc. For each function, the required output under these

conditions is defined and error counters are incremented. These error counters are available to the

application programmer using the error statistics function block.

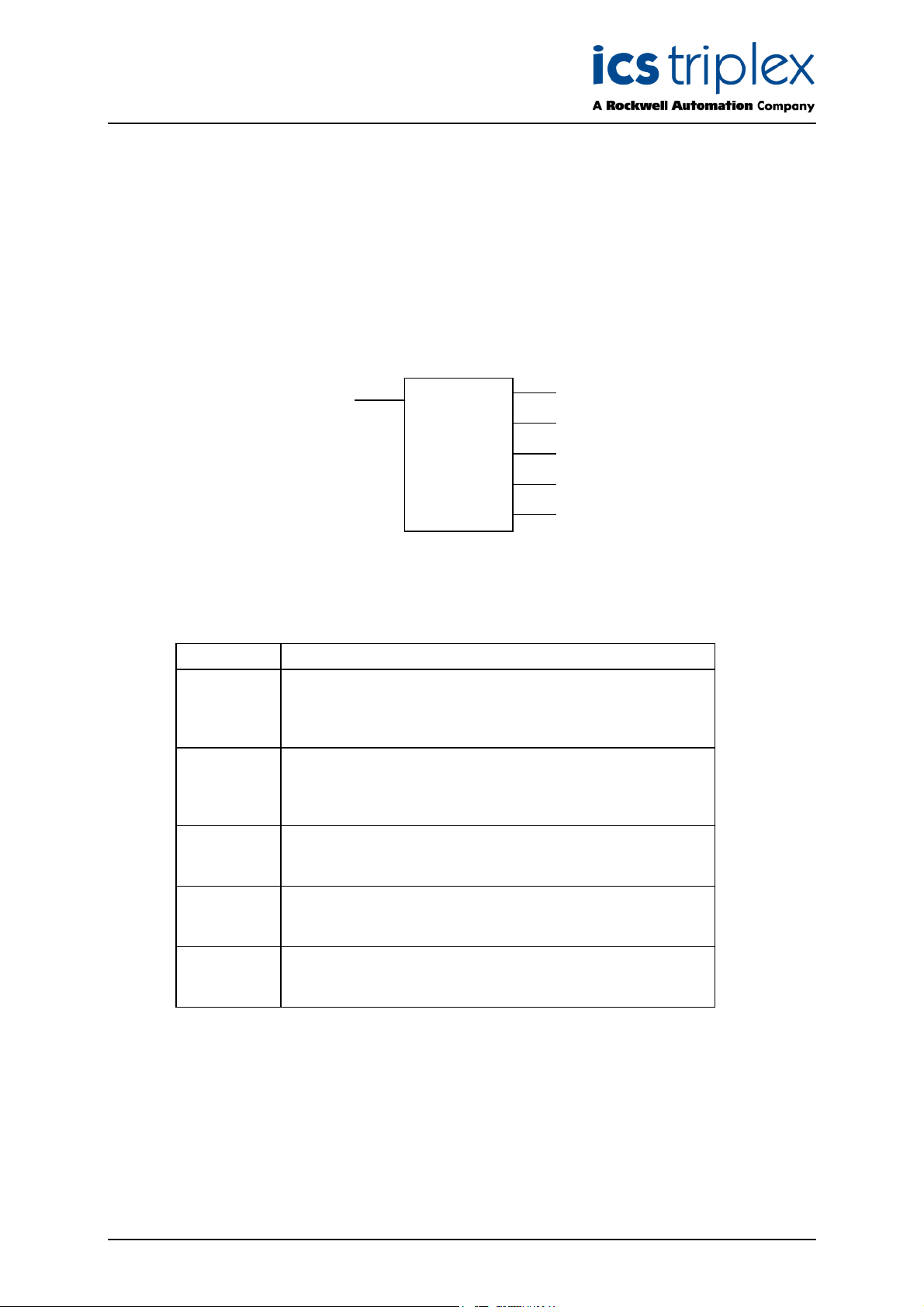

The function block has a single Boolean input that is used to reset the counters. Whilst this input is

true, the error counters will be reset to zero. The initial value of all error counters is zero.

eversed

RESET

ERRSTAT

R

Param

Overflow

Underflow

Data types are

1. RESET Boolean

2. All others Integer

Output Error condition

Reversed Pairs of function parameters are reversed, i.e. max<min.

Param A function parameter is incorrect, e.g. out of range or not

Overflow An overflow error occurred in the execution of the function.

Underflow An underflow error occurred in the execution of the function.

Zero Divide A divide by zero error occurred in the execution of the

Zero Divide

The associated function has reversed the two values in order

to obtain a valid result. The count is incremented on each

iteration of the function whilst the parameters are reversed.

consistent with the functions required operation. The count

is incremented on each iteration of the function whilst the

parameter is incorrect.

The count is incremented on each iteration of the function

whilst the overflow condition occurs.

The count is incremented on each iteration of the function

whilst the underflow condition occurs.

function. The count is incremented on each iteration of the

function whilst the divide by zero condition occurs.

