Page 1

ICS Regent+Plus

®

PD-7023

Analog Input Modules

60 Hz Rejection and Fast Response

(T7420A and T7420AF)

Issue 1,

Analog input modules provide data input for a maximum of

16 field analog signals per module. Two types of modules are

available: one for high noise immunity (60 Hz rejection) and

one with low noise immunity (fast response).

Features

·

Sixteen single-ended or eight differential

Interface to current

current to voltage conversion (resistors are provided as part of

the I/O Termination Assembly - see PD-7901).

inputs using external 250 ohm resistors for

voltage

March, 06

inputs.

·

Fault tolerant operation when connected in parallel with

redundant modules of the same type.

·

Hot replaceable.

·

Jumper-selectable input ranges.

·

12-bit analog to digital resolution (1 part in 4096).

·

Sample rate of all channels in 1.8 msec (differential) or 3.6

msec (single-ended).

·

60 Hz rejection (T7420A) and fast response (T7420AF)

versions available.

·

2500 volt isolation between analog and digital logic cir

·

Individual front panel indicators on each module show module

active and fault status.

·

TÜV certified for safety, Risk Class 5.

Each module’s triplicated I/O Safetybus interface ensures that

no failure in the module can affect the operation of the Regent

system or other I/O modules in the system. Extensive fault

detection and annunciation of critical redundant circuits help

cuits.

Industrial Control Services

1

Page 2

Analog Input Modules

prevent the controllers from receiving erroneous data from a

faulty inpu

Three analog input modules can be connected in parallel to

obtain fault tolerant input sensing. In this triple module

configuration, a failed module can be removed and replaced

without interrupting the input signals.

(T7420A, AF)

t module.

Module Operation

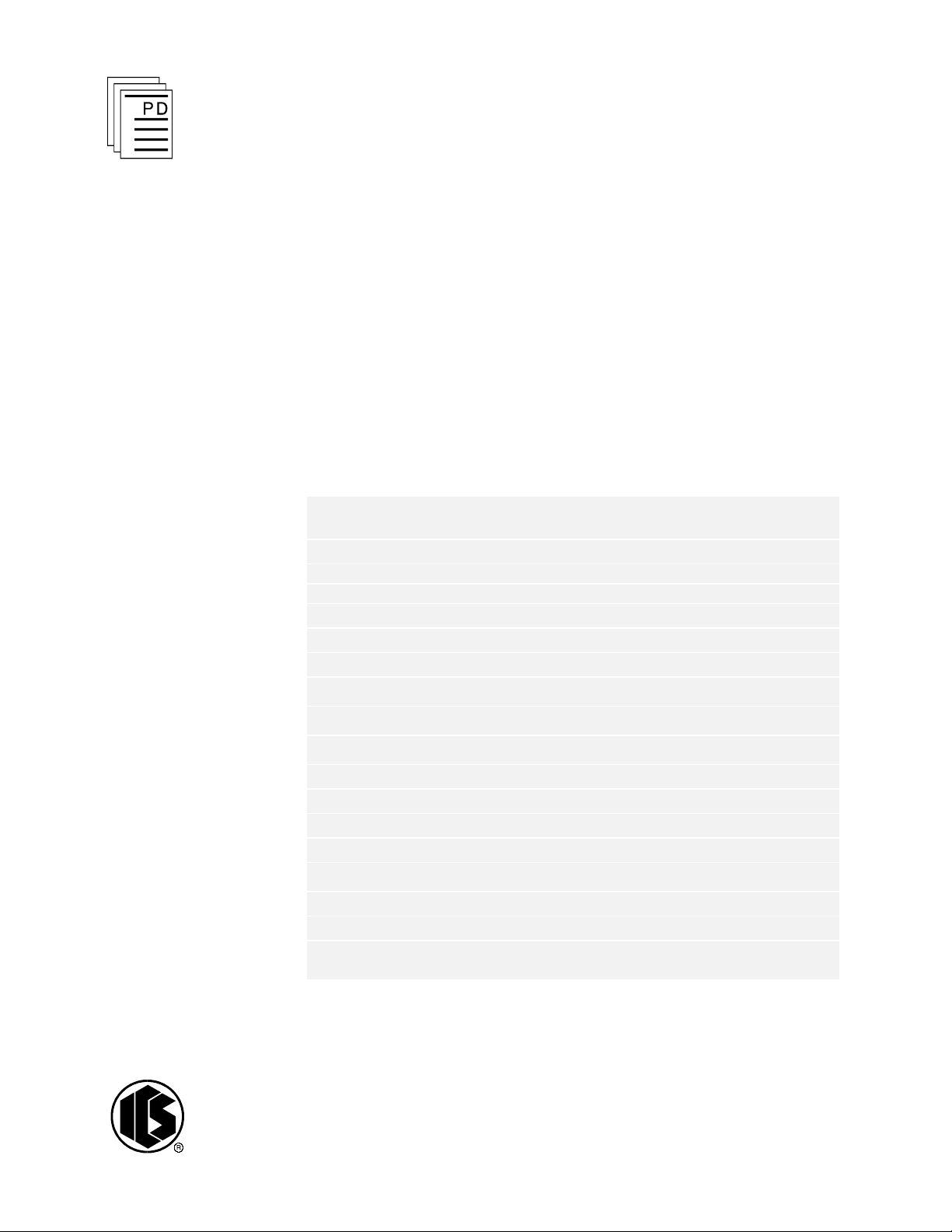

A block diagram of the analog input module is shown in

Figure 1.

2

Figure 1. Block Diagram of Analog Input Module.

Analog field signals are conditioned and multiplexed into an

analog-to-digital (A to D) converter and converted into 12-bit

digital data. These digital values are stored in the module’s

RAM. The digital logic circuits are optically isolated from the

analog field signals to protect the logic circuits from external

field signal transients and over voltages.

Industrial Control Services

Page 3

Analog Input Modules

The processor modules send triplicated read data requests to

the analog input module over the I/O Safetybus. The

processors’ addressing data and data read requests are voted

by the module (preventing I/O Safetybus failures upstream

from the module from affecting module operations). The voted

result is then passed to the I/O bus interface logic.

After receiving the voted data read request, the I/O bus

interface logic retrieves the analog data values from the RAM

and places the data into the module’s three bus drivers. Each

of the three bus drivers is independently powered and

controlled (by the I/O transceiver modules) — preventing

failures in a single driver from propagating to the other two /O

busses. The bus drivers then transmit the data via the

backplane I/O Safetybus to the I/O transceiver modules which,

in turn, transmit the data to the processors.

