Page 1

TrustedTM

AN-T80015

Trusted

Application Note

TM

/ SC300E Migration process

Issue 01 Apr 08 AN-T80015 Page 1 of 16

Page 2

TrustedTM

AN-T80015

Issue

Number

1 Apr 08 Andy Holgate Nick Owens Pete Stock Initial Issue

Date Revised by Technical

Check

Authorised by Modification

Introduction

The aim of this document is to provide a guide to the process of upgrading a Triguard SC300E system

to a Hybrid SC300E / Trusted

8161 Bridge Modules controlled by a Trusted

Starting with the initial understanding of the existing system hardware configuration and functionality,

through to the hardware upgrade process, logic programming and system test, this document will

provide the integrator with the questions that will need to be answered for a successful upgrade.

It is not intended as a step by step guide, rather information regarding the main issues to be addressed

during the system migration process.

TM

system by replacing the SC300E processors (MPPs) with TrustedTM

TM

processor.

Contents

Upgrade Process...................................................................................................................... 3

1.

1.1. Scope of supply ..................................................................................................................... 3

1.2. System layout......................................................................................................................... 3

1.3. Tags, Discretes, Registers..................................................................................................... 4

1.4. Application logic..................................................................................................................... 4

1.5. Mechanical upgrade............................................................................................................... 5

2. Case Study – 2 chassis ESD system ....................................................................................... 6

2.1. Scope of Supply..................................................................................................................... 6

2.2. System Layout ....................................................................................................................... 6

2.3. Tags, Discretes, Registers..................................................................................................... 6

2.4. Application logic..................................................................................................................... 7

2.5. Diagnostics .......................................................................................................................... 10

2.6. Mechanical upgrade............................................................................................................. 11

3. Reference Documentation...................................................................................................... 13

4. Sample logic comparisons ..................................................................................................... 14

5. Migration Process – Flow chart .............................................................................................. 16

Issue 01 Apr 08 AN-T80015 Page 2 of 16

Page 3

TrustedTM

AN-T80015

1. Upgrade Process

1.1. Scope of supply

The first step of the Trusted

required by the customer.

• Is it a test/demo setup or is it an actual plant upgrade?

• Does the client want to replicate the current user interface of the system as closely

as possible so as not to confuse the operators.

It is important to have all the ‘As Operational’ information available, ie the ‘As Built’, but with

any onsite modifications or upgrades taken into account. The application backups supplied

must be representative of the running system to ensure a smooth migration. It is essential

that the system configuration files and application logic in the backups are identical to that

which is running in the system at the time of the upgrade.

Triguard Serial I/O modules (MSR04XI) will be removed as there is no facility to

communicate with SC300E Peer links or other SC300E communications equivalents. These

must be replaced with Trusted

and Modbus links to DCS etc.

M

T

SC300E migration process is to understand just what is

TM

equivalents, namely peer links to other TrustedTM systems

1.2. System layout

1.2.1. Hardware layout

• Where is the Trusted

• Is there room in an existing cabinet for the Trusted

chassis, power supplies and fan trays will need a space up to 10U high in a cabinet.

• Does it need a new cabinet of its own? If so, is there room in the control room for

more cabinets?

The physical layout will determine such things as length of the interface cable, number of fan

trays required, comms cabling etc.

1.2.2. Toolset layout

Use the system folder to define the shape of the system as TrustedTM will see it. Create the

SYSTEM.INI file in Trusted

Care must be taken to choose the correct setup or the configuration will not run. For

example, the MDO32BNS output modules can be configured as 3-2-0 or 3-2-1 using jumpers

on the module, and it is also possible to set the MDO32BNS to ‘hold last value’ or ‘go to zero’

in the event of a trip.

TM

chassis going to be installed?

TM

chassis? The TrustedTM

TM

Toolset with any partner slots and module setup.

