Page 1

ICS Regent+Plus

®

PD-7026

Guarded Analog Output Modules

4 to 20 mA

(T7480)

Issue 1,

Guarded analog output modules provide 4 to 20 mA current

outputs for a maximum of six user loads per module. These

modules are called Guarded because the module'

redundant design ensures that no single fault within a

module will inadvertently change an output's signal. The

module's triplicated Safetybus interface ensures that no

Regent system failure will inadvertently affect the output

signal. Extensive fault detection and annunciation of critical

redundant circuits ensures the modules will continue to

operate in a fail-safe manner.

s dual

March, 06

-

Features

·

Six 4 to 20 mA output circuits.

·

Dual, high resol

·

Fault tolerant operation when connected in parallel with

another module of the same type.

·

Hot-replaceable.

·

Comprehensive self-testing of all critical circuits.

·

Front panel indicators on each module show active/fault,

shutdown, and on status.

·

2500 volt minimum electrical isolation between field and lo

circuits.

·

TÜV certified, Risk Class 5, non-interfering.

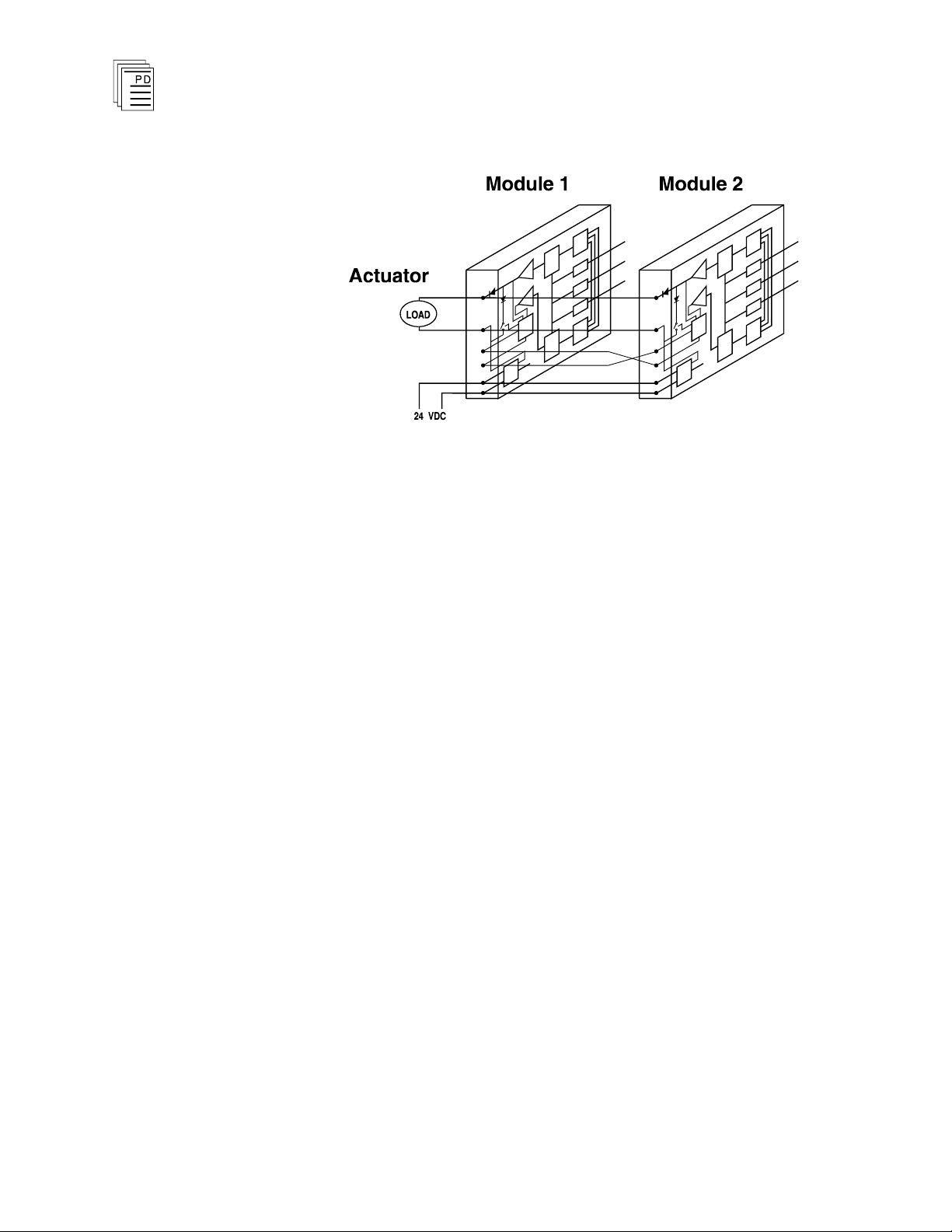

Two Guarded output modules can be connected in parallel to

obtain fault tolerant control of current to the loads. In this

parallel module configuration, either module can be removed

and replaced while the other Guarded module continues to

control the loads without interruption.

ution, 12-bit D/A converters per output.

gic

Industrial Control Services

1

Page 2

Guarded Analog Output Modules

(T7480)