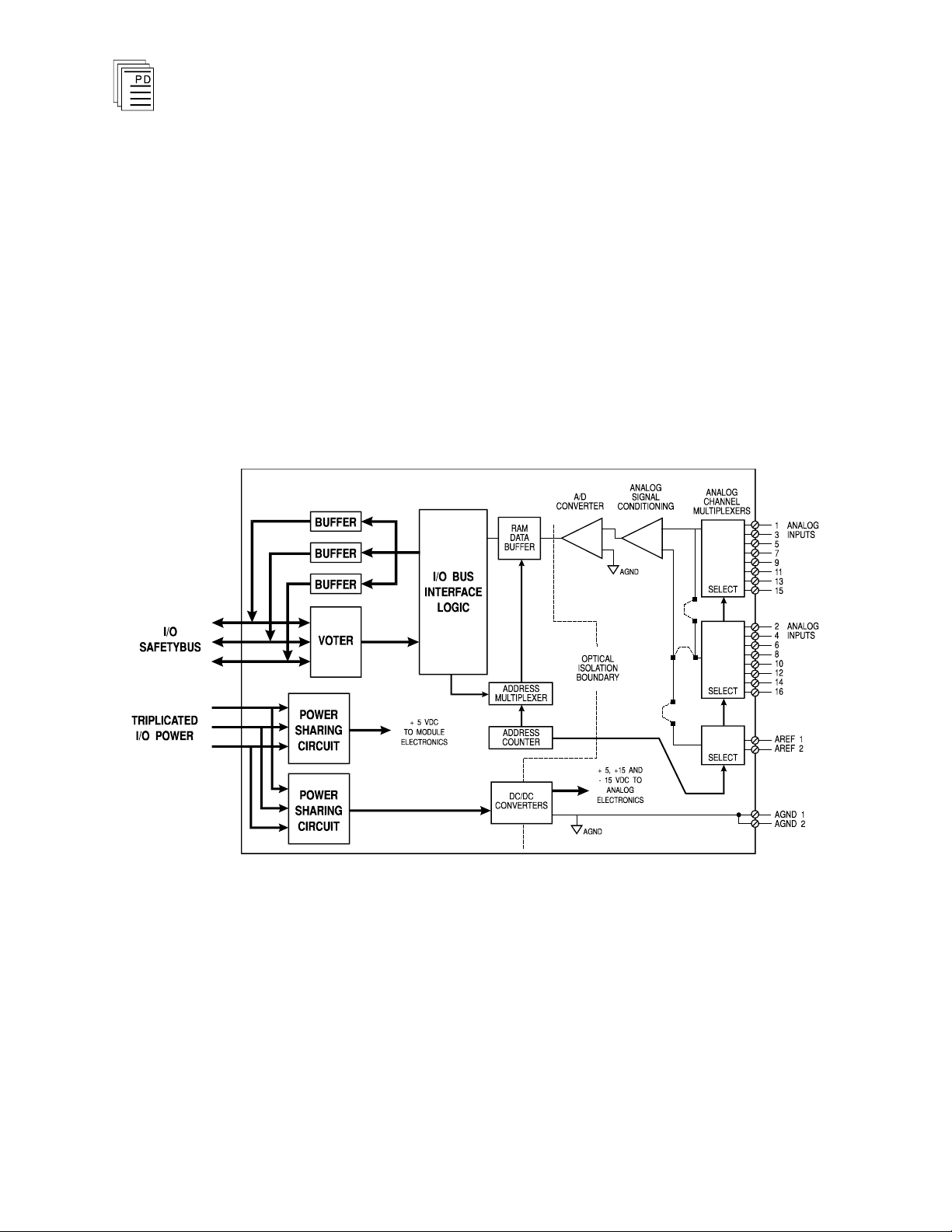

The 12-bit analog input data is packaged as a 16-bit integer.

In this format the analog data is the least significant bits,

providing analog input data ranging from 0 to 4095. Two of

the remaining four bits are used to flag alarms as shown in

Figure 2.

(T7420A, AF)

Figure 2. Analog Input Data Format.

Testing and

Each module’s voter circuits are periodically tested by the

processor modules. Discrepant data are sent through one of

three legs of the I/O Safetybus to determine whether the

module’s voter is able to outvote the incorrect data. A failure

to return the correct majority-voted result to the processors

Diagnostics

PD-7023

Mar-06

3

Page 4

Analog Input Modules

produces an I/O module error indication at the processor

modules and a module fault indication at the I/O module.

Each type of module has a unique identification code that is

read by the controll

which type of module is installed in each I/O chassis slot and

how to address that module and its points specifically. If a

module is removed, or is replaced with a module of a different

type, the processor modules will indicate an I/O module error.

Loopback logic tests periodically write data to the module and

then read it back to determine whether the module’s I/O bus

interface logic is functioning correctly.

(T7420A, AF)

er. This code lets the controller know

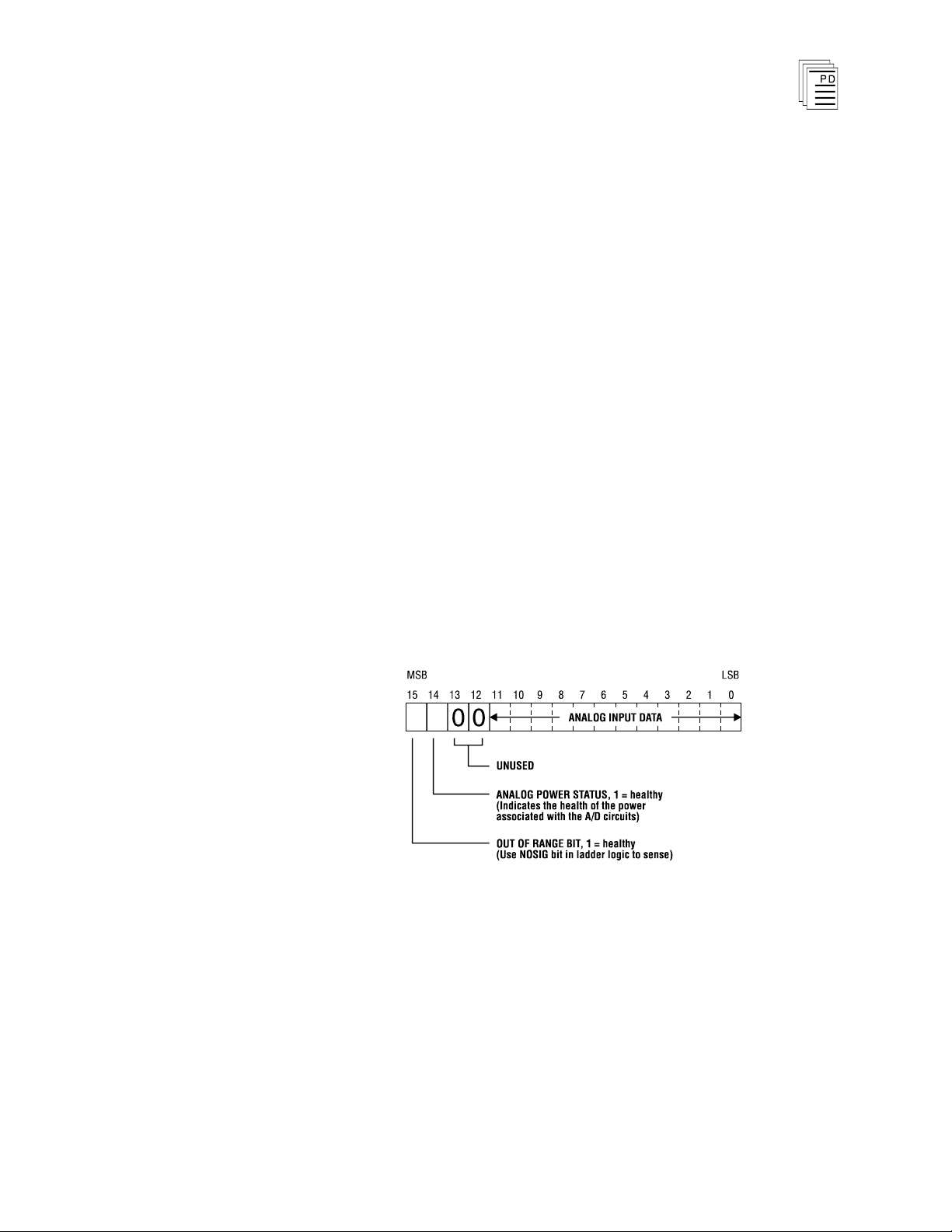

Front Panel Indicators

Figure 3 shows the physical features of the analog input

modules. The front panel of each module contains active and

fault status indicators.

