Page 1

ICS Regent+PLUS

®

PD-7027

Monitored Digital Input Modules, Field

Powered (Type F)

24 to 48 VDC, 120 VAC/DC

(T7411F, T7418F)

Issue 1,

Monitored digital input modules provide input sensing for 16

field input devices. The field powered (Type F) mod

suitable for inputs that are directly powered from an external

field power supply. Two types of modules are available for

inputs powered from 24 to 48 VDC and 120 VAC/DC. With a

line monitor device installed at the field switch, monitored

digital input modules detect input switch status and field

wiring open and short circuits (VDC powered inputs only).

Input and line status are reported back to the controller for

use in application program logic.

March, 06

ules are

Features

·

·

·

•

•

·

·

·

The input module circuits are completely and automatically

tested, providing a fail-safe interface for safety-critical inputs.

Industrial Control Services

Sixte

en input points, powered from external field supply.

Fault tolerant operation when connected in parallel with

another module of the same type.

Hot-replaceable.

Complete, automatic testing of all input circuits.

Automatic line monitoring detects open and short field wiring

faults.

Individual front panel indicators on each m

module’s active/fault and power status, as well as input status

and line fault status for each point.

2500 volt minimum electrical isolation between field and logic

circuits.

TÜV certified, Risk Class 5.

1

odule show the

Page 2

Monitored Digital Input Modules

Two or three monitored digital input modules can be

connected in parallel to obtain fault tolera

In these fault tolerant configurations, a failed module can be

removed and replaced without interrupting the input signals.

The module requires connection to the same field power

supply that powers the field switches. This field power is

internally regulated by the module to power the module’s

input interface circuits.

, Type F (T7411F, T7418F)

nt input sensing.