Module Operation

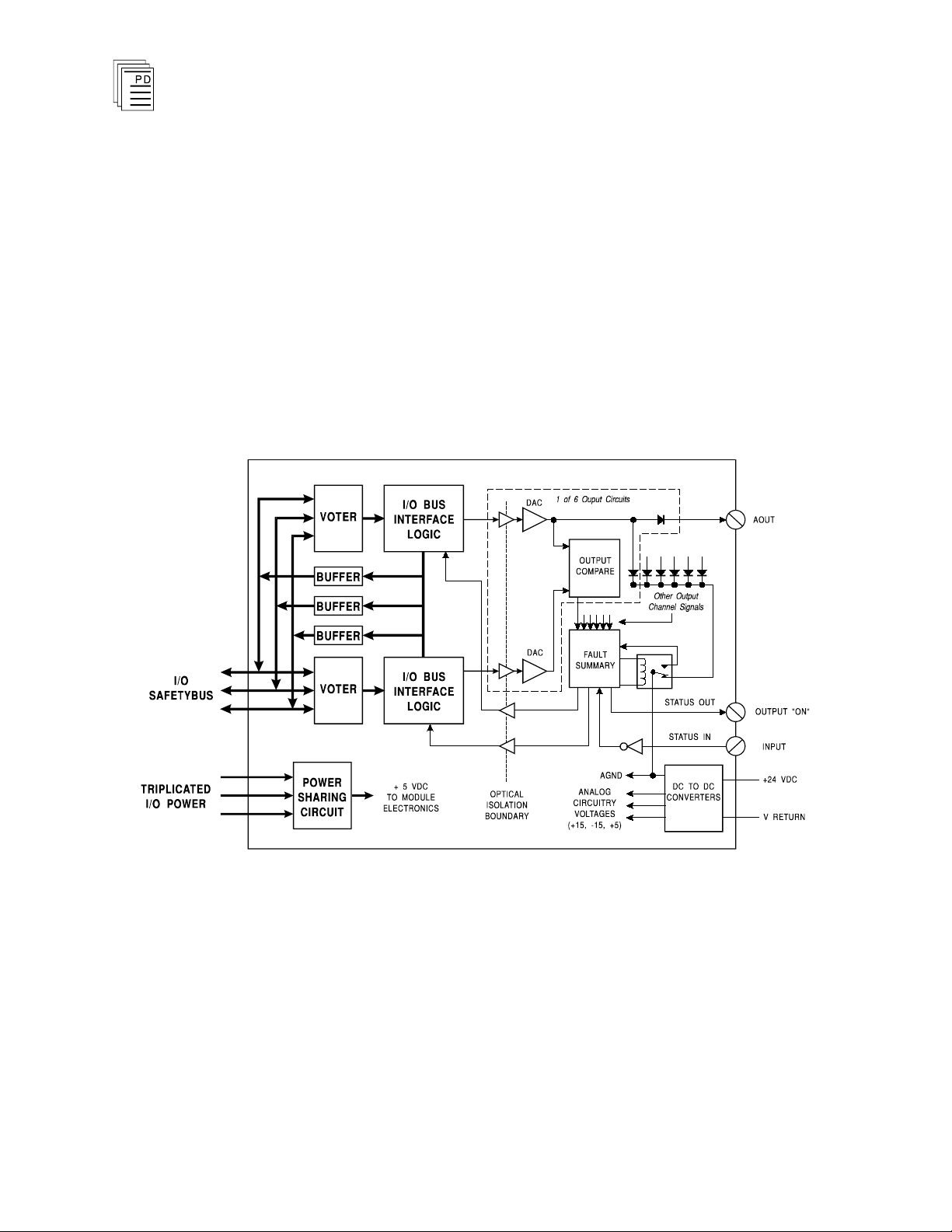

A block diagram of the Guarded analog output module is

shown in Figure 1.

The processor module

over the I/O Safetybus to the Guarded output module.

Onboard the Guarded output module the triplicated data are

routed to two independent voter and I/O Safetybus logic

sections. Each section independently votes the triplicated

data and drives one digital-to-analog (D/A) converter for each

of the six output channels.

s send triplicated write data commands

2

Figure 1. Block Diagram of Guarded Analog Output Module.

For each output channel, one of the D/A conve

signals is used for the actual analog output drive signal. The

other D/A converter output signal generates a redundant

reference output signal. When all circuits are operating

correctly each channel’s drive output and reference output

should be the same. These two signals are compared on the

module and must be the same in order for the module to

control the field outputs.

Industrial Control Services

rter output

Page 3

Guarded Analog Output Modules

(T7480)

The combination of redundant interface circuits, D/A

converters, and comparison of drive and reference signals

produces a fail-safe signal to the load.

For fault tolerant operation, two Guarded analog output

modules can be used in parallel. In this configuration, the

STATUS OUT and STATUS IN signals are cross-strapped

between the two redundant modules. This connection causes

only one of the analog output modules to control the field

devices, while the redundant module is in a standby mode. In

the standby mode the module has its D/A converter output

signals shunted to AGND. This allows the module to

completely test and validate its analog drive circuits while the

other module controls the load devices. If the controlling

module fails, it turns off and the standby module becomes the

controlling module. This switch over occurs in less than 5

msec and is effectively bumpless for most field devices.

Testing and Diagnostics

The voter and I/O bus interface logic of the Guarded analog

output module are automatically tested by the processor

modules. Discrepant data are sent through one of three legs

of the I/O Safetybus to determine whether the module’s voters

are able to outvote the incorrect data. A failure to return the

correct majority-voted result to the processors produces an I/O

module error indication at the processor modules and a

module fault indication at the I/O module.

Each type of module has a unique identification code that is

read by the controller. This code lets the controller know

which type of module is installed in each I/O chassis slot and

how to address that module and its points specifically. If a

module i

s removed, or is replaced with a module of a different

type, the processor modules will indicate an I/O module error.

Loopback logic tests periodically write data to the module and

then read it back to determine whether the module’s I/O bus

interface logic is functioning correctly.

PD-7026

Mar-06

To detect a failure in the redundant analog drive circuits,

each channel’s redundant D/A converter output signals are

compared. If they are not the same, a fault signal is sent to

the fault summary circuits to disable the module

3

’s outputs —

Page 4

Important!