Create the I/O wiring table and board definitions in the toolset. Remember that what was

Triguard Chassis 1 in the original SC300E system will now become Logical Chassis 2 and so

on since the Trusted

Issue 01 Apr 08 AN-T80015 Page 3 of 16

TM

chassis is now Chassis 1.

Page 4

TrustedTM

AN-T80015

1.3. Tags, Discretes, Registers

Create tags to get diagnostic data from modules and wire them to the appropriate board in

the Toolset. Create logic programs to derive alarms from diagnostic data, for example

processor temperature, processor voltage etc.

sing the information in the system folder create a spreadsheet of all the tag names,

U

discretes and registers along with descriptions and any other relevant data. This

spreadsheet can be easily manipulated into a format which can be imported into the Toolset.

The standard SC300E will print alarm and diagnostic data directly to a printer whereas

Trusted

TM

can not. You need to use SOE (Sequence of Events) to capture changes of

Boolean variables, so duplicate any tags needing to be monitored with a different name

(prefix with S for example) and wire them to SOE boards in the I/O wiring.

1.4. Application logic

Decide on the language to be used for the main application logic. It may be a good idea to

use ladder logic to mirror the current system so as to minimise the change for the users.

Trusted

ladder logic although not all SC300E functions can be directly replicated.

Some logic uses registers instead of individual discretes, especially where data is gathered

from a whole module or function block, eg GDIA or FALT

The application logic should include the safety ladders as described in SS728 Appendix 1

1.4.1. Execution Speed

TrustedTM operates the SC300E I/O scanning asynchronously from the application scan,

since the I/O scanning is operated by the 8161 Bridge Modules and reported to the processor

as requested. The Trusted

milliseconds, which is due to the ‘sleep period’ set in the system INI configuration. The

processor is only using about two thirds of the 32ms scan; the rest is free for diagnostics and

background functions.

The faster application scan time in Trusted

Trusted

TM

ladder logic, using the FBD/LD editor, can be made to look very similar to SC300E

TM

programs must account for the delays expected in the SC300E.

TM

application scan was measured at the minimum 32

TM

and the asynchronous I/O handling means that

1.4.2. Printed messages, reports and events

SC300E is able to print reports and events, controlled by the application. TrustedTM has no

printer output. However, it has two event logs. The processor holds an event log with 200

entries, which automatically records all system faults and actions without any intervention

from the application. This reports all module faults and swaps as well as program downloads

and Reset pushbutton presses. There is also a Sequence of Events log (SOE) which records

changes to Boolean (digital) variables, complete with timestamps. These timestamps are to

the nearest millisecond but are not absolutely accurate due to the disconnection between the

Trusted

record SOE timestamps on arrival to the system.

There is also an analogue event logger called Process Historian if required, but usually

analogues are trended on the DCS or other graphics station.

Issue 01 Apr 08 AN-T80015 Page 4 of 16

TM

application and the real I/O in a hybrid system. Native TrustedTM I/O modules can

Page 5

TrustedTM

AN-T80015

1.4.3. Firmware calls

The SC300E application has several calls to the system firmware such as USR3, USR4,

FALT etc. These are user configured and may have bespoke code designed to execute away

from the application ladder. This means that if some of the functions in SC300E systems may

need redesigning and they cannot be translated easily into ladder, structured text etc. Some

calls usually involve system diagnostic functions, and can be replaced by application logic

diagnostics.

1.4.4. Diagnostics

I/O module and system diagnostics flags are listed in PD 8161 for the SC300E products.

TM

With Trusted

commands are available to extract information on SC300E module status and chassis

configuration. Diagnostic data on module health, discrepancies and LFD errors is also

available in the application through the I/O connection boards for each module.

a terminal program may be used to access a command line interface, where

1.5. Mechanical upgrade

M

Remove the SC300E MPPs and replace with the 3x Trusted

T

8161 Bridge Modules.

The Bridge module requires minimum configuration, namely the setting of Unit ID jumpers 0

to 3 to define the chassis address to Trusted™.