Module Operation

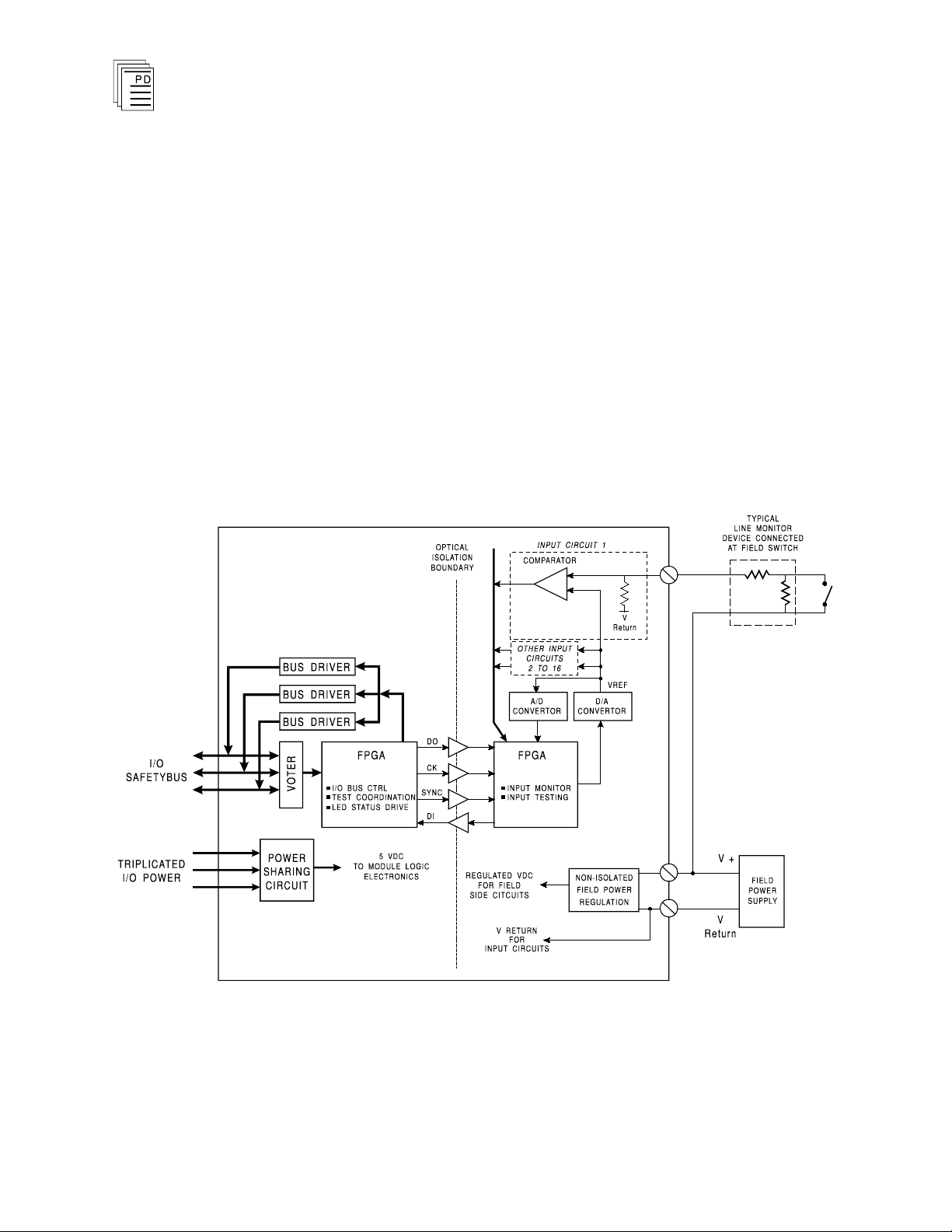

A block diagram of a typical monitored digital input module is

shown in Figure 1.

2

Figure 1. Block Diagram of the Type F, Monitored Digital Input Modules.

An external field power supply provides power directly to field

switches. This power supply is also connected to the

Industrial Control Services

Page 3

Monitored Digital Input Modules

Important:

monitored input module. The field power is internally

regulated to power the input module’s field interface circuits.

The switched side of each input is wired back to the input

module terminal screws. Inside the input module the signal

passes through an internal dropping resistor and back to the

field power supp

can be connected across the input switch in the field (as shown

in Figure 1).

Line monitoring only applies to inputs powered by a well

regulated (± 5%) DC voltage power supply. Line monitoring is

not supported for inputs powered from 120 VAC power

sources.

The input module monitors the voltage of the input circuit at

the internal dropping resistor, comparing it to a reference

voltage generated by the D/A converter inside th

The T7418F input module rectifies the input signal for

120 VAC applications. The comparator generates an on or off

state depending on which voltage signal is greater than the

other.

ly return. Optionally a line monitor device

, Type F (T7411F, T7418F)

e module.

The field-side FPGA controls and monitors the reference

voltage signal and reads the status of all 16 input

comparators. This information is stored and sent through

optical isolation to the logic-side FPGA. The logic-side FPGA

interfaces the input data to the I/O Safetybus and drives the

module’s front panel status

Testing and Diagnostics

Standard I/O Module Testing

The processor modules send triplicated read data requests to

the input module over the I/O Safetybus. The processors’

addressing data and data read requests are voted by the

module (preventing I/O Safetybus failures upstream from the

module from affecting its ability to be read). The voted result

is then passed to the I/O bus interface logic.

After receiving the voted data read request, the I/O bus

interface logic sends its input data to the modul

drivers. Each of the three bus drivers is independently

controlled — preventing failures in a single driver from being

propagated into the rest of the system.

LEDs.

e’s three bus

PD-7027

Mar-06

3

Page 4

Monitored Digital Input Modules

The bus drivers then move the data onto the I/O Safetybus

which, in turn, passes it to the processors.

Each module’s voter circuits are periodically tested by the

processor modules. Discrepant data are sent through one of

three legs of the I/O Safetybus to determine whether the

module’s voter is able to outvote the incorrect data. A failure

to return the correct majority-voted result to the processors

produces an I/O module error indication at the processor

modules and a module fault indication at the I/O module.

Each type of module has a unique identification code that is

read by the controller. This code lets the controller know

which type of module is installed in each I/O chassis slot and

address that module and its points specifically. The processor

modules periodically check each module’s identification code

to determine whether

type of module indicated in the I/O configuration that was

loaded when the system was started. If a module is removed,

or is replaced with a module of a different type, the processor

modules will indicate I/O module errors.