Note:

Guarded Analog Output Modules

shunting all six output channel signal outputs to AGND via

the diode matrix.

An open circuit wiring fault to a load will cause the output

signal comparison for that channel to fail. In single module

configurations this may produce undesirable effects. Refer to

page 8, Effects of Open Circuit Field Wiring, for further

details and recommendations.

(T7480)

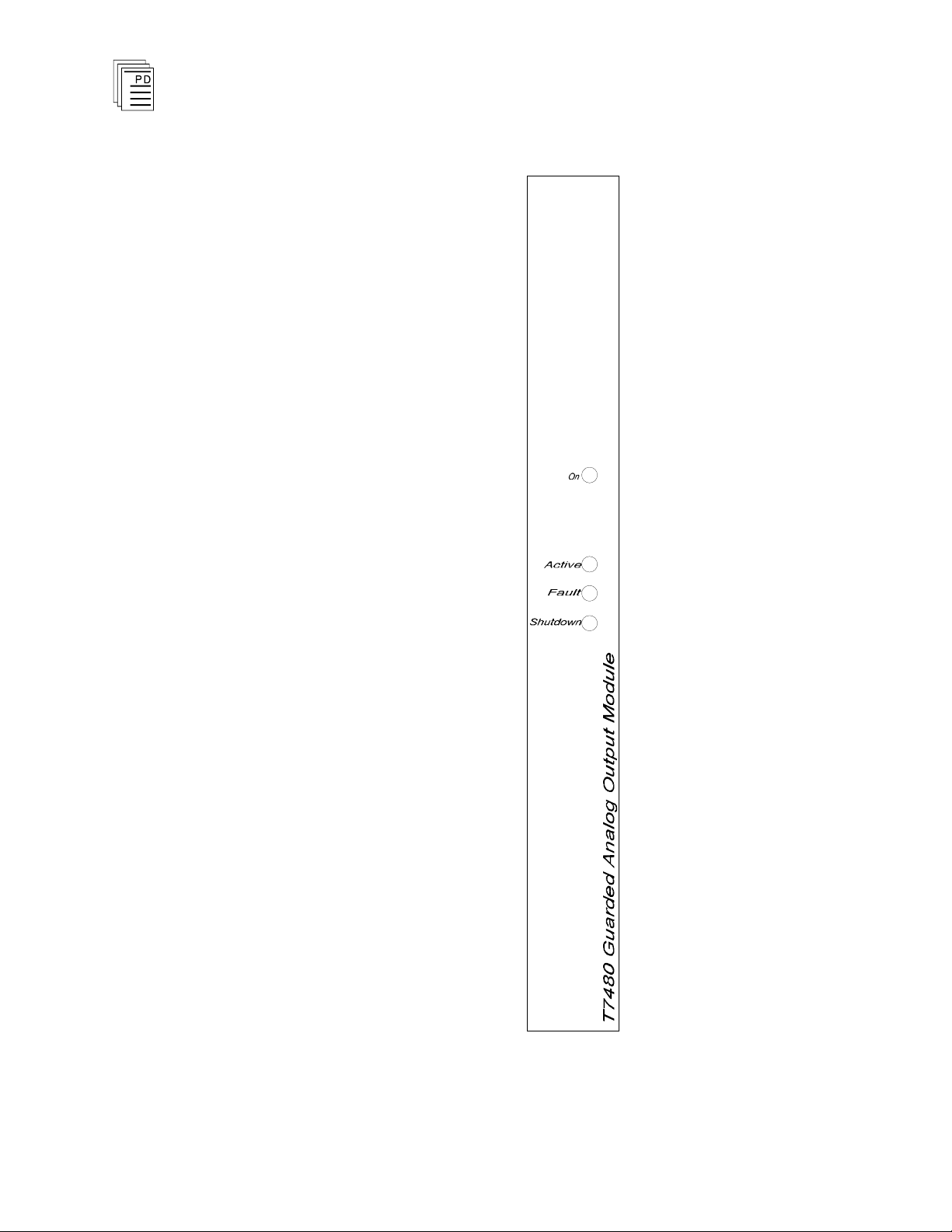

Front Panel Indicators

Figure 2 shows the physical features of a Guarded analog

output module. T

active and fault status indicators, an on status indicator, and

a shutdown indicator.

Active and Fault Status Indicators

These green and red LEDs indicate the overall health of the

module and its field circuits. During normal operation the

green ACTIVE indicator flashes at the controller's scan rate.

If a module fault occurs the red FAULT indicator turns on

and the green ACTIVE indicator turns off.

The module will indicate a FAULT if field power is not

applied.

On Status Indicator

In a single module, fail-safe configuration this green LED is

on when the module is operating correctly. If any output

channel’s dual D to A converters fail to compare, the module

shuts off and this LED turns off.

he front panel of each module contains

4

In a dual module, fault tolerant configuration only one of the

two parallel modules is controlling the load current while the

other is in a standby mode. Only the ON status indicator on

the controlling module is turned on (the standby module's ON

indicator will remain off).

ON status indicator will turn off and the standby module's ON

status indicator will turn on (as it becomes the controlling

module).

Shutdown Indicator

Upon loss of communications with the controller, output

modules enter either a shutdown or hold fault mode. If the I/O

If the controlling module fails, its

Industrial Control Services

Page 5

Guarded Analog Output Modules

Note:

(T7480)

unit is set to shutdown, the red SHUTDOWN indicator will

turn on when the communications with the controller are lost.

If the I/O unit is set to hold, the SHUTDOWN indicator will

always be off (see page 8, Fault Mode Jumper).

When the module is installed in the I/O chassis or when logic

power (from the I/O power supply modules) is first applied to

the module, it will be in the shutdown mode until the first

output scan, regardless of the fault mode jumper settings.