TM

Clicking on a SC300E chassis in the Trusted

System Configuration tool and selecting

‘Jumper config’ will display the required jumper settings for that chassis.

Connectors J1-3 on the TC-325-02 card, plug into the three 26-way diagnostic headers on

the SC300E backplane. The Hotlink cable from the Trusted

TM

Expander Interface adapter

plugs into 12-way J4.

Due to the low current requirements of the 5v supply to the 8161 Bridge modules may be

necessary to fit a MXD dummy load module in the chassis, if no I/O modules are installed.

This is to provide a minimum load for the chassis 5Vdc power supplies.

Issue 01 Apr 08 AN-T80015 Page 5 of 16

Page 6

TrustedTM

AN-T80015

2. Case Study – 2 chassis ESD system

2.1. Scope of Supply

This upgrade was performed on a test system built for the purpose of documenting the

migration process.

2.2. System Layout

2.2.1. Hardware Layout

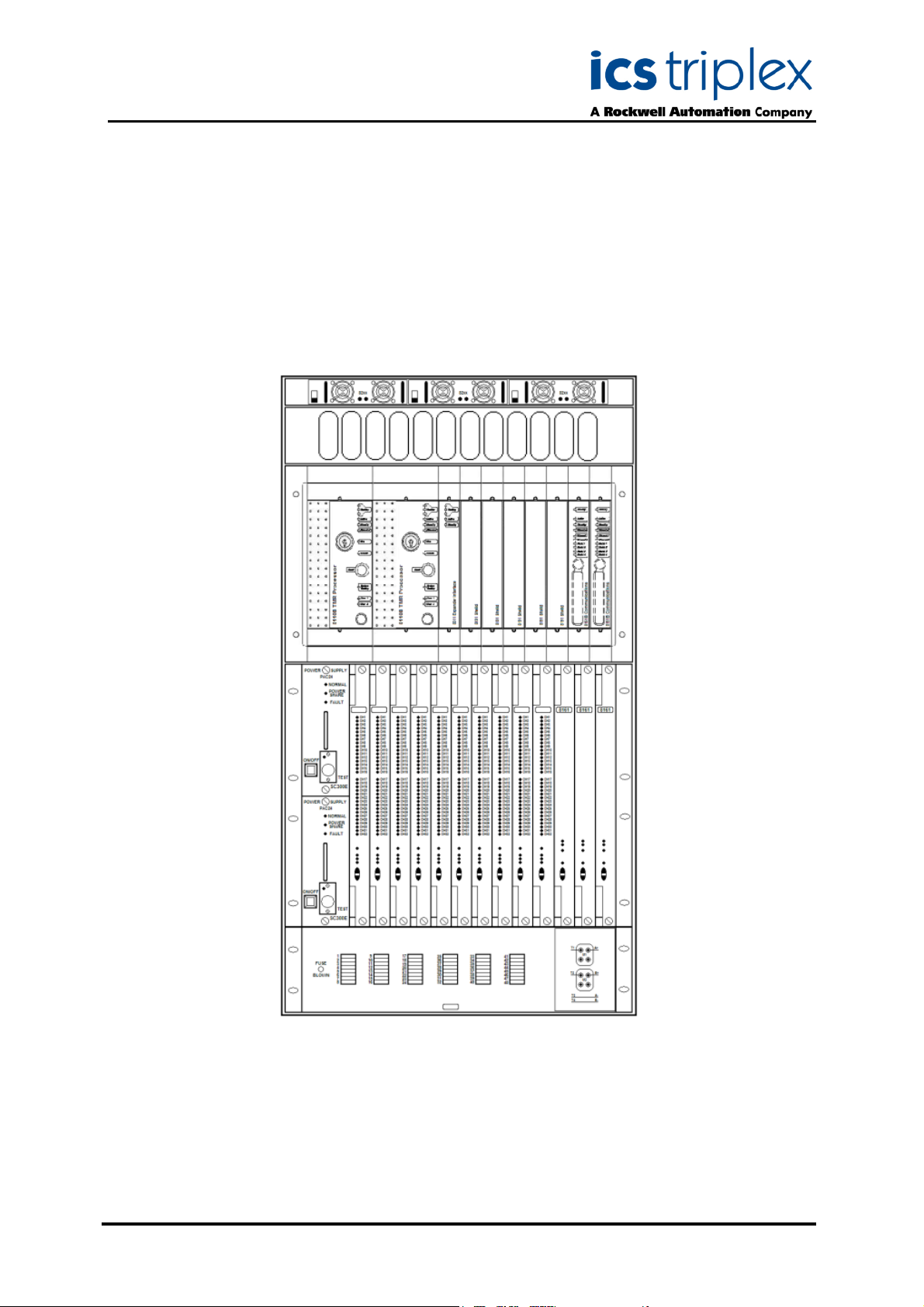

The system comprised a TrustedTM demo kit linked to a 2 chassis SC300E ESD system with

test switches and LEDs to simulate field I/O.

2.2.2. Toolset Layout

Using the information contained within the system folder, the shape of the system was

configured in the Trusted

defined. The system layout was also defined in the Toolset I/O connection tables.

Chassis 1 in the original SC300E system is now become Logical Chassis 2 and chassis 2

becomes 3 since the Trusted

TM

The Trusted

opened, and this is usually due to the board not matching the module type. Many SC300E

modules can be configured as 3-2-0 or 3-2-1, using jumpers on the module. Applying the

wrong definition will prevent the application from starting. Ensure that the correct board

definitions are used for the various I/O module configurations.

There are no restrictions in the order of the boards set out in the connection table except in

cases where TM117-DMX (64-Channel De-Multiplexed Driver) termination cards are

configured in the system. These have to be defined before any SC300E I/O modules are

specified. The DMX cards are driven from the Trusted

also general convention to specify the Trusted

connection table.

controller will not start the application if an I/O connection board cannot be