, Type F (T7411F, T7418F)

the type of module installed matches

Loopback logic tests periodically write data to the module and

then read it back to determine whether the module’s I/O bus

interface logic is functioning correctly.

Input Circuit Testing

The field interface circuits of the monitored input module are

completely tested to detect stuck-on or stuck-off input circuit

faults and optionally identify input wiring open and short

circuits. The automatic execution and evaluation of the input

testing is controlled by the triplicated Regent processor

modules.

During normal operations, the internal reference voltage is

set to three levels and the comparator output is read. These

three reference voltage levels represent thresholds that

determine whether the input signal is on or off and if the field

wiring is open

circuit or short circuit. The logic-side FPGA

determines input status and line fault status based on the

comparator data for the three voltage levels. The FPGA data

is provided to the I/O processors for application processing.

4

On a background basis, the I/O processors test the input

circuit comparators and logic circuits for stuck-on and stuck

Industrial Control Services

-

Page 5

Monitored Digital Input Modules

Note:

off failure modes. During testing the D/A converter generates

two reference voltages outside the normal operating range of

the field input voltages to test that the comparator output can

turn-off and turn-on. The I/O processors read the resulting

input status, line fault status, and reference voltage readings

for the test cycle to determine if there are faults in the input

circuits or the common data paths.

If the I/O processors detect a faulted input circuit, an I/O

module fault is indicated at the processor modules and the

Fault LED on the face of the input module is turned on.

, Type F (T7411F, T7418F)

Input Circuit Test Interval

The Regent processor modules schedule testing of the input

circuits on a background basis. The test interval for these

circuits may range from a few seconds to several minutes,

depending on the application program scan time and the size

of the I/O configuration. The equation below can be used to

estimate the test interval for monitored digital inputs.

TI = 172 * IOU

where:

TI

IOU

TSCAN

=

=

QTY

=

* TSCAN + 2

QTY

Test interval, seconds

Quantity of I/O Units in the system (1 to 16)

The application program scan time, seconds

For example, for a system with 8 I/O units and an application

scan time of 60 milliseconds, the test interval would be:

TI = 172 * IOU

TI = 84.6 seconds

* TSCAN + 2 = 172 * 8 * 0.060 + 2

QTY

In this system, all of the monitored input modules would be

tested for stuck-on and stuck-off faults approximately every 85

seconds. This test interval can be used in reliability and

availability calculations to select the fault tolerant input

configuration that meet the application’s safety requirements.

PD-7027

Mar-06

Due to I/O processor fault filtering algor

ithms, it may take up

to four test intervals to report a failed input module as a

permanent fault

5

Page 6

Monitored Digital Input Modules

, Type F (T7411F, T7418F)

Front Panel Indicators

Figure 2 shows the physical features of the type F, monitored

digital input modules. The front panel of each module

contains fault/active and power indicators for the module as

well as input status indicators for each channel.

Active/Fault Status Indicator

This green and red LED pair indicates the overall health of

the module and its field circuits. During normal operation the

green ACTIVE indicator flashes at the controller's scan rate.

If a module fault occurs the red FAULT indicator turns on

and the green indicator turns off.

Power Status Indicator

The POWER OK LED indicates the presence of field voltage

at the module’s field power input terminals and the overall

health of the module’s field power regulator circuits.

Input Status Indicators

Input status indicators show contact and line status for each

point.

A yellow contact status indicator is turned

contact is closed or the line has shorted.

on when the

A red line status indicator is turned on when the field wiring

is open circuit or short circuit. If line monitoring is not

desired, this LED can be disabled (see Disable Fault LED,

page 18 for more details).

6

Industrial Control Services

Page 7

Monitored Digital Input Modules

, Type F (T7411F, T7418F)

PD-7027

Mar-06

Figure 2. Type F, Monitored Digital Input Modules.