Also, removing two I/O transceiver modules, two I/O power

supply modules, or two power legs will cause the module to be

in the shutdown mode.

PD-7026

Mar-06

5

Page 6

Guarded Analog Output Modules

(T7480)

6

Figure 2. Guarded Analog Output

Industrial Control Services

Module.

Page 7

Guarded Analog Output Modules

(T7480)

Application

Guarded analog output modules are suited for high integrity

control of analog output devices. Guarded output modules can

be used for fail-safe or fault tolerant operation.

Fail-Safe Configuration

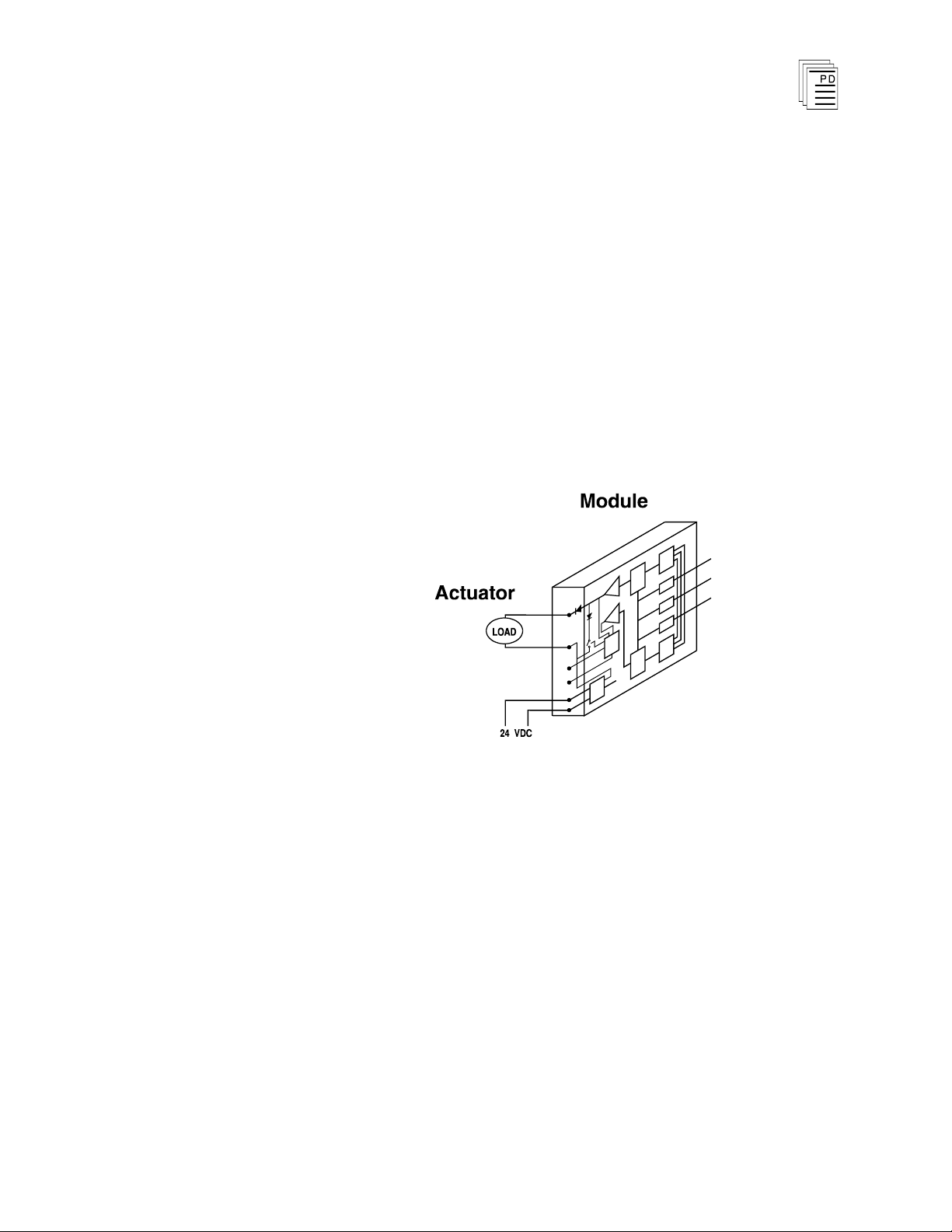

As shown in Figure 3, fail-safe configuration uses a single

Guarded module. In this configuration, the worst case failure

will cause the output to fail to the off state.

In a fail-safe configuration, a module failure and subsequent

removal of the module disables

all of its outputs.

PD-7026

Mar-06

Figure 3. Fail-Safe Configuration.

Fault Tolerant Configuration

For fault tolerant operation, two Guarded modules are

connected in parallel as shown in Figure 4. In this

configuration, operation continues even if one module fails.

In the fault tolerant configuration, a failed module can be

removed and replaced without interrupting operation of the

loads.

7

Page 8

Guarded Analog Output Modules

(T7480)

Figure 4. Fault Tolerant Configuration.

Field Wiring

For field wiring details, refer to PD-7901 - I/O Termination

Assembly.

Effects of Open Circuit Field Wiring

When a Guarded analog output module is controlling the

outputs (as opposed to the standby mode) an open circuit in

the field wiring connected to a load device will be detected as a

failure. This causes the controlling module to switch off,

annunciate a fault and enter the standby mode. Once in the

standby mode, all of its outputs are shunted to A

GND internal

to the module, thus eliminating the open circuit and the

module’s comparators become healthy. This will have one of

two effects based upon single or dual module configuration:

Single Guarded Module Configuration

8

In a single guarded output configuration the module will

toggle back and forth between the controlling and standby

modes about every one or two seconds. The ON status LED on

the face of the module will turn on and off repeatedly until the

open circuit field wiring is corrected. Durin

g this time the

module FAULT status LED will also be on and the system will

report a fault for this module.