Table 1 Error Statistics

Issue 8 Sep 07 PD-T8019 7

Page 8

Trusted

()(

)

TM

Process Control Algorithms T8019

1.1. Functions

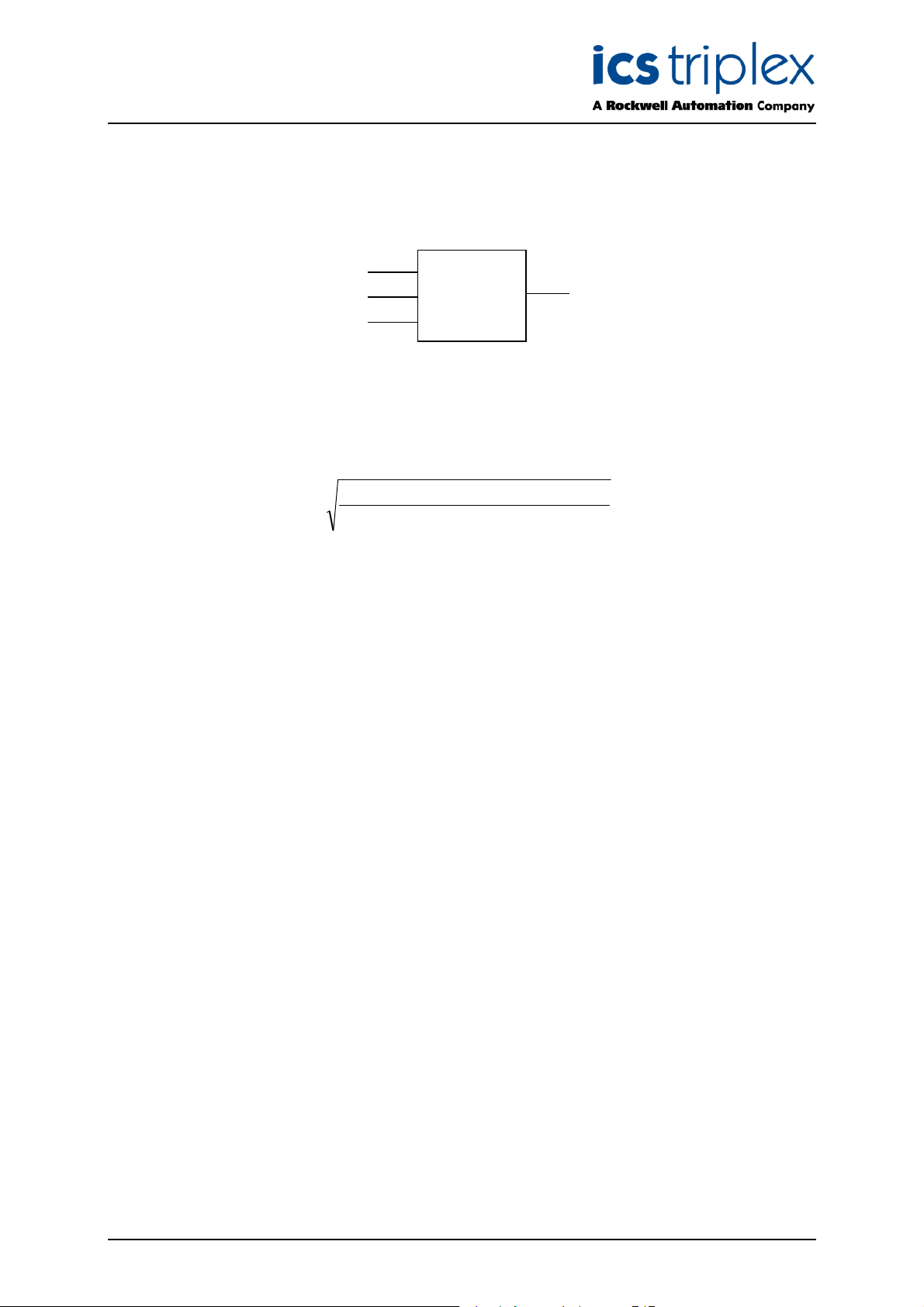

1.1.1. Square Root Extraction

SQRTX

OUT

IP

IP

PV

MAX

MIN

The Process Variable (PV) is scaled to a value 0…1 according to maximum input value (IP

minimum input value (IP

i.e. a value greater than maximum input will use the IP

will use the IP

value. The square root of the resulting value is then taken and is returned as a

MIN

). Out of range values will result in the value being clamped to the range,

MIN

value, similarly a value below the minimum

AX

M

MAX

) and

percentage.

i.e.

IPIP,IPPV,MaxMin

MINMAXMIN

100

×

Note: All inputs (PV, IP

If IP

MAX

< IP

, the function assumes that the values have been reversed and “swap” the values. The

MIN

MIN

OUT

=

and IP

IP -IP

MINMAX

) and the returned value OUT must be real.

MAX

“reversed” error counter is incremented each time the function has to swap the parameters.

If IP

MAX

= IP

, the function returns a value of zero and increments the “zero divide” error counter to

MIN

indicate that a divide by zero error would have occurred.

If PV is not a number (NaN), the function returns a value of zero and increments the “Param” error

counter.

All input range parameters (IP

MIN

and IP

) must be finite, i.e. not ±infinities or NaNs. Behaviour is not

MAX

defined for any other values.

If PV is not a NaN, and an overflow or underflow condition occurs the function returns zero and

increment the corresponding error counter.