M

T

System Configuration tool with partner slots and module setup

TM

chassis is now Chassis 1.

2.3. Tags, Discretes, Registers

Firstly tags were created to get diagnostic data from the 8000 processor and I/O modules

which were then wired to the appropriate board in the Toolset. Logic programs to derive

alarms from diagnostic data, for example processor temperature, processor voltage etc were

written to give information on the basic health of the system.

TM

serial communications module. It is

TM

main processor at the head of the

Using the information in the system folder a spreadsheet was created of all the tag names,

discretes and registers along with descriptions and any other relevant data. This

spreadsheet was manipulated into a format to be imported into the Toolset variable library.

The standard SC300E will print alarm and diagnostic data directly to a printer whereas

Trusted

tags were created for points needing to be monitored which were prefixed with ‘S’ to

differentiate them from the tags used in the main program logic. These were wired to SOE

boards in the I/O wiring.

Issue 01 Apr 08 AN-T80015 Page 6 of 16

TM

can not. You need to use SOE to capture events as they happen, so duplicate

Page 7

TrustedTM

AN-T80015

2.4. Application logic

It was decided to use ladder logic to mirror the existing system as much as possible so as to

minimise the change for the users, although there are some things to bear in mind.

ach I/O module is mapped to blocks of discretes (Booleans) in groups of eight, which are

E

not necessarily in order. Discretes above 8000 are also mapped to registers: to find the

relevant register, subtract 8000 from the discrete address and divide by 16 (or vice versa,

multiply by 16 and add 8000 to find the LSB discrete for a particular register).

Some logic uses registers instead of individual discretes, especially where data is gathered

from a whole module or diagnostic function block.

2.4.1. Ladder Logic Replication

TrustedTM ladder logic, using the FBD/LD editor, can be made to look very similar to SC300E

ladder logic. There are minor exceptions to the appearance.