Industrial Control Services

Page 9

Guarded Analog Output Modules

Important!

Each time the single module enters the standby mode all six

of the output channels are taken off line and the field signals

become 0 mA. When the module switches back to the control

mode the field signals return to their controlled values. This

causes the output loads that have healthy wiring connections

to experience an output signal that toggles between 0 mA and

their controlled values which often produces undesirable

effects. To avoid this, you should monitor the fault status

system control relay for the output module in your application

program and use it to set all of the analog output channels to

zero. Turning all of the outputs off will often be safer than

letting them toggle between 0 mA and a controlled value.

(T7480)

Dual Guarded Module Configuration

In a dual module configuration the two modules will switch

back and forth between control and standby modes. The ON

status LED will appear to “ping-pong” back and forth between

the two modules about every one or two seconds. This will

continue until the open circuit field wiring is corrected.

During this time the module FAULT status LED will also be

on for each of the modules and the system will report a fault

for both modules.

While in this mode the remaining output loads that have

healthy field wiring connections should continue to be

controlled correctly because one of the two modules is always

in the control mode.

Fault Mode Jumper

The

fault mode jumper is located behind the ID switch cover

in the lower left-hand corner of each I/O chassis. The position

of the fault mode jumper determines the module's response to

system level faults. The fault mode jumper’s position will

cause all output modules in the I/O chassis to either shutdown

(set all outputs to zero) or to hold (hold the last state) after a

system level failure occurs. An example of a system level

failure is the failure of two processor modules.

PD-7026

Mar-06

9

Page 10

Module

Upper

Connector

Lower

Connector

T7480

9 10

Guarded Analog Output Modules

(T7480)

Keying

The I/O chassis can be

physically keyed to prevent accidental

damage caused by inserting a module into a slot wired for a

different module type. Figure 5 illustrates how the slot keys

are installed on the I/O chassis slot field wiring connectors.

The slot key positions for the Guarded analog output module

are listed in Table 1.

Table 1. Slot Key Positions.

10

Industrial Control Services

Page 11

Guarded Analog Output Modules

(T7480)

PD-7026

Mar-06

Figure 5. Installing Slot Keys.

Configuration

Each output module is configured using the

W

INTERPRET

Configuration Editor. In the editor you will perform the three

steps described below to configure the output module.

I/O

11

Page 12

Guarded Analog Output Modules

(T7480)

1) Set the Module Type:

Position the cursor on the module slot you wish to define.

Choose Set Module Type from the Edit Menu and select

the Guarded analog output module from the list.

2) Edit the Module Definition:

Choose Edit Module Definition from the Edit Menu. A

dialog box will open whe

output point definitions.

re you can define the analog

Figure 6. Guarded Analog Output Module Definition.

3) Edit each point:

Choose Edit from the Module Definition dialog box to

define a name and description for each output point. In

the Analog Output Point dialog, enter names and values

for the configuration fields as described below.

12

Industrial Control Services

Page 13

Guarded Analog Output Modules

(T7480)

Name

Figure 7. Defining an Analog Output Point.

Also called the tag name, this is the name used in the

application program to reference the output point. The name

can be up to 12 characters long.

Description

This 40-character field provides a place to describe the output

point definition. The description is used to help document

your system (it does not affect application program operation).

Comm Protect

Marking the Comm Protect check box protects the point from

changes by communications functions such as data write,

forcing, and load initial value when Comm Protect is enabled.

Initial Value

The initial value for the output is loaded to the Regent when

you load the I/O configuration and also when you load the

application program that controls the output.

PD-7026

Mar-06

Final Value

The final value for the output is loaded to the Regent when

the application program that controls the output is deleted.

Unless special circumstances exist, you should always enter

zero, so that the output is turned off when you delete the

application program that controls it.

13

Page 14

Guarded Analog Output Modules

(T7480)

Programming

Outputs are controlled by writing application programs that

solve for output values. For example, placing an output tag

name in the result field of a math element in ladder logic will

set the analog output to the value calculated by the math

element. Note that the data range for analog outputs is 0 to

4095 corresponding to the output current rage of 4 to 20 mA.

Often you may choose to write analog control logic using an

engineering unit number range other than 0 to 4095 to

simplify the creation and interpretation of the control logic. If

you do so you should use the analog scaling function block

to

“unscale” your calculated value to the 0 to 4095 range

required for the analog output. An example of an analog

scaling entry for analog outputs is shown in Figure 8.

14

Figure 8. Unscaling an Analog Output.

This example implies that some other control logic solves a

value for the shared register “AO1_ENG_VAL” which ranges

from 0 to 10,000 (the low and high values). The analog

scaling entry shown in the example then converts the

engineering unit value to the analog output range of 0 to

4095, storing the converted value in the analog output “AO1”.

By using an engineering unit range of 0 to 10,000 for your

Industrial Control Services

Page 15

Guarded Analog Output Modules

control logic, you maintain the full resolution of the analog

output (1 part in 4096) and have a convenient engineering

range that represents 0.00 to 100.00% (the two decimal places

are implied).

(T7480)

Programming Fault Tolerant Guarded Analog Outputs

To program guarded analog outputs in a fault tolerant

configuration, you should create control logic to calculate the

value

calculated value to the redundant guarded analog output. If

you use the unscale entry in the analog scaling function block

you should place this “copy logic” after the analog scaling

function block in your application program. Figure

illustrates how the Assign instruction in ladder logic can be

used.

