ICS Regent+Plus

®

PD-7018

AC Isolated Digital Output Module

110 VAC

(T7454)

Issue 1,

The AC isolated digital output module provides control of

eight isolated user output loads. One type of module is

available to interface to outputs powered from is

VAC field power supplies. Each module's triplicated I/O

Safetybus interface ensures that no Regent system failure can

incorrectly apply power to an output, and that no failure in

the module can affect the operation of the Regent system or

other I/O modules in the system.

olated 110

March, 06

Module

Features

·

Eight isolated 110 VAC output circuits.

·

Hot-replaceable.

·

Automatic self-testing of triplicated I/O Safetybus circuits

many simplex logic circuits.

·

2 amp output circuits.

·

Zero-cross load switching.

·

Individual front panel indicators on each module show active

and fault, shutdown, blown fuse, and output on/off status (logic

side).

·

2500 volt minimum electrical isolation between field and logic

circuits.

·

TÜV certified, Risk Class 5, non-interfering.

Operation

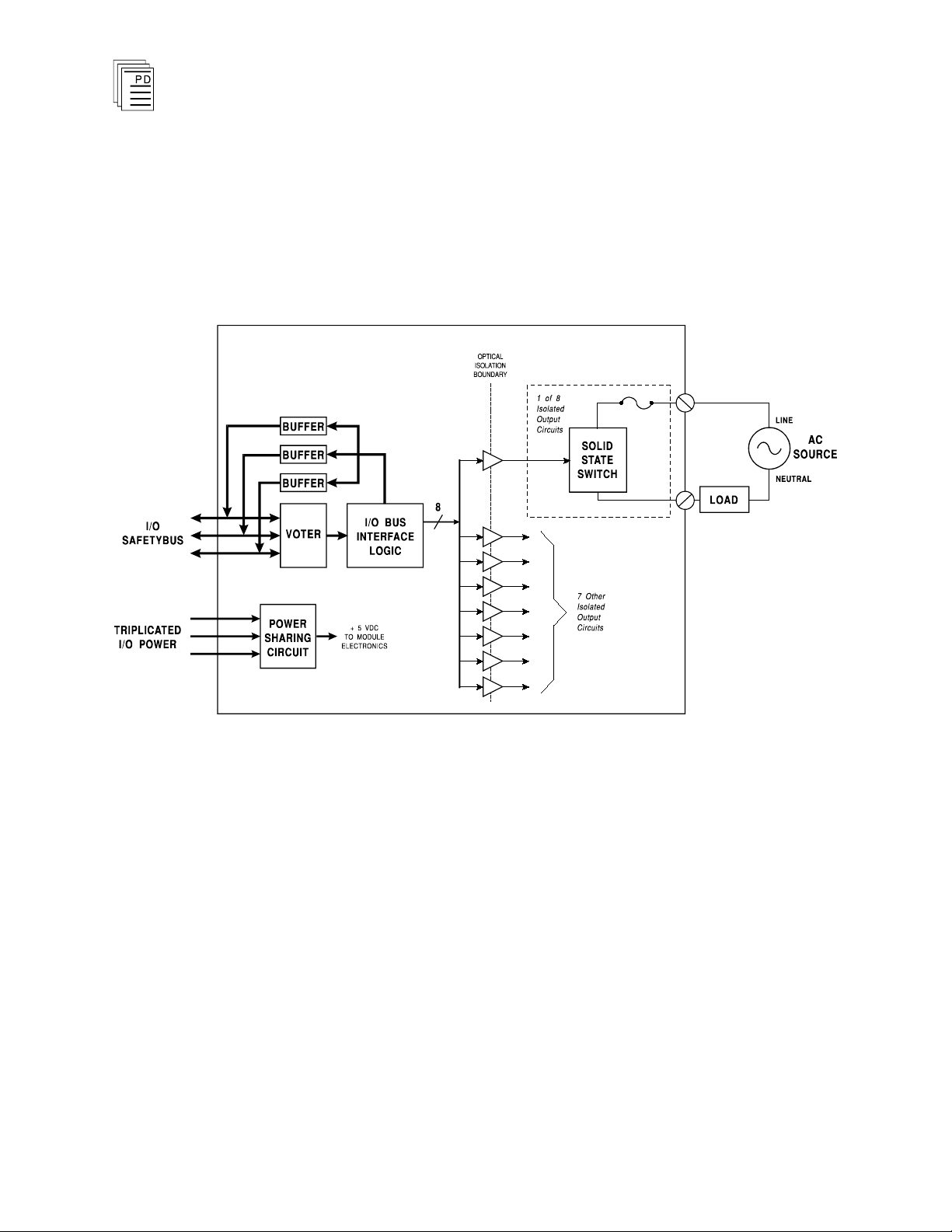

A block diagram of a typical 110 VAC isolated digital output

module is shown in Figure 1.