TM

Trusted

logic, and several power rails may be drawn for one network. Elements may be placed

anywhere. SC300E ladder logic is fitted on a grid with the left hand edge acting as a power

rail.

Vertical lines in either system act as OR gates, however in Trusted

to a power rail, the two will be connected at the top. In SC300E, horizontal connections may

be wired anywhere, so the visual appearance may be different.

requires a left-hand power rail to be drawn to ‘energise’ each branch of ladder

M

T

if an OR gate is wired

In SC300E, ladder elements are executed strictly in order through the grid. The left column is

executed from top to bottom, and the results passed to the next column, again executed

downwards. In Trusted

execution hierarchy is built so that each element is only executed when all its inputs have

been resolved by other executions. An option is available in the editor to ‘Show Execution

Order’, which highlights the calculated order.

TM

In Trusted

, ladder and function block diagram may be mixed, but follow different visual

rules in terms of shape, which will influence the layout (especially for tags in FBD, which are

very long horizontally). In SC300E, functions may be placed on the grid as part of the ladder.

2.4.2. Logic operation

There are two major differences between TrustedTM and SC300E logic operation.

In SC300E, ladder logic may include calls to synchronise I/O within the network, so that later

ladder elements may use fresh inputs, possibly based on recent outputs. This allows

sequential programming to be built using the ladder execution order; complete sequences

that have several interactions with I/O may be built in one network.

TM

In Trusted

after the application scan, so that in order to create a sequential program, the application

must suspend the logic until the next scan to deliver outputs and receive fresh inputs. This

means that the sequential ladder networks in SC300E must be replicated in Trusted

state machine logic, where the logic performs a different operation each scan depending on a

remembered state setting.

, inputs are only read before the application scan and outputs are only written

TM

, execution order is based on the inputs of each element. A tree of

TM

using

An ideal language for state machine logic is Sequential Function Chart, but this is not

recommended for safety systems for two main reasons: processor hot swaps are not

possible with SFC programs, and SFC programs may be (rarely) liable to enter indeterminate

states, either hanging or performing two steps simultaneously. For the latter reason, SFCs

are not permitted by TUV for SIL3 approved systems.

Issue 01 Apr 08 AN-T80015 Page 7 of 16

Page 8

TrustedTM

AN-T80015

An acceptable alternative is to use Structured Text, which allows complex program flow using

IF, CASE, REPEAT and other flow control statements. The CASE statement allows the

creation of a state machine

In SC300E, only one network is run at a time, so the programmer may concentrate on the

operation of that network without worrying about its influence on other networks. In

Trusted

means that all other networks will also run throughout the operation of a state machine.

Therefore, the effect of the state machine’s actions on other networks must always be

considered. For example:-

Event logs included many points which were exercised during the logic scan but provided no

useful information. These internal points were removed from SOE unless required, in which

case efforts were made to mask unwanted transitions

2.4.3. Execution Speed

TM

, the need to use a state machine to allow I/O to be synchronised between steps

SC300E logic scans can take several hundred milliseconds to operate, probably due to the

inline I/O calls and system calls. However, Trusted

asynchronously from the application scan, since the I/O scanning is operated by the 8161

bridge modules and reported to the processor as requested. The Trusted

M

T

operates the SC300E I/O scanning

TM

application scan

was measured at the minimum 32 milliseconds, which is due to the ‘sleep period’ set in the

system INI configuration. The actual scan overhead in the example system consisted of the

following elements:

I/O: 10-13ms Transactions with bridge modules, communications

modules, standby processor

Input: 3-4ms Writing input data to input boards in the application, running

conversion tables, updating variables

Application: 3-4ms Actual application processing time, rarely more than 10% of

total

Communications: 0-1ms INI changes, active/standby signals

Output: 3-4ms Transfer of output data from application to bridge modules

and communications modules.

