Page 1

ICS Regent+Plus

®

PD-7017

Relay Output Modules

Low Power and High Power

(T7446L and T7446H)

Issue 1,

Relay output modules provide control of eight user output

loads. Two types of relay output modules are available

providing dry contact relay clos

variety of AC and DC voltages to field loads. Each module's

triplicated I/O Safetybus interface ensures that no Regent

system failure can incorrectly apply power to an output and

that no failure in the module can affect the operation of the

Regent system or other I/O modules in the system.

ure outputs for switching a

March, 06

Features

·

Eight isolated, dry contact relay outputs: four Form-C, and four

form-A or Form-B selectable.

·

Hot replaceable.

·

Automatic self-testing of triplicated I/O Safetybus circuits and

many simplex logic circuits.

·

High power modules (T7446H) operate up to 250 VAC/125

VDC switching loads rated at 500 VA or 100 Watts.

·

Low power modules (T7446L) operate up to 125 VAC/VDC

switching loads rated at 60 VA or 30 Watts.

·

Individual front panel indicators on each module show active

and fault status, shutdo

side).

·

TÜV certified, Risk Class 5, non-interfering.

wn state, and output status (logic

Industrial Control Services

1

Page 2

Relay Output Modules

(T7446L, H)

Module Operation

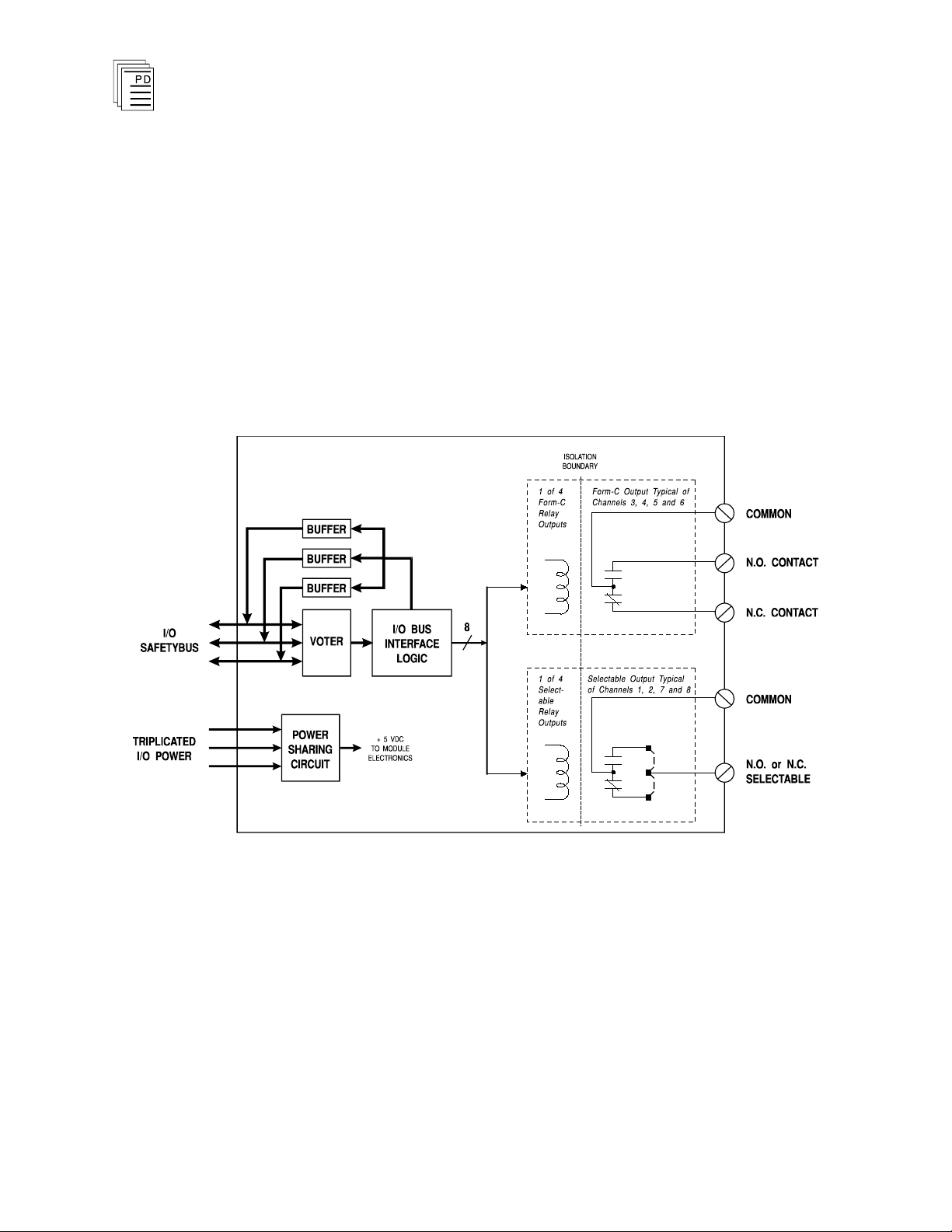

A block diagram of a typical relay output module is shown in

Figure 1.

The processor modules send triplicated write data commands

to the output module over the I/O Safetybus. The processors’

addressing data and data write commands are voted by the

module (preventing I/O Safetybus failures upstream from the

module from affecting module operatio

then passed to the I/O bus interface logic.

n). The voted result is

2