7

Page 8

Monitored Digital Input Modules

, Type F (T7411F, T7418F)

Application

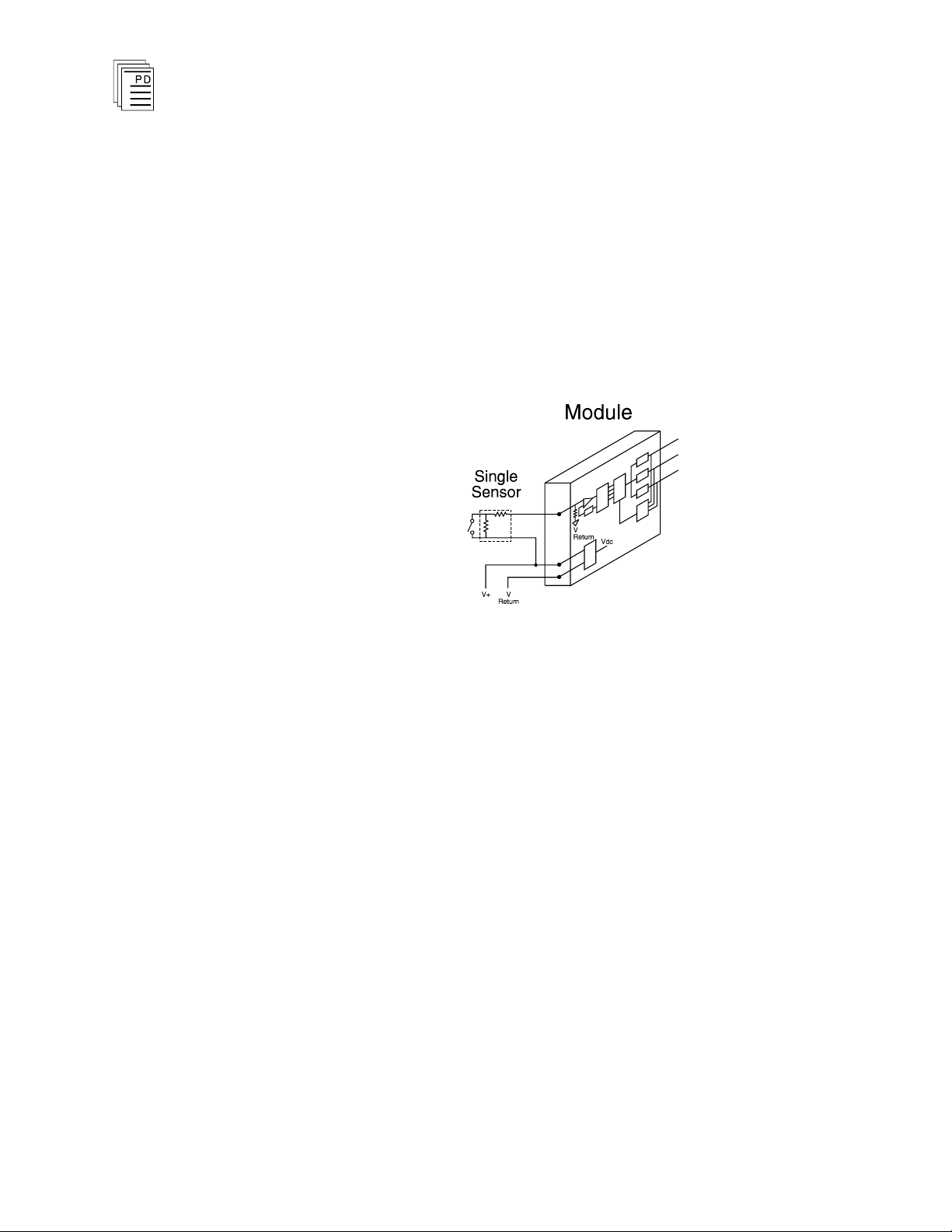

Simplex Configuration

Monitored digital input modules provide a suitable interface

to safety-critical input signals. The circuits in the monitored

digital input modules are automatically tested and

annunciated, providing a fail-safe interface to digital inputs.

This simplex input configuration is illustrated in Figure 3.