In this example GAO1A is the name of the analog output that

has been set by your control logic, and GAO1B is the

redundant analog output. When power flows to the Assign

element, it reads the value of GAO1A and stores that value to

GAO1B, so that both of the redundant analog outputs have

the same value.

for one of the guarded analog outputs and copy this

Figure 9. Programming Fault Tolerant Outputs.

9

Maintenance

PD-7026

Mar-06

There are no user replaceable parts inside the Guarded

analog output module. Re-calibration is recommended once

per year, in order to maintain the rated accuracy of the analog

output signals over an extended period of time.

procedure describes the equipment and steps necessary to

calibrate the Guarded analog output module.

Calibration Procedure

Equipment Required

·

A 5½-digit voltmeter.

·

Six 250 ohm, 0.005%, 5 ppm/°C resistors to convert the six

output signals from a current to a voltage.

The following

15

Page 16

Channel

Offset

Potentiometer

Gain

Potentiometer

1 R101

R100

2 R201

R200

3 R301

R300

4 R401

R400

5 R501

R500

6 R601

R600

Important!

Guarded Analog Output Modules

·

Potentiometer adjustment tool.

·

Phillips screwdriver

·

I/O module extender, catalog number T7322.

·

PC running the

analog output channels to the specific values for

calibration.

(T7480)

W

INTERPRET

software, used to force the

Calibration Preparation

The module must be calibrated while connected to an I/O

chassis of an operational Regent system.

During calibration, the Guarded analog output module will be

disconnected from the actual controlled field devices.

Appropriate precautions should be taken to ensure th

at the

disconnection of the control signals does not pose a safety risk

to plant personnel or process equipment.

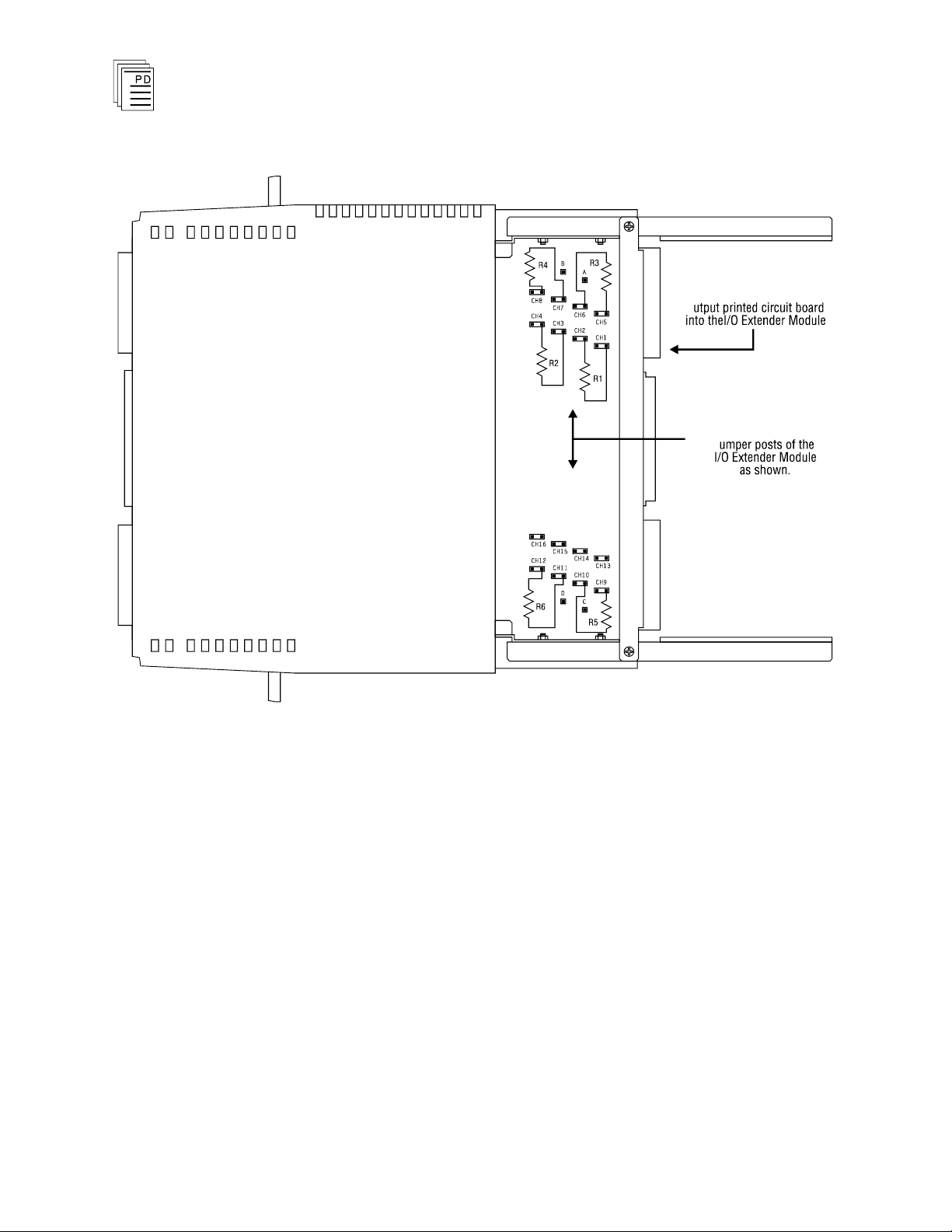

There are Offset and Gain potentiometers for each analog

output channel. In addition there are three reference voltage

potentiometers and four test points to measure the reference

voltages. These potentiometers are located on a circuit board

inside the module's protective clamshell housing (see Figure

10

). During the calibration steps you will remove the printed

circuit bo

potentiometers for adjustment.

ard from the housing in order to access these

The potentiometers for each analog output channel are

identified in Table 2. The potentiometers labeled R19, R17

and R22 are used to adjust the reference voltages.