It can be seen that the processor is only using about two thirds of the 32ms scan; the rest is

free for diagnostics and background functions.

TM

The faster application scan time in Trusted

Trusted

TM

programs must account for the delays expected in the SC300E.

and the asynchronous I/O handling means that

2.4.4. Printed messages, reports and events

SC300E is able to print reports and events, controlled by the firmware. TrustedTM has no

printer output. However, it has two event logs. The processor holds an event log with 200

entries, which automatically records all system faults and actions without any intervention

from the application. This reports all module faults and swaps as well as program downloads

and Reset pushbutton presses. There is also a Sequence of Events log (SOE). The SOE log

holds records changes to Boolean (digital) variables, complete with timestamps. These

timestamps are to the nearest millisecond but due to the disconnection between the

Trusted

Trusted

analogue event logger called Process Historian if required, but usually analogues are trended

on the DCS or other graphics station.

In order to make an entry in the SOE log, a Boolean variable is required, which must be set

up as an output and wired to an SOE board in the I/O connection table. It should have an

appropriate tagname (max 32 characters) and description (max 80 characters), which will

appear in the SOE log. It is possible to name the states True and False as appropriate, e.g.

Issue 01 Apr 08 AN-T80015 Page 8 of 16

TM

application and the real I/O in a hybrid system, are not absolutely accurate. Native

TM

I/O modules can record SOE timestamps on arrival to the system. There is also an

Page 9

TrustedTM

AN-T80015

Alarm and Normal, and these state names will also appear in the log. The point can now

transfer events from the application to the SOE log, which can be collected either by an OPC

client through the Trusted

running on a PC.

There is no need to clear the logs. The processor event log contains 200 events and is

cyclically overwritten. The SOE log contains 4000 events and is also cyclically overwritten,

although care should be taken not to create more events than a collector can extract or

events will be lost. The processor event log is stored on power loss in a backup log.

2.4.5. Firmware calls

The SC300E application has calls to the system firmware such as USR3, USR4, FALT etc.

These are user configured and may have bespoke code designed to execute away from the

application ladder. This means that if some of the functions in SC300E systems may need

redesigning and they cannot be translated easily into ladder, structured text etc. Some calls

usually involve system diagnostic functions, and can be replaced by application logic

diagnostic

Some sections of the example system logic have therefore been ignored in the transfer until

their purpose became clear through online testing. This highlights the need for a system test

to unearth all missing functionality, much of which will not be evident until real world

interactions are possible.

TM

OPC server, or using the TrustedTM SOE collector program

2.4.6. Timers

TrustedTM has three timer function blocks TON, TOF and TP. The usual timer is TON which

raises its output true after the input has been true for a preset time.

SC300E has a timer function with two discrete inputs (time and clear) and two discrete

outputs (GE and LT). GE and LT are always the inverse of each other.

Time accumulates when both inputs are on, during which LT is true. If both inputs stay true

until the timeout, GE goes true. If clear goes false, the time is reset to zero and LT goes true.

If time goes false, the time is held.

If both inputs to the timer function are wired to the same source, the timer acts like TON. If

the inputs are separated, then the logic must be examined for the implications of separately

holding or resetting the timer. TON cannot be held, and applications requiring this need a

special function block.

Issue 01 Apr 08 AN-T80015 Page 9 of 16

Page 10

TrustedTM

AN-T80015

2.5. Diagnostics

I/O module and system diagnostics flags are listed in PD 8161 for the SC300E products.

The Trusted

commands are available to extract information on module status and chassis configuration.

Diagnostic data on module health, discrepancies and LFD errors is also available in the

application through the I/O connection boards for each module. In the example system, the

module status word was masked for all fault bits and these were combined into one fault

alarm. Individual fault bits and other data were also delivered to the SOE log.

The different maintenance and diagnostics on a Trusted

must use the SOE log and command line diagnostics.