Figure 3. Single Monitored Digital Input Configuration.

Fault Tolerant Configurations

For fault tolerant applications, redundant monitored input

modules are used in a fault tolerant configuration. In one

configuration the redundant input modules are connected in

parallel to a single field input device as illustrated in Figure

4

. If redundant field sensors are installed in the field, the

modules are connected so that each sensor connects to one of

the modules as illustrated in Figure 5. In these fault tolerant

configurations, each monitored digital input module is hot

replaceable. If a fault occurs on one module, it can be

removed and replaced while the system continues to correctly

sense the inputs from the remaining module(s).

8

Industrial Control Services

Page 9

Monitored Digital Input Modules

, Type F (T7411F, T7418F)

Figure 4. Fault Tolerant Monitored Digital Input Modules

Connected to a Single Sensor.

PD-7027

Mar-06

9

Page 10

Monitored Digital Input Modules

, Type F (T7411F, T7418F)

10

Figure 5. Fault Tolerant Monitored Digital Input Modules

Connected to Redundant Sensors.

Field Wiring

For field wiring details, refer to PD-7901 - I/O Termination

Assembly.

Industrial Control Services

Page 11

Monitored Digital Input Modules

Line

Monitoring

For DC powered inputs, the monitored digital input module

can perform line monitoring of the field wiring when a

suitable line monitor device is installed across the field input

switch. A variety of line monitor devices are available to

match the voltage and input redundancy used in the

application.

Figure 6 shows a single switch connected to a single monitored

input module. This type of configuration uses a line monitor

device which contains two resistors, one in ser

switch and one in parallel with the field switch. Figure 6 also

applies to fault tolerant input configurations that include

redundant sensors connected to redundant input modules.

, Type F (T7411F, T7418F)

ies with the field

PD-7027

Mar-06

Figure 6. Line Monitoring, Single Switch Connected to

Single Module.

11

Page 12

Monitored Digital Input Modules

Figure 7 shows a single switch connected to a redundant

monitored input modules. This type of configuration

line monitor device which contains two zener diodes, one in

series with the field switch and one in parallel with the field

switch.

, Type F (T7411F, T7418F)

uses a

Figure 7. Line Monitoring, Single Switch Connected to

Redundant Modules.

12

Industrial Control Services

Page 13

Monitored Digital Input Modules

V

ref

Threshold

Voltage

Vin with Line

Monitor

Vin without

Line Monitor

Stuck-on Test

32 Vdc

24 Vdc

Wire Open

Switch Open

Open Circuit

20 Vdc

16 Vdc

Switch Open

NA

On/Off

12 Vdc

8 Vdc

Switch Closed

NA

Short Circuit

4 Vdc

0 Vdc

Wire Short

Switch Closed

Stuck-Off Test

-

5 Vdc

Note:

With the line monitor device installed, the input voltage, Vin,

has four possible states as represented in Table 1. When the

input module reads the input, the reference voltage, V

set to the values shown in Table 1 to detect the state of the

input.

, Type F (T7411F, T7418F)

ref

,

is

Table 1. Input States and Reference Voltage Thresholds.

The actual voltage levels for the T7418

F are half that shown

in Table 1, e.g. the On/Off threshold is 6 Vdc and a line

monitored Switch Open is 8 Vdc. However, when configuring

the input module voltage thresholds, the settings should be as

shown in Table 1, i.e. 4 Vdc, 12 Vdc and 20 Vdc. The input

module will automatically halve these setting values for the

input module reference voltages.

PD-7027

Mar-06

Keying

The I/O chassis can be physically keyed to prevent accidental

damage caused by inserting a mo

dule into a slot wired for a

different module type. Figure 8 illustrates how the slot keys

are installed on the I/O chassis slot field wiring connectors.

The slot key positions for the monitored digital input module

are listed in Table 2.

13

Page 14

Module

Upper

Connector

Lower

Connector

T7411F

9

7

T7418F

17

7

Monitored Digital Input Modules

, Type F (T7411F, T7418F)

Figure 8. Installing Slot Keys.

Table 2. Slot Key Positions.