and

Industrial Control Services

1

AC Isolated Digital Output Module

The processor modules send triplicated write data commands

to the output module over the I/O Safetybus. The processors’

addressing data and data write commands are voted by the

module (preventing I/O Safetybus failures upstream from the

module from affecting module operation). The voted result is

then passed to the I/O bus interface logic.

(T7454)

2

Fig

ure 1. Block Diagram of 110 VAC Isolated Digital Output Module.

The voted output data from the I/O bus interface logic is then

used to drive the output circuits. Zero crossing turn-on

TRIAC drivers are used to convert the logic level output drive

signals to switch 110 VAC power to load devices.

When the output is logically turned on, the field device is

energized, and when the output is logically turned off, the

field device is de-energized.

Optical isolation between the module’s logic and fi

provides logic-to-field isolation

— protecting the output

module from field signal over voltages, transients, and other

electrical disturbances. It also provides a safety barrier

between the primary field voltages and user accessible

circuits. Additionally each output is isolated from the other

Industrial Control Services

eld circuits

(T7454)

outputs, to operate load devices powered from isolated field

power supplies.

Each output is individually fused to protect the circuits from

short circuit conditions in output wiring and field devices.

AC Isolated Digital Output Module

Testing and Diagnostics

Each module’s voter circuits are periodically tested by the

processor modules. Discrepant data are sent through one of

three legs of the I/O Safetybus to determine whether the

module’s voter is able to outvote the incorrect data. A failure

to return the correct majority-voted result to the processors

produces an I/O module error indication at the processor

modules and a module fault indication at the I/O module.

Each type of module has a unique identification code that is

read by t

which type of module is installed in each I/O chassis slot and

how to address that module and its points specifically. If a

module is removed, or is replaced with a module of a different

type, the processor modules will indicate an I/O module error.

Loopback logic tests periodically write data to the module and

then read it back to determine whether the module’s I/O bus

interface logic is functioning correctly.

Fuses are continually checked for continuity.

the minimum load (see Specifications, page 12) must be

connected to each output in order to detect a blown fuse.

he controller. This code lets the controller know

Field power and

PD-7018

Mar-06

Front Panel Indicators

The 110 VAC isolated digital output module is shown in

Figure 2. The front panel contains the active and fault status

indicators, shutdown indicator, and output status and blown

fuse indicators for each output circuit.

Active and Fault Status Indicators

These green and red LEDs indicate the overall health

module. During normal operation, the green ACTIVE

indicator flashes at the controller’s scan rate. If a module

fault is detected the red FAULT indicator turns on and the

green indicator turns off.

3

of the

Note:

AC Isolated Digital Output Module

(T7454)

Shutdown Indicator

Upon loss of communications with the controller, output

modules enter either a shutdown or hold fault mode. If the I/O

assembly is set to shutdown, the red SHUTDOWN indicator

will turn on when communications with the controller are lost.

If the I/O assembly is set to hold, the SHUTDOW

will always be off (see page 7, Fault Mode Jumper).

N indicator

When the module is installed in the I/O chassis or when logic

power (from the I/O power supply modules) is first applied to

the module, it will be in the shutdown mode until the first

output scan, regardless of the fault mode jumper settings.

Also, removing two I/O transceiver modules, two I/O power

supply modules, or two power legs will cause the module to be

in the shutdown mode.

Output Status Indicators

The output status indicators are yellow LEDs, located on the

logic side of the output. There are 8 output status indicators

— one for each output. These indicators are lit when the

output TRIAC is energized to turn on the load.

Blown Fuse Indicators

The red BLOWN FUSE indicators turn on when the

associated output’s internal fuse opens. A blown fuse will also

cause the module’s FAULT indicator to turn on.

The module must be connected to a load and field power must

be present to detect a blown fuse. Refer to Maintenance, page

11

, for fuse replacement instructions.

4

Industrial Control Services

Loading...

Loading...