Active and Fault Status Indicators

These green and red LEDs indicate the overall health of the

module. During normal operation the green ACTIVE

indicator flashes at the controller's scan rate. If a module

fault occurs the red FAULT indicator turns on and the green

ACTIVE indicator turns off.

4

Industrial Control Services

Page 5

Analog Input Modules

(T7420A, AF)

PD-7023

Mar-06

Figure 3. Analog Input Module.

5

Page 6

Voltage Ranges

Current Ranges

(using external 250 Ohm resistor)

0 to 5 Vdc

0 to 20 mA

1 to 5 Vdc

4 to 20 mA

-

5 to +5 Vdc

-

20 to +20 mA

0 to 10 Vdc

0 to 40 mA

-

10 to +10 Vdc

-

40 to +40 mA

Analog Input Modules

(T7420A, AF)

Application

Analog Input Range Selection

The possible input voltage ranges are the same for both

differential and single-ended modes. Since current

measurements are converted to voltages using external

precision resistors, the same voltage ranges apply. Choices of

input voltage ranges include unipolar, bipolar, and offset

ranges. All ranges are selected by setting jumpers located

inside the module.

Table 1. Analog Input Ranges.

Input Out of Range Detection

If the analog signal is well beyond the normal operating range

selected, the NOSIG contact associated with the analog point

will be enabled. Note that there are some out-of-range signals

that do not set the NOSIG bit. The out of range thresholds for

each input range are shown on page 27.

Absolute Signal Ranges

The absolute workin

from -10.3 volts to +10.3 volts with regard to AGND (analog

ground). The acceptable common mode voltage range (either

differential or single-ended with regard to its appropriate

analog reference input) is from -10.3 volts to +10.3 volts.

g range for any analog input signals is

6

Industrial Control Services

Page 7

Analog Input Modules

(T7420A, AF)

Sampling Speed

The rate at which each of the analog input channels is

sampled depends upon the mode of operation. Each channel

is given a 225 msec time slot during the multiplexing process.

During that time s

measuring system, the measuring system is allowed to settle,

the settled value is sampled (and held), and is then converted

to a 12-bit value by an analog-to-digital converter. The

channels are sampled in numerical order. In single-ended

mode, the 16 channels are sampled in 3.60 msec on a

continuous repeating basis. In differential mode, the eight

channel pairs are sampled in 1.80 msec on a continuous

repeating basis. Converted data are stored in the module’s

R

AM and can be accessed by the controller. Data for a given

channel is available at the previously stored value until an

updated conversion replaces it.

Sampling speed is unrelated to internal access speed within

the Regent system. Programming and other features

determine how often the Regent system can access the

converted data. There are no “lockout times” when the Regent

system is prevented from reading the current stored values of

the converted data.

lot, the input voltage is connected to the

PD-7023

Mar-06

Single-Ended References

When single-ended input mod

reference for all eight signals on the same input field wiring

terminal block is AREF1 on the top terminal block and

AREF2 on the bottom. This ground reference may be

different from the external I/O analog ground AGND also

available on the same connector. When used with the I/O

Termination Assembly (see PD-7901), both AREF1 and

AREF2 are isolated from AGND by 1K Ohm resistors.

When the single-ended signals are measured, the appropriate

ground reference for the signal is selected by another

multiplexer on the board, and becomes the reference for the

measurement. In differential mode, AREF1 and AREF2 are

not used as references.

7

e is selected, the ground

Page 8

Analog Input Modules

(T7420A, AF)

Input Over Voltage Protection

All analog inputs, regardless of mode and analog references

(AREF1 and AREF2), are protected from over-voltages (these

ranges are shown on page 27).

Current Measurement Considerations

Precision resistors external to the module are required to

convert currents to voltages that can be measured directly by

the module. The resistors can be mounted on field marshaling

terminals or are provided using the appropriate analog input

termination blocks. For differential current measurements,

both sides of the external resistor are brought onto the

module.

It is possible to mix current and voltage measurements on the

same module as long as they can work with the same voltage

range selected. In the case of single-ended measurements,

this either requires that both current and voltage

measurements are referenced to the sa

(AREF1 or AREF2), or that voltage inputs be on one set of

eight inputs and current inputs on the other set.

me reference point

Input Range and Mode Selection Jumpers

The jumpers that determine the mode and input range for the

module are set at manufacturing time for an input range of 1

to 5 volts and the 16-channel, single-ended input mode. If

other input ranges or another mode is desired these jumpers

must be repositioned to the appropriate settings.

There are 17 jumper locations that are used. They are

summarized in Tables 2 and 3, below. The module’s cover

must be removed to access and reposition the jumpers.