14

Industrial Control Services

Page 15

Monitored Digital Input Modules

, Type F (T7411F, T7418F)

Configuration

Each monitored input module is configured using the

W

INTERPRET I/O Configuration Editor. In the editor, you will

perform the steps described below to configure the input

module.

1) Set the Module Type:

Position the cursor on the module slot you wish to define.

Choose Set Module Type from the Edit Menu and select

either the T3411F or T3418F monitored digital input

module from the list.

2) Edit the Module Definition:

Choose Edit Module Definition from the Edit Menu. A

dialog box will open where you can define the input module

and point definitions. The figure below shows the dialog

for the T3418F input module.

PD-7027

Mar-06

Figure 9. Monitored Digital Input Module Definition.

3) Define the Input Module Fields and Thresholds:

With the cursor at the top of the list in the Module

Definition dialog shown in Figure 9, open the Line

Monitored Input Module dialog by pressing Enter or

double clicking on the “(Module)” selection. The dialog box

shown in Figure 10 will

open.

15

Page 16

Monitored Digital Input Modules

, Type F (T7411F, T7418F)

Figure 10. Defining the Input Module Fields and Thresholds.

In the module definition dialog you can define a tag names

representing all sixteen input points as a 16-bit word. The

Name field represents the On/Off status of all sixteen

inputs and the Fault Name represents the Line Fault

status of all sixteen inputs.

The module tag names represents the 16 inputs as a

signed, 16-bit integer. In this format, input point one is

the least significant bit (LSB) and input point 16 is the

most

significant bit (MSB). Enter tag names up to 12

characters long and descriptions up to 40 characters long.

In the module definition dialog you can also set the

threshold values used to determine the Open Circuit,

On/Off, and Short Circuit input status. Normally these

should be left at the default values of 20, 12 and 4 Vdc

shown in Figure 10. These values are applicable to field

inputs with no line monitor device installed and also for

inputs with the standard line monitor

devices installed. If

non-standard line monitor devices are installed, then the

threshold values may need to be adjusted.

16

3) Edit each point:

Choose Edit from the Module Definition dialog box to

define a name and description for each input point. In the

Industrial Control Services

Page 17

Monitored Digital Input Modules

Line Monitored Input Point dialog, enter names and

values for the configuration fields as described below.

, Type F (T7411F, T7418F)

Figure 11. Defining a Monitored Digital Input Point.

Name

Also called the tag name, this is the name used in the

application progra

On/Off state. The name can be up to 12 characters long.

Description

m to reference the field input switch’s

This 40-character field provides a place to describe the input

point definition. The description is used to help document

your system (it does not affect application program operation).

Fault Name

This is the name used in the application program to reference

the input point line fault status. The name can be up to 12

characters long.

During operations the input circuit is monitored for open

circuit and short circuit wiring faults. This bit is normally on

and turns off if either an open circuit or short circuit is

detected.

PD-7027

Mar-06

17

Page 18

Note:

Monitored Digital Input Modules

Line fault status is only reported through the Fault Name

variables. Line faults are not reported as a permanent I/O

module fault and do not turn on the associated system control

relay fault bit for the module. Line faults are not latched. If a

line fault condition returns to normal, the Fault Name

variable status also returns to normal.

, Type F (T7411F, T7418F)

Fault Name Description

This 40-cha

racter field provides a place to describe the input

point fault name definition. The description is used to help

document your system (it does not affect application program

operation).

Disable Fault LED

Marking the Disable Fault LED check box disables the fault

LED for this input point on the face of the input module.

Marking this box does not stop the module from line

monitoring the input circuit and updating the state of the

Fault Name variable, it only stops the module from displaying

line faults on t

he face of the input module. Line faults are still

reported to the Regent and are available to the application

program through the fault name variable.

This box can be checked for those input points that do not

have line monitor devices (LMDs) installed, or that are spare

and have no field switches connected. In this configuration

the line fault LED will always be off. If you do not check this

box for input points without LMDs installed or unconnected

spare input points, the line fault LED will always be

on.