Issue 8 Sep 07 PD-T8019 8

Page 9

Trusted

()(

)

TM

Process Control Algorithms T8019

1.2. BCD Translation

IP0

I

P1

IP2

IP3

M

N

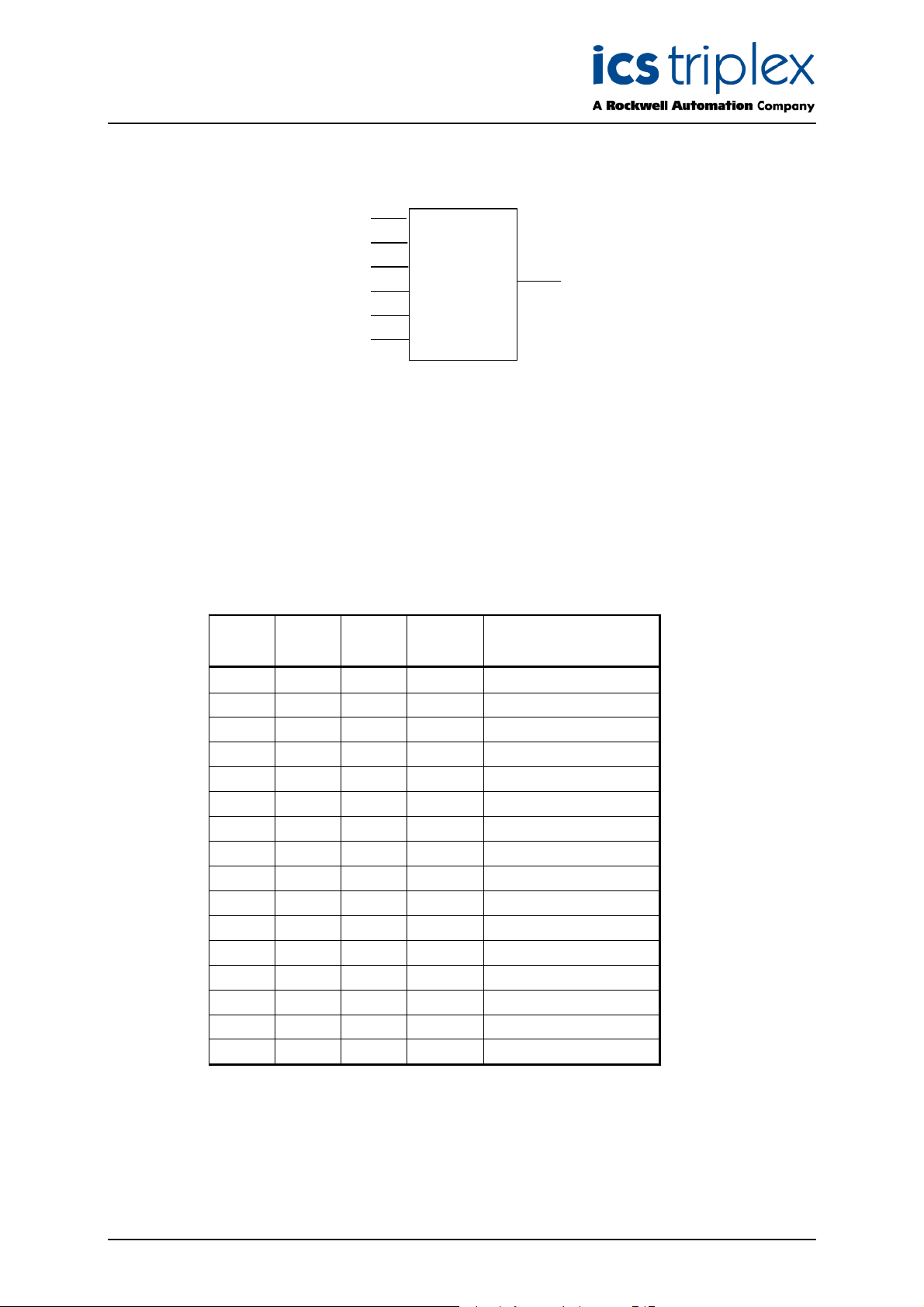

The BCD translation function requires the 4-bit BCD value represented as 4 Boolean parameters (IP0,

IP1, IP2, and IP3), IP0 being the least significant bit, IP3 the most significant bit. All four inputs must

be defined; inputs not required for specific application must be set to FALSE. M and N are of type

integer.

M specifies the value multiplier and must be a power of 10, i.e. 1, 10, 100, etc. N allows the BCD

functions to be cascade, by adding the value from a previous function. A value of -1 is assumed to be

the result of an up-stream conversion error and will result in all chained BCD functions generating

values of -1. The returned value OUT is an integer.

BCD

OUT

NMIP3IP2,IP1,IP0,BCDOUT +×=

Invalid BCD number (see table below) are to result in OUT = -1.

IP3

IP2

IP1

IP0

OUT

(with M=1 and N=0)

0 0 0 0 0

0 0 0 1 1

0 0 1 0 2

0 0 1 1 3

0 1 0 0 4

0 1 0 1 5

0 1 1 0 6

0 1 1 1 7

1 0 0 0 8

1 0 0 1 9

1 0 1 0 -1

1 0 1 1 -1

1 1 0 0 -1

1 1 0 1 -1

1 1 1 0 -1

1 1 1 1 -1

Table 2 BCD Translation

Multiple values (M) that are not powers of 10 are to result in a value of -1. If an overflow condition

occurs, the function is to return a value of -1 and increment the “Overflow”, error counter.

Issue 8 Sep 07 PD-T8019 9

Page 10

Trusted

TM

Process Control Algorithms T8019

1.3. Analogue Select

SEL

PV1

PV2

R_SEL

OUT

The process variables (PV1 and PV2) and the output (OUT) must all be of type REAL

1

. The select

signal (SEL) is of type BOOLEAN. When SEL is FALSE, PV1 is copied to the output; when SEL is

TRUE, PV2 is copied to the output.

if SEL

Set OUT = PV2

else

Set OUT = PV1

end if

Out is finite if, and only if, the selected PV1 or PV2 is finite.