8

Industrial Control Services

Page 9

Analog Input Modules

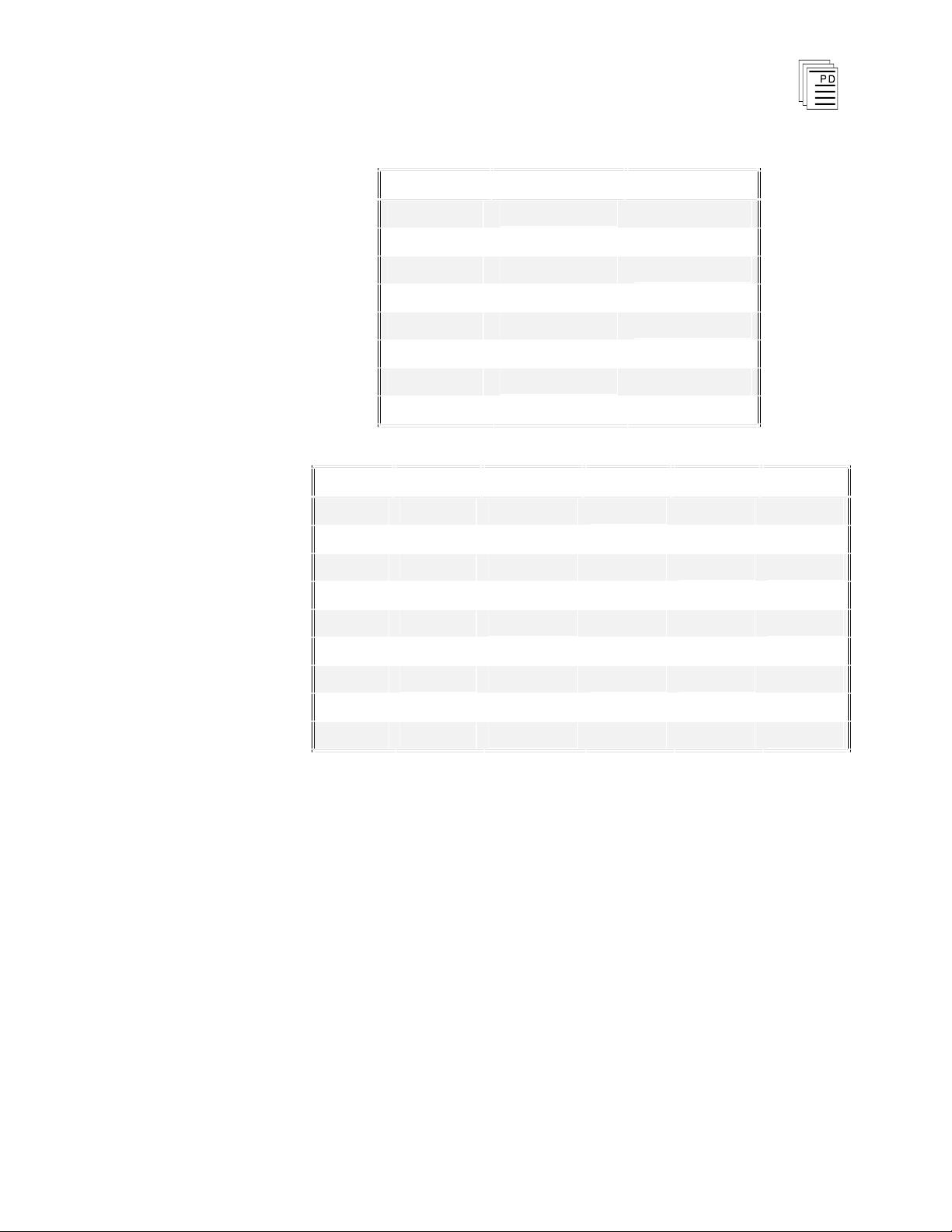

Jumper

Single-Ended

Differential

J251

n

J252

n

J501

n

J502

n

J503

n

J504

n

J505

n

J701

n

Jumper

0 to +10

-

10 to +10

+1 to +5

0 to +5

-

5 to +5

J551

n

J552

n

n

J553

n

n

J601

n

n

n

J602 n

n

J651 n

n

J652

n

n

n

J653

n

n

n

J654 n

n

(T7420A, AF)

Table 2. Mode Selection.

Table 3. Input Range Selection.

Input Low-Pass Filters

Two rows of jumper connections (J506 and J507) allow

selection of onboard capacitors to create single-pole low-pass

input filters on the board. Jumpers are placed on these

connections to select either single-ended or differential filters

as appropriate.

I

n single-ended mode, the filtering is done with respect to the

appropriate AREF1 (or AREF2) input line. A 10K Ohm

resistor is in series with each analog input line (this resistor is

also a part of the over voltage protection system for the

module as well), and the capacitor is on the multiplexing side

of the resistor. There are four rows of eight pins labeled J506

and J507, for single-ended mode filtering install jumpers

across row J506 and row J507 (for a total of 16 jumpers).

PD-7023

Mar-06

9

Page 10

Analog Input Modules

(T7420A, AF)

In differential mode, a 10K

Ohm resistor is in series with each

input line of each input analog channel pair. The capacitors

are placed on the multiplexing side of the resistors. The

filtering is then differential. There are four rows of eight pins

labeled J506 and J507, for differential mode filtering install

jumpers between rows J506 and J507 (for a total of eight

jumpers).

Frequency response data for the T7420A and T7420AF is

provided on page 27.

10

Industrial Control Services

Page 11

Analog Input Modules

(T7420A, AF)

PD-7023

Figure 4. Analog Input Configuration Jumper Locations.

Mar-06

11

Page 12

Analog Input Modules

(T7420A, AF)

Simplex Configuration

Analog input modules provide a suitable interface to non

critical input signals. Although many of the circuits in the

analog input modules are automatically tested and

annunciated, some logic circuits and all of the field-side

sensing circuits are simplex and non-tested. This simplex

input configuration is illustrated in Figure 5.

Figure 5. Simplex Ana

log Input Configuration.

-

Fault Tolerant Configurations

For critical inputs, redundant input modules are used in a

2oo3 or 1oo2 fault tolerant configuration. In these

configurations the redundant input modules are connected to

single or multiple sensors. If redundant sensors are installed

in the field, the redundant modules are connected so that each

sensor connects to one of the redundant modules. These

configurations are illustrated in Figure 6, showing triple

redundant input modules. Each analog input module is hot

replaceable. In redundant input configurations, if a fault

occurs on one module, it can be removed and replaced while

the system continues to sense the inputs from the remaining

two input modules.

12

Industrial Control Services

Page 13

Analog Input Modules

(T7420A, AF)

PD-7023

Mar-06

Figure 6. Fault Tolerant Analog Input Configurations.

Field Wiring

For field wiring details, refer to PD-7901 - I/O Termination

Assembly.

13

Page 14

Analog Input Modules

(T7420A, AF)

Keying

The I/O chassis can be physically keyed to prevent accidental

damage caused by inserting a module into a slot wired for a

different module type. Figure 7 illustrates how the slot keys

are installed on the I/O chassis slot field wiring connectors.

The slot key positions for the analog input modules are listed

in Table 4.

14

Figure 7. Installing Slot Keys.

Industrial Control Services

Page 15

Analog Input Modules

Module

Upper

Connector

Lower

Connector

T7420A

9 15

T7420A

F

9 15

Important!

(T7420A, AF)

Table 4. Slot Key Positions.

Configuration

Each input module is configured using the

W

INTERPRET

I/O

Configuration Editor. In the editor, you will perform the

three steps described below to configure the input module.

1) Set the Module Type:

Position the cursor on the module slot you wish to define.

Choose Set Module Type from the Edit Menu and select

the appropriate analog input module from the list.

There are four different analog input module types listed

in the Set Module Type dialog. Be sure to select the

app

ropriate module, i.e. standard response (T7420A) vs.

fast response (T7420AF) and single-ended (16-channel) vs.

differential (8-channel).

2) Edit the Module Definition:

Choose Edit Module Definition from the Edit Menu. A

dialog box will open where you can define the input point

definitions. Single-ended analog input modules will show

sixteen points that you can configure, while differential

analog input modules will show eight points that you can

configure.

PD-7023

Mar-06

15

Page 16

Analog Input Modules

(T7420A, AF)

Figure 8. Analog Input Module De

3) Edit each point:

finition.

Position the cursor on a Point definition and choose Edit

from the Module Definition dialog box to define a name

and description for each I/O point. In the Analog Input

Point dialog, enter a tag name (up to 12 characters) and a

description (up to 40 characters). The tag names are used

in the application program to represent the value of the

analog input in your control algorithms and interlocks.

Figure 9. Defining an Analog Input Point.

16

Programming

Inputs are referenced in the application program through the

tag names defined in the I/O Configuration Editor. The

analog inputs will range in value from 0 to 4095 over the

voltage range configured for the analog input module. Most

Industrial Control Services

Page 17

Analog Input Modules

(T7420A, AF)

often you will want to scale the analog input values to a more

convenient engineering unit number range.

Scaling Analog Inputs

The scaling function block is used to convert the raw 0 to 4095

units of the analog input to an engineering unit number. The

result of this scaling conversion is usually stored in a shared

variable register that you define in the shared variable editor.

After scaling the analog input to a register, you can use the

register tag name in your applications to work with the

process variable in engineering units.