Figure 1. Block Diagram of a Relay Output Module.

The voted output data from the I/O bus interface logic is then

used to drive the output circuits. Logic output drive signals

energize the coils of relays mounted on the printed circuit

board. Relay contacts provide dry-contact switching of load

devices.

When the output is logically turned on, the relay coil is

energized (closing the N.O.

contact), and when the output is

Industrial Control Services

Page 3

(T7446L, H)

logically turned off, the relay coil is de-energized (closing the

N.C. contact).

The relay provides logic-to-field isolation between the

module’s logic and field circuits — protecting the output

module from field signal over voltages, transients, and other

electrical disturbances.

Both types of relay output module use UL 508 approved

relays.

Relay Output Modules

Testing and Diagnostics

Each module’s voter circuits are periodically tested by the

processor modules. Discrepant data are sent throug

three legs of the I/O Safetybus to determine whether the

module’s voter is able to outvote the incorrect data. A failure

to return the correct majority-voted result to the processors

produces an I/O module error indication at the processor

modules and a module fault indication at the I/O module.

Each type of module has a unique identification code that is

read by the controller. This code lets the controller know

which type of module is installed in each I/O chassis slot and

how to address that m

module is removed, or is replaced with a module of a different

type, the processor modules will indicate an I/O module error.

Loopback logic tests periodically write data to the module and

then read it back to determine whether the module’s I/O bus

interface logic is functioning correctly.