1.4. Multiple Value Averaging

N

PV1

PV2

PV3

PV4

PV5

PV6

PV7

PV8

PV9

PV10

AVG

OUT

The multiple value averaging calculates the average of between 1 and 10 values (PV1 to PV10). N

specifies the number of values averaged; the first N values are averaged. E.g. if N=3, the average of

PV1, PV2 and PV3 is returned. N is of type INTEGER, PV1 to PV10 and OUT are of type REAL. All

input values must be connected; unused inputs should be tied to either one of the other used inputs or

a constant value.

If the value of N is out of range, i.e. 1>N>10, the average of all ten input values is to be returned and

the “param” error count incremented. Overflow errors occurring whilst calculating the average are to

result in a value of PV1 being returned and the “overflow” error count incremented. If an “underflow”

condition occurs, the function is to set OUT to zero and increment the “underflow” error counter.

1

Issue 8 Sep 07 PD-T8019 10

The standard ISaGRAF SEL function provides the equivalent operation for integer values.

Page 11

Trusted

LV

(

)

(

)

(

)

(

)

TM

Process Control Algorithms T8019

1.5. Drum Level Control

PP

This function is to provide the pressure compensated drum level. PP is the differential pressure, and

LV is the level in percentage of full-scale, the output (OUT) is return as a value 0 to 100%. PP, LV and

OUT are all of type REAL. The function additionally to compensates for the reverse acting output of the

level input (increasing PP value of decreasing differential pressure).

OUT

=

Underflow, overflow and divide by zero error conditions are to result in value of zero being returned and

the corresponding error counter incremented.

PC_DRUM

OUT

3

LV P105.43101

××

3

P100.1730.88

××

1.6. Mass Flow Computation

Error! Objects cannot be created from editing field codes.

The mass-flow computation block provides the mass flow corrected for the current operating

conditions.

hemZCOUT

+

××××××=

()

+

14.7P

273T

PP is the differential pressure, P is pressure and T is temperature. C, Z, m, e and h are intended to be

constant values. All parameters are of type REAL.

0

PP and P are in psi, T is in

If T=-273, a divide by zero error condition is generated, this is to increment the associated error

counter and the mass flow function is to return a value of -1. Over and underflow conditions are to

result in an output value of -1 and increment the associated error counter.

C.

Issue 8 Sep 07 PD-T8019 11

Page 12

Trusted

PV

MAX

MAX

()(

)

TM

Process Control Algorithms T8019

2. Function Blocks

2.1. Analogue Scaling

SCALE

IP

OUT

OUT

IP

MIN

M

IN

OUT

LIMIT

The scale function linearly scales the input value (PV) according to the low input (IP

), low output (OUT

(IP

AX

M

to IP

IP

MIN

greater than IP

between OUT

. I.e. a PV value less than IP

MAX

results in the IP

MAX

and OUT

MIN

indicate that the input value (PV) is out of range, i.e LIMIT = IP

) and high output (OUT

IN

M

MIN

value being used). The output (OUT) value varies linearly

as the input (PV) varies between IP

MAX

MAX

) values. The input value is clamped to the range

AX

M

results in the IP

value being used, similarly a value

MIN

min

>PV>IP

MIN

and IP

. The LIMIT output is to

MAX

, LIMIT is set TRUE if PV

MAX

), high input

MIN

is out of range.

, IP

IP

MAX

MIN

, OUT

and OUT

MAX

are typically constants but may, in practise, use any analogue or

MIN

register value.

OUTOUTOUT

MINMINMAX

Note: PV, IP

OUT +

=

MAX

, IP

, OUT

MIN

MAX

IP-IP

and OUT

MINMAX

have to be of type REAL, the result (OUT) is returned as

MIN

IPIP,IPPV,MaxMin

MINMAXMIN

()

×

type REAL and LIMIT is of type BOOLEAN.

MAX

< IP

If IP

Similarly, if OUT

, the function is to assume that the values have been reversed and “swap” the values.

MIN

MAX

< OUT

the two values are to be swapped. In both cases, the “reversed” error

MIN

counter is to be incremented each time the function has to swap the parameters. All range parameters

, IP

(IP

MAX

MIN

, OUT

MAX

, OUT

) must be finite, i.e. not ±infinities or NaNs. Behaviour is not defined for

MIN

any other values.

If IP

MAX

= IP

, the function is to set OUT to OUT

MIN

, LIMIT to FALSE and increment the “Zero Divide”

MIN

error counter to indicate that a divide by zero error would have occurred.

If PV is a NaN, the function is to set OUT to OUT

, LIMIT to FALSE and increment the “Param” error

MIN

counter. If PV is not a NaN and overflow or underflow conditions occur during the execution of the

function, the function is to set OUT to OUT

or OUT

MAX

respectively, LIMIT to FALSE and increment

MIN

the corresponding error counter. If both overflow and underflow conditions occur, the function is to set

OUT to OUT

Issue 8 Sep 07 PD-T8019 12

, LIMIT to FALSE and increment both corresponding error counters.

MIN

Page 13

Trusted

()(

)

(

)

TM

Process Control Algorithms T8019

2.2. Analogue Value Clamping

CLAMP

OUT

LIMIT

IP

IP

MIN

PV

MAX

The process variable (PV), IP

(OUT) is clamped to the range specified by IP

Boolean, is set to TRUE if the clamp is in operation, i.e. LIMIT = IP

If IP

MAX

<IP

, the parameters are to be “swapped” and the reversed error count incremented.

MIN

Input range parameters (IP

M

IP,IPPV,MaxMin OUT =

and IP

IN

M

AX

MAXMIN

, IP

and OUT values are all of type REAL2. The output value

IN

M

) must be finite, i.e. not ±infinities or NaNs. Behaviour is

AX

M

and IP

MIN

. The LIMIT output, which is of the type

MAX

>PV>IP

MIN

MAX

.

undefined for any other values. If PV is a NaN, the function is to set OUT to OUT

“Param” error counter.