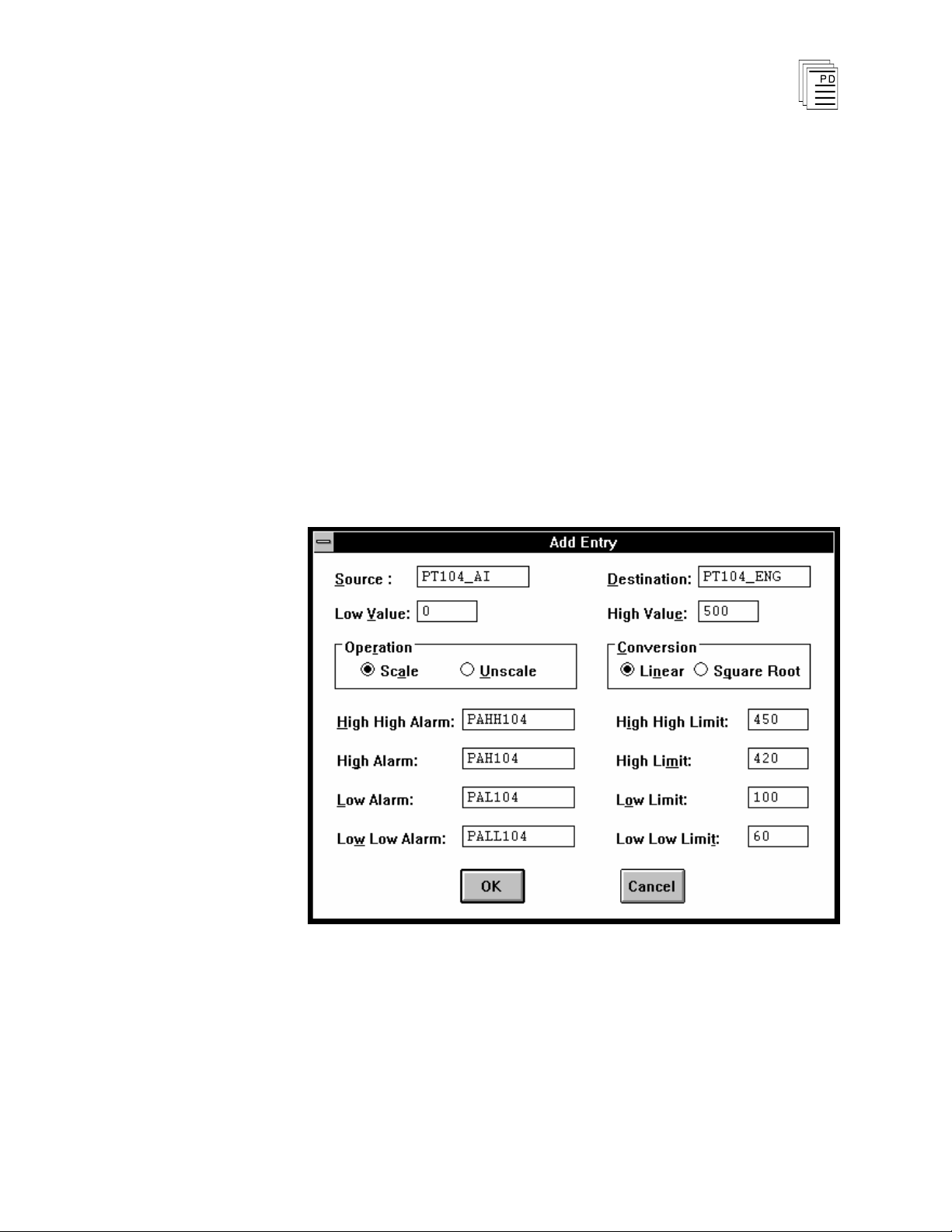

An example of an analog scaling entry is shown in Figure 10.

For more details about configuring analog scaling function

blocks refer to Using the Analog Scaling Editor in Section 5

Working with Programs and Function Blocks in the Regent

User’s Guide.

PD-7023

Mar-06

Figure 10. Analog Scaling Example.

17

Page 18

Analog Input Modules

(T7420A, AF)

Programming Fault Tolerant Analog Inputs

To program fault tolerant configurations using triplicated

analog input modules, a midvalue element can be used as

shown in Figure 11.

Figure 11. Programming Fault Tolerant Analog Inputs.

In this illustration, VALUE_A_NAME, VALUE_B_NAME,

and VALUE_C_NAME represent the three analog inputs to

be mid-value selected. ERROR_A_NAME,

ER

ROR_B_NAME and ERROR_C_NAME are the error bits

for the analog inputs. RESULT_NAME is the result of the

mid-value instruction. The field Limit is the integer value, in

similar units to the Value A, B and C variables, that an

analog input can deviate from the mid-value result before

signaling an error (via the Error A, B or C bits). Once an

error bit is set, it is latched. RESET_NAME is the reset bit

used to reset the latched error bits.

Maintenance

18

There are no user-replaceable parts inside the module.

Modules must be calibrated for the particular input range

within which they will operate. All modules are calibrated

before being shipped by ICS; however, modules require

calibration whenever:

· the module is configured for a different operating voltage

range (factory configuration is 1 to 5 VDC),

· the module is configured for a different operating mode

(factory configuration is 16 channel, single-ended), or

· once per year after installation, to adjust for drift in the

analog circuitry. Drift rates are

Specifications, below. These drift rates should be used to

listed under

Industrial Control Services

Page 19

Analog Input Modules

(T7420A, AF)

help you determine the frequency for checking the

calibration of the modules in your installation.

Calibration Methods

Calibrating the analog input module requires that you

connect calibration voltages to all of the analog input

channels of the module and adjust the trimming

potentiometers until the analog inputs read the correct

calibration values. During calibration the module must be

installed in a Regent system and disconnected f

rom the field

signal wiring while the calibration voltages are connected to

the module input signals.

There are three trimming potentiometers which are accessible

through the front face of the module making calibration

adjustments possible without opening the module’s cover.

However, the corresponding field wiring will have to be

disconnected from the I/O chassis terminals.

If you do not wish to disturb the field wiring during

calibration, the I/O Extender module (catalog T3322), can be

used. With the analog input module PCB removed from the

module housing and plugged into the I/O extender module,

you can connect the calibration voltages to the I/O extender

module and leave the analog input field wiring in place. This

is the recommended method for calibrating the analog inputs.

and is described below in the calibration procedure.

PD-7023

Mar-06

Calibration Procedure

Equipment Required

·

DC signal source with a range from -10 VDC to +10 VDC @

10 mA minimum and with an accuracy and resolutio

better than 100 mVDC.

·

Potentiometer adjustment tool.

·

Phillips screwdriver

·

I/O module extender, catalog number T7322

(recommended).

·

PC running the

analog input channel values during calibration.

W

INTERPRET

n of

software, used to monitor the

19

Page 20

Important!

Analog Input Modules

(T7420A, AF)

Calibration Preparation

The module must be calibrated while connected to an I/O

chassis of an operational Regent

system.

During calibration, the analog input module will be

disconnected from the actual field devices. Appropriate

precautions should be taken to ensure that the disconnection

of the field sensors does not pose a safety risk to plant

personnel or process equipment.