odule and its points specifically. If a

Front Panel Indicators

h one of

PD-7017

Mar-06

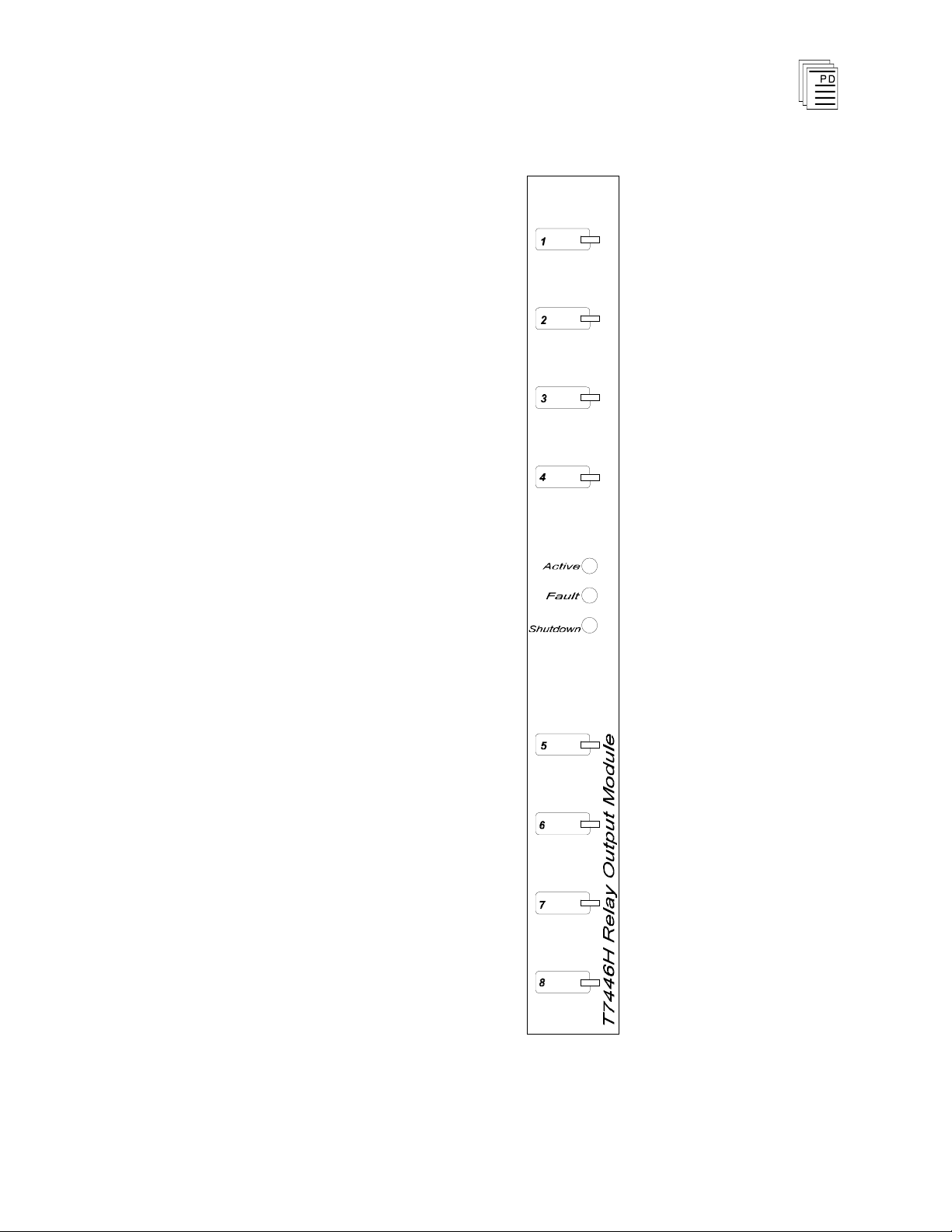

The relay output module is shown in Figure 2. The front

panel contains active and fault status indicators, a shutdown

indicator, and output status indicators for each output circuit.

Active and Fault Status Indicators

These green and red LEDs indicate the overall health of the

module. During normal operation the green ACTIVE

indicator flashes at the controller's scan rate. If a module

fault is detected the red FAULT indicator turns on and the

green indicator turns off.

3

Page 4

Note:

Relay Output Modules

(T7446L, H)

Shutdown Indicator

Upon loss of communications with the controller, output

modules enter either a shutdown or hold fault mode. If the I/O

assembly is set to shutdown, the red SHUTDOWN indicator

will turn on when communications with the controller are lost.

If the I/O assembly is set to hold, the SHUTDOWN indicator

will always be off (see page 11, Fault Mode Jumper).

When the module is installed in the I/O chassis or when logic

power (from the I/O power supply modules) is first applied to

the module, it will be in the shutdown mode until the first

output scan, regardless of the fault mode jumper settings.

Also, removing two I/O transceiver mo

dules, two I/O power

supply modules, or two power legs will cause the module to be

in the shutdown mode.

Output Status Indicators

The output status indicators are yellow LEDs located on the

logic-side (coil) of the relay output. There are eight output

status indicators

— one for each output. These indicators are

lit when the output relay coil is energized, closing the

normally open contact.

4

Industrial Control Services

Page 5

(T7446L, H)

Relay Output Modules

PD-7017

Mar-06

Figure 2. Relay Output Module.

5

Page 6

Relay Output Modules

(T7446L, H)