2.3. Low Value Select

PV1

PV2

The process variables (PV1 and PV2) and the output (OUT) are all REAL values

is set to the lower of the two process variable values.

LVS

OUT

SEL

and increment the

MIN

3

. The output (OUT)

PV2PV1,MINOUT =

The SEL output indicates which of the process variables is being used to generate OUT. SEL is of

type BOOLEAN, and is FALSE if using PV1 and TRUE if using PV2.

If PV1 or PV2 is a NaN, the function is to set OUT to PV1, SEL to FALSE and increment the “Param”

error counter. OUT is not a NaN if, and only if, PV1 is not a NaN and finite if, and only if, the lower of

PV1 and PV2 is finite.

2

integer values (without the limit output).

3

(without the SEL output).

The standard ISaGRAF LIMIT function provides the equivalent of the CLAMP operation for

The standard ISaGRAF MIN function provides the equivalent functionality for integer values

Issue 8 Sep 07 PD-T8019 13

Page 14

Trusted

(

)

TM

Process Control Algorithms T8019

2.4. High Value Select

PV1

PV2

The process variables (PV1 and PV2) and the output (OUT) are all REAL

the higher process variable value.

HVS

OUT

SEL

4

. The output (OUT) is set to

PV2PV1,MAXOUT =

The selected output (SEL) indicates which of the process variables is being used to generate OUT.

SEL is of type Boolean, and is FALSE if using PV1 and TRUE if using PV2.

If PV1 or PV2 is a NaN, the function is to set OUT to PV1, SEL to FALSE and increment the “Param”

error counter. OUT is not a NaN if, and only if, PV1 is not a NaN and finite if, and only if, the higher of

PV1 and PV2 is finite.

2.5. Median Value Select

PV1

PV2

PV3

DEVIATION

The median value select sets OUT to the mean of the three process variables (PV1, PV2 and PV3) if

the deviation between their values is less than the maximum (DEVIATION). If the variation in inputs is

less than the allowed deviation the LIMIT output is set to FALSE. If the input values vary by more than

DEVIATION, OUT is set to the median value and LIMIT is set to TRUE.

MVS

OUT

LIMIT

If an overflow condition occurs during the execution of the function, e.g. if the deviation is huge, the

function is to set OUT to the median value, LIMIT to TRUE, and increment the “overflow” error counter.

All input parameters (PV1, PV2, PV3 and DEVIATION) must be finite, i.e. not ±infinities or NaNs.

4

(without the SEL output).

The standard ISaGRAF MAX function provides the equivalent functionality for integer values

Issue 8 Sep 07 PD-T8019 14

Page 15

Trusted

PV

X

TM

Process Control Algorithms T8019

2.6. Proportional PID Function

NOTE

The PID_II function block has been superseded by the IPID function block, which provides incremental

ID and enhanced functions. All new strategies should use IPID. PID_II is retained for compatibility,

P

but may be replaced in an application by IPID if desired.

A PID is a process regulator. Using the feedback concept, an output is regulated according to the

difference between its current value (PV) and its required value (SP).

PID-II

S

INC

DEC

Auto

XO

Kp

Td

Ts

X

MAX

X

MIN

STOP

STOP

P

Ti

OUT

LIMIT

LIMIT

HI

LO

Auto is the auto/manual mode select (type BOOLEAN). When set to TRUE the PID calculation is in

auto mode. XO is the manual set-point and is type REAL. Kp is the proportional constant (type

REAL). Ti is the integral time constant (type TIMER). If this is set to zero the function provides only the

P and D terms. Td is the derivative time constant (type TIMER). Ts is the sample time (type TIMER).

If the specified sample time is less than the application program scan time, then the effective Ts will be

the greater of the application scan time or PID function execution interval.

Issue 8 Sep 07 PD-T8019 15

Page 16

Trusted

S

TM

Process Control Algorithms T8019

The figure 1 below gives a simplified overview of the PID function:

SP

1

T

+

-

PV

e

Error

Kp

Proportional

TK

DP

d

dt

Integral

+

Xout

+

-

Derivative

Figure 1 PID Function

At entry the error

S is calculated as the difference between the set-point (SP) and the process variable

(PV). This error value is used in the calculation of the proportional and integral terms. The derivative

term is derived from PV as shown.

INC

prevents the output X

STOP

increasing when TRUE. When this input is TRUE and the PID is in

OUT

AUTO mode, the output is compared with the previous output and only values less than or equal to the

previous output will be returned and LIMIT

provide windup protection. Similarly, when DEC

or equal to the previous value, and LIMIT

will be set to TRUE. The integral term is also adjusted to

I

H

will be set to TRUE.

LO

is TRUE Xout will only return values greater than

STOP

In manual mode (AUTO = False), the output (Xout) follows the input XO. The function provides

manual to automatic bumpless transfer by adjusting the integral term. If set-point tracking is required

then the MANTRK function should be used in conjunction with the PID_II function.

The PID function provides reset windup protection by allowing high and low limits (Xmax and Xmin) to

be specified and anti-reset windup on the integral term. If the PID output would have exceeded the

specified high or low limits, the corresponding limit output (LIMIT

and LIMITLO) is generated. Note

HI

that the limit outputs are updated on each iteration of the PID function. The maximum and minimum

limits on Xout apply in both auto and manual modes.

In auto mode, the PID function will return only the proportional element on the first application scan,

and will the integral and derivative terms.