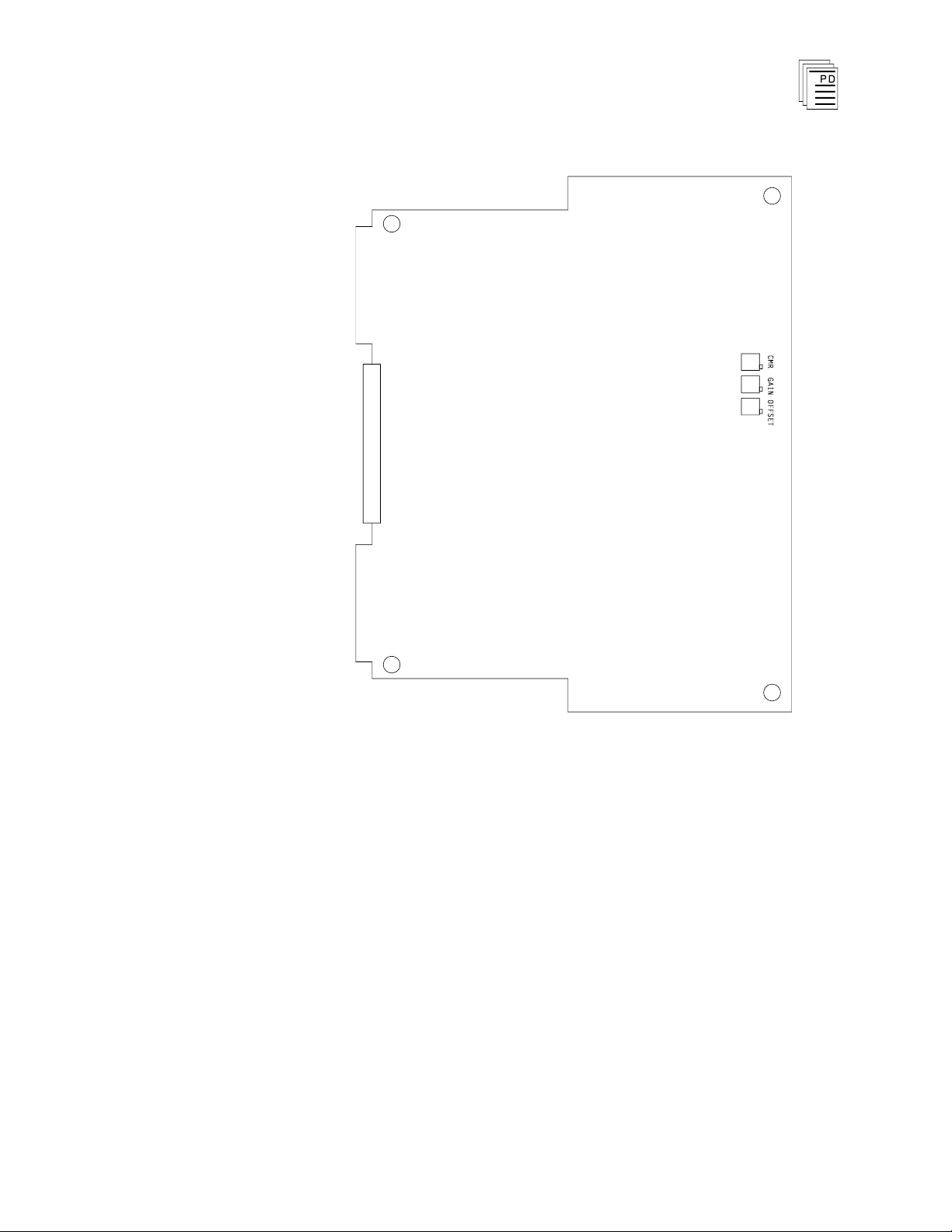

There are Offset, Gain and CMR (Common Mode Rejection)

potentiometers that are common to all of the analog input

channels. These potentiometers are located on the front of the

analog input PCB (see Figure 12).

During the calibration

procedure the Offset and Gain potentiometers will be adjusted.

The CMR potentiometer is factory adjusted and does not

require adjustment in the field.

20

Industrial Control Services

Page 21

Analog Input Modules

(T7420A, AF)

PD-7023

Mar-06

Figure 12. Analog Input Module Calibration Potentiometer

Locations.