Application

Simplex Configuration

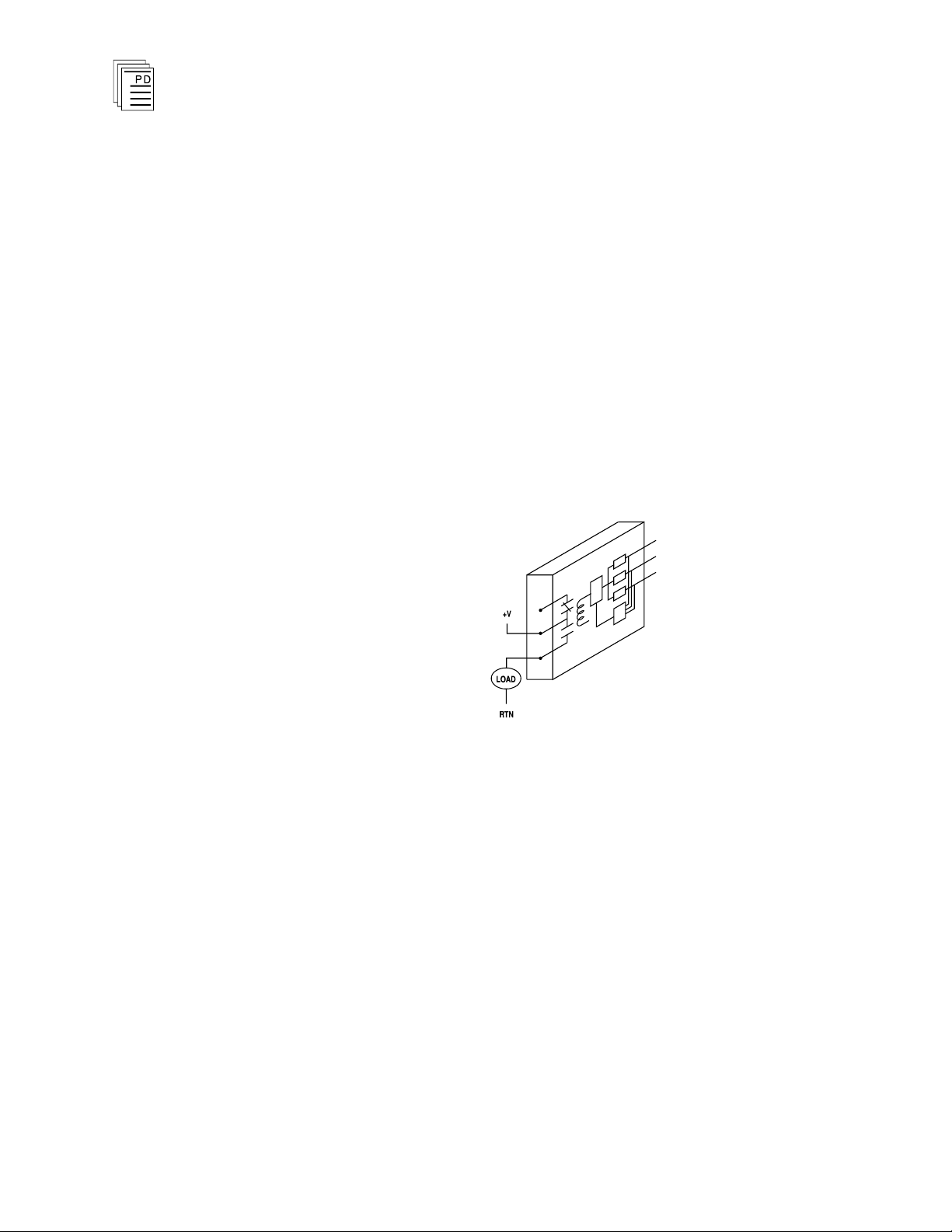

Relay o

critical output devices. These non-critical devices typically

include status alarms or other field devices that are not used

for primary safety shutdown purposes. Although much of the

circuitry on the relay output module is automatically tested,

some logic circuits and the field-side output switch are simplex

and non-tested. This simplex configuration is illustrated in

Figure 3. For safety-critical outputs requiring fail-safe

fault tolerant output configurations, Guarded digital output

modules should be used.

utput modules provide a suitable interface to non

-

or

6

Figure 3. Simplex Relay Output Configuration.

Field Wiring

For field wiring details, refer to PD-7901 - I/O Termination

Assembly (ITA).