If Xmax < Xmin, the function assumes that the values have been reversed and “swaps” the values. On

each execution of the PID_II function with reversed parameters the ‘reversed’ error count will be

incremented. If an overflow condition occurs during the execution of the PID function the output Xout

will be set to Xmin in auto mode or XO in manual mode, and the integral term will be adjusted to

provide windup protection.

Issue 8 Sep 07 PD-T8019 16

Page 17

Trusted

PV

X

Tdf

TM

Process Control Algorithms T8019

2.7. Incremental PID Function

A PID is a process regulator. Using the feedback concept, an output is regulated according to the

difference between its current value (PV) and its required value (SP).

he IPID function block is an improved version of the PID_II block with incremental calculation,

T

derivative term switch for PV or error, and a derivative term filter. The IPID block is recommended for

all new applications. It is also a relatively simple retrofit for the PID_II to provide a more stable output.

IPID

S

P

Auto

XO

Kp

Ti

Td

Ts

X

MAX

X

MIN

INC

STOP

DEC

STOP

D

ERR

Fwd

Auto is the auto/manual mode select (type BOOLEAN). When set to TRUE the IPID calculation is in

auto mode. XO is the manual set-point and is type REAL. Kp is the proportional constant (type

REAL). Ti is the integral time constant (type TIMER). If this is set to zero the function provides only the

P and D terms. Td is the derivative time constant (type TIMER). Kp, Ti and Td may be dynamically

changed in Auto mode without process bump.

OUT

LIMIT

LIMIT

D

QP

D

QI

D

QD

D

XOUT

HI

LO

Fwd switches between Forward and Reverse action (type BOOLEAN). When Fwd is FALSE and Kp is

positive, an increasing PV causes a decreasing Xout (reverse action). When Fwd is TRUE and Kp is

positive, an increasing PV causes an increasing Xout (forward action). If Kp is negative, the action is

also inverted.

Ts is the sample time (type TIMER). If the specified sample time is less than the application program

scan time, then the effective Ts will be the greater of the application scan time or PID function

execution interval. Changing Ts when in Auto mode may cause a process bump due to recalculation of

dynamic variables.

Tdf is the derivative action filter time constant (type TIMER). This may be used to reduce reaction to

process noise, or to spread derivative action over time. Tdf sets the exponential time constant of a first

order lag. If set to zero, the derivative action will act on the process fluctuations immediately.

switches the derivative action input (type BOOLEAN). When set to TRUE, the derivative action is

D

ERR

calculated based on the change in error (SP – PV). When set to false, the derivative action is

calculated based on the change in PV. This allows a choice on whether setpoint changes demand a

derivative kick or not. Note that when D

is false, the proportional action will still react to setpoint

ERR

changes, but with less step than P + D action.

The IPID calculation is incremental; at each scan, the required change in output is calculated. This

means that the P,I and D settings may be dynamically tuned without significant change to the output.

The total change at each scan is output as D

are output as D

, DQI and DQD (all type REAL). These may be used for continuous incremental action

QP

(type REAL). The change due to the P,I and D terms

XOUT

or for commissioning data.

Issue 8 Sep 07 PD-T8019 17

Page 18

Trusted

SP

PV+-

(Error)

d/dt

d/dt

dSd

S

d/dt

d/dt

d2PV

D

Tdf

W

S

Derivative

I

Integral

X++

+

X

Switch

TM

Process Control Algorithms T8019

The figure below gives an overview of the IPID function:

1

T

Proportional

K

KpTS/T

p

Y

S

2

-t/W

1 - e

KPTD/T

Figure 2 IPID Function

The calculation is performed one step into the derivative and is then integrated back for the real output.

At entry the error S is calculated as the difference between the set-point (SP) and the process variable

(PV). This error value is used directly for the integral action, after one differentiation for the proportional

action, and after two differentiations for the derivative action. The derivative action can be switched

using D

INC

STOP

to either use the second differential of error or PV, with a filter.

ERR

prevents the output X

increasing when TRUE. When this input is TRUE and the IPID is in

OUT

AUTO mode, the output is compared with the previous output and only values less than or equal to the

previous output will be returned and LIMIT

continue to update. Similarly, when DEC

D

XOUT

equal to the previous value, and LIMIT

will be set to TRUE. The delta outputs DQP, DQI, DQD and

HI

will be set to TRUE.

LO

is TRUE Xout will only return values greater than or

STOP

In manual mode (AUTO = False), the output (Xout) follows the input XO. Bumpless transfer to auto is

inherent because only the change in output is calculated. If set-point tracking is required then the

MANTRK function should be used in conjunction with the IPID function.

The IPID function provides high and low limits (Xmax and Xmin) to be specified. If the PID output

would have exceeded the specified high or low limits, the corresponding limit output (LIMIT

LIMIT

) is generated. Note that the limit outputs are updated on each iteration of the IPID function.

LO

and

HI

The maximum and minimum limits on Xout apply in both auto and manual modes. There is no need for

anti-windup protection because there is no stored integral term.

On the first application scan, the PID function will clear its registers and will not calculate an output.

If Xmax < Xmin, the function assumes that the values have been reversed and “swaps” the values. On

each execution of the IPID function with reversed parameters the ‘reversed’ error count will be

incremented. If an overflow condition occurs during the execution of the PID function the output Xout

will be set to Xmin in auto mode or XO in manual mode, and the stored registers are cleared.