As a minimum for SC300E safety applications, the sample networks listed in the SC300E

Safety Manual must be implemented.

Network 1

T

M

terminal program may be used to access a command line interface, where

TM

system means that operators

MPP out of synchronisation is not applicable

Single slot module offline alarm – 60s alarm after any I/O module is taken offline

Network 2

If the system has any single element safety outputs, or any dual element safety

outputs are configured on a single output module, then the system must be configured

with a time constraint (Mandatory). This time constraint is set in hours; a minimum

2,353 hours for SIL 3, 7,440 hours for SIL 2 or 23,528 hours for SIL 1. The time

constraint timer is reset once the output fault is cleared and remains clear for the

system test time. The system test time is set in the INI file to a default of 5 minutes ie

every 5 minutes the modules are interrogated for the result of their self-tests.

Networks 3 & 4

Individual reporting of system and module fault bits.

Network 5 &10

External triplicated watchdog signal. The watchdogs are retriggered once a second.

This is to ensure that the application logic does not hang in a routine.

Networks 6, 7 & 8

Analogue input monitoring for alarm levels and slice faults. Failsafe conditions for the

signals to be defined and alarmed as appropriate.

Network 9 & 11

It is Mandatory that the diagnostic shutdown the scan is the first scan (system

incorrectly configured), or the system time constraint is exceeded, or a critical I/O

module is offline for more than the process safety time or an I/O module is removed

from the chassis without first being taken offline, or an I/O chassis is lost due power

failure or loss of two MBB modules.

Network 12

Analogue outputs must not be driven below 256 decimal which will result in the module

losing health. Low and high limits must be set eg 4mA = 895 and 20mA = 3455.

Issue 01 Apr 08 AN-T80015 Page 10 of 16

Page 11

TrustedTM

AN-T80015

2.6. Mechanical upgrade

Remove the SC300E ICCBs and replace with the 3x TrustedTM 8161 Bridge Modules.

The Bridge module requires minimum configuration, namely the setting of Unit ID jumpers 0

o 3 to define the chassis address to Trusted™. These are situated on the Triguard chassis

t

as shown here.

The four backplane jumpers represent the binary address bits 1, 2, 4 & 8 respectively. On the

first SC300E chassis (containing the SC300E Bridge Modules), remove jumper 1 to

represent a Trusted

left as they are.

Connectors J1-3 on the TC-325-02 card, plug into the three 26-way diagnostic headers on

the SC300E backplane. The Hotlink cable from the Trusted

plugs into 12-way J4.

TM

address '2'. On the subsequent SC300E chassis the jumpers must be

TM

Expander Interface adapter

Issue 01 Apr 08 AN-T80015 Page 11 of 16

Page 12

TrustedTM

Expanders

AN-T80015

Clicking on a SC300E chassis in the TrustedTM System Configuration tool and selecting

‘Jumper Config’ will display the required jumper settings for that chassis.

The link settings on the Triguard BIC chassis refer to the ‘Triguard Chassis Number’ not the

‘Logical Chassis Number’ which is the overall position of the chassis in the Trusted

TM

system.

Expander

Expander

interface

The Controller rear view shows all connections

available via the Interface Adapters.

The Processor Interface Adapter provides

connection for system alarms and Modbus RTU

Interface cable

Interface cable

interface

adapter

adapter

Processor interface

Processor interface

adapter

adapter

(IRIG-b, MODBUS)

(IRIG-b, MODBUS)

ports on the TMR Processor, as well as

enabling features such as Modbus master and

IRIG-B time synchronisation.

The Expander Interface Adapter has four or

seven connections available to individual

Trusted

Chassis using the Trusted

TM

Expanders or the SC300E Main

TM

SC300E Interface

Cable Assembly TC-322-02.