Industrial Control Services

Page 7

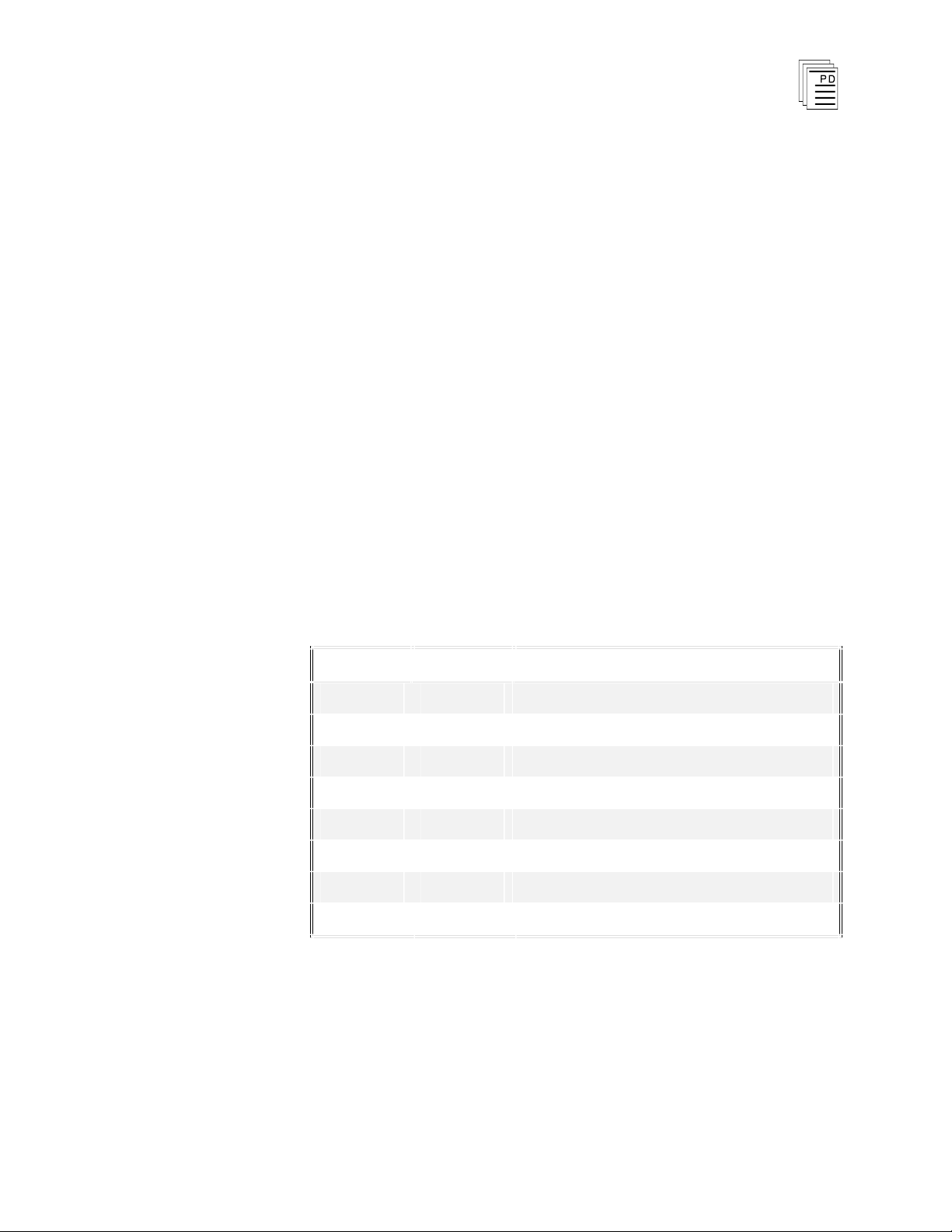

(T7446L, H)

Jumper

Form

Description

E110

NO1

Selects normally open for relay 1

E111

NC1

Selects normally closed for relay 1

E120

NO2

Selects normally open for relay 2

E121

NC2

Selects normally closed for relay 2

E170

NO7

Selects normally open for relay 7

E171

NC7

Selects normally closed for relay 7

E180

NO8

Selects normally open for relay 8

E181

NC8

Selects normally

closed for relay 8

Relay Output Modules

Relay Operation

The relays used on the T7446L contain SPDT contacts. For

the Form-A or Form-B selectable outputs, a jumper in the

module is used to select Form-A (N.O.) or Form-B (N.C.)

action.

The relays used on the T7446H contain t

(one normally closed and one normally open). Jumpers within

the module are also used to select the relay form. On the

Form-C output, there is no guarantee for make-before-break

or break-before-make.

Output Form Selection

Two sets of jumper posts are used to select the output form for

the selectable relays. The jumper locations are shown in

Figure 4. The jumper post designations are shown in Table 1.

Only one jumper shunt can be installed for each relay. The

modules are shipped with the jumpers positioned for normally

open contact outputs.

wo SPST contacts

Table 1. Jumper Designations.