18

Programming

Inputs are referenced in the application program through the

tag names defined in the I/O Configuration Editor. When

current flows through the input (field switch closed) the input

is said to be on, or have a value of one. In ladder logic, the on

state would produce power flow in a normally open (N.O.)

contact.

Field wiring open circuit or short circuit conditions are

referenced in the application program using the Fault Name

tag names defined in the I/O configuration Editor. When a

line

monitor device is installed across the field switch and the

wiring is healthy, the Fault Name status is on. If there is a

Industrial Control Services

Page 19

Monitored Digital Input Modules

With Line Monitor Device

Installed

Without Line Monitor

Device Installed

Field Input

Condition

Name

Fault Name

Name

Fault Name

Switch Open

OFF ON OFF

OFF

Switch Closed

ON ON ON OFF

Open Circuit

OFF OFF

Same as Switch Open

Short Circuit

ON

OFF

Same as Switch Closed

short or open circuit (or there is no line monitor device

installed) the Fault Name status is off.

The status of the Name and Fault Name input variables are

summarized in Table 3 for the various field input conditions.

, Type F (T7411F, T7418F)

Table 3. Input Status for Field Input Conditions.

Programming Dual Fault Tolerant Monitored Inputs

To program fault tolerant configurations using dual

monitored input modules, ladder logic is used to check the

status of the inputs and the system control relays (that report

a faulted I/O module) and provide a voted input value. Two

examples are shown below.

PD-7027

Mar-06

N

ormally Energized Inputs

Figure 12 shows a ladder logic rung that would be suited for

normally energized inputs that de-energize to trip.

Figure 12. Dual Voting for Normally Energized Inputs.

In this example, IN1A and IN1B represent the input

variables from two redundant monitored input modules.

IO01U01 and IO01U02 are the system control relays that

report a fault for the monitored input modules (one installed

in slot 1 of chassis 1 a

nd the other in slot 1 of chassis 2). The

variable IN1VOTE is a shared control relay that will

19

Page 20

Monitored Digital Input Modules

represent the voted value of the two inputs. This variable

would be used elsewhere in the application program to

represent the status of the field input in the associated safety

interlock logic.

When both input modules are healthy, both inputs must turn

off to turn off the voted result and initiate a trip. Because the

inputs are normally energized, the voted result is normally

on. If a fault occurs on one of the input modules, the voted

result will remain on, eliminating a nuisance trip. Automatic

testing of the input module will detect the fault and the

associated fault bit will be turned on, leaving the voted result

under the control of the remaining healthy input module.

The faulted module can be removed and replaced. After

replacing the input module and performing a voted reset, the

fault bit is turned off, restoring the input configuration to the

dual mode.

, Type F (T7411F, T7418F)

Normally De-Energized Inputs

Figure 13 shows a ladder logic rung that would be suited for

normally de-energized inputs that energize to trip.

Figure 13. Dual Voting for Normally De-Energized Inputs.

In this example the variables represent the same status

information as described above for normally energized inputs.

When both input modules are healthy, both inputs must turn

on to turn on the voted result and initiate a trip. Because the

inputs are normally de-energized, the voted

result is normally

off. If a fault occurs on one of the input modules, the voted

result will remain off, eliminating a nuisance trip. Automatic

testing of the input module will detect the fault and the

associated fault bit will be turned on, allowing the voted result

to be controlled by the remaining healthy input module. The

faulted module can be removed and replaced. After replacing

20

Industrial Control Services

Page 21

Monitored Digital Input Modules

the input module and performing a voted reset, the fault bit is

turned off, restoring the input configuration to the du

, Type F (T7411F, T7418F)

al mode.

Programming Triple Fault Tolerant Monitored Inputs

Fault tolerant applications that include triplicated monitored

input modules should use the Voter instruction in ladder

logic. The voter instruction performs two-out-of-three voting

of triplicated inputs, storing the voted result in the defined

shared variable. Refer to the Regent User’s Guide section 5,

Working with Programs and Function Blocks for more details

on using the ladder logic Voter instruction.

Maintenance

No periodic maintenance or calibration is required for the

monitored digital input modules. There are no user

replaceable parts inside these modules.