Other serial and Ethernet communications

capability is accessed through the

Communications Interface Adapters. Ethernet

RJ45 connection is specifically required for Peer

Comms interface

Comms interface

adapter - DCS, peer

adapter - DCS, peer

to peer & EWS

to peer & EWS

Connections to bus

Connections to bus

Connections to bus

adapter and Plantguard

adapter and Plantguard

adapter and

Expanders

Expanders

Trusted

TM

to Peer and OPC.

Due to the low current requirements of the 5Vdc supply to the 8161 Bridge modules it may be

necessary to fit a MXD dummy load module in the chassis, if no I/O modules are installed.

This is to provide a minimum load for the chassis 5Vdc power supplies.

Issue 01 Apr 08 AN-T80015 Page 12 of 16

Page 13

TrustedTM

AN-T80015

3. Reference Documentation

• PD-T8100 Controller Chassis

• PD-T8110B TMR Processor

• PD-T8151B Communications Interface

• PD-8161 SC300E Bridge Module

• PD-T8311 Expander Interface

• PD-T8082 Toolset Suite

• PD-T8013 SOE & Process Historian Software Package

• PD-T8017 Peer to Peer Communications Software Package

• PD-T8312 Expander Interface Adaptor Unit

• PD-T8153 Communication Interface Adapter

• SS0728 Triguard SC300E Safety Manual

Issue 01 Apr 08 AN-T80015 Page 13 of 16

Page 14

TrustedTM

AN-T80015

4. Sample logic comparisons

Some of the networks can be programmed in TrustedTM to closely mirror the original.

SC300E programming

Trusted

TM

programming

Issue 01 Apr 08 AN-T80015 Page 14 of 16

Page 15

TrustedTM

AN-T80015

Some networks cannot be programmed the same way in TrustedTM as in SC300E, for example those

which handle the internal diagnostics:

SC300E programming

Trusted

5.

TM

programming

Issue 01 Apr 08 AN-T80015 Page 15 of 16

Page 16

TrustedTM

AN-T80015

Migration Process – Flow chart

Test setup or full plant upgrade.?

What Communication links are required. (Peer-to-Peer, DCS, DMX, OPC etc.

How many Trusted controllers required. (cannot communicate with SC300E directly with Peer-to-Peer

so all linked systems must be upgraded)

Scope of Supply

In many instances the system will have had software modified and archived without updating the

operational or as-built files. It is very important to base the migration on up to date information to

avoid nasty surprises on site

System sizing – mounting of controller, is there room in an existing cabinet?

If in a test or demo system what test panels are needed for inputs and outputs?

Cables and lengths required

Chassis 1 = Trusted controller chassis

What was SC300E chassis 1, is now logical chassis 2

Communication, Modbus settings

SC300E I/O modules have the option of 3-2-1 or 3-2-0. make sure the correct one is selected.

TM117-DMX TMs must appear in the list before any SC300E I/O modules

Set chassis / slot definitions

Create spreadsheet of tags, discretes, registers etc in Excel, then create library in Trusted Toolset

Create and wire up tags for faults on the Trusted controller chassis, eg. Expander, Bridge and

comms modules

Obtain ‘As

Operational’ system

file

Identify

Hardware

Create ini file + hot

repair associations

Board definitions

Identify / create

Registers,

Discretes and Tags

Trusted

fault flags

Create and wire up tags for faults on the SC300E chassis, eg. Slice, internal power, field power,

watchdog etc

Timers issues

Mirror existing system by using ladder logic or start again with FBD

Register mapping

SOE – duplicate tags required

Go through the test procedure on the existing system before making any changes to give you a

performance benchmark to test the system against after the upgrade is completed

Swap MPPs for 8161 Bridge modules

Set links for each chassis, remember Trusted chassis is No1, first SC300E is No2

Fit load resistors to Chassis 2 5v supply to compensate for low current drawn by Bridge modules

SC300E

fault flags

Application logic

Pre-upgrade tests

Hardware Upgrade

Debug System

Issue 01 Apr 08 AN-T80015 Page 16 of 16

Loading...

Loading...