PD-7017

Mar-06

7

Page 8

Relay Output Modules

(T7446L, H)

8

Figure 4. Jumper Locations.

Operating Envelope

Figure 5 shows the voltage and current operating envelopes

for the T7446L and T7446H. The T7446L relays are initially

gold clad and have an initial resistance of 50 mOhm

maximum. However, operation at high voltages and currents

will remove the gold and the closed resistance will increase

substantially. This increased resistance reduces its ability to

subsequently s

witch very low power loads.

Industrial Control Services

Page 9

(T7446L, H)

Relay Output Modules

As with any relay, operating at higher voltages and currents

will result in decreased relay life. Figure 6 shows the voltage

and current versus service life for the relays.

PD-7017

Mar-06

Figure 5. Voltage and Current Operating Envelopes.

9

Page 10

10

100

1000

10000

100000

0

0.4 0.8 1.2 1.6

2

2.4

10

100

1000

10000

100000

0

0.4 0.8 1.2 1.6

2

2.4

Relay Output Modules

(T7446L, H)

Figure 6. Voltage and Current vs. Service Life.

Relay Protection

Each relay circuit must be fused externally to protect the

relay and the load. Modules are also fused internally with

factory-replaceable fuses to protect the I/O assembly and the

module’s printed circuit board.

If an inductive load is connected, a suitable snubber must be

externally provided.

10

Industrial Control Services

Page 11

(T7446L, H)

Module

Upper

Connector

Lower

Connector

T7446H

T7446L

17 2

Relay Output Modules

Fault Mode Jumper

The fault mode jumper is located behind the ID switch cover

in the lower left-hand corner of each I/O chassis. The position

of the fault mode jumper determines the module's response to

system level faults. The fault mode jumper’s position will

cause all output m

(turn off all outputs) or to hold (hold the last state) after a

system level failure occurs. An example of a system level

failure is the failure of two processor modules.

Keying

The I/O chassis can be physically keyed to prevent accidental

damage caused by inserting a module into a slot wired for a

different module type. Figure 7 illustrates how the slot keys

are installed on the I/O chassis slot field wiring connectors.

The slot key pos

Table 2. Both versions of the relay output module use the

same slot key positions.

odules in the I/O chassis to either shutdown

itions for the relay output module are listed in

Table 2. Slot Key Positions.

PD-7017

Mar-06

11

Page 12

Relay Output Modules

(T7446L, H)

12

Figure 7. Installing Slot Keys.

Configuration

Each output module is configured using the

W

INTERPRET

I/O

Configuration Editor. In the editor you will perform the three

steps described below to co

nfigure the output module.

Industrial Control Services

Page 13

(T7446L, H)

Relay Output Modules

1) Set the Module Type:

Position the cursor on the module slot you wish to define.

Choose Set Module Type from the Edit Menu and select

the relay output module from the list.

2) Edit the Module Definition:

Choose Edit Module Definition from the Edit Menu. A

dialog box will open where you can define the output point

definitions.

Figure 8. Relay Output Module Definition.

3) Edit each point:

Choose Edit from the Module Definition dialog box to

define a name and description for each output point. In

the Digital Output Point dialog, enter names and values

for the configuration fields as described below.

Figure 9. Defining a Digital Output Point.

PD-7017

Mar-06

13

Page 14

Relay Output Modules

(T7446L, H)

Name

Also called the tag name, this is the name used in the

application program to reference the output point. The name

can be up to 12 characters long.

Description

This 40-character field provides a place to describe the output

point definition. The description is used to help document

your system (it does

Comm Protect

not affect application program operation).

Marking the Comm Protect check box protects the point from

changes by communications functions such as data write,

forcing, and load initial value when Comm Protect is enabled.

Initial Value

The initial value for the output is loaded to the Regent when

you load the I/O configuration and also when you load the

application program that controls the output.

Final Value

The final value for the output is loaded to the Regent when

the application program th

at controls the output is deleted.

Unless special circumstances exist, you should always enter

zero, so that the output is turned off when you delete the

application program that controls it.

Output Module Definition

In addition to configuring output point definitions, you can

configure an output module definition to represent the

combined state of all eight output points. The module

definition represents the eight output point definitions as

signed, 16-bit integers. In this format, the eight outputs are

the least significant bits with output point 1 as the LSB. The

eight most significant bits are always zero.