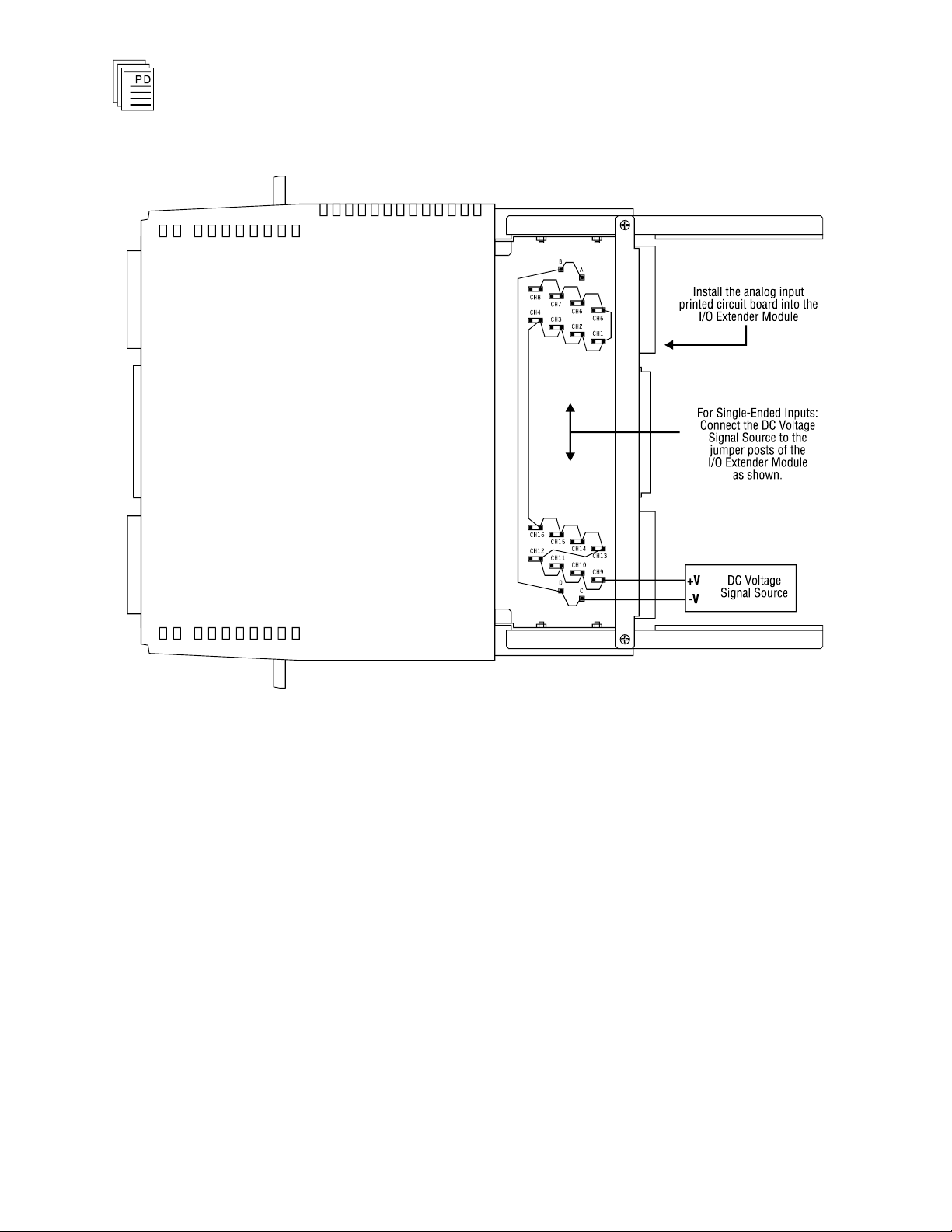

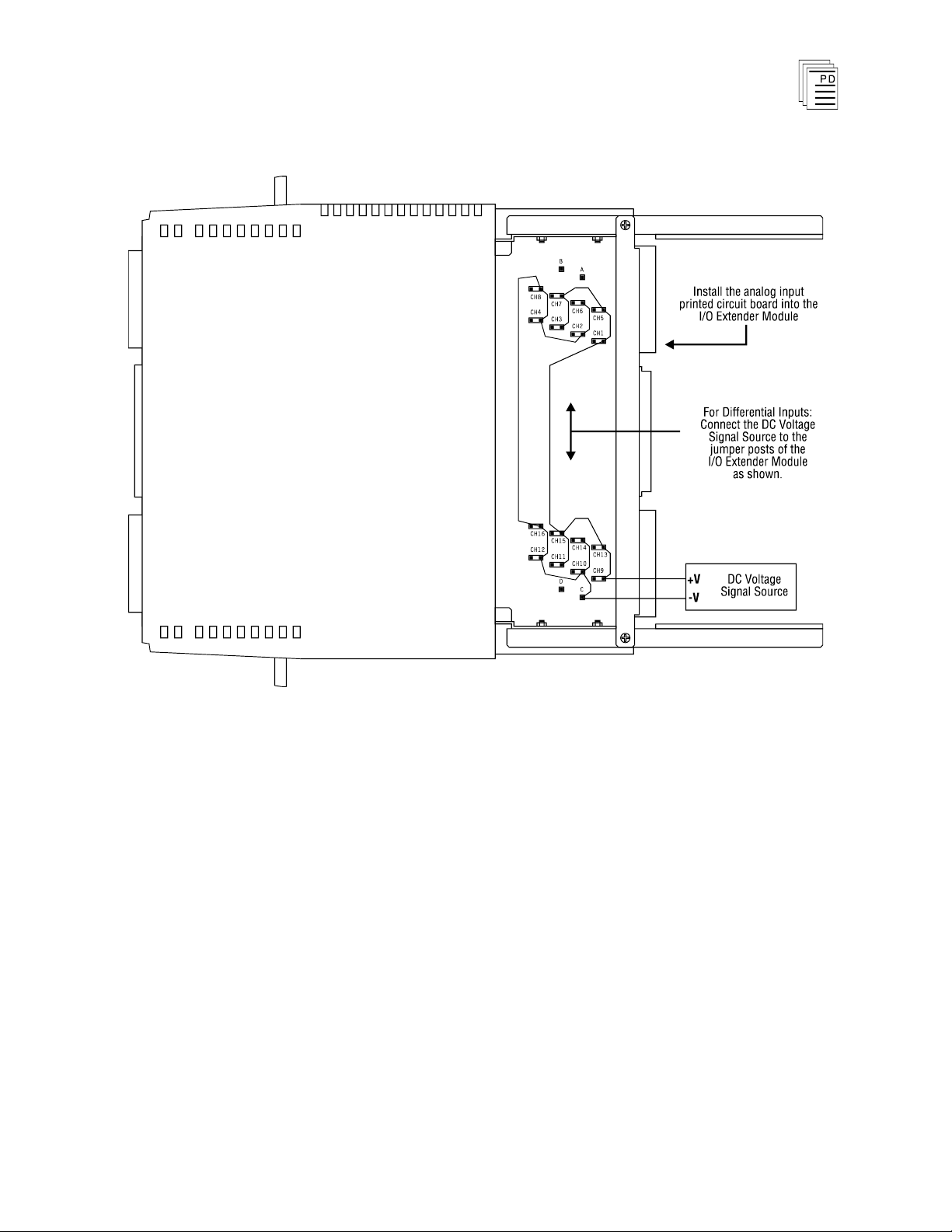

The I/O extender module has jumper posts that allow you to

connect or disconnect the I/O slot field wiring on the I/O

chassis to the printed circuit board plugged into the I/O

extender. During the calibration steps yo

u will remove any

jumpers installed on these posts in order to connect the DC

voltage signal source to the analog inputs. For modules

configured for 16-channel, single-ended inputs, Figure 13

shows the jumper posts to which you should connect the signal

source for each analog input channel. For modules configured

for 8-channel, differential inputs, Figure 14 shows the jumper

posts to which you should connect the signal source for each

analog in

put channel.

21

Page 22

Analog Input Modules

(T7420A, AF)

Figure 13. I/O Extender Connections for Single-Ended Analog Input Calibration.

22

Industrial Control Services

Page 23

Analog Input Modules

Important!

(T7420A, AF)

Figure 14. I/O Extender Connections for Differential Analog Input Calibration.

Within each pair of jumper posts, make sure that you connect

the voltage source to the jumper posts nearest the front of the

I/O extender. Do not make any connections to the jumper

posts nearest the I/O chassis backplane —

these connect to the

actual field wiring attached to the I/O slot terminals on the I/O

chassis.

Calibration Steps

1. Remove the module to be calibrated from the I/O chassis.

2. Install the I/O extender module into the slot from which

the module was removed.

3. Remove the jumpers (if installed) labeled CH1 through

CH16 from the I/O extender module.

PD-7023

Mar-06

23

Page 24

Analog Input Modules

4. Connect the DC voltage signal source to the I/O extender

5. Remove the four screws on one side of the module and

6. Install the printed circuit board into the I/O extender

7. Adjust the DC voltage source to the Offset Input Voltage

(T7420A, AF)

jumper posts as shown in Figures 13 or 14.

as required to make the connections.

Use test clips

remove the printed circuit board from the module

clamshell housing.

module. Allow the board to warm up for approximately one

minute.

value indicated in Table 5 for the configured input range

of the input module. Wait approximately one minute for

the analog

inputs to stabilize.

8. Using the monitoring functions of

W

INTERPRET

, monitor

the values of all the analog input channels. Refer to the

Regent User’s Guide for more details about the monitoring

functions.

9. Adjust the Offset potentiometer (R569) for an average

reading of 2 ±1 for all input channels. Verify that all input

channels read between 1 and 3. If one or more channels

reads significantly different, return the module to ICS for

repair.

10. Adjust the DC voltage source to the Gain Input Voltage

v

alue indicated in Table 5 for the configured input range

of the input module. Wait approximately one minute for

the analog inputs to stabilize.

11. Adjust the Gain potentiometer for a reading of 4093 ±1 for

all channels. Verify that all input channels read between

4092 and 4094. If one or more channels reads significantly

different, return the module to ICS for repair.

12. Repeat steps 7 through 11 and make adjustments if

necessary until both the Offset and Gain values read

corre

ctly. There is some interaction between the Offset and

Gain adjustments so often you will need to repeat these

steps a few times until both the Offset and Gain readings

read correctly without further adjustments.

24

13. Calibration is complete. Unplug the printed circuit board

from the I/O extender module and replace it in its

Industrial Control Services

Page 25

Analog Input Modules

Configured Voltage

Range

Offset Input Voltage

Gain Input Voltage

0.00 to +10.00 volts

0.0049 VDC

9.9951 VDC

-

10.00 to +10.00 volts

9.9902 VDC

9.9902 VDC

+1.00 to +5.00 volts

1.0020 VDC

4.9980 VDC

0.00 to +5.00 volts

0.0024 VDC

4.9976 VDC

-

5.00 to +5.00 volts

4.9951 VDC

4.9951

VDC

(T7420A, AF)

clamshell housing. Remove the I/O extender module from

the I/O chassis and reinstall the calibrated module in the

I/O chassis.