Issue 8 Sep 07 PD-T8019 18

Page 19

Trusted

PV

OUT

XO

AUTO

TM

Process Control Algorithms T8019

2.8. Deviation Alarm

DEV_AL

DEV

EV

D

SP

US

S

D

DEV

EV

D

HI

LO

The deviation alarm function block takes the current process variable (PV) and set-point (SP), together

with the up-scale and down-scale deviation between the PV and SP (DEV

PV, SP, DEV

= ( (PV – SP) DEV

DEV

I

H

DEV

= ( (SP – PV) DEV

O

L

If an overflow condition occurs during the execution of the function, DEV

and DEVDS are of type REAL, both outputs (DEVHI and DEVLO) are of type Boolean.

US

)

S

U

)

S

D

HI

and DEV

S

U

is to be set to PV>0, DEVLO

respectively).

S

D

to PV<0 and the “overflow” error counter is to be incremented.

PV, SP, DEV

and DEV

S

U

must be finite, i.e. not ±infinities or NaNs.

S

D

2.9. Manual Tracking

X

MANTRK

XO

OUT

The manual tracking function requires the current PID function output (X

(XO) and auto/manual mode control (AUTO). Xout, XO and XO

OUT

), the manual set-point

OUT

are of type REAL, AUTO is

BOOLEAN.

Whilst AUTO is TRUE XO

will be set to the current value of X

OUT

i.e. AUTO changes to FALSE, the XO

value will remain at its previous value until the value of the

OUT

. On a transition to manual mode,

OUT

manual set-point input (XO) changes. Following a change to the manual set-point, the value of XO

will reflect the value of XO whilst AUTO is FALSE.

OUT

Issue 8 Sep 07 PD-T8019 19

Page 20

Trusted

Ts

Ts

TM

Process Control Algorithms T8019

2.10. Time Averaged Value

PV

Tp

Ts

EN

T_AVG

OUT

The average function calculates the average process variable (PV) value over the specified period

(Tp). The Ts specifies the minimum interval between samples. If the sample period is less than the

elapsed period between application program scans, Ts will be the application scan time. PV and OUT

are of type REAL; Tp and Ts are of type TIMER.

The enable input (EN) enables the use of the time averaged value; if this input is TRUE, OUT returns

the time averaged value, if this input is FALSE, out is set to the current process variable (PV) value.

The calculation of the time-averaged value continues irrespective of the EN state.

The function assumes that the input value (PV) changes linearly between samples, i.e. between

application program scans. The maximum number of samples taken must be less than 64, i.e.

Tp

64

. If the number of samples required to support

used and the time averaged value over these 64 samples returned

Tp

is greater than 64, then 64 samples will be

5

. The function is to include time

weighting of the sampled values to correct for variation in application scan times. If the sample period

(Tp) is less than the sample interval (Ts) the function will effectively average over a single sample, and

return OUT = PV.

The output value (OUT) will be updated only after a sample has been taken, i.e. after Ts.

If an underflow condition occurs during the execution of the function, the function is to set OUT to zero

and increment the “underflow” error counter.

Overflow conditions are to result in OUT = PV, and increment the “overflow” error counter.

On initialisation, i.e. first application program scan, the average value is set to the current input value,

and is assumed to have been stable at this value for greater than Tp.

Note: Tp and Ts are variable at run-time. Although the function should not normally be used in this

manner, it is important that the behaviour with varying values is predictable. Changes in Tp or

Ts are to result in OUT being held at its previous value until sufficient samples have been taken

to calculate the valid time weighted average, i.e. after Tp.

5

ISaGRAF does not support the verification of the values used for Tp and Ts within the

workbench. Also, note that these values are variables and may be changed at runtime, although this is

not recommended. Changing these values at runtime will result in the same behaviour as on

initialisation, i.e. the input will be assumed to have been stable for Tp and the output set to PV.

Issue 8 Sep 07 PD-T8019 20

Page 21

Trusted

TM

Process Control Algorithms T8019

Example:

PV

250ms

20ms

T_AVG

OUT

T (ms) 350 390 432 475 521 565 607 650 690 732 777 821

PV 23.5 15.46 10.01 56.03 58.61 90.17 85.68 84.56 18.09 95.94 75.66 49.38

Ts (ms) 46 40 42 43 46 44 42 43 40 42 45 44

% of Tp 103.2 102.4 101.6 102.8 102.8 104.4 102.8 104.0 103.2 102.8 102.4 102.4

OUT 23.5022.87 21.09 22.71 28.76 37.26 48.00 58.53 64.87 68.91 73.96 71.92

Table 3 Example Time Average

The example assumes that PV has been static at 23.5 for greater than 250 ms before the first sample

shown. The Ts row shows the actual interval between samples. The % of Tp row shows the figure

used for the overall output adjustment; e.g., the actual period between the 521ms and 777ms iterations

is 256ms, i.e. 102.4% of Tp.

Issue 8 Sep 07 PD-T8019 21

Page 22

Trusted

TM

Process Control Algorithms T8019

2.11. Rate of Change Detection

Error! Objects cannot be created from editing field codes.

The Rate of Change Detection function requires 4 parameters: the process variable to be monitored

(PV), the sample interval (Ts), the maximum rate of change parameter (R), and rate of change

hysteresis (H). The function detects when the rate of increase or decrease of the process variable (PV)

has exceeded the defined limit R. When the rate of change has exceeded R, the output (Q) is set to

TRUE. Once the output is TRUE, it is set to FALSE as soon as the rate of increase or decrease has

fallen below R by at least the hysteresis value (H).

The process variable is sampled at the specified sample interval; the sample period used will be the

greater of Ts and the application scan time

samples is determined and used to establish the rate of change.