16

Table 2. Potentiometer Identification.

Industrial Control Services

Page 17

Guarded Analog Output Modules

(T7480)

PD-7026

Mar-06

Figure 10. Guarded

Potentiometer Locations.

Analog Output Module Calibration

The I/O extender module has jumper posts that allow you to

connect or disconnect the I/O slot field wiring on the I/O

chassis to the printed circuit board plugged into the I/O

extender. During the calibration steps you will remove any

jumpers installed on these posts in order to connect the

precision load resistors to the analog outputs. Figure 11

shows the jumper posts to which you should connect the

precision resisto

rs for each analog output channel.

17

Page 18

Important!

Guarded Analog Output Modules

(T7480)

Figure 11. I/O Extender Connections for Guarded Analog Output Calibration.

Within each pair of jumper posts, make sure that you connect

the resistors to the jumper posts nearest the front of the I/O

extender. Do not make any connections to the jumper posts

nearest the I/O chassis backplane —

these connect to the

actual field wiring attached to the I/O slot terminals on the I.O

chassis.

Calibration Steps

1. Remo

ve the module to be calibrated from the I/O chassis.

2. Install the I/O extender module into the slot from which

the module was removed.

3. Remove the jumpers (if installed) labeled CH1 through

CH16 from the I/O extender module.

18

Industrial Control Services

Page 19

Guarded Analog Output Modules

(T7480)

4. Connect the six precision resistors to the I/O extender

jumper posts as shown in Figure 11. Use test clips as

required to make the connections.

5. Remove the four screws on one side of the module and

remove the printed circuit board from the module

clamshell housing.

6. Install the printed circuit board into the I/O extender

module. Allow the board to warm up for approximately one

minute.

7. Connect the voltmeter's negative probe to test point TP4.

Measure the voltage at TP1. The voltage should be

10.0000 VDC (±0.0003 VDC). Use R22 to adjust the

voltage.

8. Connect the voltmeter’s negative probe to TP4. Measure

the voltage at TP2. The voltage should be 8.0000 VDC

(±0.0002 VDC). Use R17 to adjust the voltage.

9. Connect the voltmeter negative probe to TP4. Measure

the voltage at TP3. The voltage should be 2.0000 VDC

(±0.0001 VDC). Use R19 to adjust the voltage.

10. Using the forcing functions of WINTERPRET

, force all of the

six analog outputs to zero. Refer to the Regent User’s

Guide for more details about the forcing functions. Wait

approximately one minute after forcing the outputs to

allow them to stabilize.

11. Adjust each of the six Offset potentiometers until the

voltage measured across the corresponding precision

resistor is +1.0000 V (± 0.0002 V). Connect the voltmeter

across the resistor leads to measure the voltage.

12. Force all six of the outputs to 4095. Wait approximately

one minute after forcing the outputs to allow them to

stabilize.

13. Adjust each of the six Gain potentiometers until the

voltage measured across the corresponding precision

resistor is +4.9990 V (± 0.0002 V).

PD-7026

Mar-06

After completing one iteration of the calibration, repeat the

offset and gain adjustments (steps 10 through 13) until the

readings are within specificati

ons. It is necessary to repeat

19

Page 20

Guarded Analog Output Modules

these steps as there may be some interaction between the gain

and offset adjustments.

(T7480)

14. As a final check, use

W

INTERPRET

to force all six outputs to

2048. Wait one minute and verify that the voltage

measured across each of the precision resistors is +3.0000

VDC (±0.0002 VDC). If the Offset and Gain adjustments

are within the limits stated in steps 11 and 13 above, but

this midvalue point is not, return the Guarded analog

output module to the factory for repair or replacem

ent.

15. Calibration is complete. Unplug the printed circuit board

from the I/O extender module and replace it in its

clamshell housing. Remove all forcing of the analog

outputs from the force table using

W

INTERPRET

. Remove

the I/O extender module from the I/O chassis and reinstall

the calibrated module in the I/O chassis.

The module’s red Fault indicator will be on until you

perform a voted reset by pressing the Reset buttons on two

of the Regent processor modules. After the voted reset is

complete, t

on.

he module’s green Active indicator should turn

Latent Fault Testing Procedure

Equipment Required

·

A digital multimeter with diode test mode (2 mA current

source).

·

Six 250 ohm, 0.005%, 5 ppm/°C resistors to terminate the

analog output channels.

·

One 47K ohm, 5%, ¼ Watt resistor for fault injection tests.

·

Phillips screwdriver

·

I/O module extender, catalog number T7322.

·

PC running the

W

INTERPRET

software, used to force the

analog output channels to the specific values for

calibration.

Testing Preparation

A portion of the tests are performed on the module while it is

disconnected from the rest of the system and removed from its

protective clamshell housing. For the remainder of the tests

20

Industrial Control Services

Page 21

Guarded Analog Output Modules

(T7480)

the module must be connected (using the I/O extender) to an

I/O chassis of an operational Regent syst

em. It is

recommended that these tests are performed each time that

you calibrate the Guarded analog output module.

There are two diodes for each analog output channel that

must be tested for latent faults. In addition the fault

summary logic is exercised by injecting a fault. The locations

of the diodes and other necessary test and measurement

points for this procedure are shown in Figure 12.

The I/O extender module has jumper posts that allow you to

connect the six 250 Ohm termination resistors to the printed

circuit board plugged into the I/O extender. During the

calibration steps you will remove any jumpers installed on

these posts in order to connect the termination resistors to the

analog outputs. Figure 11 shows the jumper posts to which

you should connect the resistors for each analog output

channel.

PD-7026

Mar-06

21

Page 22

Guarded Analog Output Modules

(T7480)

22

Figure 12. Location of Test Points for Latent Fault Testing.