Safety Considerations

The monitored digital input modules are TÜV certified for

Risk Class 5 safety critical inputs. Safety critical

configurations include dual and triple redundant input

modules and associated application voting methods.

PD-7027

Mar-06

In safety critical input applications using a single sensor, it is

important that the sensor failure modes be predictable and

well understood, so there is little probability of a failed sensor

not responding to a critical process condition. In such a

configuration, it is important that the sensor be tested

regularly, either by dynamic process conditions that are

verified in the Regent, or by manual intervention testing.

Redundant sensors can be used with redundant input

modules to eliminate any single points of failure and extend

fault tolerance to include the sensors.

If energize to trip inputs are used in safety critic

applications, line monitor devices must be installed at the

field switches. The Fault Name variables must be configured

and line fault status must be alarmed to plant operations

personnel.

al

21

Page 22

Safetybus Power

0.85 load units

Number of Inputs

16, common power

T7411F

T7418F

Field Power

Voltage, min.:

Voltage, max.:

Current:

24 or 48 Vdc

15 Vdc

80 Vdc

450 mA,

maximum

120 Vac

/dc

90 Vac/dc

150 Vac/dc

150 mA,

maximum

Turn-On Voltage

(default)

> 12 Vdc

> 51 Vdc

Turn-Off Voltage

(default)

< 12 Vdc

< 51 Vdc

Input Current

8.0 mA,

maximum

2.0 mA,

maximum

Turn-On Delay

10 msec,

maximum

10 msec,

maximum

Turn-Off Delay

10 msec,

maximum

100 msec,

maximum

Over Voltage Protection

Field Power Terminals:

Input Terminals:

100 Vdc

continuous

100 Vdc

continuous,

160 Vdc for

5

seconds

165 Vac

continuous

230 Vac

continuous,

350 Vac for

5

seconds

Heat Dissipation

8.5 Watts, 29

BTUs/hour

10 Watts, 34

BTUs/hour

Fusing

None, external if required

Isolation

2500 volts minimum (field

wiring to control logic)

Monitored Digital Input Modules

For additional safety considerations, please refer to the Safety

Considerations section of the Regent User’s Guide.

, Type F (T7411F, T7418F)

Specifications

22

Industrial Control Services

Page 23

Monitored Digital Input Modules

Input Circuit Test Interval

Function of application

program scan time and size

of I/O configuration.

Typically less than 2 seconds

(see page 5 for details).

Intrinsic Safety

External barrier, if required.

(requires threshold

adjustment, see page 15).

Operating Temperature

0°

to 60° C

(32° to 140° F)

Storage Temperature

-40°

to 85° C

(-40°

to 185° F)

Operating Humidity

0 to 95% relative humidity,

non-condensing

Vibration

10 to 55 Hz:

±0.15mm

Shock

Operating:

15 g, ½ sine wave, 11 msec

Electromagnetic

Interference

•

IEC 801 Part 2 - Electrostatic

Discharges

•

IEC 801 Part 3 - Radiated

Electromagnetic Fields

•

IEC 801 Part 4 - Transients

and Bursts

•

ANSI/IEEE C37.90 - Surge

Withstand Capability

Level 3: Contact discharge of

6 kV

Level 3: 10 V/M, 27 MHz 500 MHz

Level 4: 2 kV, 2.5 kHz for t =

60 seconds

2.5 kV damped 1 MHz sine

wave

4 kV bi-directional impulse,

10 nsec rise time, fast

transient

Safety

Pending certification to DIN

V VDE 0801 for Risk Class 5.

Also designed to me

et UL

508 and CSA 22.2, No. 142

-

M1981

, Type F (T7411F, T7418F)

PD-7027

Mar-06

23

Page 24

Dimensions

Height:

Width:

Depth:

12.6" (320 mm)

1.27" (32 mm)

10.12" (257 mm)

Weight

3.3 lbs (1.5 kg)

Monitored Digital Input Modules

, Type F (T7411F, T7418F)

24

Industrial Control Services

Loading...

Loading...