On initialisation, Q is set to FALSE and the previous PV value to the current PV value

PV, R and H must be of type REAL. Ts must be of type TIMER, the output (Q) is of type Boolean. The

rates of change parameters (R and H) are specified as rate of change per second.

i.e.

where:

()()

UP

Q

=

is the input value on the previous sample, on the first sample this value is set to

PV

t1

the current value of the input, i.e. PV

.is the current input value

PV

t2

.is the time the previous sample was taken.

T

t1

is the current time.

T

t2

R is the rate of change limit value

H is the rate of change hysteresis value

PVPV

12

tt

TT

12

tt

6

. The change in PV and the actual period between

>

R

.

t2

PVPV

12

tt

()

TT

12

tt

.

QHR

>

UP

1

t

is the previous value of Q

Q

1

6

maximum period between samples is T plus the application scan time.

Issue 8 Sep 07 PD-T8019 22

The actual sample interval will be NOT LESS THAN the specified sample interval. The

Page 23

Trusted

TM

Process Control Algorithms T8019

Parameters PV, R and H must be finite, i.e. not ±infinities or NaNs. Behaviour is not defined for any

other values. If negative values are specified for R or H, their ABS value will be used and the “param”

error counter will be incremented.

The function must record the sample time for the previous input value and calculate the rate of input

value change for the actual elapsed period.

In an overflow condition occurs, the function is to set Q

to PV>0, Q

P

U

to PV<0 and increment the

OWN

D

“overflow” error counter. In an underflow condition occurs, the function is to set Q

FALSE and increment the “underflow” error counter.

and Q

UP

DOWN

to

Issue 8 Sep 07 PD-T8019 23

Page 24

Trusted

TM

Process Control Algorithms T8019

2.12. Analogue Value Slew

PV

RATE

The analogue value slew function limits the rate of change of the output value (OUT) to the maximum

specified by the RATE input. On initialisation, OUT is set to PV. Changes in the input (PV) will be

tracked by the output with the maximum rate of change. If the rate of change of PV is less than the

maximum rate, the output will immediately follow the input. PV is assumed to be in units, RATE is then

in units per second.

OUT

PV

i.e.:

if PV > OUTt1 then

2 else

()

×+= RATE,

MinTTOUTOUT

t1t1

SLEW

OUT

()

OUTPVABS

TT

2

t1

t1

()

2

()

t1

Where:

is the current time (seconds)

T

2

is the time the algorithm was previously executed (seconds)

T

t1

PV is the current input value

is the output value the time the algorithm was previously executed

OUT

t1

RATE is the current RATE input value

All input parameters (PV and RATE) must be finite, i.e. not ±infinities or NaNs. Behaviour is not

defined for any other values. If RATE is negative, its ABS value will be used and the “param” error

counter incremented.

If an overflow condition occurs during the execution of the function, the function is to set OUT to its

previous value and increment the “overflow” error counter. If underflow occurs, the function is to set

OUT to its previous value and increment the “underflow” error counter.

t1

()

OUTPVABS

×= RATE,

MinTTOUTOUT

2

t1

TT

t1

()

end if

Issue 8 Sep 07 PD-T8019 24

Page 25

Trusted

TM

Process Control Algorithms T8019

3. Other Functions

3.1. Lead/Lag Control

The lead/lag facility will be provided using the high value select and low value select functions to select

the set-point values to be used for the fuel and airflow PID functions. The Lead/Lag is not a function or

function block in its own right; this paragraph illustrates the use of the previously defined high value

select and low value select functions to provide the required lead/lag control function.

Fuel Flow

Steam Demand

Air Flow

HVS

Fuel Flow PID Controller

Set Point

LVS

Air Flow PID Controller

Set Point

Issue 8 Sep 07 PD-T8019 25

Page 26

Trusted

TM

Process Control Algorithms T8019

4. Sample Application Program

A sample application program using selected Process Control Algorithms to implement a simple PID

oop is shown in Figure 3. Note that many of the input parameters to the ipid function block will usually

l

be program constants, and the extra outputs are not necessary for a single loop.

The mantrk blocks allow read/write control of setpoint and output. For the setpoint, the mantrk block

copies the measured variable to the setpoint input whilst the loop is in manual, to allow a bumpless

transfer to automatic mode. On entering automatic mode the setpoint will remain at this value until the

setpoint is changed. Note that since the ipid function block uses incremental action, this function is only

necessary if the output should not move on entering automatic mode until the setpoint is entered.

Without this function, the output will move to control to the setpoint but without a bump to the output.

The second mantrk block allows manual control of the output in manual mode, using the ‘operator

manual output’ tag. In automatic mode, the mantrk block follows the automatic output and writes to the

ipid’s XO input. On entering manual mode, the ipid block output follows XO, but the operator can now

change the output using ‘operator manual output’.

The slew function block limits the rate of change of the output, and is optional. Note that although this

will smooth the action to the control valve, it will also change the control response in a non-linear

fashion.

For cascade (master-slave) pairs of ipid blocks, wire the LIMIT outputs of the slave back to the

INCst/DECst inputs of the master. This will stop the master’s action if the slave output has hit its limit.

Wire the output of the master to the setpoint of the slave. If the slave is not in auto and reading its

setpoint from the master’s output (‘remote’ mode) then the master should be forced into manual mode

because its output is not being used. For any loop, if the measured variable is suspect, force the loop

into manual mode. If the remote setpoint is suspect, force the loop into local automatic mode with a

manually adjustable setpoint. Always wire intermediate signals like remote setpoints and master-slave

interactions through variables, so that their state can be monitored.

Figure 3 Sample Application Program

Issue 8 Sep 07 PD-T8019 26

Page 27

Trusted

TM

Process Control Algorithms T8019

This page is intentionally blank

Issue 8 Sep 07 PD-T8019 27

Page 28

Loading...

Loading...