Testing Steps

1. Remove the modul

e to be tested from the I/O chassis.

2. Install the I/O extender module into the slot from which

the module was removed.

3. Remove the jumpers (if installed) labeled CH1 through

CH16 from the I/O extender module.

Industrial Control Services

Page 23

Guarded Analog Output Modules

(T7480)

4. Connect the six termination resistors to the I/O extender

jumper posts as shown in Figure 11. Use test clips as

required to make the connections.

5. Remove the four screws on one side of the module and

remove the printed circuit board from the module

clamshell hous

ing.

6. With the printed circuit board removed from the system,

check the forward voltage drop (in-circuit) on all 12 output

diodes with a digital multimeter in the diode test mode (2

mA current source). Verify that the forward voltage drop

is within the following tolerances:

0.6 to 0.8 volts for CR100, CR200, CR300, CR400, CR500,

and CR600.

0.2 to 0.45 volts for CR101, CR201, CR301, CR401. CR501

and CR601.

7. Check the resistance (in-circuit) of the 12 output diodes

reversely polarized with a digital mu

ltimeter set to 20

MOhm resistance range, by connecting the (+) lead of the

meter to the cathode and the (-) lead of the meter to the

anode of the diode. Verify that the resistance is within the

following tolerances:

PD-7026

Mar-06

> 20 MOhm for CR100, CR200, CR300, CR400, CR500,

and CR600.

> 1 MOhm for CR101, CR201, CR301, CR401. CR501 and

CR601.

8. If any of the tests in steps 6 or 7 fails, the board should be

returned to the factory for repair or replacement. If the

tests passed continue to step 9.

9. Install the printed circuit board into the I/O extender

module. Perform a voted reset (press two of the processor

module Reset buttons) and verify that the module is Active

(green Active LED is on and red Fault LED is off). Allow

the board to warm up for approximately one minute.

10. Connect a 47K Ohm, 5% resistor between TP4 (AGND) and

the top lead of the first resistor (10K Ohm) on the SIP

resistor network RN101 (Figure 12 shows the exact

location of this resistor). Verify that the module signals a

23

Page 24

Guarded Analog Output Modules

fault (green Activity LED turns off and the red Fault LED

turns on).

11. Disconnect the one end of the 47K Ohm resistor from TP4.

The other end should still be connected to the top lead of

the 10K Ohm resistor on RN101. Restore the module to

the Active state by performing a voted reset. Now take the

end of the 47K Ohm resistor that you removed from TP4

and reconnect it to TP3 (+2VREF). Verify that the module

indicates a fault.

12. Restore the module to the Active state by performing a

voted reset.

13. Repeat steps 10 through 12 for output channels 2 through

6 connecting the 47K Ohm resister to the appropriate

resistor network (RN201 through RN601). Use the same

test points TP4 and TP3 as used for output channel 1. In

each case, verify that the fault injection procedure causes a

fault indication on the module.

(T7480)

14. If any of the fault injection tests does not produce a fault

indication, the module should be returned to the factory for

repair or replacement.

15. Calibration is complete. Unplug the

from the I/O extender module and replace it in its

clamshell housing. Remove the I/O extender module from

the I/O chassis and reinstall the module in the I/O chassis.

The module’s red Fault indicator will be on until you

perform a voted reset. After the voted reset is complete,

the module’s green Active indicator should turn on.

Safety Considerations

The Guarded analog output module is TÜV certified as non

interfering, and can be used in a safety syste

critical outputs.

Analog outputs are rarely used to perform safety critical

interlock functions, but processes may have control

applications that demand a high integrity for analog control

functions. The guarded analog output module is ideally

suited for these types of applications. In all applications the

printed circuit board

-

m for non-safety

24

Industrial Control Services

Page 25

Guarded Analog Output Modules

Safetybus Power

0.8 load units

Number of Outputs

Six

External Power

Voltage:

Current:

24 VDC ±10%

0.5 amps

Output Range

4 to 20 mA

Data Range

0 to 4095

Resolution

12-bit (1 in 4096)

Accuracy

0.05% of full scale @ 25° C

Drift

±50 ppm/

°C

Load Resist

ance

0 to 400 ohms

Settling Time

0.1 ms (to 0.1% of full scale)

Heat Dissipation

14 Watts, 47 BTUs/hour

Isolation

2500 volts minimum (field

wiring to control logic)

Operating Temperature

0°

to 60° C

(32° to 140° F)

Storage Temperature

-40°

to 85° C

(-40°

to 185° F)

Operating Humidity

0 to 95% relative humidity,

non-

condensing

Vibration

10 to 55 Hz:

±0.15mm

Shock

Operating:

15 g, ½ sine wave, 11 msec

(T7480)

safety of the process should not be dependent on the

operations of the guarded analog output module.

To maintain the highest level of integrity, users are advised to

periodically perform the calibration and latent fault testing

described in the Maintenance section of this document. Refer

to page 15 for specific details on performing these procedures.

Specifications

PD-7026

Mar-06

25

Page 26

Electromagnetic

Interference

•

IEC 801 Part 2 - Electrostatic

Discharges

•

IEC 801 Part 3 - Radiated

Electromagnetic Fields

Level 3: Contact discharge of

6 kV

Level 3: 10 V/M, 27 MHz 500 MHz

Safety

Certified to DIN V VDE

0801 (non-interfering) and

designed to meet UL 508 and

CSA 22.2, No. 142-M1981

Dimensions

Height:

Width:

Depth:

12.6" (320 mm)

1.27" (32 mm)

10.12" (257 mm)

Weight

3.5 lbs (1.6 kg)

Guarded Analog Output Modules

(T7480)

26

Industrial Control Services

Loading...

Loading...