The module’s red Fault indicator will be on until you

pe

rform a voted reset by pressing the Reset buttons on two

of the Regent processor modules. After the voted reset is

complete, the module’s green Active indicator should turn

on.

Safety Considerations

Table 5. Analog Calibration Voltages.

The analog input modules are TÜV certified as non

interfering and when properly configured are also certified for

Risk Class 5 safety critical inputs. Safety critical

configurations include midvalue selection methods.

In safety critical input applications using a single sensor, it is

important that the sensor failure modes be predictable and

well understood, so there is little probability of a failed sensor

not responding to a critical process cond

ition. In such a

configuration, it is important that the sensor be tested

regularly, either by dynamic process conditions that are

verified in the Regent, or by manual intervention testing.

-

PD-7023

Mar-06

Redundant sensors can be used with redundant input

modules to eliminate any single points of failure and extend

fault tolerance to include the sensors.

For additional safety considerations, please refer to the Safety

Considerations section of the Regent User’s Guide.

25

Page 26

Safetybus Power

1.85 load units

Numbe

r of Inputs

Eight differential or 16

single-ended (jumper

selectable)

Inputs Per Group

Eight single-ended or four

differential

Ranges

Voltage:

Current:

(using external 250W resistors)

0.00 to +10.00 volts

-

10.00 to +10.00 volts

+1.00 to +5.00 volts

0.00 to +5.00 volts

-

5.00 to +5.00 volts

0.00 to +20.00 mA

-

40.00 to +40.00 mA

+4.00 to +20.00 mA

0.00 to +20.00 mA

-

20.00 to +20.00 mA

External Power

None for module electronics;

however, analog field loop

power is not s

upplied by the

module

Accuracy and Drift

(Accuracy/Drift)

-

10 to +10 volts:

0.00 to +10.00 volts:

-

5.00 to +5.00 volts:

0.00 to +5.00 volts:

+1.00 to +5.00 volts:

Note: Initial accuracy (% of span)

represents the initial accuracy @

22ºC to 28ºC calibration

temperature.

0.12%/100 ppm/

°C

0.08%/55 ppm/

°C

0.13%/110 ppm/

°C

0.10%/65 ppm/

°C

0.10%/70 ppm/

°C

Analog Input Modules

(T7420A, AF)

Specifications

26

Industrial Control Services

Page 27

Analog Input Modules

Out of Range Thresholds

Over-range

-

10.00 to +10.00 volts:

0.00 to +10.00 volts:

-

5.00 to +5.00 volts:

0.00 to +5.00 volts:

+1.00 to +5.00 volts:

Under-range

-

10.00 to +10.00 volts:

0.00 to +10.00 volts:

-

5.00 to +5.00 volts:

0.00 to +5.00 volts:

+1.00 to +5.00 volts:

Expressed in volts:

+10.30 min., +10.70 max.

+10.30 min., +10.70 max.

+5.15 min., +5.35 max.

+5.15 min., +5.35 max.

+5.12 min., +5.28 max.

-

10.30 min., -10.70 max.

-

0.30 min., -0.70 max.

-

5.15 min., -5.35 max.

-

0.15 min., -0.35 max.

+0.88 min., +0.72 max.

Over

Voltage Protection

Powered

AI1-AI16:

AREF 1,2:

Acceptable Duration:

Unpowered

AI1-AI16:

AREF 1,2:

Acceptable Duration:

±60 VDC/85 VAC RMS/±400 VDC

±40 VDC/55 VAC RMS/±60 VDC

Indefinite/Indefinite/1 msec

±45 VDC/45 VAC RMS/±400 VDC

±25 VDC/25 VAC RMS/±45 VDC

Indefinite/Indefinite/1 msec

Frequency Response

(-

3 dB/-30 dB/Atten. @ 60 Hz)

Single-Ended

T7420A:

T7420AF:

Differential

T7420A:

T7420AF:

7.23 Hz/229 Hz/18.4 dB

10.6 KHz/335 KHz/0.0 dB

3.62 Hz/114 Hz/24.4 dB

5.31 KHz/168 KHz/0.0 dB

Data Update Rate

Single-ended or 16

channel mode:

Differential or 8-channel

mode:

3.60 msec on a continuous

repeating basis

1.80 msec on a continuous

repeating basis

Isolation

2500 volts minimum (field

wiring to control logic)

Heat Dissipation

9 Watts, 31 BTUs/hour

(T7420A, AF)

PD-7023

Mar-06

27

Page 28

Operating Temperature

0°

to 60° C

(32° to 140° F)

Storage Temperature

-40°

to 85° C

(-40°

to 185° F)

Operating Humidity

0 to 95% relative humidity,

non-condensing

Vibration

10 to 55 Hz:

±0.15mm

Shock

Operating:

15 g, ½ sine wave, 11 msec

Electromagnetic

Interference

•

IEC 801 Part 2 - Electrostatic

Discharges

•

IEC 801 Part 3 - Radiated

Electromagnetic Fields

Level 3: Contact discharge of

6 kV

Level 3: 10 V/M, 27 MHz 500 MHz

Safety

Certified to D

IN V VDE

0801 for Risk Class 5. Also

designed to meet UL 508 and

CSA 22.2, No. 142-M1981

Dimensions

Height:

Width:

Depth:

12.6" (320 mm)

1.27" (32 mm)

10.12" (257 mm)

Weight

3.0 lbs (1.4 kg)

Analog Input Modules

(T7420A, AF)

28

Industrial Control Services

Page 29

Analog Input Modules

Function

Signal

Mode

Value

I leakage

AI1 through AI16

—

50 nanoA (max.)

Rin (re AGND)

AI1 through AI16

—

100 Mohm (min.)

Rin (re AREF2)

AREF1

—

100 Mohm (min.)

Rin (note 1)

AI1 through AI16

SE

100 Mohm (min.)

CMR (note 2)

AI1 through AI16

SE

51 dB min.

CMR (note 3)

AI1 - AI16

SE

41 dB min.

CMR (note 4)

AI1 through AI16

SE

66 dB min.

NMR (note 5)

AI1 through AI16

SE

(note 5)

Rin (re AGND)

AI1/2 - AI15/16

DIFF

100 Mohm (min.)

CMR (note 6)

AI1/2 - AI15/16

DIFF

72 dB min.

CMR (note 7)

AI1/2 - AI15/16

DIFF

49 dB min.

CMR (note 8)

AI1/2 - AI15/16

DIFF

81 dB min.

NMR (note 9)

AI1/2 - AI15/16

DIFF

(note 9)

Notes:

1) AI1 through AI8 are referenced to AREF1. AI9 through AI16 are

referenced to AREF2.

2) CMR: DC to 20 kHz, AI1-AREF1 through AI8-AREF1, AI9-AREF2

throug

h AI16-AREF2. Referenced to AGND (model T7420A).

3) CMR: Same as note 2 except model T7420AF.

4) CMR: 60Hz, AI1-AREF1 through AI8-AREF1, AI9-AREF2 through AI16

-

AREF2. Referenced to AGND.

5) Normal mode rejection (single ended).

6) CMR: DC to 20 kHz, Differential signal referenced to AGND.

7) CMR: Same as note 6 except model T7420AF.

8) CMR: 50 Hz, Differential signal referenced to AGND.

9) Normal mode rejection (differential).

(T7420A, AF)

Miscellaneous Input Circuit Specifications

PD-7023

Mar-06

29

Loading...

Loading...