Programming

Outputs are controlled by writing application programs that

solve for output values. For example, placing an output tag

name on a coil in ladder logic will cause the output to turn on

when there is power flow to the coil in the ladder logic rung.

You can also reference the logic state of the output in your

14

Industrial Control Services

Page 15

(T7446L, H)

control logic by using a contact element (or similar element)

with the output point name.

Relay Output Modules

Maintenance

No periodic maintenance or calibration is required for this

module. If a module is to be replaced, verify the replacement

module’s relay form configuration matches the original relay

output module.

Fuses for each output are located inside the module.

fuses are for protection of the I/O chassis connectors and

module circuit board only, and are not field-replaceable

Should an internal fuse blow, it indicates that the module is

being used for output loads in excess of the safe r

module and the I/O chassis.

Modules with blown fuses should be returned to ICS for repair

or replacement.

Safety Considerations

The relay output modules are TÜV certified as non

interfering, and can be used in a safety system for simplex

non-safety critical outputs. For safety critical outputs,

guarded output modules should be used (model T7481, T7484,

T7485 or T7488 are recommended).

These

.

ating of the

-

PD-7017

Mar-06

15

Page 16

Safetybus Power

1.0 load units

Number of Outputs

Eight isolated c

ircuits (four

Form-C contacts, four

selectable N.O. or N.C.

contacts)

T7446L

T7446H

Voltage Range

0.1 to 125 VAC/DC

5 to 250 VAC

5 to 125 VDC

Load Current

2.0 amps

2.0 amps

Minimum Load

0.1 VDC/10 mA

5 VDC/10 mA

Surge Current

20 amps, 16 msec

20 amps, 16 msec

Over Voltage

Protection

750 VAC, 1 minute

1000 VAC, 1

minute

Rated Load

resistive

110 VAC, 0.3 amps

24 VDC, 1 amp

250 VAC, 2 amps

50 VDC, 2 amps

inductive

110 VAC, 0.2 amps

24 VDC, 0.3 amp

250 VAC, 2 amps

30 VDC,

2 amps

Maximum

Switching

resistive

60 VA, 30 W

500 VA, 100 W

inductive

20 VA, 10 W

500 VA, 60 W

Contact

Resistance

50 mOhms, initial

30 mOhms, initial

Breakdown

Voltage

Logic to field

Same channel

Chnl to chnl

1000 VAC

750 VAC

2500 VAC

2000 VAC

1000 VAC

2500 VAC

Turn-On Delay

5 msec

10 msec

Turn-Off Delay

2 msec

10 msec

Heat Dissipation

4.5 Watts, 15

BTUs/hour

4.5 Watts, 15

BTUs/hour

Relay Output Modules

(T7446L, H)

Specifications

16

Industrial Control Services

Page 17

(T7446L, H)

Fusing (internal)

One 3.5 A, slow blow per

output

Note:

Internal fuses are for

protection of the printed cir

cuit board only. Each output

should be individually fused

outside the module with a

fuse rated for the output

load.

Operating Temperature

0°

to 60° C

(32° to 140° F)

Storage Temperature

-40°

to 85° C

(-40°

to 185° F)

Operating Humidity

0 to 95% relative humidity,

non-condensing

Vibration

10 to 55 Hz:

±0

.15mm

Shock

Operating:

15 g, ½ sine wave, 11 msec

Electromagnetic

Interference

•

IEC 801 Part 2 - Electrostatic

Discharges

•

IEC 801 Part 3 - Radiated

Electromagnetic Fields

•

ANSI/IEEE C37.90 - Surge

Withstand Capability

Level 3: Contact discharge of

6 kV

Level 3: 10 V/M, 27 MHz 500 MHz

1 kV damped 1 MHz sine

wave

Safety

Certified to DIN V VDE

0801 (non-interfering) and

design

ed to meet UL 508 and

CSA 22.2, No. 142-M1981

Dimensions

Height:

Width:

Depth:

12.6" (320 mm)

1.27" (32 mm)

10.12" (257 mm)

Weight

4.0 lbs (1.8 kg)

Relay Output Modules

PD-7017

Mar-06

17

Page 18

Relay Output Modules

(T7446L, H)

18

Industrial Control Services

Loading...

Loading...